Patents

Literature

115results about How to "Significant energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

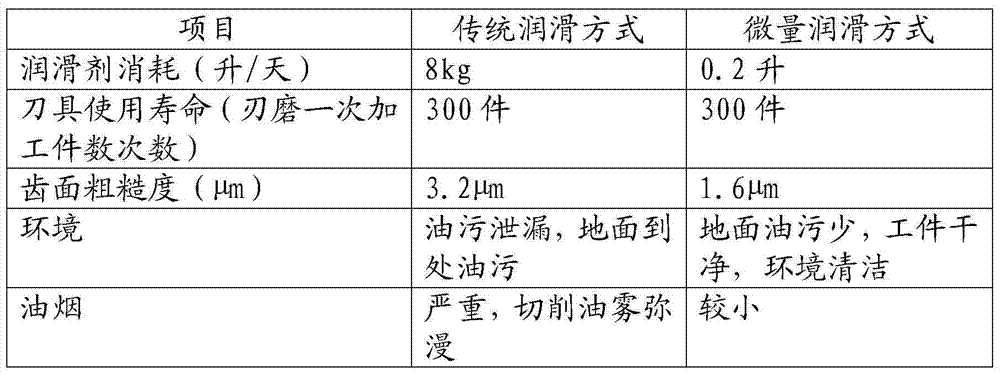

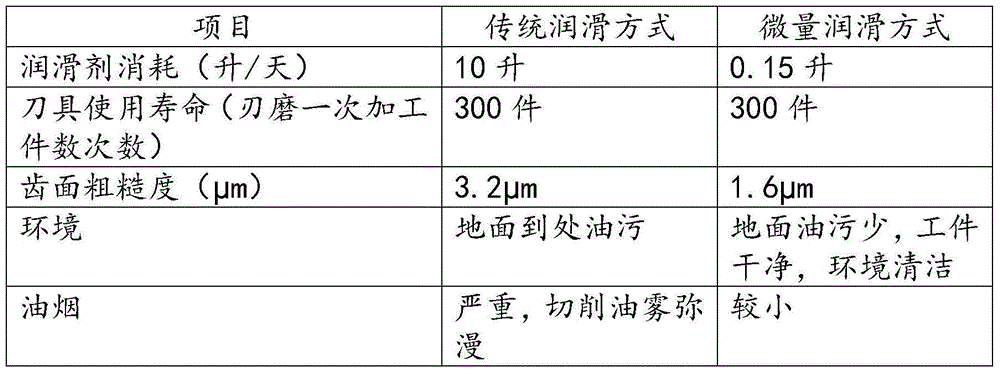

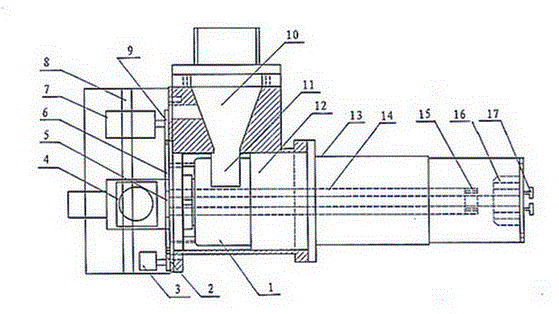

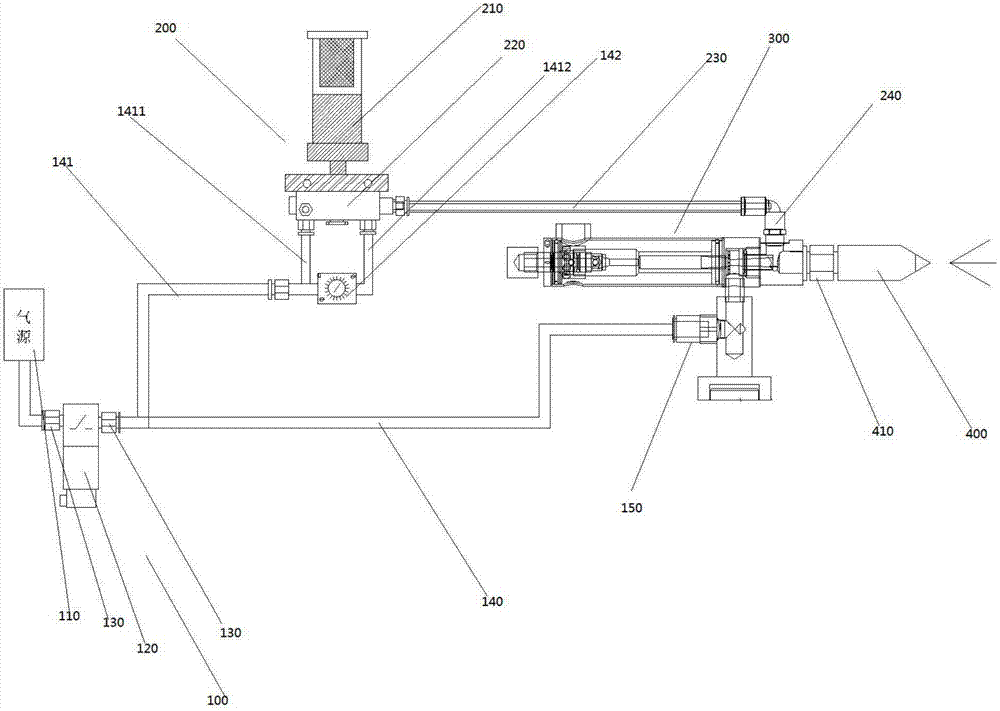

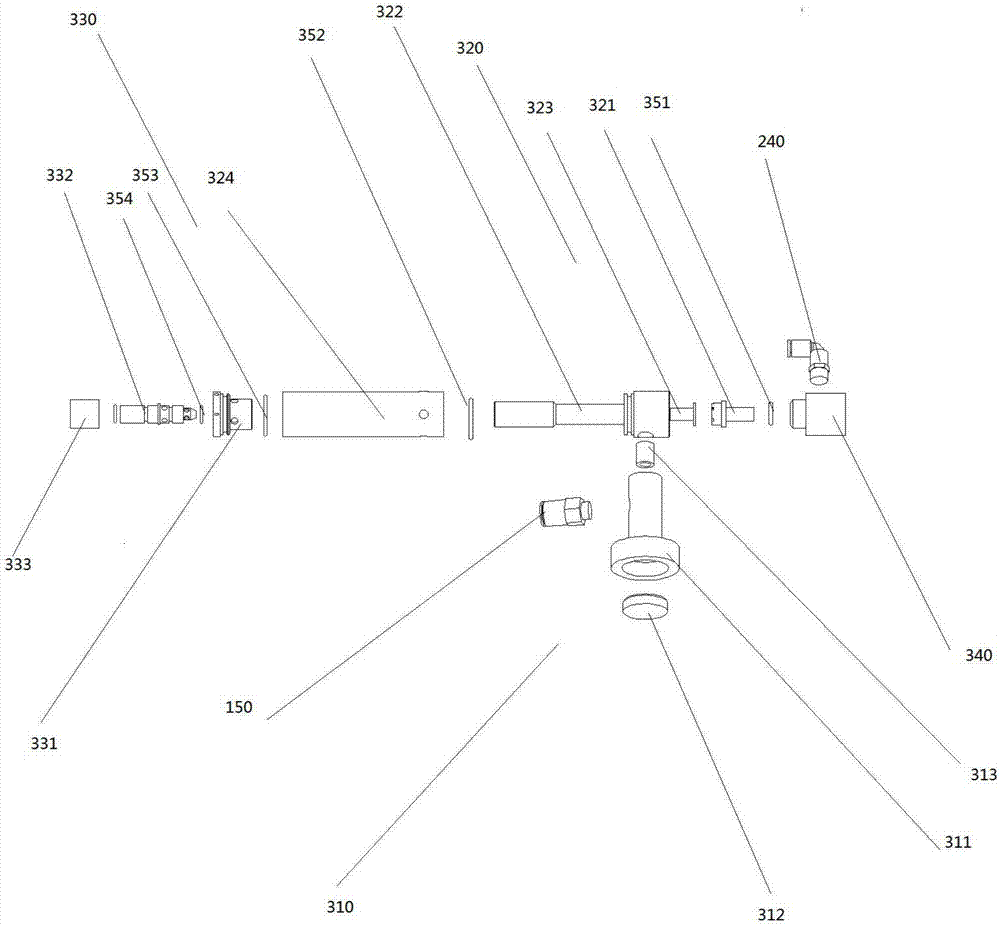

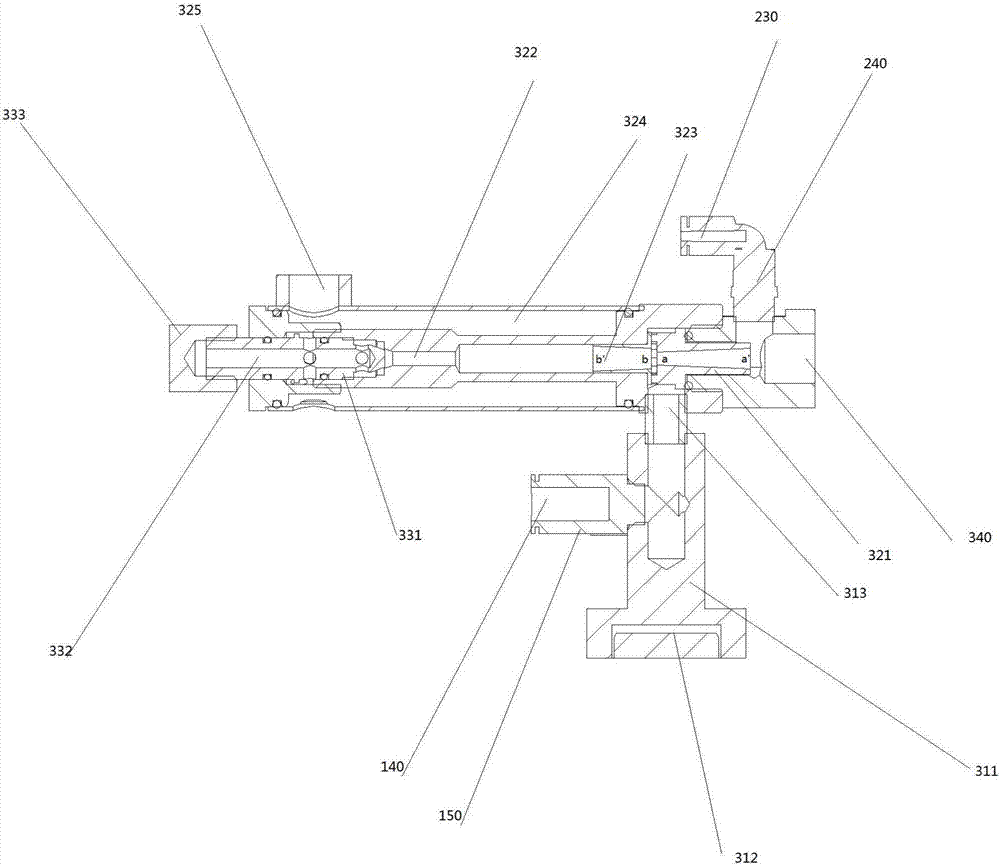

Oil water gas three-phase energy-saving minimal quantity lubrication system

ActiveCN103722447AReduce the use effectEmission reductionMaintainance and safety accessoriesAir compressorLubrication

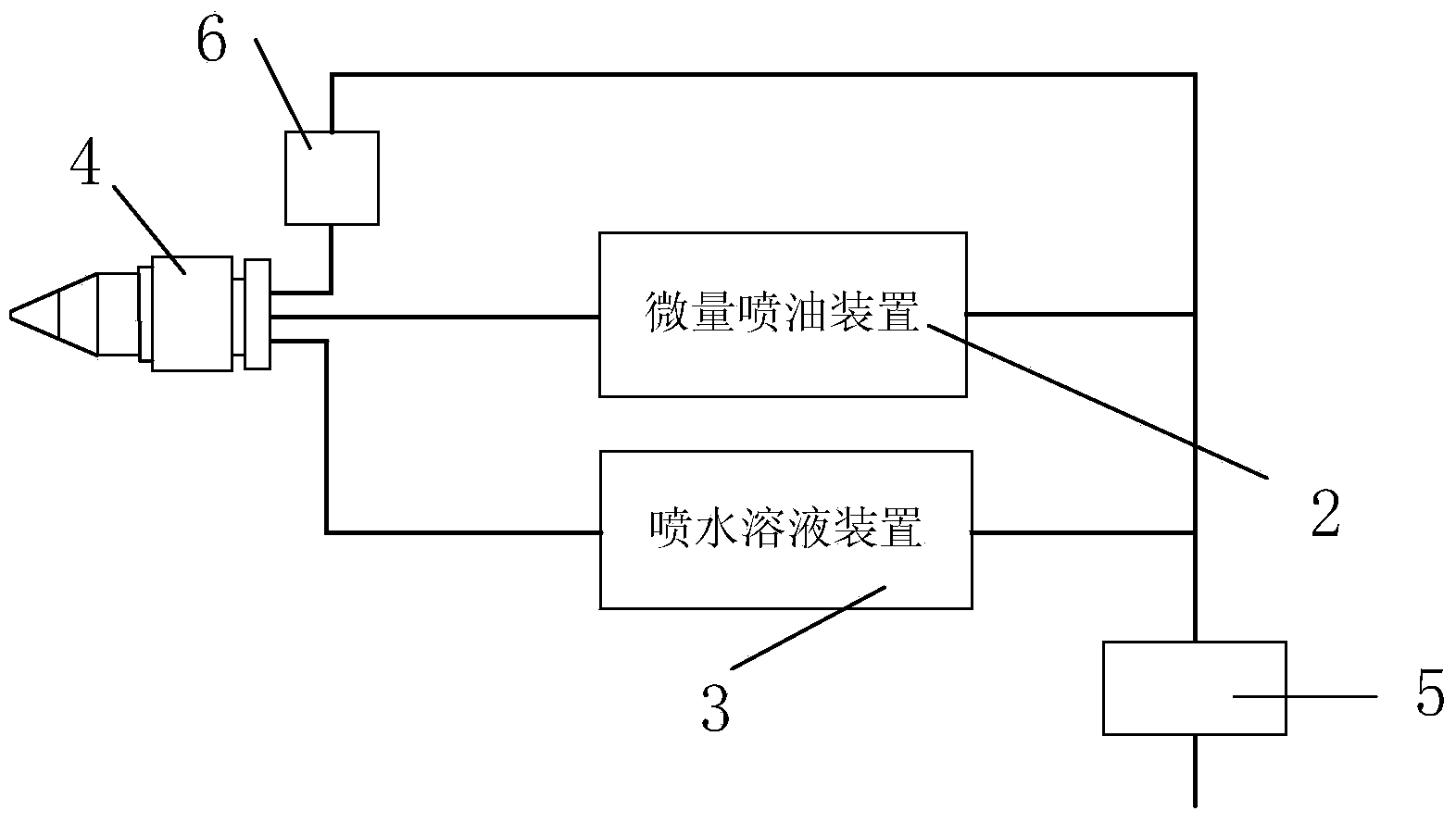

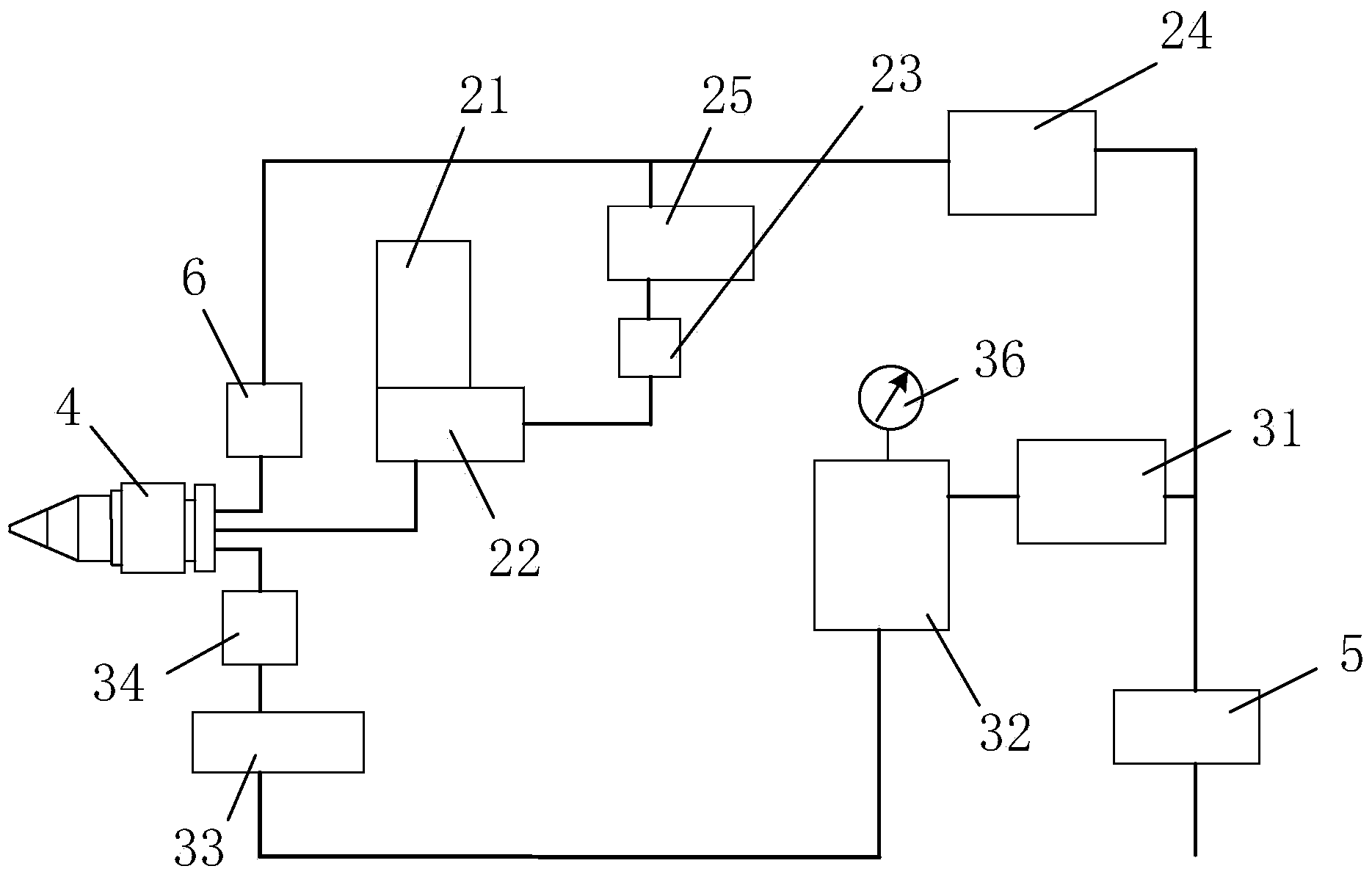

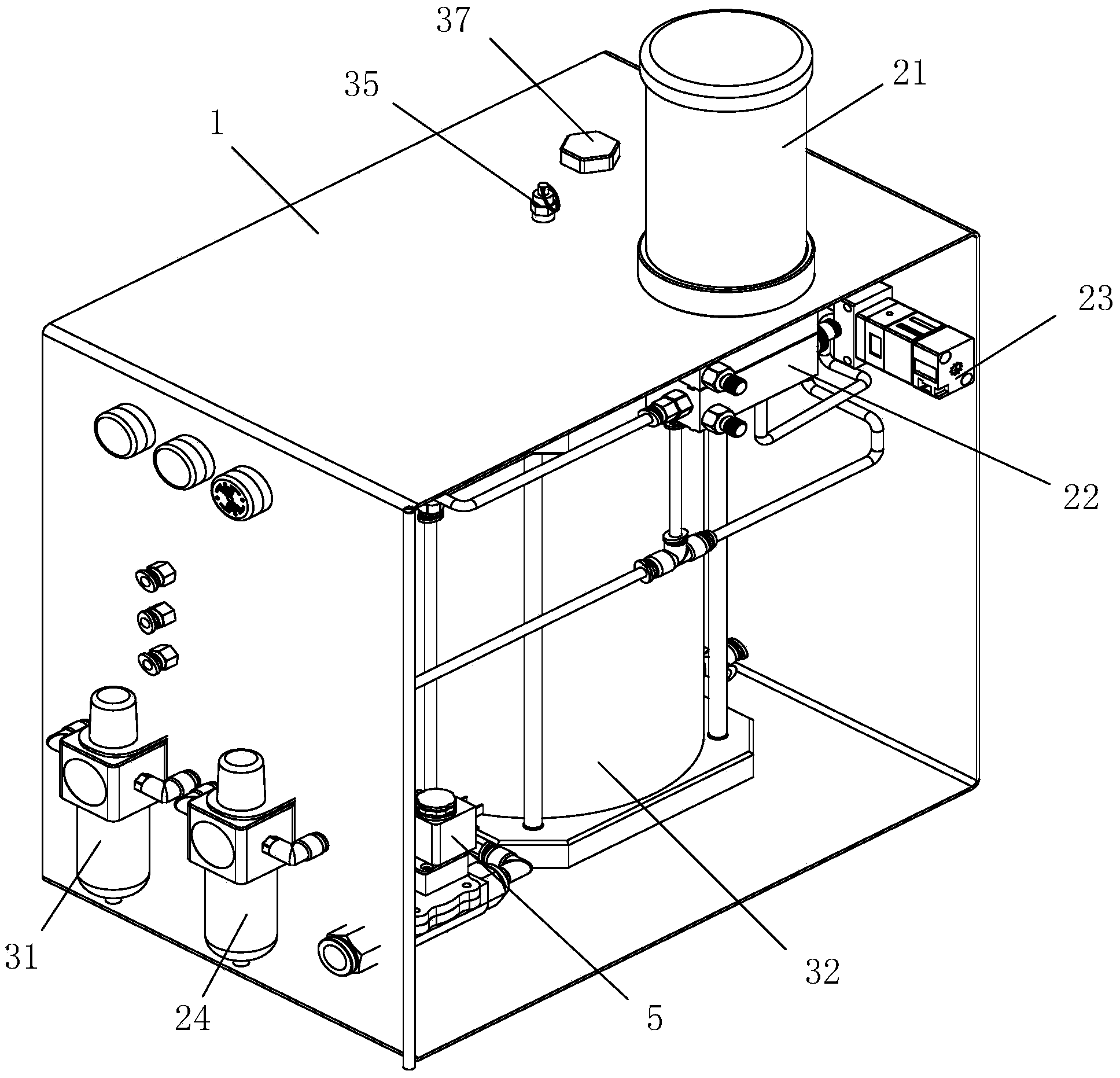

The invention discloses an oil water gas three-phase energy-saving minimal quantity lubrication system which comprises a minimal quantity oil injection device, a water solution injection device and a nozzle device. Minimal quantity lubricating oil is contained in the minimal quantity oil injection device, and water solutions are contained in the water solution injection device. Compressed air is introduced into the oil water gas three-phase energy-saving minimal quantity lubrication system and is divided into two paths, one path reaches the water solution injection device, the other path of the compressed air is divided into two branches, one branch passes the oil injection device, and the other branch is communicated with the nozzle device through a pipeline. The minimal quantity oil injection device and the water solution injection device are communicated with the nozzle device through pipelines. Flow of oil, gas and water is controlled, so that the problems that in the prior art, the water and the oil can not be evenly mixed, and the liquid outlet effect is not good are solved, and electricity use amount of an air compressor can be saved by 70-90%. Compared with a traditional lubricating technology, the oil water gas three-phase energy-saving minimal quantity lubrication system can reduce the use quantity of lubricants by more than 95% and reduce emission amount by more than 95%, and the energy conservation, emission reduction and environment protection effects are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

