Patents

Literature

63 results about "Dry machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

InactiveCN103273687AImprove friction and wear propertiesReduce residual stressVacuum evaporation coatingSputtering coatingAlloyDry machining

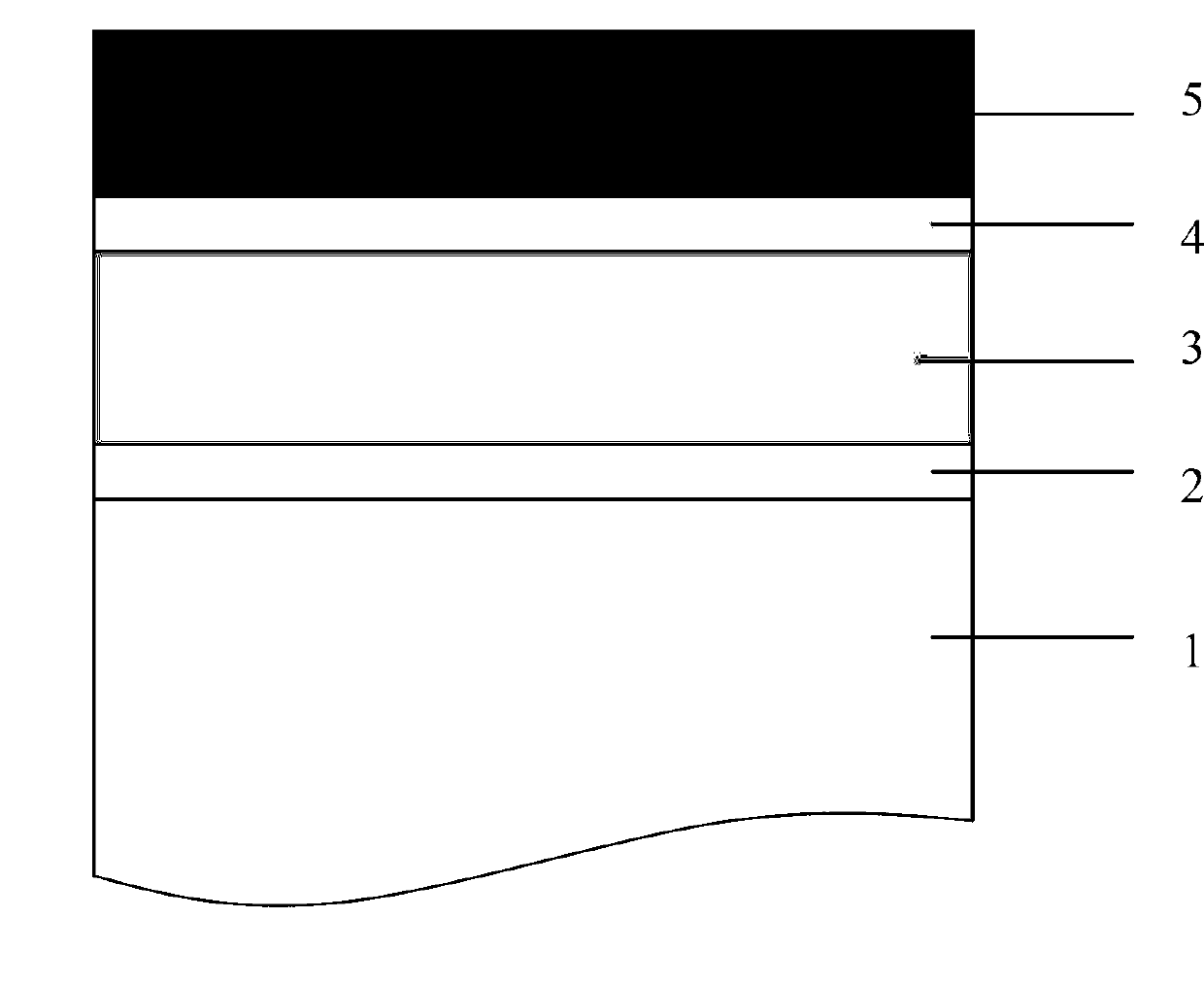

The invention provides a TiSiN+ZrSiN composite nanometer coated cutting tool and a preparation method thereof and belongs to the field of mechanical machining. A base material of the coated cutting tool is a hard alloy or high-speed steel. The TiSiN+ZrSiN composite nanometer coated cutting tool is manufactured by adopting a multi-arc ion plating+intermediate frequency magnetron sputtering method. The TiSiN+ZrSiN composite nanometer coated cutting tool is of multilayered structure, a ZrSiN coating is formed on the surface of the cutting tool, a TiZrSiN transition coating is formed between the ZrSiN coating and a TiSiN coating, and a Ti transition coating is formed between the TiSiN coating and a substrate, wherein the atomic percentage of Si content in the TiSiN coating and the ZrSiN coating is 6%-10%. The TiSiN+ZrSiN composite nanometer coated cutting tool well combines the high hardness of the TiSiN coating and the low friction coefficient of the ZrSiN coating and has high hardness, good friction and wear property and excellent high-temperature oxidation resistance; and the bonding can be alleviated in the cutting process, and the wearing of the cutting tool is reduced, so that the service life of the cutting tool is prolonged. The coated cutting tool can be widely applied to drying machining and machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

Insert

InactiveUS20070292671A1Improve wear resistanceExcellent heat crack resistancePigmenting treatmentMilling cuttersCompacted graphite ironAlloy

The present invention relates to a coated cemented carbide milling insert for either wet or dry machining of cast iron such as nodular cast iron (NCI), grey cast iron (GCI), austempered ductile iron (ADI) and compacted graphite iron (CGI) where a high wear resistance and an excellent resistance against thermo cracks are required comprising: a substrate comprising from about 5 to about 7 wt-% Co, from about 140 to about 250 ppm Ti+Ta and balance WC with a weight ratio Ti / Ta of from about 0.8 to about 1.3 and a PVD-layer consisting of AlxTi1-xN, with x=from about 0.50 to about 0.70 and with a thickness of from about 1 to about 10 μm. The invention also relates to a method for making cutting tool inserts and their use.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Insert

InactiveUS7767319B2Improve wear resistanceExcellent heat crack resistancePigmenting treatmentMilling cuttersHigh resistanceCompacted graphite iron

The present invention relates to a coated cemented carbide milling insert for either wet or dry machining of cast iron such as nodular cast iron (NCI), grey cast iron (GCI), austempered ductile iron (ADI) and compacted graphite iron (CGI) where a high wear resistance and an excellent resistance against thermo cracks are required comprising:a substrate comprising from about 5 to about 7 wt-% Co, from about 140 to about 250 ppm Ti+Ta and balance WC with a weight ratio Ti / Ta of from about 0.8 to about 1.3 anda PVD-layer consisting of AlxTi1−xN, with x=from about 0.50 to about 0.70 and with a thickness of from about 1 to about 10 μm. The invention also relates to a method for making cutting tool inserts and their use.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

