Patents

Literature

192results about How to "Improve trimming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

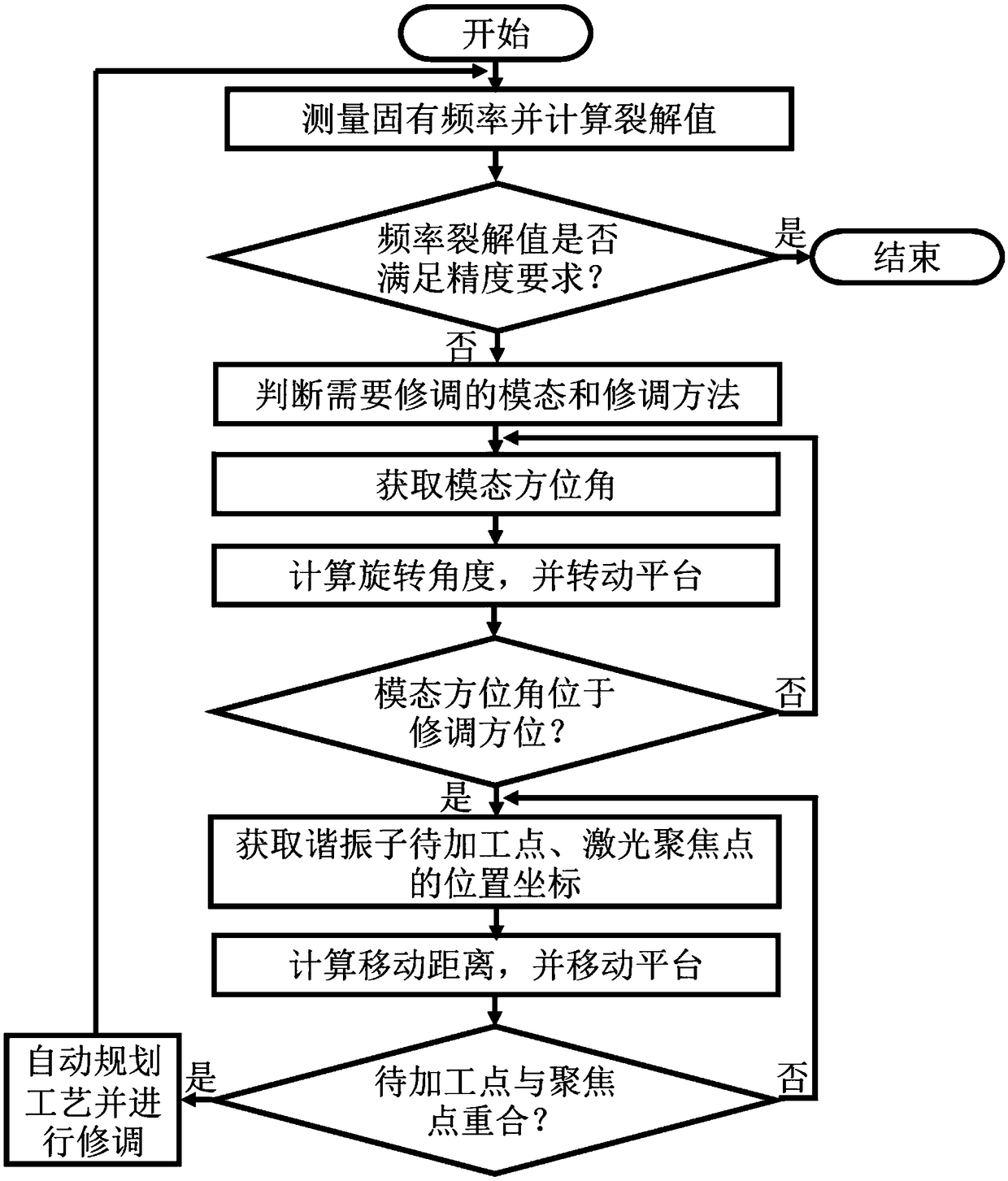

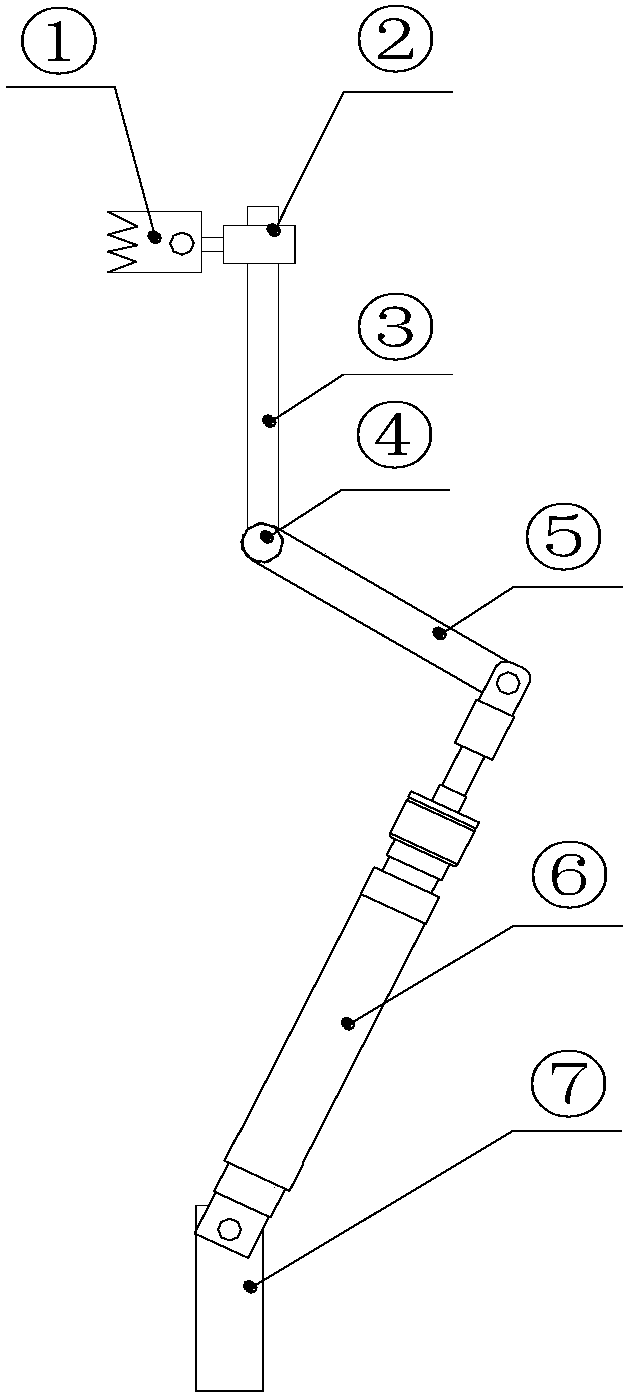

Automatic vibrating gyroscope trimming method

The invention belongs to the field of sensors, and discloses an automatic vibrating gyroscope trimming method. The automatic vibrating gyroscope trimming method comprises the following steps: (1), automatically measuring the intrinsic frequencies of a harmonic vibrator of a vibrating gyroscope in two working modes, and calculating ta frequency cracking value according to the intrinsic frequencies;(2), if the frequency cracking value does not meet an accuracy requirement, comparing the two intrinsic frequencies to automatically determine a trimming mode and a corresponding trimming method; (3), controlling the gyroscope to move to an expected machining position by automatically positioning the relevant physical position of the gyroscope and the physical position of a trimming mechanism ofmachining equipment; (4), automatically planning a machining technology according to a relationship between the required removed mass and machining technological parameters, automatically trimming thegyroscope according to the planned machining technology, and returning to the step (1) after completion of trimming. By the method, the degree of automation is high and the trimming accuracy and thetrimming efficiency are improved.

Owner:CENT SOUTH UNIV

Flat edge-trimming machine

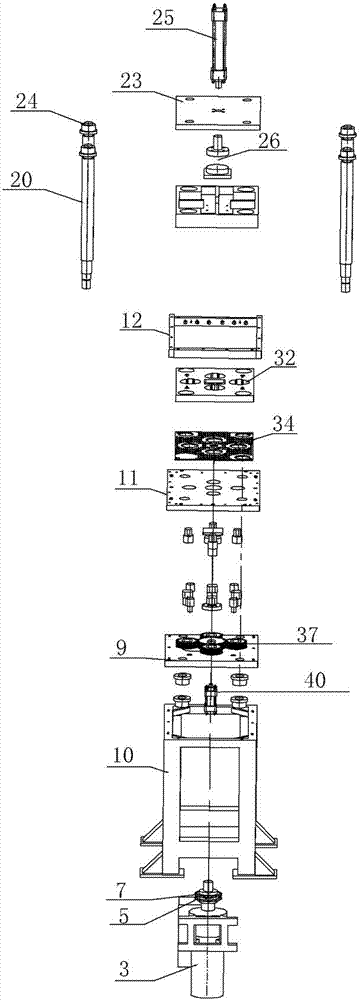

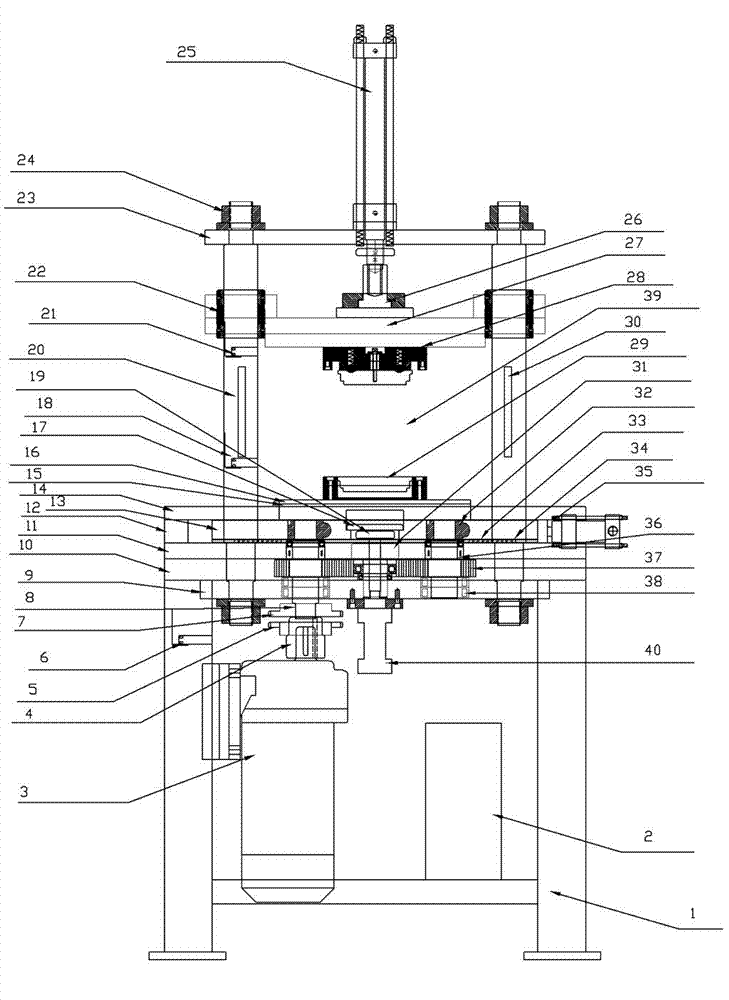

The invention relates to equipment for machining metallic sheet metal pieces, in particular to a flat edge-trimming machine. The flat edge-trimming machine mainly comprises a frame (1), an electrical appliance control box (2) and a braking motor (3) which are arranged in the frame (1), an oil cylinder or cylinder device which is arranged on the upper part of the frame (1), a die assembly (39) which is divided into upper and lower parts, a transmission component which transmits the power of the braking motor (3) to the lower part of the die assembly (39), and a guide oil cylinder or cylinder (35) which ensures that the lower part of the die assembly resets, wherein the transmission component comprises a spindle (8); and the spindle (8) in the transmission component is directly connected with a braking motor shaft (4) on the braking motor (3) through a chain wheel, and the power of the braking motor (3) is transmitted to the spindle (8) after a braking motor shaft single-row chain wheel (5) on the braking motor shaft (4) is engaged with a spindle single-row chain wheel (7) on the spindle (8). The invention is characterized in that the flat edge-trimming machine can trim regularly, is low in cost, and is safe and reliable; and the flat edge-trimming machine can easily remove excess materials on the edges of drawn pieces, so that the processes are simplified, the labor intensity of workers and the machining time are reduced, the production efficiency is improved, and accident work injuries can be avoided.