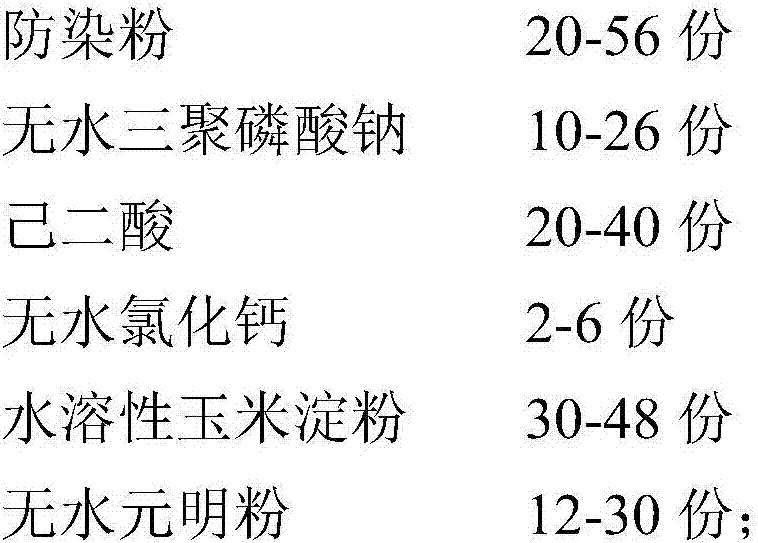

Low-carbon high-performance concrete supplementary cementitious material

The invention discloses a low-carbon high-performance concrete supplementary cementitious material which is prepared from 20-70 parts of slag, 20-70 parts of coal ash, 5-10 parts of silica fume, 3-10 parts of desulfurized gypsum and 1-3 parts of water reducing agent by weight to form an admixture, wherein the slag, the coal ash, the silica fume and the desulfurized gypsum are micro aggregates of 100 nanometers to 100 microns; and the materials are sequentially placed in a mixer and stirred for 60-120 minutes at a speed of 60-120 rpm at normal temperature under normal pressure to obtain the supplementary cementitious material. The low-carbon high-performance concrete supplementary cementitious material disclosed by the invention can replace 70% of cement in concrete when applied to concrete; and even if the 70% of cement is replaced, the strength of the prepared concrete also can reach C15-C60. The low-carbon high-performance concrete supplementary cementitious material is suitable to be used as a building material and also has special purposes of back-fill grouting, toxic waste solidification and the like.

Owner:宁夏新丰益节能科技有限公司

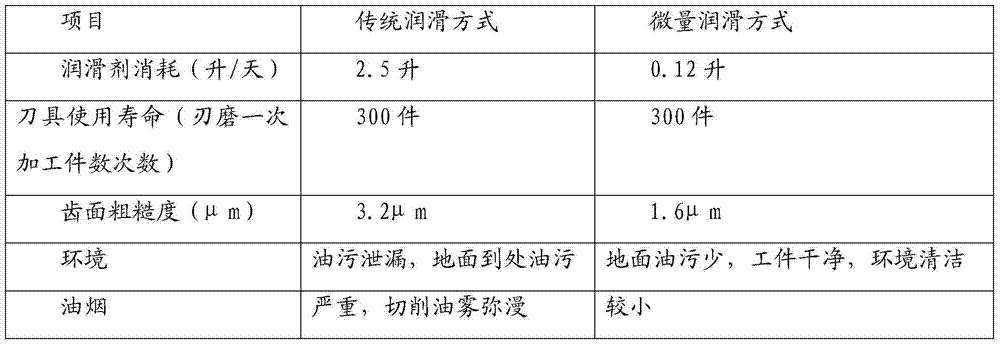

Biodegradable micro-lubricating oil and preparation method thereof

InactiveCN104263476APromote degradationGood extreme pressure and anti-wear propertiesLubricant compositionCooling effectSarcosine

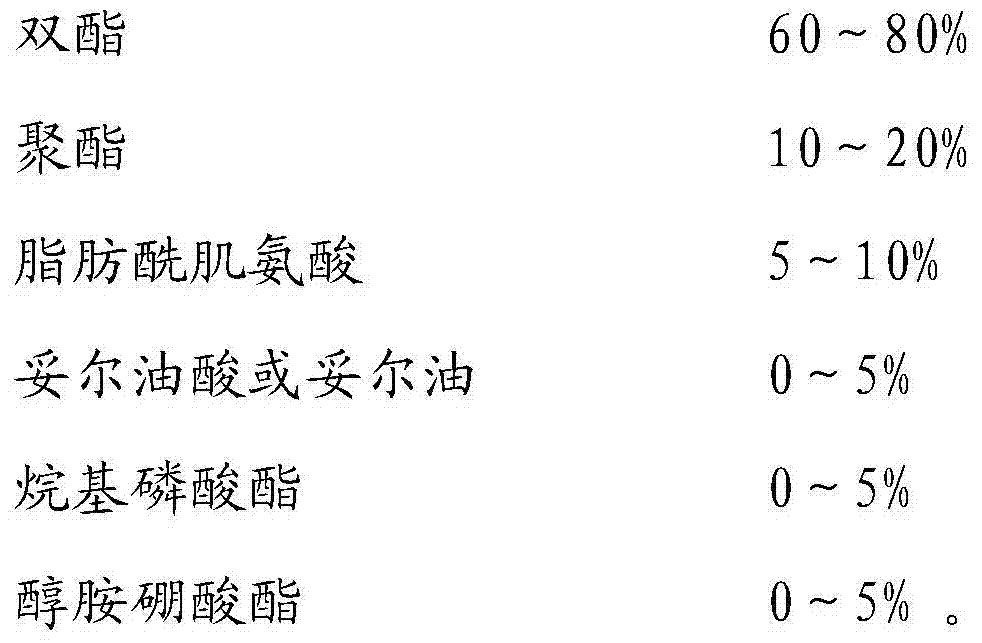

The invention provides biodegradable micro-lubricating oil. The biodegradable micro-lubricating oil is characterized by comprising fatty acyl sarcosine with the mass percent content being 5-10%, wherein the fatty acyl sarcosine is prepared from carboxylic acid and sarcosine through acylation reaction. The biodegradable micro-lubricating oil provided by the invention has good biodegradability, and good extreme pressure antiwear property and lubricating property, and is used by matching with a micro-lubricating device; the usage amount can be reduced to below 5% of the original amount; good lubricating and cooling effects are achieved; and the biodegradable micro-lubricating oil has significant benefits of energy conservation and emission reduction, and environmental protection.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH +1

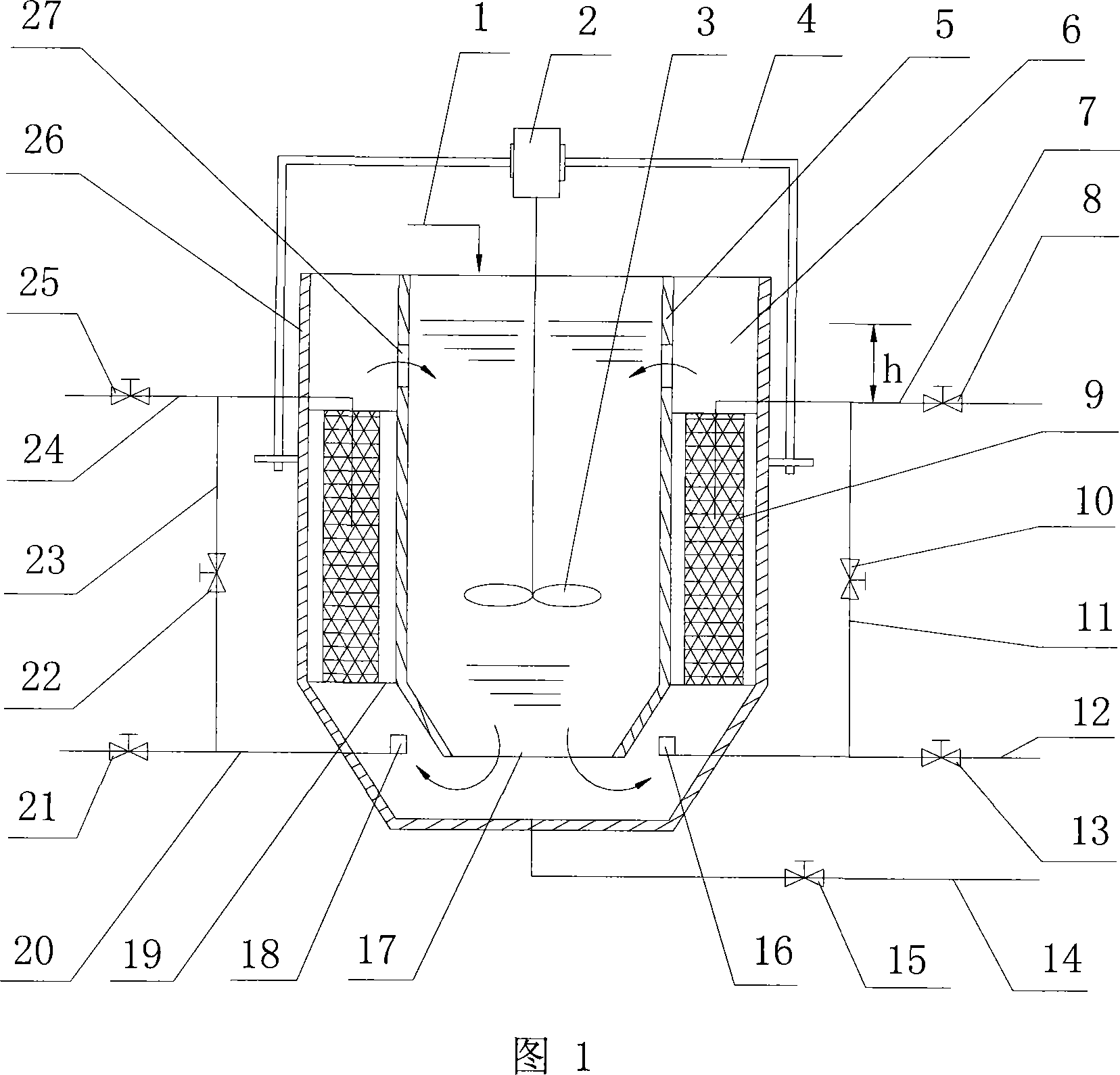

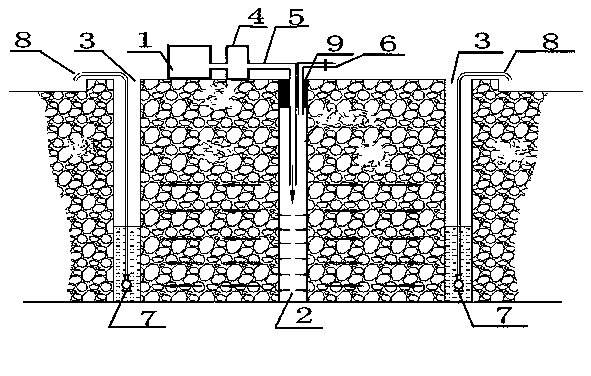

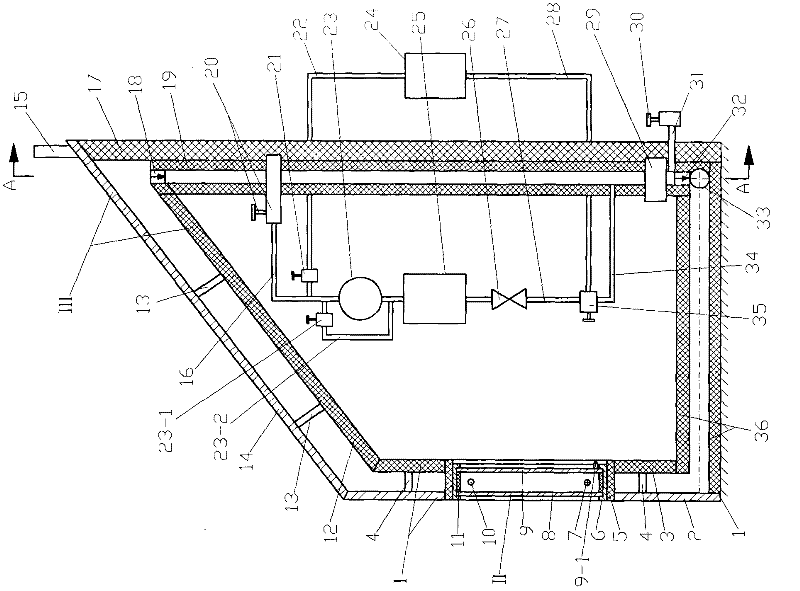

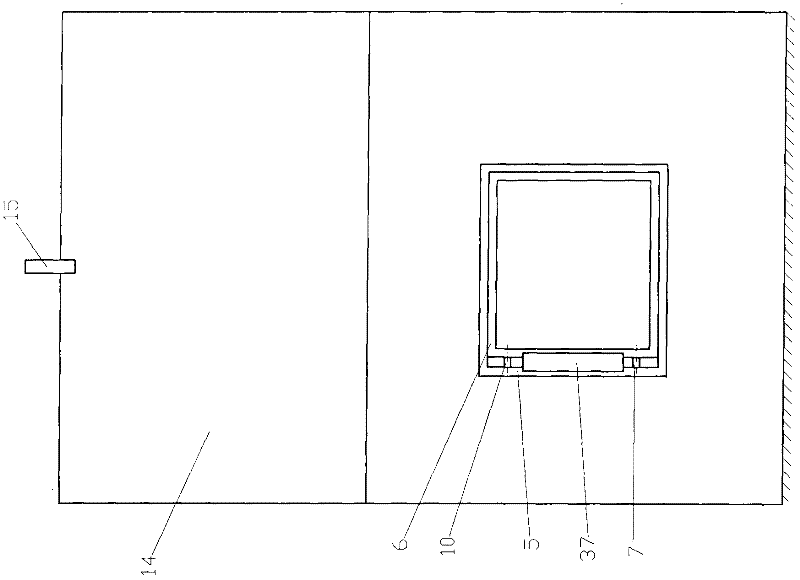

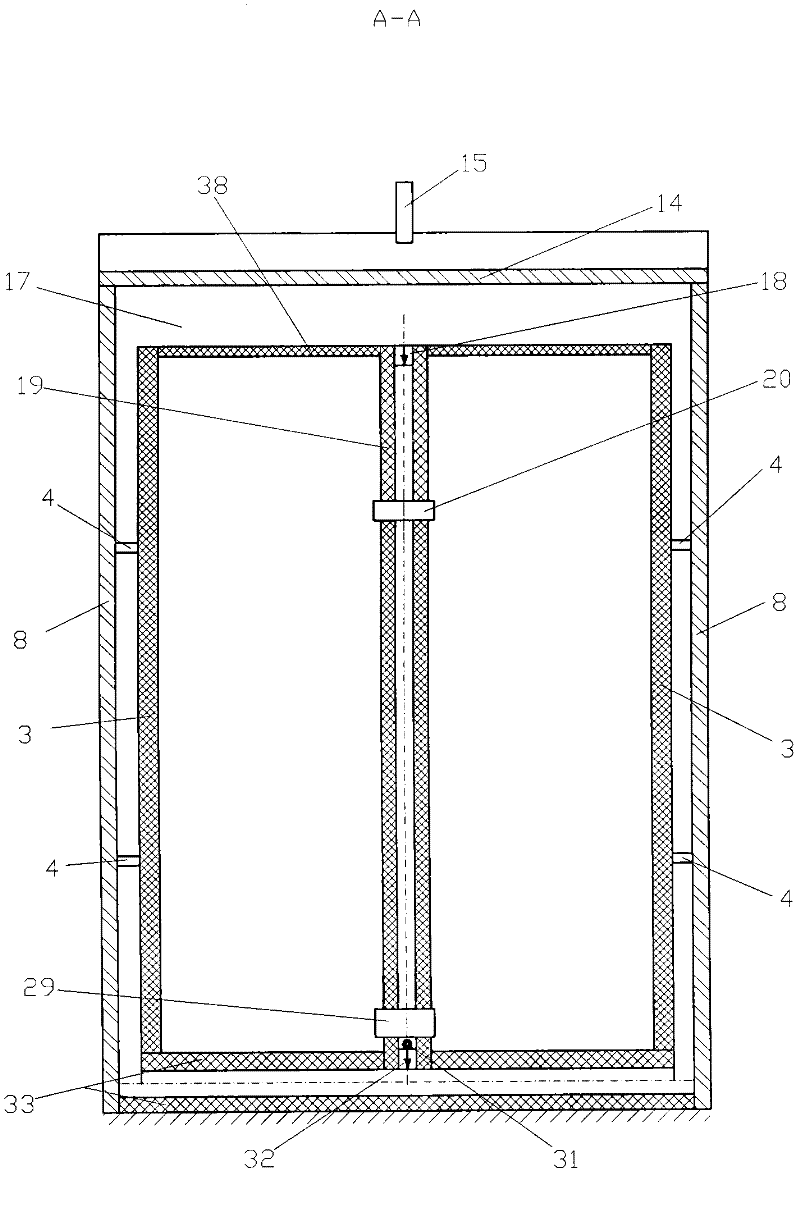

Integrated sequencing-batch method for treating sewage by plant micro-net dynamic membrane and apparatus therefor

InactiveCN101205098AImprove filtering effectGood removal effectSustainable biological treatmentBiological water/sewage treatmentSewageMembrane bioreactor

The invention relates to a method for treating sewage and a device thereof.The method for treating the sewage by integrative sequencing batch botanical bench-scale dynamic membrane is characterized in that the method comprises the following steps: (1) preparation of the device comprises the processes that: a separation bucket is arranged in cavity of a membrane bioreactor; the botanical bench-scale dynamic membrane is arranged in a dynamic membrane filter room which is between a fixed support of the up and under dynamic membrane; (2) sludge is poured into the cavity of the membrane bioreactor to a height of 45 percent to 50 percent of the height of the cavity from an entrance which is on the top of the separation bucket; (3) an outlet valve on a water pipe is closed, and then the sewage is poured into the cavity of the membrane bioreactor to a height of 90 percent to 98 percent of the height of the cavity from the entrance which is on the top of the separation bucket through a sewage inlet pipe; (4) after stirred for 2.0 to 4.0h, aeration is injected into the membrane bioreactor and stirring is kept for 2.0 to 4.0h; (5) after stopping stirring for 1.0 to 2.0h, the outlet valve on the outlet pipe is opened to drain water and aeration supply is stopped; (6) steps (3) to (5) are repeated to carry out the sequencing batch sewage treatment.The invention is characterized by good sewage treatment effect.

