Omnibearing trimming device for blow molding tray

An all-round, trimming technology, applied in machine tools, grinding machines, metal processing and other directions suitable for grinding the edge of workpieces, can solve the problems of low trimming efficiency, etc., to improve trimming efficiency, smooth outer wall, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

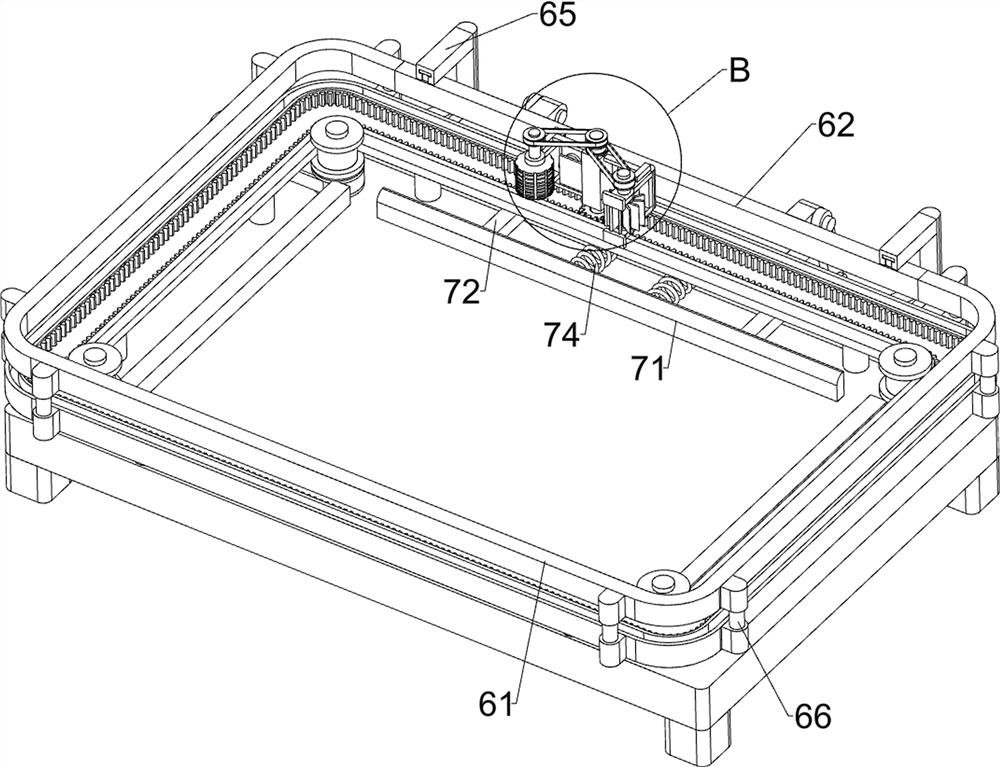

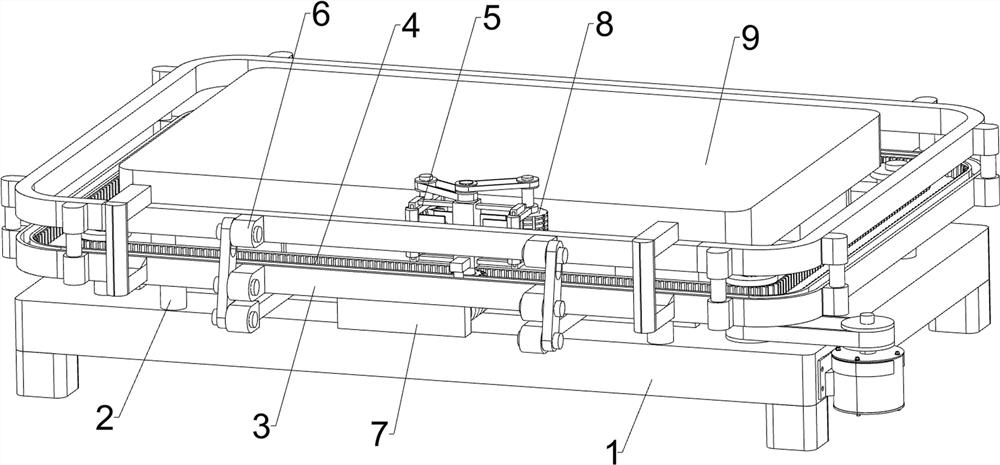

[0024] An all-round edge trimming device for a blow molding tray, such as Figure 1 to Figure 5 As shown, it includes a base 1, a support frame 2, a rail frame 3, a moving mechanism 4, a cutting mechanism 5, a movable guide frame mechanism 6, and a trigger structure 7. A plurality of support frames 2 are connected to the outside of the top of the base 1, and a plurality of support frames 2 is connected with a guide rail frame 3, a moving mechanism 4 is installed between the base 1 and the guide rail frame 3, a cutting mechanism 5 is installed on the moving mechanism 4, and a movable guide frame mechanism 6 and a triggering structure are respectively installed on the guide rail frame 3 7.