Owner:黄开强 +1

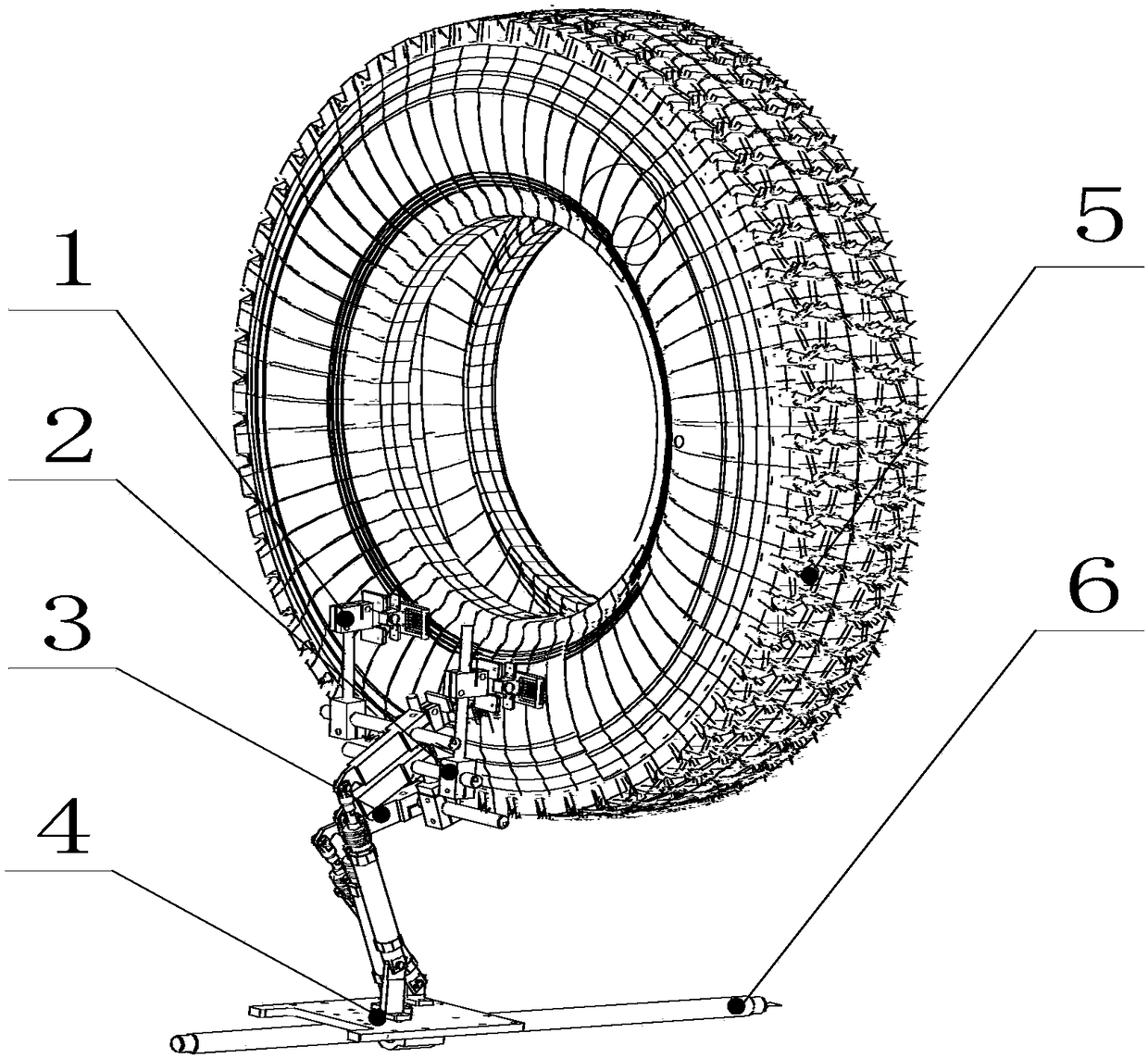

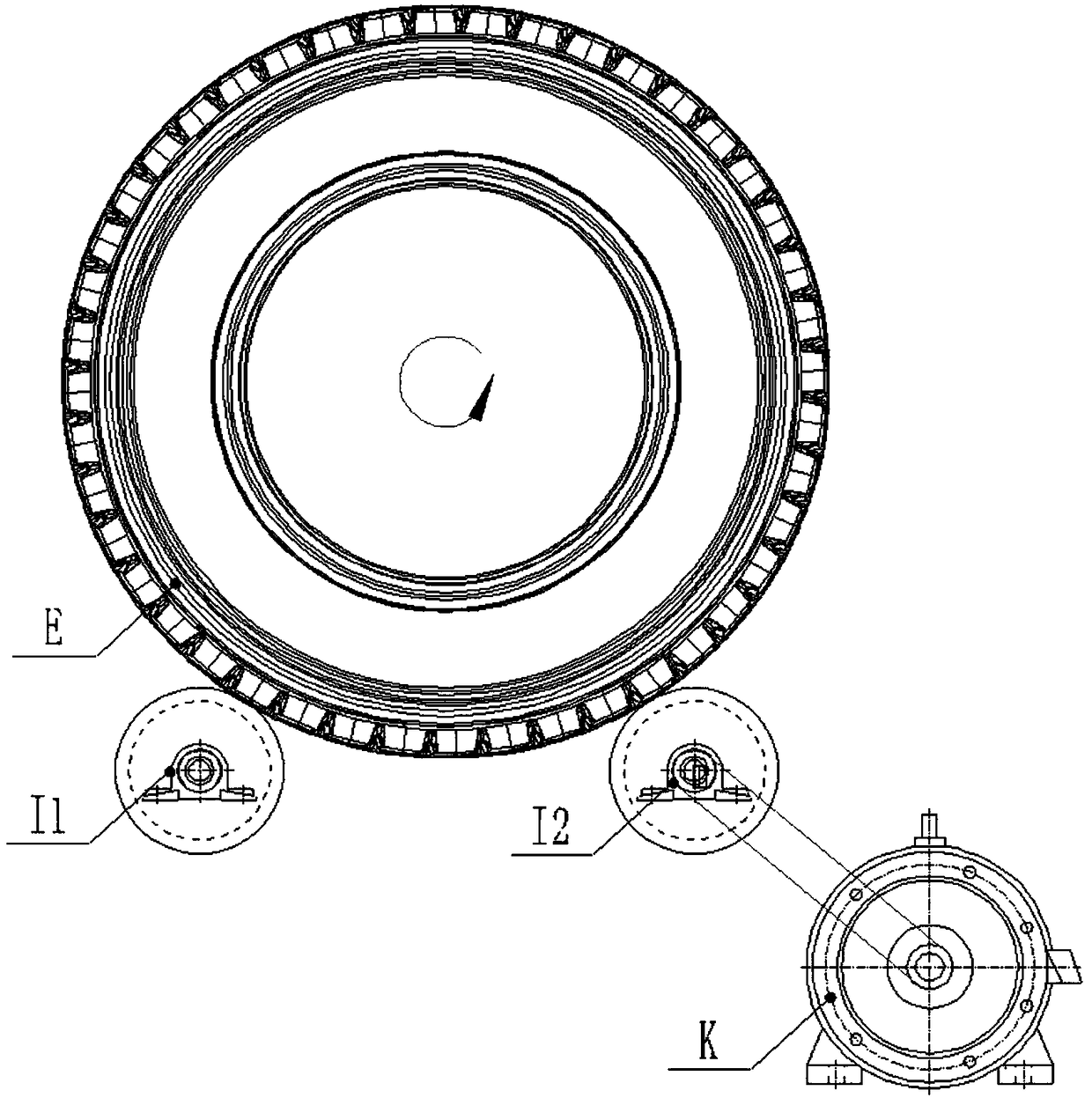

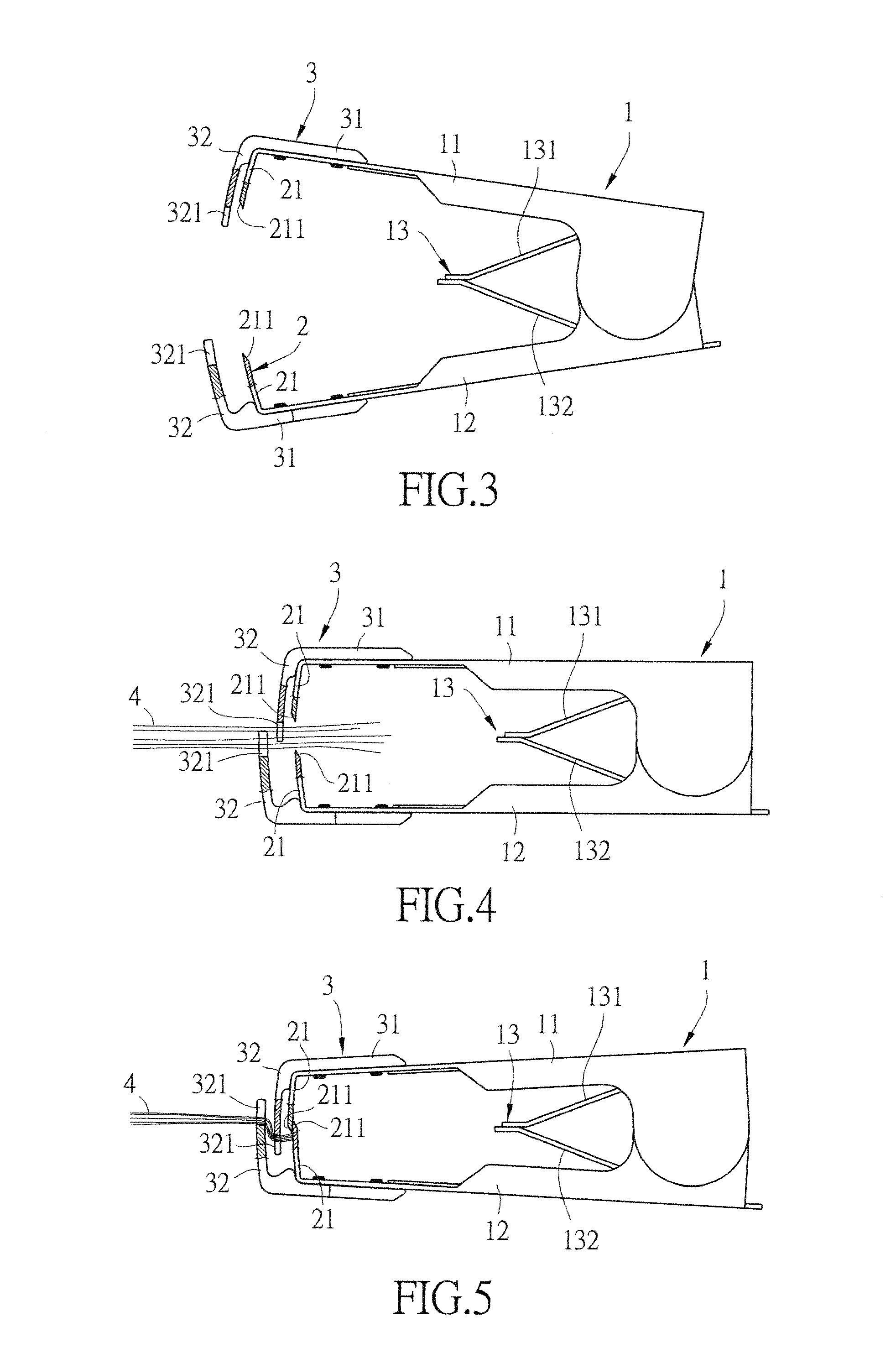

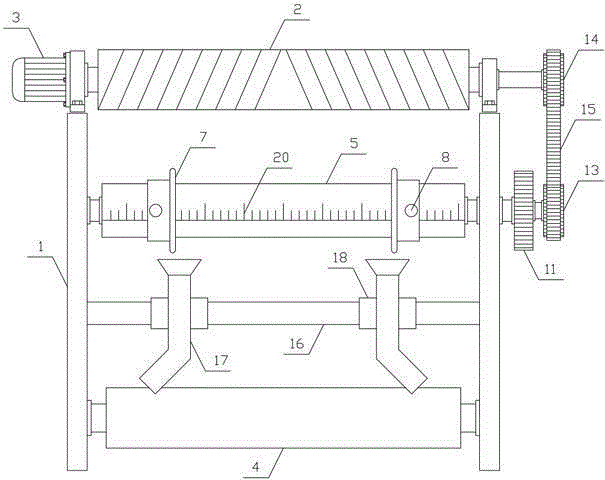

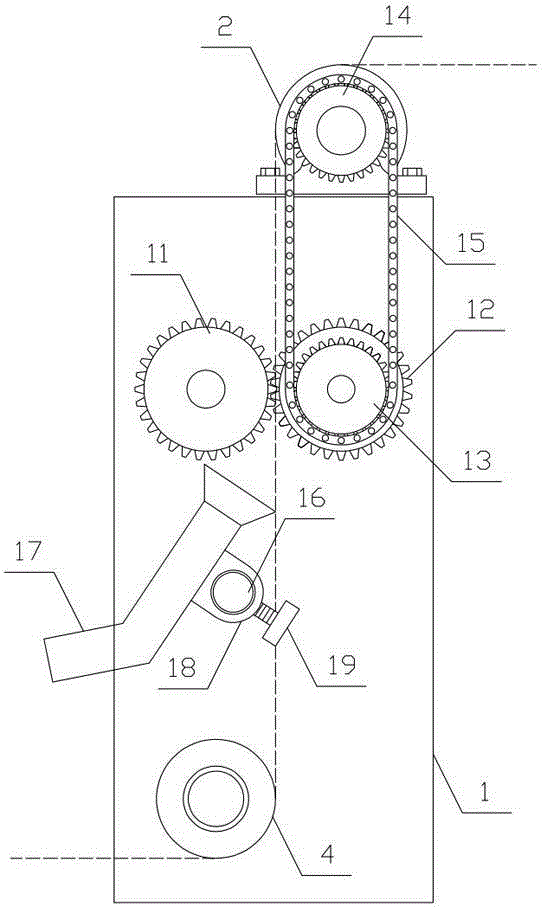

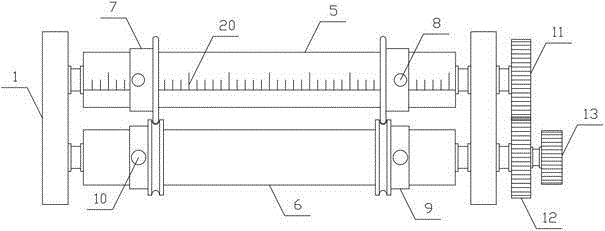

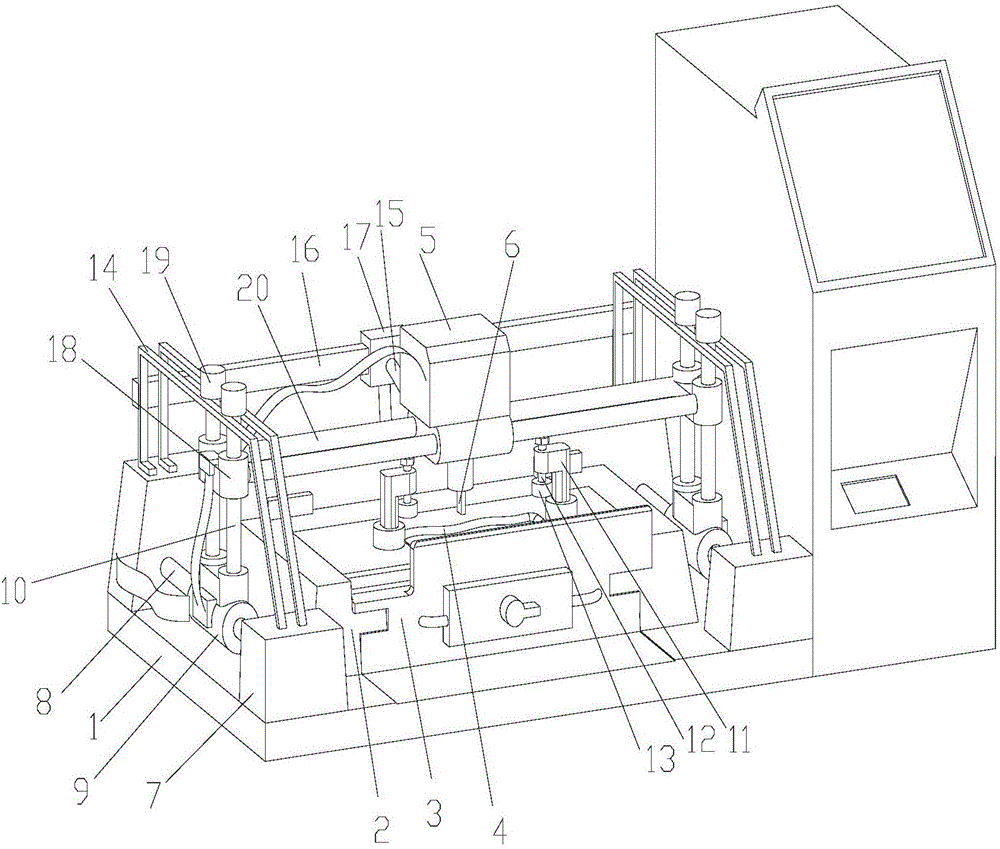

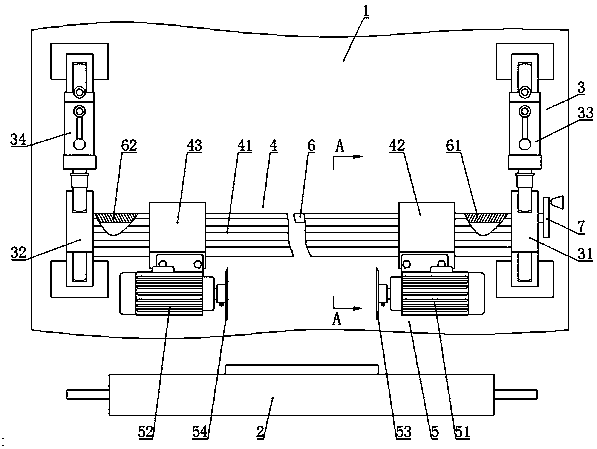

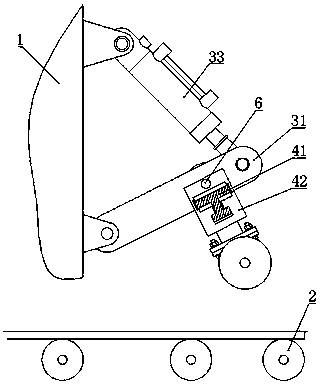

Deburring device for TB tyre side surface

The invention relates to the field of tyre manufacture and particularly relates to a deburring device for a TB tyre side surface. The device includes two sets of cutting tool assemblies that are symmetrical left and right, a rack translation assembly, a tyre and a ball screw. The two sets of cutting tool assemblies are installed on the rack translation assembly and are disposed at both sides of the tyre; opening and closing motion driven by the ball screw is performed on the rack translation assembly to control the distance from the tyre side surface; the tyre is driven by a clamping rotationdevice to perform uniform speed rotary motion, and when the motion is smooth, the cutting tool assemblies are driven by the ball screw to move the tire at a uniform speed on the rack translation assembly, and stop when the cutting tool assemblies move to a suitable distance; at this time, cylinders of cutting tool mechanisms in the cutting tool assemblies perform air inlet work, and cutting toolsare pushed out on a to-be-trimmed tire, and then the cutting assemblies move downward as a whole, and when cutting blades complete trimming deflashing on a tyre surface, the cylinders work at this time, and the cutting tools are recovered; and the cutting tool assemblies are driven by the ball screw to move away from the tyre at the uniform speed until an entire trimming deflashing process is completed.