Owner:WUHAN UNIV OF TECH

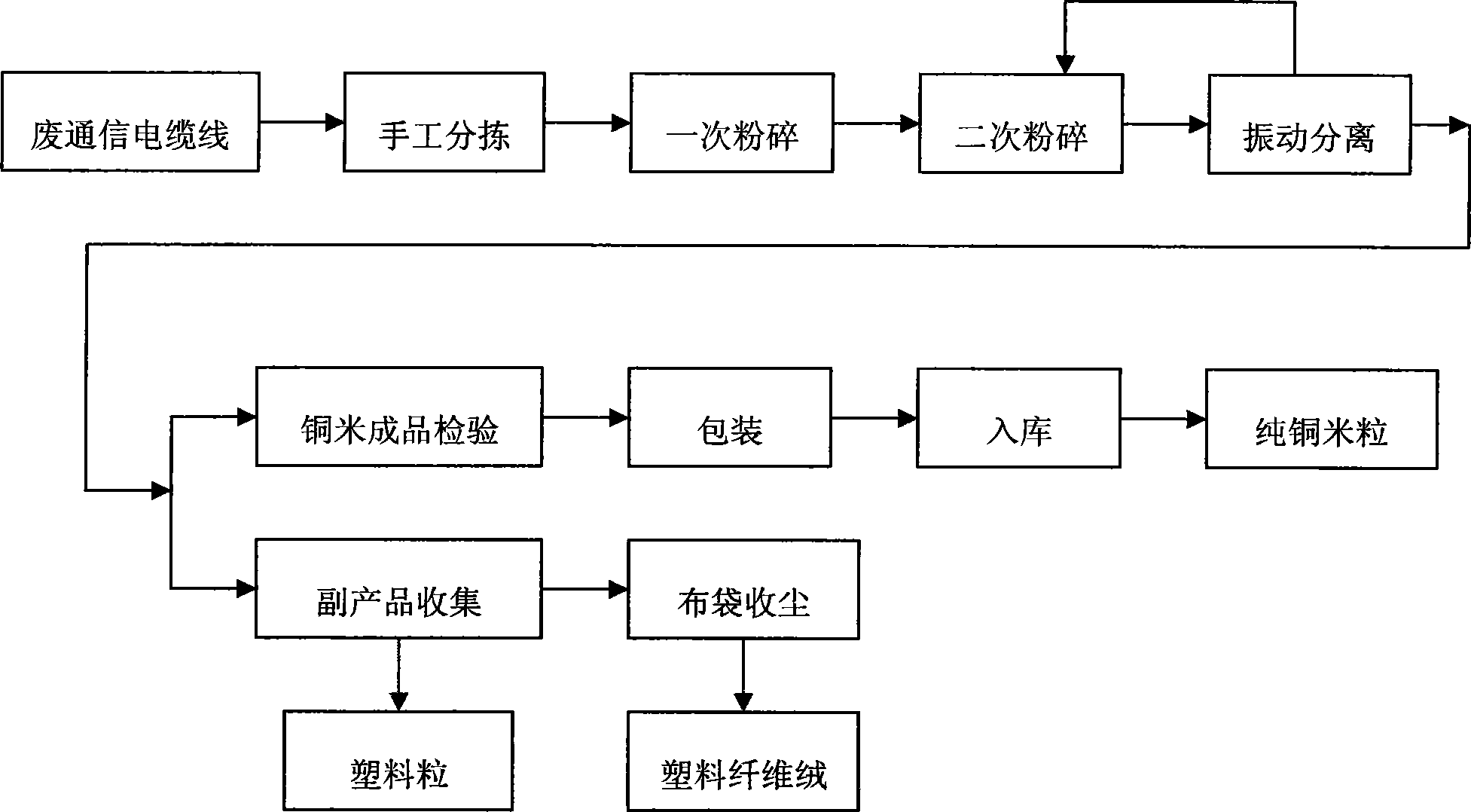

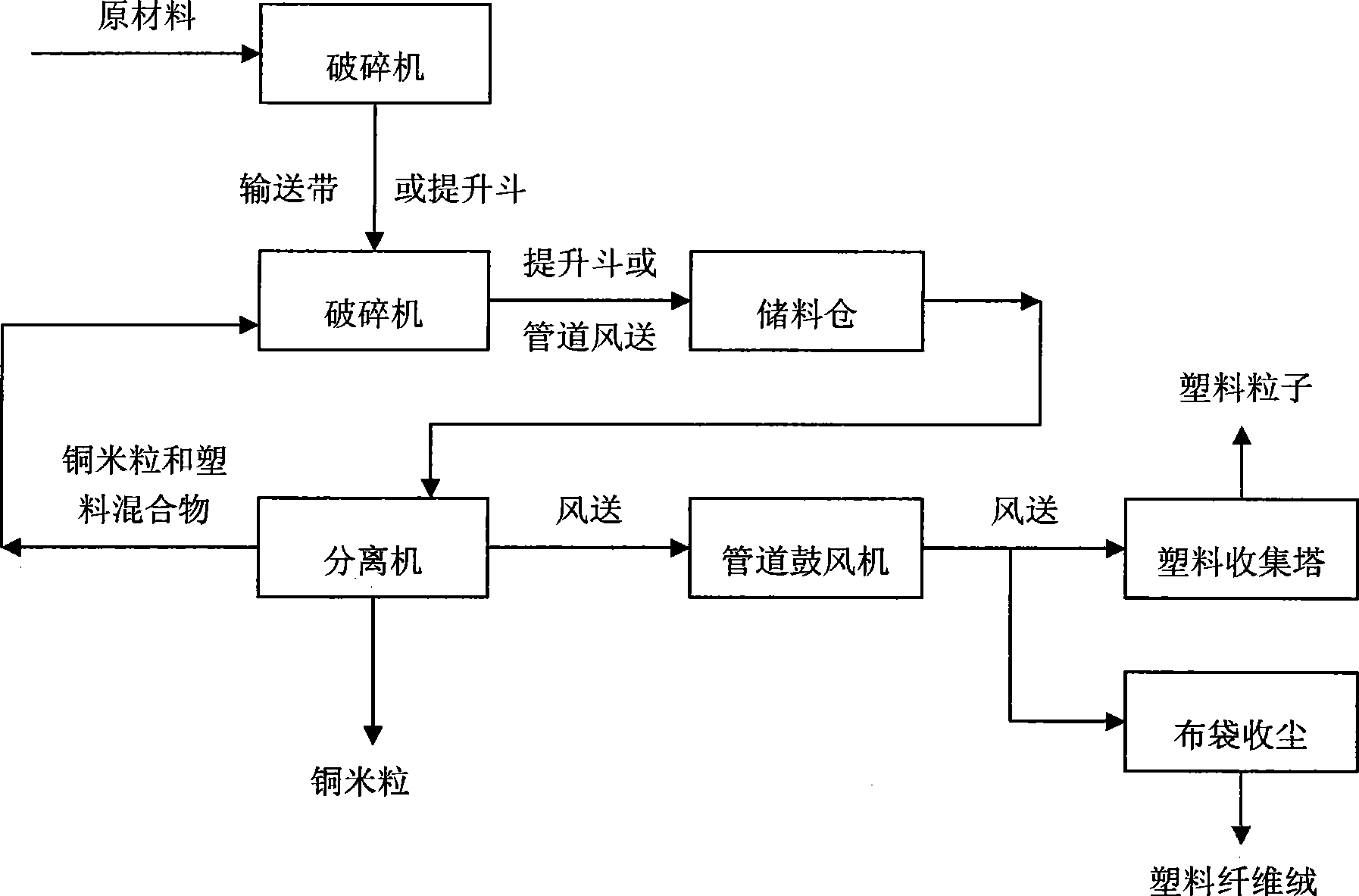

Process for recycling and manufacturing copper granule from waste and old electric wire and cable

InactiveCN101367084ALow costReduce energy consumptionSievingSolid waste disposalEngineeringMixed materials

The invention discloses a technological method for producing copper rice grains by recovering waste wires and cables based on an improvement of the prior production mode that the waste wires and cables recover copper raw materials. The technological method has low cost, small energy consumption, less discharge and no waste pollution, meets the requirement of circular economy development, and can obtain a copper rice grain product the purity of which reaches 99.9 percent. The technological process comprises the steps of classification inspection, loading, primary crushing, secondary crushing, and vibration separation; the angle of a vibration sieve is adjusted according to the content of copper and the wire diameter, and the copper rice grains and plastic are subjected to optional separation through vibration sieving; a material from a mixed material port flows into an air suction pipe, and is sent for secondary crushing through a circulating air pipe; the air suction pipe above the vibration sieve sucks plastic fibers and other dust in the space of the vibration sieve to a dust collector for treatment; the qualified copper rice grains obtained at a copper outlet flow into a packing bag; and the finished product inspection is performed, namely the obtained copper rice grains enter a warehouse through the inspection.

Owner:南京东南铜业有限公司

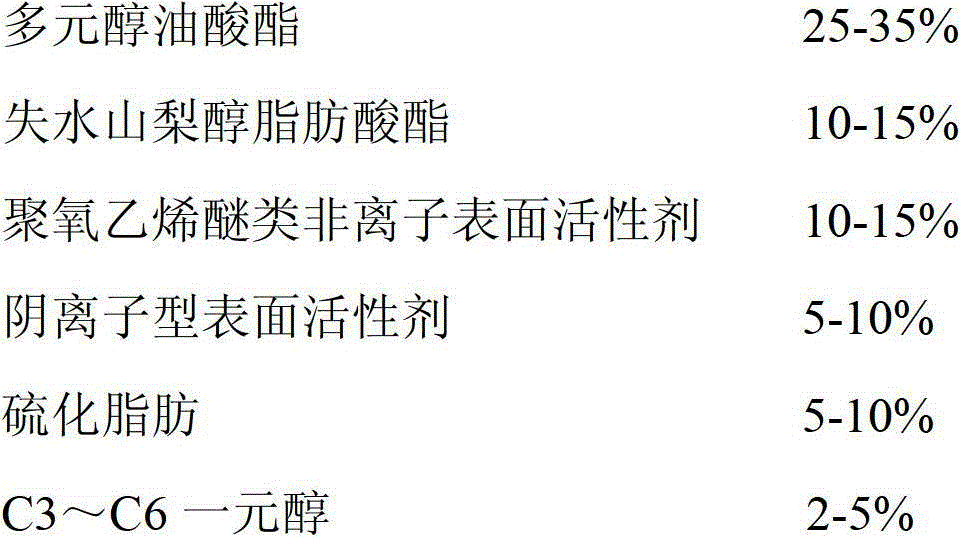

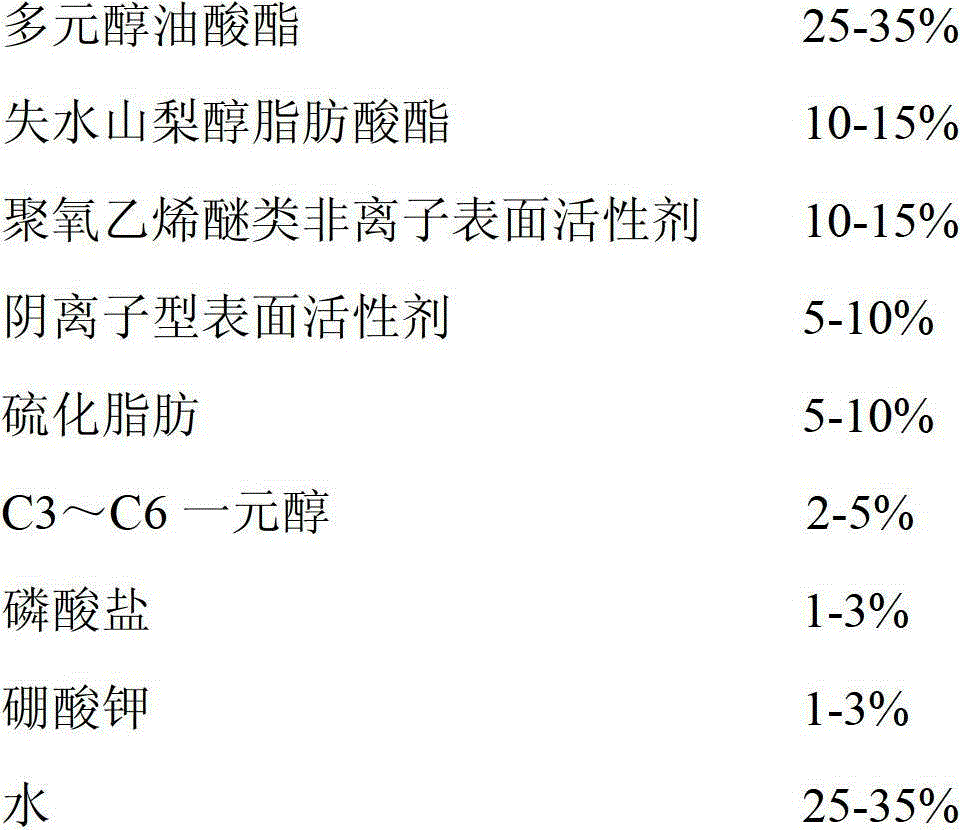

Aluminum alloy near-dry cutting processing microemulsion and preparation method thereof

ActiveCN103146467ASignificant protection benefitsImprove extreme pressure performanceLubricant compositionAlcoholPhosphate

The invention discloses an aluminum alloy near-dry cutting processing microemulsion and a preparation method thereof. The aluminum alloy near-dry cutting processing microemulsion is prepared through the following steps: preparing a mother solution, wherein the mother solution is prepared by mixing raw materials, heating to 30-50 DEG C and stirring, and the mother solution comprises the following raw materials in percentage by weight: 25-35% of polyalcohol oleate, 10-15% of sorbitan fatty acid ester, 10-15% of polyethenoxy ether nonionic surfactant, 5-10% of anionic surfactant, 5-10% of sulfurized fat, 2-5% of C3-6 monobasic alcohol, 1-3% of phosphate, 1-3% of potassium borate and 25-35% of water; and mixing the mother solution and water according to a weight ratio of 1:(1-3), sufficiently stirring, adding 0.005-0.01wt% of polysiloxane, and sufficiently stirring to obtain the aluminum alloy near-dry cutting processing microemulsion working fluid. The aluminum alloy near-dry cutting processing microemulsion disclosed by the invention has excellent extreme pressure performance, antiwear property and lubricating property; when the microemulsion is used with a near-dry cutting and lubricating device, the consumption of the microemulsion can be reduced to 10% or below of the original consumption; and favorable effects of lubricating and cooling as well as remarkable benefits of energy saving, emission reduction and environment protection can be achieved.

Owner:江苏麦格美节能科技有限公司

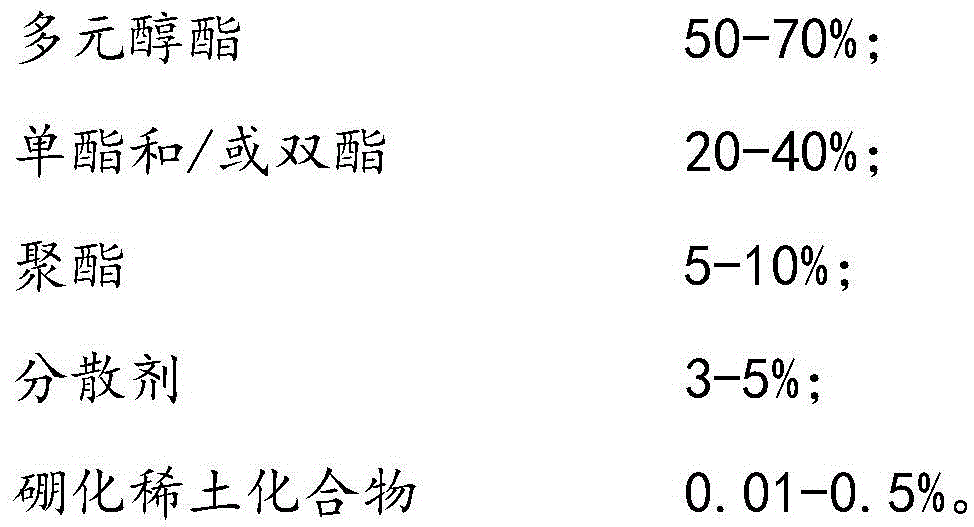

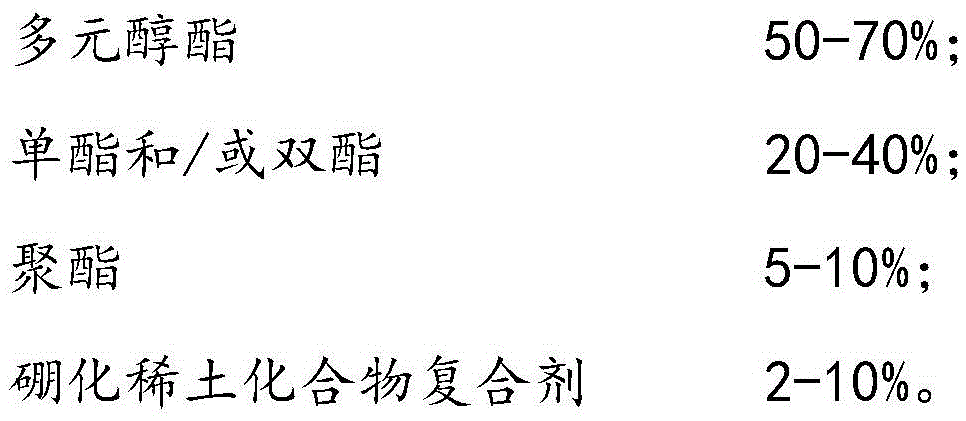

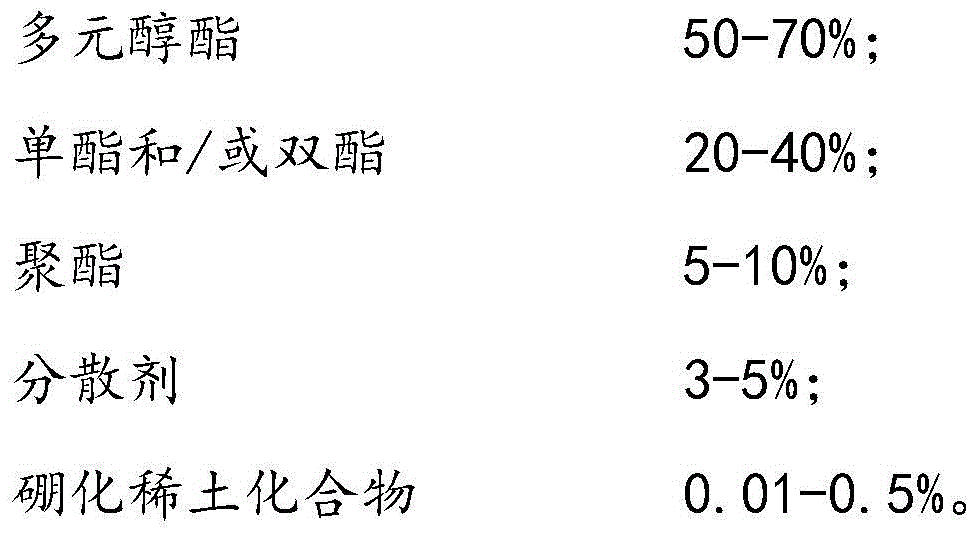

Intelligent repair trace lubricating oil and preparation method thereof

ActiveCN105524678AImprove the lubrication effectGood extreme pressure and anti-wear propertiesAdditivesBoridePolyester

The invention provides intelligent repair trace lubricating oil which is characterized by being prepared from the following components by the weight percentage: 50-70% of polyol ester, 20-40% of monoester and / or diester, 5-10% of polyester, 3-5% of a dispersion agent, and 0.01-0.5% of a rare earth boride compound. The intelligent repair trace lubricating oil provided by the invention is used with cooperation of a trace lubrication device, the use amount can be reduced to 5% or less of the original, good lubrication and cooling effects are achieved, and energy-saving, emission-reduction and environment-friendly effects are significant.

