Turritella tail cutting device

A cone screw and fixing device technology, applied in the field of kitchen utensils, can solve the problems of low work efficiency, low efficiency, affecting the business of merchants, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

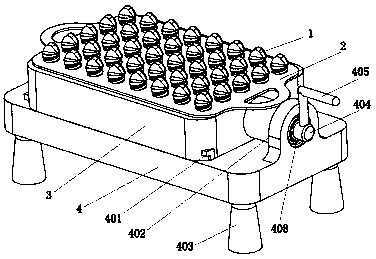

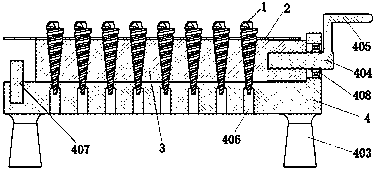

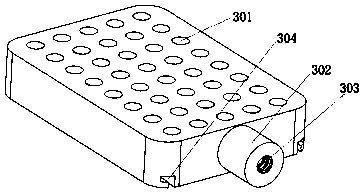

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0023] Such as Figures 1 to 5 As shown, a taper screw tail cutting device includes a taper screw fixing device 3, a supporting plate 2 and a support frame 4, the upper surface of the support frame 4 is provided with two slide rails 401, and the lower surface is provided with 4 support feet 403, the left side is provided with a limit pin fixing hole for installing a limit pin 407, the middle part is provided with regularly arranged waste holes 406, and the right side is provided with a bearing seat 402; said bearing seat 402 is provided with a bearing 408, said A screw mandrel 404 is installed in the bearing 408, and two snap rings are installed in the screw mandrel 404...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com