Owner:JIANGSU UNIV

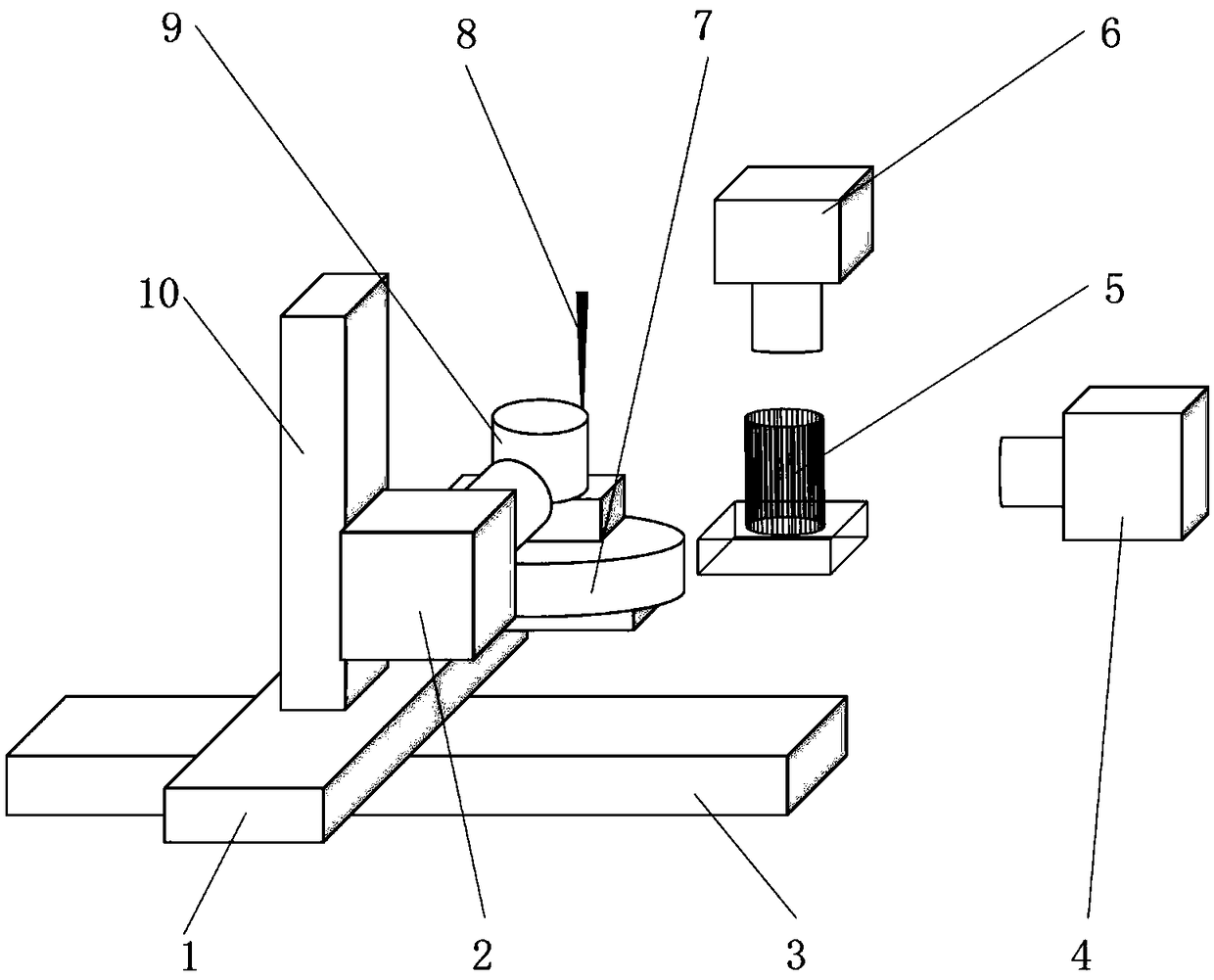

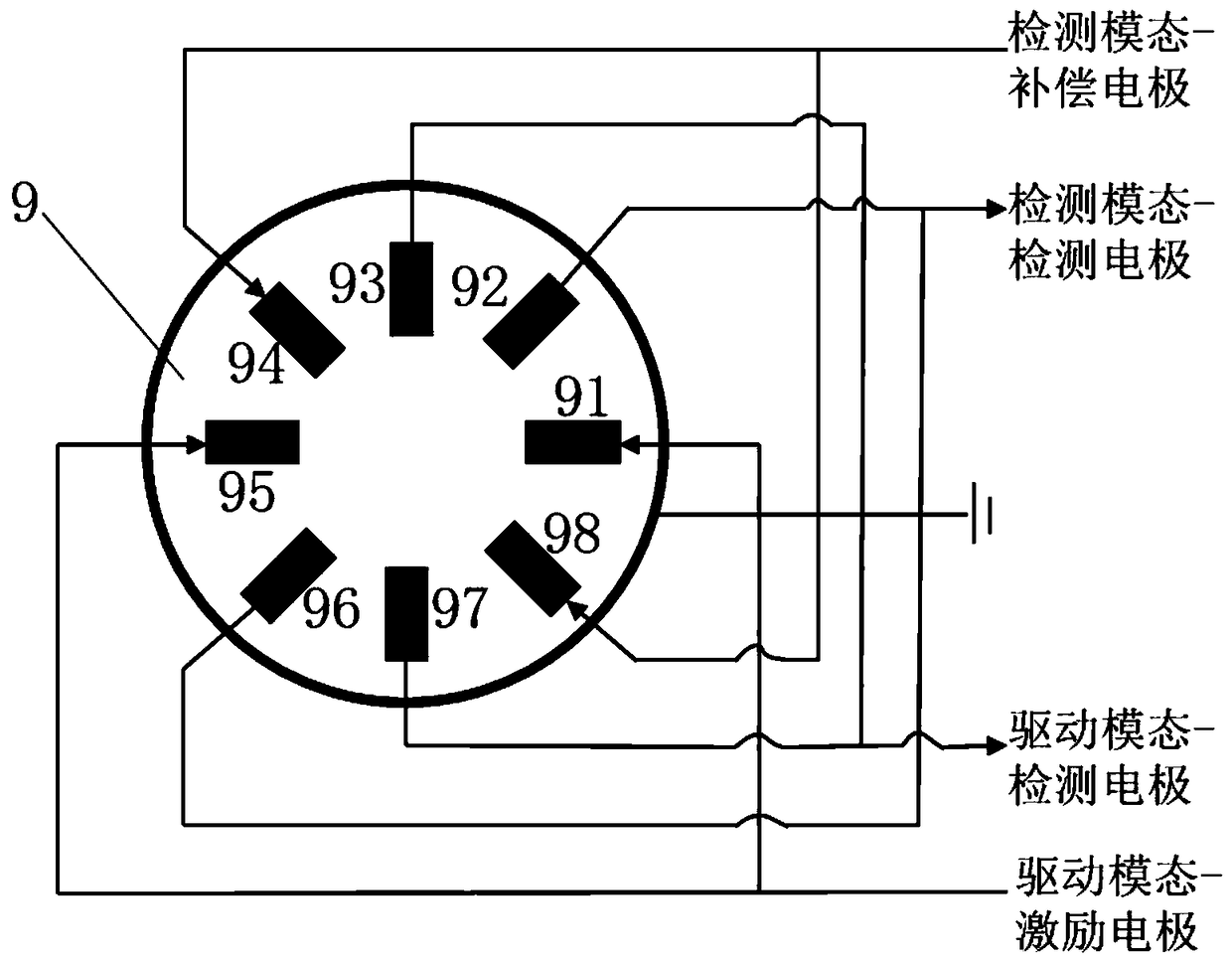

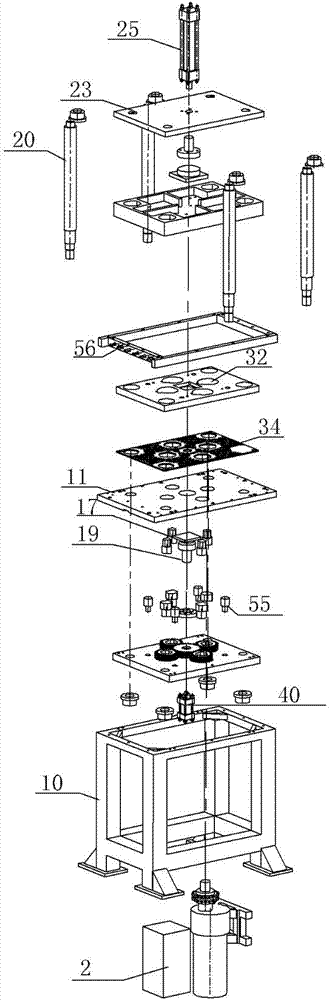

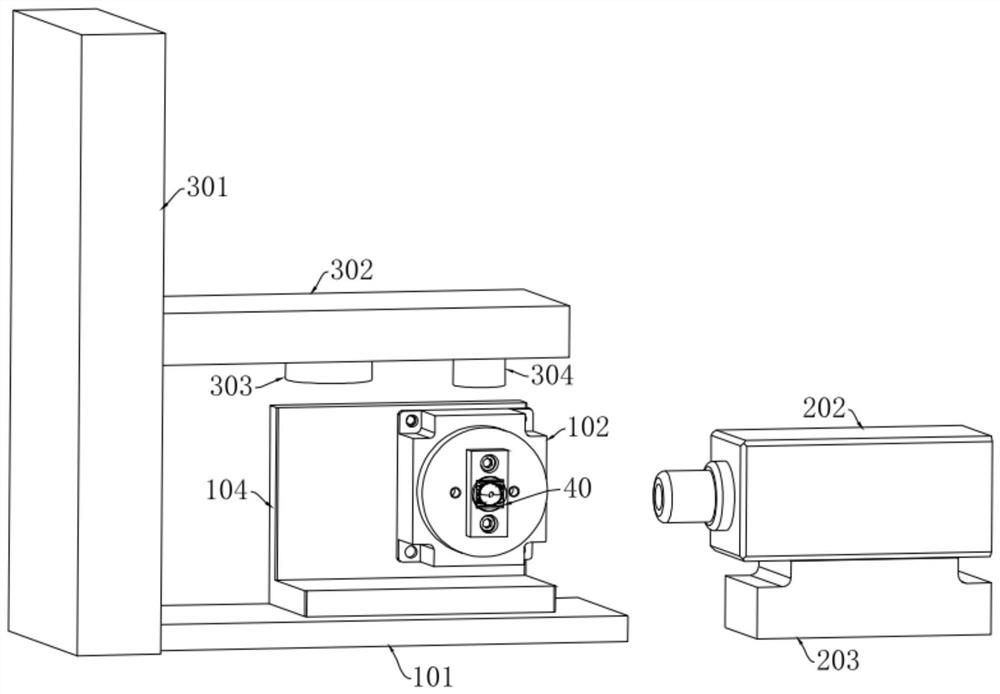

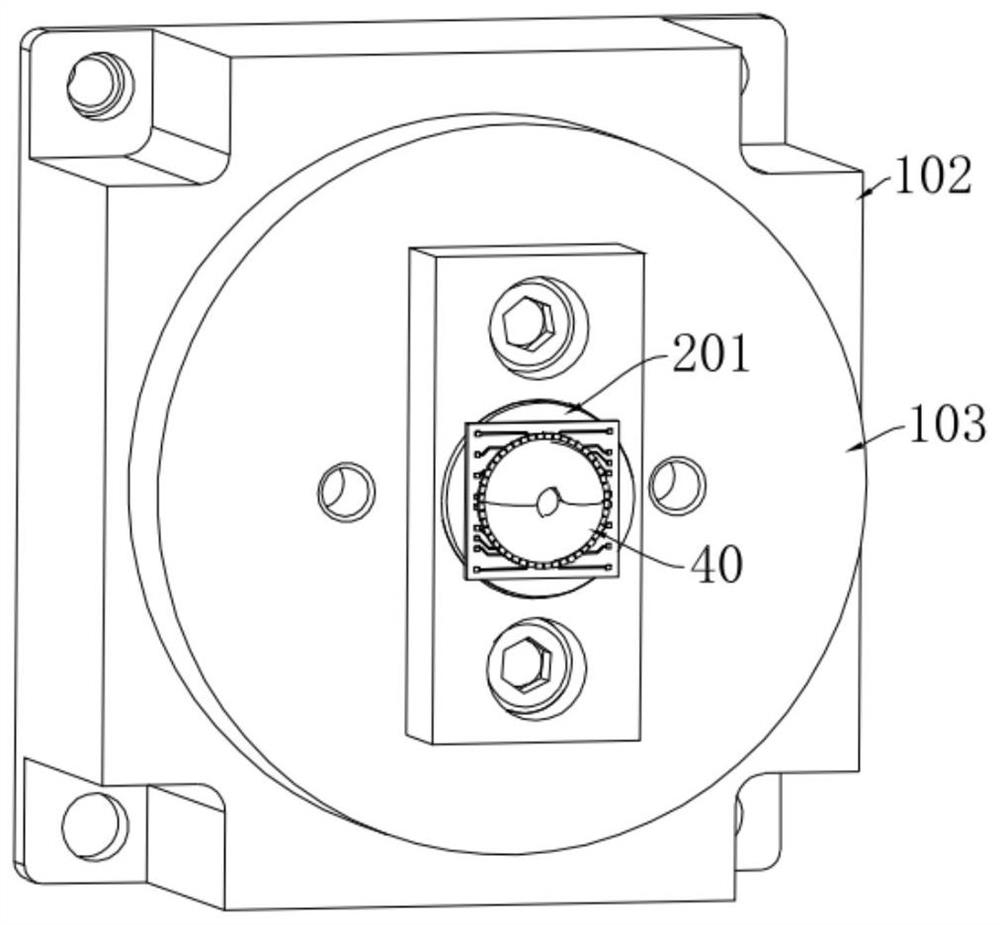

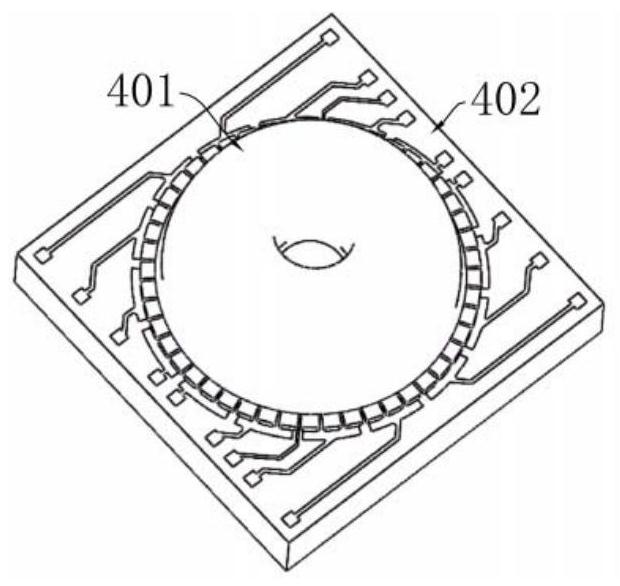

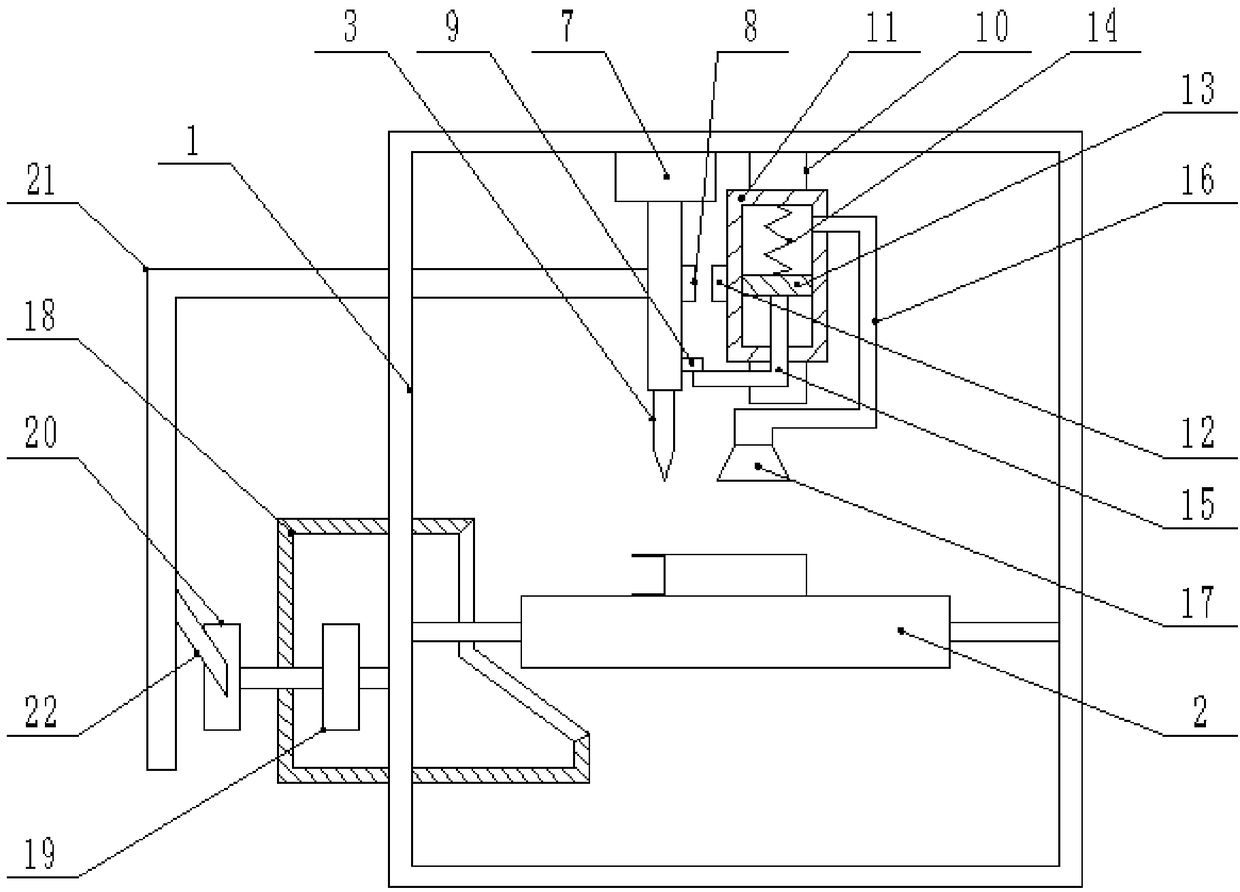

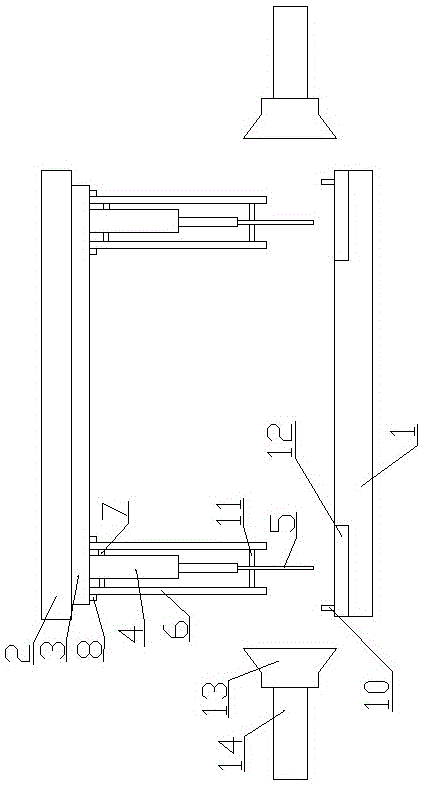

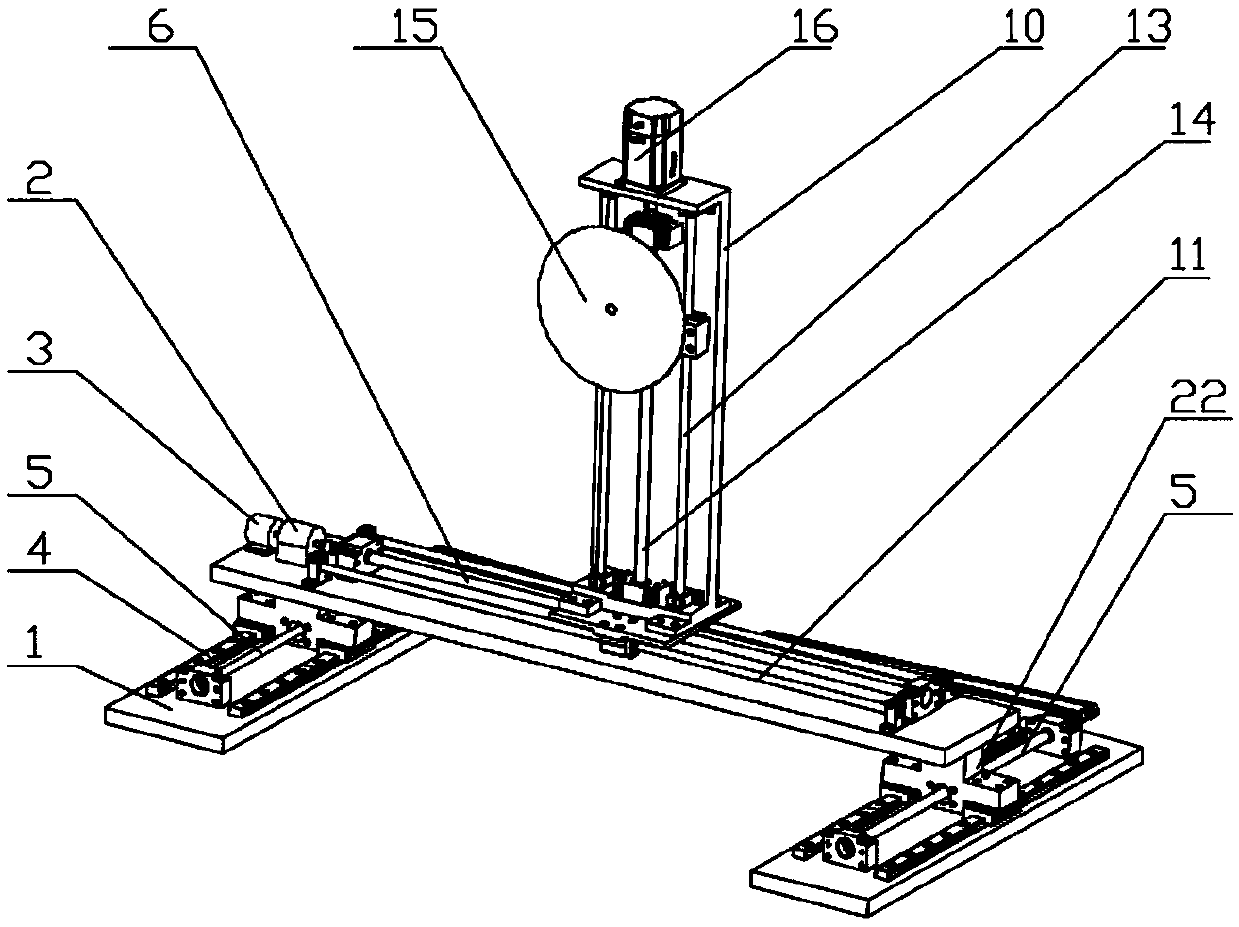

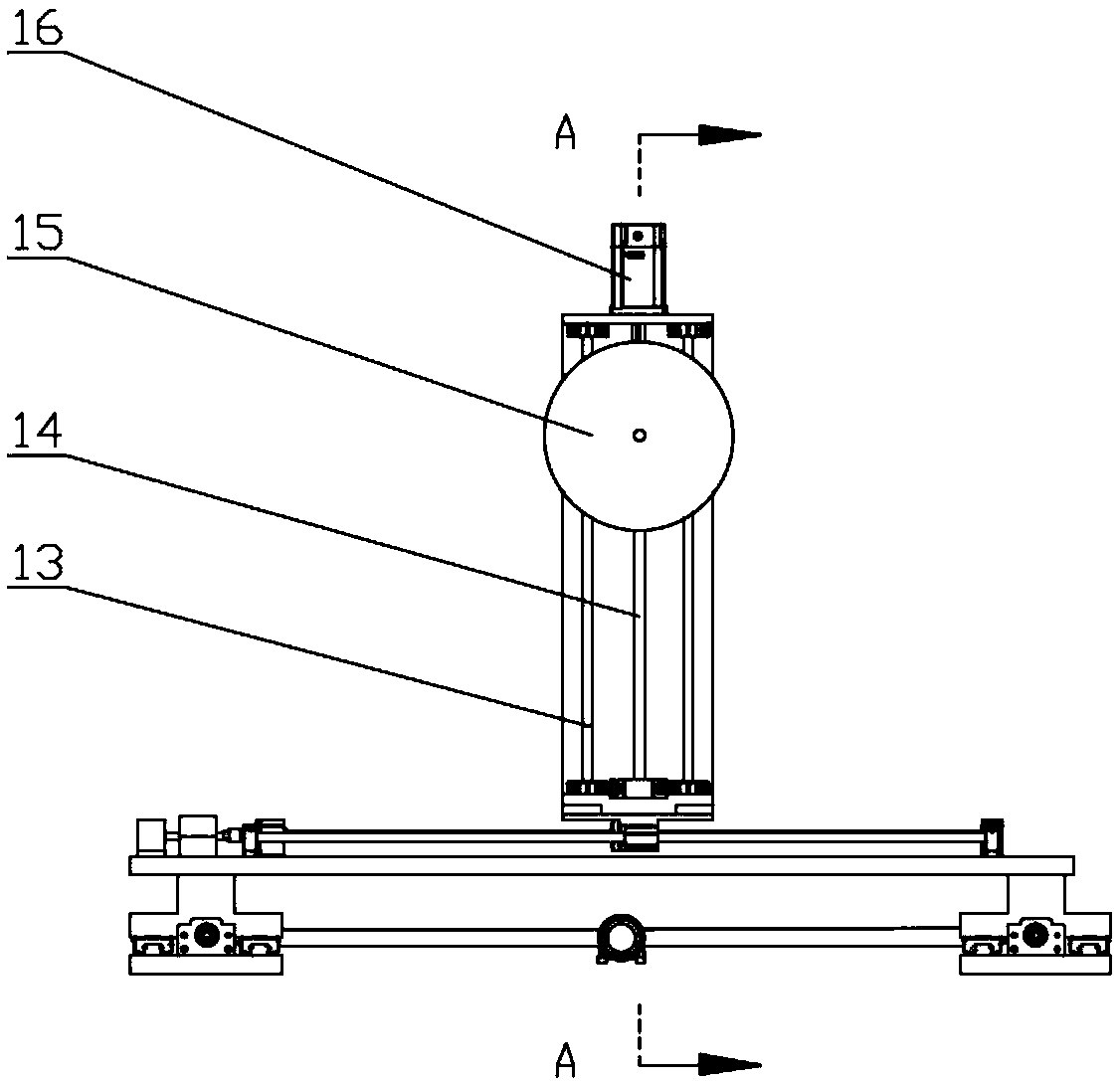

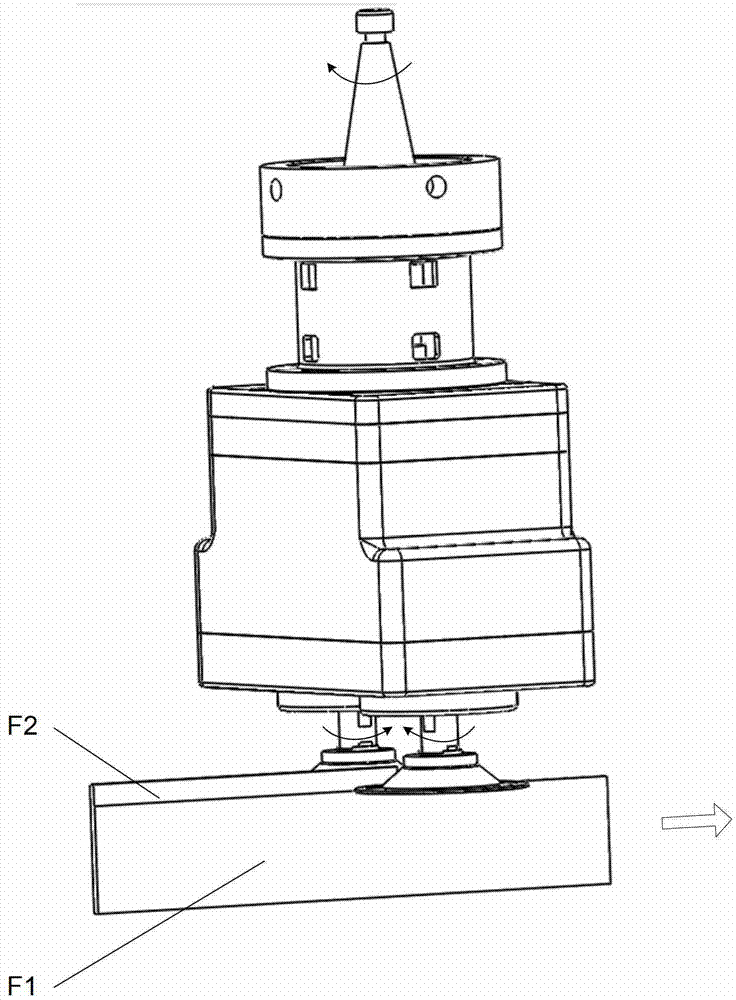

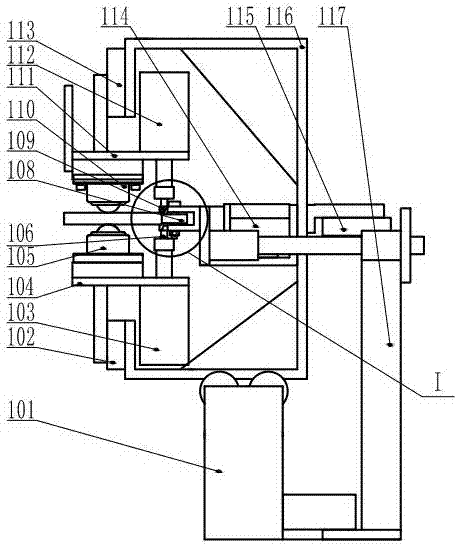

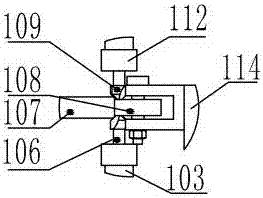

Online laser trimming system and method for micro-hemispherical resonator gyroscope with frequency measurement function

ActiveCN113551691ASolve test problemsObserve the adjustment effect in timeMeasurement devicesLaser processingEngineering

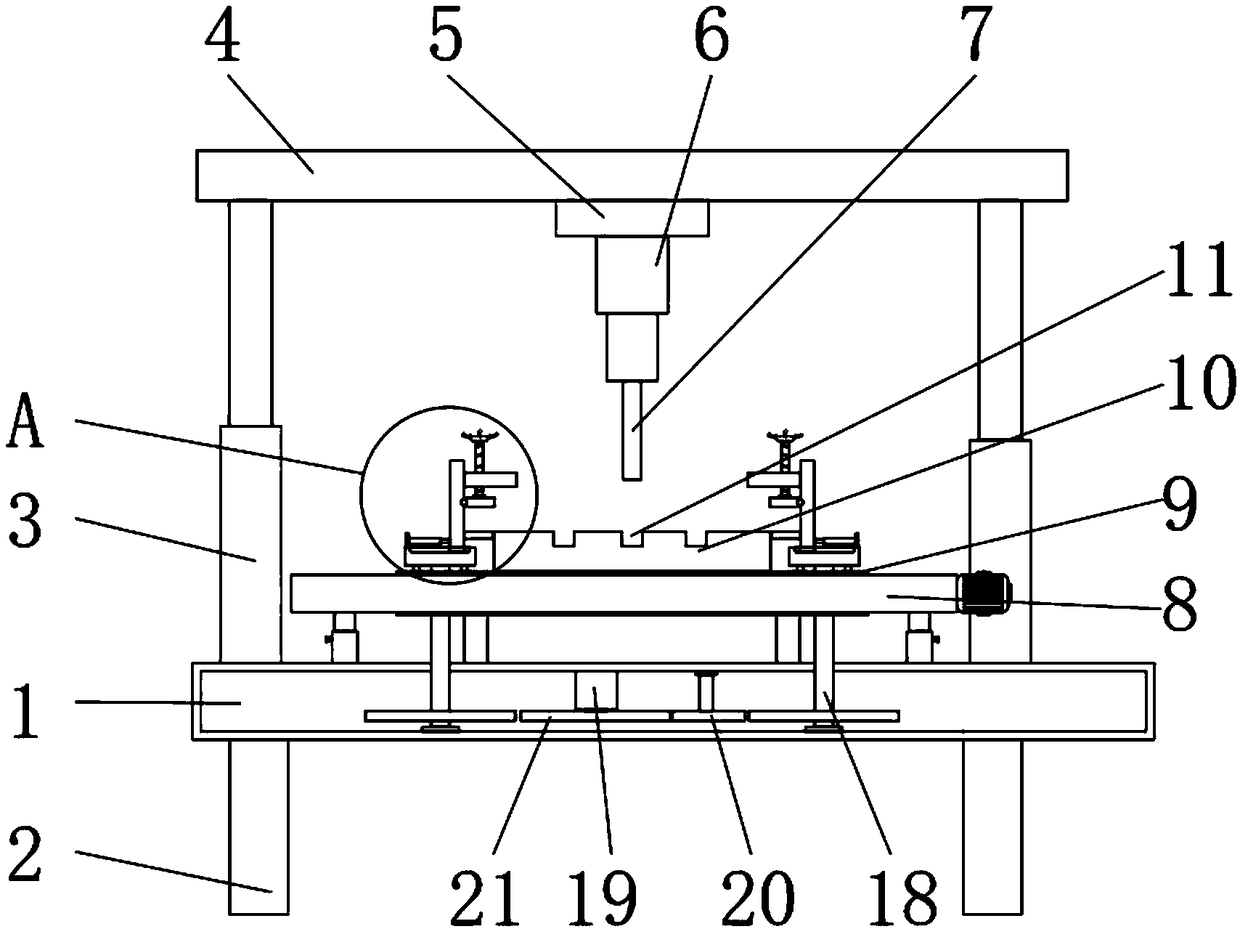

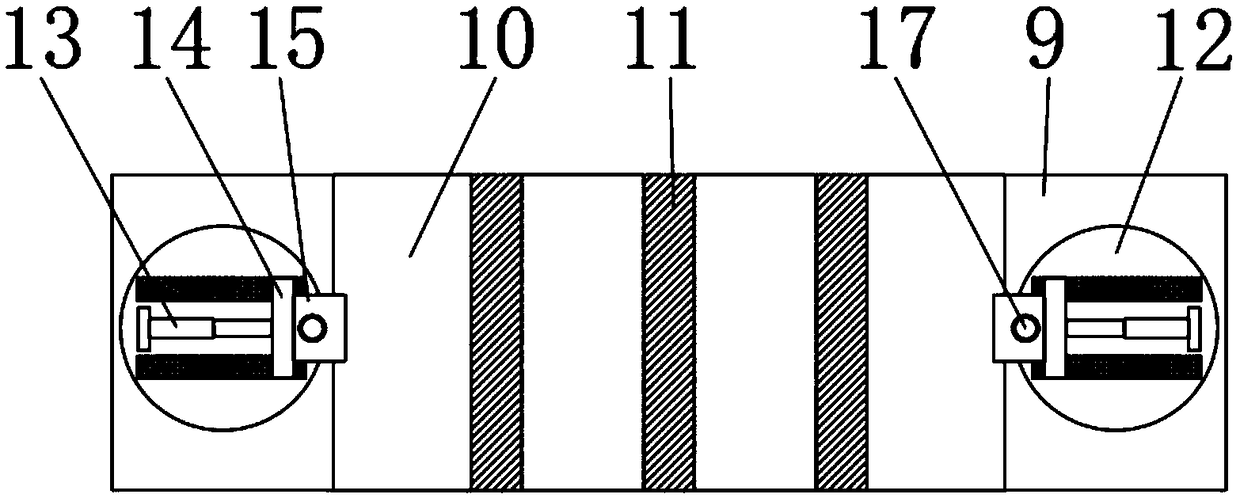

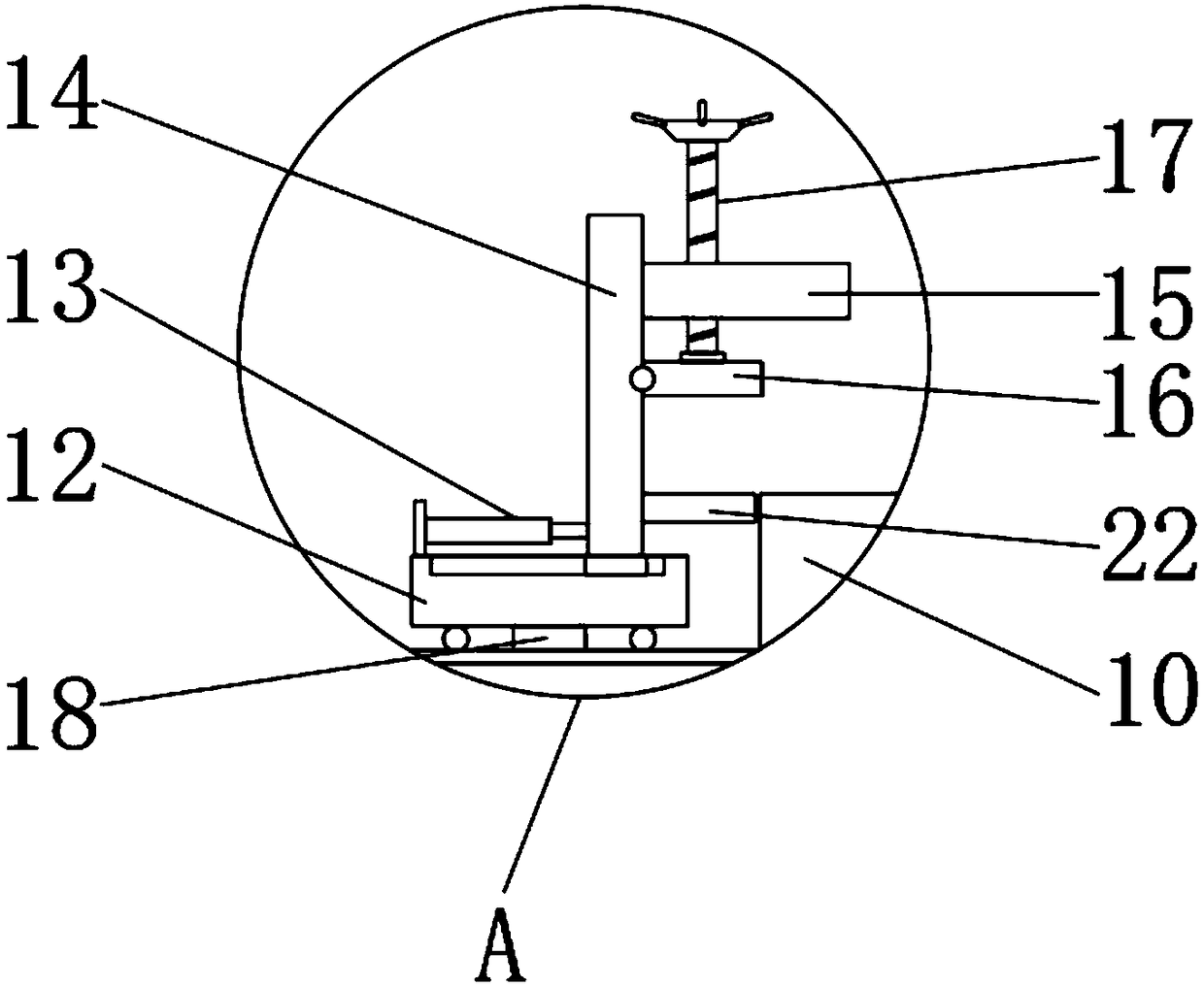

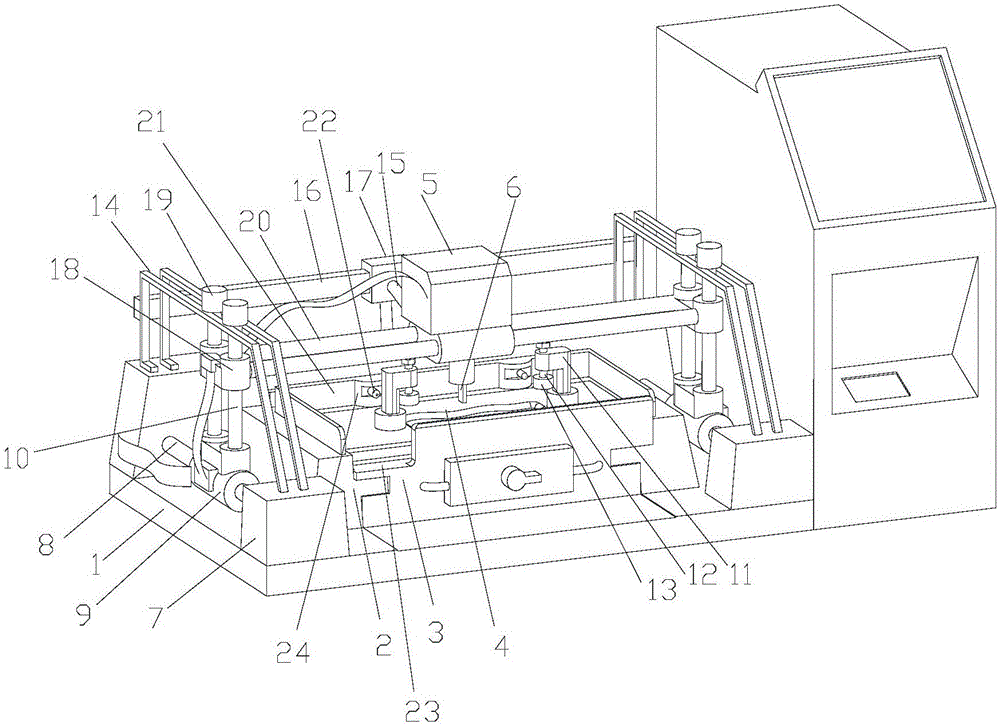

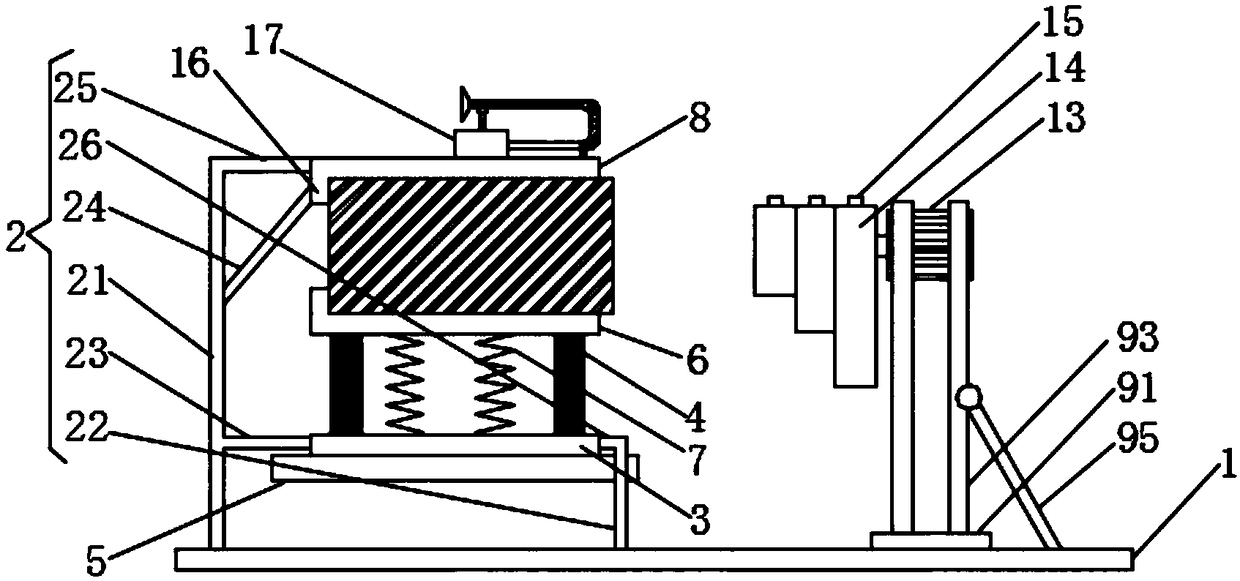

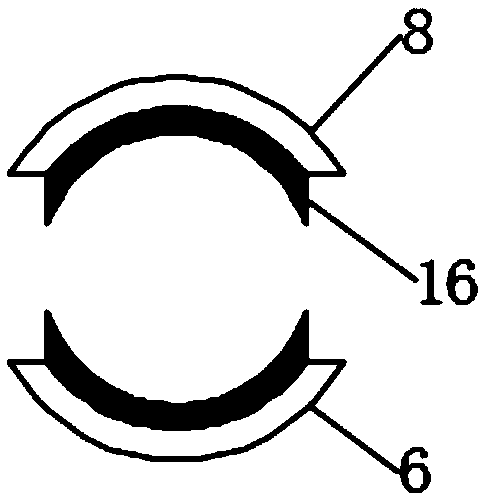

The invention discloses an online laser trimming system and method for a micro-hemispherical resonator gyroscope with a frequency measurement function. The system comprises a laser processing module, a frequency measurement module, a supporting module and a control module, the micro-hemispherical resonator gyroscope is arranged on the supporting module and has degrees of freedom of multi-directional movement and rotation; the frequency measurement module comprises a vibration element and a laser vibration meter, the vibration element is fixedly connected to the micro-hemispherical resonator gyroscope, and the laser vibration meter faces the side part of the micro-hemispherical resonator gyroscope; the control module is in communication connection with the frequency measurement module so as to obtain the trimming opening depth and diameter required by the micro-hemispherical resonator gyroscope; and the laser processing module is located around the micro-hemispherical resonator gyroscope so as to complete trimming of the micro-hemispherical resonator gyroscope based on the needed trimming opening depth and diameter. The system is applied to the technical field of vibrating gyroscopes, the depth of removal mass is controlled in the trimming process, meanwhile, online frequency measurement can be achieved, the trimming effect can be observed in time, and the trimming efficiency is greatly improved.