Owner:大庆欧冠润滑油有限公司

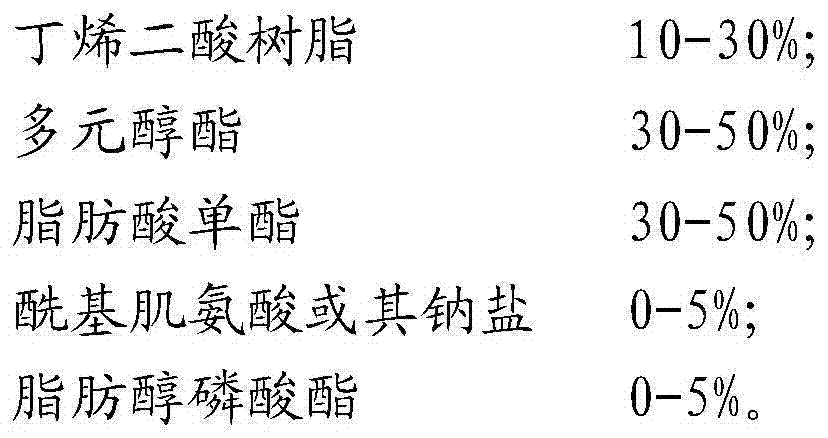

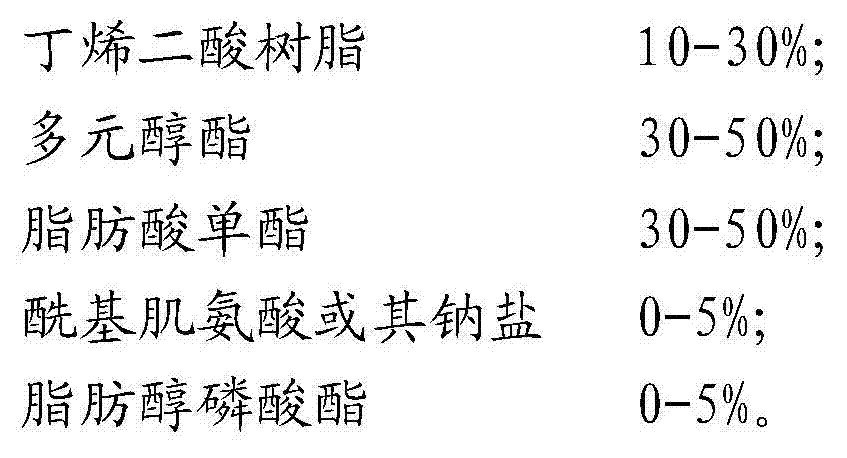

Butenedioic acid resin and preparation method therefor, and degradable micro lubricating oil prepared by using butenedioic acid resin

ActiveCN104844747AImprove the lubrication effectGood extreme pressure and anti-wear propertiesLubricant compositionFatty alcoholWear resistance

The invention provides a butenedioic acid resin and a preparation method therefor, and degradable micro lubricating oil prepared through the butenedioic acid resin. The butenedioic acid resin is characterized by being prepared from the following substances comprising the following components: butenedioic acid or anhydride maleique, and fatty alcohol, wherein the molar ratio of the butenedioic acid or the anhydride maleique to the fatty alcohol is 1: (1.9-2); raw materials for preparing the degradable micro lubricating oil comprise the butenedioic acid resin. According to the degradable micro lubricating oil prepared by using butenedioic acid resin, a small quantity of the micro lubricating oil is used, so that the requirements of lubrication cooling, wear resistance under extreme pressure and rust prevention of metal processing can be met.

Owner:无锡奇比特润滑油有限公司

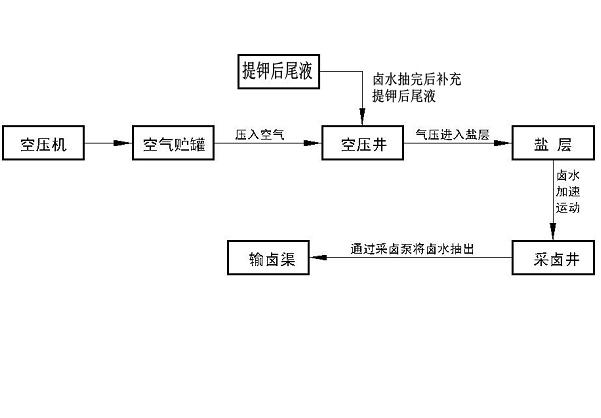

Method for extraction of deep-seated intercrystalline bittern of salt lake mining area

ActiveCN102659139AIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakeMining engineering

The invention relates to a method for extraction of deep-seated intercrystalline bittern of a salt lake mining area. The method comprises the following steps of 1, excavating a gas-injection well, brine mining wells and a brine transportation channel on a salt lake ore bed, arranging an air compressor on the salt lake ore bed, arranging a brine tail liquid injection pipe in the gas-injection well around which the brine mining wells each provided with a brine transportation pipe in the interior are uniformly arranged; and arranging a brine mining pump in each one of the brine mining wells, wherein the brine mining pump is connected to one end of the brine transportation pipe of which the other end is connected to the brine transportation channel, 2, continuously pumping compressed air into the salt lake ore bed by the air compressor so that deep-seated intercrystalline bittern gushes out, 3, pumping out the deep-seated intercrystalline bittern from underground by the brine mining pumps and outputting the deep-seated intercrystalline bittern to the brine transportation channel, 4, injecting a brine tail liquid subjected to potassium extraction into the salt lake ore bed in the gas-injection well so that the brine tail liquid reaches a salt bed and forms novel potassium-containing brine, and 5, repeating the steps of 2-4 so that a cycle is finished. The method utilizes compressed air to realize extrusion of intercrystalline bittern and deep-seated bittern so that resources are fully utilized.

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

Desizing, enzyme-washing and bleaching integrated one-bath process

InactiveCN107419510AWater saving realizedRealize water savingDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsWorking fluidProcess engineering

The invention discloses a desizing, enzyme-washing and bleaching integrated one-bath process which includes the steps of (1), adding water and denim garments in an industrial washing machine and starting steam-heating; (2), stopping the steam-heating; (3), adding in desizing and enzyme-washing two-in-one enzyme powder for processing; (4), adding in blenching enzymes for processing; (5), discharging working fluid in the industrial washing machine; (6), adding in water to wash denim garments in the industrial washing machine; (7), discharging bath foam in the industrial washing machine, and (8) dewatering and drying the denim garments to obtain the desized, enzyme-washed and bleached denim garments. By the desizing, enzyme-washing and bleaching integrated one-bath process, denim garments are processed with excellent and unique washing effect, while energy saving and environmental protection are achieved during processing. The desizing, enzyme-washing and bleaching integrated one-bath process is a good choice for washing of denim garments.

Owner:JIANGSU NEW REBA TECH CO LTD

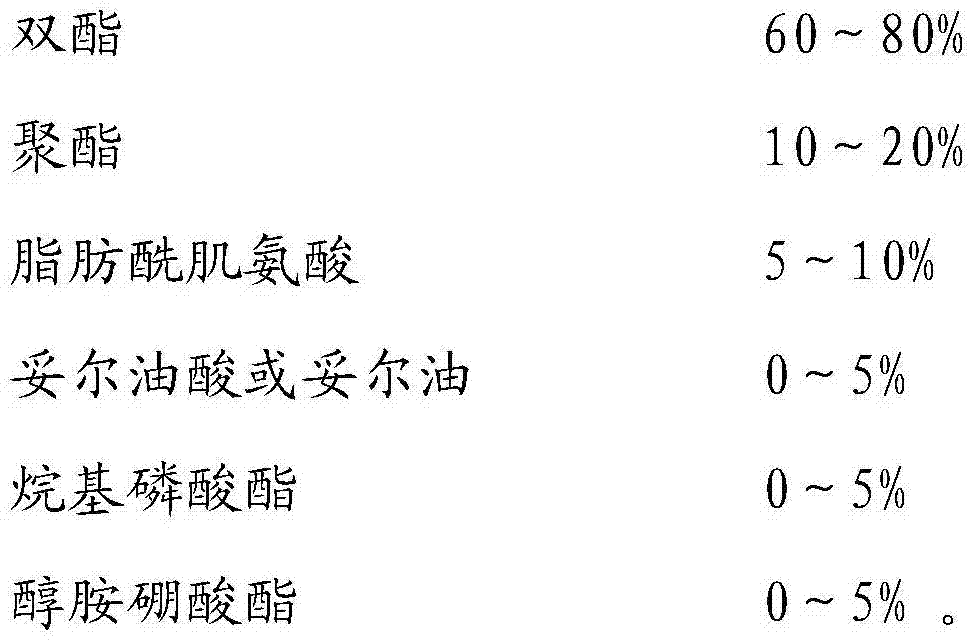

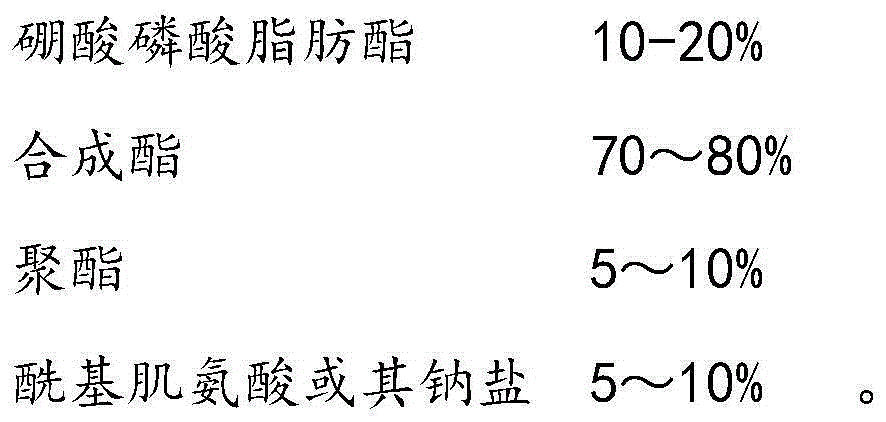

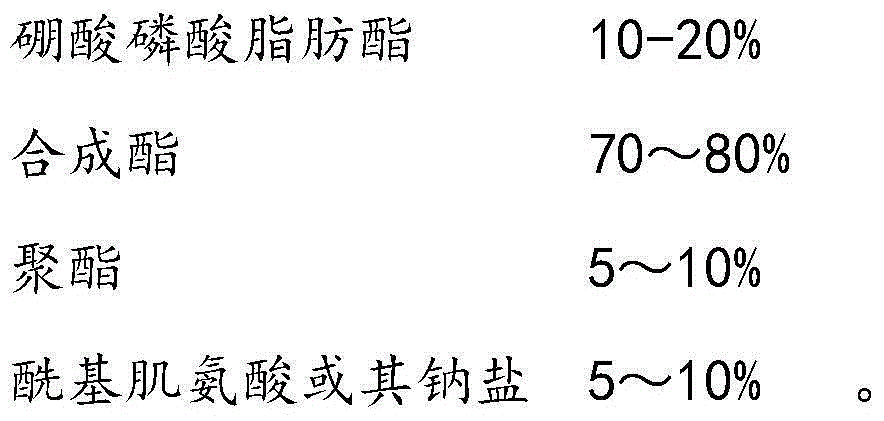

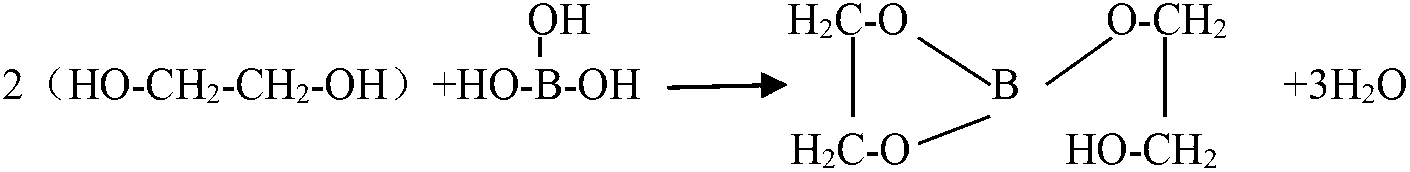

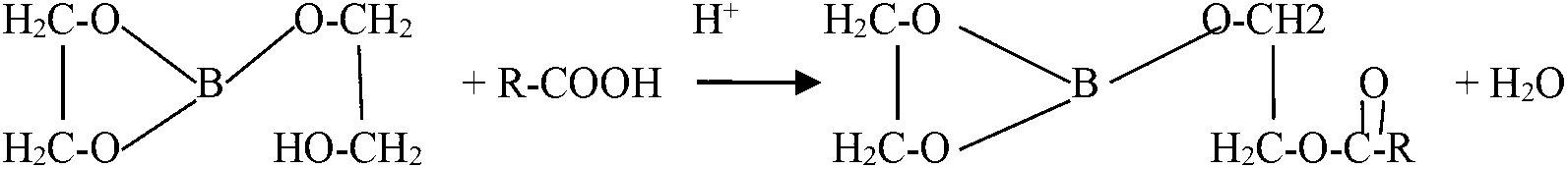

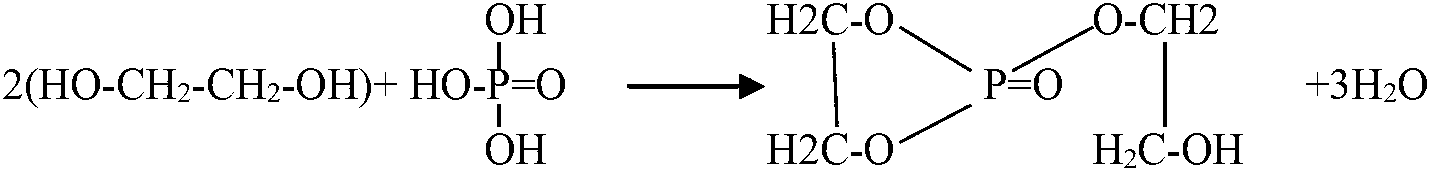

Boric acid and phosphoric acid containing fatty ester, preparation method thereof and minimal quantity lubricating oil prepared from boric acid and phosphoric acid containing fatty ester

ActiveCN105062643AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionPolyesterSarcosine

The invention relates to boric acid and phosphoric acid containing fatty ester. The boric acid and phosphoric acid containing fatty ester is characterized by being prepared from components in percentage by weight as follows: 80%-90% of fatty alcohol, 5%-10% of phosphoric acid and 5%-10% of boric acid. The invention further provides minimal quantity lubricating oil prepared from the boric acid and phosphoric acid containing fatty ester. The minimal quantity lubricating oil is characterized by being prepared from components in percentage by weight as follows: 10%-20% of the boric acid and phosphoric acid containing fatty ester, 70%-80% of synthetic ester, 5%-10% of polyester and 5%-10% of acyl sarcosine or sodium salt of acyl sarcosine. When the minimal quantity lubricating oil cooperates with a minimal quantity lubricating device for use, the use amount can be reduced to be lower than 5% of the conventional use amount, and the minimal quantity lubricating oil can have good lubricating, cooling and rust prevention effects and has obvious energy saving and emission reduction benefits and environmental protection benefits.

Owner:FOSHAN SHUNDE FUYANSHENG LUBRICANT

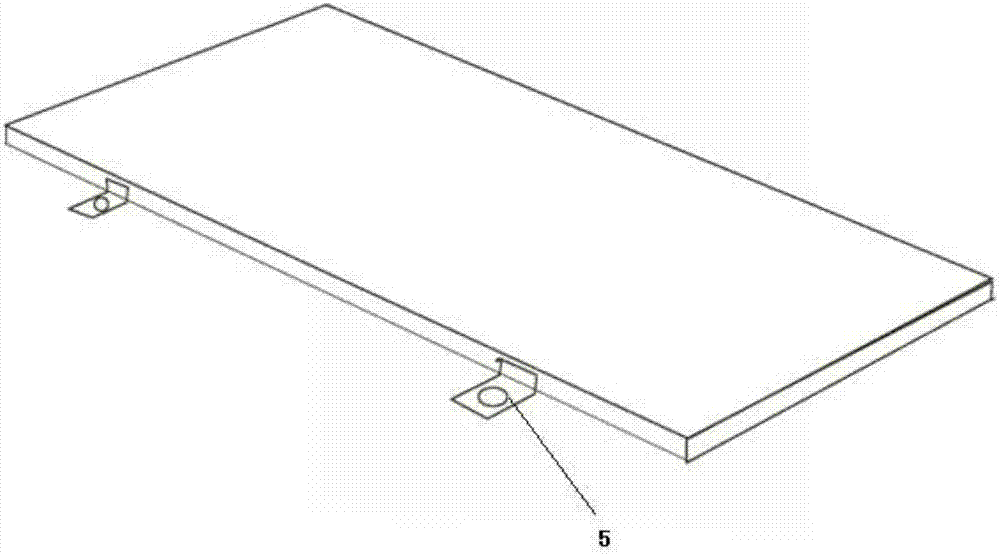

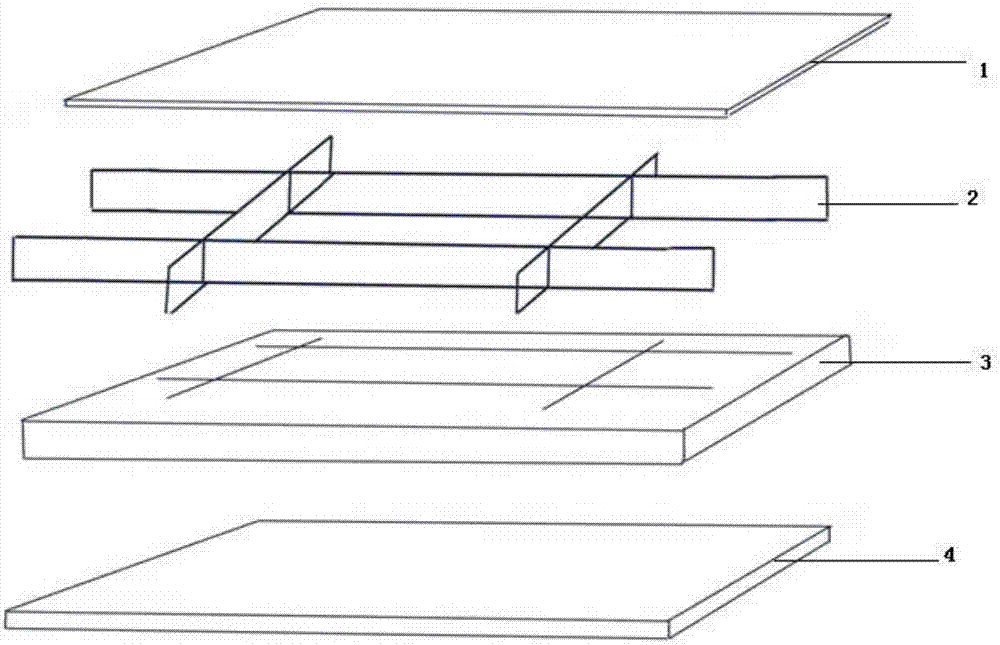

Exterior wall fireproof composite board with built-in keel

PendingCN107401258AEnhanced wind load resistancePrevent collapseCovering/liningsFlooringInsulation layerChinese characters

The invention relates to an exterior wall fireproof composite board with a built-in keel. The exterior wall fireproof composite board successively comprises a backboard layer, a heat-insulation layer and a surface decoration layer outwardly from an exterior wall, the keel is embedded in the heat-insulation layer, and the backboard layer, the heat-insulation layer and the surface decoration layer are bonded with each other to form the composite board. The exterior wall fireproof composite board also comprises wall anchoring members for fixing and connecting the composite board to the wall. The keel is an aluminum alloy keel of a structure shaped like a Chinese character 'jing', 'tian', 'wang', or 'shi'. The exterior wall fireproof composite board has the advantages that through building the aluminum alloy keel in the heat-insulation layer, wind load anti-compression performance of the whole composite board is largely enhanced, and collapse and deformation of the whole composite board are effectively prevented; and service lifetime of exterior wall heat-insulation materials is effectively prolonged, and heat-insulation lifetime of the exterior wall can be prolonged to be over 10-15 years.

Owner:江贤梁 +1

Energy-efficient ceramic kiln burner

The invention discloses an energy-efficient ceramic kiln burner. A base consists of an air intake chamber and an air outlet chamber, a cylindrical shell is connected with the air outlet chamber in a sealing manner, a cup-shaped burning head is fixed at the front end of the cylindrical shell in a sealing manner, a gas pipeline is arranged in the cylindrical shell, and a gas nozzle at the front end of the gas pipeline is aligned to the bottom of the cup-shaped burning head. The gas nozzle is arranged at the rear end of the burner and keeps a certain distance from the burning head, so that gas and air are premixed at the rear end of the burning head and form mixing concentration gradient, thereby effectively eradicating the backfire detonation phenomenon due to uniform mixing of the air and the gas in the cylindrical shell. The energy-efficient ceramic kiln burner automatically controls an air volume through a circuit to reach the best ratio of the gas to the air, can save above 20% of the gas than the existing burner, and has huge social and economical benefits of energy conservation, emission reduction, low carbon and environment friendliness.

