Cold air micro-quantity lubrication system

A micro-lubrication and air-conditioning technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of the cooling effect needs to be improved, and achieve the effect of significant environmental protection effect, prolonging service life and processing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

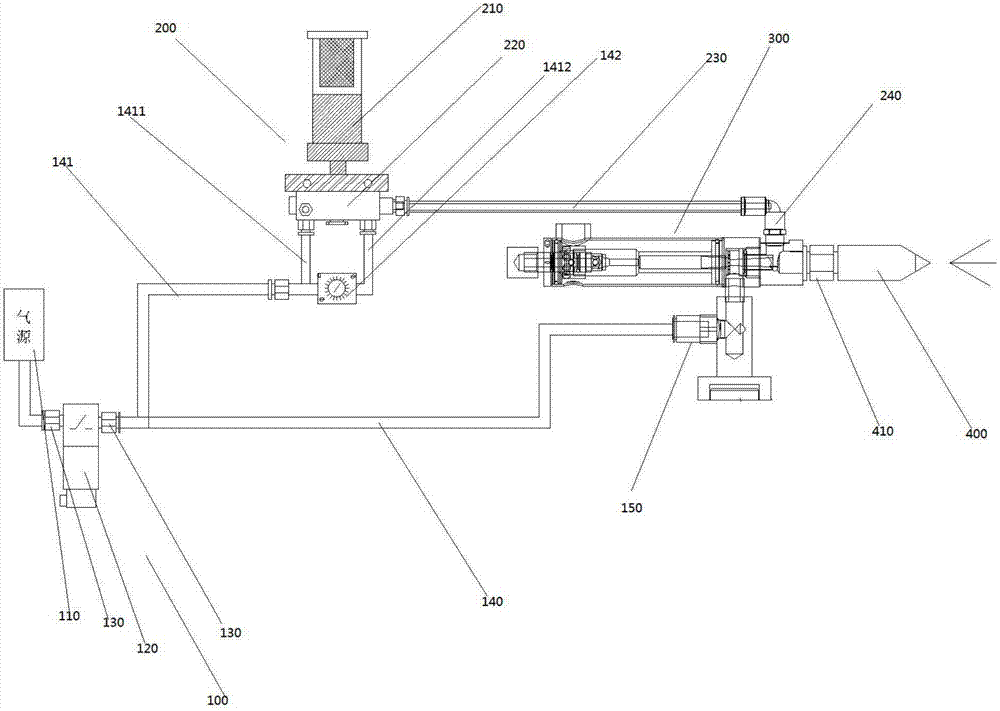

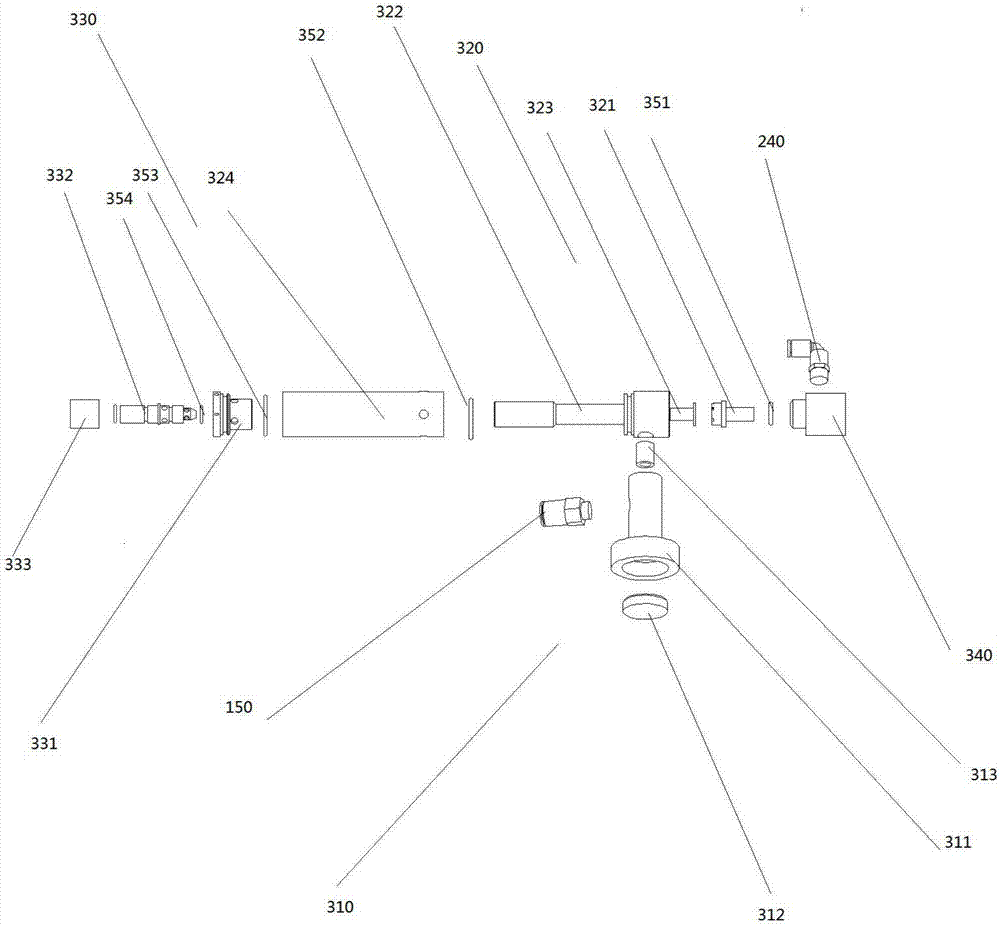

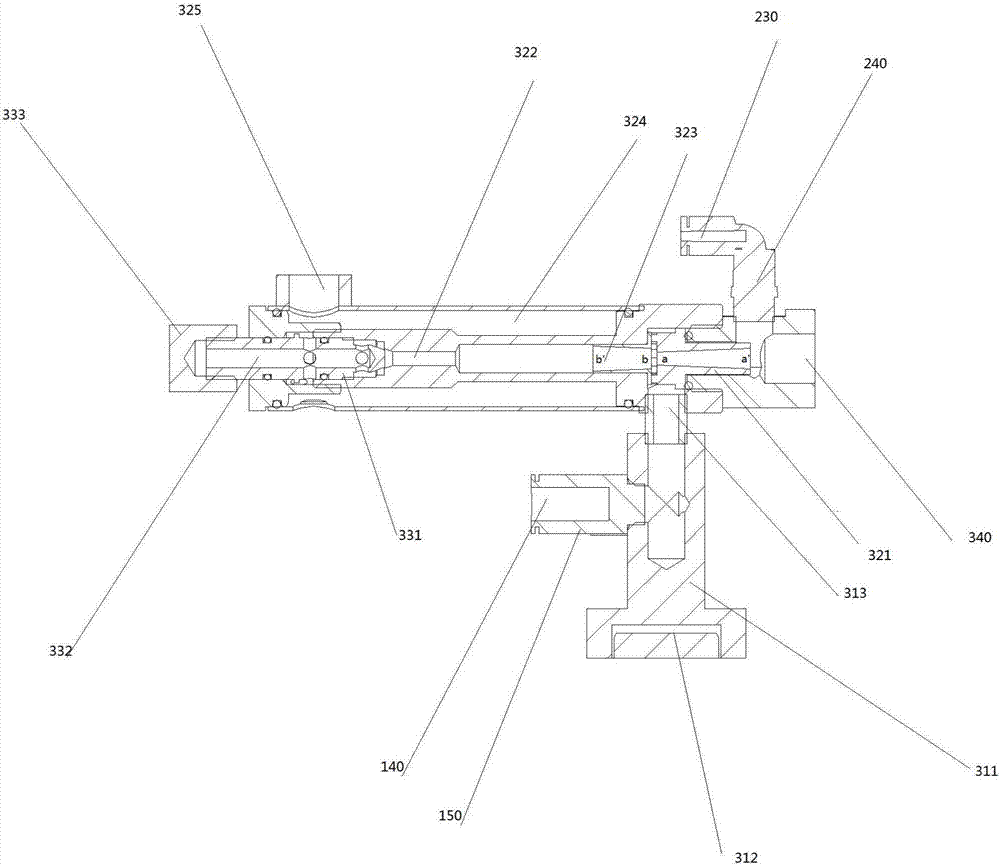

[0051] Such as figure 1 As shown, this embodiment provides a cold air minimal quantity lubrication system, including a gas generator 100, a liquid generator 200, a gas converter 300 and a minimum quantity lubrication nozzle 400;

[0052] The gas generator 100 includes a gas source 110, a solenoid valve 120 and a gas conduit 140;

[0053] Wherein, the air source 110 stores compressed air, communicates with the solenoid valve 120 through the compressed air interface 130 , the solenoid valve 120 communicates with the gas conduit 140 through the compressed air interface 130 , and the delivery end of the gas conduit 140 passes through the quick-plug air nozzle 150 It communicates with the gas converter 300 to deliver compressed air into the gas converter 300 .

[0054] The liquid generator 200 includes an oil reservoir 210, a precision oil pump 220 and a liquid conduit 230;

[0055] Wherein, the oil reservoir 210 stores a small amount of lubricating oil, which communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com