Owner:NAT UNIV OF DEFENSE TECH

Book edge-cutting device

ActiveCN108356869ARealize automatic trimmingRealize transportationMetal working apparatusMechanical engineering

The invention relates to the technical field of paper cutting, and discloses a book edge-cutting device. The book edge-cutting device comprises a machine frame, the machine frame is rotatably connected with a belt transport mechanism, the machine frame is slidably connected with a cutter and a first connecting rod, and the cutter is located above the belt transport mechanism. The first connectingrod is fixedly provided with a first ratchet claw, the belt transport mechanism is coaxially connected with a first ratchet wheel which meshes with the first ratchet claw, and the machine frame is provided with a fixing mechanism used for fixing a book. The book edge-cutting device can automatically fix the book with the edge to be cut while cutting the edge, the book is prevented from deviation,and the efficiency of cutting edge and the qualified rate of the product are improved.

Owner:普天印务(重庆)股份有限公司

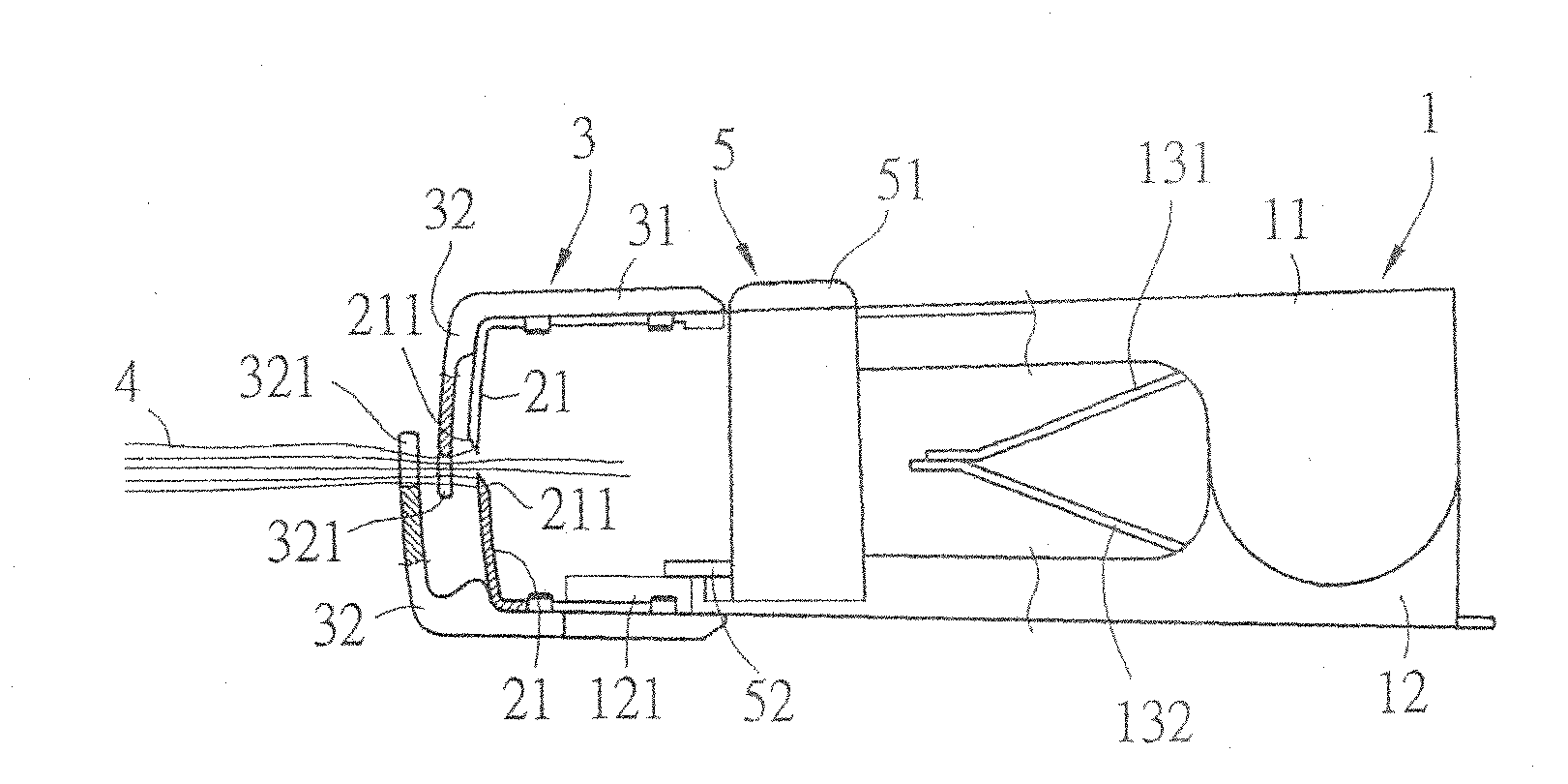

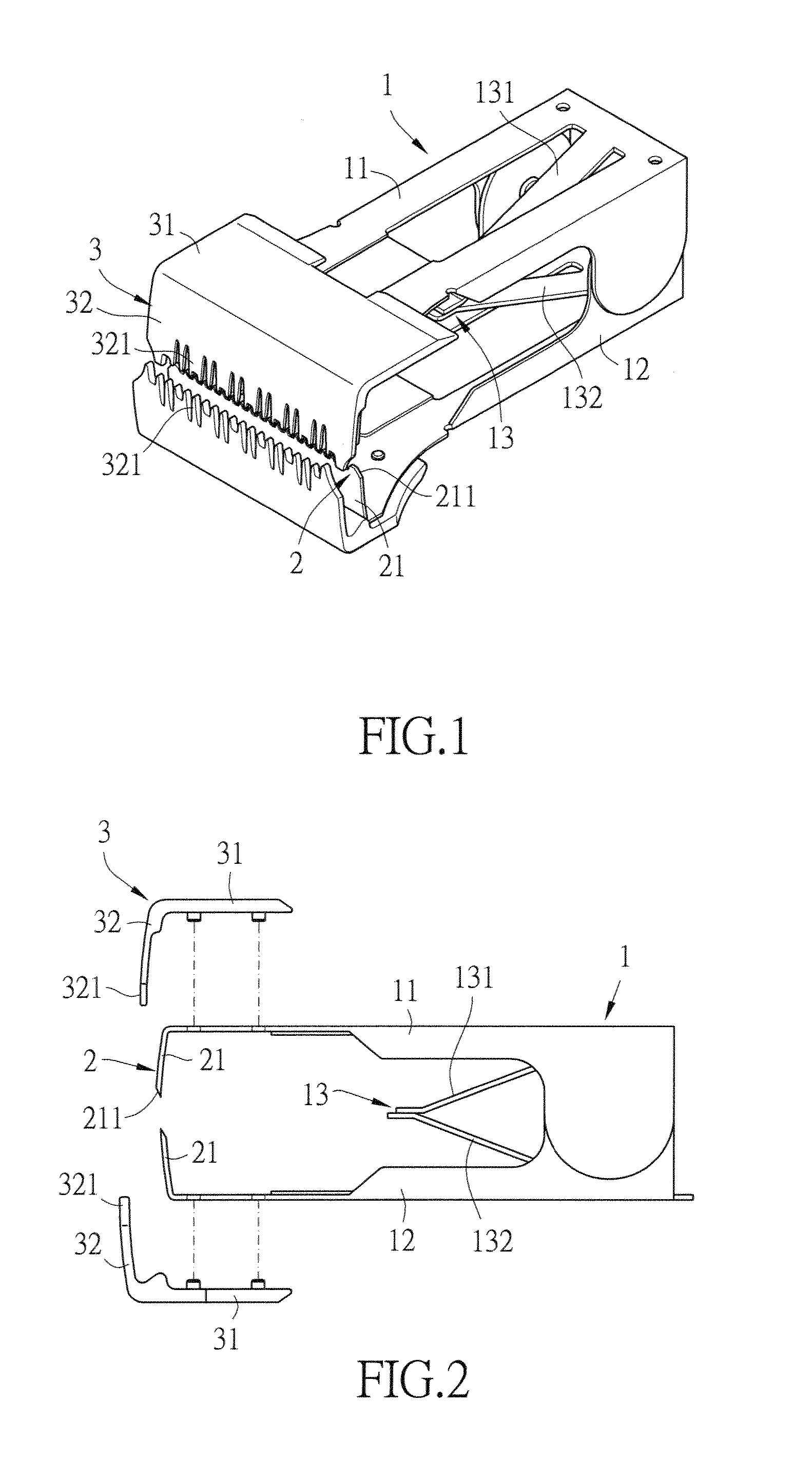

Hair Trimmer

InactiveUS20110302789A1Improve hair trimming efficiencyImprove trimming efficiencyMetal working apparatusCombingEngineering

A hair trimmer includes a fixture having an upper and a lower tie plates, with an elastic element between the upper and lower tie plates; at least two cutting units at an end of the upper and lower tie plates, with each cutting unit having a corresponding cutting part, and an end of each cutting part having notches of different depths; and at least two combing units assembled with the upper and lower tie plates and corresponding to an exterior side of each cutting unit, with each combing unit including a teeth part which corresponds to each other and is parallel to the cutting part, and an end of each teeth part having comb slots of different depths. Therefore, a multiedged thinning can be carried out while trimming and it allows the hair to have more different levels of edge and a sense of beauty.

Owner:TZENG FONG INDAL CORP

Trimming device for industrial fabrics

InactiveCN105133284AEfficient and fast trimmingImprove trimming efficiencyCleaningSevering textilesPulp and paper industryTextile

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

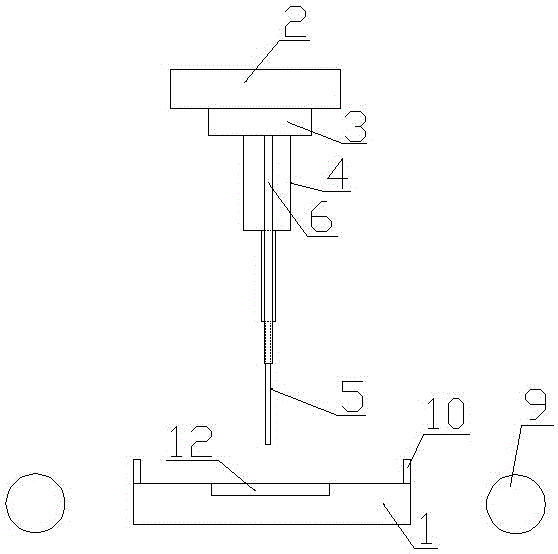

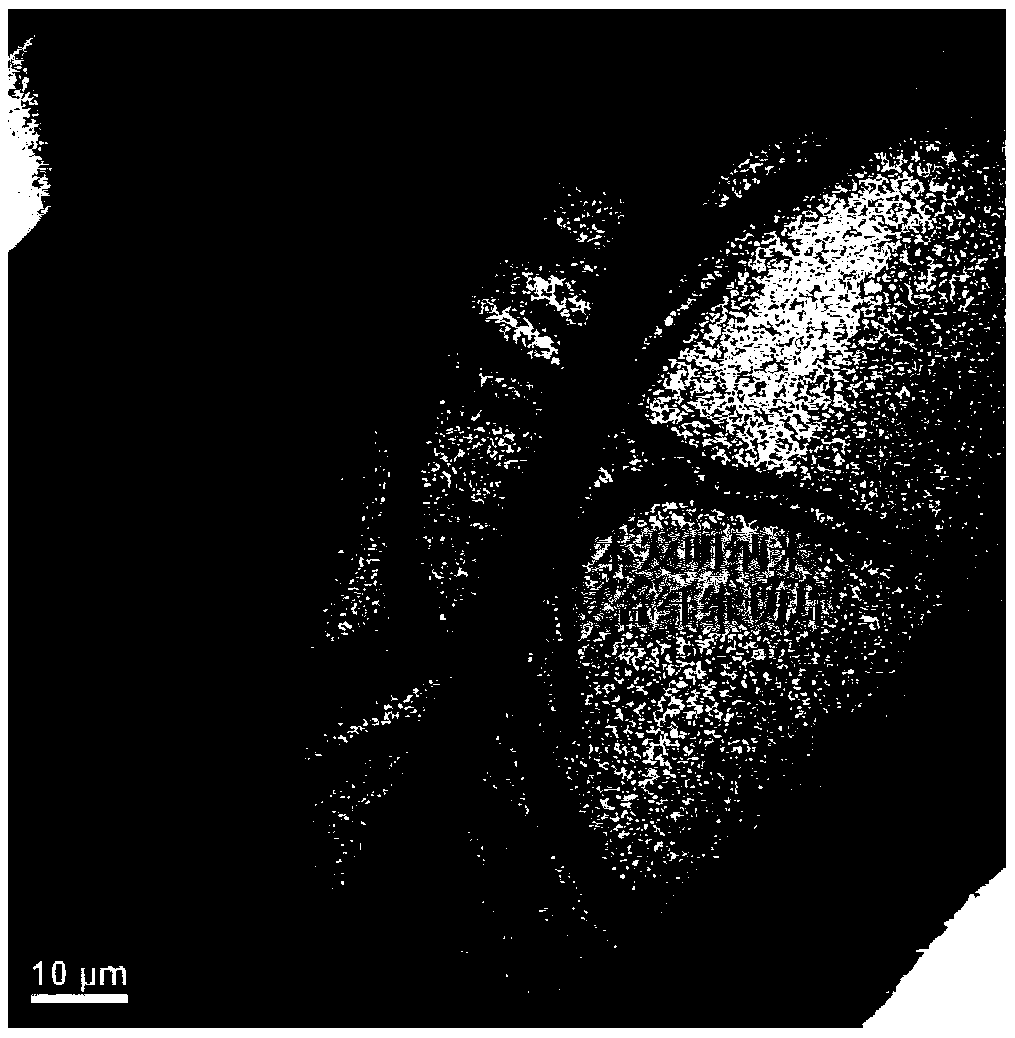

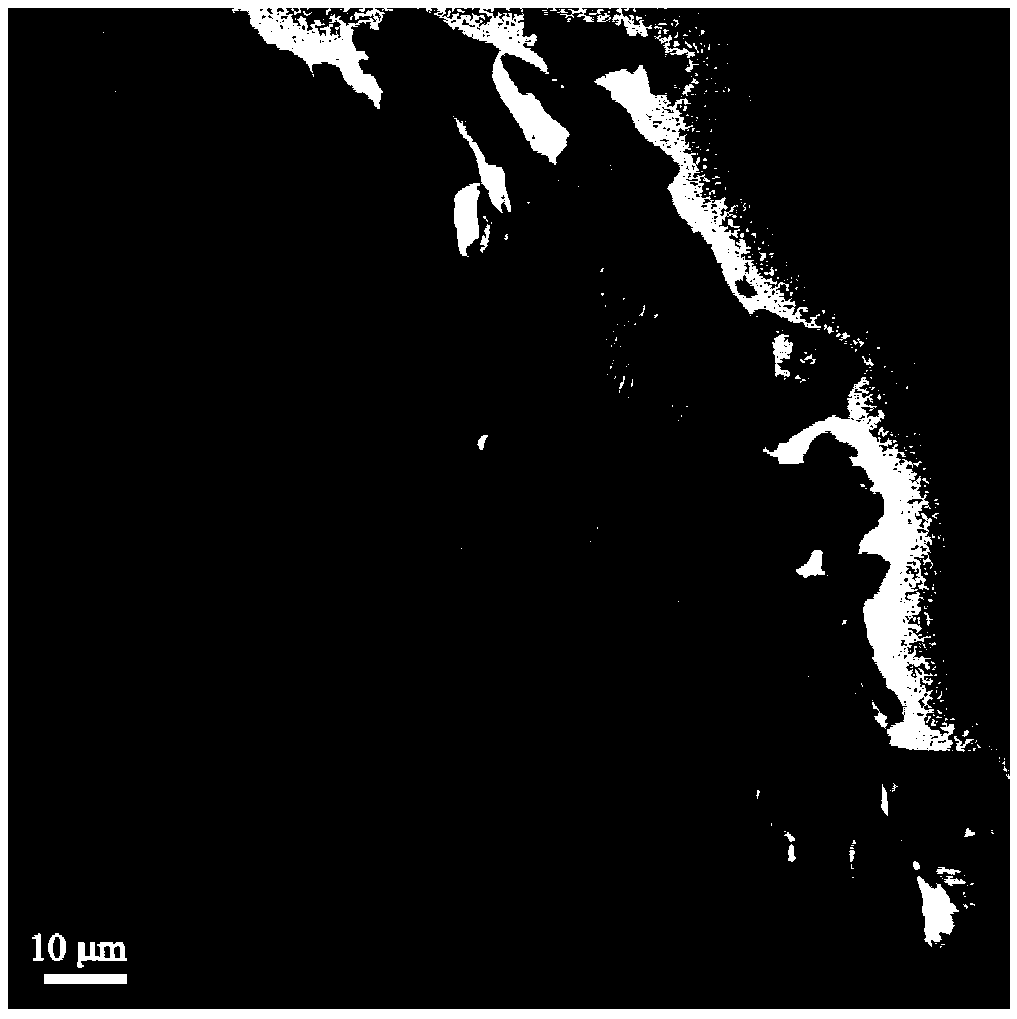

Embedding method of fiber-shaped sample for axial ultrathin slice

InactiveCN108709787AOvercome the inability to accurately locate itImprove trimming efficiencyPreparing sample for investigationFiberEngineering

The invention discloses an embedding method of a fiber-shaped sample for an axial ultrathin slice. The embedding method comprises the following steps: fixing the fiber-shaped sample on a substrate toenable the fiber-shaped sample to be linear on the substrate; adding a liquid embedding agent into an open container; then covering the substrate fixed with the fiber-shaped sample on the top of the open container and enabling the surface fixed with the fiber-shaped sample of the substrate to be arranged toward the open container; fixing the substrate and the open container; then integrally overturning the substrate and the open container; reversely buckling the open container on the surface fixed with the fiber-shaped sample of the substrate; curing the liquid embedding agent to form an embedding block; separating the open container and the substrate and enabling the fiber-shaped sample to be located at a position of the topmost end of the embedding block, so as to obtain an embedded fiber-shaped sample for the axial ultrathin slice. The method disclosed by the invention can be used for accurately determining the position of the sample and remarkably improving the later-period block trimming efficiency and the success rate of slicing.

Owner:EAST CHINA UNIV OF SCI & TECH

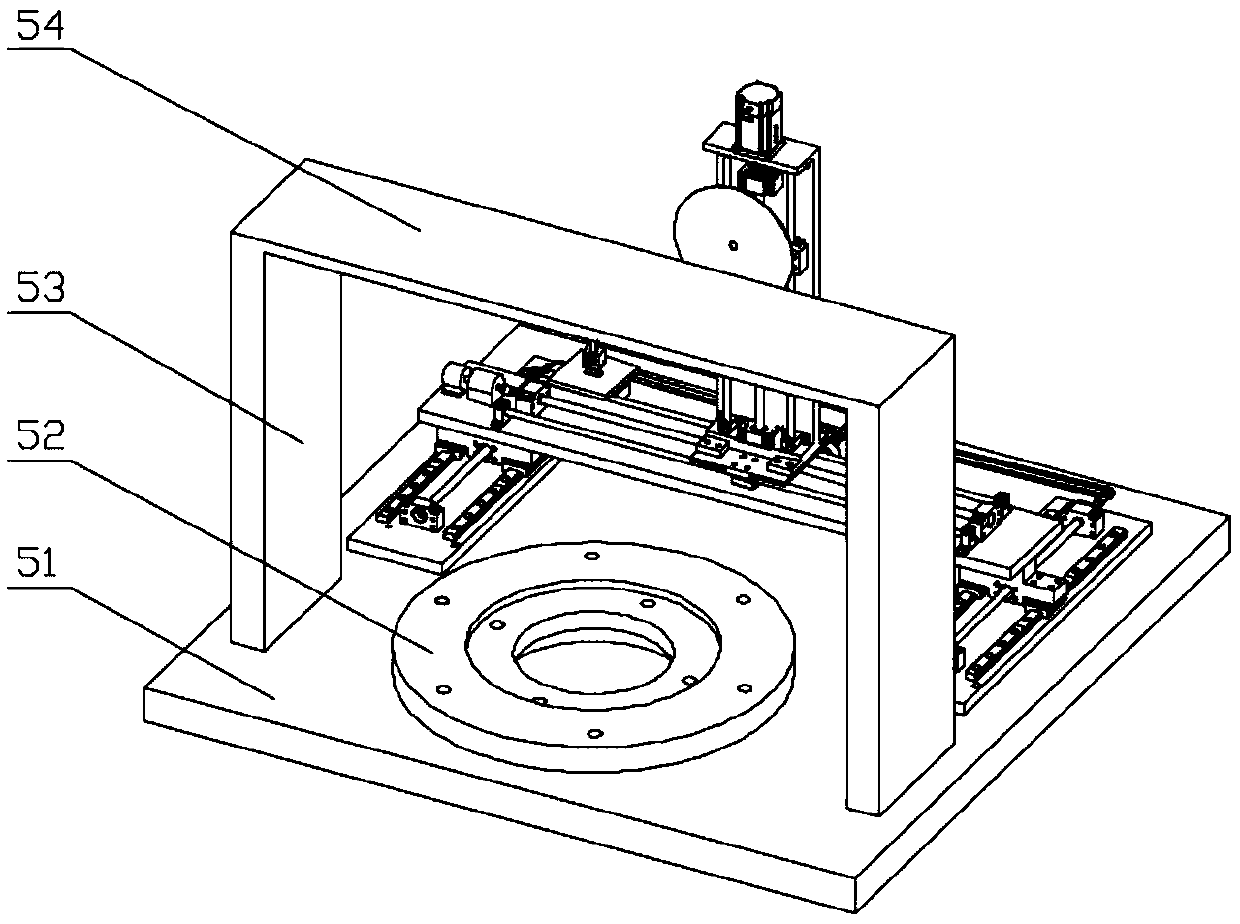

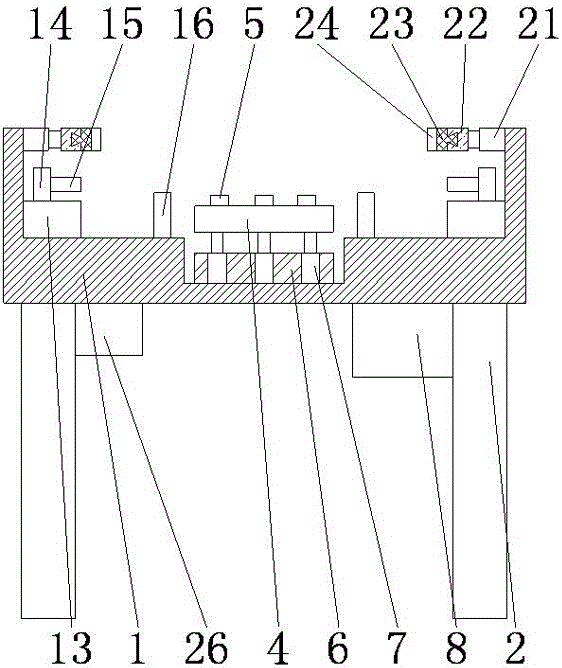

Single-spindle glass magnesium plate trimming machine and trimming method

ActiveCN109591198ARealize edge trimmingSimple structureWorking accessoriesStone-like material working toolsCircular sawEngineering

The invention discloses a single-spindle glass magnesium plate trimming machine and a trimming method. The trimming machine comprises a support component, a main body component and a pressing component, and the support component is used for installing the main body component and the pressing component; during trimming operation of a glass magnesium plate, a slewing bearing of the support componentis used for placing and driving the glass magnesium plate to be trimmed to rotate in an indexing manner; the main body component is used for driving a circular saw blade to move in X-axis, Y-axis andZ-axis directions, so that the trimming of the glass magnesium plate is achieved; and the pressing component is used for pressing the glass magnesium plate to be trimmed and preventing the glass magnesium plate to be trimmed from being moved in the trimming process. According to the trimming machine, four edges of glass magnesium plates in different sizes and specifications after maintenance anddrying can be cut, and the operation efficiency and the degree of automation are high; the operation is convenient, and human intervention is reduced in the trimming process; and the influence of dustgenerated during trimming on the physical and mental health of workers is reduced effectively.