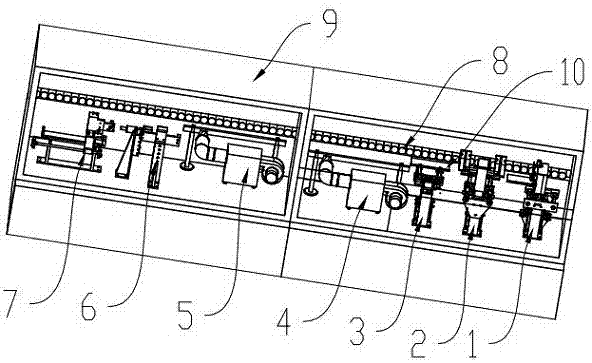

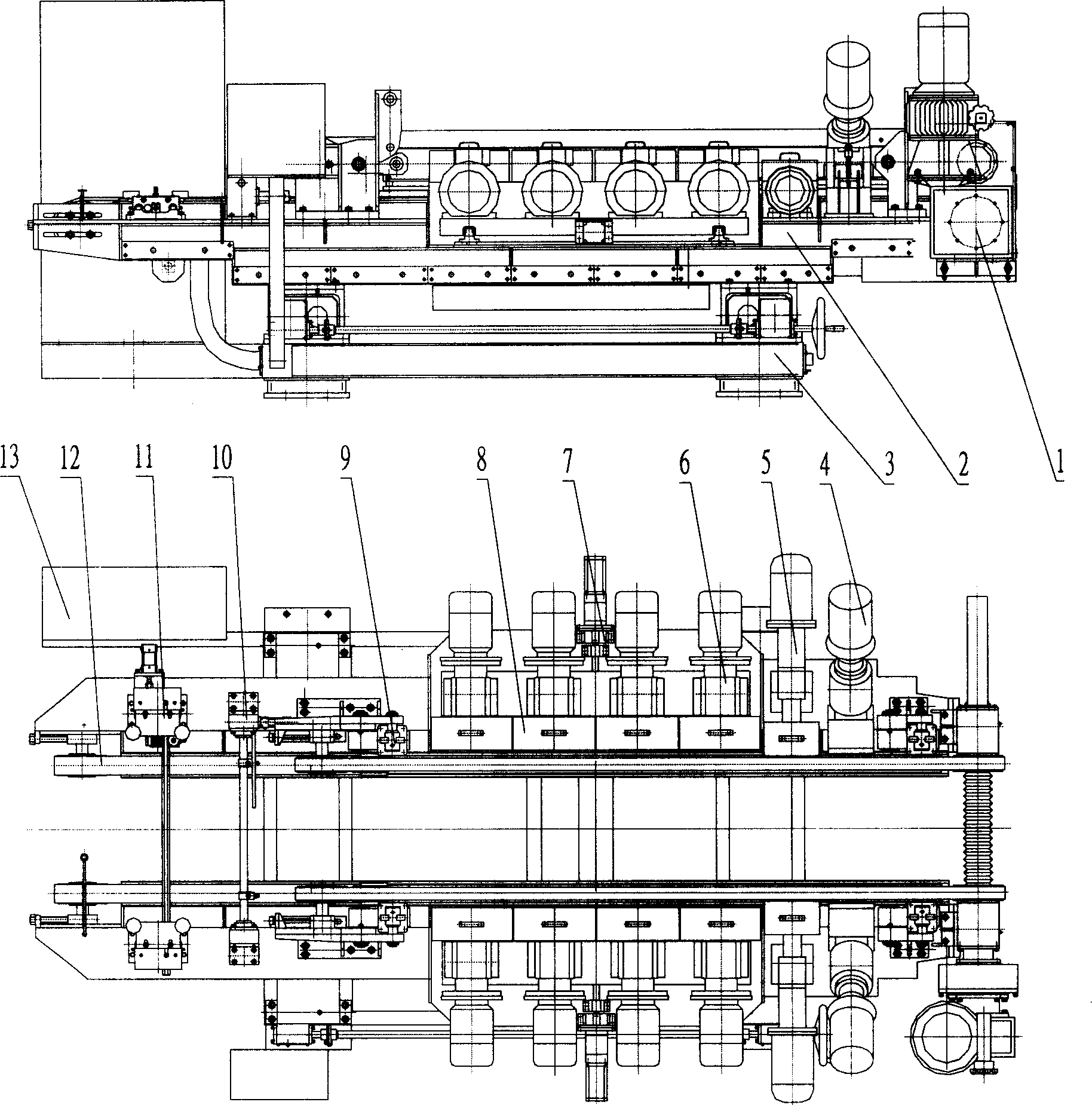

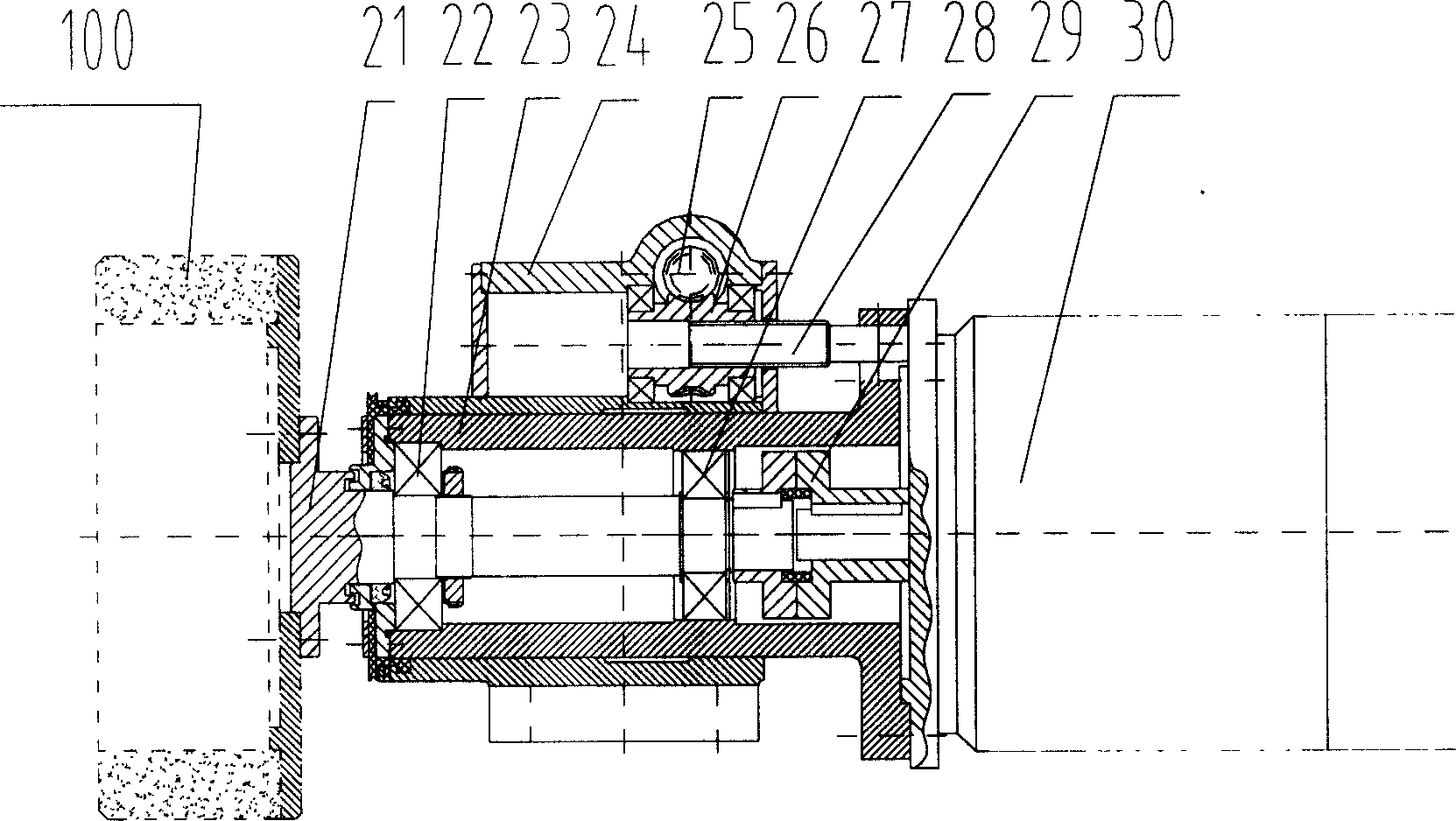

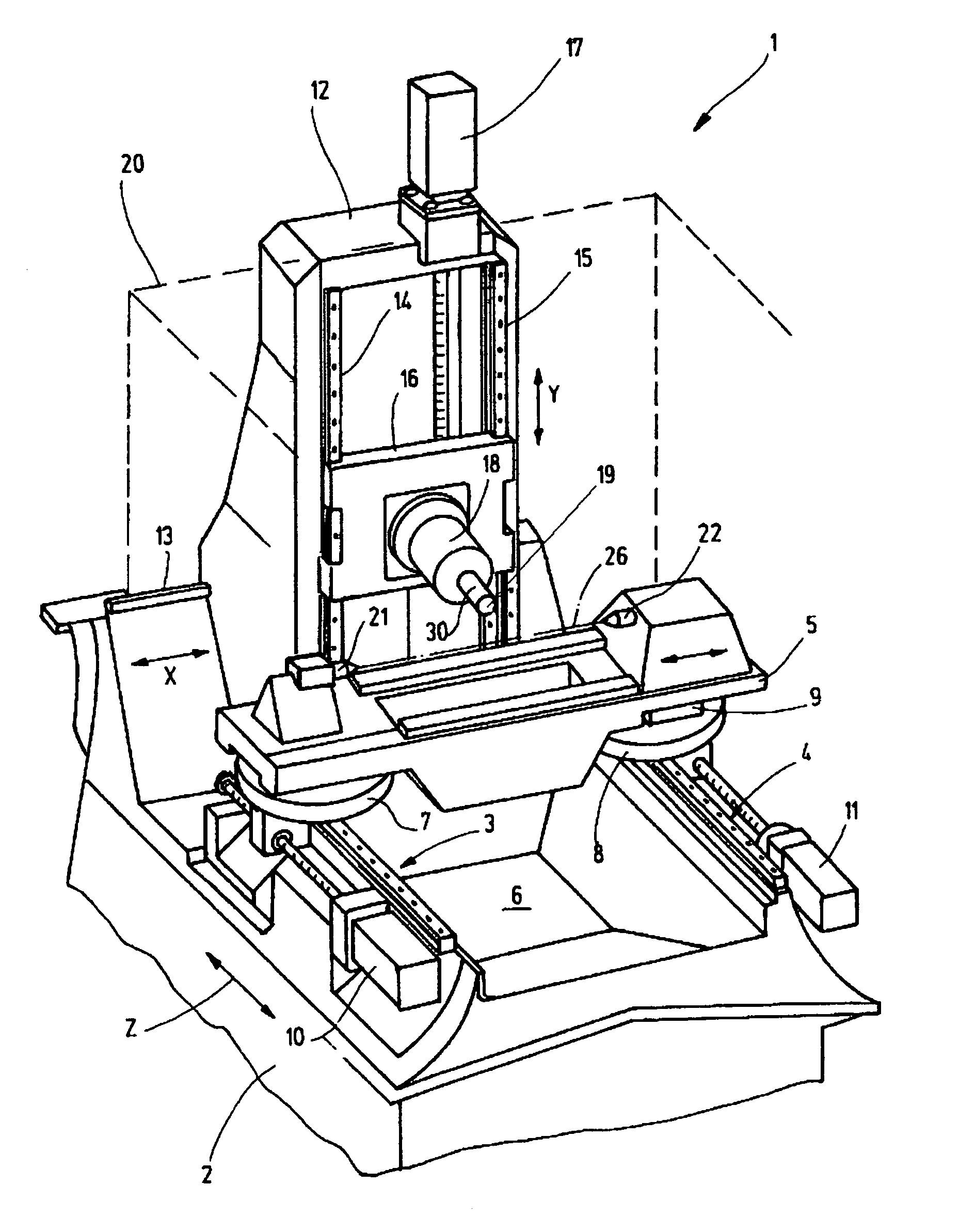

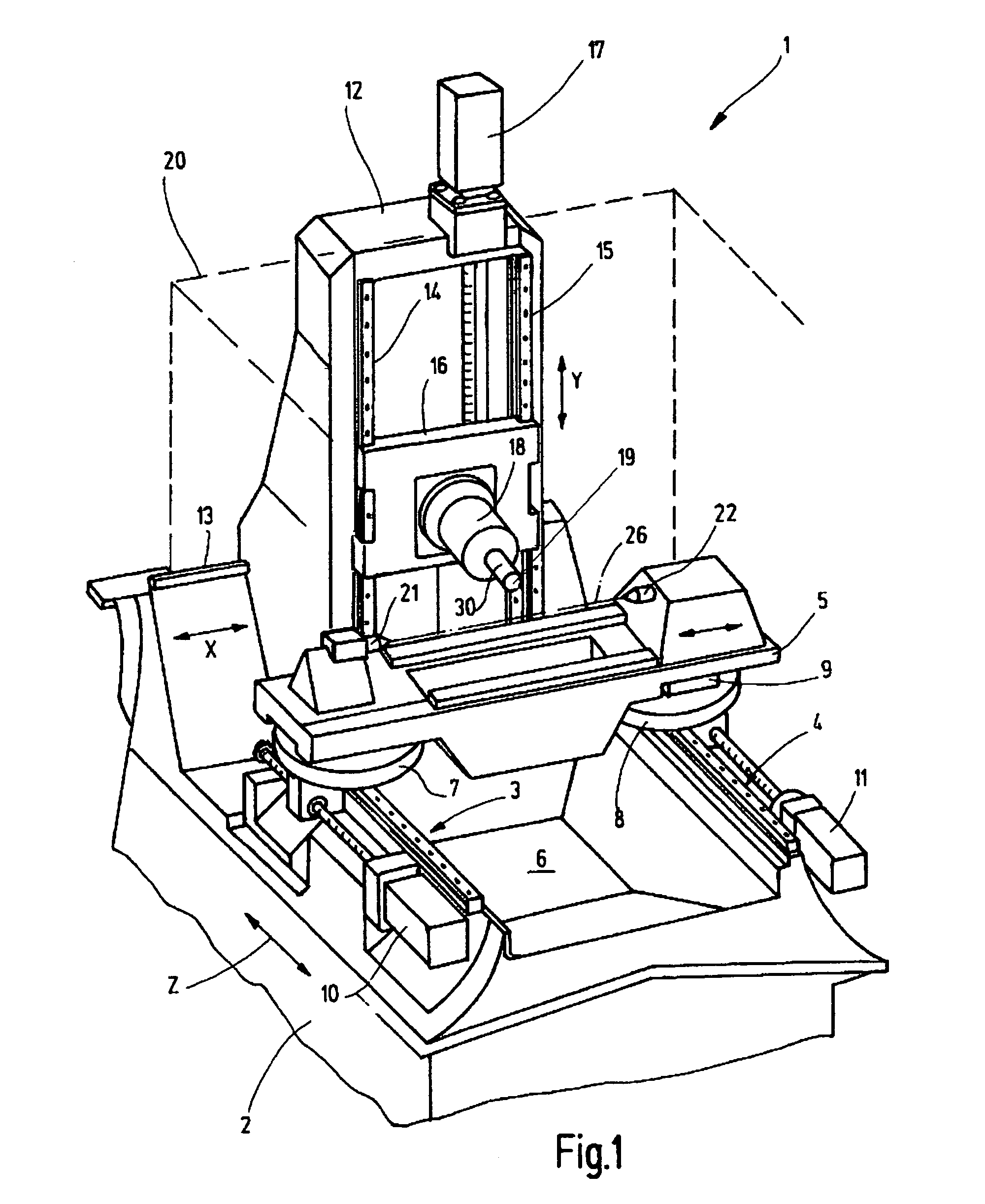

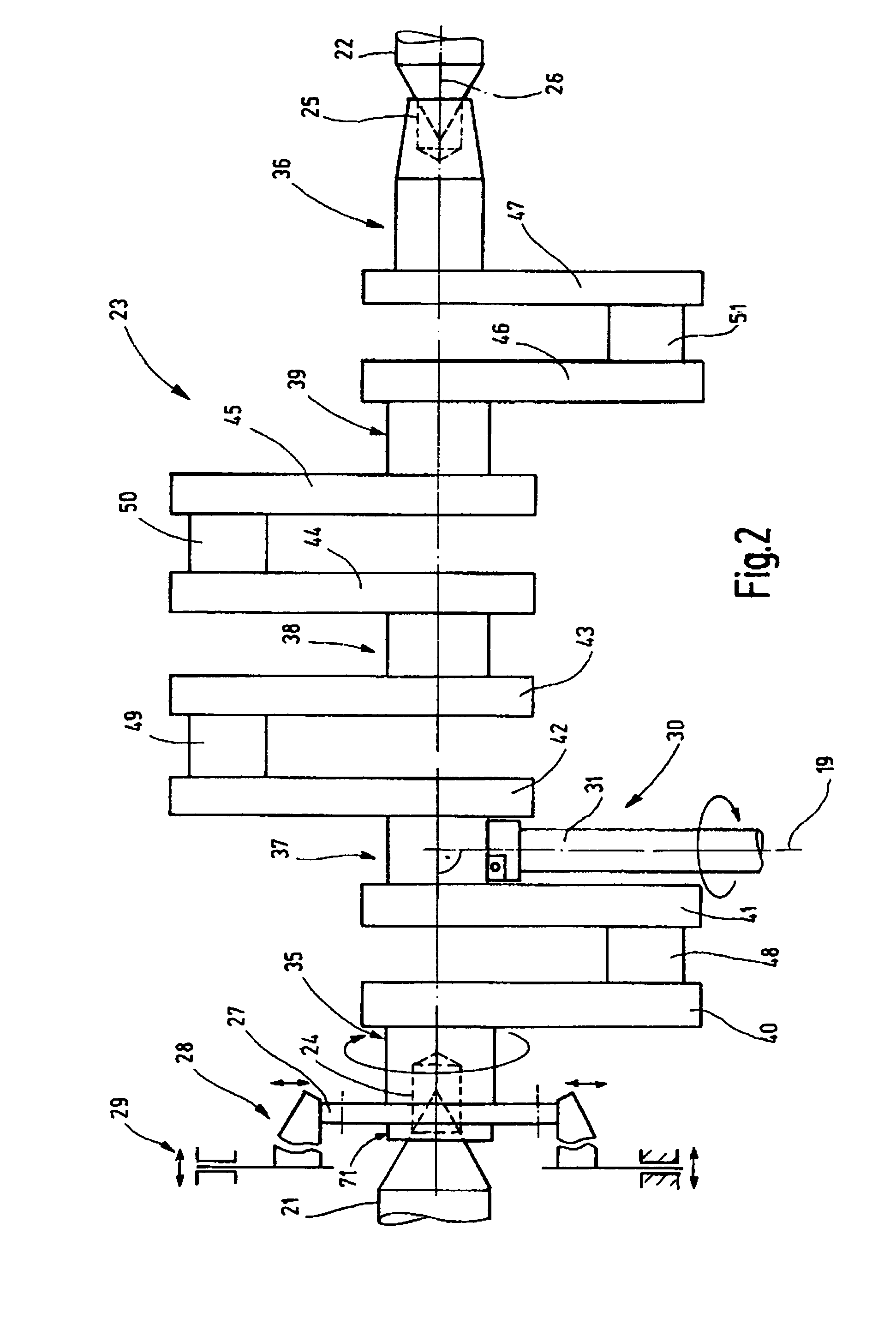

Method for fine-machining crankshafts and machining center therefor

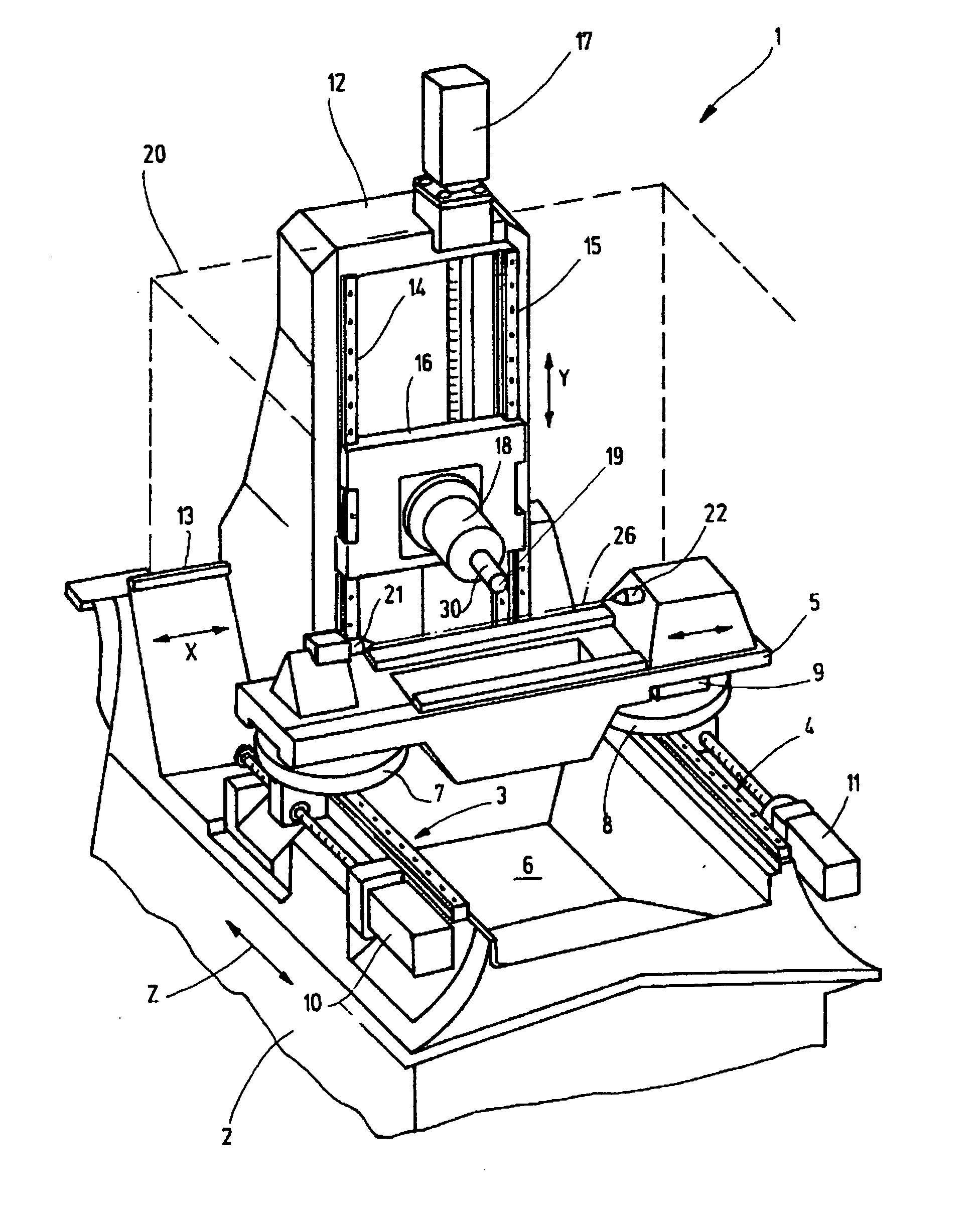

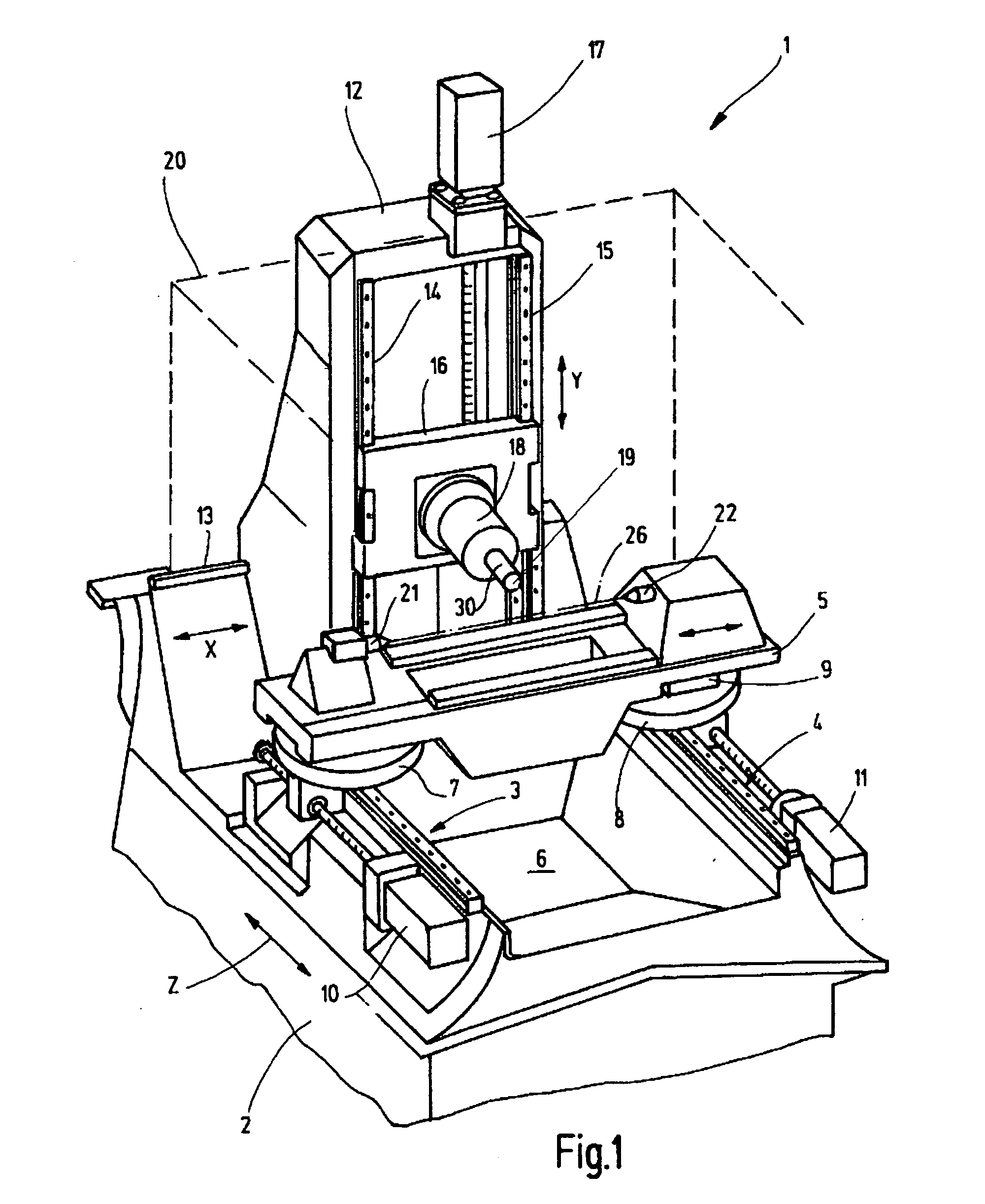

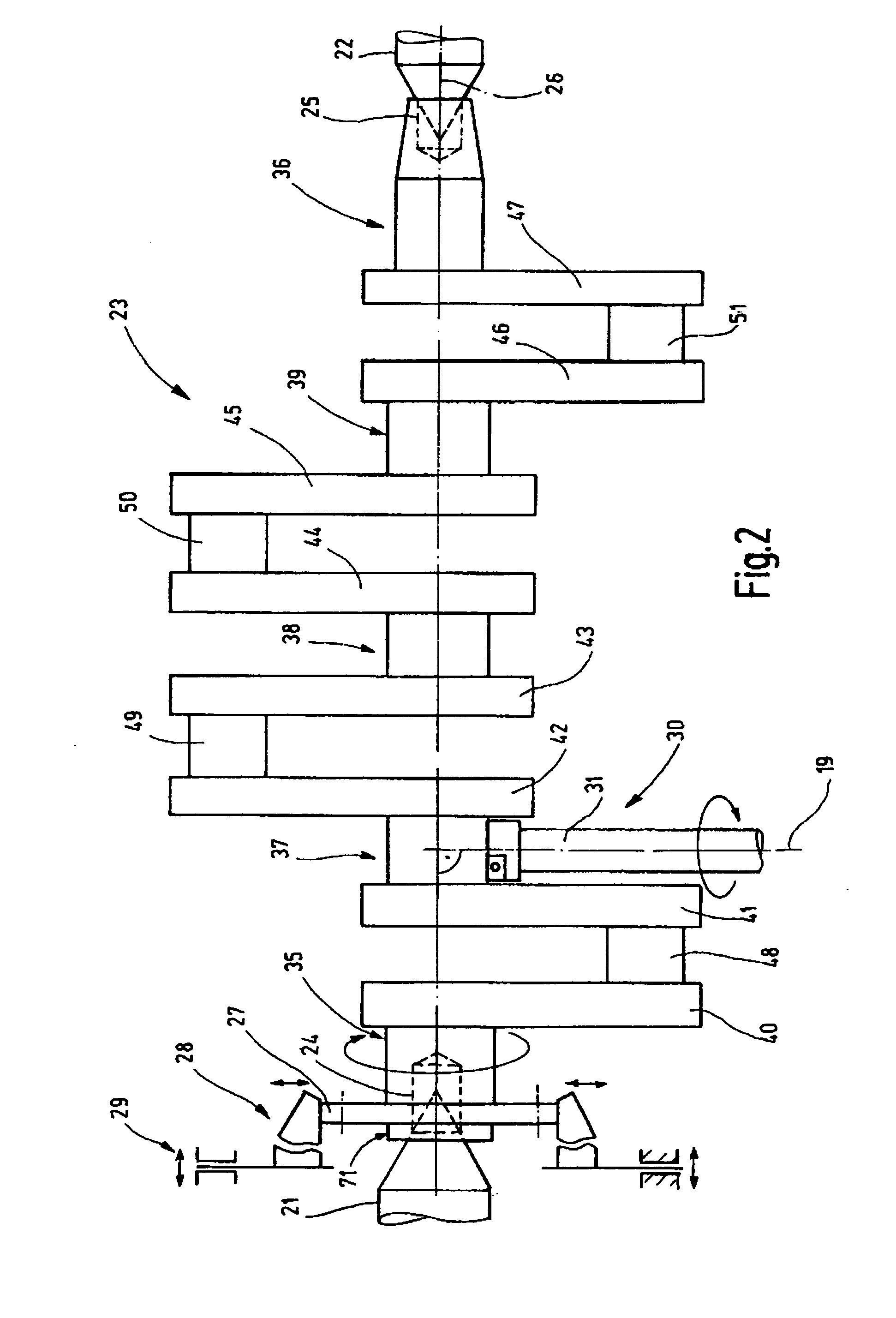

ActiveUS20100003098A1Improve accuracyQuality improvementLarge fixed membersMilling equipment detailsDry machiningInternal combustion engine

A method and machine for machining shafts, such as crankshafts of an internal combustion engine wherein the shaft supported on a workpiece carrier rotatably about its axis and the carrier is movable relative to a milling tool adjustably supported on the machine, the bearing surfaces of the shaft are fine-machined by a milling tool taking into consideration the resiliency and the bending of the shaft by the engagement force of the milling tool during fine cutting of the bearing surfaces in the various angular rations of the shaft and the axial bearing location between the shaft ends so as to provide for a perfect final round cutting of the bearings without the need for wet grinding. The fine machining is preferably achieved by dry machining and orthogonal rotational milling, all main bearings and lifting bearings being machined in a single clamping from the rough machining dimensions to the final dimension. For a second machining sequence, some of the main bearings and lifting bearings are used as clamping surfaces.

