Automatic plate trimming machine

A trimming machine and plate technology, applied in the field of plate processing, can solve the problems of insufficient scraping and excessive scraping, and achieve the effects of avoiding waste, increasing utilization rate, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

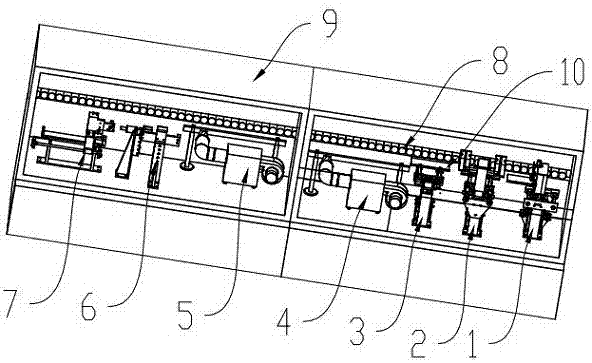

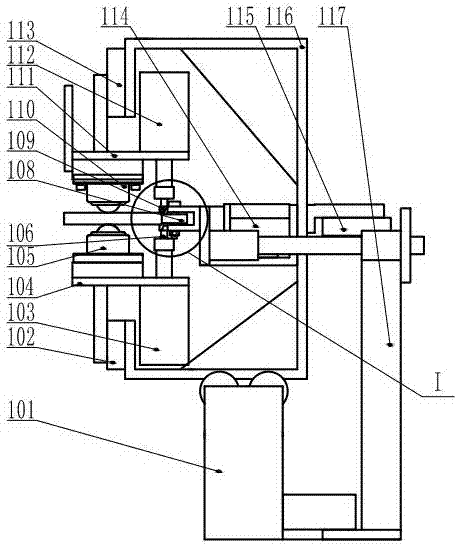

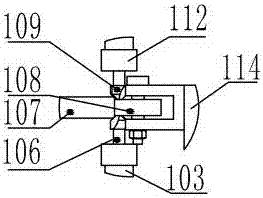

[0040] According to attached figure 1 It can be seen that the present invention is specifically an automatic trimming machine for plates, which specifically includes a frame 9, on which is provided a pressure roller set 8 that provides feeding power for the plate 10, and the pressure roller set 8 clamps the plate 10, along the According to the feeding direction of the board, the upper and lower edge chamfering modules 1, the upper corner painting module 2, the lower corner painting module 3, the upper drying module 4, the lower drying module Corner module 6 and back vertical edge chamfering module 7, above-mentioned each module is fixed on the steel plate of frame 9 by screw.

[0041] The whole equipment is controlled by PLC, and the conveying motion is driven by the motor driven by the conveyor belt, so as to drive the plate 10 forward; in order to ensure that the plate 10 does not deviate during the movement, a whole row of pressure rollers 8 are installed on the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com