Owner:北京中宇先创能源科技有限公司

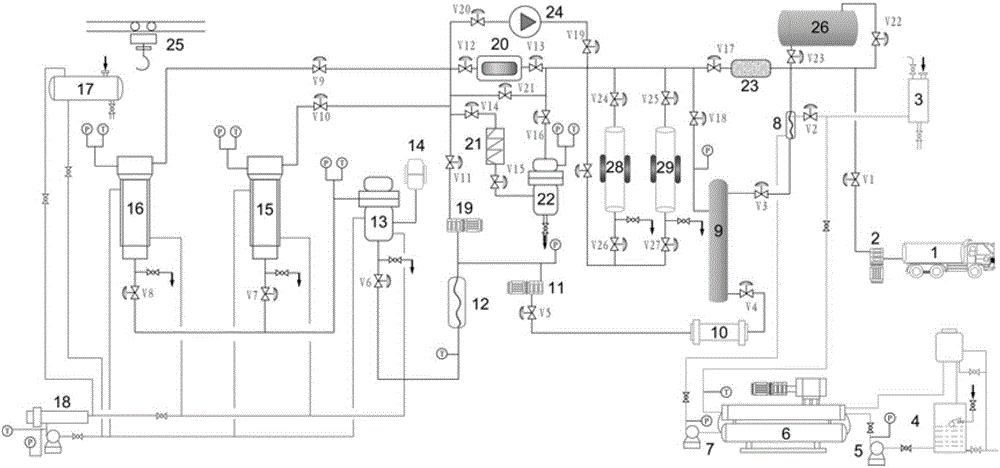

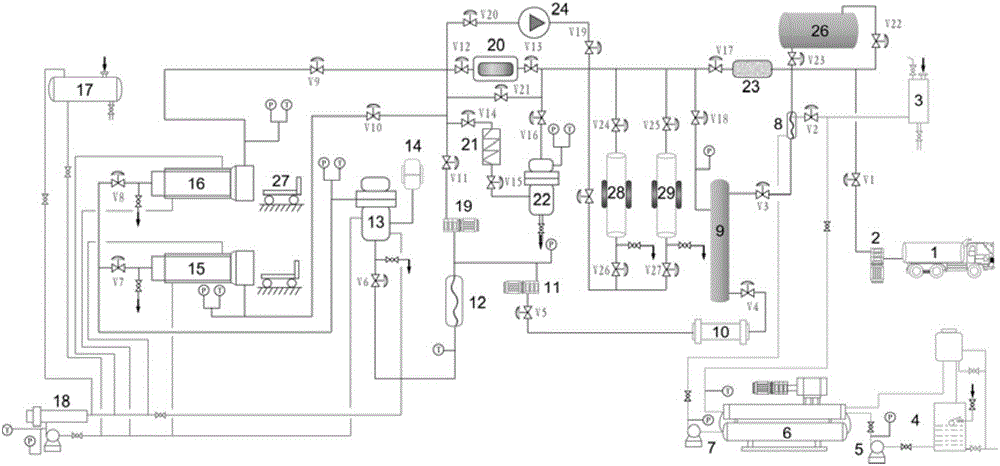

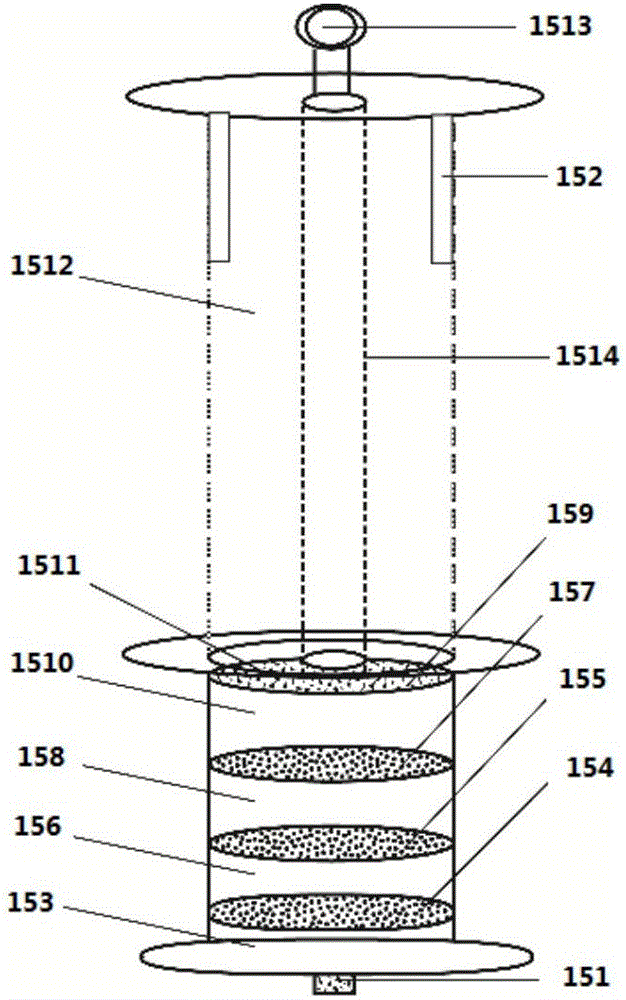

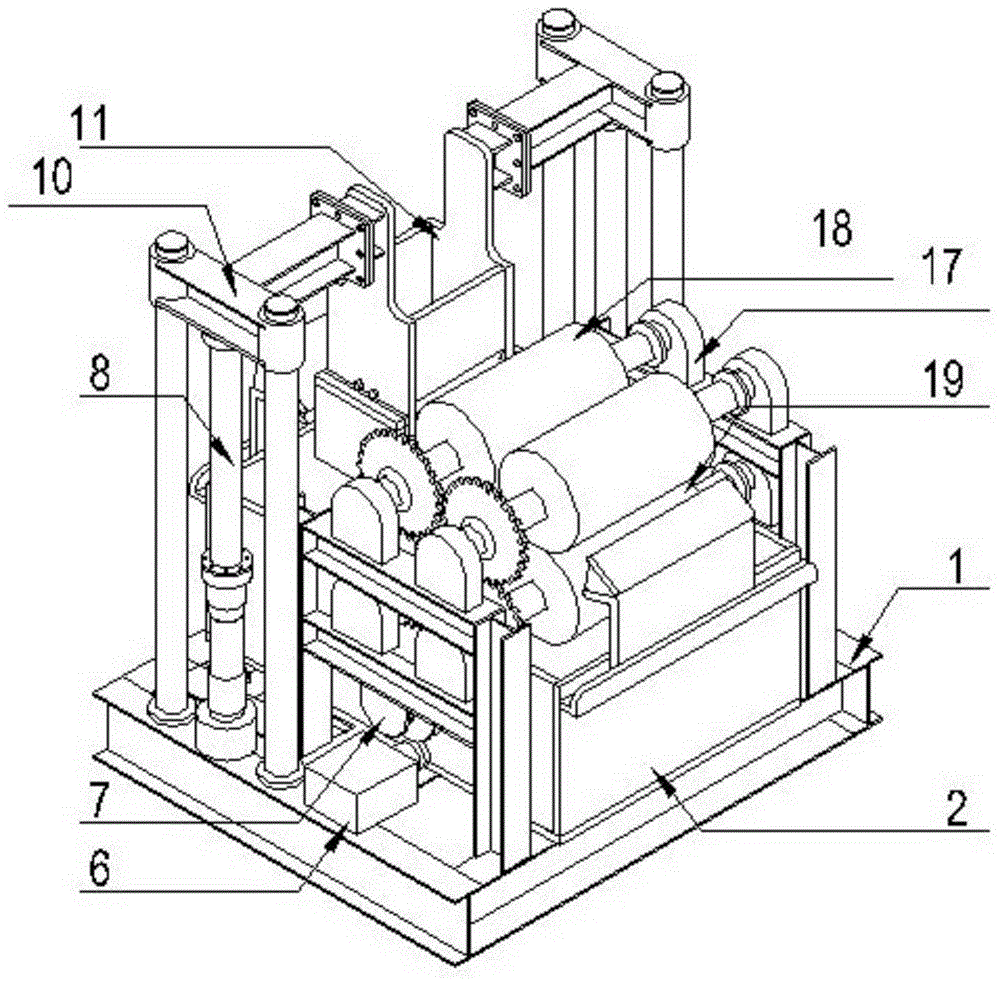

Multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with scale of 1000L or more

ActiveCN106835560ASolve the color changing problemRealize finishing productionTextile treatment containersSolvent treatment with solvent recoveryAutomatic controlSupply Storage

The invention discloses a multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with the scale of 1000L or more. The industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment mainly comprises a CO2 low-temperature storage tank, a CO2 supply storage tank, a low-temperature delivery pump, an ethanediol head tank, an ethanediol pump, a water cooling tower, a water pump, a refrigerating unit, a condenser, a heat exchanger, a conduction oil system, a conduction oil supplementing system, a precooler, a CO2 booster pump, a dye kettle, a feeder, the multi-element dyeing and finishing kettle, a CO2 circulating pump, a cooler, a separating kettle, an adsorber, a recovery compressor, an online monitoring system and an automatic control system. The equipment is provided with the multi-element dyeing and finishing kettle and therefore is capable of achieving dyeing and finishing production of multiple kinds of monochromatic or polychromatic textiles. The dye kettle has the function of feeding at the right moment and can meet the requirement for fully dissolving dye and adding polychromatic dye; the dyeing and finishing equipment is connected with ultraperformance convergence chromatography and has the online monitoring function. The whole equipment achieves intelligence, automatic processing, energy conservation and environmental protection of the whole anhydrous dyeing and finishing process.

Owner:晋江国盛新材料科技有限公司

Steel coating device and production method thereof

InactiveCN104451496AAvoid investmentImprove pollutionHot-dipping/immersion processesProduction lineOne-hot

The invention relates to the field of metallurgical pressure machining and coating, and provides a steel coating device and a production method of the steel coating device. Production of hot-rolled acid-pickling-free steel and coating steel of other varieties such as galvanized steel is achieved. The steel coating device comprises a reduction cooling device, a coating device and an after-coating cooling device. The hot-rolled acid-pickling-free steel with glass films can be produced through the coating device arranged on an outlet of a hot rolling finishing mill. The steel coating device has the advantages that technical feasibility is high, investment is low, and the effect is remarkable; the requirements of various industries are met; coating materials are cheap, easy to obtain and high in renewable utilization value; energy conservation and emission reduction of multiple industries can be promoted, and meanwhile sound development of downstream industries is driven; online and simultaneous production of the acid-pickling-free steel and the coating steel can be achieved on one hot rolling production line.

Owner:夏征

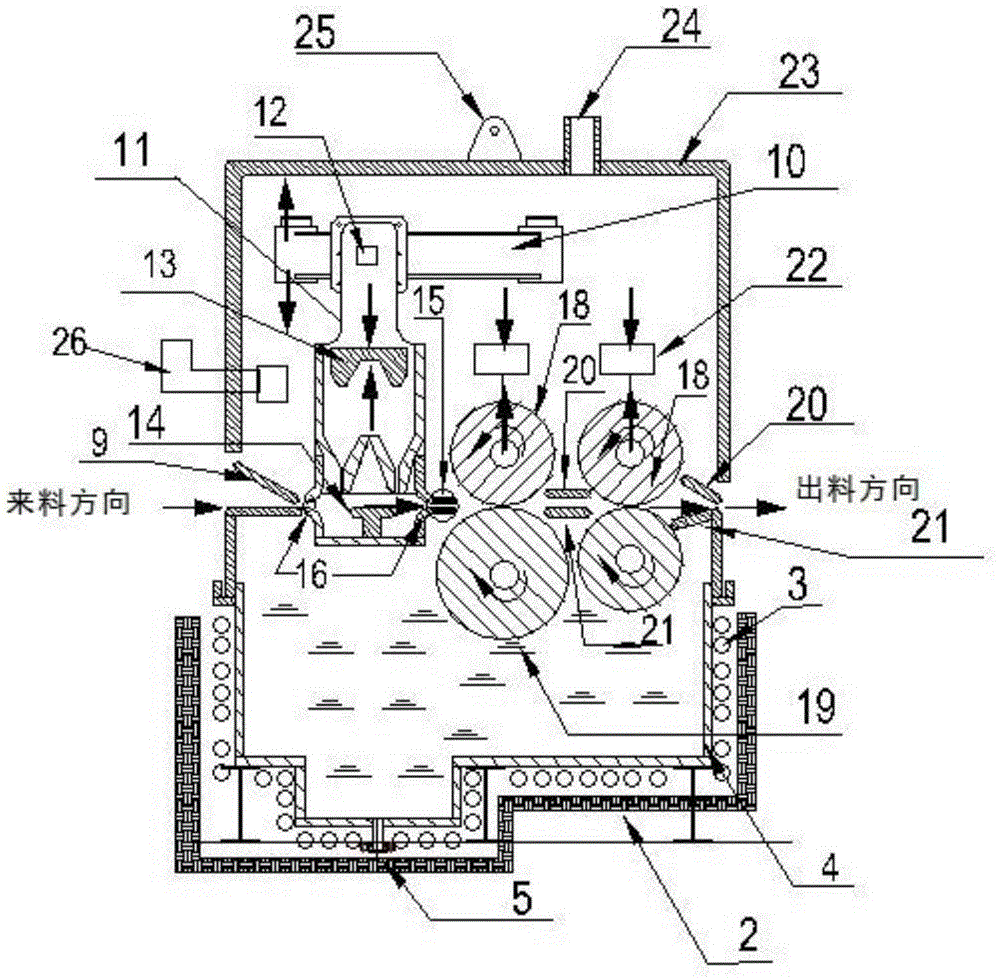

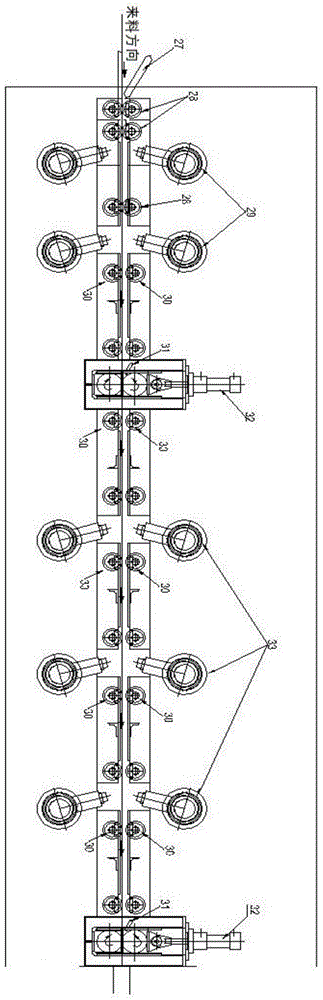

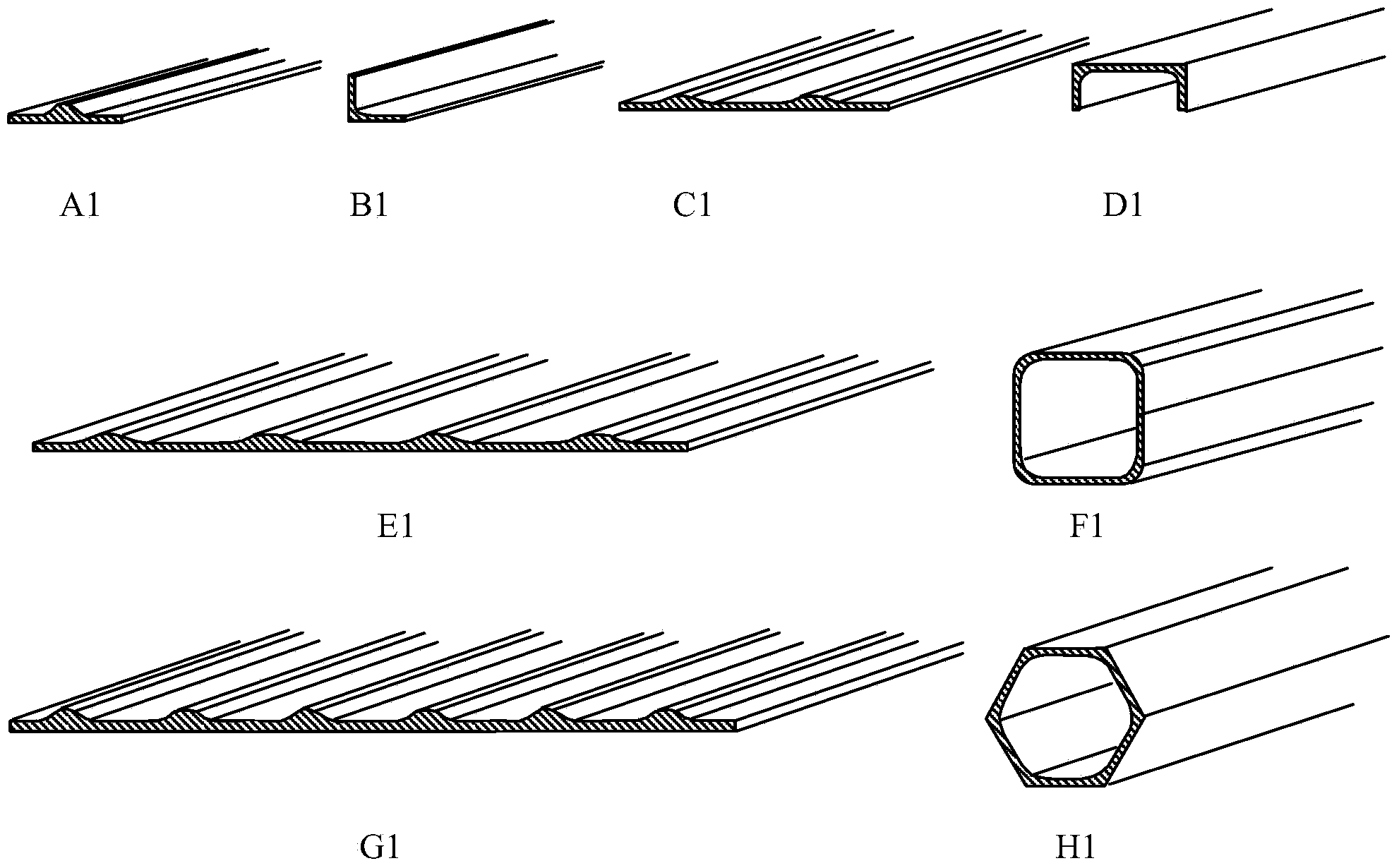

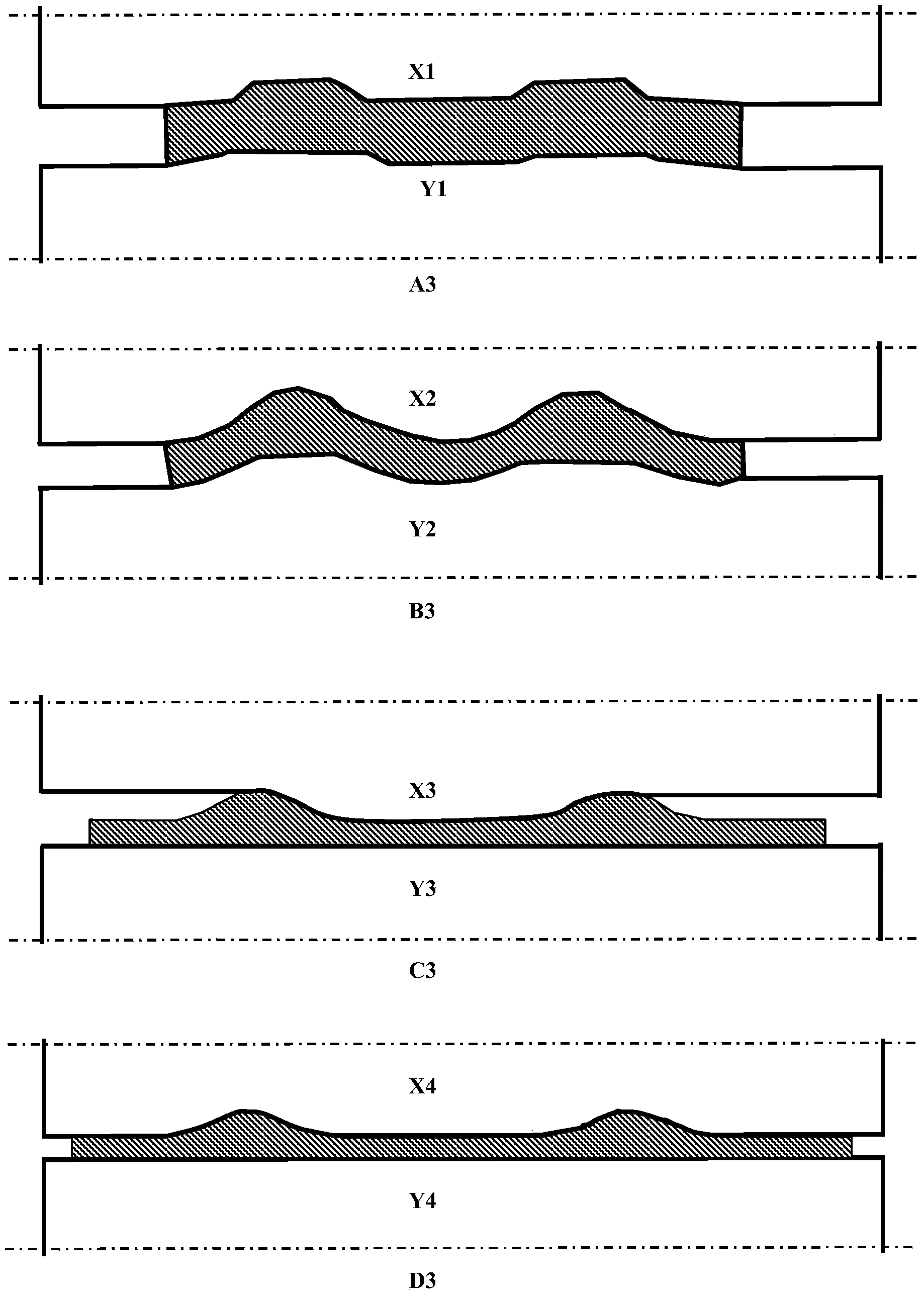

Transversely locally thickened plate strip and manufacturing method thereof

ActiveCN103831297AEase of high-volume industrial productionSave materialMetal rolling arrangementsWork rollMetallic materials

The invention discloses a transversely locally thickened plate strip and a manufacturing method thereof, and belongs to the technical field of rolling. The transversely locally thickened plate strip comprises a base plate and at least one longitudinal rib. The manufacturing method includes firstly, preparing a plate strip to be rolled; secondly, performing a first rolling by a rolling machine with a trapezoidal groove on one working roll and a trapezoidal projection on another working roll; thirdly, performing a second rolling by a rolling machine with an arced groove on one working roll and an arced projection on another working roll; fourthly, performing a last rolling by a rolling machine with rib grooves circumferentially arranged on the cylindrical surface of one working roll. By the optimal design of the shape of the cross section of plates, local metal distribution, load conditions and structural characteristics on the cross section can be matched, and therefore metal materials are saved, and the target for reducing structural weight is achieved.