Owner:JIANGSU UNIV OF SCI & TECH

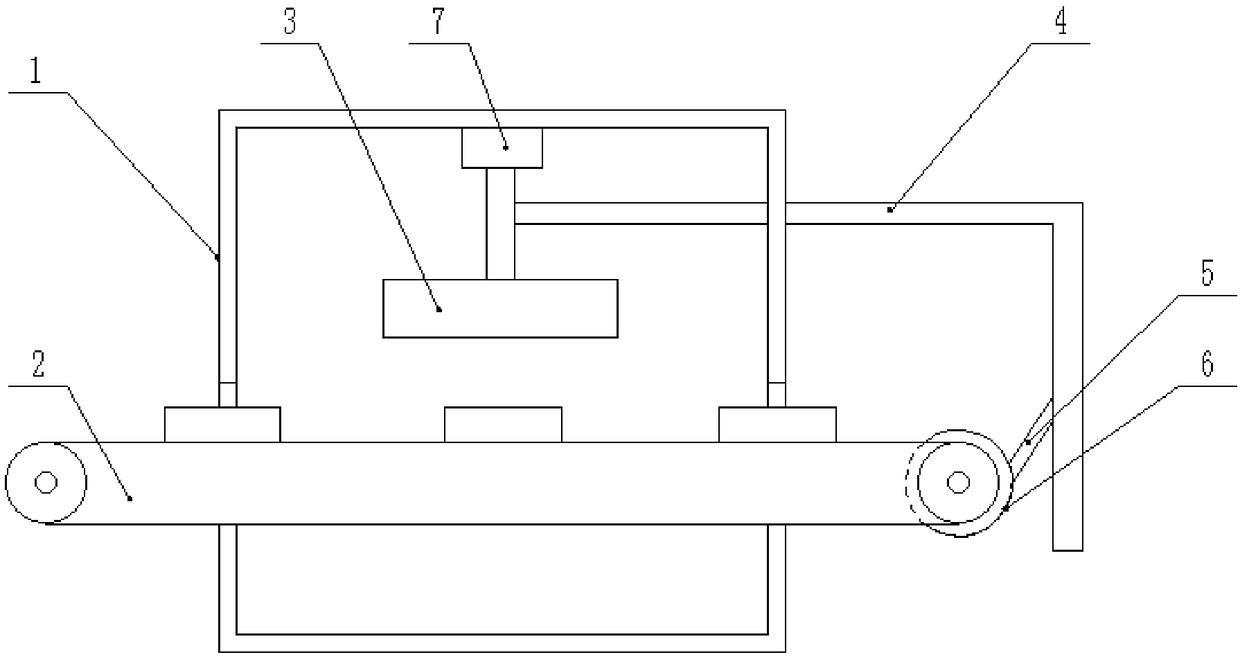

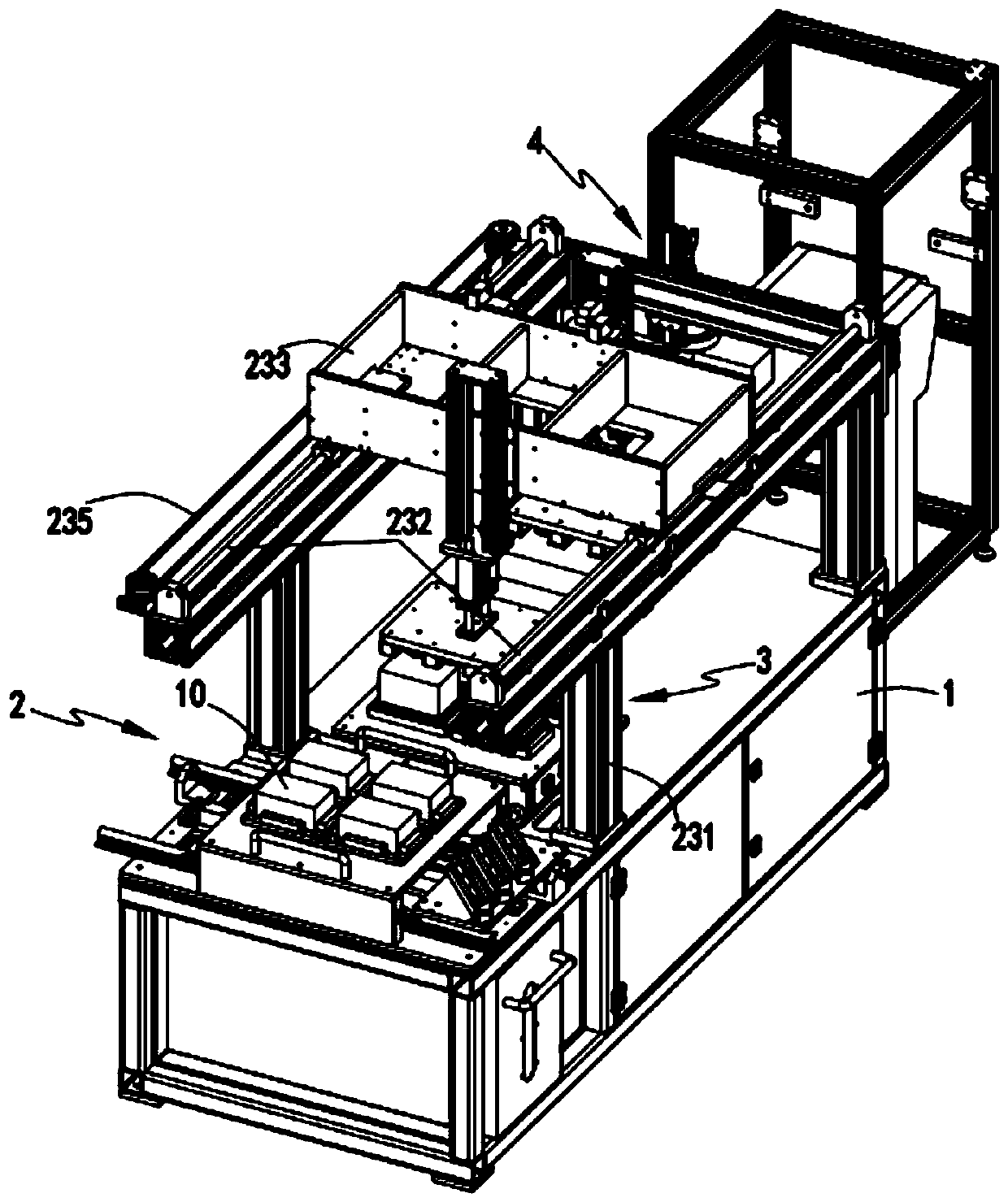

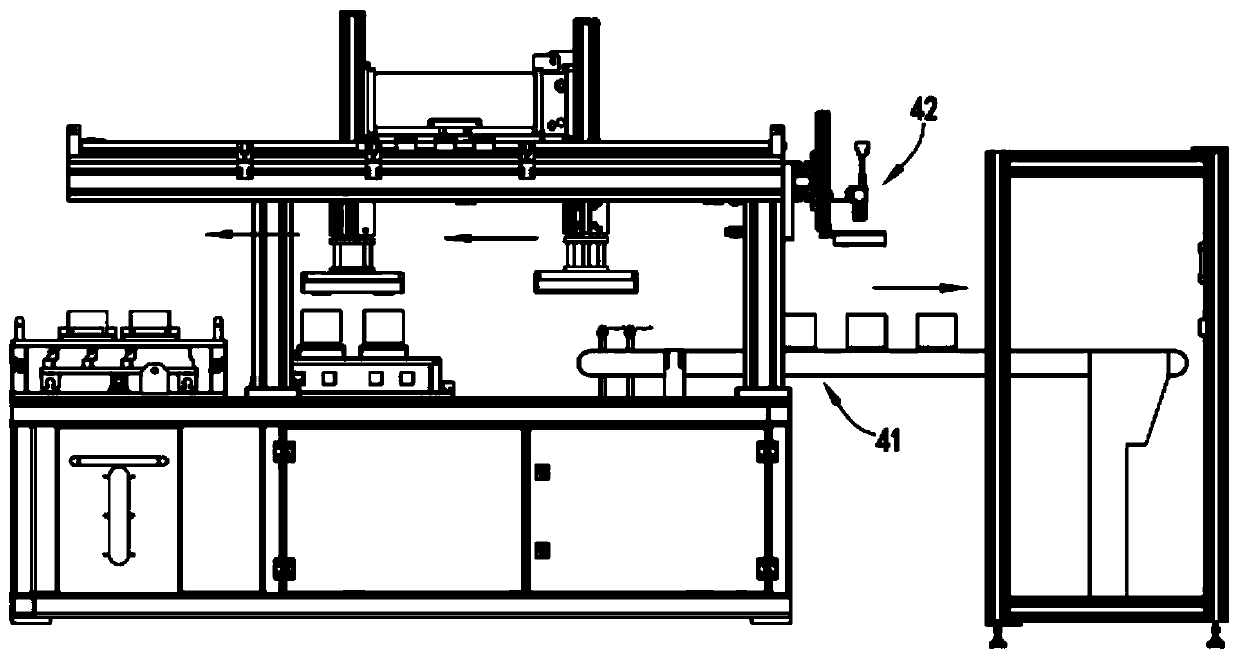

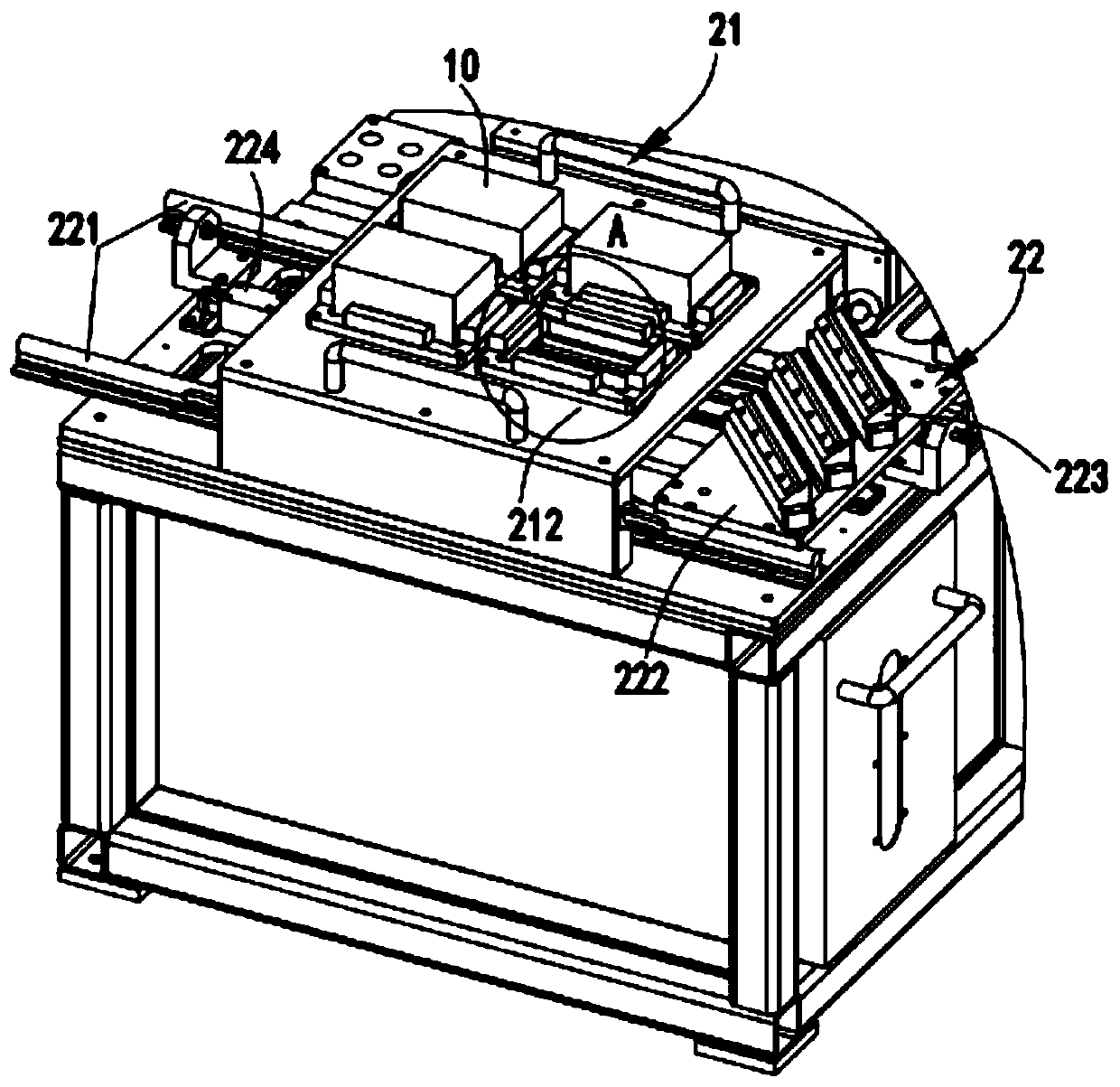

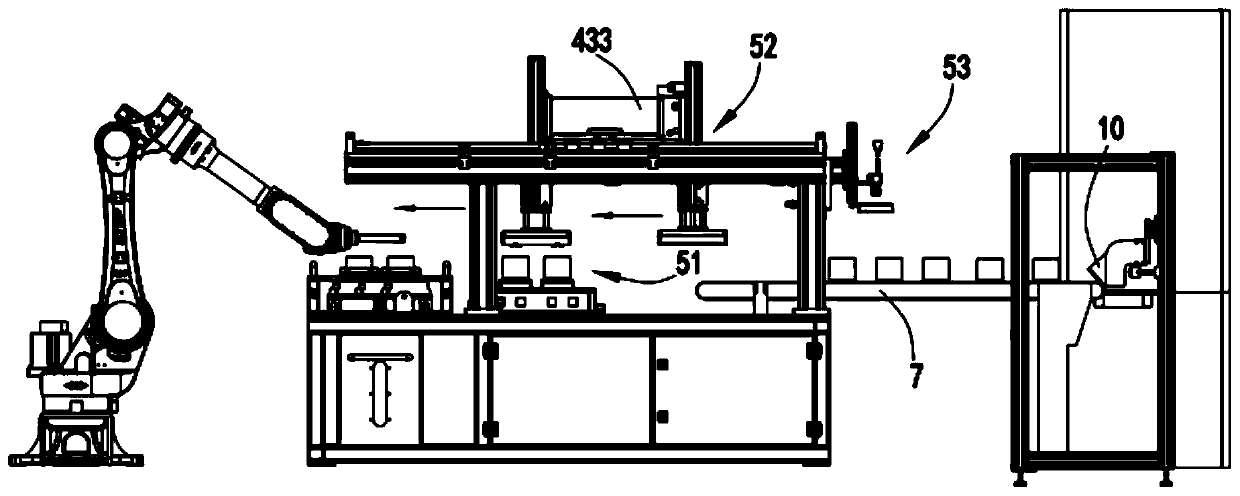

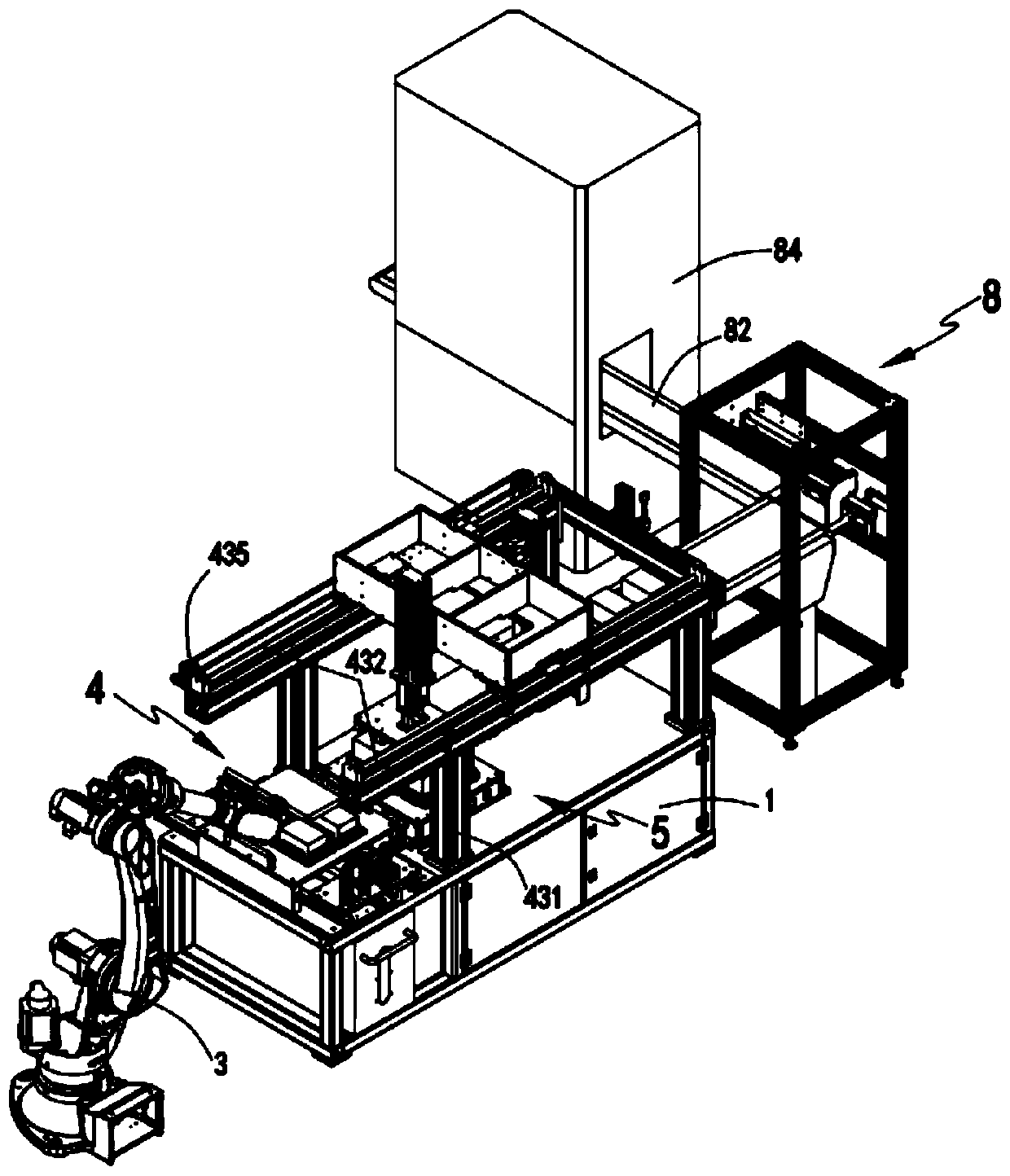

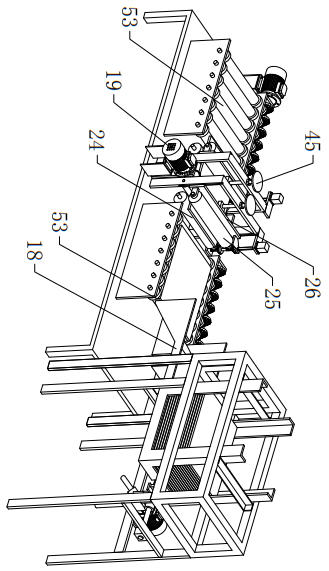

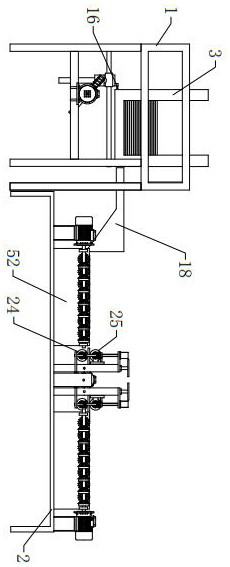

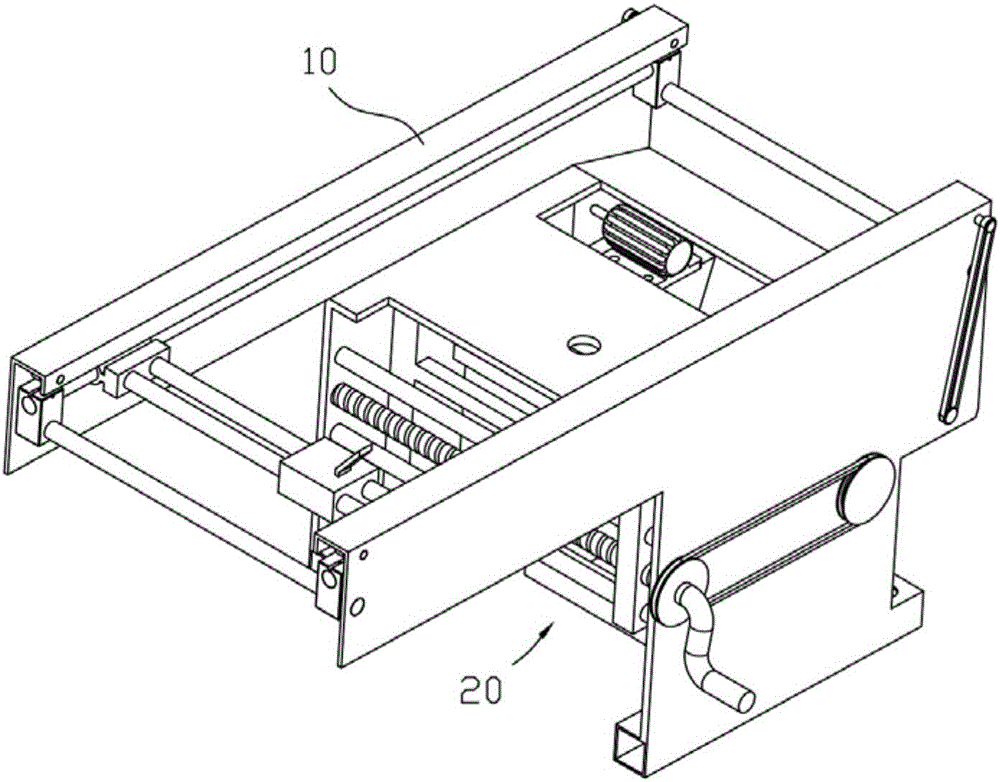

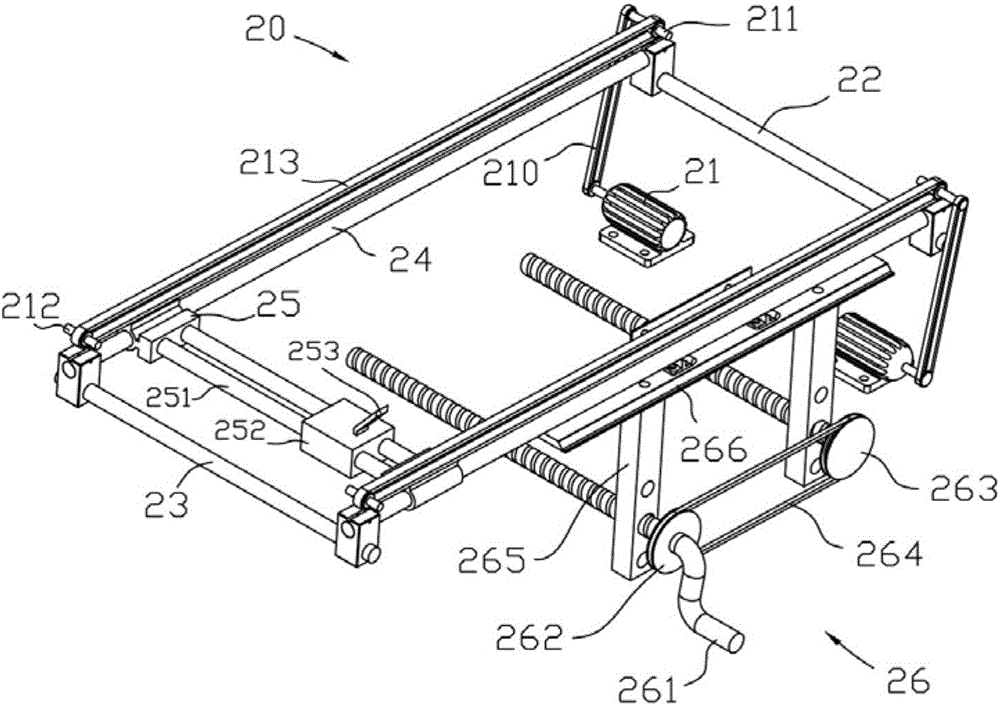

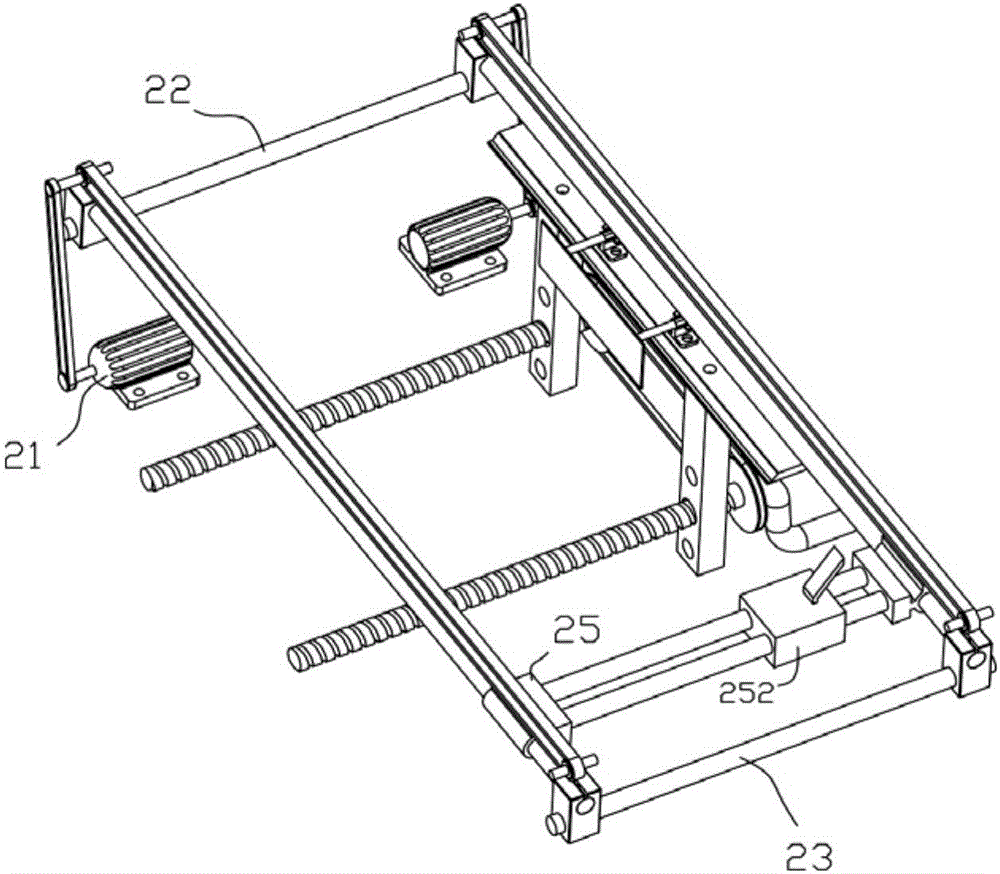

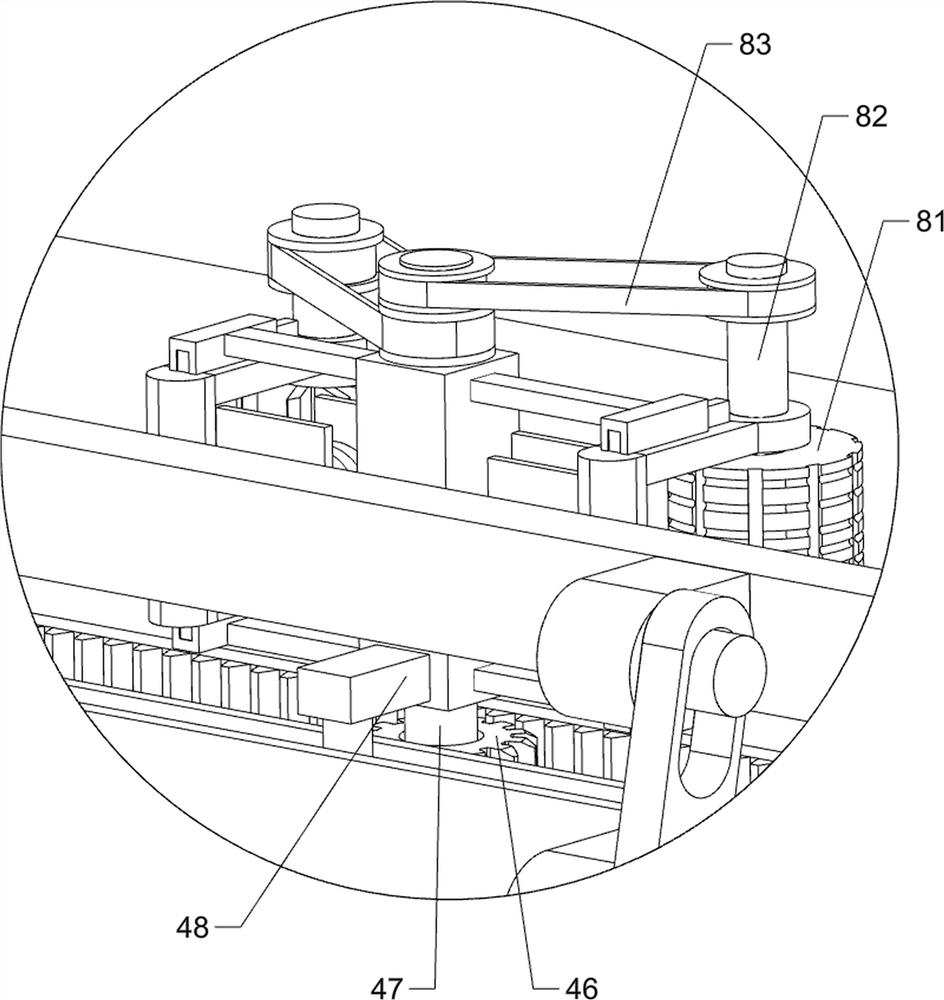

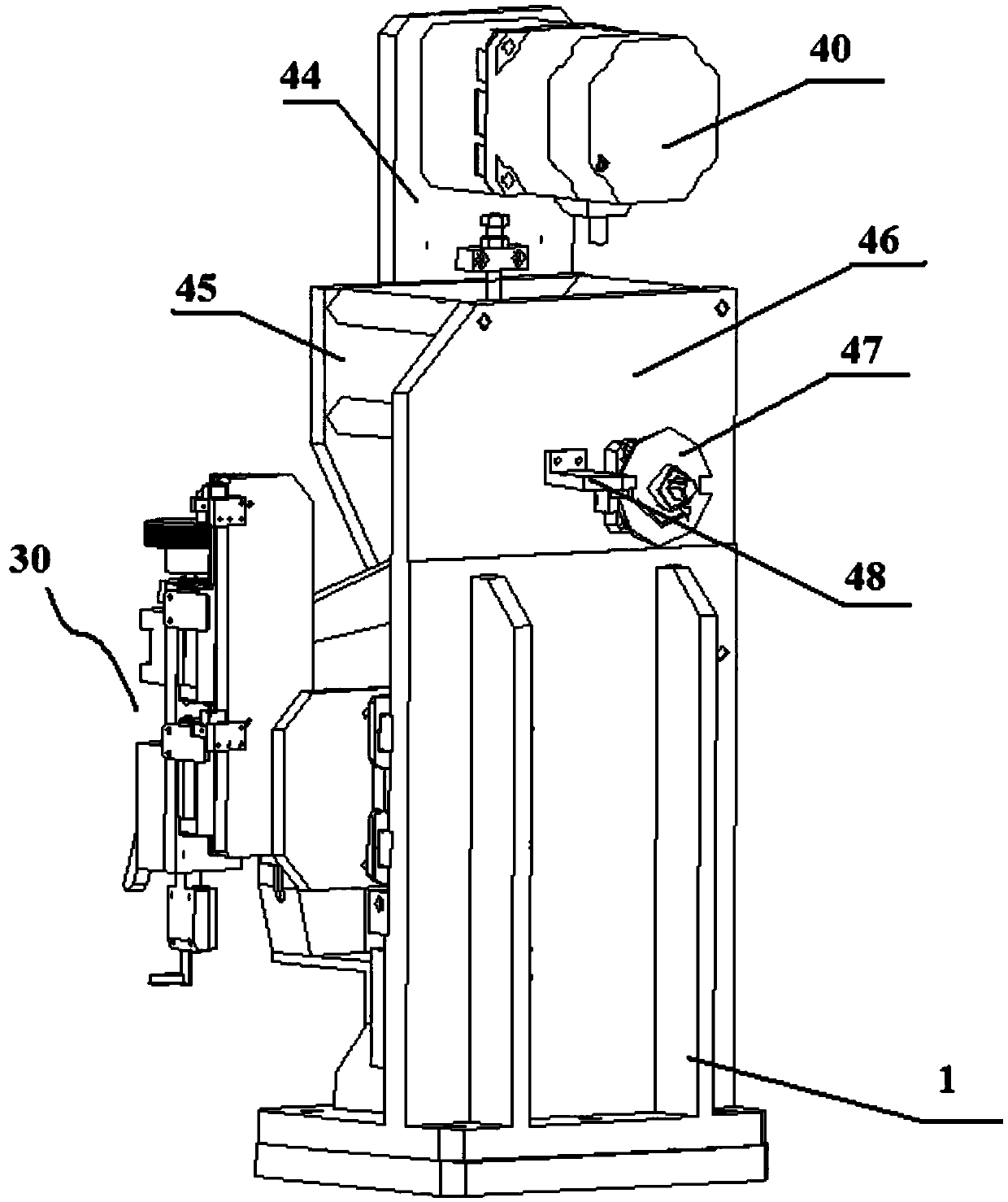

Automatic battery box edge trimming detection equipment

PendingCN110014455AImprove trimming efficiencyQuality assuranceSortingMetal working apparatusTesting equipmentEngineering

The invention relates to automatic battery box edge trimming detection equipment. The automatic battery box edge trimming detection equipment comprises a supporting table, an edge trimming device, a first detection device, a second detection device and a removal device are sequentially arranged on the supporting table from front to back, the edge trimming device trims the upper end surface of a battery box, the first detection device detects whether a notch exists in the battery box or not, the second detection device detects the appearance of the battery box, and the removal device removes the battery box detected with defects; and the edge trimming device comprises a positioning mechanism, a slicer mechanism arranged below the positioning mechanism and a supporting transferring mechanisma arranged above the positioning mechanism, the slicer mechanism cuts the battery box while the supporting transferring mechanism a presses and supports the battery box, after the slicer mechanism completes cutting the battery box, the supporting transferring mechanism a supports the battery box to transfer to the rear along the supporting table. The automatic battery box edge trimming detectionequipment solves the problems that in the battery box production process, the functions of multiple simultaneous edge trimming processing and multiple simultaneous defect detection after the edge trimming do not provided and the detection reliability is not high.

