One-step new technology for separating ferrum, titanium and vanadium in vanadium-titanium-ferrum concentrate

A vanadium-titanium-iron concentrate and a new process technology, applied in the new process of vanadium, titanium, one-step separation of iron in vanadium-titanium-iron concentrate, can solve the problems of long process, high production cost, large environmental pollution, etc., and achieve reduction The effect of low temperature and operating cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

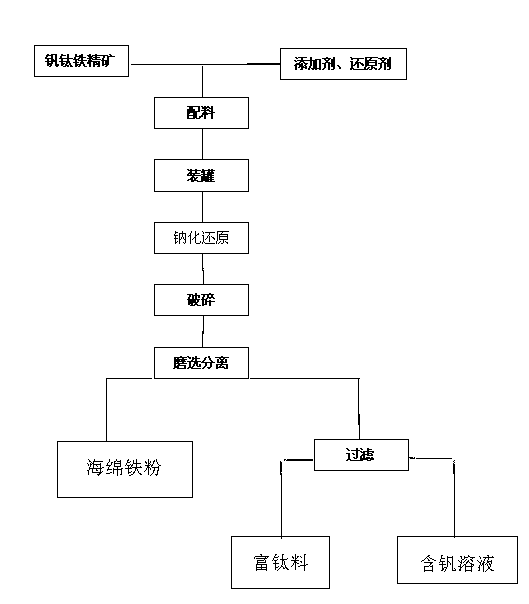

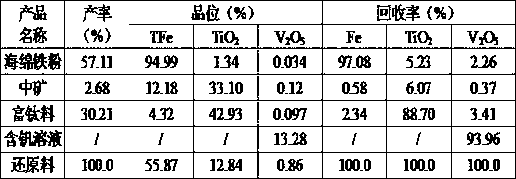

[0008] Example 1: Mix 100 parts of vanadium-titanium-iron concentrate with 40 parts of additives and 22 parts of solid reducing agent and briquette it, and keep it in a muffle furnace with a firing temperature of 900°C for 4 hours to obtain the reduction material; the reduction material is crushed and ground to -200 mesh 95%, magnetic separation to obtain rough concentrate and tailings, coarse concentrate is then ground to -200 mesh 98%, magnetic separation to obtain concentrate and middle ore, tailings and middle ore are mixed into titanium-rich material. Among them, the chemical composition content of the vanadium-titanium iron concentrate is shown in Table 1, and the separation results of the obtained sponge iron powder, titanium-rich material and vanadium-containing solution are shown in Table 2.

Embodiment 2

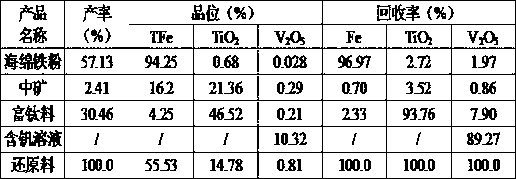

[0009] Example 2: Mix 100 parts of vanadium-titanium-iron concentrate with 40 parts of additives and 25 parts of solid reducing agent, and press it into a block, and keep it in a muffle furnace with a firing temperature of 850°C for 5 hours to obtain the reducing material; the reducing material is crushed and ground to -200 mesh 95%, magnetic separation to obtain rough concentrate and tailings, coarse concentrate is then ground to -200 mesh 98%, magnetic separation to obtain concentrate and middle ore, tailings and middle ore are mixed into titanium-rich material. Among them, the chemical composition content of the vanadium-titanium iron concentrate is shown in Table 1, and the separation results of the obtained sponge iron powder, titanium-rich material and vanadium-containing solution are shown in Table 3.

Embodiment 3

[0010] Embodiment 3: Mix 100 parts of vanadium-titanium-iron concentrate with 30 parts of additives and 20 parts of solid reducing agent and briquette it, and keep it in a muffle furnace with a firing temperature of 950°C for 5 hours to obtain the reducing material; the reducing material is crushed and ground to -200 mesh 95%, magnetic separation to obtain rough concentrate and tailings, coarse concentrate is then ground to -200 mesh 98%, magnetic separation to obtain concentrate and middle ore, tailings and middle ore are mixed into titanium-rich material. Among them, the chemical composition content of the vanadium-titanium iron concentrate is shown in Table 1, and the separation results of the obtained sponge iron powder, titanium-rich material and vanadium-containing solution are shown in the following table.

[0011] Table 1 Analysis results of three vanadium-titanium iron ore concentrates in the embodiment (%)

[0012] Sample No. TF TiO 2 V 2 o 5 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com