Owner:NORTHEASTERN UNIV

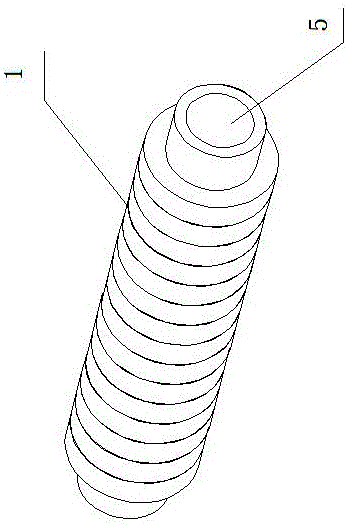

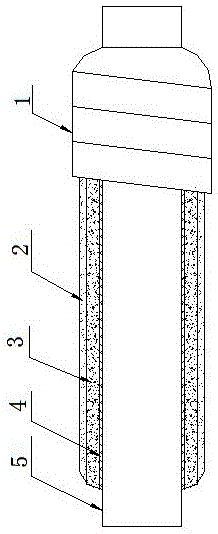

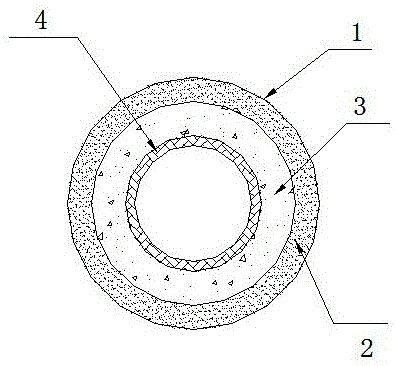

Ultrahigh-temperature prefabricated direct burial heat preservation pipe and heat preservation method

PendingCN106523856AEfficient use ofLow thermal conductivityThermal insulationPipe protection by thermal insulationPetrochemicalEngineering

The invention discloses an ultrahigh-temperature prefabricated direct burial heat preservation pipe and a heat preservation method. According to the current original heat preservation technology, the technology adopting polyurethane, rock wool, silicate and other heat preservation materials is adopted for conducting heat preservation on ultrahigh-temperature pipelines, although the above structure can play a certain heat preservation role, the energy dissipation rate is high, and the service life of a heat preservation layer is short. The ultrahigh-temperature prefabricated direct burial heat preservation pipe comprises a steel pipe (1), an aerogel heat preservation layer (2) and a polyurethane heat preservation layer (3). The outer wall of the steel pipe is annularly wrapped through the rock wool in a closed manner, and a rock wool heat preservation layer is formed. The outer side of the rock wool heat preservation layer is annularly wrapped by aerogel felt in a closed manner, and the aerogel heat preservation layer is formed. The outer side of the aerogel heat preservation layer is evenly wrapped by a heat reflection layer. Polyurethane is sprayed to the outer sides of the aerogel heat preservation layer and the reflection layer, rigid polyurethane spray expanding foam is formed, and the polyurethane heat preservation layer is formed. The ultrahigh-temperature prefabricated direct burial heat preservation pipe and the heat preservation method are applied to 2,000 DEG C ultrahigh-temperature prefabricated heat isolation and heat preservation pipelines used in the fields of heat supply, cold supply, petroleum and petrochemicals and ships.

Owner:哈尔滨朗格思特供热装备科技有限公司

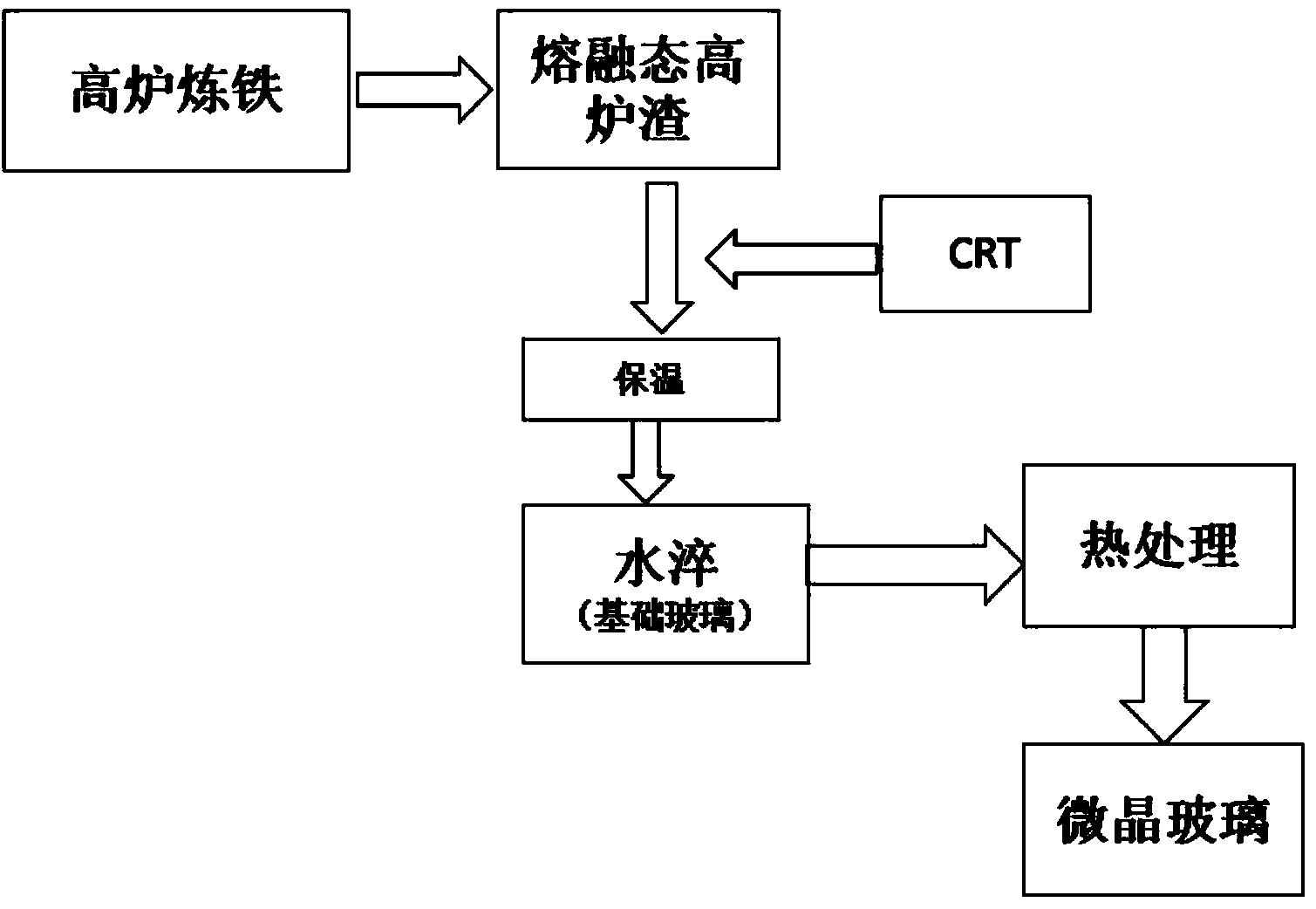

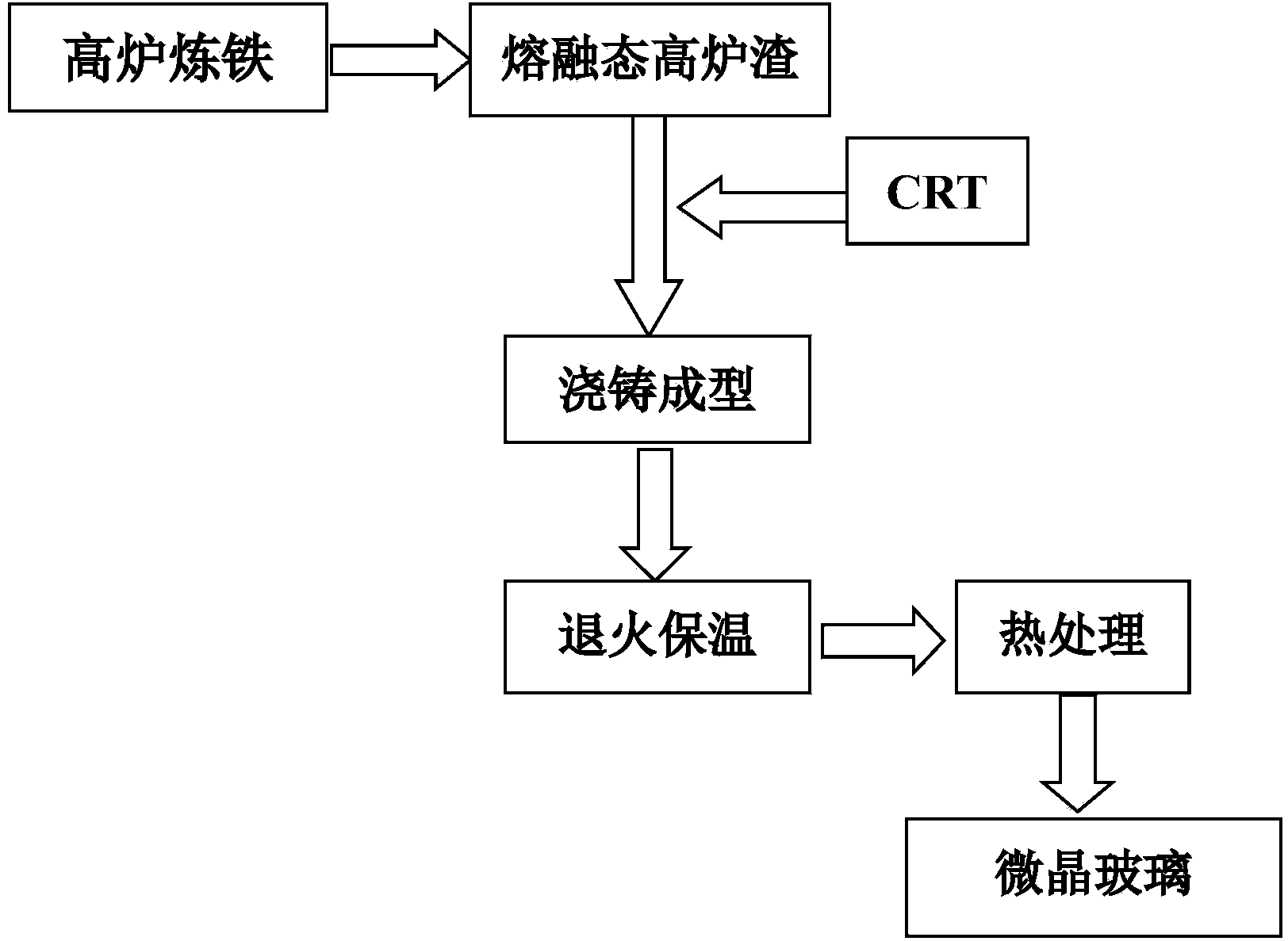

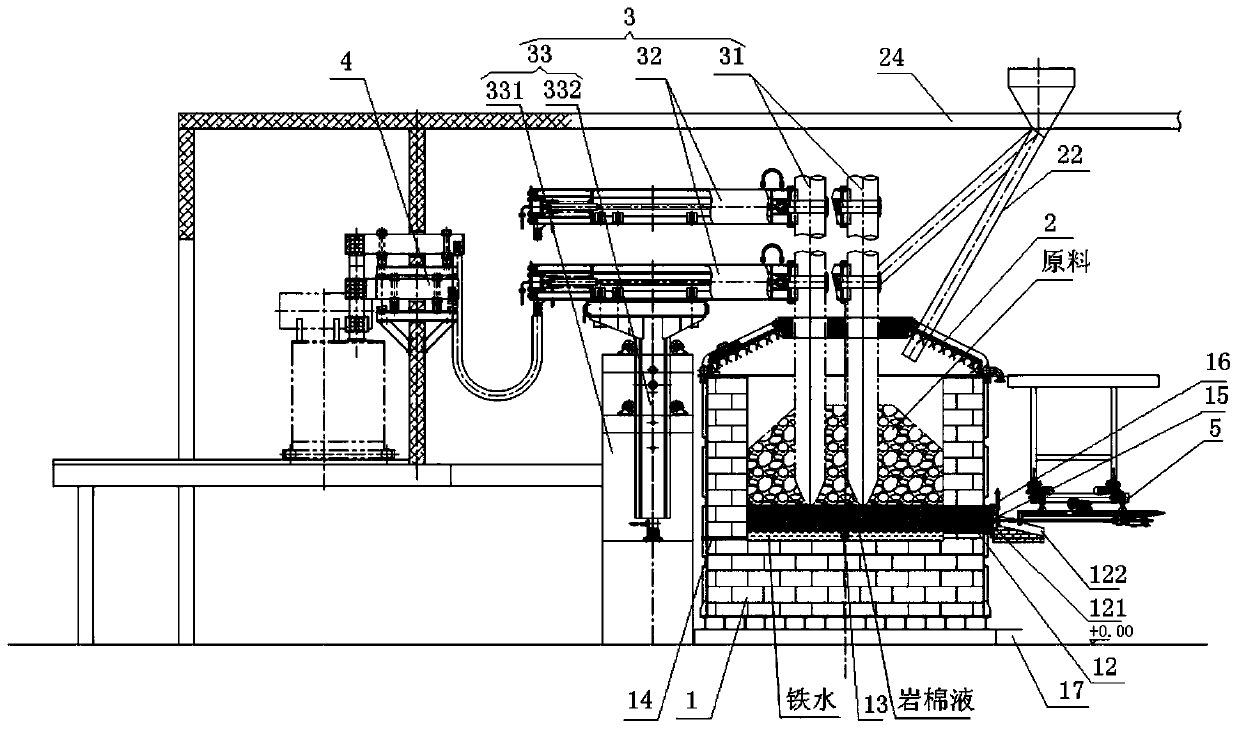

Method for treating waste CRT (cathode ray tube) and preparing glass ceramics by using slag

The invention provides a method for treating waste CRT (cathode ray tube) and preparing glass ceramics by using slag, belonging to the field of comprehensive utilization of resources. The full name of CRT is Cathode Ray Tube, namely cathode ray tube. The method disclosed by the invention comprises the main process as follows: prepared waste CRT powder is synchronously added into the slag in proportion in the process of high-temperature metallurgical slag discharge, and the blended slag is further used as a material for preparing the glass ceramics. According to the method disclosed by the invention, the heat of the slag is directly utilized, a large amount of waste CRT can be treated, heavy metal ions in the slag can be solidified, and a product with a high additional value can be prepared, so that the method has good economic and social benefits and is suitable for large-scale application in industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Low-temperature solidification spray coating and construction method thereof

ActiveCN105130475AReduce consumptionSignificant energy saving and emission reductionLiquid surface applicatorsCoatingsSpray coatingMullite

The invention discloses low-temperature solidification spray coating, comprising a dry material and an inorganic binding agent, wherein the dry material is formed by stirring and mixing flint clay granules, electric ceramic granules, mullite granules, mullite fine powder, white corundum powder, activated aluminium oxide powder, nanoscale silicon micro powder, Guangxi white mud and a PT organic binding agent, wherein the inorganic binding agent is liquid sodium silicate. The scientific grain size distribution is adopted, and the materials such as the nanoscale silicon micro powder, the activated aluminium oxide powder and the inorganic binding agent which are added in a compounding way enable the spray coating to be solidified under a low temperature condition, so as to form a whole high-intensity low-temperature solidification lining body; the inorganic binding agent and the organic binding agent mutually react to improve the construction performance of the spray coating, so that the rebound is lowered to10 percent. After being used during the construction of a large sintering flue, a warm-air pipeline, a dust removal pipeline and the like in practice, the spray coating can be solidified to form the whole high-intensity lining body by self-combination under lower temperature without sintering, thus obviously reducing material consumption and achieving the aim of energy conservation and emission reduction.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