Owner:德玛克(浙江)精工科技有限公司

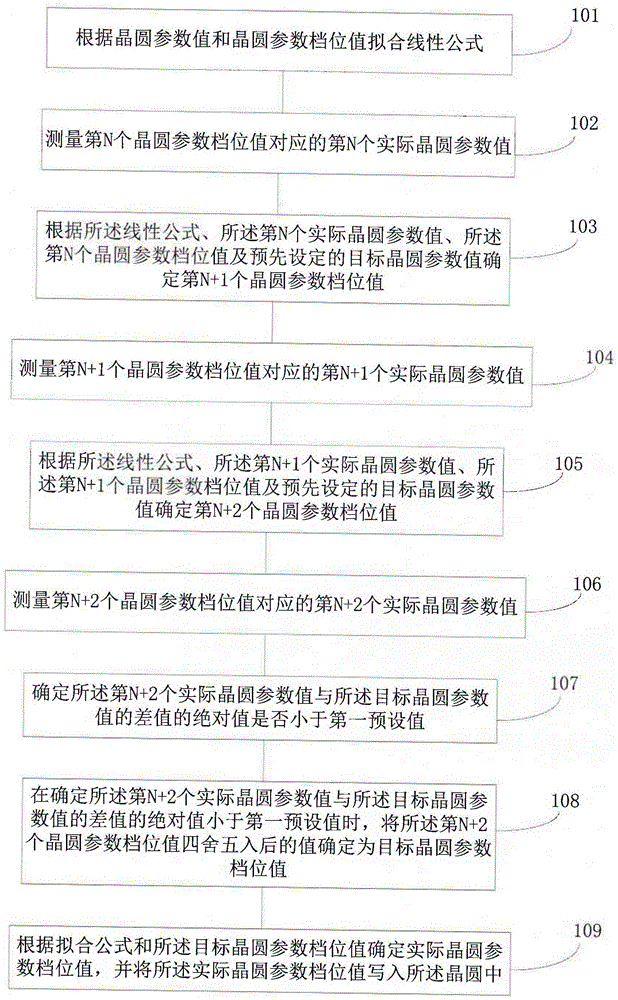

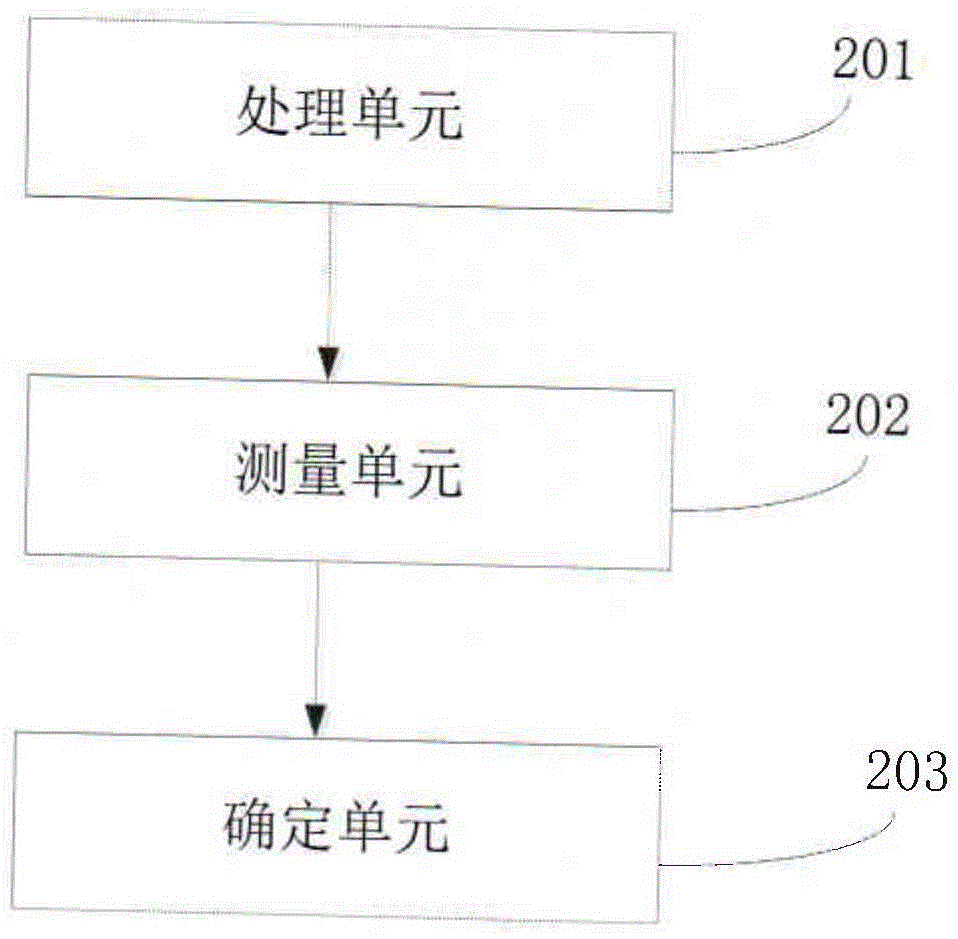

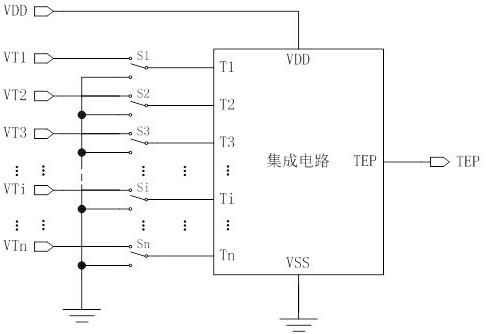

Trimming method and device of wafer parameter

ActiveCN105551993AShort adjustment timeImprove trimming efficiencySemiconductor/solid-state device testing/measurementEngineeringLinear formula

The invention discloses a trimming method and device of a wafer parameter. The method comprises the following steps of fitting a linear formula according to a wafer parameter value and a wafer parameter shift value; measuring N(th) actual wafer parameter value; determining (N+1)th wafer parameter shift value according to the linear formula, the N(th) actual wafer parameter value, N(th) wafer parameter shift value and a target wafer parameter value; measuring (N+1)th actual wafer parameter value; determining (N+2)th wafer parameter shift value according to the linear formula, the (N+1) actual wafer parameter value, (N+1)th wafer parameter shift value and a target wafer numerical value; measuring (N+2)th actual wafer parameter value; determining whether an absolute value of the difference between the (N+2)th actual wafer numerical value and the target wafer numerical value is smaller than a first preset value or not; and determining a value of the (N+2)th wafer parameter shift value after rounding as the target wafer parameter shift value when the absolute value is smaller than the first preset value. The trimming time is short, and the trimming efficiency is improved.

Owner:上海威伏半导体有限公司

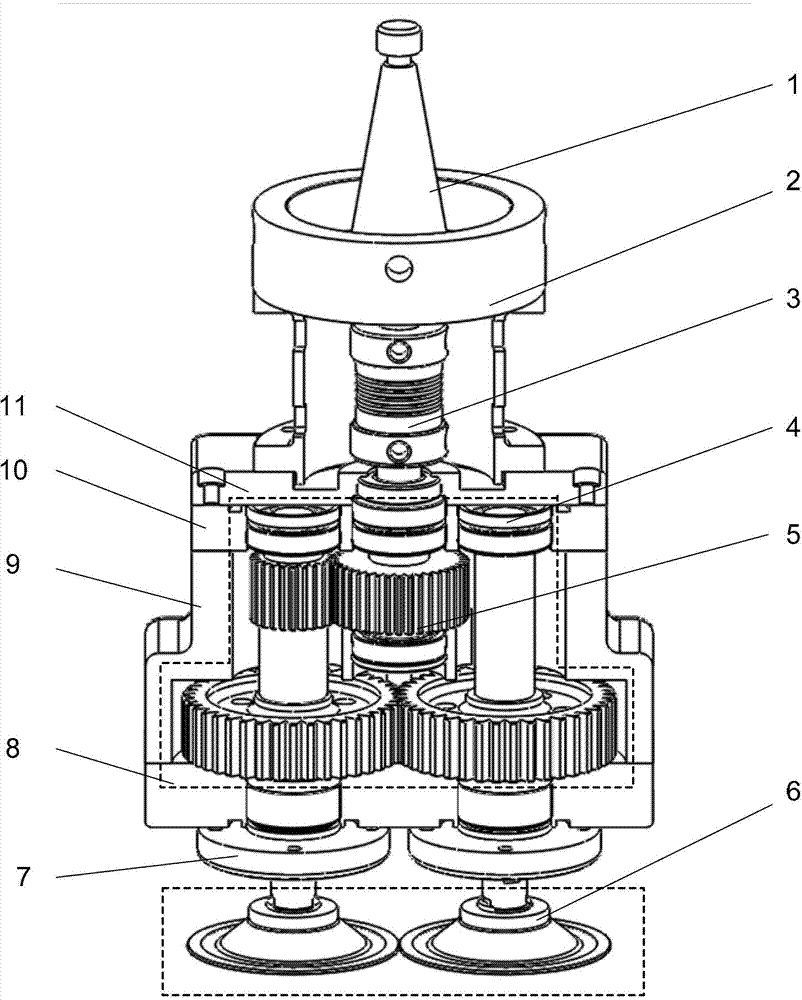

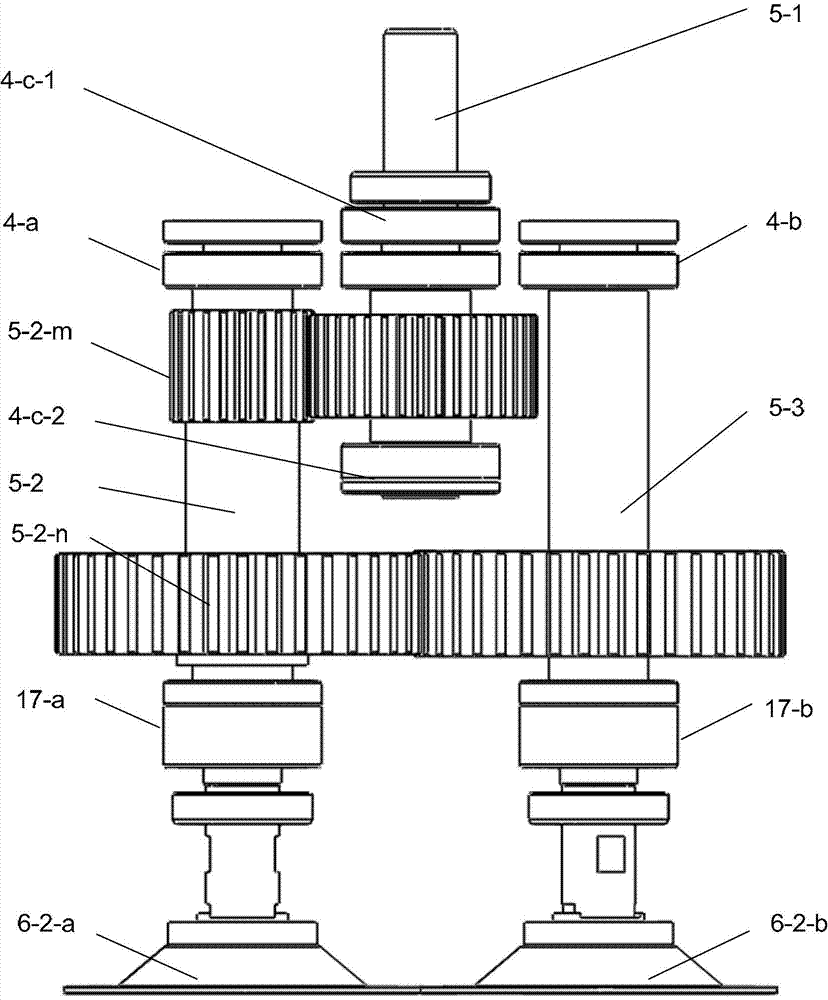

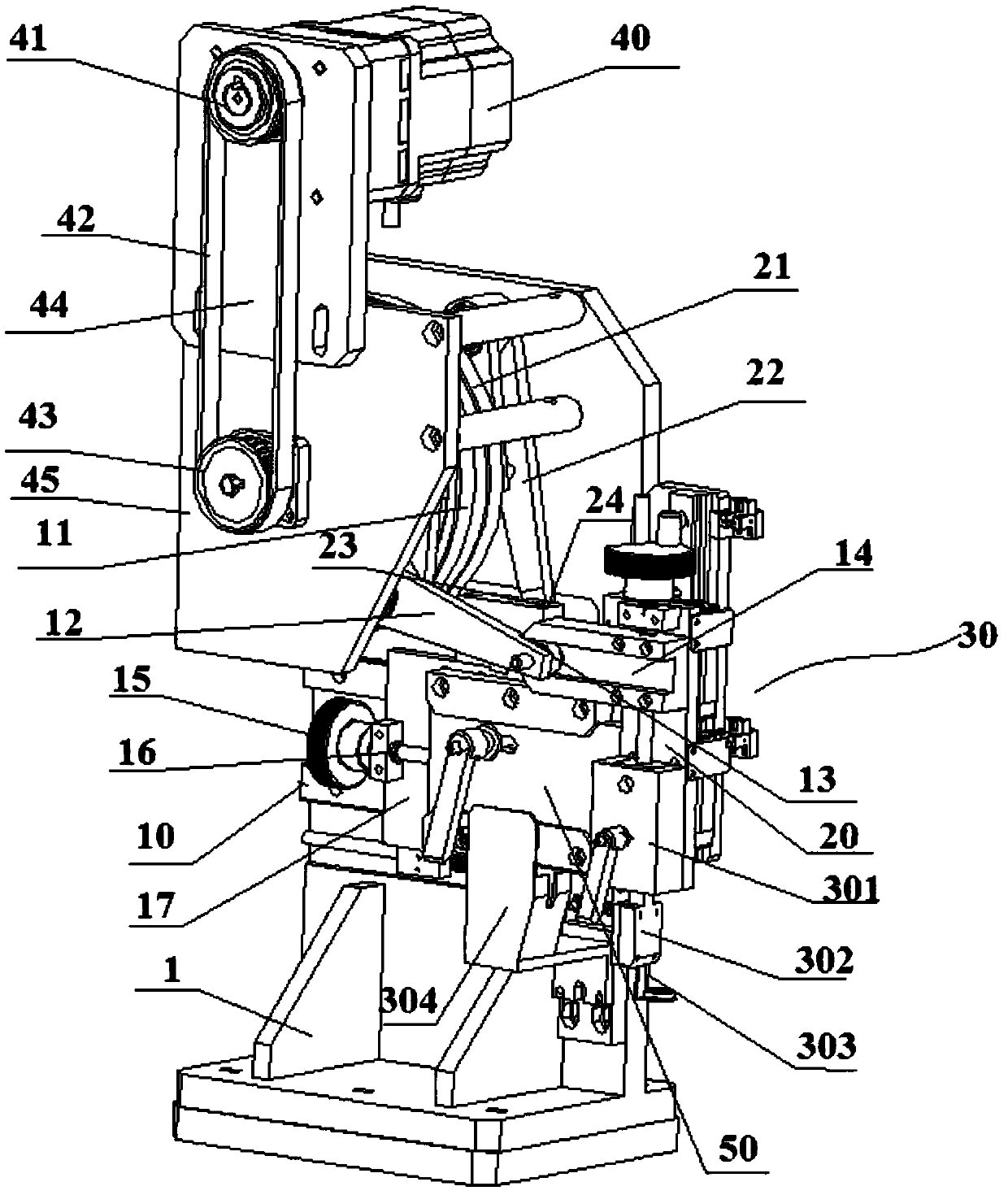

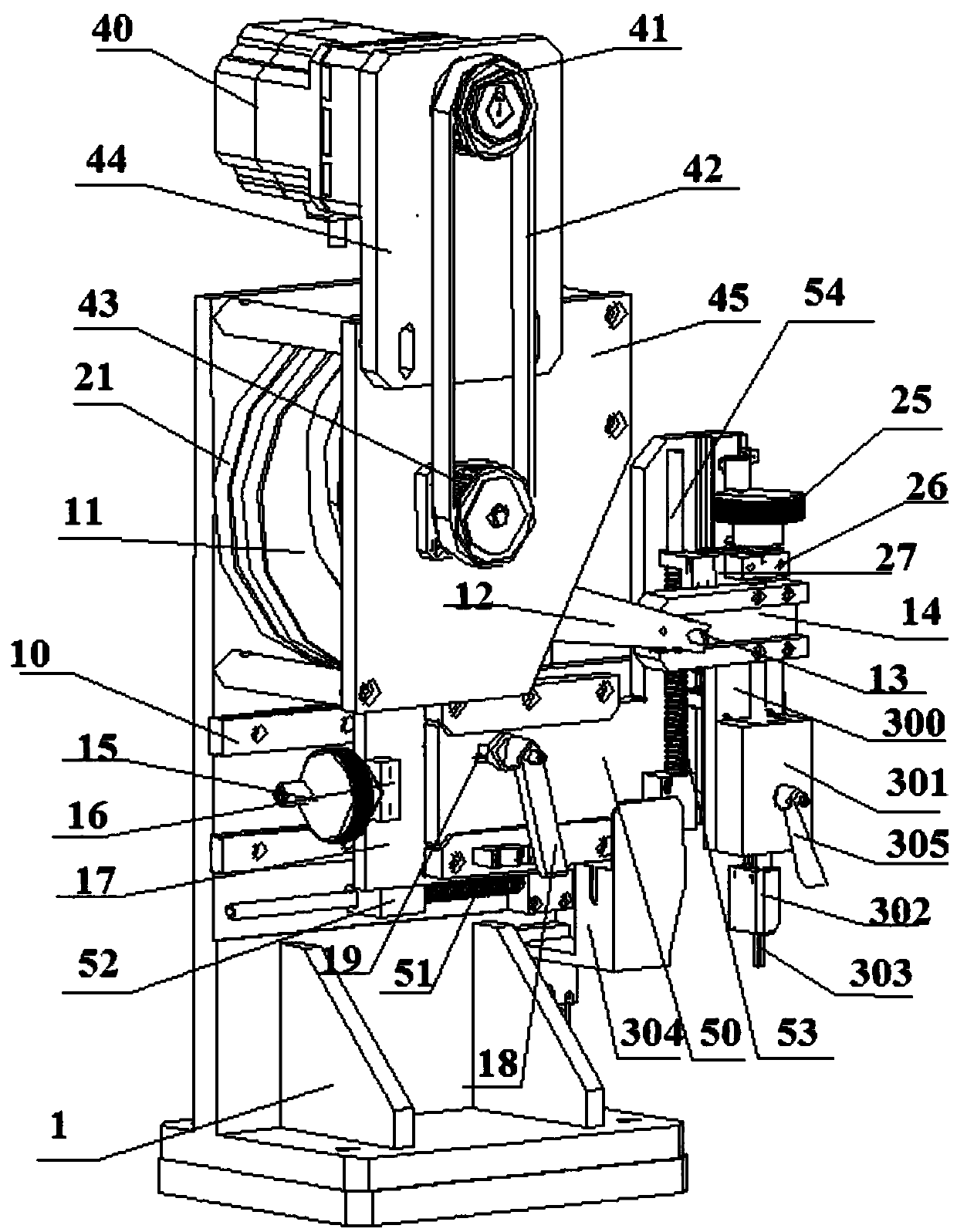

Grinding and edge cutting device of composite material

ActiveCN103042459ATrim stableThe cutting speed of the trimming mechanism is stabilized by the machine feedGrinding drivesGrinding machinesNumerical controlGear wheel