Owner:GEBR HELLER MASCHFAB GMBH

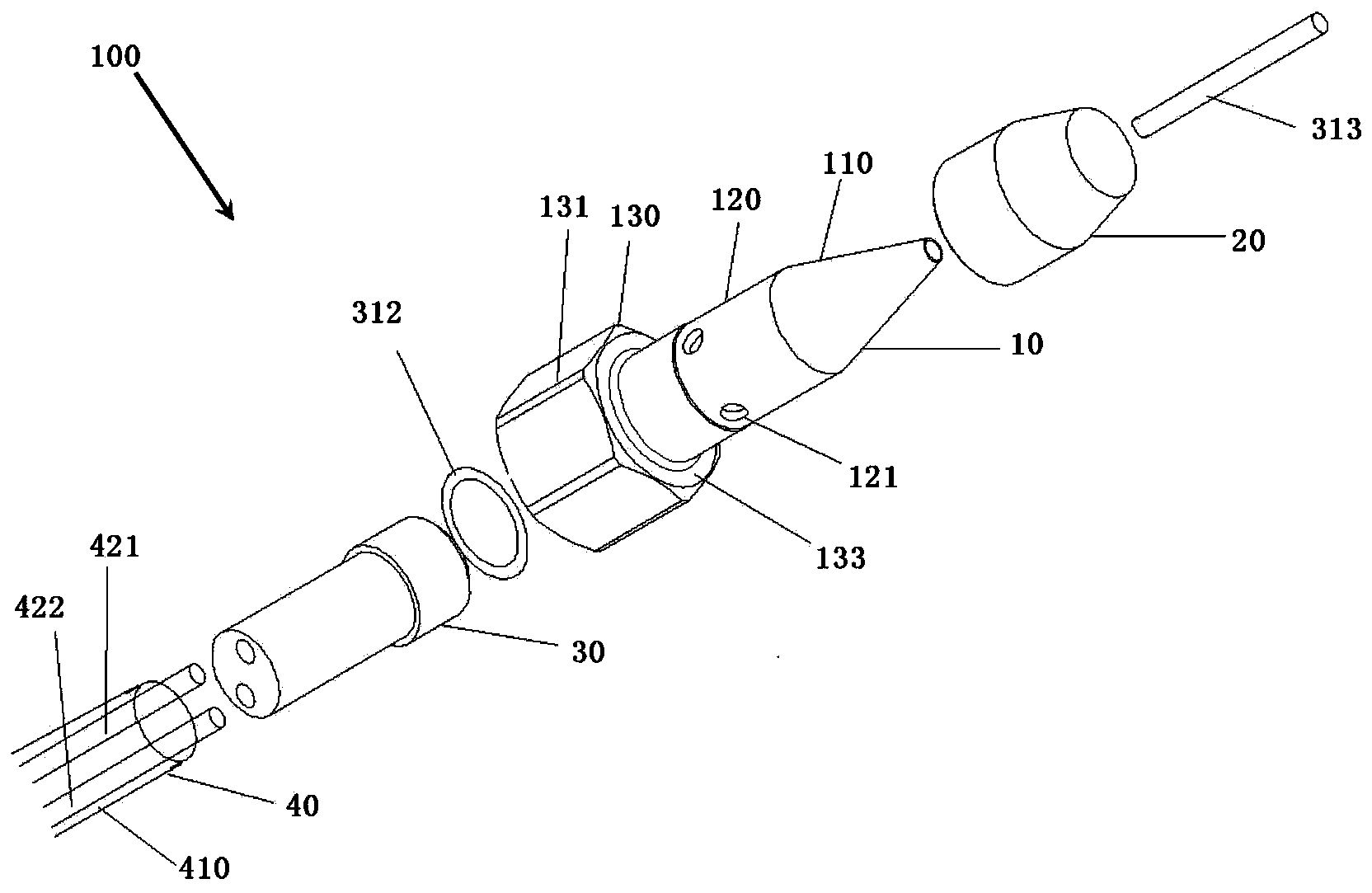

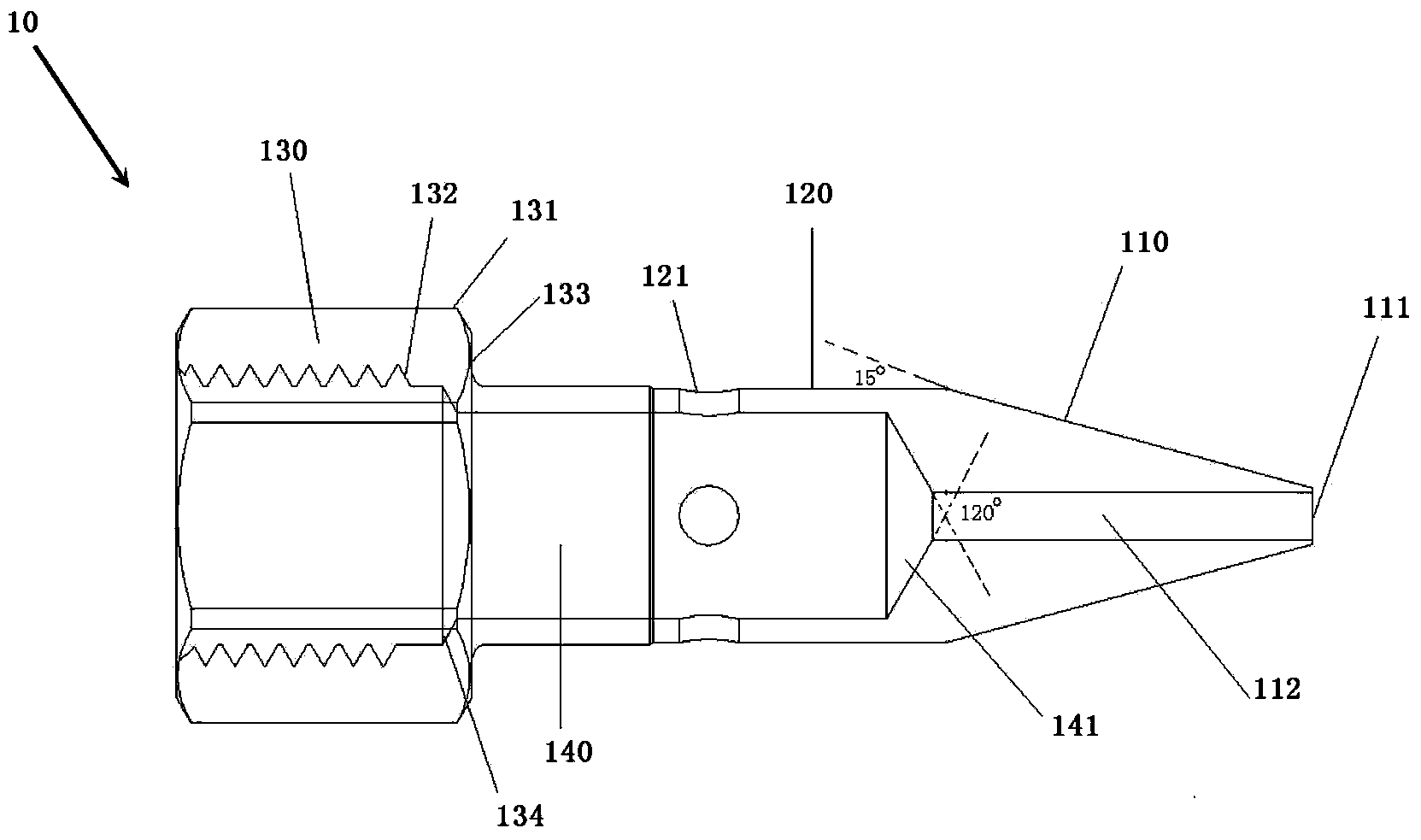

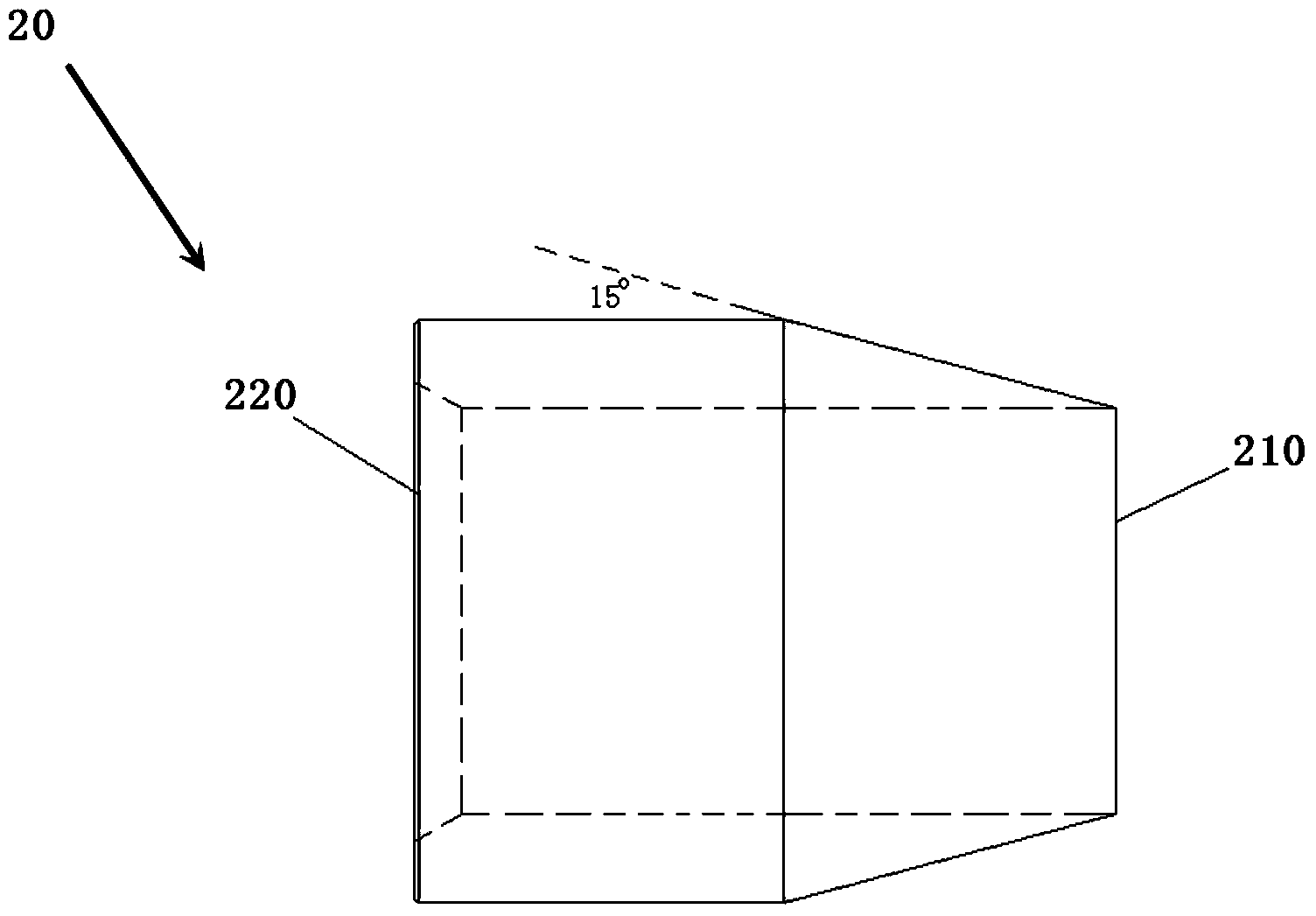

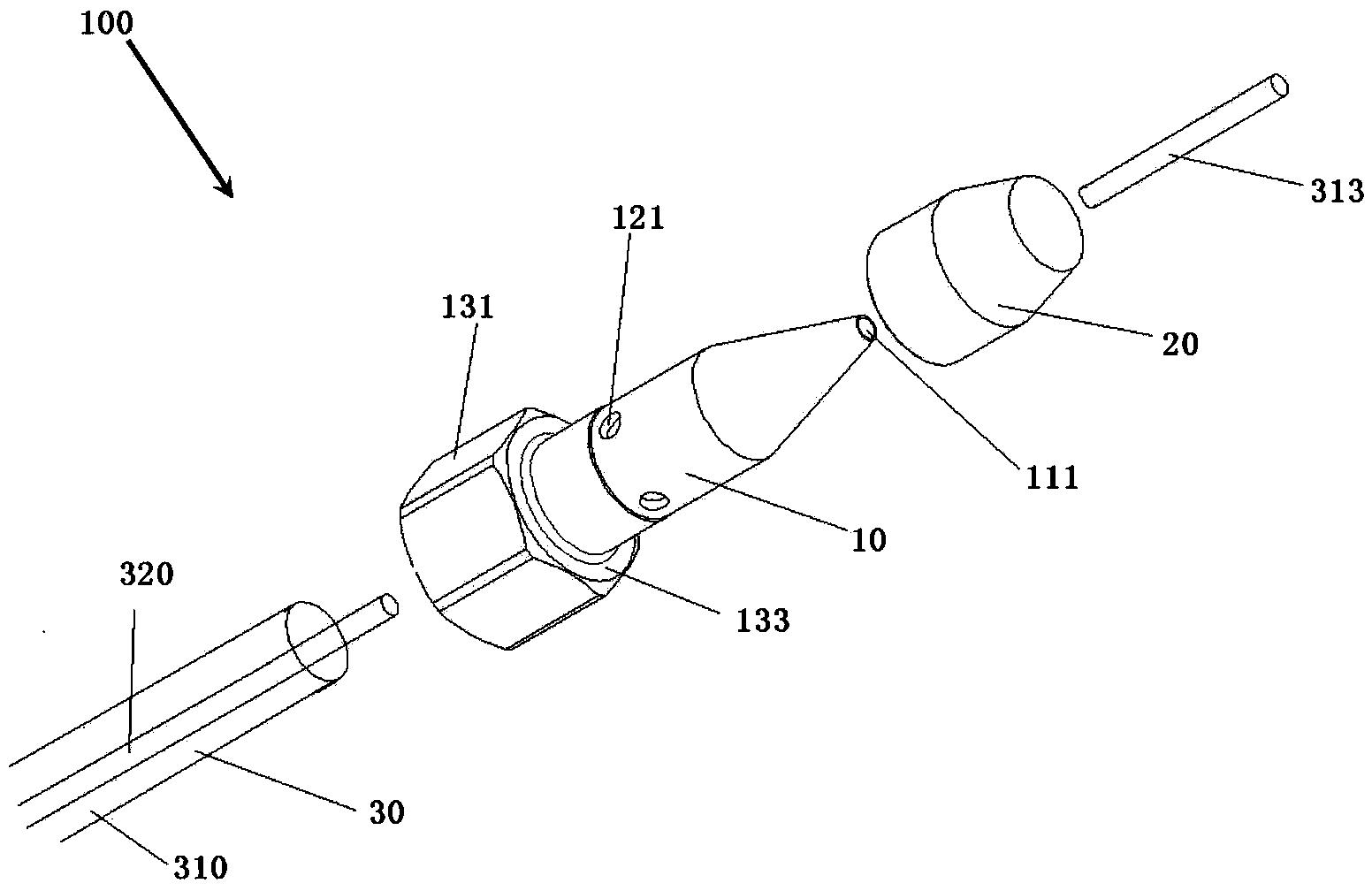

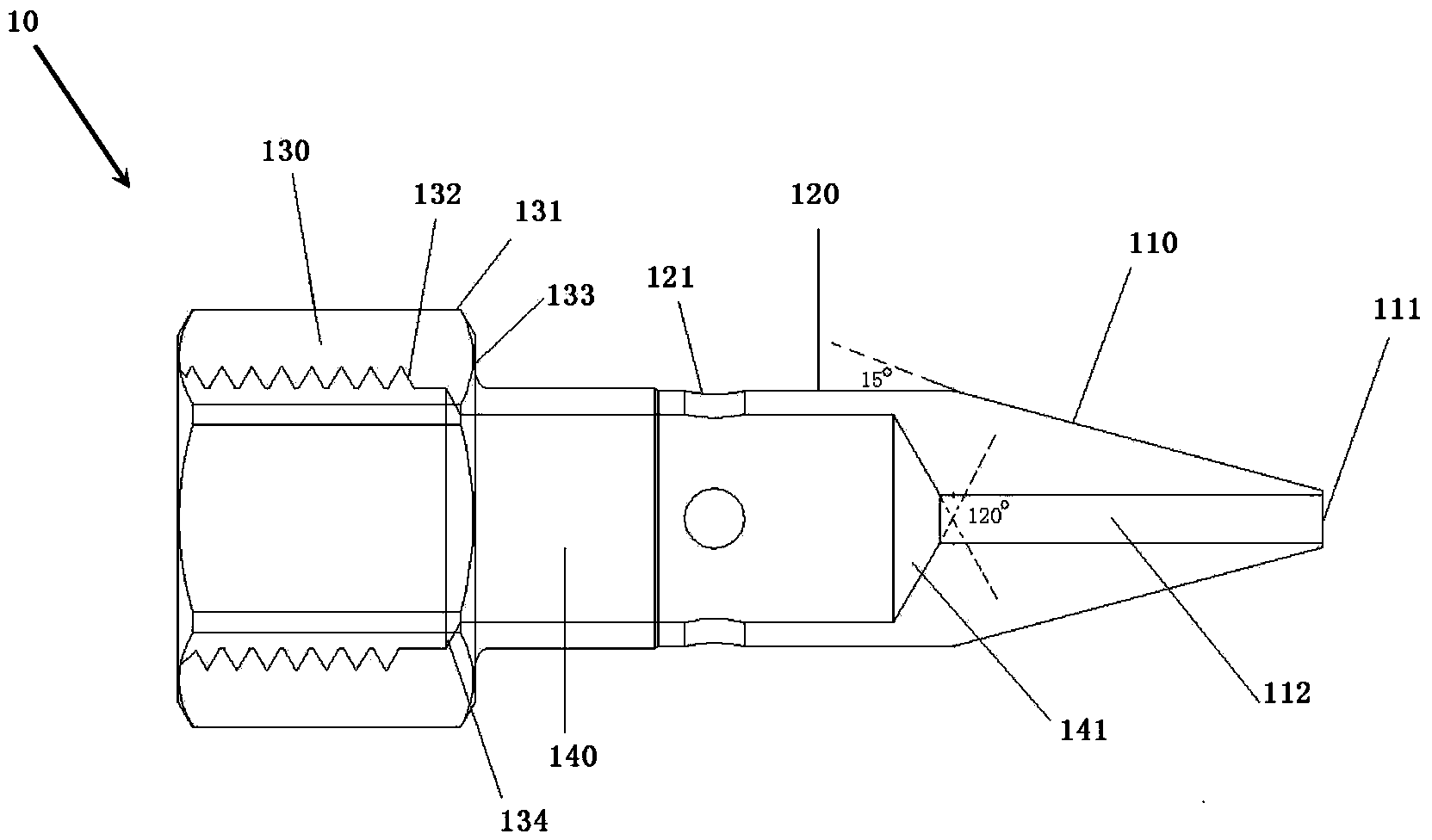

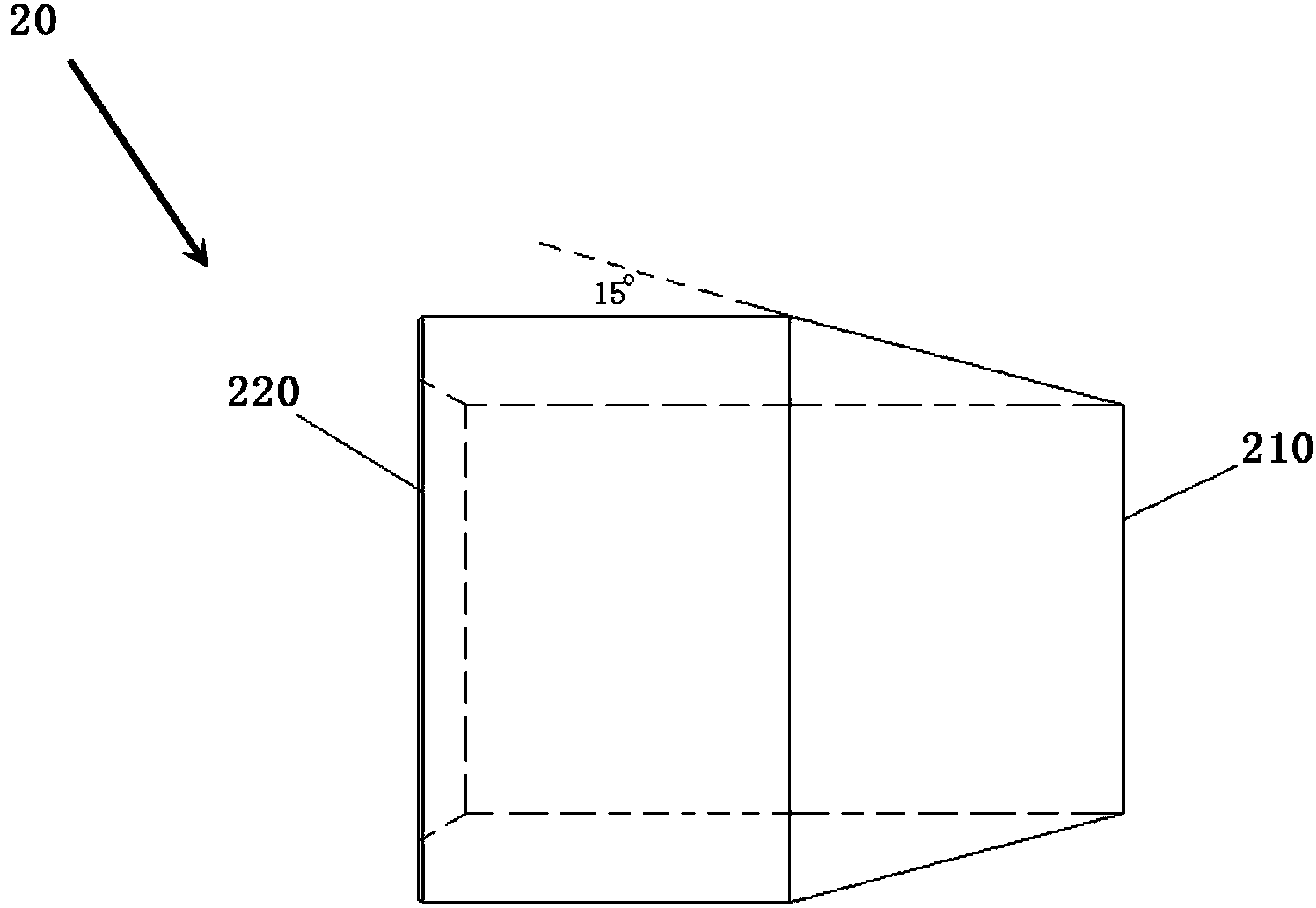

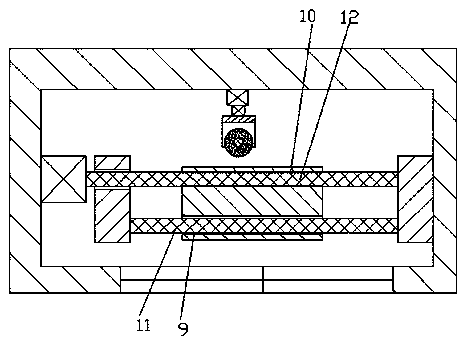

Nested type three-phase mixing nozzle of water, oil and gas and nozzle system with same

ActiveCN103522118AReduce precisionHigh surface finishLiquid spraying apparatusMaintainance and safety accessoriesSpray nozzleThree-phase

The invention provides a nested type three-phase mixing nozzle of water, oil and gas. The nested type three-phase mixing nozzle comprises a nozzle body, a nesting ring and a mixing chamber, and is characterized in that the nozzle body comprises a head portion, a middle portion and a bottom, the head portion of the nozzle body is a cone, and a spray hole is formed in the top end of the head portion of the nozzle body; the middle portion of the nozzle body is a cylinder, and at least two gas holes are evenly formed in the cylinder; the bottom of the nozzle body is of a thread structure; the nesting ring and the middle portion of the nozzle body are matched to form a clearance structure; an inner chamber with the top of a cone is arranged inside the nozzle body; the mixing chamber is arranged in the inner chamber and corresponds to the position of the middle portion of the nozzle body; a fluid channel communicated with the spray hole is further formed in the top of the inner chamber. The nozzle is arranged in a metal processing lubricating device, point lubricating is achieved, the problem that gas consumption is large in existing novel metal near-dry type processing lubricating is solved, meanwhile, a power source is saved, and the advantages of saving lubricating oil and being more environmentally friendly are achieved.

Owner:苏州金兆环保节能设备有限公司

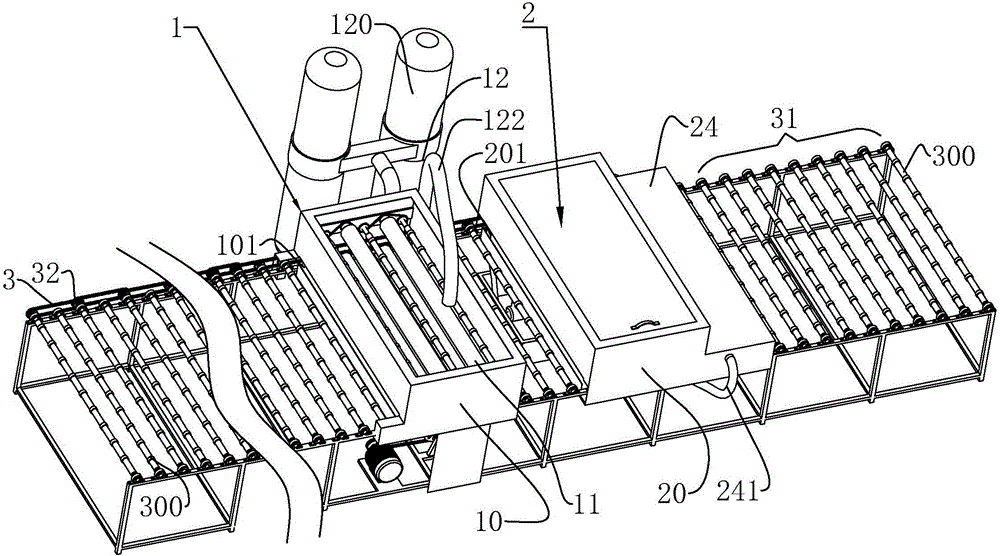

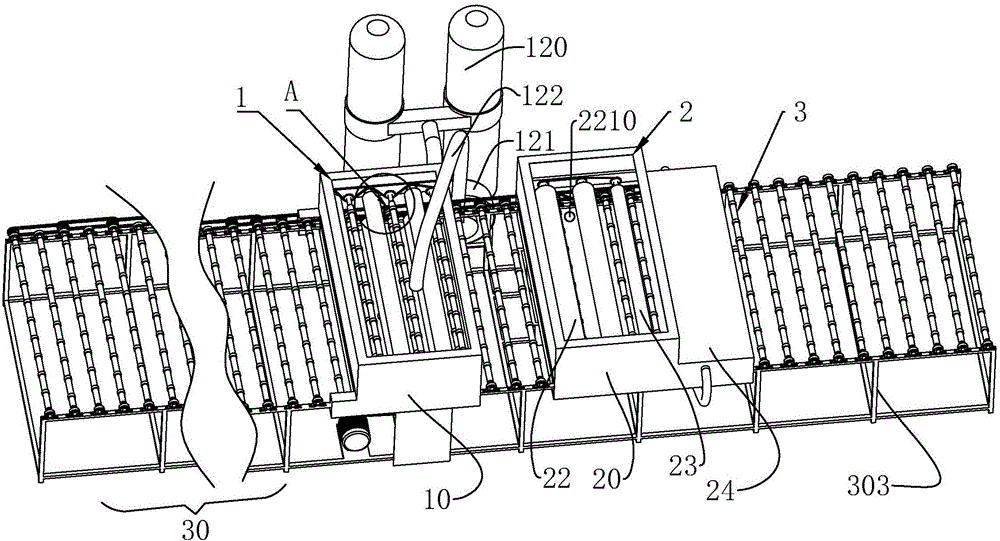

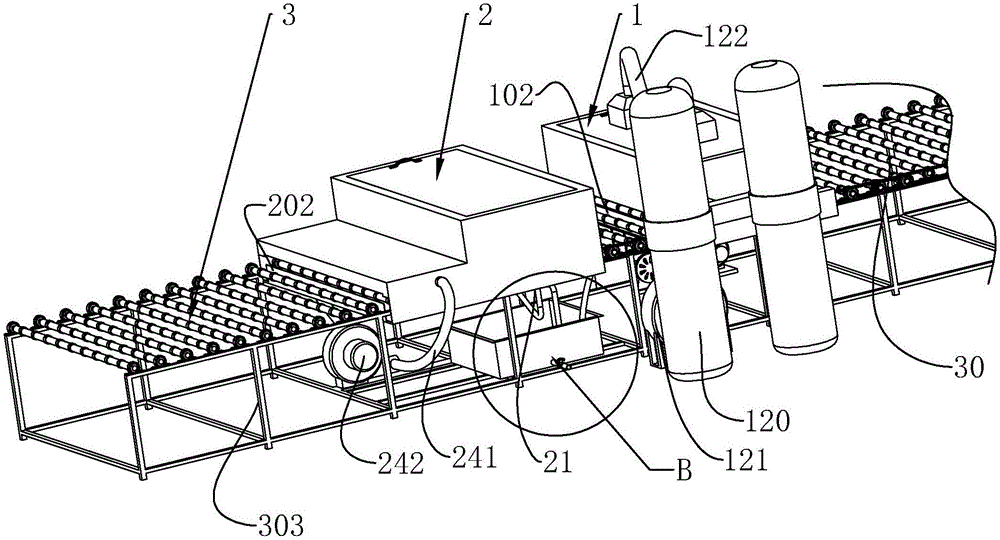

Automatic cleaning, spraying protection and drying machining equipment for thermal insulation composite board

InactiveCN105834139AIncrease productivityEliminate human interventionPretreated surfacesCleaning using toolsThermal insulationDry machining

The invention relates to automatic cleaning, spraying protection and drying machining equipment for a thermal insulation composite board. According to the technical key points, automatic machining equipment is used for a stone panel processing process in composite stone panel processing. The equipment comprises a cleaning device, a protecting liquid coating device and a stone panel conveying device used for driving the stone panel to sequentially pass through the two devices according to the processing process, thus realizing automation of the whole machining process and improving production efficiency.

Owner:BEIJING JIUTIANLONG BUILDING STONE MATERIAL ENG CO LTD

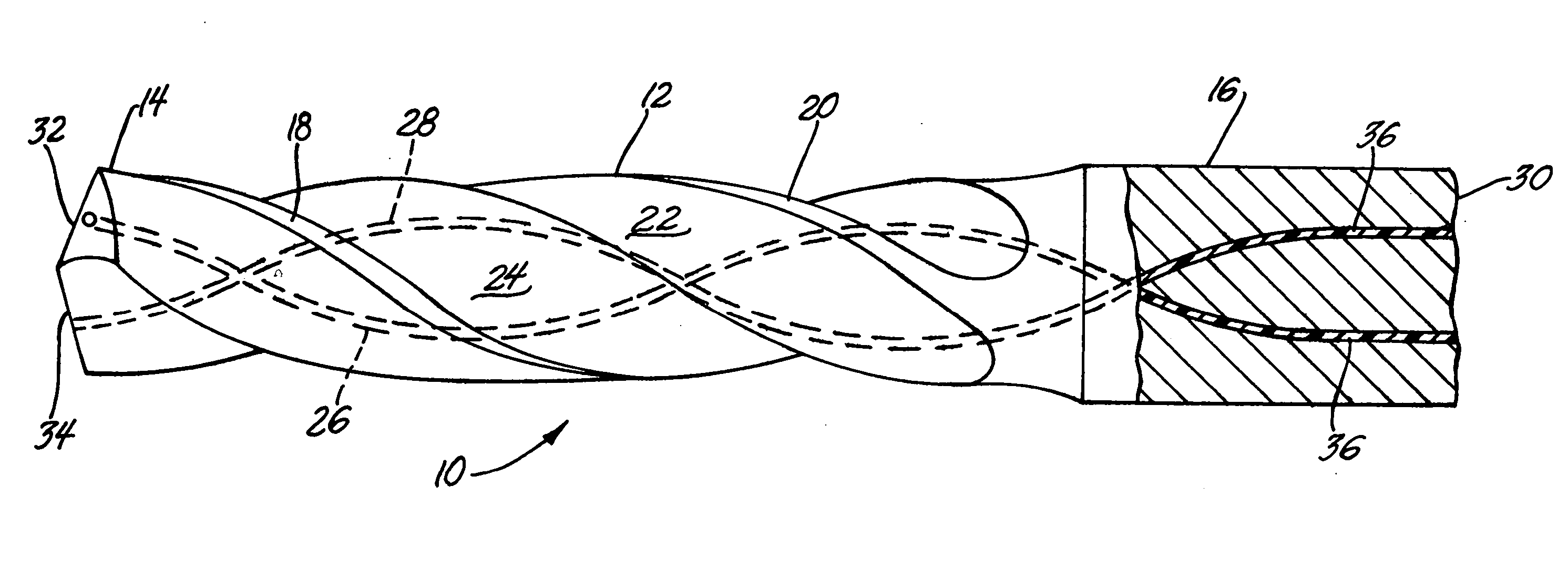

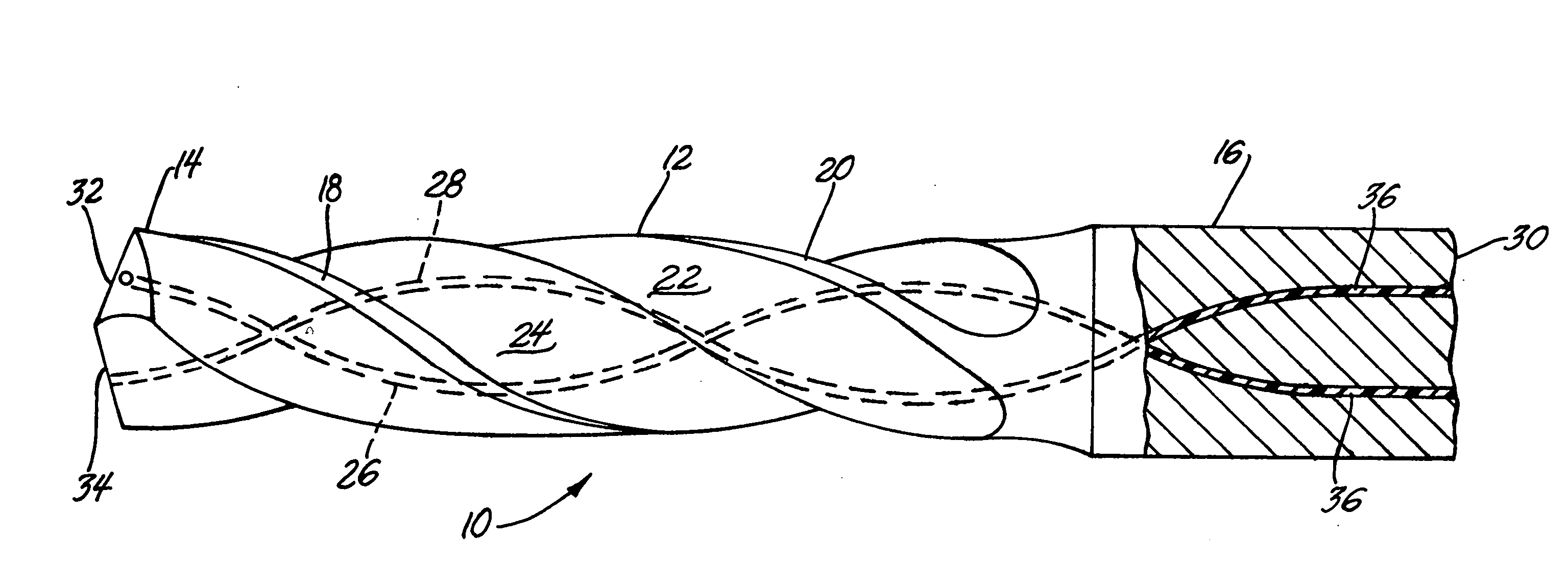

Lubricants in cutting tools for dry machining

InactiveUS20050214082A1Reduce power consumptionReduce vibrationTransportation and packagingMulti-purpose machinesEngineeringDry machining

Workpiece cutting tools, such as drills, are often provided with through holes that preferably extend from the cutting end of the tool along its length to the holding end. In accordance with this invention, such through holes of a cutting tool are filled with a lubricating oil-in a thermoplastic polymer matrix by injection or molding of the mixture into the holes. In the operation of the tool, the oil thus stored within the tool flows in the polymer matrix to the cutting site to reduce cutting power requirements and wear of the tool. Through the use of such cutting tools, the use of metal removal fluids can be eliminated and dry machining facilitated.

Owner:GENERAL MOTORS COMPANY

Nested-type energy-saving nozzle and nozzle system with same

ActiveCN103521368AReduce precisionHigh surface finishSpray nozzlesLiquid spraying apparatusMetal machiningEngineering

The invention provides a nested-type energy-saving nozzle which comprises a nozzle body and a nesting ring. The nested-type energy-saving nozzle is characterized in that the nozzle body comprises a head portion, a middle portion and a bottom portion; the head portion of the nozzle body is a conic body and a jet hole is formed in the top end of the head of the nozzle body; the middle of the nozzle body is a cylindrical body and at least two air holes are evenly formed in the cylindrical body; the bottom portion of the nozzle body is of a threaded structure; the nesting ring is matched with the middle portion of the nozzle body so that a gap structure can be formed, wherein an inner cavity with a conic top is formed in the nozzle body and a fluid channel communicated with the jet hole is further formed in the top of the inner cavity. After the nested-type energy-saving nozzle is installed in a metal machining lubricating device, point lubrication is achieved, the problem that gas consumption for metal near-dry machining lubrication is large in the prior art is solved, power sources are saved, and the nested-type energy-saving nozzle has the advantages of saving lubricating oil and being more environmentally friendly.

Owner:启东通润润滑液压设备有限公司

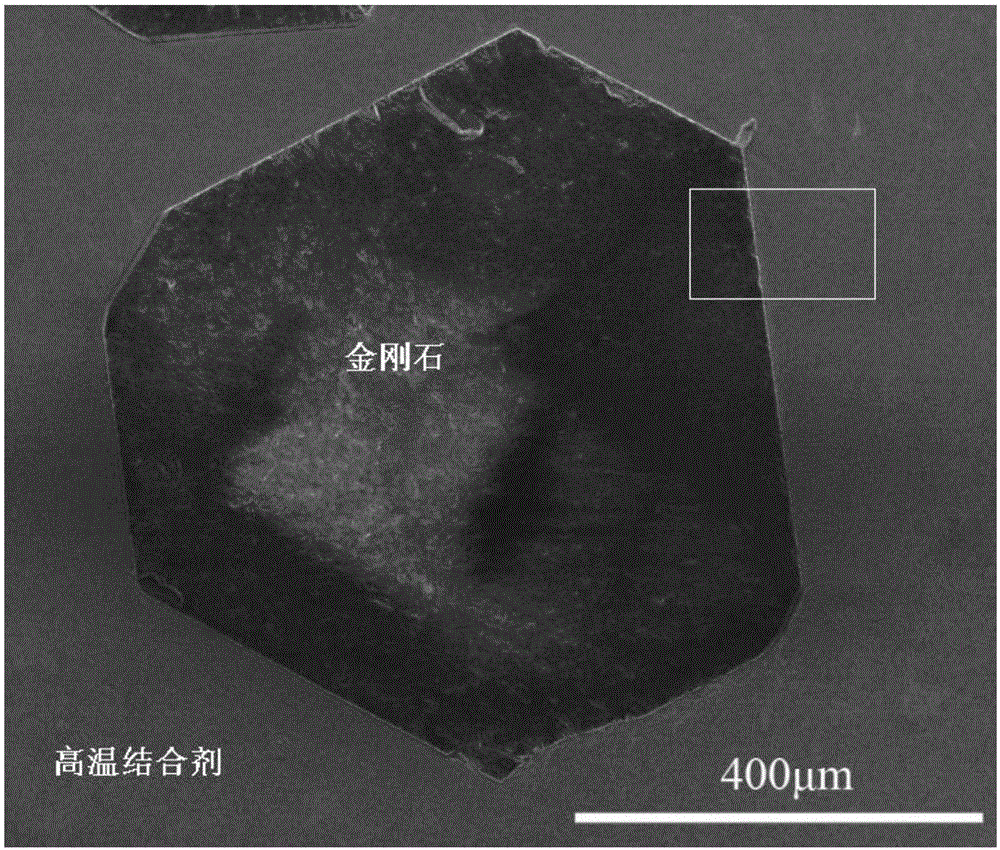

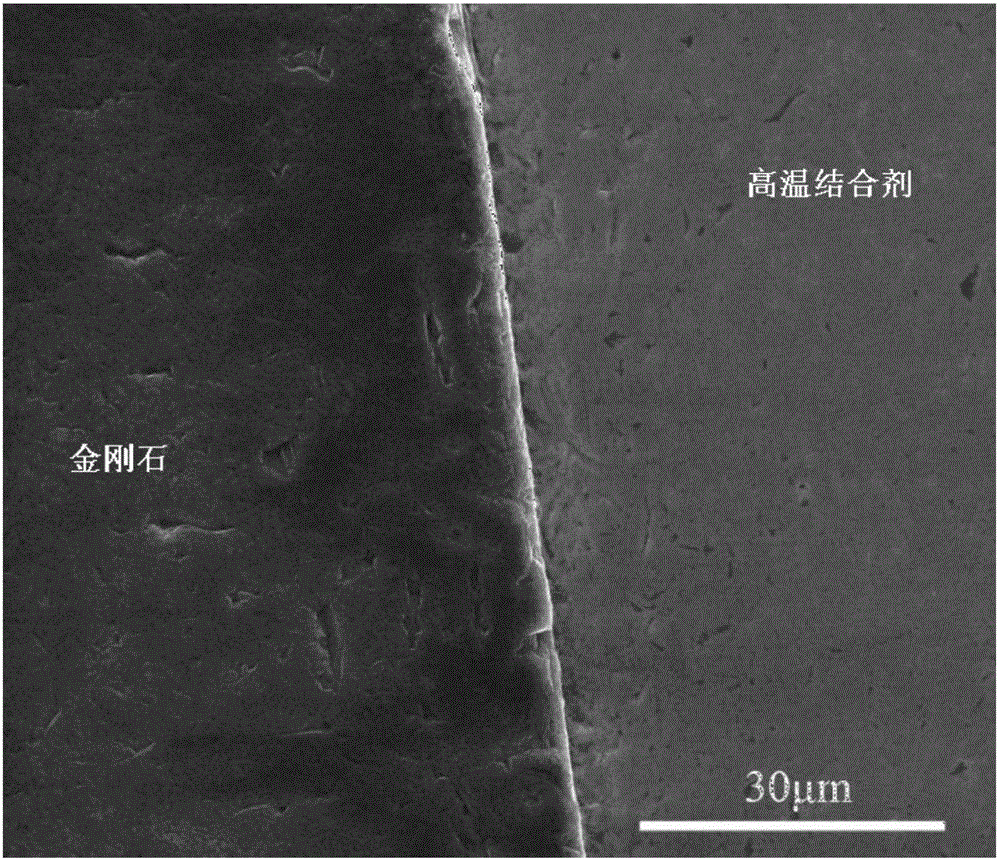

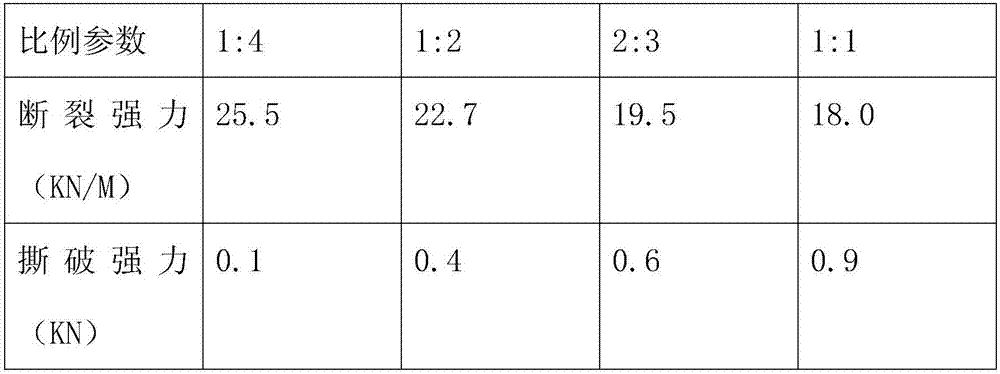

Novel dry type machining grinding tool and preparation method thereof

InactiveCN105773447AImprove high temperature sintering performanceHigh hardnessAbrasion apparatusGrinding devicesHardnessDry machining

The invention provides a novel dry type machining grinding tool. Raw materials of the novel dry type machining grinding tool include a high-temperature bonding agent, an ordinary bonding agent and an abrasive material. The high-temperature bonding agent includes Ni3Al powder. The ordinary bonding agent includes one or more of a nickel-based bonding agent, a copper-based bonding agent, an iron-based bonding agent and a cobalt-based bonding agent. According to the novel dry type machining grinding tool, the high-temperature sintering performance of the grinding tool can be improved through matching of the high-temperature bonding agent including the Ni3Al powder and the ordinary bonding agent, and the grinding tool can have higher hardness. In addition, the novel dry type machining grinding tool can have good oxidation resistance under the high-temperature condition, and meanwhile the yield strength of the grinding tool is improved along with temperature rise. The experiment result shows that the Rockwell hardness of the grinding tool is 93 HRB. The invention further provides a preparation method of the novel dry type machining grinding tool.