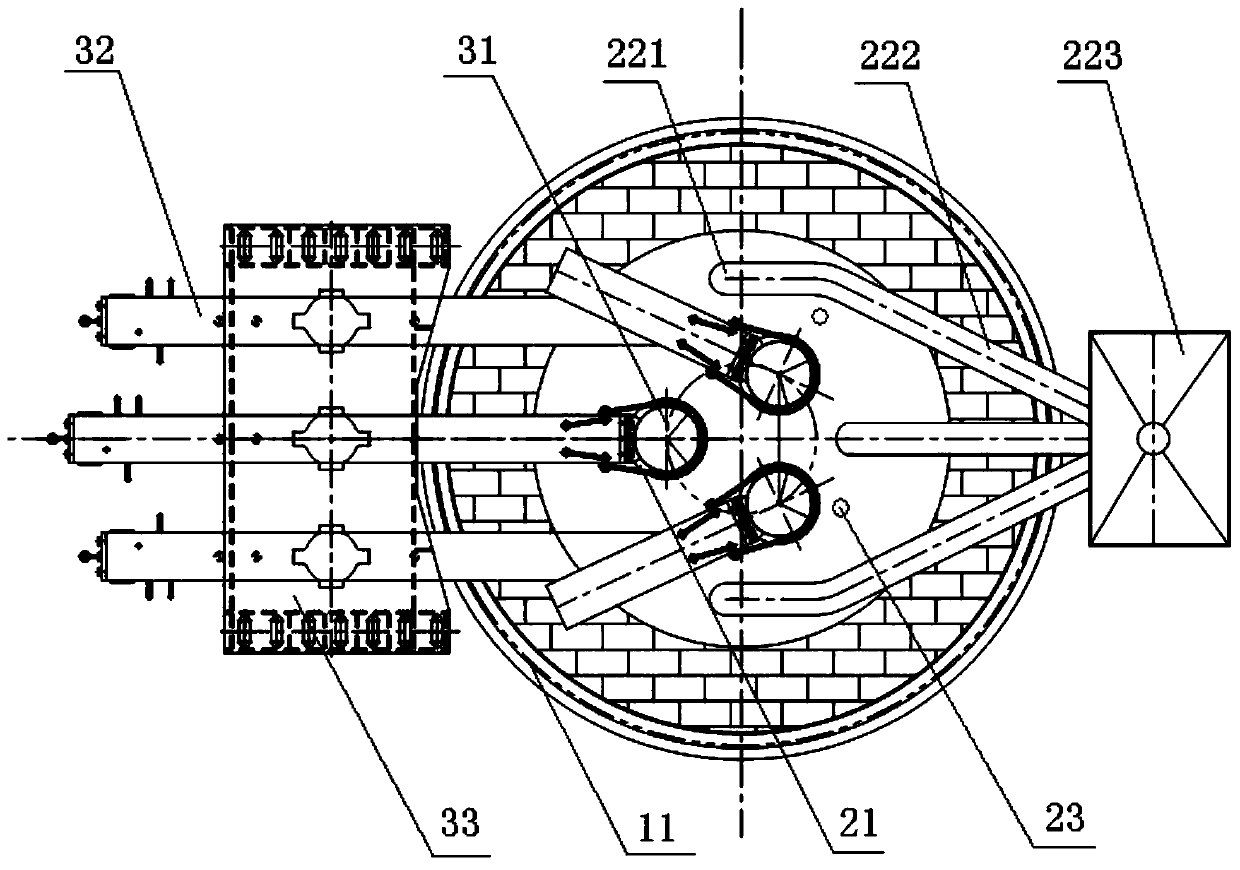

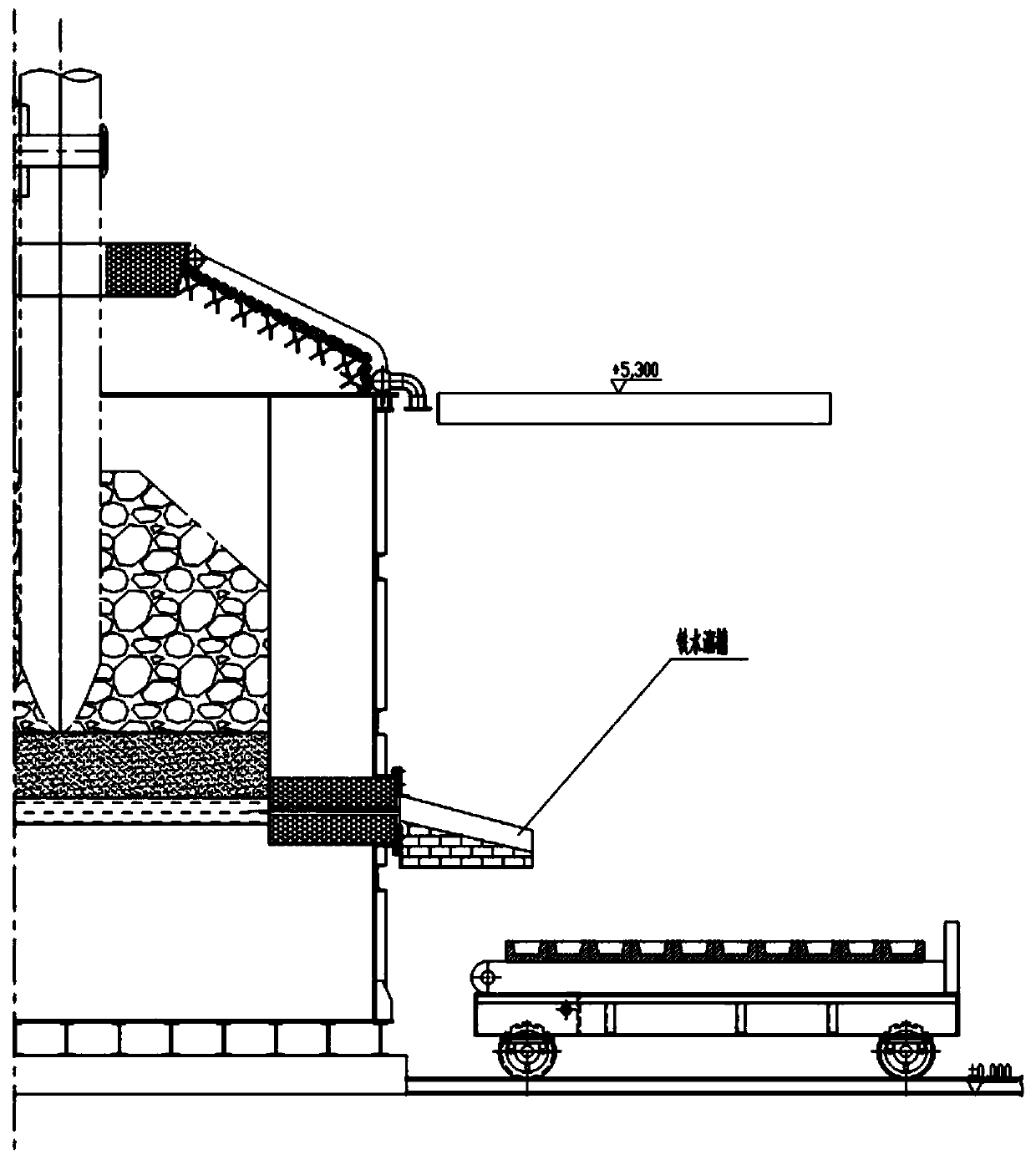

Electric melting furnace, electric melting method and method for producing rock wool by using electric smelting red mud

PendingCN110342782AArc stabilizationNo pollution in the processGlass furnace apparatusElectric furnaceWoolPower grid

The invention provides an electric melting furnace, an electric melting method and a method for producing rock wool by using electric smelting red mud, and relates to the field of high-temperature melting. An electric melting furnace body is in structure matching with an ignition device, and electric discharging points of graphite electrodes of the ignition device are respectively and electricallyconnected with resistance wires; an electrode automatic adjusting mechanism comprises an electrode lifting mechanism, the electrode lifting mechanism is electrically connected with the three-phase graphite electrodes, and the electrode lifting mechanism drives the three-phase graphite electrode to ascend and descend; and the electric melting furnace body is provided with channels for moving the graphite electrodes. According to the technical scheme, the contact area between the three-phase graphite electrodes and a molten liquid can be adjusted, and the voltage can be converted under an on-load condition, so that electric arc heat is concentrated, the electric arc is stable, and the phenomena of large fluctuation of voltage and current, unstable arc burning, short circuit and arc breakingare avoided. Impact on the power grid in an implementation process is avoided, and no harmonic pollution is caused.

Owner:北京金亚润环保科技有限公司

Near-dry cutting oil for aluminum alloy and preparation method thereof

ActiveCN102977971AGood extreme pressureGood lubrication and cooling effectBase-materialsPhosphateDiethylene glycol

The invention provides a near-dry cutting oil for aluminum alloy and a preparation method thereof. The near-dry cutting oil for aluminum alloy comprises, by weight, 20 to 80% of diethylene glycol carboxylic borate (containing a small amount of glycol dicarboxylate and boric acid) and 20 to 80% of diethylene glycol carboxylic phosphate (containing a small amount of glycol dicarboxylate and phosphoric acid). The preparation method for the aluminum alloy near-dry cutting oil is to uniformly mix diethylene glycol carboxylic borate (containing a small amount of glycol dicarboxylate and boric acid) and diethylene glycol carboxylic phosphate (containing a small amount of glycol dicarboxylate and phosphoric acid) in proportion under stirring so as to prepare the near-dry cutting oil for aluminum alloy. The near-dry cutting oil for aluminum alloy provided by the invention has excellent extreme pressure properties, abrasion resistance and lubricity; when the cutting oil is used together with a near-dry cutting lubricating device, no smoke is generated in the process of near-dry machining of aluminum alloy, the application amount of the cutting oil is reduced to less than 5% of the application amount of original cutting oil, and good energy saving and environmental protection effects are realized.

Owner:上海德润宝特种润滑剂有限公司

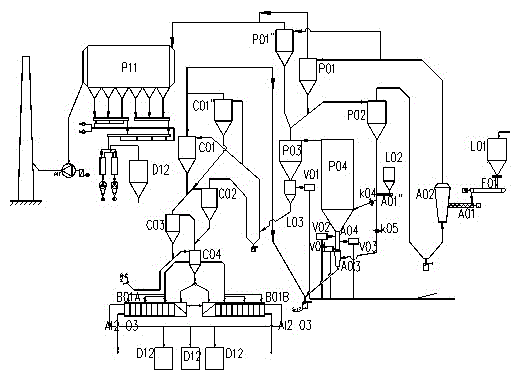

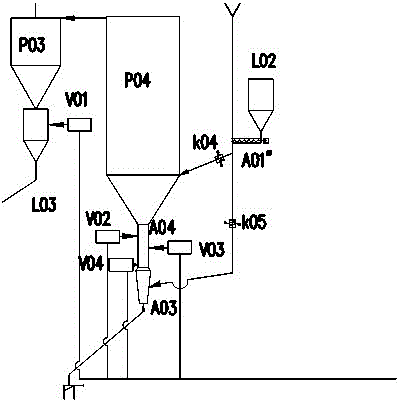

Equipment and method for calcining alpha aluminum oxide by using aluminum oxide gaseous suspension calciner

InactiveCN104058435AIncrease profitReduce manufacturing costAluminium oxide/hydroxide preparationFluidized bedCyclonic spray scrubber

The invention relates to the technical field of high-temperature aluminum oxide production and discloses equipment and method for calcining alpha aluminum oxide by using an aluminum oxide gaseous suspension calciner. The equipment adopted in the method is characterized in that the input end of a dust-contained waste gas filtering system is communicated with a feeding system through an aluminum oxide drying system, and the output end of the dust-contained waste gas filtering system is connected with the end for communicating a valve K04 and a valve K05; the other end of the valve K04 is communicated with a calciner P04; the other end of the valve K05 is communicated with the calciner P04 through a combined combustion station; the calciner P04 is communicated with a heat insulation retention tank L03 through a cyclone dust collector P03; the heat insulation retention tank L03 is connected with a high-temperature aluminum oxide storage tank D12 through a step-by-step cooler and a fluidized bed B01. The equipment and method can be used for meeting the requirement for alternate production of high-temperature aluminum oxide and aluminum oxide, and are very suitable for building or modifying the traditional calciner, capable of increasing the utilization ratio of the equipment as well as more advantageous and environment-friendly on the aspects of saving energy and reducing emission as comparison with the traditional rotary kiln when used for calcining high-temperature aluminum oxide.

Owner:鞠复勇

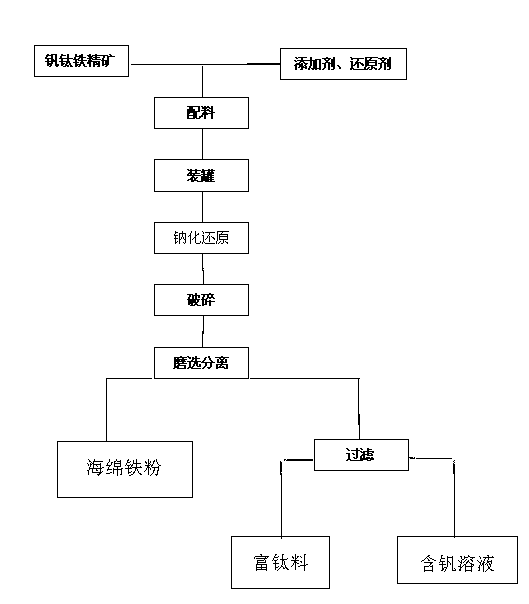

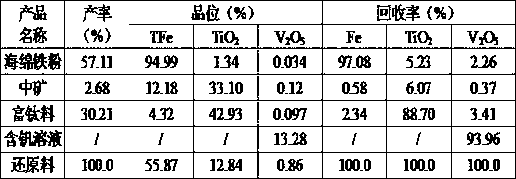

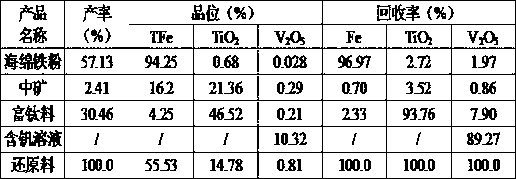

One-step new technology for separating ferrum, titanium and vanadium in vanadium-titanium-ferrum concentrate

InactiveCN103276213AChoose Requirements WideLow reduction temperatureChemical industryChemical industrySteelmaking

The invention relates to a one-step new technology for separating ferrum, titanium and vanadium in vanadium-titanium-ferrum concentrate. The new technology technically comprises the steps of: directly separating out ferrum, titanium and vanadium at one step through new reducing, grinding and separating technology to produce three products: ferrum product for steelmaking or powder metallurgy or chemical industry, rich-titanium material with good acid solubility for sulfate process titanium dioxide, sodium poly-vanadium solution for extracting vanadium pentoxide, thus creating a high-efficiency and economic new technology for comprehensively utilizing the vanadium-titanium-ferrum concentrate. Compared with two-step and three-step methods, the one-step new technology has a series of advantages of being short in technological flow, economic for fixed assert investment, low in production cost, less in environment pollution, high in comprehensive utilization yield, excellent in product cost performance, obvious in energy conservation, emission reduction and the like, and provides a new technology for efficiently and economically comprehensively utilizing the abundant vanadium-titanium-ferrum concentrate resources for China, thus having wide application prospects.