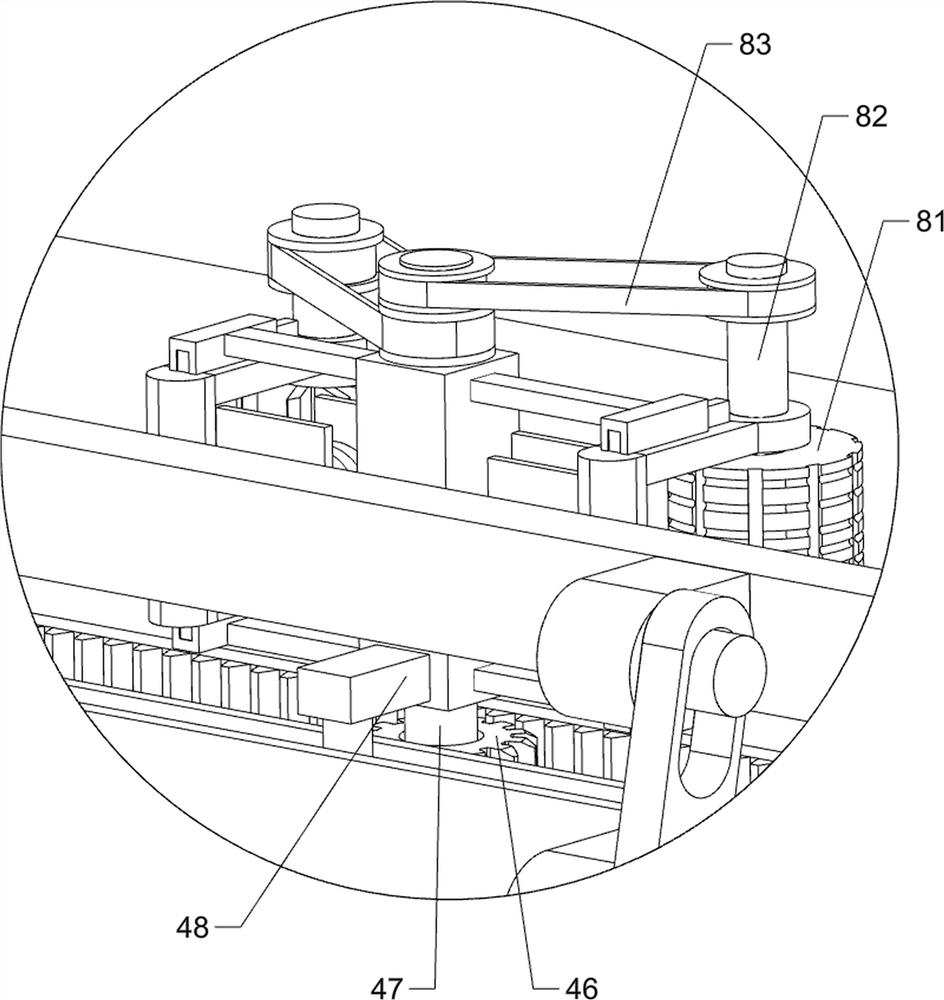

[0025] The moving mechanism 4 includes a servo motor 41, the first transmission belt set 42, a pulley 43, a rack belt 44, a fixed rack 45, a transmission gear 46, a transmission shaft 47 and a positioning frame 48, and a servo motor is installed on the front side of the right side of the bas...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 4As shown, also includes grinding mechanism 8, and grinding mechanism 8 includes grinding wheel 81, connecting shaft 82 and the 3rd transmission belt group 83, and right side sliding installation frame 52 rear parts are connected with connecting shaft 82 in rotation, on connecting shaft 82 A grinding wheel 81 is connected, and a third transmission belt set 83 is connected between the connecting shaft 82 and the transmission shaft 47 .

[0032] The transmission shaft 47 rotates through the third transmission belt set 83 to make the connecting shaft 82 rotate, and the connecting shaft 82 rotates to drive the grinding wheel 81 to rotate. The rotation of the grinding wheel 81 can polish the periphery of the blow molding tray 9, making the outer wall of the blow molding tray 9 smoother .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com