Owner:GUANGDONG UNIV OF TECH

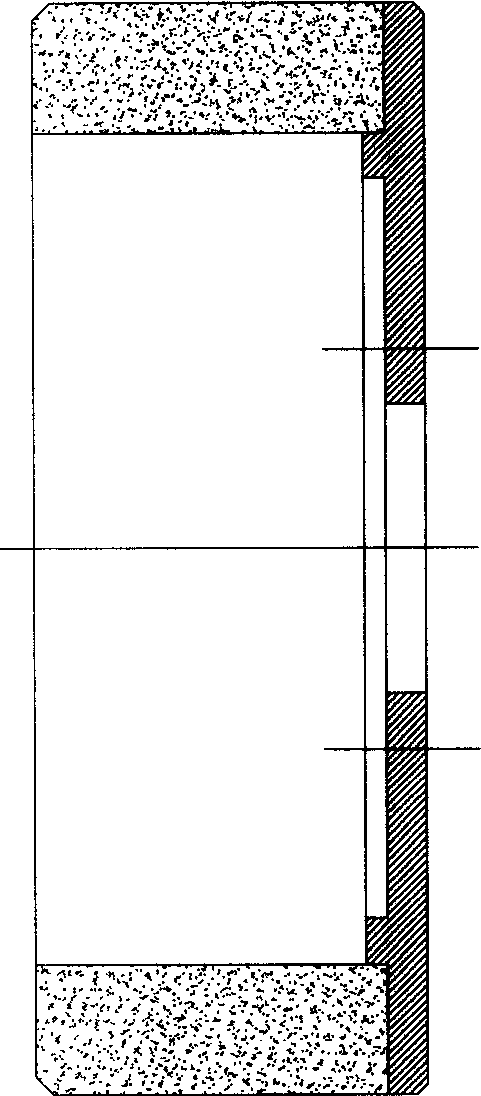

Coated cutting insert

Coated cemented carbide inserts (cutting tools), particularly useful for wet or dry machining of steels and stainless steels, are disclosed. The cutting tool insert is characterized by a cemented carbide substrate and a coating comprising an about 0.5 to 5 μm thick innermost layer of (Ti,Al)N and an about 1 to 5 μm thick layer of (Al,Cr)2O3.

Owner:SECO TOOLS AB

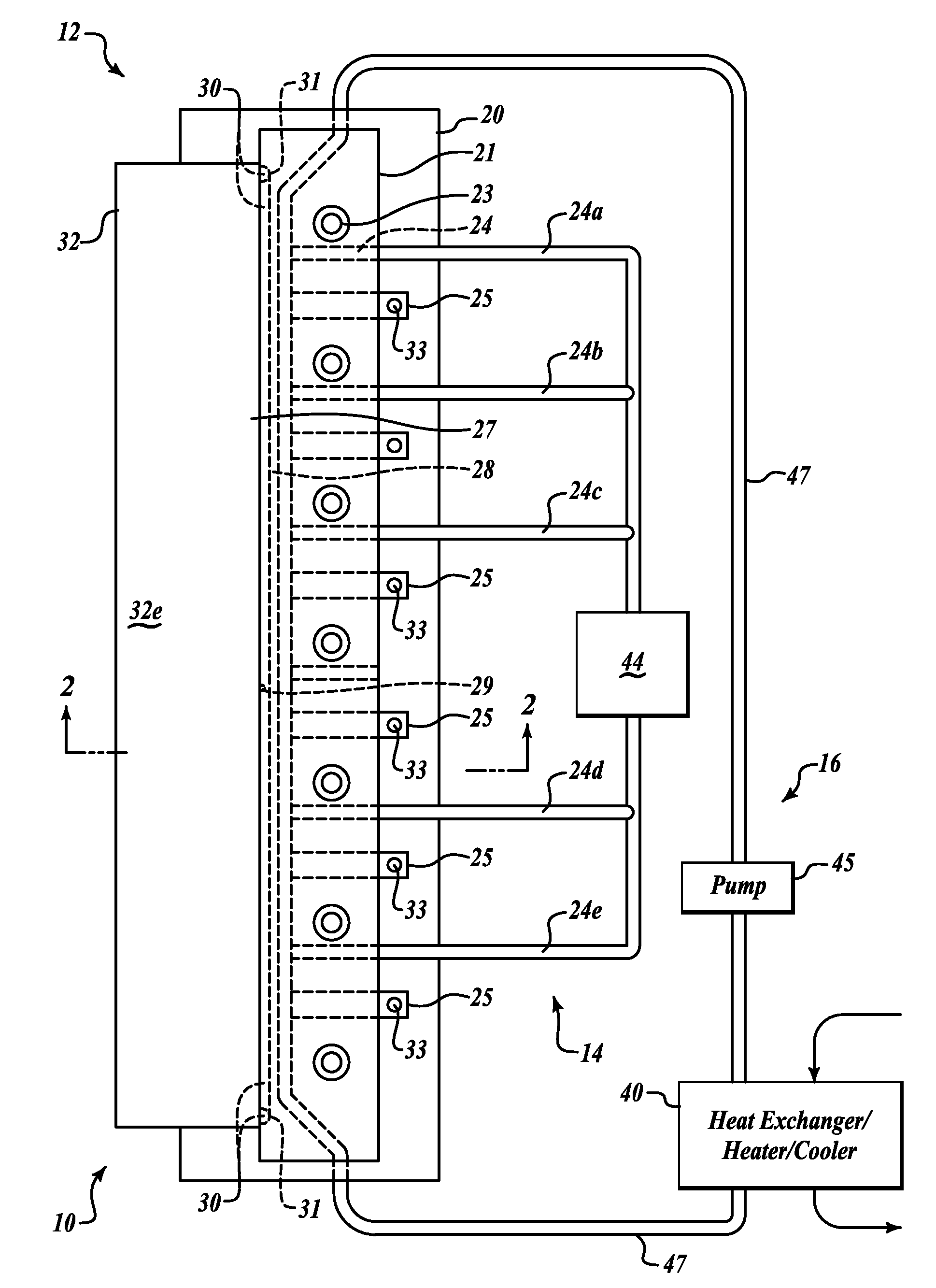

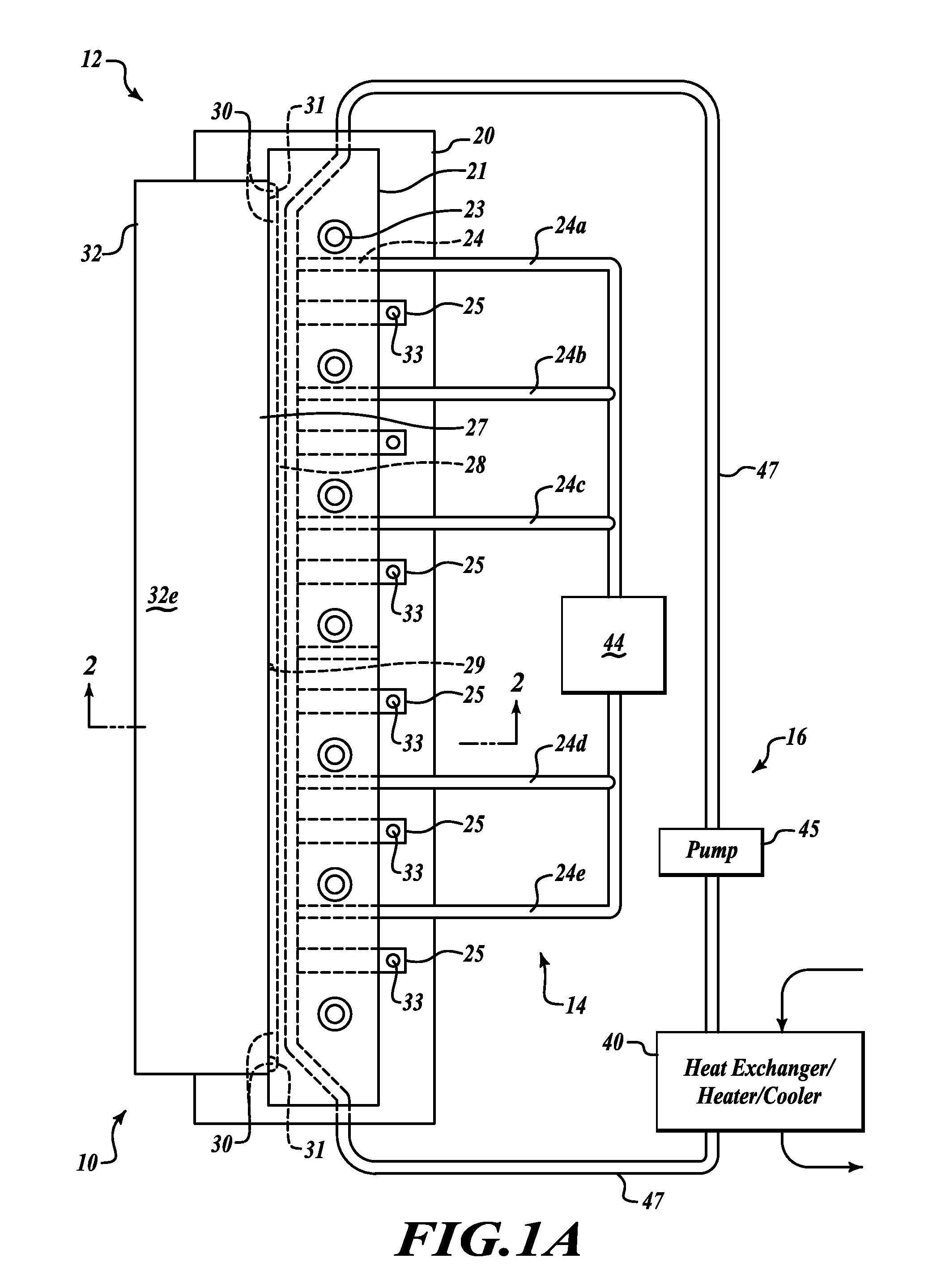

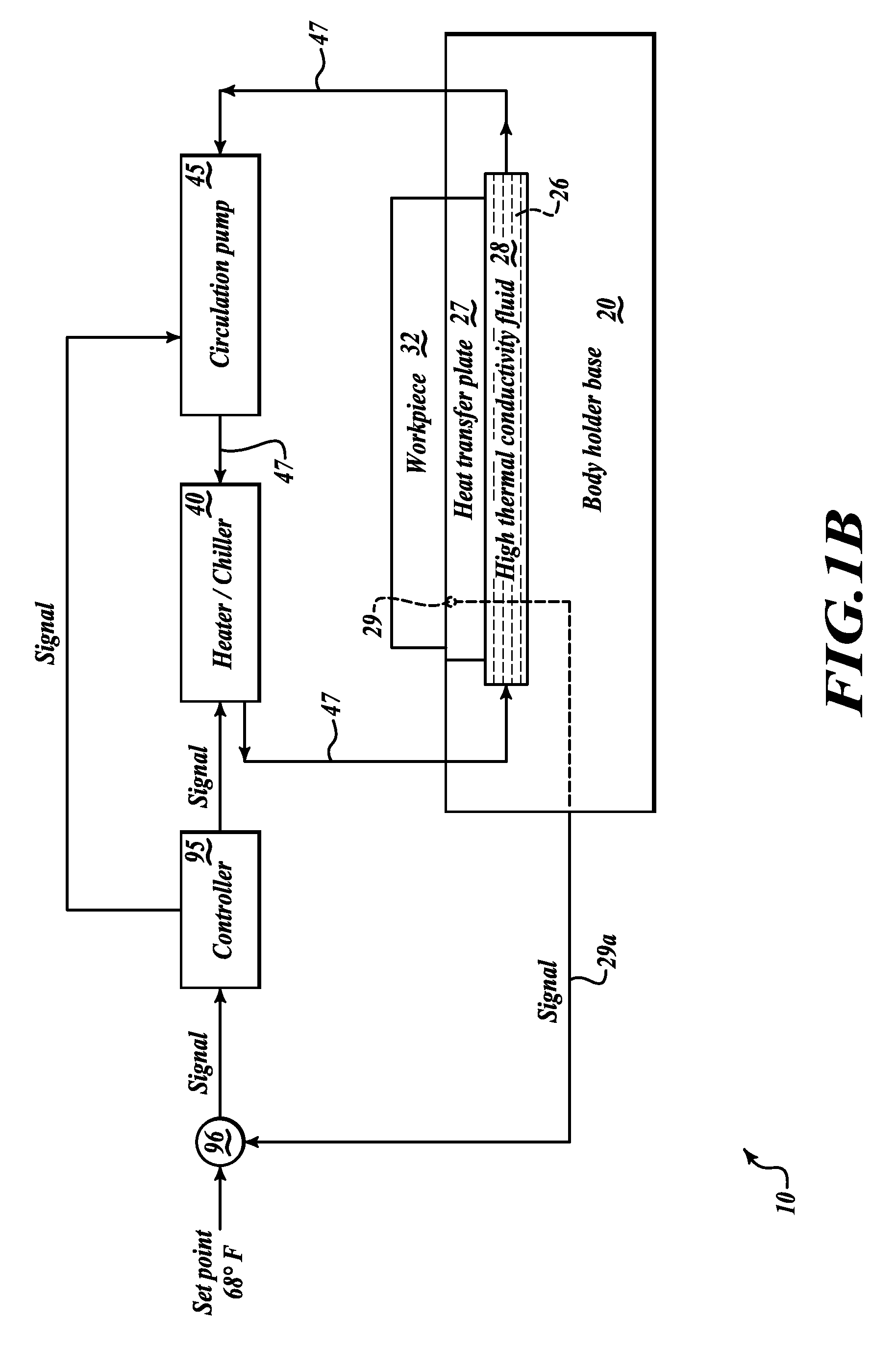

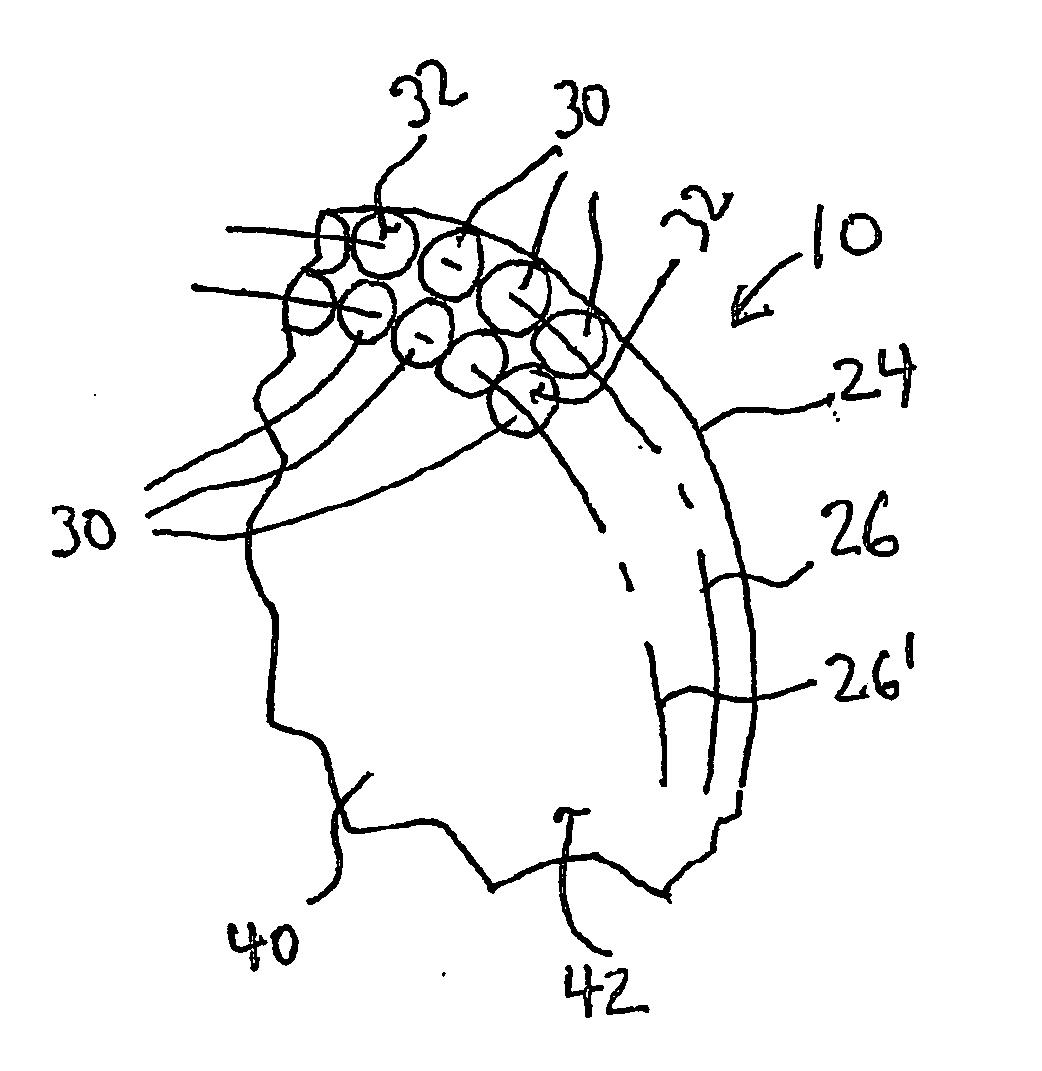

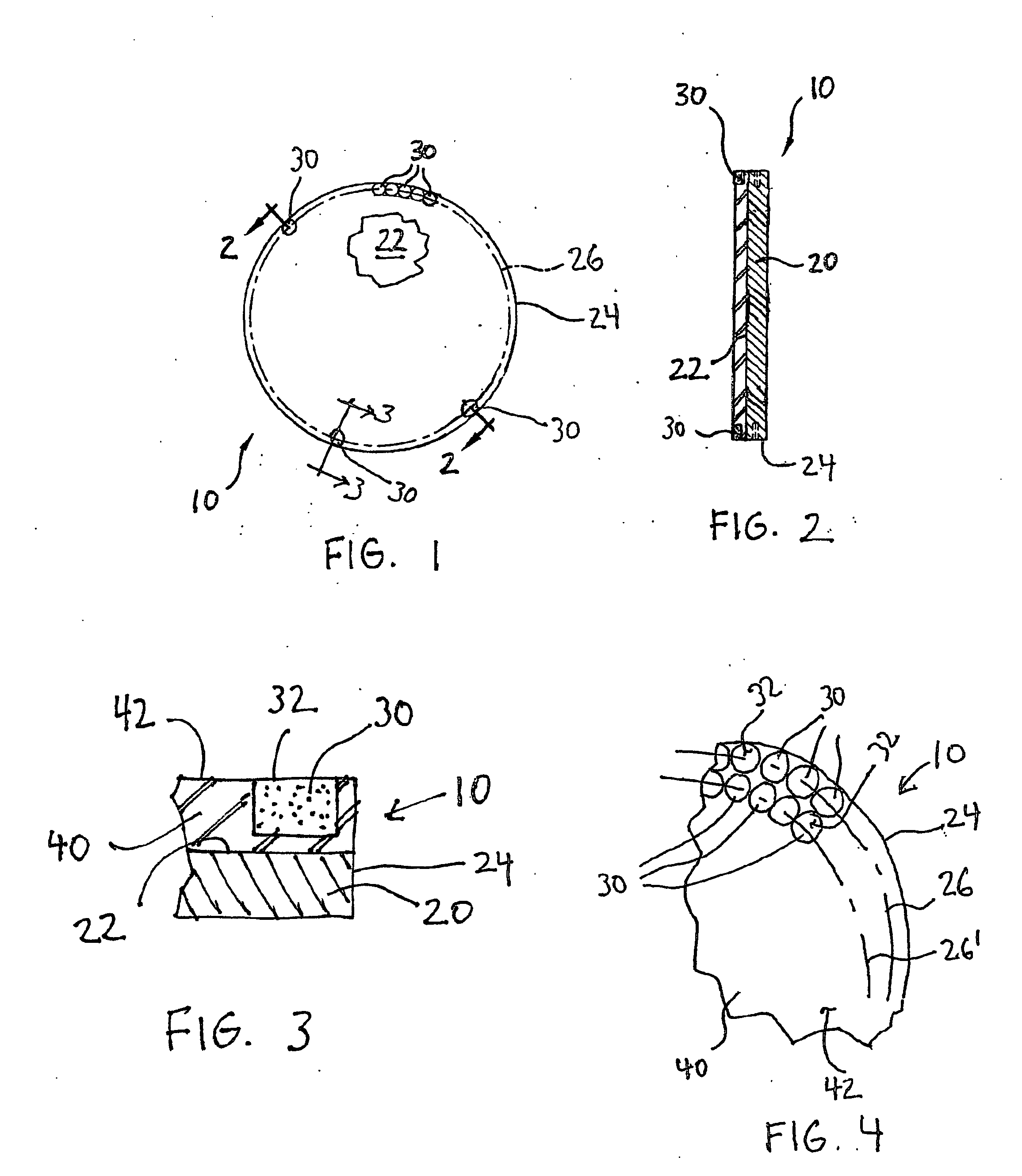

Apparatus, Systems and Methods for Work Piece Isothermal Dry Machining and Assembly Fixtures

ActiveUS20080111290A1Minimal costMaintain temperatureWork holdersFeeding apparatusThermal energyEngineering

Isothermal work piece holding system uses vibration-damping, low thermal conductivity, low TCE polymer-composite holding body(ies) to damp machine tool vibration and chatter while accurately, rigidly maintaining the work piece in position by vacuum and / or mechanical clamps during machining. Cooling fluid channels having high thermal conductivity plates in contact with the work piece transfer thermal energy to / from it to maintain it isothermal during machining, inspection and assembly, eliminating dimensional changes and increasing process repeatability. Minimizing chatter reduces cycle time and improves surface finish which eliminates manual re-work. The system employs vacuum and coolant fluid pumps, heater / cooler(s), temperature sensor(s) and controller(s) to achieve highly accurate dimensional tolerances machining of parts which reduces error stack-up and assembly costs. Isothermal fixtures are disclosed for assembling parts and automated rivet settings in precise locations with reduced use of shims. The inventive isothermal system is applicable to control of TCE / I2R effects in linear induction motors.

Owner:JENSEN ROBERT M

Iron nickel aluminum base bonding agent diamond tool and preparation method thereof

ActiveCN107914019AChanging the Low Creep Strength FeatureImprove bindingTurbinesOther manufacturing equipments/toolsDry machiningUltimate tensile strength

The invention discloses an iron nickel aluminum base bonding agent diamond tool and a preparation method thereof. The diamond tool comprises a metal bonding agent, a sintering aid and an abrasive; themetal bonding agent consists of 35-45 mass parts of Fe3Al powder and 35-45 mass parts of Ni3Al; the sintering aid consists of 5-20 mass parts of Cu-Sn prealloy powder, 0.5-2 mass parts of Si powder,0.5-2 mass parts of B powder and 0.5-2 mass parts of TiH2 powder; the abrasive is diamond; and the diamond abrasive is 5-25 volume% of a grinding layer. Meanwhile, the invention discloses the preparation method of the iron nickel aluminum base bonding agent diamond tool. Fe3Al and Ni3Al are fully mixed as a bonding agent of a dry machining diamond tool; the high-temperature creep strength and themedium-temperature strength can be fully used to obtain the performance of resisting microscale high-temperature creep in grinding; and Fe3Al and Ni3Al can be preferably bonded with a basal body to change the low-creep strength characteristic of a traditional metal bonding agent.