A grinding and edge cutting device of a composite material is composed of a casing connection part, a casing part, a power input part, a motion transformation part and a tool part. The casing connection part is located at the top of the device, the casing part is connected with a machine tool spindle casing through the casing connection part, the power input part is located between a machine tool spindle and a casing upper end cover, three transmission shafts of the motion transformation part are installed in the casing part through bearings, an input gear shaft of the motion transformation part is connected with the power input part through a coupling, output ends of two output gear shafts are used for being connected with a tool part and driving two tools to perform opposite rotation motion of the same size, and the tool part is located below a casing and fixed on two output gear shafts of the motion transformation part through a group of compression nuts. The grinding and edge cutting device of the composite material can be connected with a numerical control machine tool directly and is light and compact in structure, cutting grinding disks can rotate at the same speed synchronously, and accurate outline cutting can be performed on the upper surface and the lower surface of a carbon fiber reinforced composite material.

Owner:BEIHANG UNIV +1

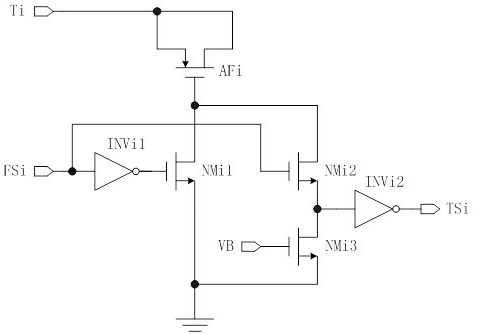

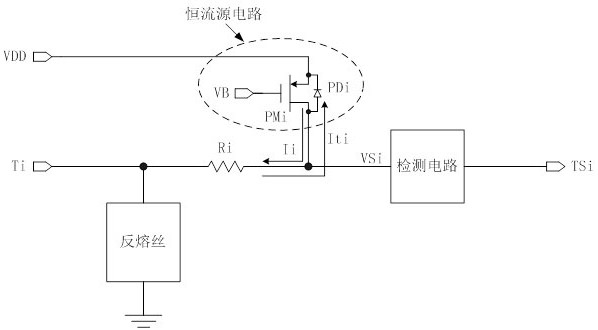

Chip peripheral anti-fuse pre-trimming circuit and trimming method thereof

ActiveCN112702055AShorten the adjustment timeSimplify the preconditioning processInput/output impedence modificationElectric variable regulationAlgorithmFuse (electrical)

The invention relates to a chip peripheral anti-fuse pre-trimming circuit and a trimming method thereof. The trimming method comprises the following steps: calculating a rough pre-trimming value by using a formula according to an electrical parameter initial value and an electrical parameter target value which are tested before melting, and converting to obtain a rough pre-trimmed anti-fuse combination; according to the rough pre-trimming anti-fuse combination, carrying out the rough virtual fusion burning on the anti-fuse, and testing a rough electrical parameter value; calculating a pre-trimming value deviation by using the designed trimming step length of the electrical parameter, the rough electrical parameter value and the electrical parameter target value; determining an accurate pre-trimming range according to the pre-trimming value deviation, performing virtual fusion burning on the anti-fuse according to each anti-fuse trimming combination in the accurate pre-trimming range, testing a corresponding electrical parameter pre-trimming value, and obtaining an accurate anti-fuse combination when the tested electrical parameter value is closest to a target value under a certain anti-fuse combination; carrying out fusion burning on the antifuse according to the precise antifuse combination, and testing and verifying whether an error between the final value and the target value of the electrical parameter meets the requirement or not.

Owner:QX MICRO DEVICES

Plate shearing machine with trimming device

PendingCN109175485AEasy to follow upGuaranteed stabilityEdge grinding machinesShearing machinesMotor driveDrive motor

The invention discloses a plate shearing machine with a trimming device in the technical field of plate shearing machines. The plate shearing machine comprises a base. An upper blade is arranged at the bottom of a buffering rod. A bearing plate is arranged above the top of the base. A shearing carrying plate is arranged on the top of the bearing plate. Shearing grooves matched with the upper bladeare evenly and longitudinally formed in the top of the shearing carrying plate. Rotating discs are arranged on the left side and the right side of the top of the bearing plate. A panel and a supporting plate are sequentially and fixedly arranged on the outer wall of the inner side of each supporting plate from top to bottom. A trimming device is arranged on the top of the base. After the plate shearing machine conducts plate shearing, a first servo motor is controlled to drive a drive gear to rotate so that the two sets of rotating discs can rotate forwards by 90 degrees from the interior, the sheared edge of a plate workpiece corresponds to a frosting disc, during trimming, a second servo motor drives a screw rod to rotate forwards and backwards, a movable block then moves left and rightin a transverse sliding groove, meanwhile, a drive motor drives the frosting disc to rotate and move left and right to conduct trimming, and the shearing quality of the plate workpiece is ensured.

Owner:NANTONG KANGHAI MACHINERY

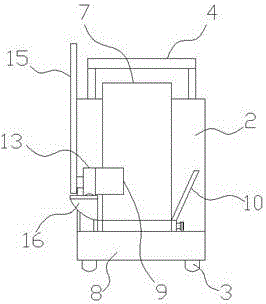

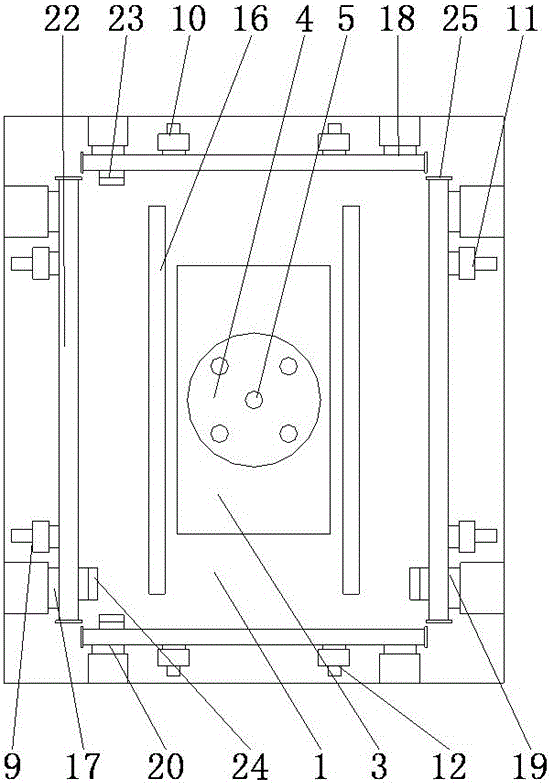

Edge trimming method for packaging barrel

ActiveCN106735477AGuaranteed to proceed normallyAvoid damageMilling equipment detailsPositioning apparatusEngineeringDrive shaft

The invention discloses an edge trimming device for a packaging barrel. The edge trimming device comprises a base, a fixed die installed on the base, a movable die detachably connected to the fixed die and an edge trimming mechanism arranged above the movable die; baffles are fixed to the periphery of the fixed die, a plurality of air blowing pipes are arranged on the baffles, a chip groove is formed in the movable die, and air openings of the air blowing pipes face the chip groove so that chippings can be blown into the chip groove; and arc-shaped grooves matched with the air blowing pipes are installed on the baffles, one end of each air blowing pipe penetrates the corresponding arc-shaped groove, the other end of each air blowing pipe is connected to a driving shaft of a positive and negative motor so that the air blowing pipes can move in the arc-shaped directions of the arc-shaped grooves, and planes formed by the two ends points of the arc-shaped grooves and the circle centers of the arc-shaped grooves are parallel to the horizontal face. By means of the edge trimming device, an operator is prevented from being hurt in the edge trimming process, and the edge trimming efficiency can be improved.

Owner:芜湖立创包装有限公司

Edge cutting mechanism for airbrushed fabric

ActiveCN104960966AImprove trimming efficiencyImprove trimming qualityUnfolding thin materialsArticle deliveryMotor driveEngineering

The invention discloses an edge cutting mechanism for airbrushed fabric, and belongs to the field of advertisement processing mechanical equipment. The edge cutting mechanism comprises a main support, an unfolding roller, a transmission motor, a fabric sending roller, an edge cutting mechanism and a material guiding mechanism; the unfolding roller rotates horizontally to be connected to the upper side of the main support, the transmission motor drives the unfolding roller, the fabric sending roller rotates horizontally to be connected to the lower side of the main support, and the edge cutting mechanism is arranged on the main support horizontally; the edge cutting mechanism comprises an edge cutting roller and a fabric bearing roller which rotate horizontally to be connected to the main support respectively, two sides of the edge cutting roller are provided with edge cutting knives respectively and symmetrically, and two sides of the fabric bearing roller are provided with limiting knife grooves matched with the edge cutting knives respectively and symmetrically; the material guiding mechanism comprises translation rods and material guiding pipes, two sides of the translation rods are horizontally provided with translation sleeves matched with the translation rods respectively, and the material guiding pipes are arranged on one sides of the translation sleeves. According to the edge cutting mechanism, the structure is simple, transmission and edge cutting can be rapidly, efficiently and conveniently carried out on the airbrushed fabric, and requirements for producing and machining are met.

Owner:徐州辰耀针织有限公司

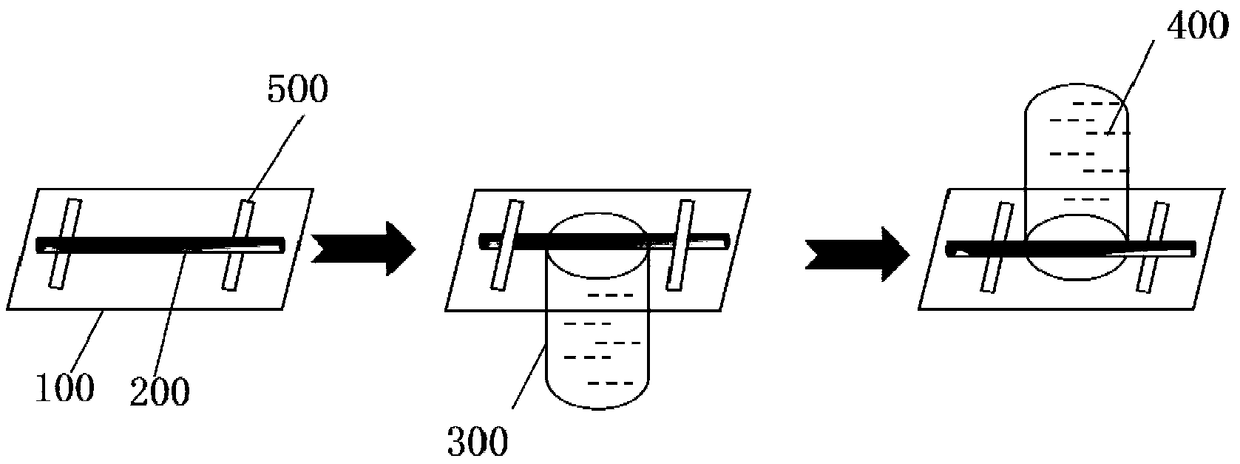

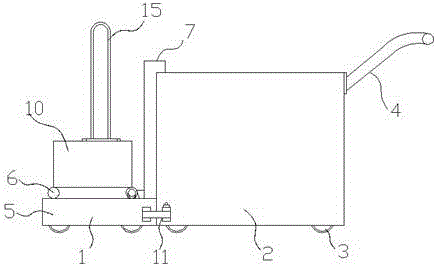

Trimming device for packaging barrel

ActiveCN106583814AAvoid damageSave human resourcesMilling equipment detailsPositioning apparatusMilling cutterEngineering

The invention discloses a trimming device for a packaging barrel. The trimming device comprises a base (1), a fixed die (2) installed on the base (1), a movable die (3) connected to the fixed die (2), and a trimming mechanism arranged above the movable die (3); the movable die (3) is provided with a notch (4) matched with the packaging barrel; a motor is connected to a milling cutter (6); a positioning mechanism comprises a plurality of positioning rods (11) installed on the movable die (3), and movable rods (12) connected to the positioning rods (11) in a threaded mode; the movable rods (12) are vertically arranged, and the bottom ends of the movable rods (12) are provided with positioning blocks (13); each positioning rod (11) comprises a first-section rod body vertically installed on the movable die (3) and a second-section rod body perpendicularly connected to the first-section rod body; and the movable rods (12) are connected to the second-section rod bodies in a threaded mode. By means of the trimming device, operators can be prevented from being injured in the trimming process, and meanwhile, the trimming efficiency can be improved.

Owner:芜湖立创包装有限公司

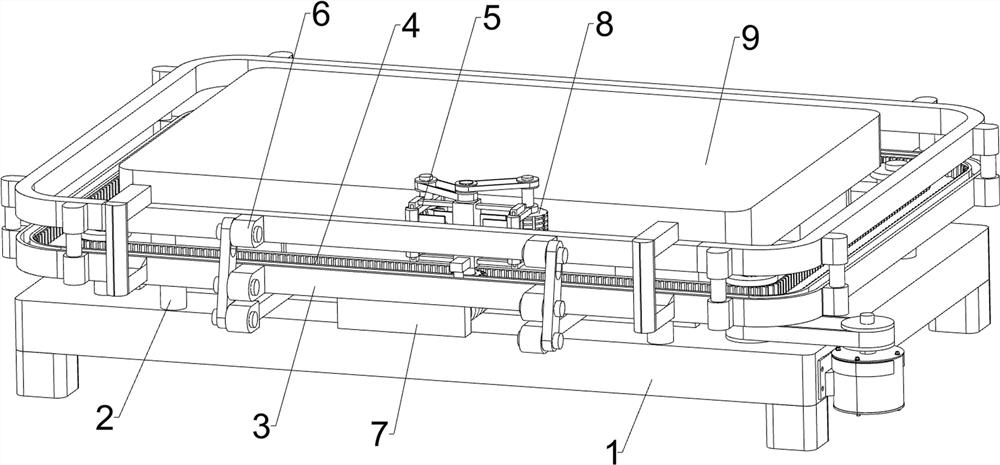

Oddment cutting table for plastic products

The invention discloses an oddment cutting table for plastic products, and belongs to the technical field of oddment cutting equipment for plastic products. The oddment cutting table comprises a cutting table board, a support, a fixing plate and the like. The plastic products are clamped and limited through an upper limiting plate and a lower limiting plate, and the positions of the plastic products are stable, so that the opening trimming precision is improved, the inner walls of openings of the plastic products are consistent and uniform, the quality consistency of final products is effectively ensured, and operation is convenient; and the diameters of a plurality of rotary rings are different, so that the oddment cutting table is suitable for plastic products with different opening diameters, and the application range of the oddment cutting table for the plastic products is widened; the position of a supporting plate is fixed, so that the opening trimming precision of the plastic products is further ensured; and a motor works to drive the rotary rings to rotate, a cutting knife rotates accordingly to completely scrap oddments on the inner walls of the openings of the plastic products. The oddment cutting table for the plastic products can replace manual operation to complete opening trimming work; and meanwhile, the opening trimming precision is high, and the quality consistency of the products is effectively ensured.

Owner:嘉善中佳电路板有限公司

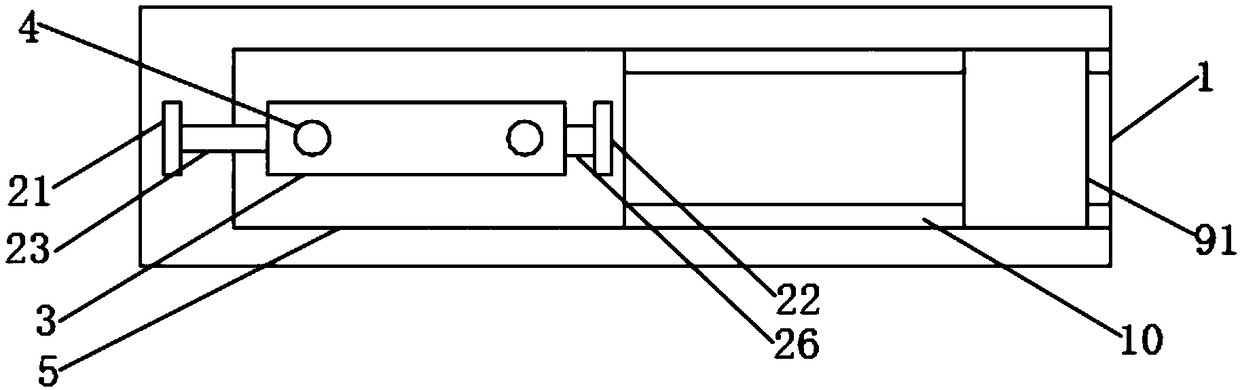

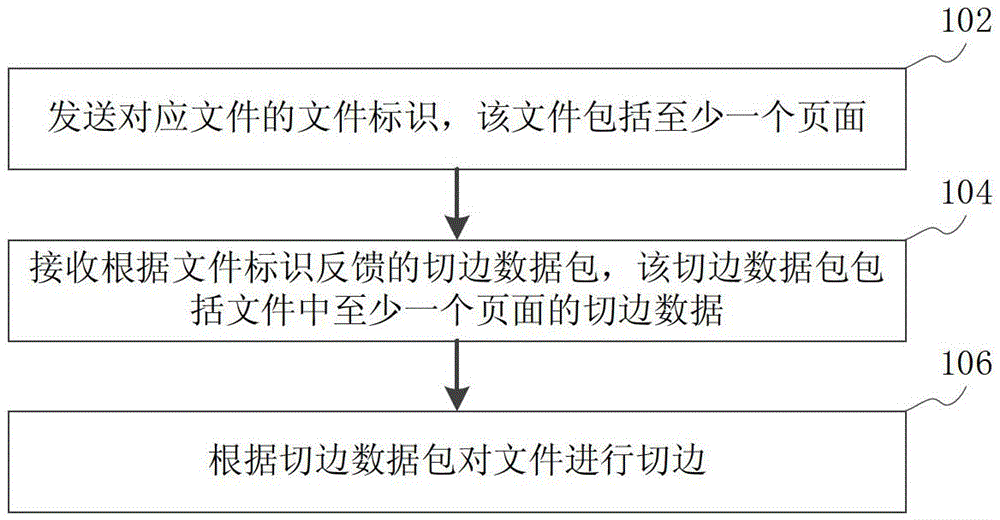

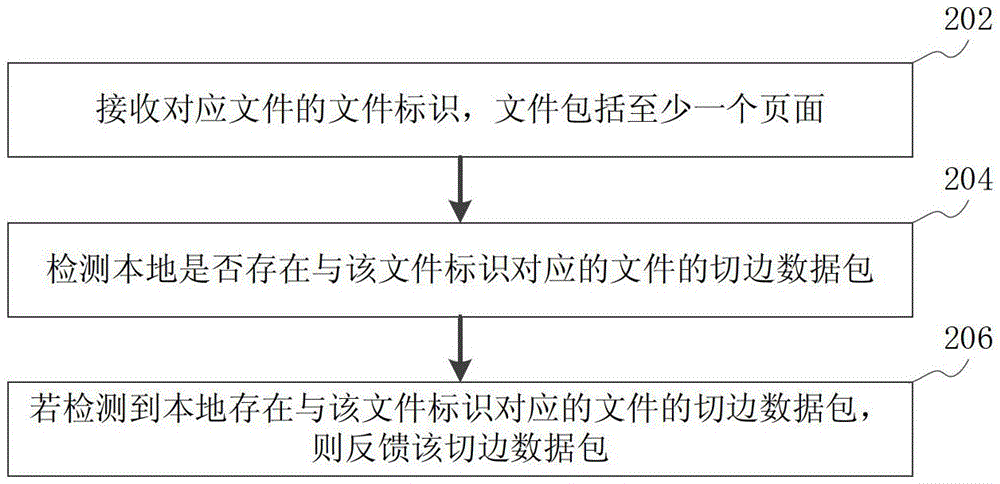

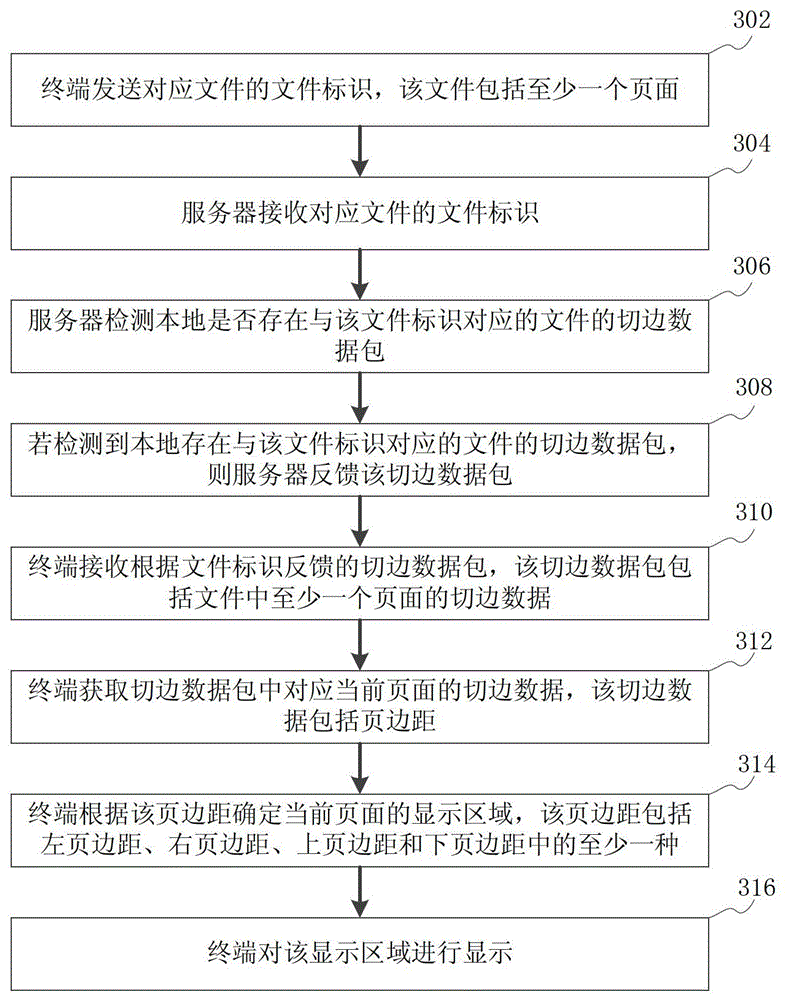

File trimming method, terminal and server

ActiveCN103150291AImprove trimming efficiencySolve the problem that takes up a lot of resourcesText processingSpecial data processing applicationsElectronic documentDigital document

The invention discloses a file trimming method, a terminal and a server, and belongs to the technical field of computers, particularly relates to the field of electronic document display. The file trimming method comprises the following steps of sending a file identification of a corresponding file, wherein the file comprises at least one page; receiving a trimming data package which is fed back by the file identification, wherein the trimming data package comprises trimming data of at least one page in the file; and trimming the file according to the trimming data package. The terminal comprises a first sending module, a receiving module and a trimming module. The server comprises a third receiving module, a first detection module and a feedback module. The file trimming method, the terminal and the server solve the problem that a large amount of resources are occupied by trimming the file due to the fact that a trimming area of each page in the file needs to be detected in real time according to an algorithm, and achieve the effect that the trimming efficiency of the file is improved.