Owner:CHANGSHA DONGXIN MINING & METALLURGICAL TECH DEV

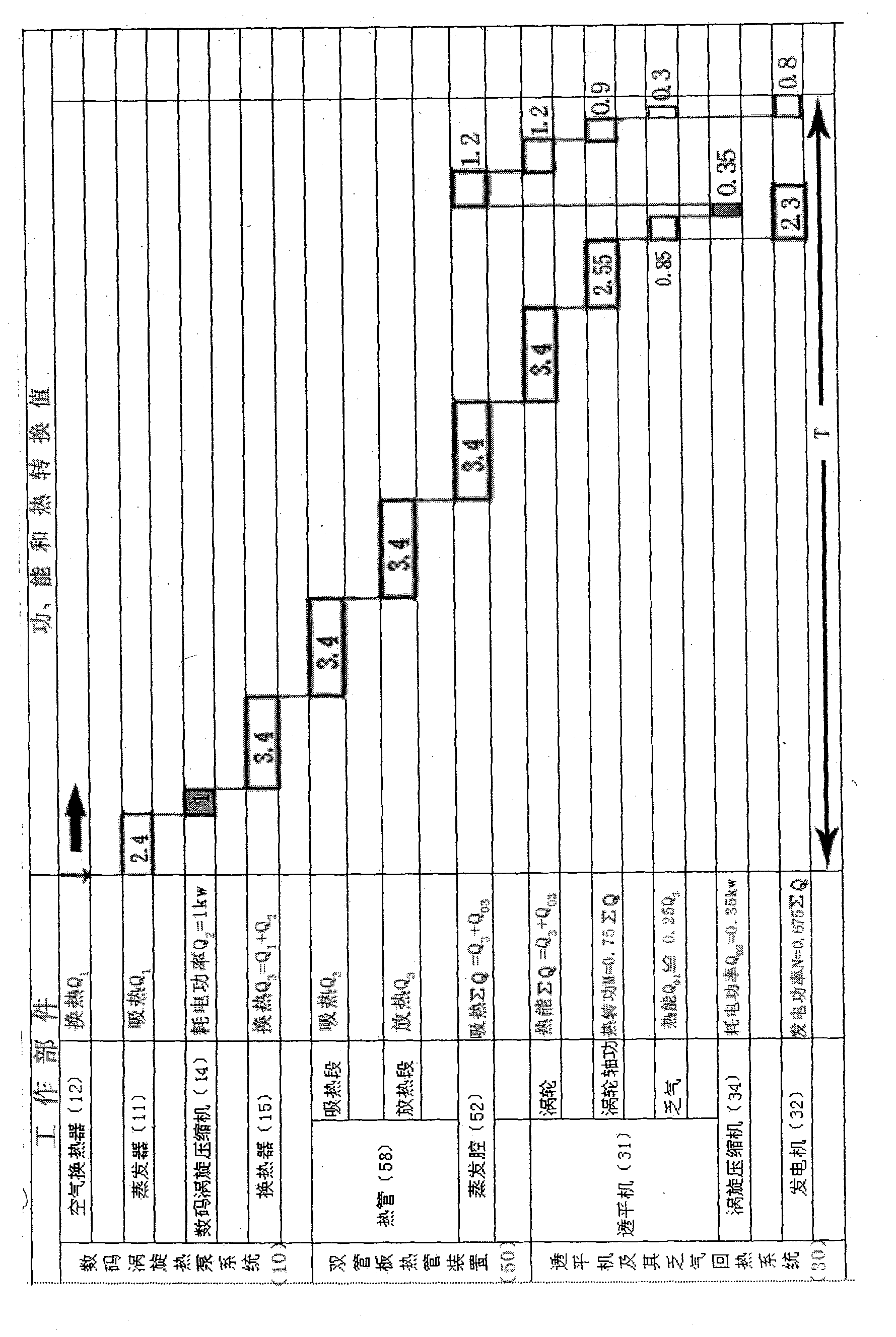

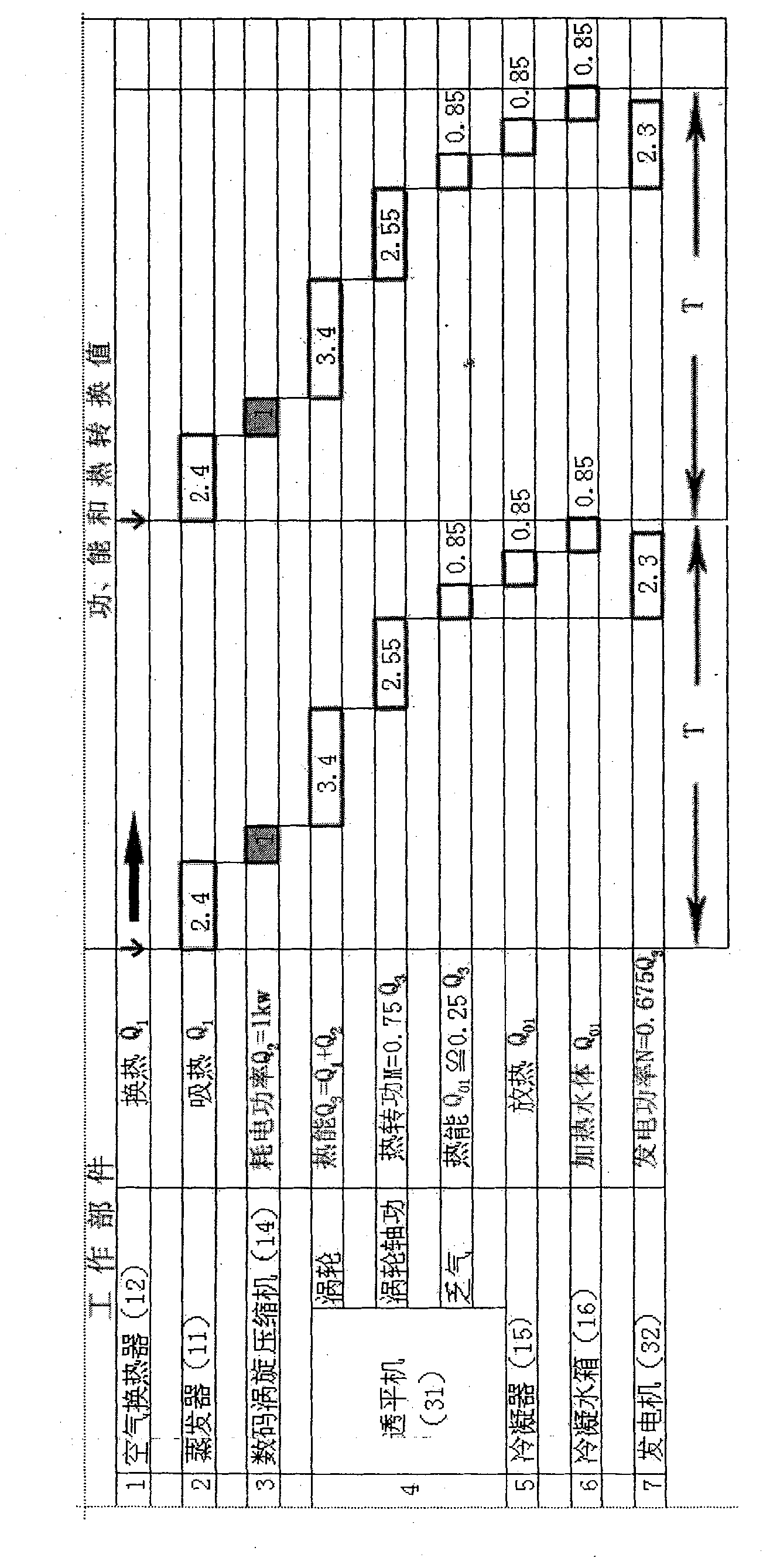

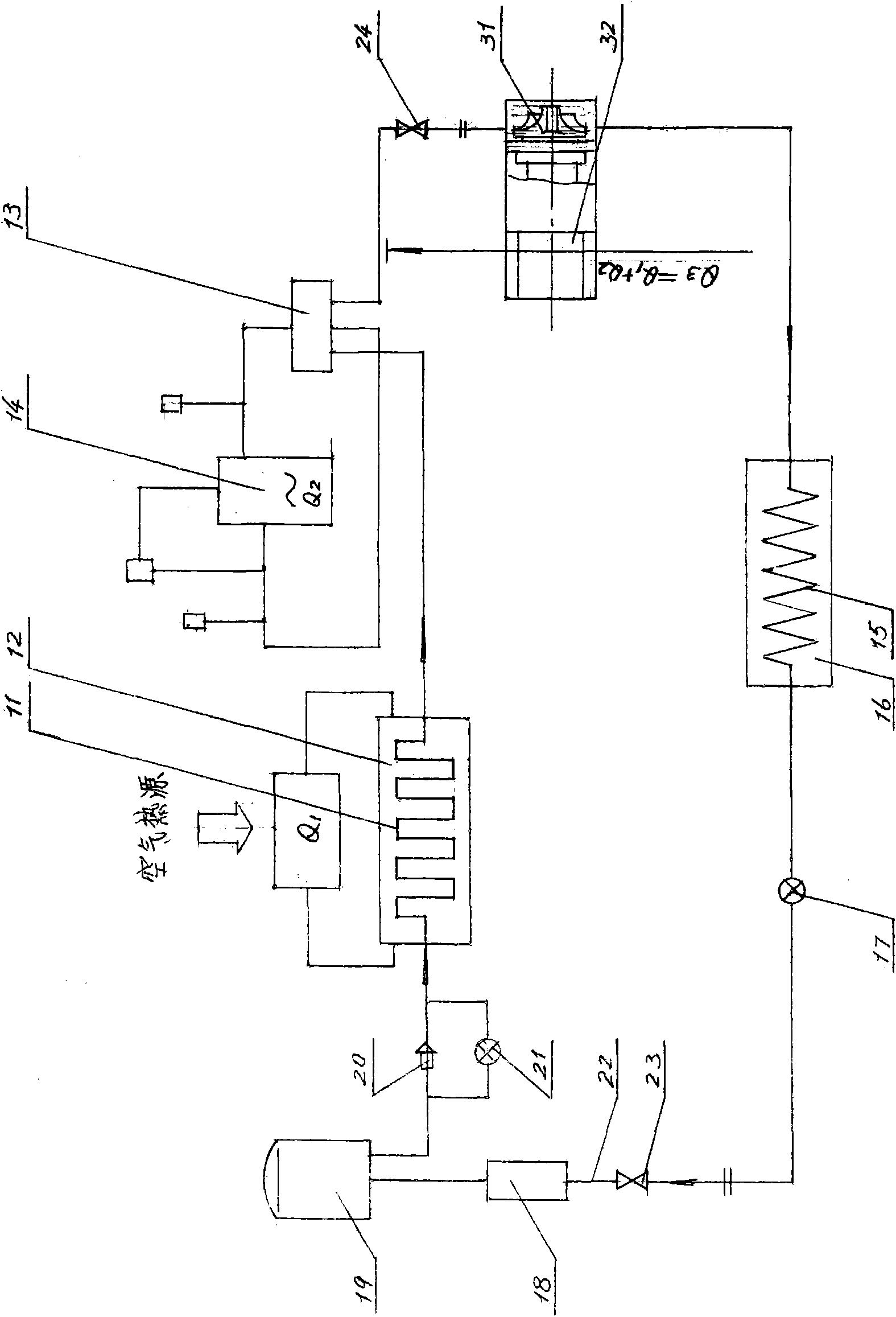

Digital vortex thermo-motive generation device

InactiveCN101813010AAdaptation to climate changeImprove seasonal energy efficiency ratioSteam useThermodynamicsEngineering

The invention relates to a digital vortex thermo-motive generation device, in particular to the digital vortex thermo-motive generation device which utilizes heat of air heat sources or other low-temperature heat sources and uses working medium with low boiling point to apply work and automatically circulate. The invention designs a digital vortex thermo-motive generation device and a working method thereof, aiming at the problems that inadaptability to climatic changes, low energy efficiency ratio COP of the conventional heat pump generation device and the low-temperature thermo-motive device, motive seal medium leakage of a turbomachine output shaft, and low loading rate of discontinuous operation of the turbomachine. The device comprises a single and dual cycle digital vortex thermo-motive generation device integrated by a digital vortex heat-pump system, a working medium zero-leakage low-temperature turbomachine and a dead-steam extraction cycle system thereof, and a heat pipe device, a multi-split online, heat pump combined supply one-online and heat pump combined supply multiple-online generation systems. The device can adapt to climatic changes, has the energy efficiency ratio COP of between 3.4 and 5.6w / w, and can realize clean environment with working medium zero-leakage zero-pollution and no heat drainage pollution.

Owner:杨德林 +2

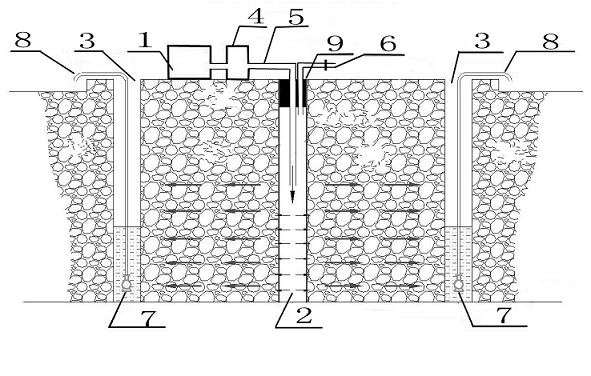

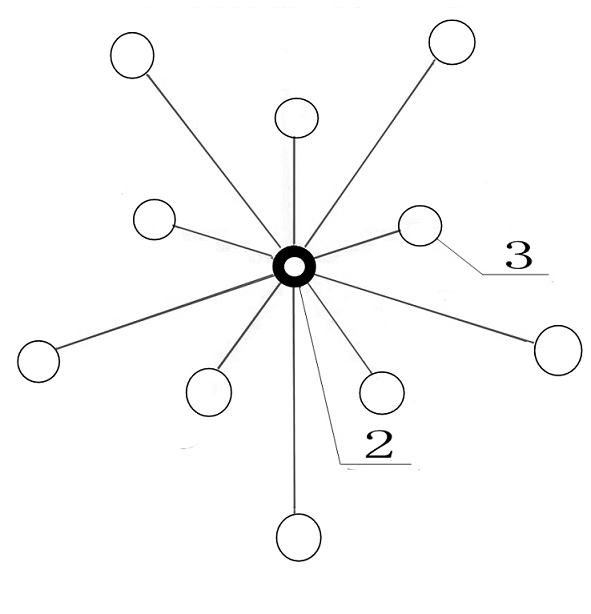

System for extracting deep intercrystalline brine in salt lake mining area

ActiveCN103373736AIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakePotassium

The invention relates to a system for extracting deep intercrystalline brine in a salt lake mining area. The system comprises an air compressor which is arranged on a salt lake mining layer, and an air-injection well, brine collecting wells and a brine conveying channel, which are formed in the salt lake mining layer in a digging manner, wherein the air compressor is connected with a high-pressure air pipe by an air reservoir; the high-pressure air pipe extends into the air-injection well; a brine tail liquid injection pipeline is arranged in the air-injection well; the brine collecting wells are distributed around the air-injection well; a brine conveying pipeline is arranged in each brine collecting well; a brine collecting pump is arranged in each brine collecting well and is connected with one end of the corresponding brine conveying pipeline; the other end of each brine conveying pipeline is connected with the brine conveying channel; sealing materials are arranged between the high-pressure air pipe and the brine tail liquid injection pipeline, between the high-pressure air pipe and the wall of the air-injection well, and between the brine tail liquid injection pipeline and the wall of the air-injection well respectively. According to the system, intercrystalline brine and deep brine can be pressed out by using compressed air, and simultaneously tail liquid after potassium extraction can be used for resolving low-grade solid potassium or high-grade solid potassium after dilution, so as to realize the aim of fully utilizing resources.

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

Preparation method for full-body polished porcelain tiles

The invention relates to a method for manufacturing porcelain full-body polished King Beige tiles, which mainly comprises the following steps: firstly, green bricks of the King Beige tiles are manufactured; and secondly, glaze is applied to the surfaces of the finished green bricks, wherein, the manufacture of the green bricks of glazed tiles and the King Beige tiles further comprises the following steps: raw material selecting, slurry preparing, color matching, drying, powder making, green brick pressing, green brick drying, etc., and the step of applying the glaze to the surfaces of the finished green bricks mainly comprises the following procedures: the glaze slurry is prepared, the glaze slurry is applied, glazed tile products, etc. are sintered, etc. The method has the advantages of extremely low water absorption rate, high strength, good anti-skid and anti-fouling effects, good durability, etc., and is widely applicable to the decorative walls or floors of advanced hotels, grand and large-scale activity places, airports, homes, etc.

Owner:关锐华

Solar house

InactiveCN102635158AAvoid spreadingSimple processRoof covering using slabs/sheetsRoof covering using tiles/slatesWhole bodyEngineering

The invention relates to a solar house. The upper end of a double-layer spacing half-column cylindrical wall is linked with a double-layer spacing wobble plate; both the outer-layer wall and the outer-layer wobble plate are transparent and heat-insulating or a solar cell is bonded on the outer surface of the transparent heat-insulating plate; both the inner-layer wall and the inner-layer wobble plate are heat-insulating; the lateral end surfaces of the wall and the wobble plate are linked with a heat-insulating wall; the outer transparent heat-insulating plate and the inner transparent heat-insulating plate are spaced at an interval, the periphery is sealed by using sealing strips and the whole body is inlayed in a framework to form a window; the window is placed on the wall, and the insides of the window and the wall are connected through a connecting pipe; the wall, the window and the wobble plate form a solar thermal collector; the upper and the lower ends of the heat-insulating column pipe are linked with an upper valve and a lower valve, wherein the upper valve penetrates through the inner wobble plate, the lower valve is communicated with a horizontal pipe which is communicated with the wall; a fluid generator is mounted on the lower part of the column pipe; an air conditioning system is arranged on the heat-insulating column pipe; in summer, the air conditioning system is used for refrigerating; and in winter, an outdoor condenser or a solar thermal collector serves as the evaporator of the air conditioning system so that heating of the air conditioning system is achieved.

Owner:刘新广

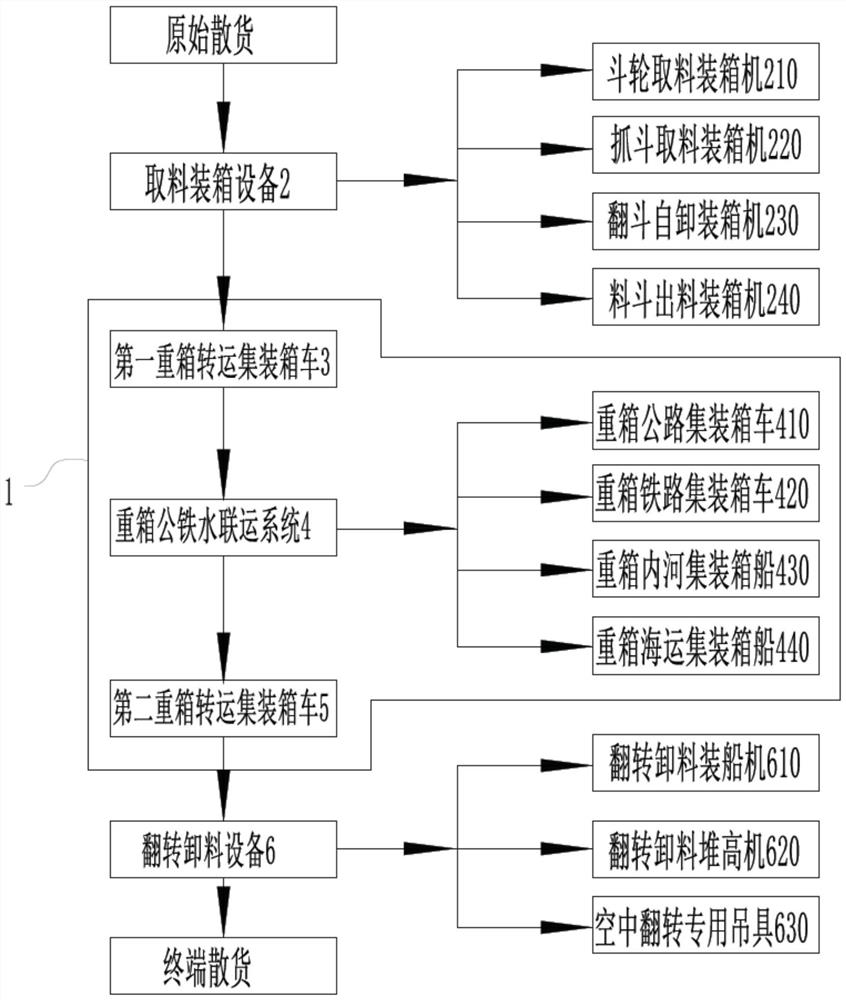

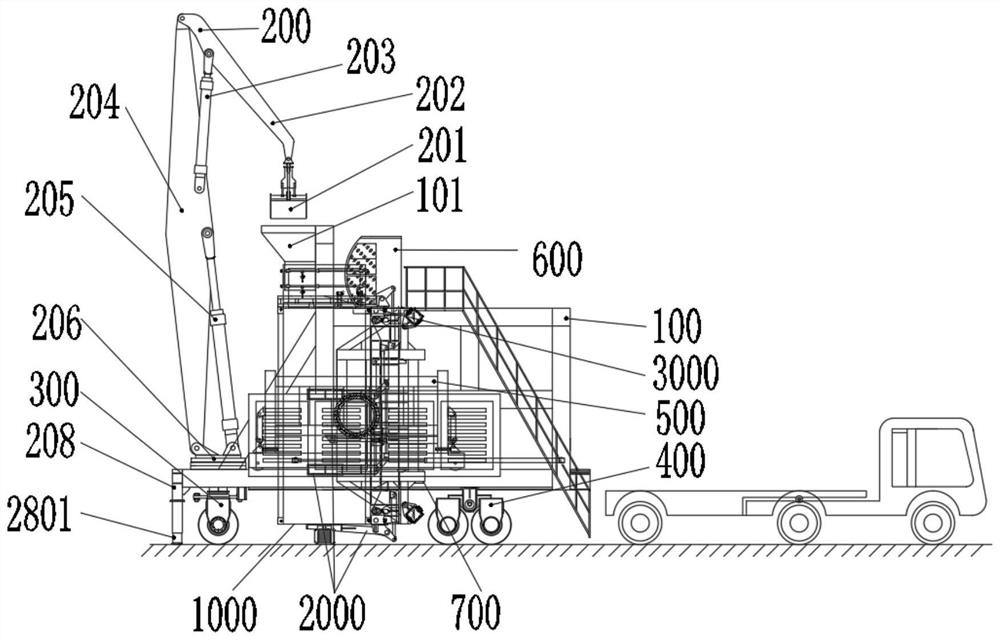

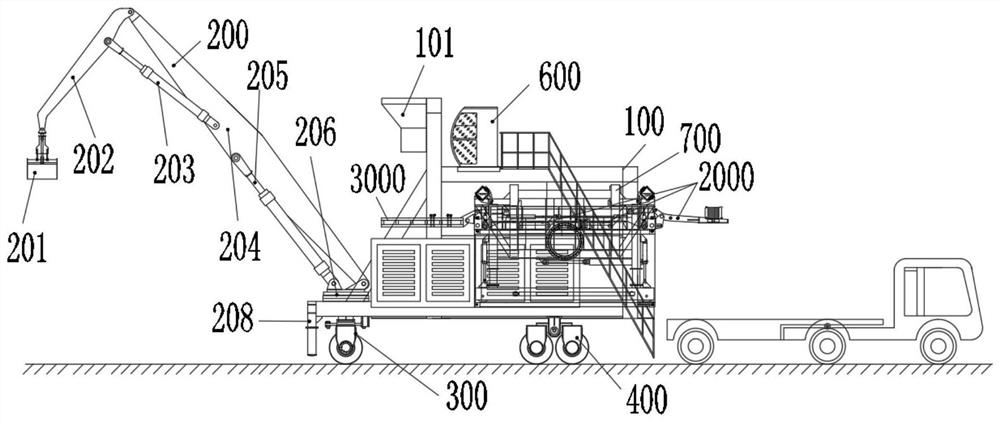

Container transporting, loading and unloading system and method

PendingCN112124987ALess damage and leakageSave on interest costsBottle emptyingLoading/unloadingStructural engineeringMechanical engineering

The invention discloses a container transporting, loading and unloading system and method. The system involves a material taking loading device, a container transferring system and an overturning unloading device; the material taking loading device is located at a material sending place and used for taking and conveying original materials into vacant containers; the container transferring system is used for transferring the heavy containers filled with the materials to a material unloading place with the overturning unloading device; and the overturning unloading device is positioned at the material unloading place and used for unloading the materials in the transferred heavy containers. According to the system, the material taking loading device located at the material sending place is used for taking and conveying the original materials into the vacant containers; the heavy containers filled with the materials are transferred to the material unloading place with the overturning unloading device by utilizing the container transferring system; and the materials in the transferred heavy containers are unloaded through the overturning unloading device located at the material unloading place, and the unloaded materials are used as terminal materials; and the system has the comprehensive characteristics of high efficiency, low cost, excellent environmental protection, less goods loss, full container, thorough unloading, wide application range, safety, operability and the like.

Owner:苗林展

Method for preparing roller brush fabric from thermoplastic fiber

InactiveCN109868542AHas the effect of hot melt adhesionNot fusion strongBristlePile-fabric loomsFiberEnvironmental resistance

The invention provides a method for preparing a roller brush fabric from thermoplastic fiber. A certain proportion of thermoplastic fiber serves as main fiber materials of upper-layer base cloth and lower-layer base layer, conventional fiber is used for connection of the upper-layer base cloth and the lower-layer base cloth, blank cloth is prepared through a machine knitting method, the upper-layer base cloth and the lower-layer base cloth have hot melting adhesion effects through pile cutting, heating and solidification, and the solidification and non-nap-off effects are achieved without gluing. The fabric can be used for a roller brush and a scrubbing brush, the environmental protection purpose is achieved by omitting the coating process, compared with the similar products, the fabric has fuller suede, a thick and solid hand feeling and non-silk-off and non-nap-off effects, and the solidification effect and the bottom stiffness are good.

Owner:沂水恒泰纺园有限公司

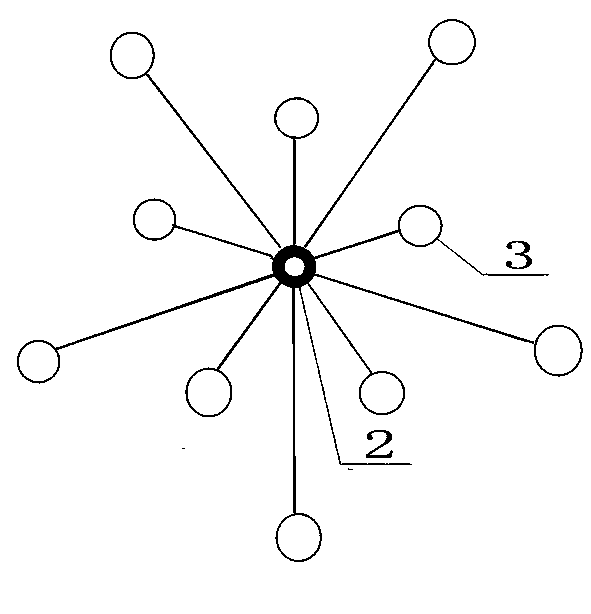

Cold air micro-quantity lubrication system

InactiveCN107263203AEasy to useExtend your lifeMaintainance and safety accessoriesCold airMachine parts

The invention provides a cold air micro-quantity lubrication system. The cold air micro-quantity lubrication system is characterized by comprising a gas generator, at least one liquid generator, a gas converter and a micro-quantity lubrication ejector, wherein the gas generator communicates with the gas converter and conveys gas to the gas converter; the liquid generator communicates with the gas converter and conveys liquid to the gas converter; the gas converter converts gas into cold air; the micro-quantity lubrication ejector is mounted at the cold air output end of the gas converter, and the cold air and the liquid are ejected through the micro-quantity lubrication ejector after being mixed separately. The cold air micro-quantity lubrication system can release cold air to cool a machined part through a turbine refrigerating system when a workpiece is machined through the system, and the effect of cold working is realized.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com