Owner:GUANGDONG UNIV OF TECH

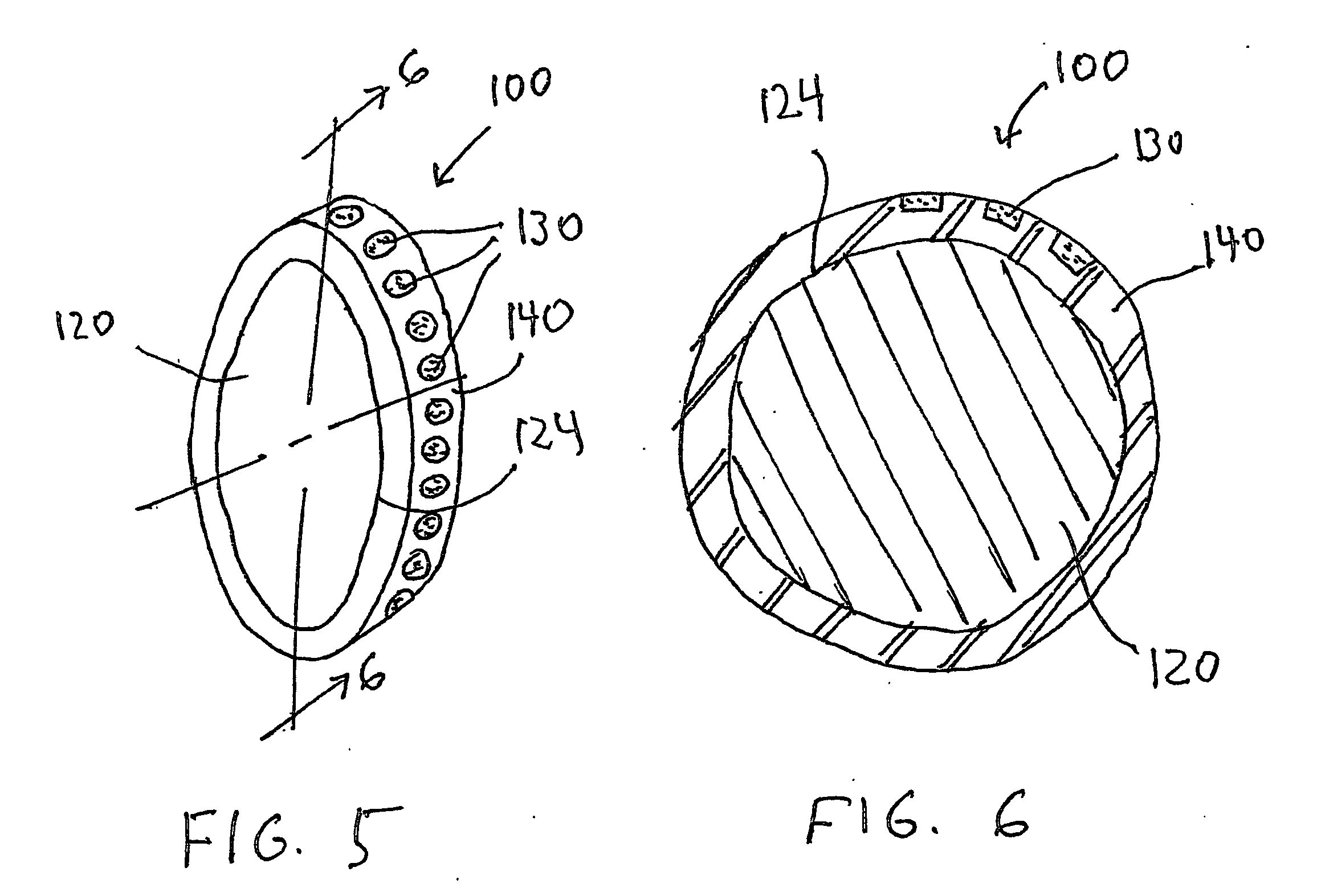

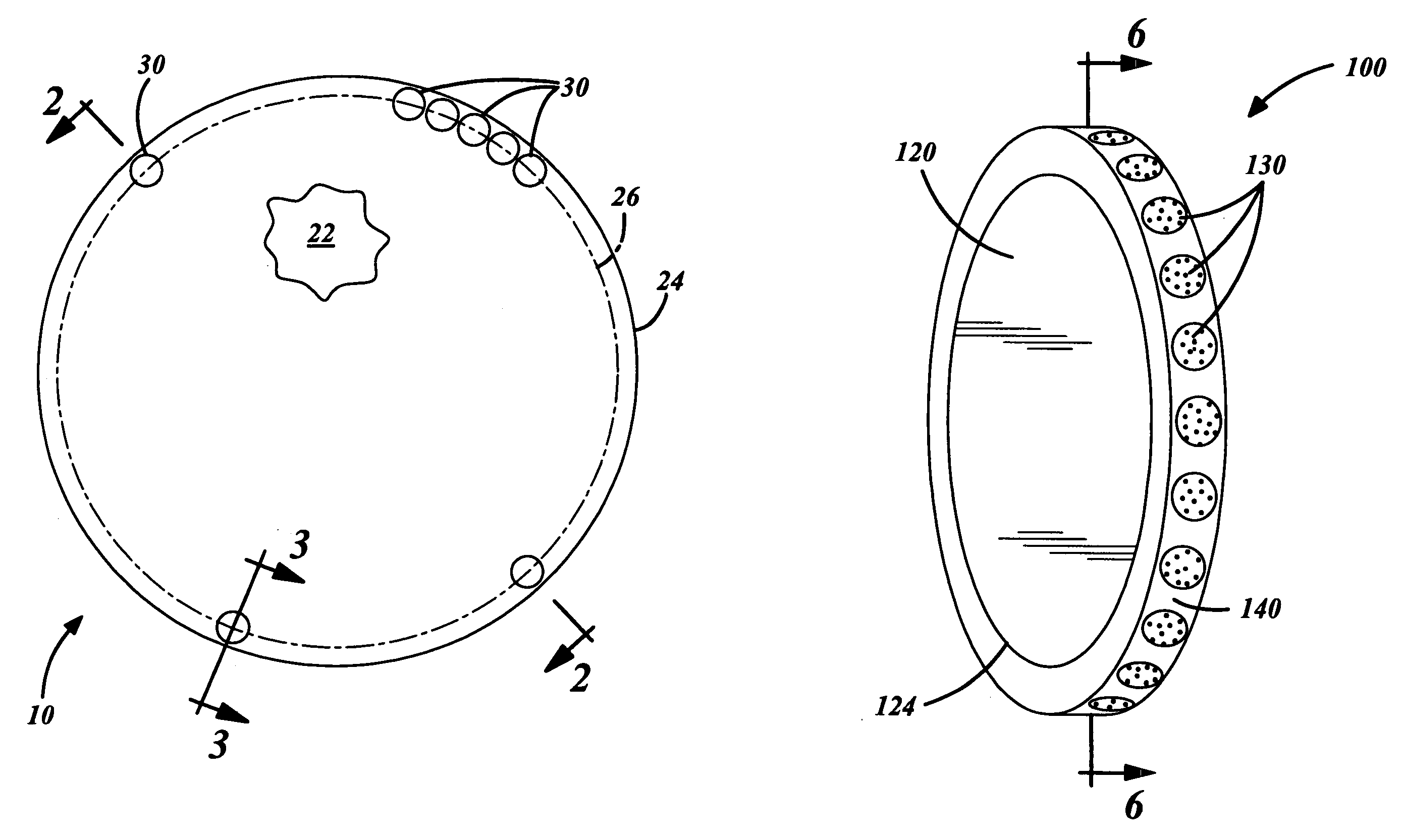

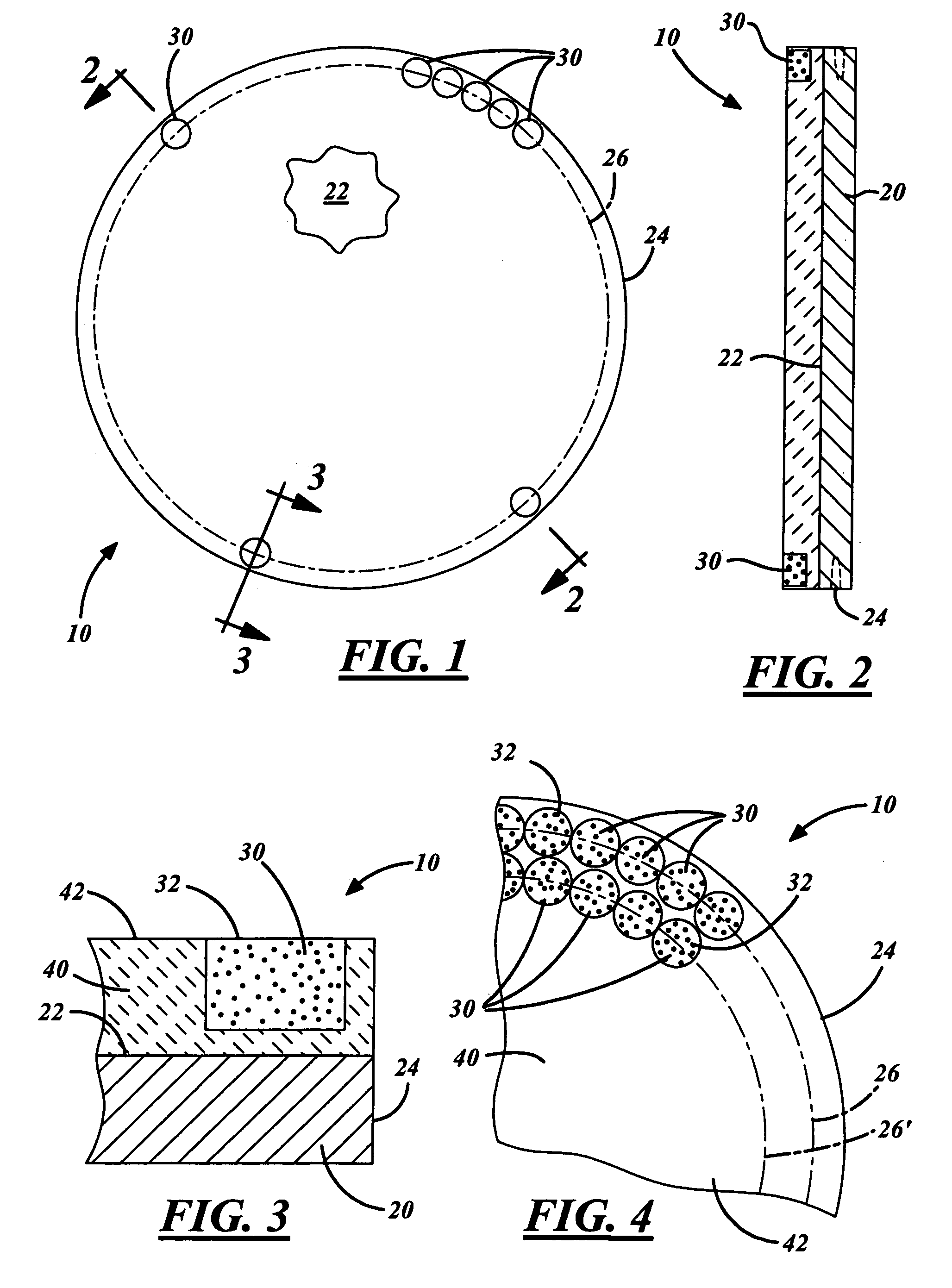

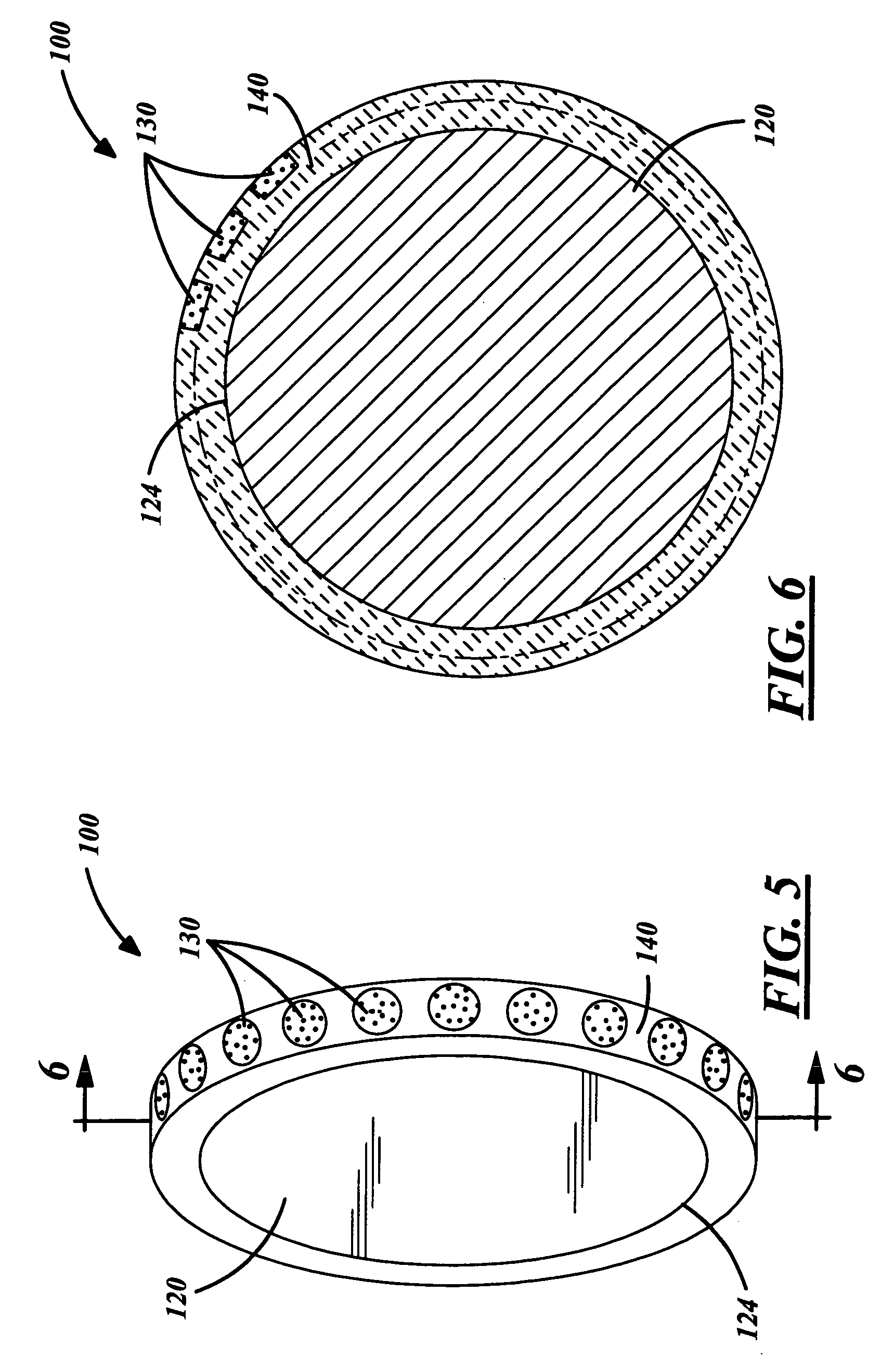

Segmented superabrasive grinding device

InactiveUS20050181715A1Improve cooling effectImprove machine efficiencyRevolution surface grinding machinesOther chemical processesHexagonal boron nitrideBoron nitride

The present invention is for a grinding device, such as a surface grinding disc or an annular grinding wheel, constructed from a plurality of abrasive segments arranged in an array thereon, wherein the plurality of abrasive segments are embedded in a matrix composition, and wherein the device is abapted to perform a “dry machining” operation. The abrasive segments may be resin bonded or vitrified and may include diamond or other superhard or superabrasive particles, such as, for example, cubic boron nitride (“cBN”), dispersed therein. Both the abrasive segments and the matrix composition include a dry lubricant, such as hexagonal boron nitride, molybdenum disulfide or graphite, dispersed therein. The abrasive segments further include a melt phase metal composition, such as bronze or other copper alloys, to aid in heat dissipation.

Owner:FIVES LANDIS

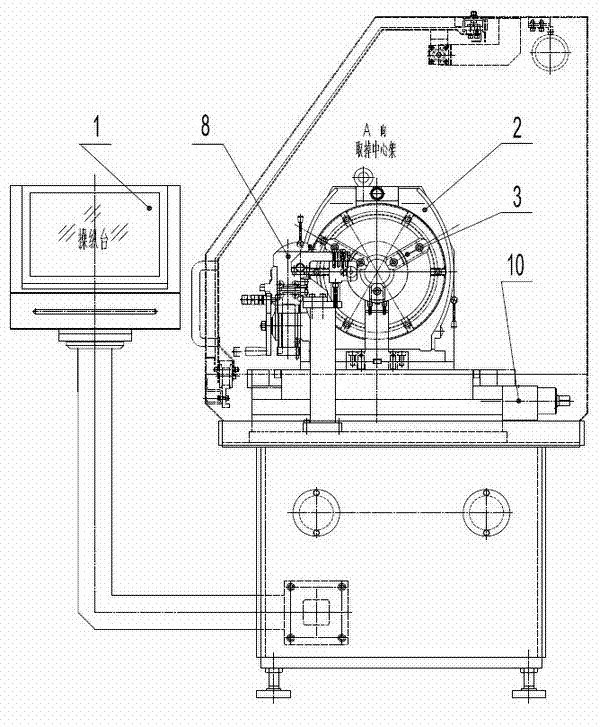

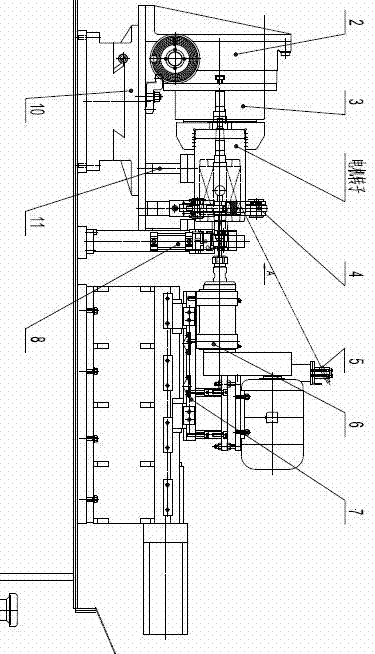

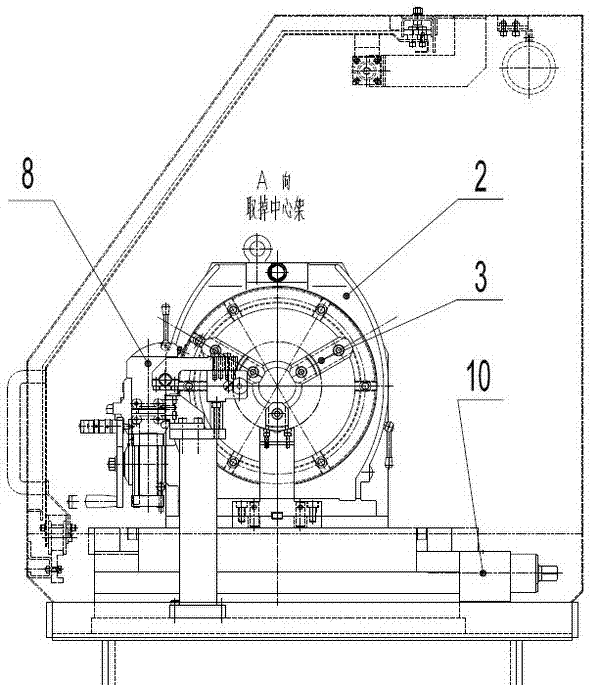

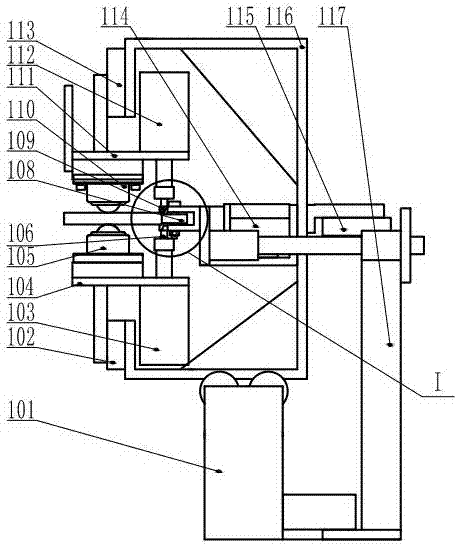

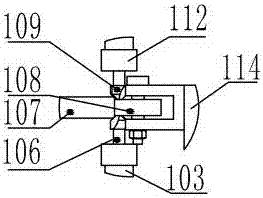

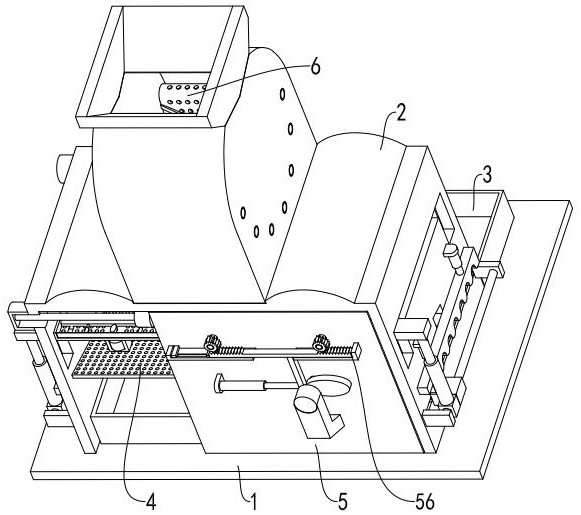

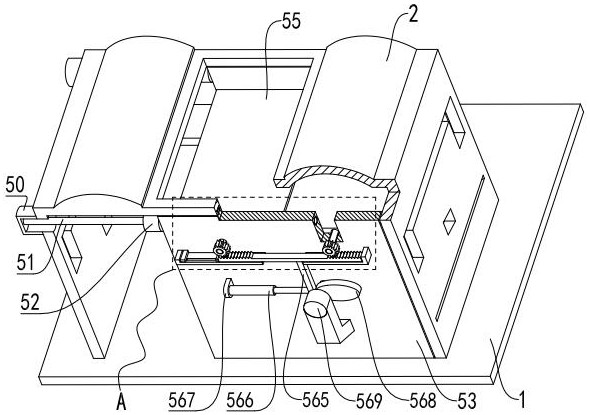

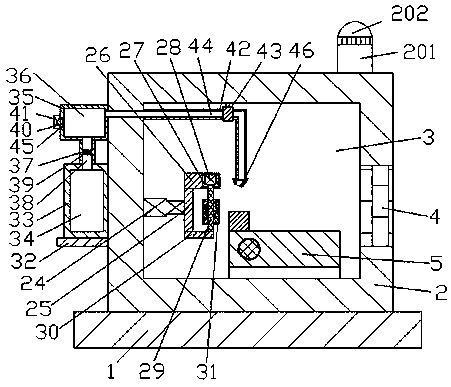

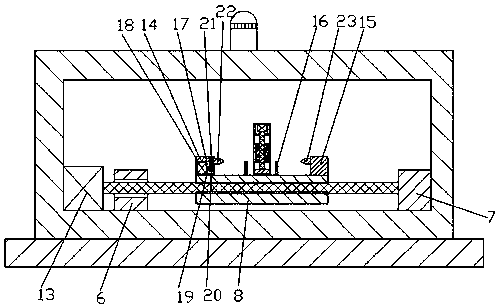

New-energy electric vehicle traction motor rotor de-weight machine

ActiveCN103240437AEnsure consistencyEasy to operateMeasurement/indication equipmentsBoring/drilling machinesHigh volume manufacturingNew energy

The invention relates to a new-energy electric vehicle traction motor rotor de-weight machine, in particular to a new-energy electric vehicle traction motor rotor de-weight machine adopting techniques of de-weighting a rotor by laser alignment, dial dividing and drill processing. The new-energy electric vehicle traction motor rotor de-weight machine comprises a control board, a machine body, a transverse-sliding table, a movable drill bushing and a servo sliding table, wherein the transverse-sliding table, the movable drill bushing and the servo sliding table are arranged in the machine body in sequence. Center lines of the transverse-sliding table and the servo sliding table are mutually perpendicular. The new-energy electric vehicle traction motor rotor de-weight machine is applicable to de-weighting mass-produced motor rotors by drilling under the condition of dry machining, de-weight information is reached in one step quickly and accurately so as to facilitate operation; de-weighting by the laser alignment is quick and accurate, the dial dividing can standardize the drilling processing to be operated, and de-weighting by drilling workpieces different in diameter and length without polluting the work pieces and surroundings can be realized; when in mass production, a plurality of kinds of products can be placed on the same device to be drilled to de-weight, and the workpieces different in diameter and length are clamped tightly to keep consistency of de-weight surfaces.