Owner:XIAOMI INC

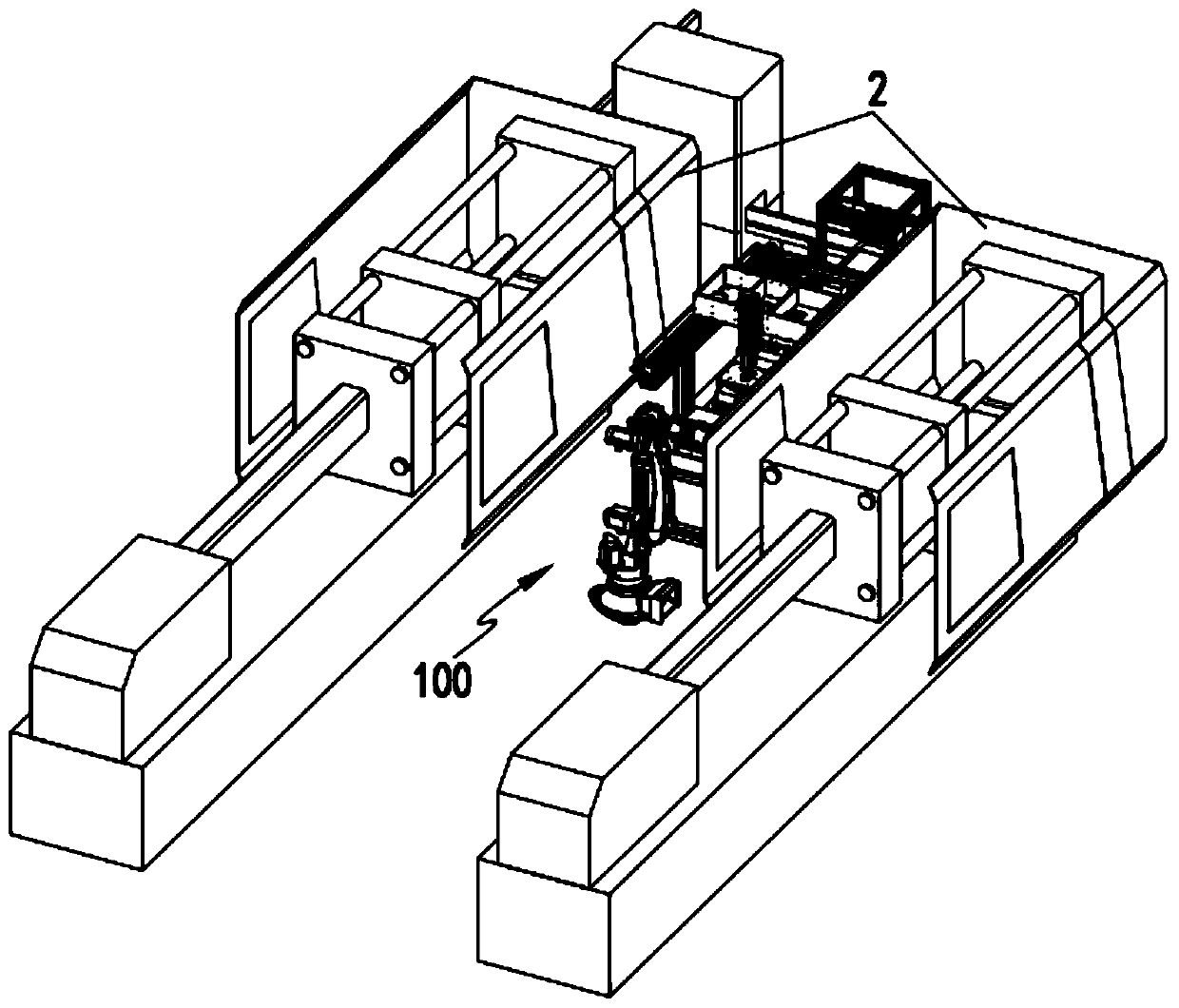

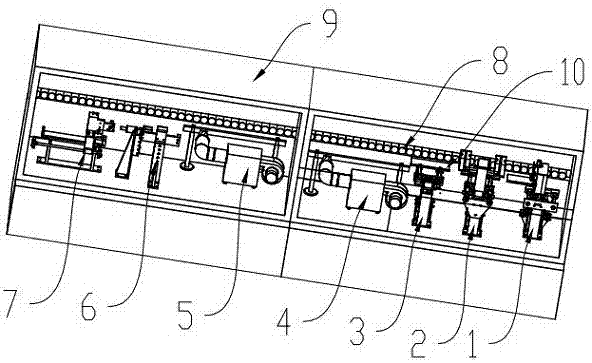

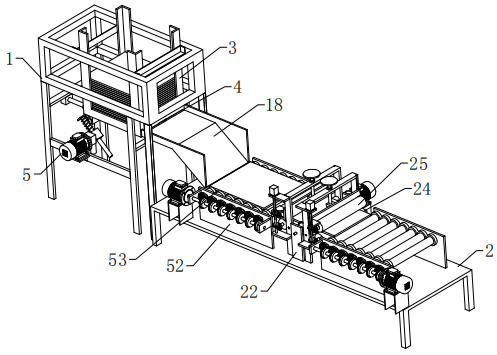

Automatic battery box production equipment

PendingCN110014456AQuality assuranceGuaranteed flatnessSortingMetal working apparatusAfter treatmentEngineering

The invention relates to automatic battery box production equipment which comprises an injection molding machine for automatically injection molding battery boxes, a battery box after-treatment processing line and a manipulator. The battery boxes molded on the injection molding machine are taken out to the battery box after-treatment processing line through the manipulator, so that the operationscomprising automatically trimming opening edge parts, detecting internal air-tightness and removing wastes are carried out sequentially; and according to the after-treatment processing line, the battery boxes trimmed at a trimming station are transferred to a detection station through a transferring mechanism, and meanwhile, the battery boxes detected at a detecting station are transferred to a rejecting station. The automatic battery box production equipment provided by the invention solves the problems that in the battery box production process, equipment does not have automatic trimming, detecting and waste removing functions and is poor in trimming and detecting reliability, and the batter box quality is hard to ensure.

Owner:德玛克(浙江)精工科技有限公司

Automatic plate trimming machine

InactiveCN107009480ARealize follow-up trimmingGuaranteed accuracyLiquid surface applicatorsProfiling/shaping machinesVertical edgeEngineering

The invention discloses an automatic plate trimming machine. The automatic plate trimming machine comprises a frame; the frame is provided with a pressing wheel set for providing the feeding power to plates; the pressing wheel set clamps the plates; and in a plate feeding direction, the frame is provided with upper and lower edge chamfering modules, an upper angle painting module, a lower angle painting module, an upper drying module, a lower drying module, a front vertical edge chamfering module and a back vertical edge chamfering module in sequence. The automatic plate trimming machine can realize machining of transverse and vertical edges of the plates, meanwhile, is provided with automatic painting and drying machining modules to form trimming equipment with higher automation degree, and has such characteristics as high machining precision and simple operation.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

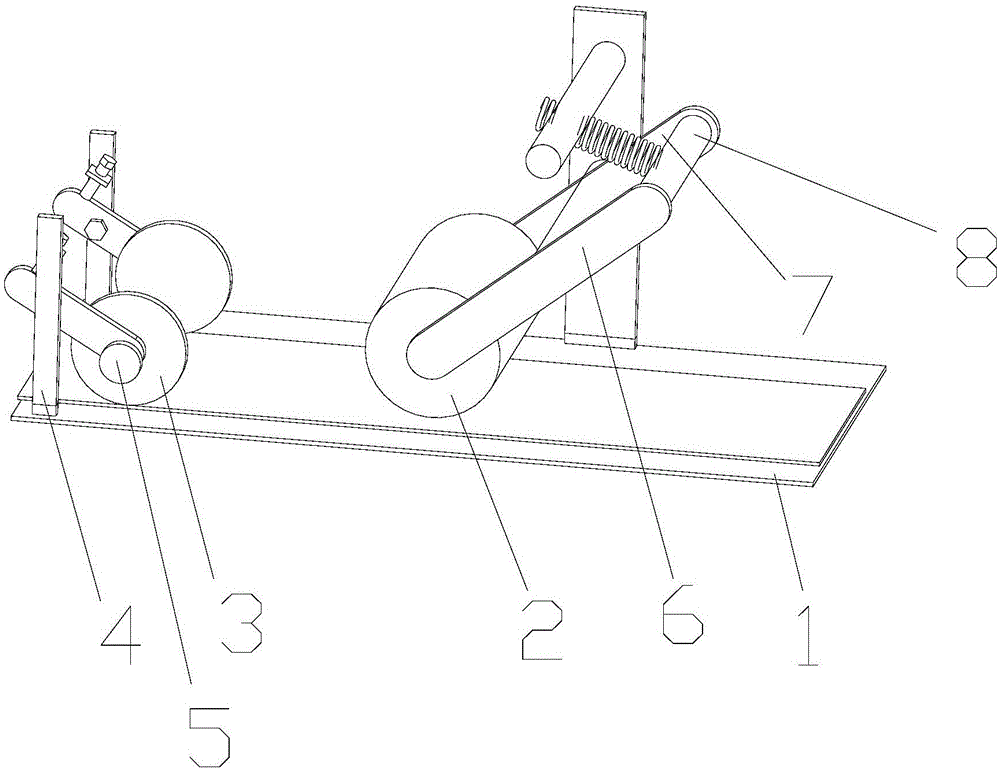

Edge cutting device for rubber conveyor belt

PendingCN107775698AEasy to useImprove trimming efficiencyMetal working apparatusEngineeringDrive motor

The invention discloses an edge cutting device for a rubber conveyor belt, and aims at solving the problems of time and force waste, low edge cutting efficiency and low edge cutting quality in manualedge cutting. The device comprises a base, a conveyor belt conveying mechanism, a swinging mechanism, an adjusting mechanism and a cutting mechanism, wherein two swinging rods of the swinging mechanism are correspondingly symmetrically hinged with two ends of the base; two oil cylinder bodies are hinged with two ends of the base and are corresponding to the two swinging rods; piston rods of the oil cylinders are correspondingly hinged with swinging ends of the two swinging rods; two ends of a slide rail of the adjusting mechanism are correspondingly fixed to the two swinging rods; two slidingblocks are correspondingly arranged on the slide blocks in a sliding mode; two disc shaped cutters of the cutting mechanism are correspondingly assembled to output shafts of two driving motors which are correspondingly fixedly connected to the sliding blocks. According to the device, the disc shaped cutters are driven through the driving motors to cut an edge of a conveyor belt blank; the edge cutting efficiency is high, and the edge cutting quality is high; the swinging rods are driven to swing through the oil cylinders so as to lift or lower down the disc-shaped cutters.

Owner:山东通泰橡胶股份有限公司

Automatic edge cutting equipment for microcrystalline plate

InactiveCN112209606AWon't hurtCause damageGlass severing apparatusGlass productionFeed driveAgricultural engineering

The invention relates to the technical field of microcrystalline plate processing, in particular to an automatic edge cutting equipment for a microcrystalline plate. The equipment comprises a feedingsupport, a cutting table, a feed driving mechanism, a feed moving mechanism and an edge cutting mechanism, wherein the feeding support and the cutting table are distributed in parallel, a rectangularfeeding basket is arranged on the feeding support, the feed driving mechanism is arranged on the feeding support, the feed moving opening is formed in the lower end, close to the cutting table, of therectangular feeding basket and used for conveying a microcrystalline plate in the rectangular feeding basket to the cutting table, the feed moving mechanism at least comprises two feed moving assemblies, the two feed moving assemblies are arranged on the cutting table in parallel in a spaced mode, the edge cutting mechanism comprises a feed cutting assembly and at least two feed guiding assemblies, the feed cutting assembly is located between the two feed moving assemblies, and the two feed guiding assemblies are arranged on the two sides of the feed cutting assembly. According to the automatic edge cutting equipment, automatic feeding can be achieved, edge cutting efficiency is high, vibration is small, damage to the microcrystal plate is avoided, the microcrystal plate is smooth and tidy after an outer edge is cut off, and production efficiency and production precision are improved.

Owner:石小凡

Window film edge cutting machine with adjustable cutter body

ActiveCN106695911AEasy to moveImprove trimming efficiencyMetal working apparatusArticle deliveryEngineeringLeather belt

The invention discloses a window film edge cutting machine with an adjustable cutter body. The window film edge cutting machine comprises a rack and a rotating assembly. The rotating assembly comprises a front fixing rod, a rear fixing rod and middle fixing rods, and the front fixing rod and the rear fixing rod are connected through the two middle fixing rods; two motors are arranged below the front fixing rod, each motor is connected with a front rotating shaft through a belt, and the corresponding front rotating shaft is connected with a rear rotating shaft through a conveyor belt. The rotating assembly furthermore comprises a cutting assembly; and the cutting assembly comprises a handle, the handle is connected with a driving belt wheel, the driving belt wheel is connected with a driven belt wheel through a synchronous belt, the driving belt wheel and the driven belt wheel are both connected with a screw rod, the screw rod penetrates through vertical rods, and the tops of the vertical rods are provided with a transverse rod. Existing window film edge cutting equipment is designed and improved, window films are transported by the motors and the conveyor belts, deviation of the window films is corrected by a deviation correcting device, edges are cut by the cutter body with the position capable of being adjusted manually, and window film edge cutting efficiency can be improved.

Owner:苏州威仕薄膜科技有限公司

Garden shrub trimming device

InactiveCN106212069AImprove flatnessImprove trimming efficiencyCuttersCutting implementsElectric machineryShrub

The invention relates to a garden shrub trimming device. The garden shrub trimming device includes a trimming device and a collection device. The trimming device includes a base; a conveying device, a lifting mechanism and a fixing seat are arranged on the base; a discharge end of the conveying device communicates with a feeding opening of the lifting mechanism; a first driving device is arranged in the base; the conveying device and the lifting device are connected to the first driving device through a drive mechanism; the fixing seat is arranged at one side of the conveying device, and a first baffle plate is arranged at one side away from the fixing seat, of the conveying device; the upper end of the fixing seat is rotatably connected to a motor installation plate through a rotation mechanism; a second driving device is fixed at one side near the conveying device, of the motor installation plate; and an output shaft of the second driving device passes through the motor installation plate and is connected to a trimming saw blade. The garden shrub trimming device can greatly improve the flatness of shrub trimming and improve the efficiency of shrub trimming; and in addition, workers do not have to clean shrub branches after trimming, and great convenience is brought to garden maintenance workers.

Owner:皖建生态环境建设有限公司

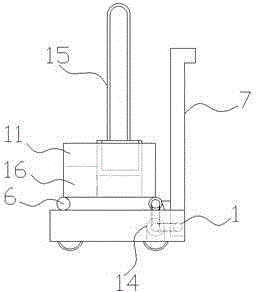

Edge cutting device

InactiveCN105058065AImprove trimming efficiencyOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses an edge cutting device. The edge cutting device comprises a bottom plate, a supporting frame, two rolling wheels and a flattening mechanism. The supporting frame is fixedly connected to the upper portion of the bottom plate, a groove matching a metal strap is formed in the bottom plate, and the groove extends from one end to the other end in the direction of a long edge of the bottom plate. The two rolling wheels are both mounted on the supporting frame, and clearances capable of allowing the metal strap to pass are formed by the rolling wheels and the groove faces, adjacent to two side edges in the sliding direction of the metal strap, in the groove respectively. The peripheries of the rolling wheels are fixedly connected with cutters, and the edges of the cutters face the metal strap. The flattening mechanism is arranged on the rear side, opposite to the rolling wheels, of the bottom plate, and the side face of a pressing wheel of the flattening mechanism is in close contact with the metal strap to flatten the metal strap. The edge cutting device is high in edge cutting efficiency, burrs of the metal strap can be reduced, and the defective rate of the metal strap can be lowered.

Owner:ANHUI JIANGWEI PRECISION IND

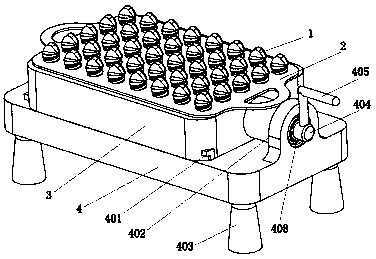

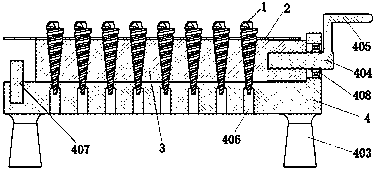

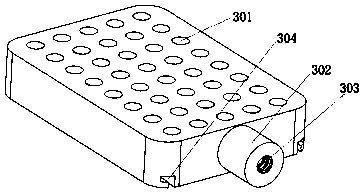

Turritella tail cutting device

ActiveCN108782717AImprove trimming efficiencyRealize the function of cutting tailShellfish processingKitchen utensilsPulp and paper industry

The invention relates to a turritella tail cutting device, and belongs to the technical field of kitchen utensils. The turritella tail cutting device comprises a turritella fixing device and a supporting frame, wherein two sliding rails are arranged on the upper surface of the supporting frame; four supporting feet are arranged on the lower surface of the supporting frame; a limiting pin fixing hole is formed in the left side of the supporting frame; waste material holes which are regularly arrayed are formed in the middle part of the supporting frame; a bearing seat is arranged on the right side of the supporting frame; a bearing is arranged in the bearing seat; a screw rod is mounted in the bearing; a rotating handle is arranged at the tail end of the screw rod; sliding grooves are formed in two sides of the lower surface of the turritella tail cutting device; turritella fixing holes which are regularly arrayed are formed in the middle part of the turritella tail cutting device; anda limiting block is arranged on the right side of the turritella tail cutting device. The turritella tail cutting device disclosed by the invention is convenient, swift, safe and labor-saving, so thatthe turritella tail cutting efficiency is improved; turritella tails can be cut in batch; through rotation of the rotating handle, the turritella fixing device slides to the leftmost end to be in contact with a limiting needle, and the turritella tails can be cut off; the cut-off turritella tails can drop out from the waste material holes; and then turritella can be taken out through taking up ofthe supporting plate, so that the function of tail cutting of the turritella is realized.

Owner:徐超

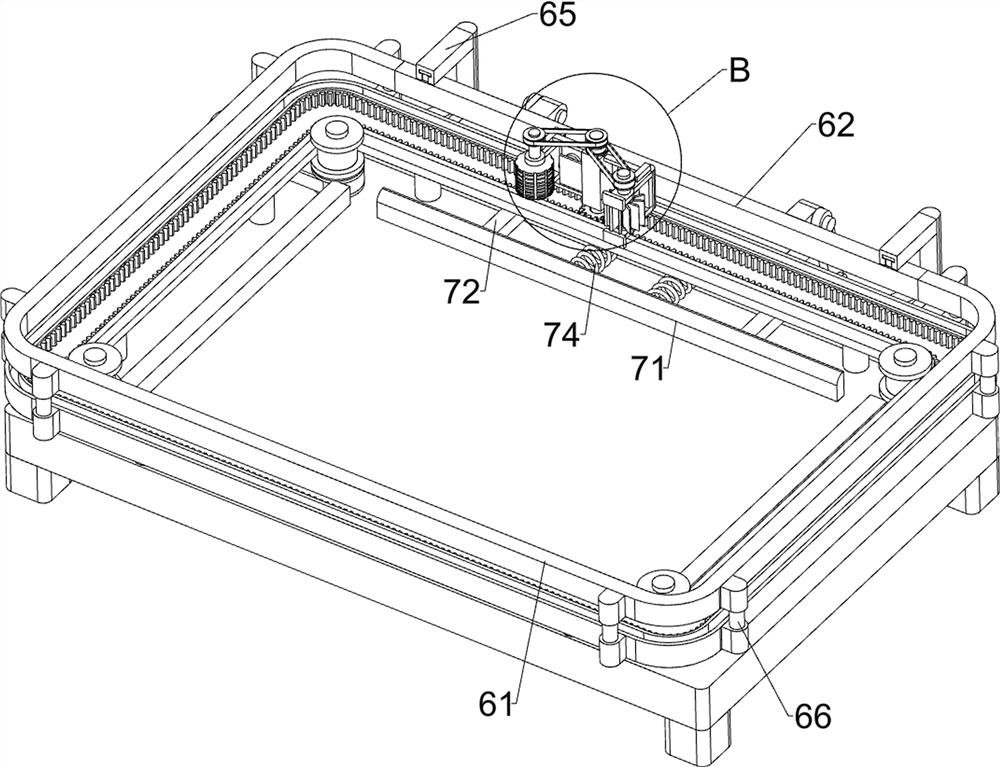

Omnibearing trimming device for blow molding tray

InactiveCN112265039AImprove trimming efficiencyReduce labor intensityEdge grinding machinesMetal working apparatusBlow moldingSupport plane

The invention relates to a trimming device, in particular to an omnibearing trimming device for a blow molding tray. According to the omnibearing trimming device for the blow molding tray, manual trimming is not needed, and the trimming efficiency can be improved. The omnibearing trimming device for the blow molding tray comprises a base, a guide rail frame, a moving method, a cutting mechanism, aguide frame mechanism and a triggering structure, wherein a plurality of supporting frames are connected to the upper outer side of the base; the guide rail frame is connected between the support frames; the moving mechanism is mounted between the base and the guide rail frame; the cutting mechanism is mounted on the moving mechanism; the guide rail frame is provided with the movable guide framemechanism; and the triggering structure is mounted on the guide rail frame. The movable guide frame mechanism can be triggered to work through the trigger structure, the movable guide frame mechanismcan work to enable the cutting mechanism to be tightly attached to the blow molding tray, the blow molding tray can be trimmed through cooperation of the moving mechanism and the cutting mechanism, manual trimming is not needed, the trimming efficiency can be improved, and labor intensity can be reduced.

Owner:王剑

Trimming device based on cam structure

ActiveCN105500417AConsistent thicknessGuarantee the quality of glue cuttingMetal working apparatusMotor driveEngineering

The invention discloses a trimming device based on a cam structure. The trimming device comprises a motor, the motor drives a rotary shaft to rotate, an X-axis cam and a Z-axis cam are arranged on the rotary shaft, the X-axis cam is connected with an X-axis connecting rod, and the end of the X-axis connecting rod is connected with a first cam driven bearing. The first cam driven bearing moves in an X-axis sliding groove, and a groove plate with the X-axis sliding groove is fixed to a cutter assembly. The Z-axis cam is connected with a Z-axis connecting rod, a second cam driven bearing is arranged at the end of the Z-axis connecting rod, the second cam driven bearing slides in a Z-axis sliding groove, and a groove plate with the Z-axis sliding groove is fixed to the cutter assembly. When the motor drives the rotary shaft to drive the X-axis cam and the Z-axis cam to rotate at the same time, the cutter assembly is moved in place in the X-axis direction and the Z-axis direction through the cooperation of the X-axis cam and the Z-axis cam, and then trimming is carried out through a cutter. The trimming device is simple in structure, reasonable in design, high in trimming efficiency and small in occupied space.

Owner:SUZHOU HYH AUTOMATION EQUIP CO LTD

Photovoltaic assembly trimming device

ActiveCN106737921AWork fasterImprove trimming efficiencyMetal working apparatusHydraulic cylinderEngineering

The invention discloses a photovoltaic assembly trimming device which comprises a workbench. An installation groove is formed in the middle of the workbench. A bottom hydraulic cylinder installation seat is arranged at the bottom of the installation groove. The upper side of a bottom electric hydraulic cylinder is connected with a supporting frame through a piston. Vacuum suction cups are arranged on the supporting frame. A vacuum pump is arranged on the lower right side of the workbench. Photovoltaic assembly conveying belts are arranged on the two sides of the installation groove. A left side trimming device is arranged on the upper side of a left side positioning device. A rear side trimming device is arranged on the upper side of a rear side positioning device. A right side trimming device is arranged on the upper side of a right side positioning device. A front side trimming device is arranged on the upper side of a front side positioning device. The photovoltaic assembly trimming device is novel in structure, by arranging four sets of trimming tools, EVA trimming removal can be conducted on the four edges of a photovoltaic assembly at the same time, and the trimming efficiency of the photovoltaic assembly is improved; and meanwhile, the positioning devices are arranged, photovoltaic assemblies of different dimensions can be positioned, the sizes of the photovoltaic assemblies can be judged, the dimension requirements of the different photovoltaic assemblies can be met, and the working speed of trimming is increased.

Owner:礼德新能源江苏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com