Owner:大连德欣新技术工程有限公司

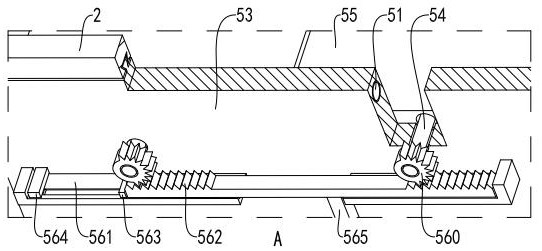

Automatic plate trimming machine

InactiveCN107009480ARealize follow-up trimmingGuaranteed accuracyLiquid surface applicatorsProfiling/shaping machinesVertical edgeEngineering

The invention discloses an automatic plate trimming machine. The automatic plate trimming machine comprises a frame; the frame is provided with a pressing wheel set for providing the feeding power to plates; the pressing wheel set clamps the plates; and in a plate feeding direction, the frame is provided with upper and lower edge chamfering modules, an upper angle painting module, a lower angle painting module, an upper drying module, a lower drying module, a front vertical edge chamfering module and a back vertical edge chamfering module in sequence. The automatic plate trimming machine can realize machining of transverse and vertical edges of the plates, meanwhile, is provided with automatic painting and drying machining modules to form trimming equipment with higher automation degree, and has such characteristics as high machining precision and simple operation.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

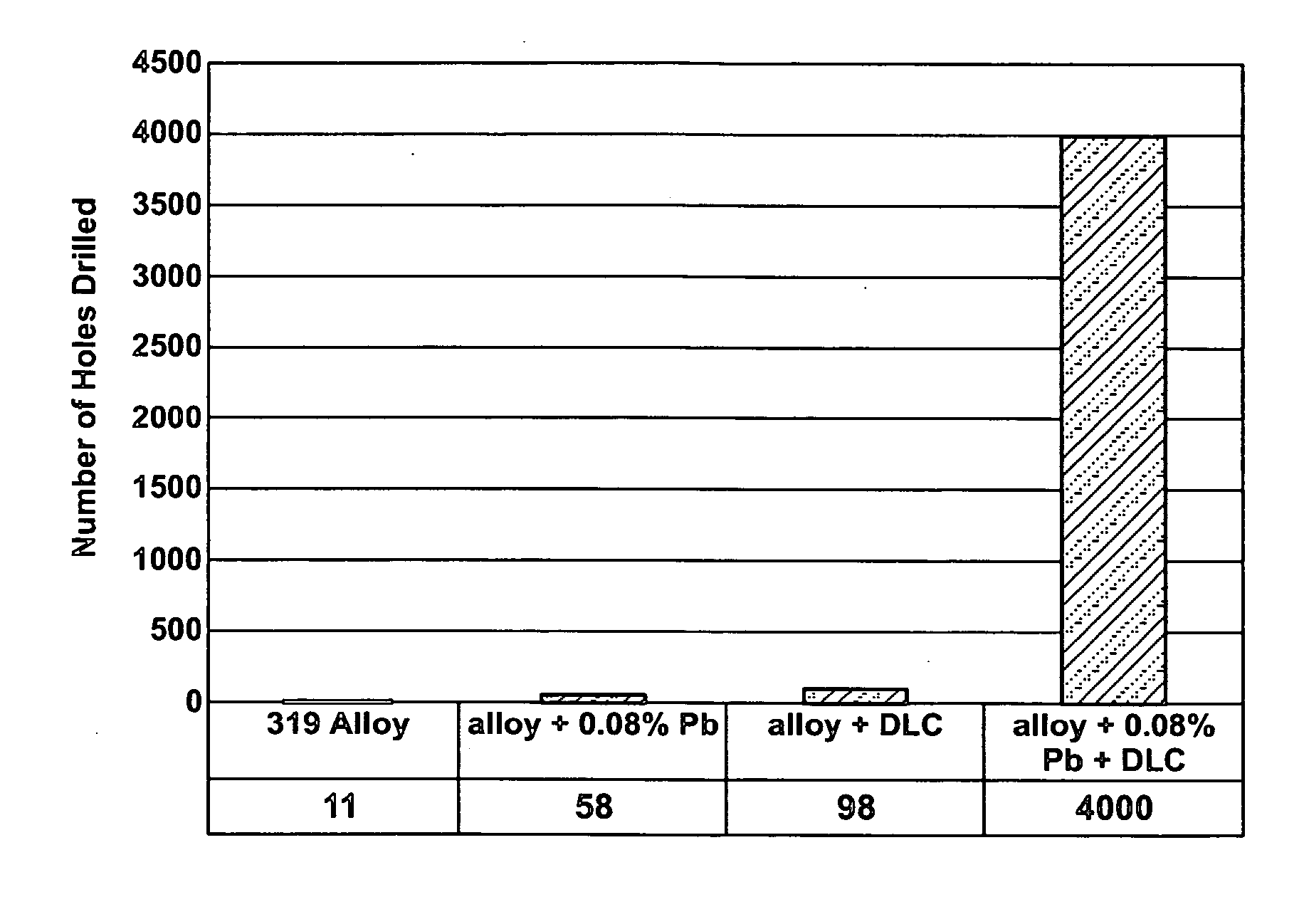

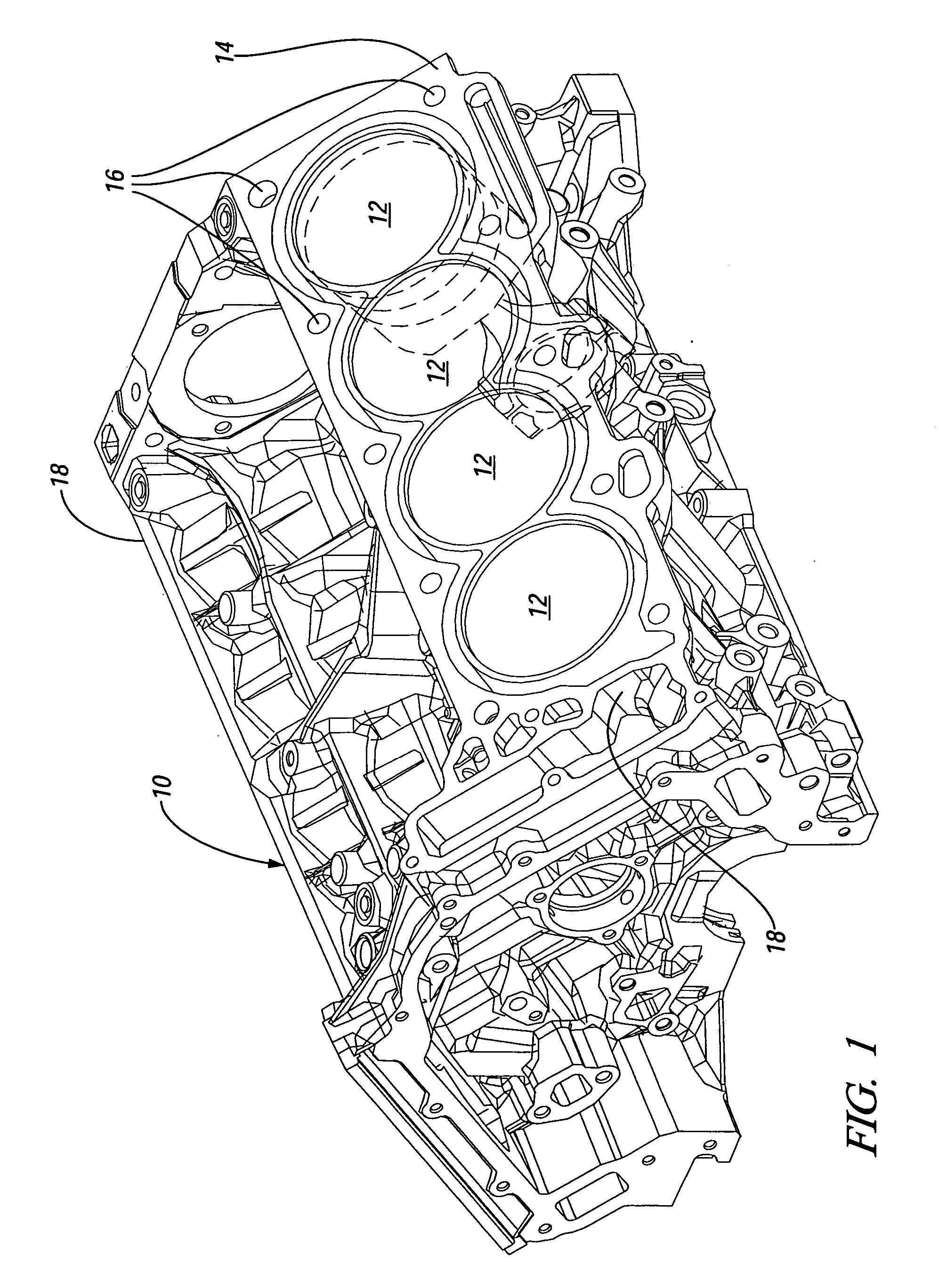

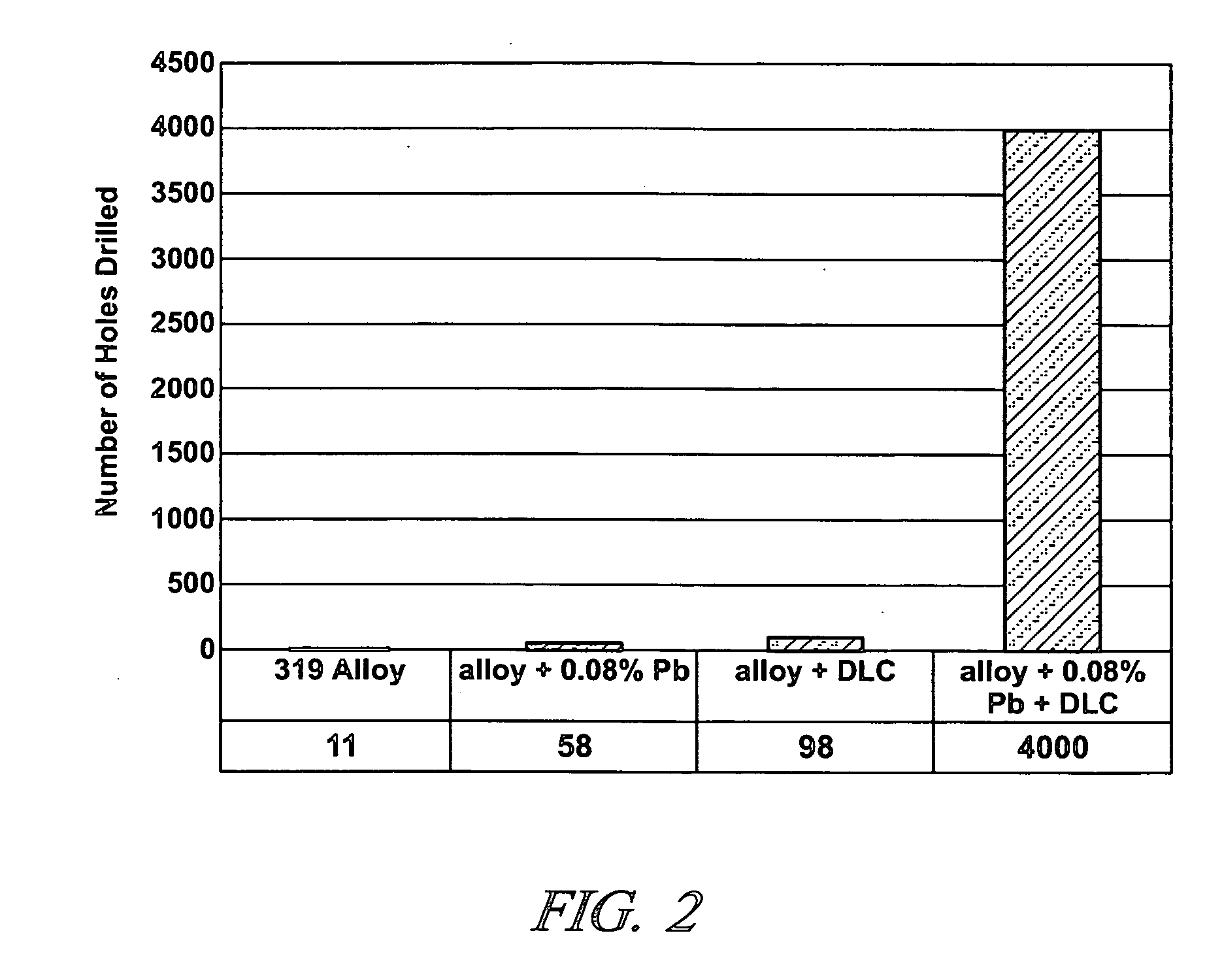

Dry machining of soft metal-modified aluminum castings with carbon-coated tools

Additions of small but effective amounts of one or more of bismuth, indium, lead and / or tin to a silicon-containing aluminum casting alloy markedly improves the dry machinability of a casting made from the modified alloy. But dry machining of such castings is synergistically improved by the use of cutting tools with cutting surfaces coated with microcrystalline diamond or diamond-like carbon coatings. The use of such carbon-coated tools enables remarkable improvement in dry machinability even at reduced levels of the soft metal in the alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

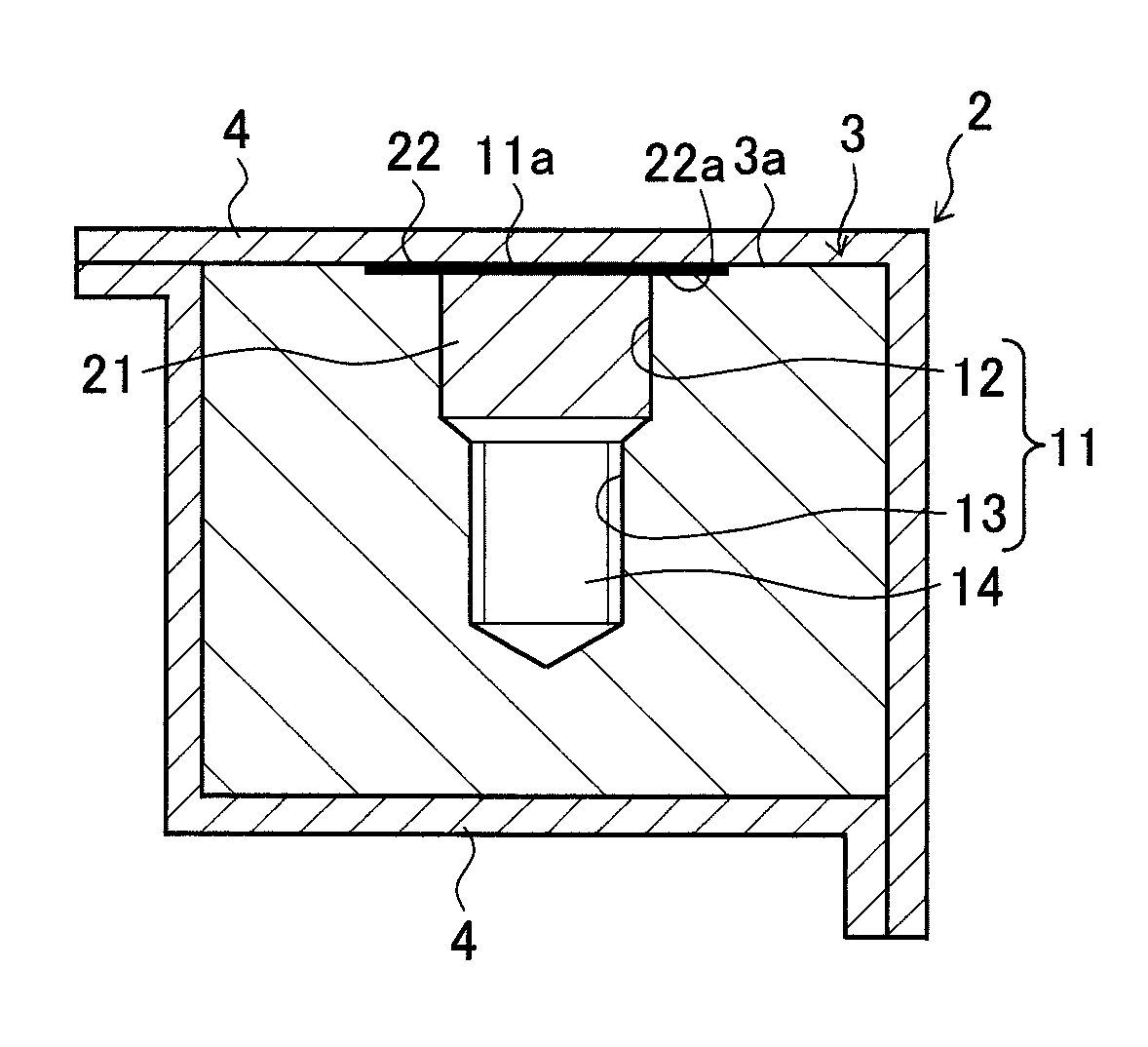

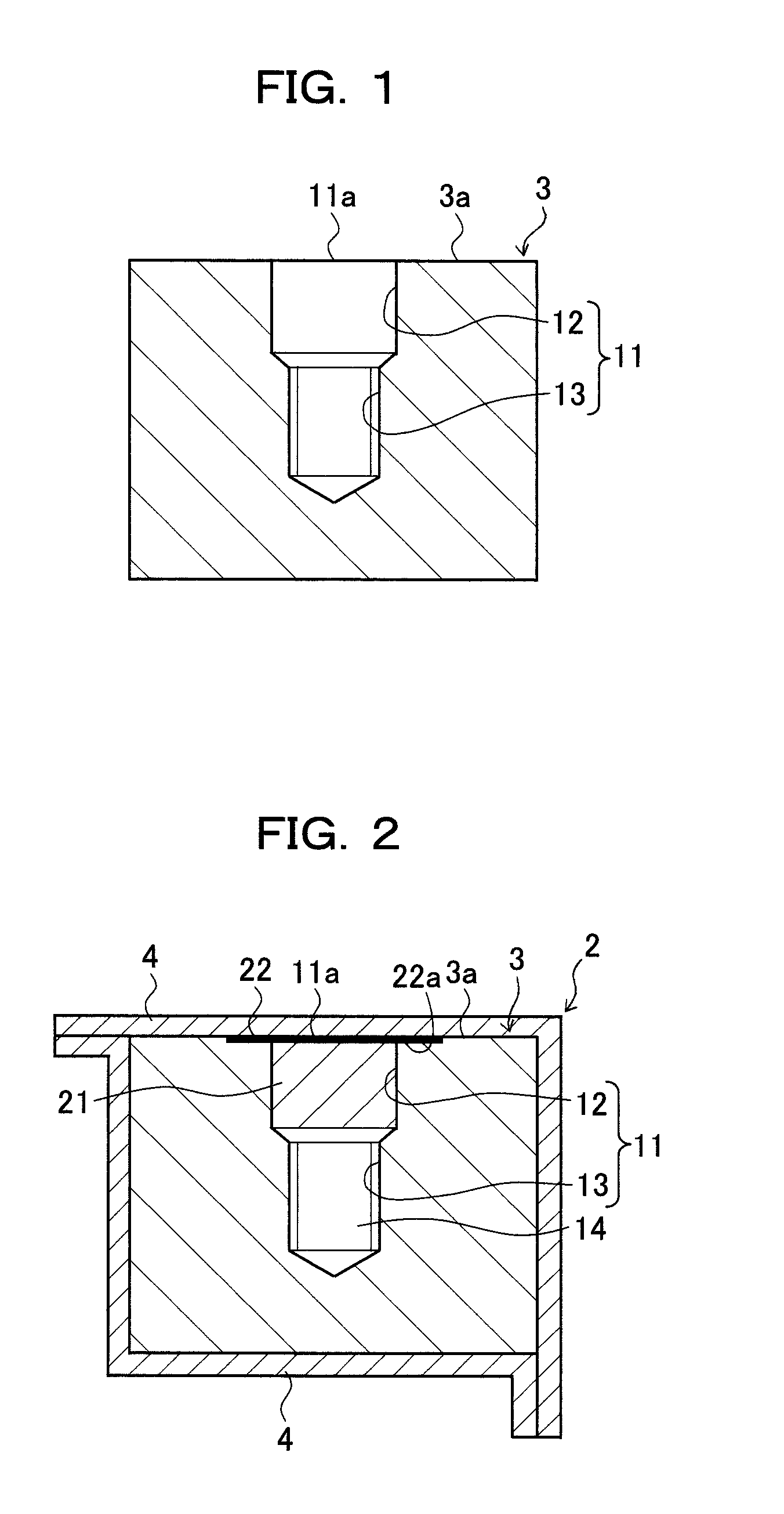

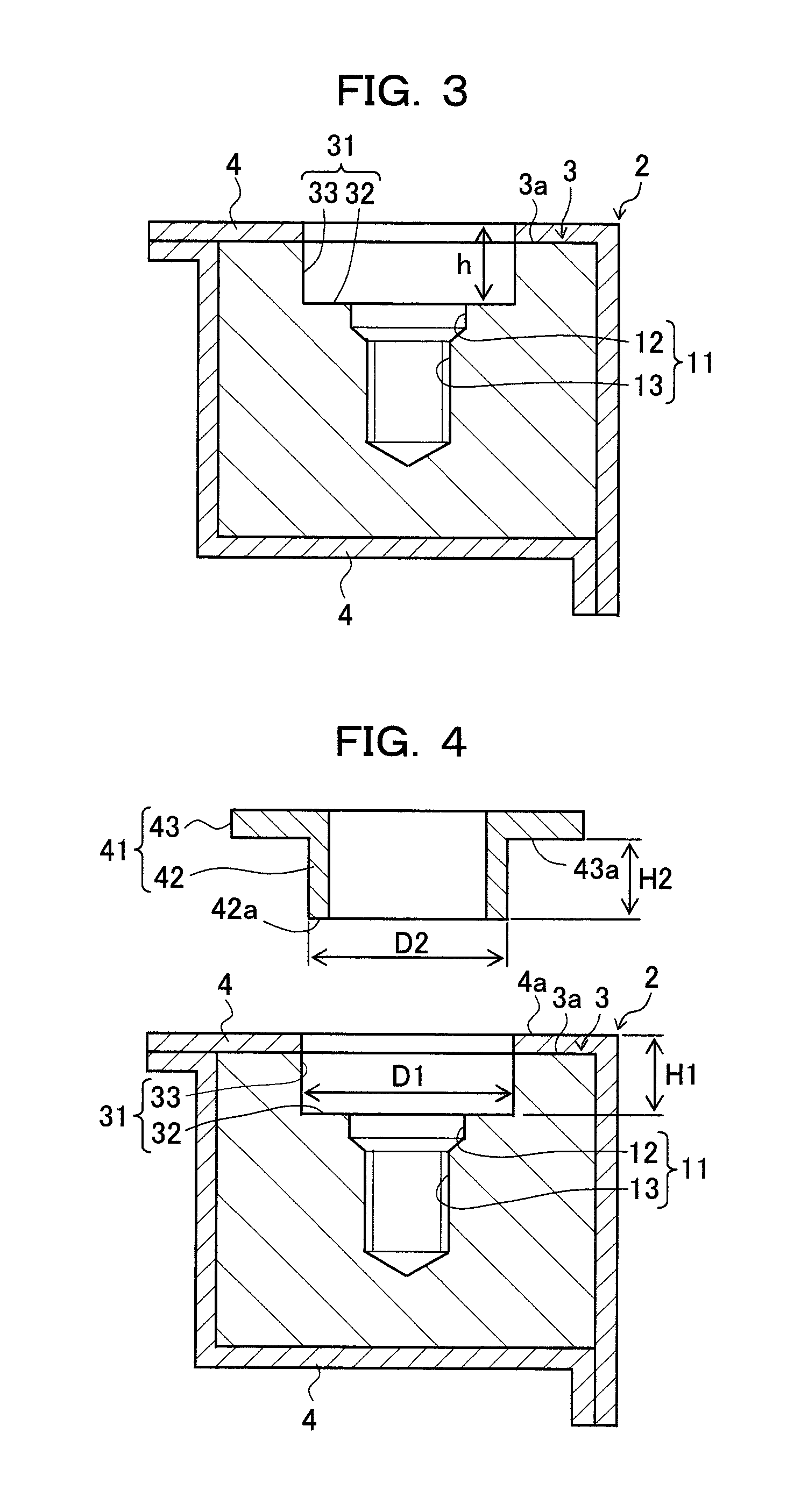

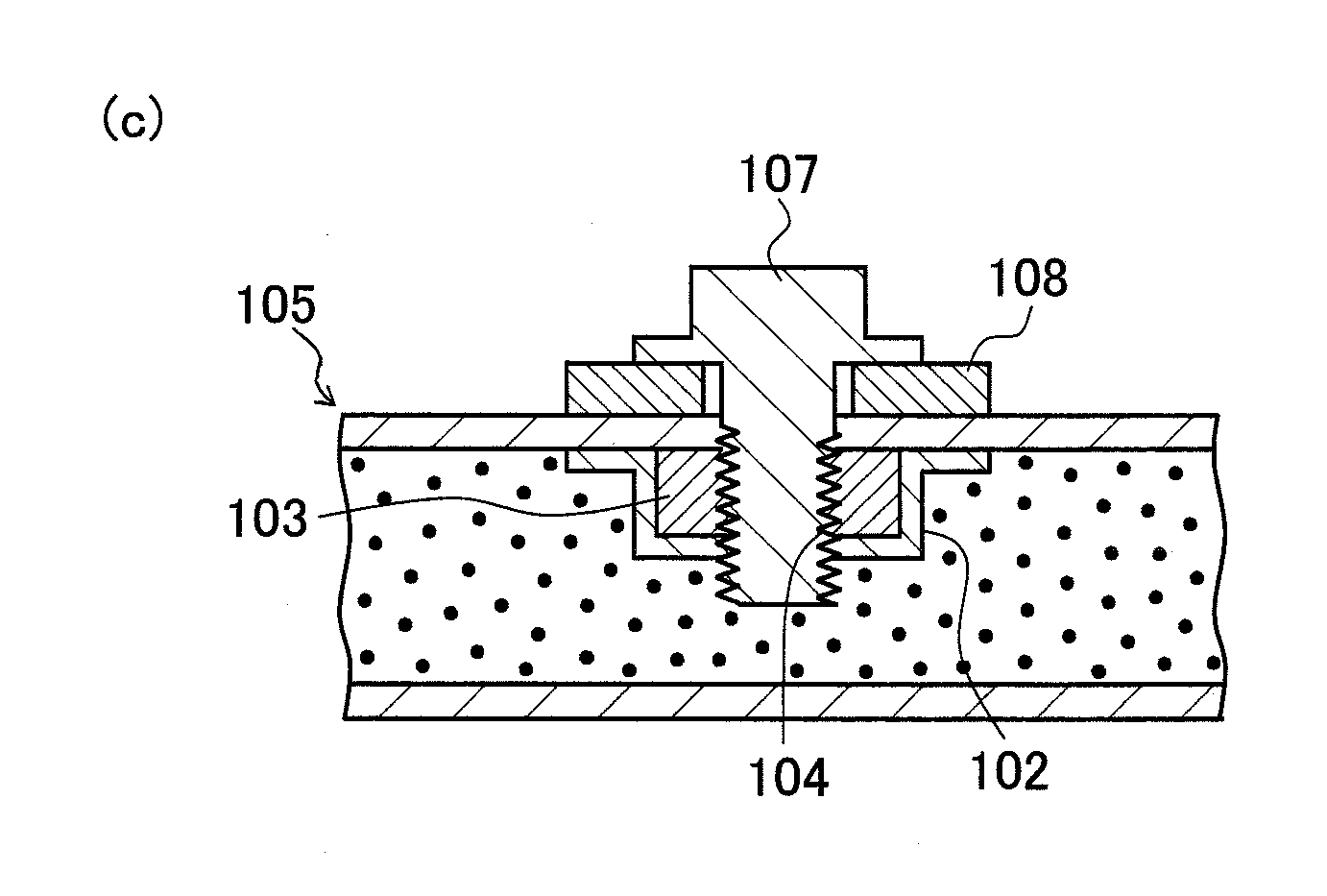

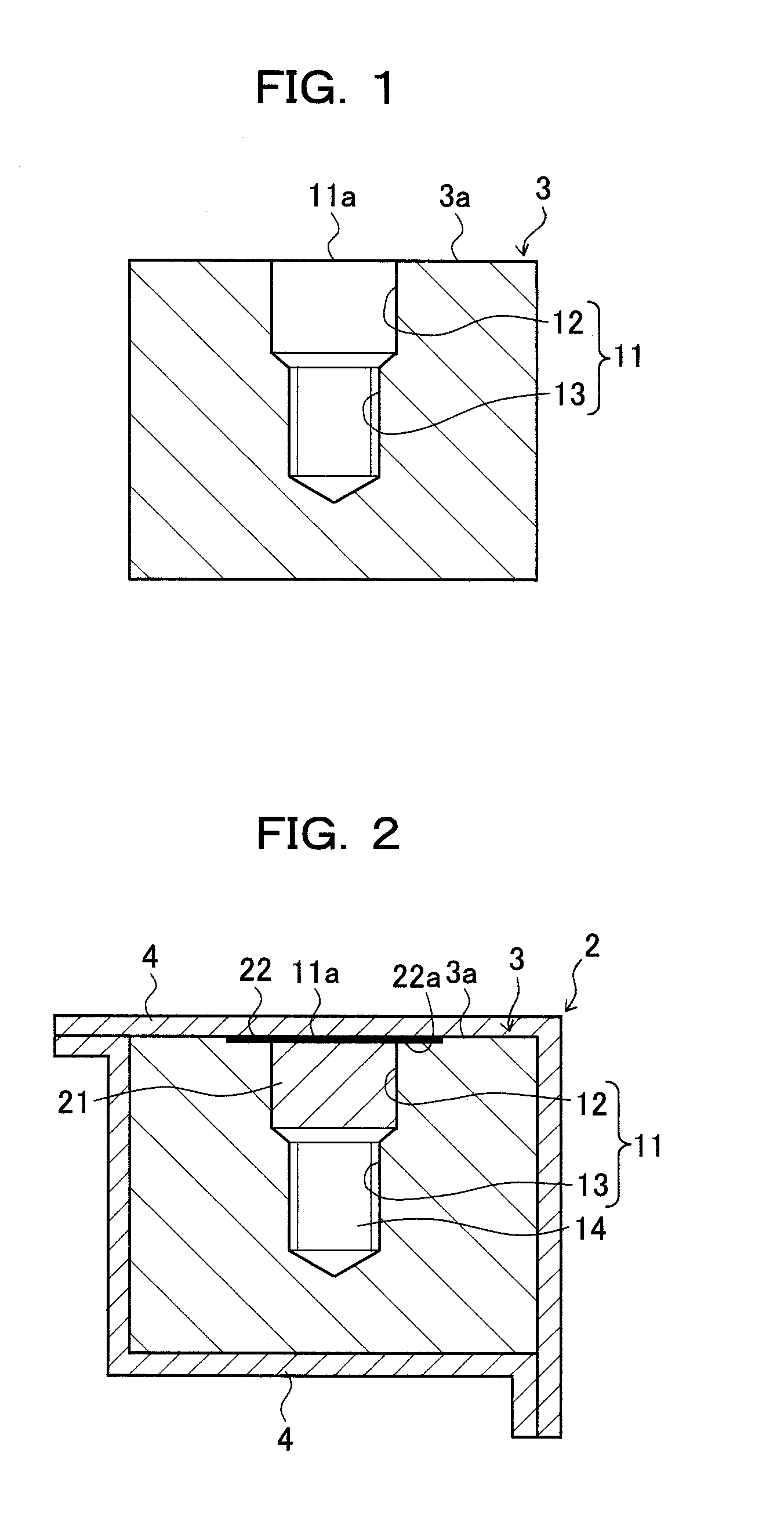

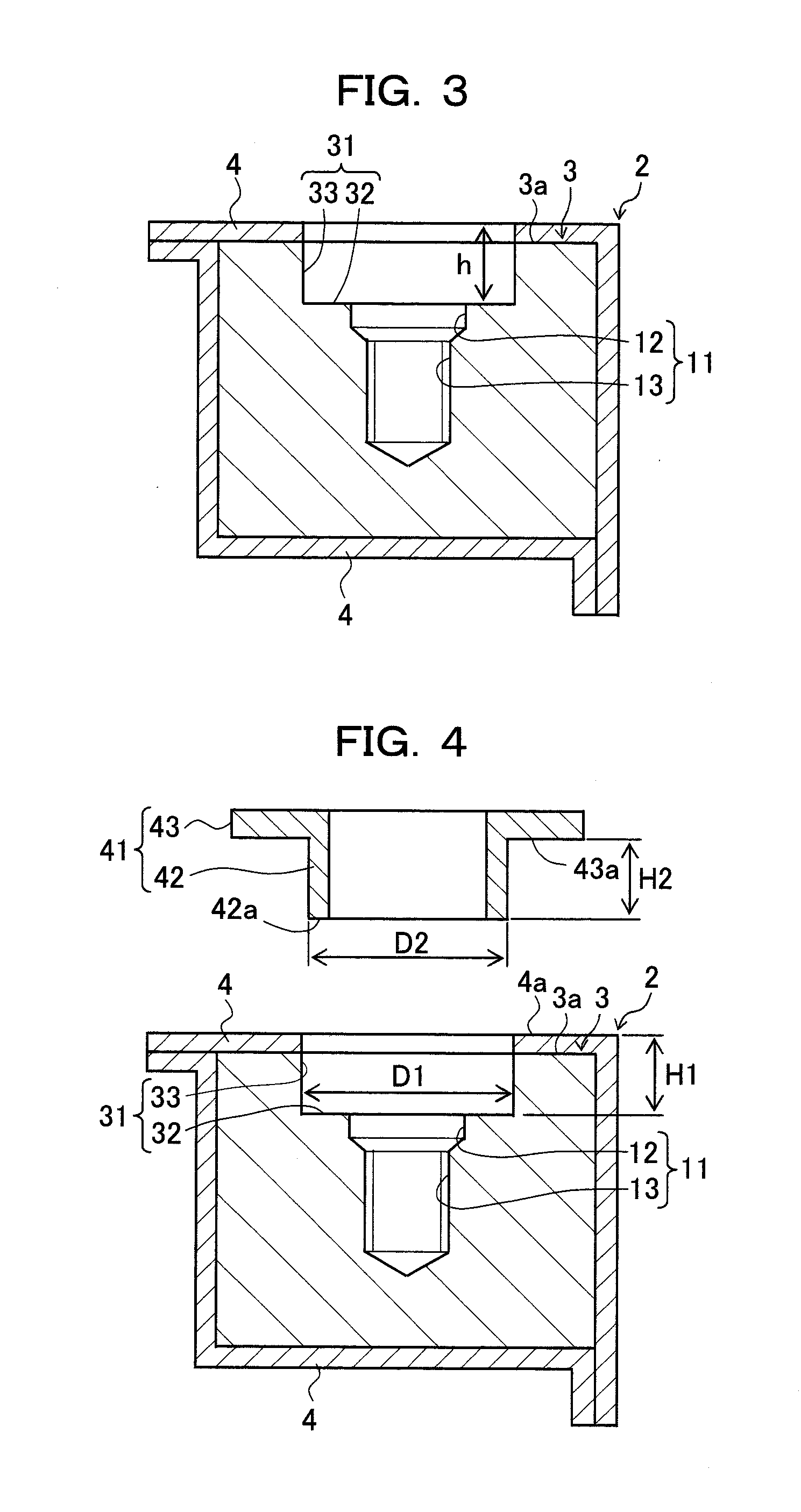

Method for manufacturing FRP member with insert and FRP member with insert

Provided is a method for manufacturing an FRP member with insert which enables to reduce a machining time to improve productivity. First, a threaded hole 11 is formed in an insert 3. An FRP member 2 where at least the threaded hole 11 of the insert 3 is covered with a coating 4 made of FRP is molded. A counter-bored hole 31 that penetrates the coating 4 of the FRP member 2 to communicate with the threaded hole 11 of the insert 3 is formed, to thereby obtain an FRP component 1 with insert. Accordingly, a machining step after molding the FRP member 2 in which dry machining is required includes only the boring step of forming the counter-bored hole 31 in the FRP member 2. Thus, the machining time can be reduced, and the productivity can be improved.

Owner:TOYOTA JIDOSHA KK

Shell machining process for communication equipment

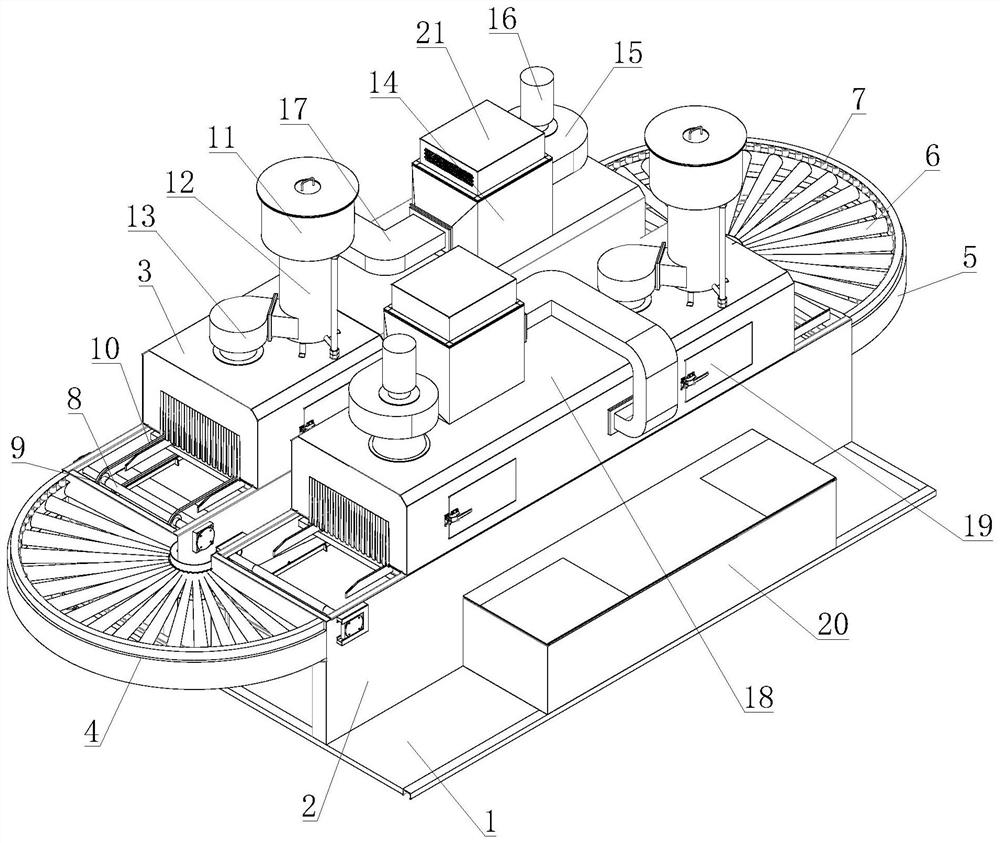

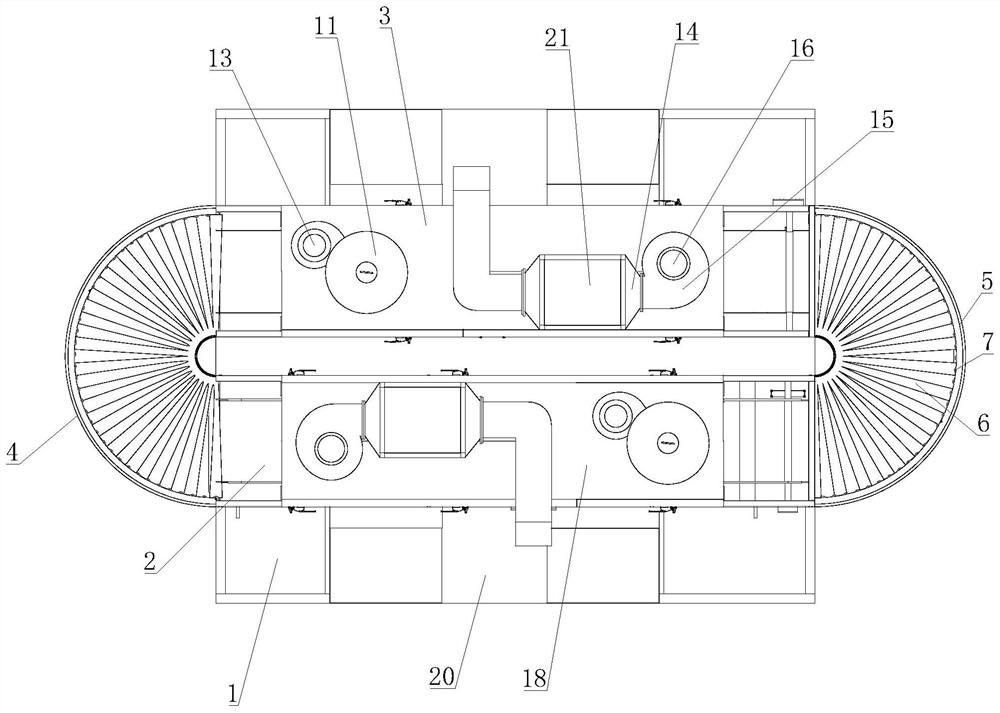

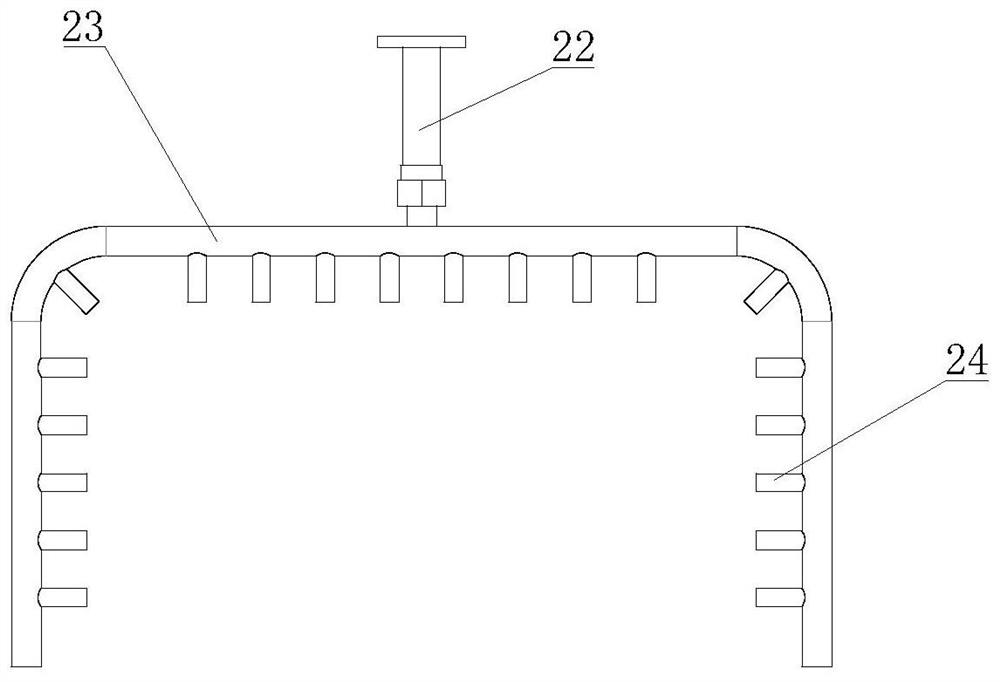

ActiveCN112718346AImprove spray processing efficiencyAchieve steeringPretreated surfacesCoatingsNumerical controlDry machining

The invention discloses a shell machining process for communication equipment. The shell machining process specifically comprises the following steps: 1, forming a communication equipment shell body through injection molding or casting; 2, placing the communication equipment shell body on a numerical control machine tool to be ground and drilled to obtain a formed shell body; and 3, putting the formed shell body into spraying and drying equipment to be subjected to spraying and drying machining, wherein firstly, the formed shell body is conveyed to a conveying roller of a first arc-shaped frame, and the formed shell body is conveyed into a first drying and spraying box through the conveying roller on the first arc-shaped frame. According to the shell machining process, an overturning assembly is arranged to conduct automatic overturning on shell spraying, automatic overturning and steering of the shell are achieved through an overturning and steering mechanism, comprehensive and uniform spraying treatment is conducted on different positions of the surface of the shell, and a drying mechanism is arranged in a box body to conduct timely drying treatment on the sprayed surface, so that the spraying quality is ensured while the machining efficiency is improved.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

Dry processing method for ceramic brick and a dry edging and bevelling machine

InactiveCN1611336AFast processingReduce labor intensityAbrasive surface conditioning devicesStone-like material working toolsBrickElectrical control

The present invention relates to a dry processing method ofm ceramic tile and a dry edging chamfering machine for processing ceramic tile by using said method. Said processing method comprises three produres of edging, finishing and chamfering, and the described three procedures have not need of adding water or other cooling lubricant solutions. The described dry edging and chamfering machine comprises machine frame, crossbeam positioned on the machine frame, transmission device, driving device, press belt, centring and positioning device positioned on the crossbeam, also includes several dry edging grinding heads, several finishing grinding heads, several chamfering grinding heads and several automatic feeding compensation device which are positioned on machine frame and an electric control cabinet.

Owner:广东科信达科技有限公司

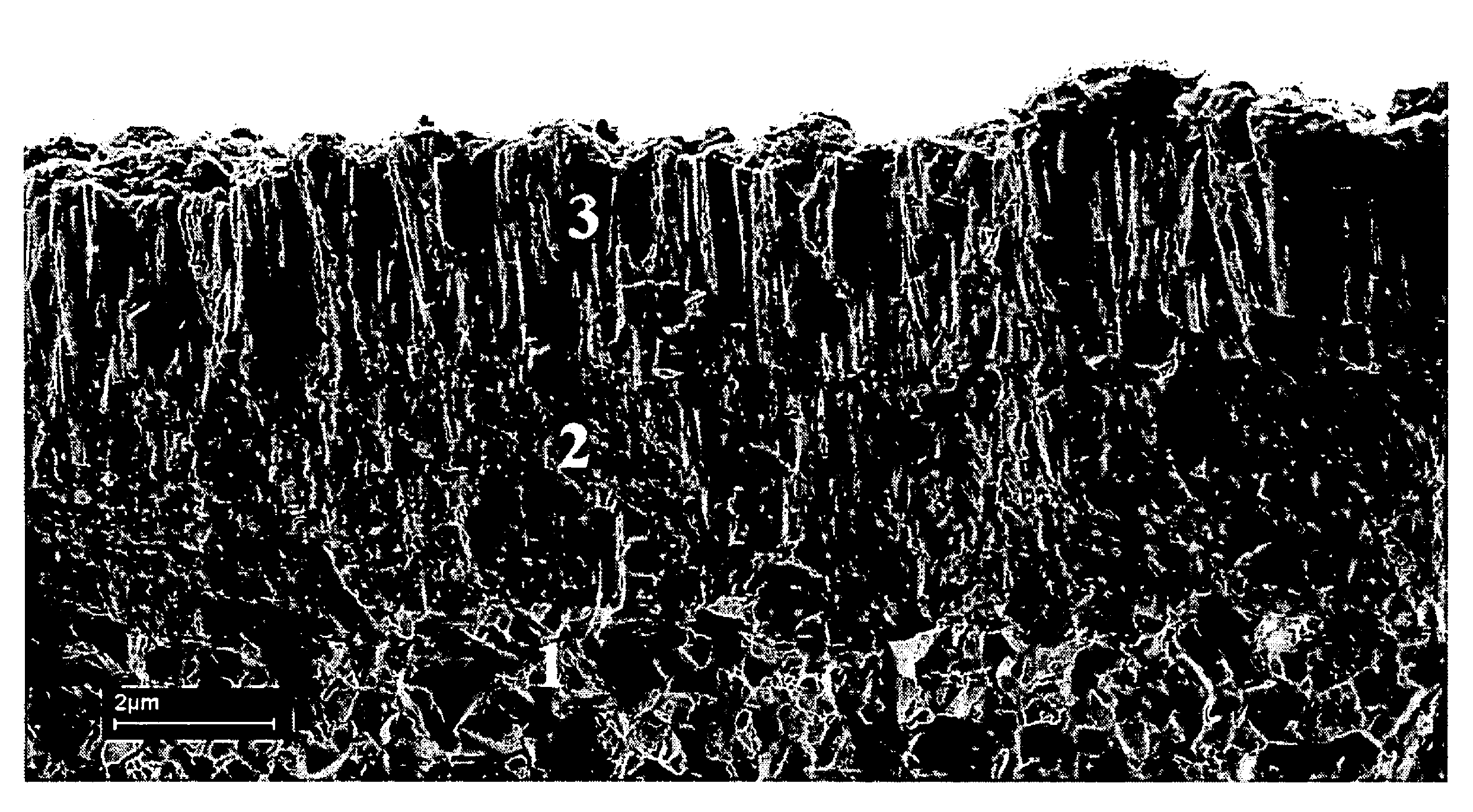

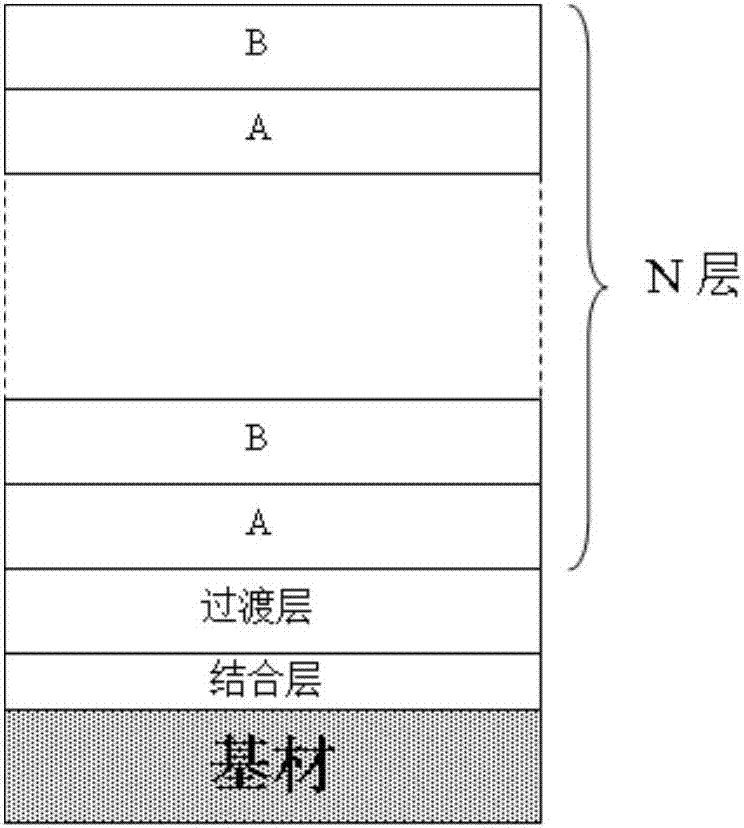

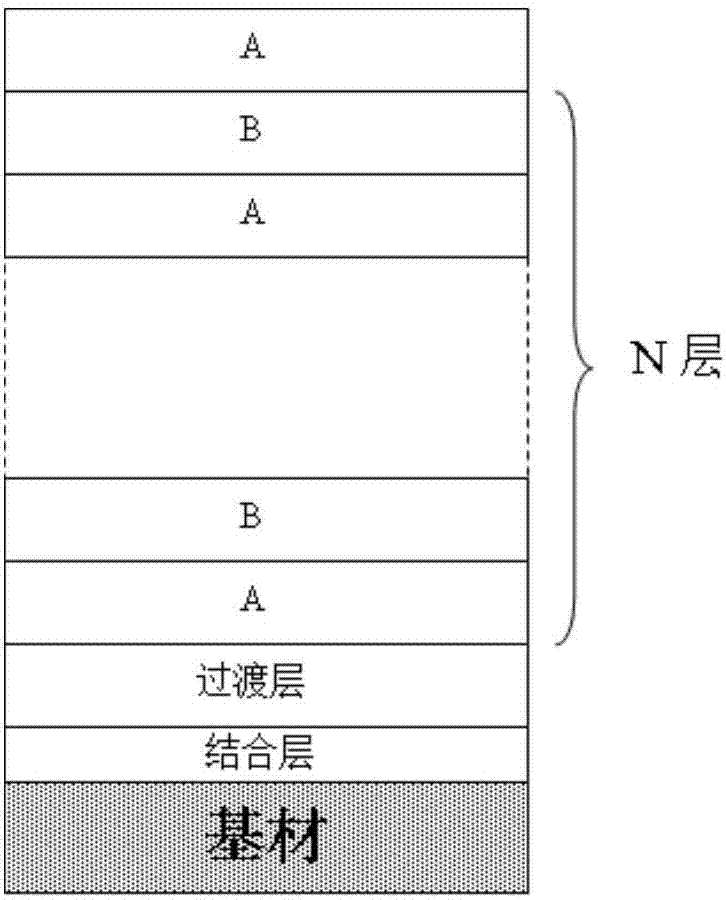

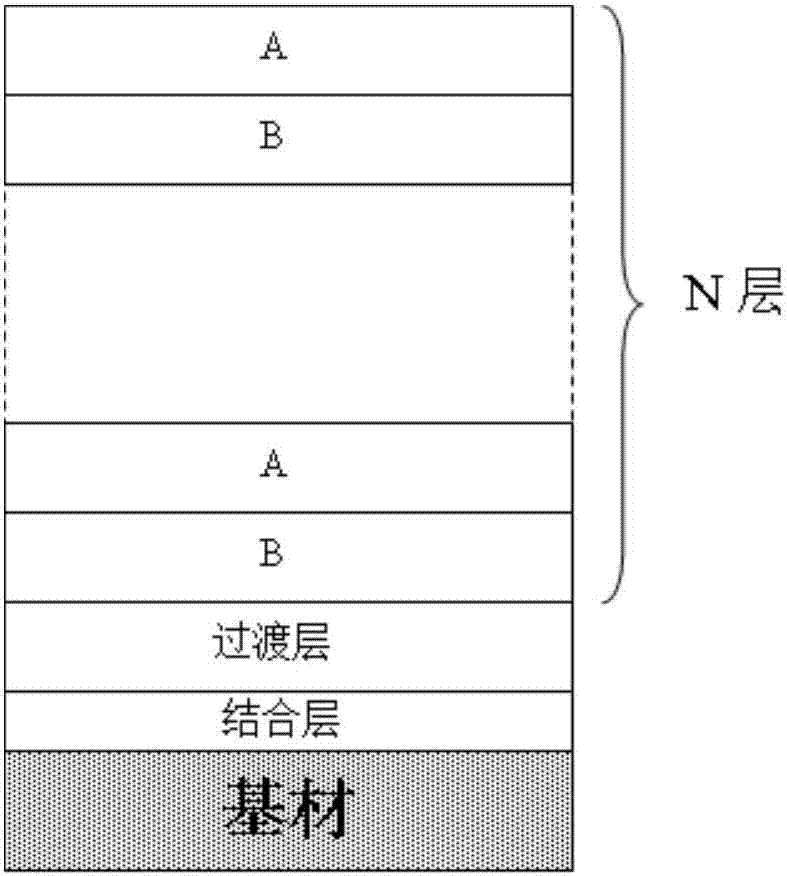

Amorphous cutting tool coating used for dry machining of aluminum alloy and preparation method of the coating

ActiveCN107099778AGood high temperature wear resistanceImprove stabilityVacuum evaporation coatingSputtering coatingChemical reactionComposite structure

The invention provides an amorphous cutting tool coating used for dry machining of aluminum alloy. The amorphous cutting tool coating includes a binding layer which is laminated to the surface of a cutting tool, a transition layer which is laminated to the surface of the binding layer, and a functional film layer which is laminated to the surface of the transition layer and is composed of a layer A and a layer B that are alternately overlapped on each other. Number of the layer A is not less than 1 and number of the layer B is not less than 1. The layer A has an amorphous chromium carbide-amorphous carbon composite structure, wherein the amorphous chromium carbide is dispersed and distributed in the amorphous carbon as a substrate. The layer B is a diamond-like layer. The application also provides a preparation method of the amorphous cutting tool coating used for dry machining of aluminum alloy and provides a coated cutting tool. The amorphous cutting tool coating has high-temperature wear resistance, in particular, high hardness, low friction coefficient and good thermostability, and also is non-stick to aluminum. After machining with the cutting tool, aluminum alloy has smooth surface and stable chemical performance. The cutting tool is not chemically reacted with an aluminum work piece.

Owner:CHONGQING UNIV

Grinding machine and process for preparing concrete additive

ActiveCN113559990AReduce procurement costsReduce maintenance costsSievingScreeningSlagMagnetic separator

The invention relates to the field of concrete ingredient preparation, in particular to a grinding machine and process for preparing concrete additive. The grinding machine comprises a base, a right-angle-C-shaped frame, a material receiving mechanism, a screening mechanism, a magnetic separation mechanism and a ball milling mechanism, wherein the right-angle-C-shaped frame is installed on the upper end face of the base, the material receiving mechanism is arranged on the portion, located on the inner side of the right-angle-C-shaped frame, of the upper end face of the base, the screening mechanism and the magnetic separation mechanism are sequentially arranged in the right-angle-C-shaped frame from bottom to top, the screening mechanism is located at the upper end of the material receiving mechanism, and the ball milling mechanism is arranged in the middle of the top end of the right-angle-C-shaped frame. The grinding machine and process for preparing the concrete additive can solve the following problems existing in the process of grinding the steel slag by adopting a dry machining mode in the prior art that the purchase cost and the maintenance cost of machining equipment required when a steel slag machining enterprise makes the steel slag into micro-powder are higher, the occupied field area of the equipment required by steel slag machining is large, the distance between the machines is long, and the machining efficiency of the steel slag is affected by the steel slag conveying process.

Owner:江苏金雷建材有限公司

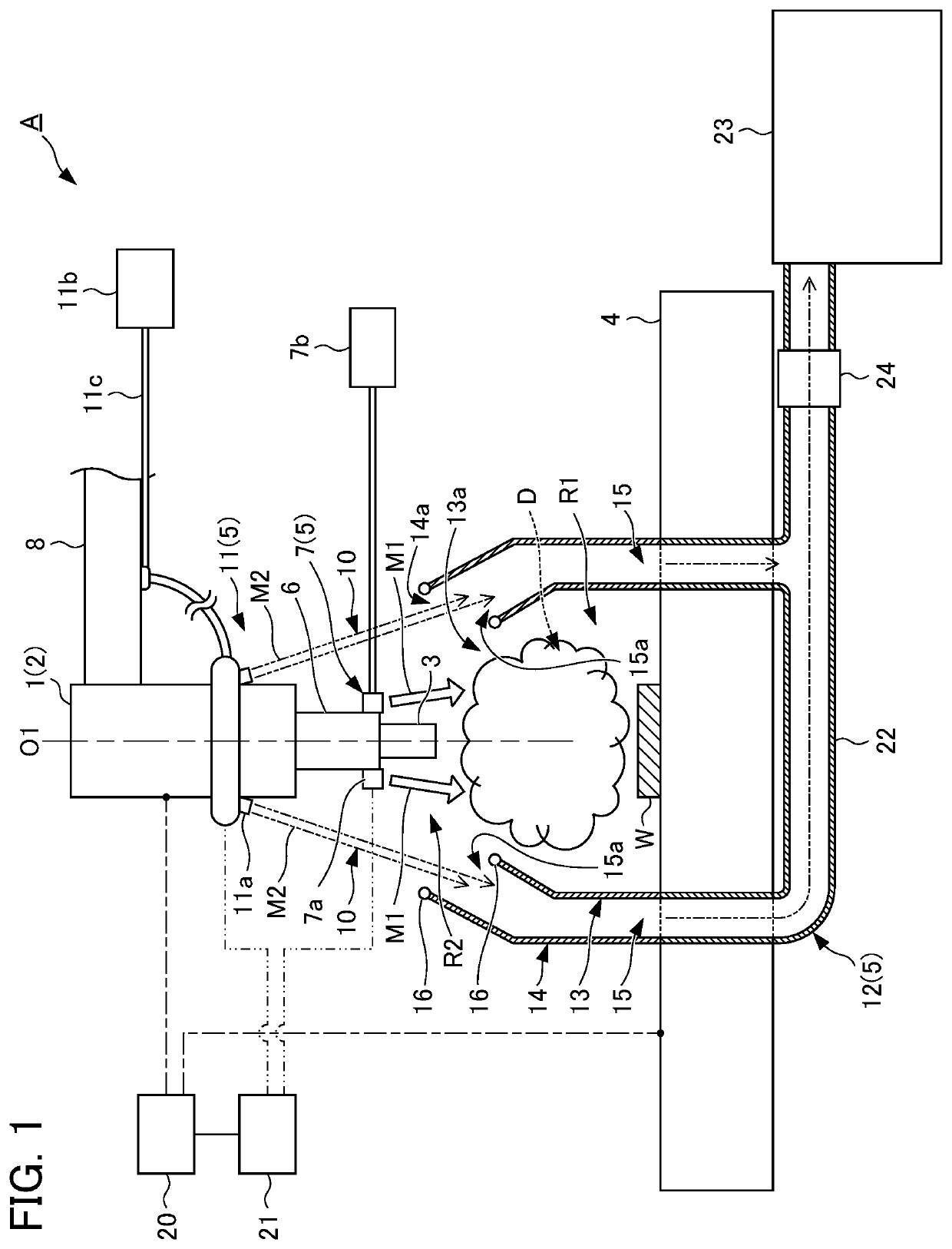

Machine tool

ActiveUS20200078893A1Suppress scatterDischarging chipOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringDry machining

A chip antiscatter mechanism is included and configured to suppress scattering of chips generated during machining of a machining object. The chip antiscatter mechanism includes chip stirring means configured to stir the chips, by jetting a gas into a dry machining region above a table including the machining object, fluid curtain forming means configured to form a fluid curtain by jetting a fluid such as liquid or gas membranously from above to an outside of the dry machining region so as to surround the dry machining region, and to form a closed region including the dry machining region by the membranous fluid curtain, and discharging means configured to receive and discharge the fluid jetted membranously by the fluid curtain forming means.

Owner:FANUC LTD

Method for fine-machining crankshafts and machining center therefor

ActiveUS8419323B2Improve accuracyQuality improvementLarge fixed membersMilling equipment detailsDry machiningInternal combustion engine

A method and machine for machining shafts, such as crankshafts of an internal combustion engine wherein the shaft supported on a workpiece carrier rotatably about its axis and the carrier is movable relative to a milling tool adjustably supported on the machine, the bearing surfaces of the shaft are fine-machined by a milling tool taking into consideration the resiliency and the bending of the shaft by the engagement force of the milling tool during fine cutting of the bearing surfaces in the various angular rations of the shaft and the axial bearing location between the shaft ends so as to provide for a perfect final round cutting of the bearings without the need for wet grinding. The fine machining is preferably achieved by dry machining and orthogonal rotational milling, all main bearings and lifting bearings being machined in a single clamping from the rough machining dimensions to the final dimension. For a second machining sequence, some of the main bearings and lifting bearings are used as clamping surfaces.

Owner:GEBR HELLER MASCHFAB GMBH

Ce-Y-containing A1-Ti-N multicomponent composite coating and preparation thereof

InactiveCN101353776AReduce oxidation rateReduce in quantityVacuum evaporation coatingSputtering coatingSuperhard materialOxidation resistant

The invention pertains to the technical field of ultrahard materials and provides a Al-Ti-N multielement compound coating layers containing Ce-Y and a preparation method thereof, aiming at lowering the number and size of 'bulky grain' in a coating layer, promoting the anti-strip performance and anti-oxidation temperature of the coating layer and increasing film forming speed simultaneously. The compound coating of the invention adopts that the Ce-Y is deposited at least one of coating layers of Ti-N and Al-Ti-N. Simultaneously, the preparation method of the invention adopts the technical proposal that Ti target containing 0.5 percent to 3 percent of the Ce-Y by weight percentage and Ti-Al target with atomic ratio of 1: 2 or 1: 3 are vaporized and ionized, and gas of N2 is conveyed to a vacuum chamber for carrying out sedimentation of the TiN coating layers and the Al-Ti-N coating layers both containing Ce-Y. The method of the invention greatly enhances the stiffness, the abrasive resistance and the high-temperature oxidation resistance of workpieces and obviously prolongs the service life and leads the Al-Ti-N multielement compound coating layers to be applicable to the processing fields, such as cutting, dry machining and the like, with high accuracy and high speed.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

Segmented superabrasive grinding device

InactiveUS7131903B2Improve cooling effectRevolution surface grinding machinesOther chemical processesHexagonal boron nitrideBoron nitride

The present invention is for a grinding device, such as a surface grinding disc or an annular grinding wheel, constructed from a plurality of abrasive segments arranged in an array thereon, wherein the plurality of abrasive segments are embedded in a matrix composition, and wherein the device is abapted to perform a “dry machining” operation. The abrasive segments may be resin bonded or vitrified and may include diamond or other superhard or superabrasive particles, such as, for example, cubic boron nitride (“cBN”), dispersed therein. Both the abrasive segments and the matrix composition include a dry lubricant, such as hexagonal boron nitride, molybdenum disulfide or graphite, dispersed therein. The abrasive segments further include a melt phase metal composition, such as bronze or other copper alloys, to aid in heat dissipation.

Owner:FIVES LANDIS

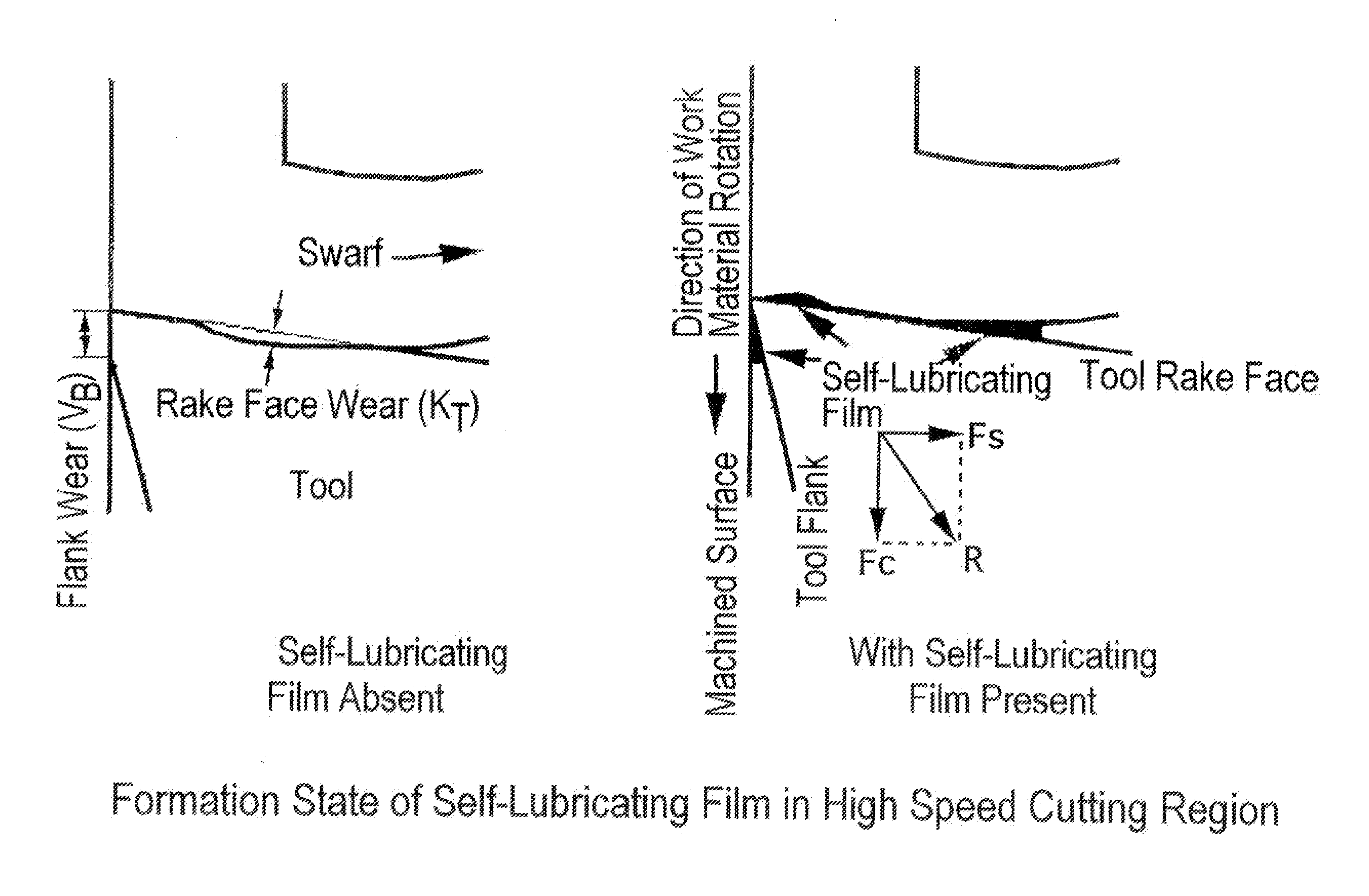

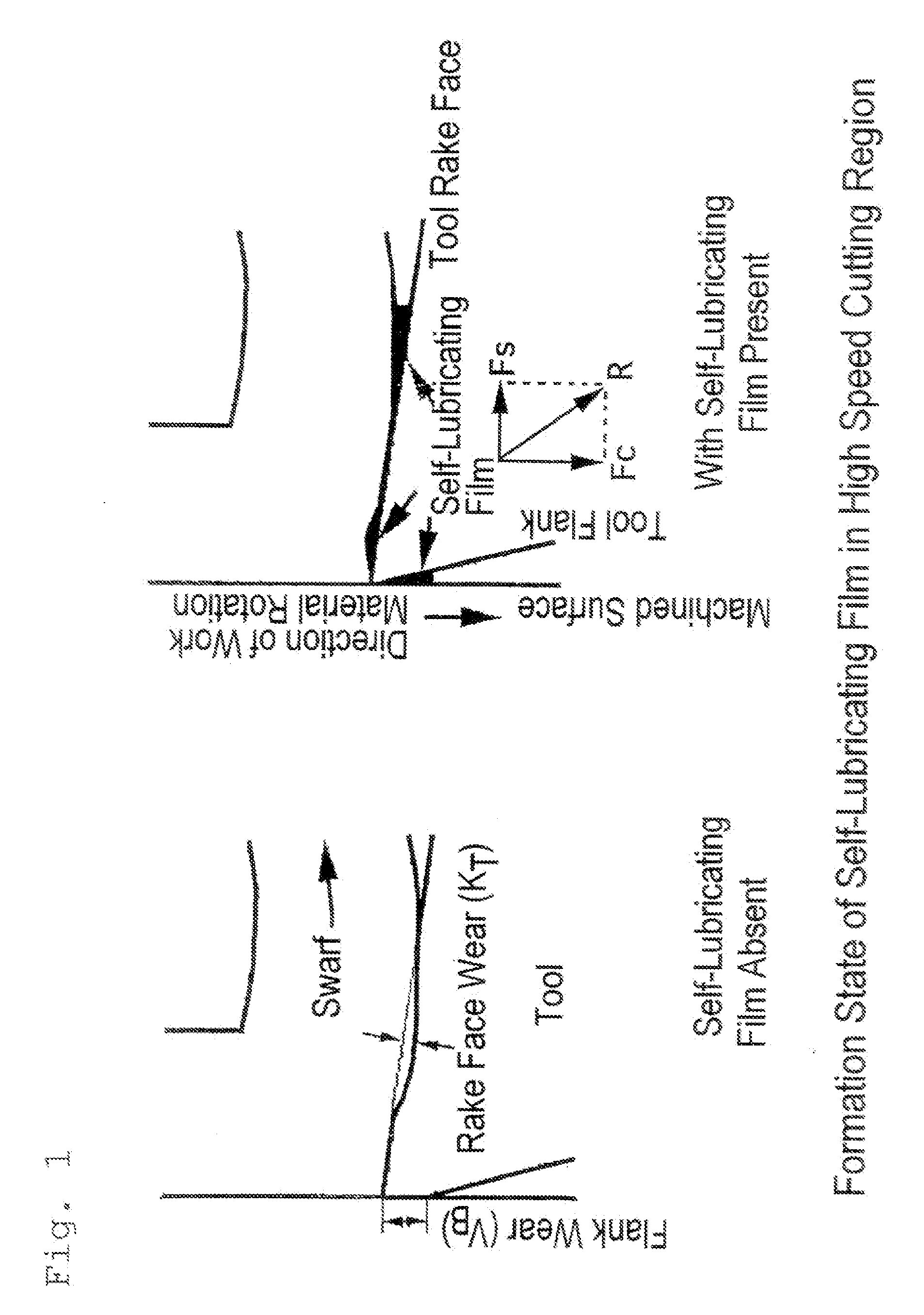

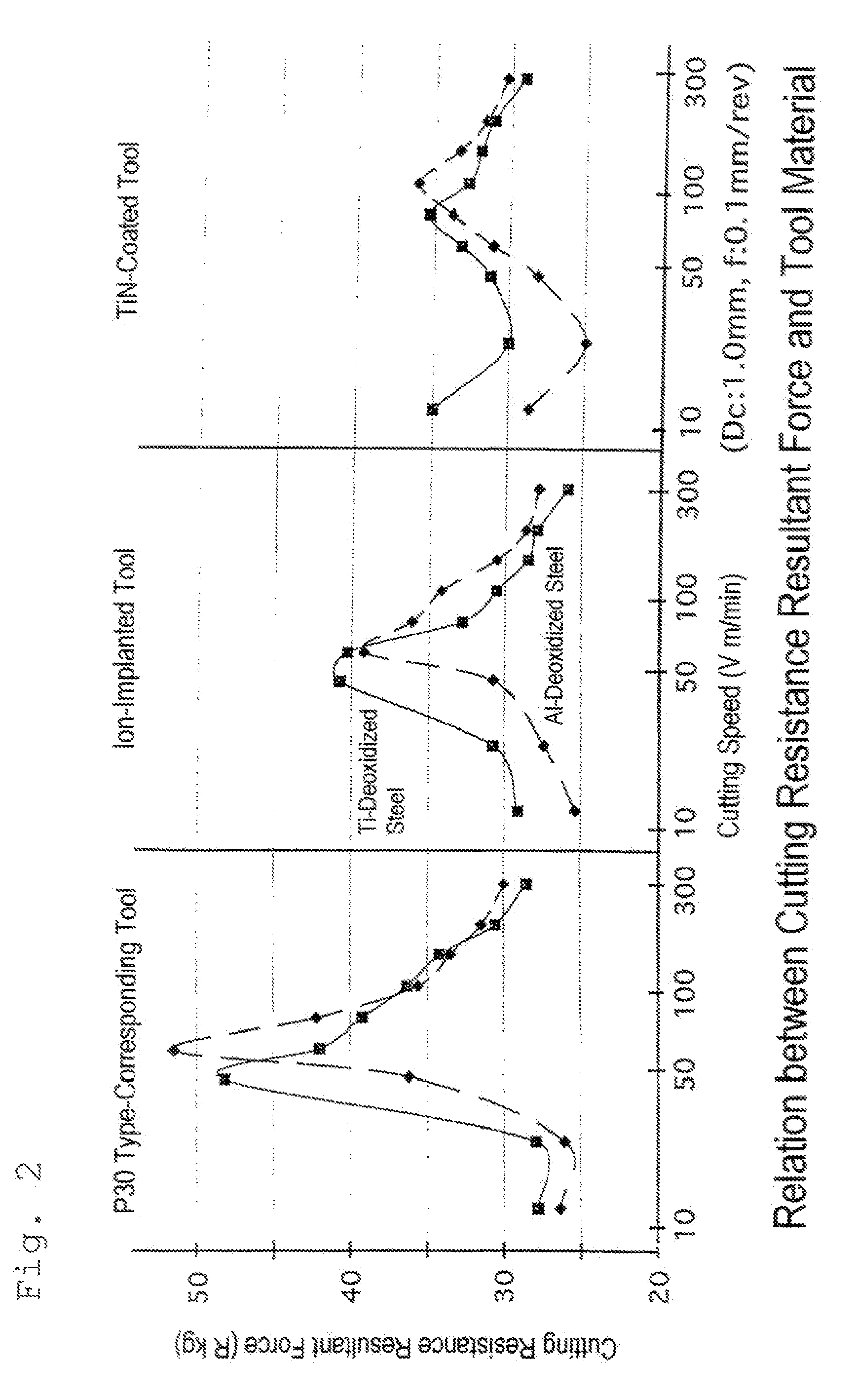

High-speed machining tool

InactiveUS20070054146A1Increase speedHigh regionPig casting plantsVacuum evaporation coatingHalogenEngineering

Object: A high speed machining component, which has been improved in wear resistance and lubricating properties, and a high speed dry machining method using the component are provided. Particularly, a high speed cutting tool and a high speed cutting method are provided. Means for solution: A halogen element is ion-implanted into a machining component having a cemented carbide as a base material, and the machining component is contacted with a workpiece at a speed of 150 m / min or higher, whereby the wear resistance and lubricating properties of the component can be improved. If the machining component has a Ti-containing coating layer, its wear resistance and lubricating properties can be improved similarly. The use of a cutting tool including such a component enables high speed dry cutting without a cutting oil. By bringing the machining component of the present invention into contact with the workpiece at a high speed, a self-lubricating film can be formed on a surface of contact of the component with the work material.

Owner:AIZAWA TATSUHIKO

Regeneration charcoal manufactured from durian shells

InactiveCN108264912AReduce generationExtended burn timeBiofuelsSpecial form destructive distillationROSIN POWDERPollen

The invention discloses regeneration charcoal manufactured from durian shells. The regeneration charcoal is manufactured from, by weight, 50-80 parts of durian shell powder, 10-15 parts of Arabian jasmine flower powder, 60-80 parts of sawdust, 5-8 parts of rosin powder and 5-8 parts of kieselguhr. The particle diameters of the durian shell powder, the Arabian jasmine flower powder, the sawdust andthe rosin powder range from 2 mm to 4 mm. The manufacturing method of the regeneration charcoal comprises the following steps of 1, preparing materials, wherein the raw materials are dried until thewater content is 15-20%; 2, manufacturing rods, wherein the dried machining powder and kieselguhr are mixed to be uniform, hollow cylinder firewood rods are manufactured, and the cylinder firewood rods are provided with a plurality of small holes running through the inner and outer walls of the cylinder firewood rods; 3, charring, wherein the firewood rods are placed into a container, under the anaerobic condition, under the temperature of 200-300 DEG C, the firewood rods are burnt and charred for 80-90 h, natural cooling is performed, and the regeneration charcoal is obtained. The charcoal has the durian flavor, and the durian shells are recycled.

Owner:黎娟

Novel fiberboard manufacturing process

The invention discloses a novel fiberboard manufacturing process. The novel fiberboard manufacturing process is characterized in that a fiberboard comprises a middle layer, and the middle layer is externally provided with a surface chemical fiber layer and is a composite layer made of coconut fiber and chemical fiber; the fiberboard manufacturing process comprises the following steps of S1, raw material preparation, S2, raw material storage, S3, primary middle layer raw material mixing, S4, primary middle layer raw material carding, S5, secondary middle layer raw material mixing, S6, secondary middle layer raw material carding, S7, surface-layer chemical fiber raw material preparation, S8, surface-layer chemical fiber net paving, S9, surface-layer chemical fiber needling, S10, semi-finished product synthesis, S11, drying machining, S12, cooling shaping, and S13, finished product completion. According to the novel fiberboard manufacturing process, the natural coconut fiber and the chemical fiber are composited, the produced fiberboard is of a three-layer structure, and the coconut fiber is covered with the chemical fiber, so that the fiberboard is more beautiful, and the toughness of the fiberboard is improved; and fiber on the surface layer is subjected to needling treatment, the strength of the fiberboard is improved, and thus, the fiberboard is not prone to being abraded.

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Improved environment-friendly manufacturing device

InactiveCN108500718AAvoid scratchesPrevent frostbiteFeeding apparatusPositioning apparatusMilling cutterEngineering

The invention discloses an improved environment-friendly manufacturing device which comprises a fixing base. A machine enclosure is fixedly connected to the upper end face of the fixing base. A machining space is arranged inside the machine enclosure. A mobile clamping device is arranged on the front side of the lower end face of the machining space. A middle rod body of a tool loading rod is sleeved with a gear milling cutter. A liquid nitrogen cylinder is arranged at the upper end of a storage plate. An air pump is arranged on the rear end face of a mixing tank. An inward-extending cooling pipe is arranged at the upper end of the rear end wall of the machining space. The front end of the cooling pipe extends downwards and is fixedly connected with a supercharging sprayer. In the operating process, high-pressure liquid nitrogen plays roles in cooling the machined portion and blowing away scrap iron, and pollution to the environment is reduced while the dry machining quality is ensured; and the air pump can pump air into the mixing tank, gas temperature after liquid nitrogen is vaporized rises to a certain height, and frost damage to machines and workpieces caused by excessively-low temperature is prevented.

Owner:嵊州市诺米克进出口有限公司

Method for manufacturing FRP member with insert and FRP member with insert

ActiveUS20110158764A1Reduce processing timeImprove productivityLiquid surface applicatorsMetal rolling stand detailsProduction rateDry machining

Provided is a method for manufacturing an FRP member with insert which enables to reduce a machining time to improve productivity. First, a threaded hole 11 is formed in an insert 3. An FRP member 2 where at least the threaded hole 11 of the insert 3 is covered with a coating 4 made of FRP is molded. A counter-bored hole 31 that penetrates the coating 4 of the FRP member 2 to communicate with the threaded hole 11 of the insert 3 is formed, to thereby obtain an FRP component 1 with insert. Accordingly, a machining step after molding the FRP member 2 in which dry machining is required includes only the boring step of forming the counter-bored hole 31 in the FRP member 2. Thus, the machining time can be reduced, and the productivity can be improved.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com