Trimming device based on cam structure

A cam and trimming technology, applied in metal processing and other directions, can solve the problems of inconsistent trimming thickness, reduced cutter efficiency, and large space occupied, so as to ensure the quality of cutting glue, improve trimming efficiency, and take up less space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

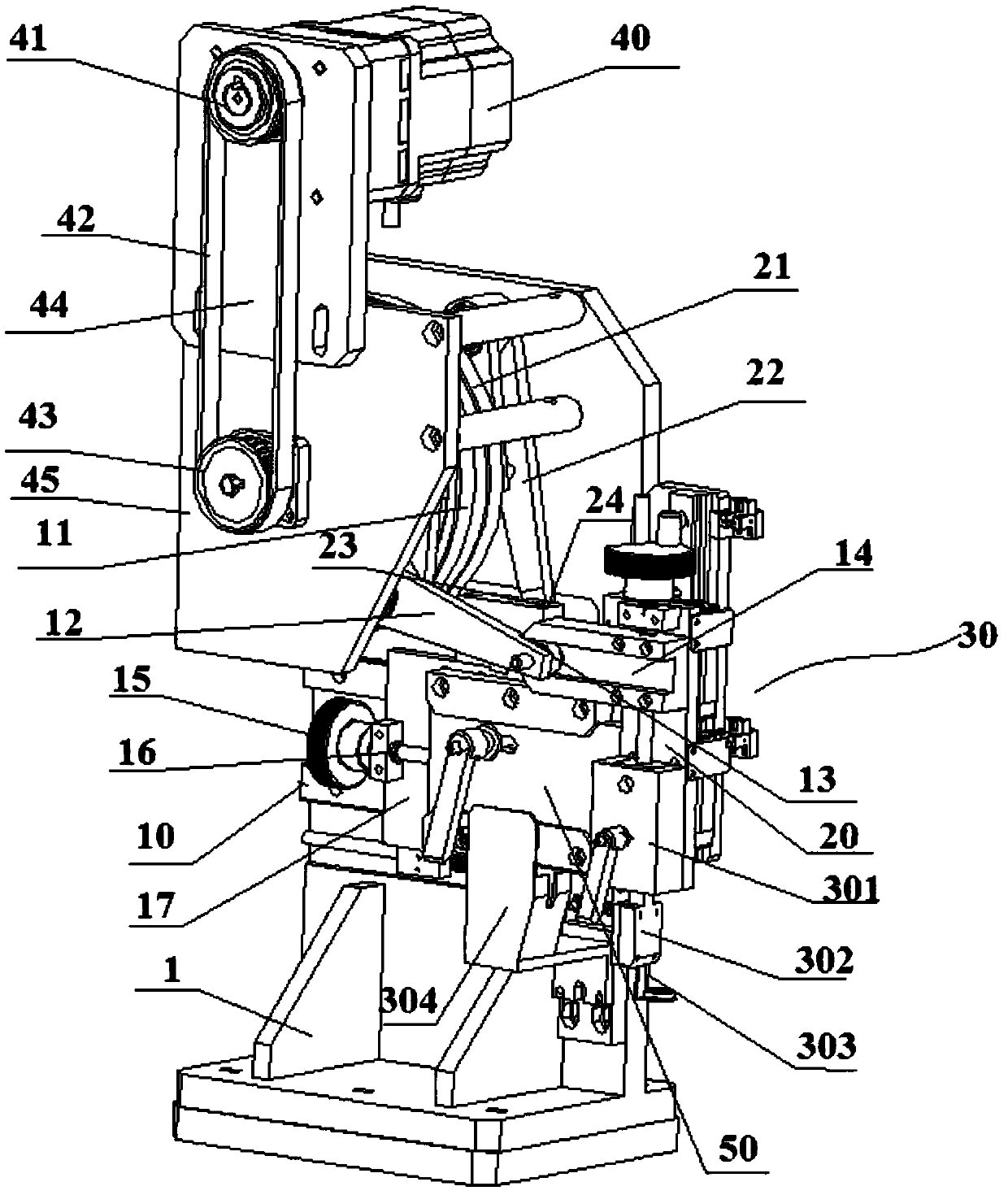

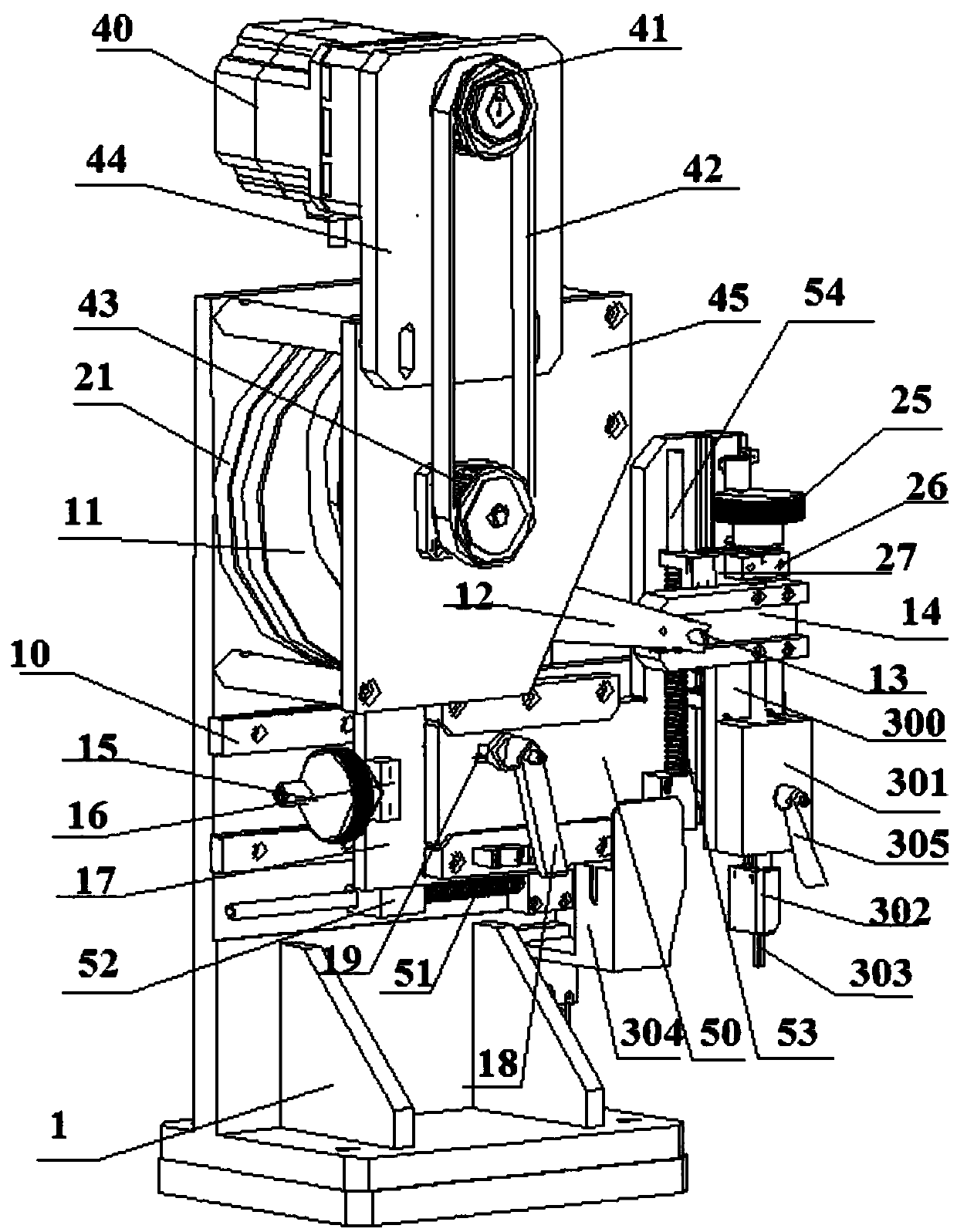

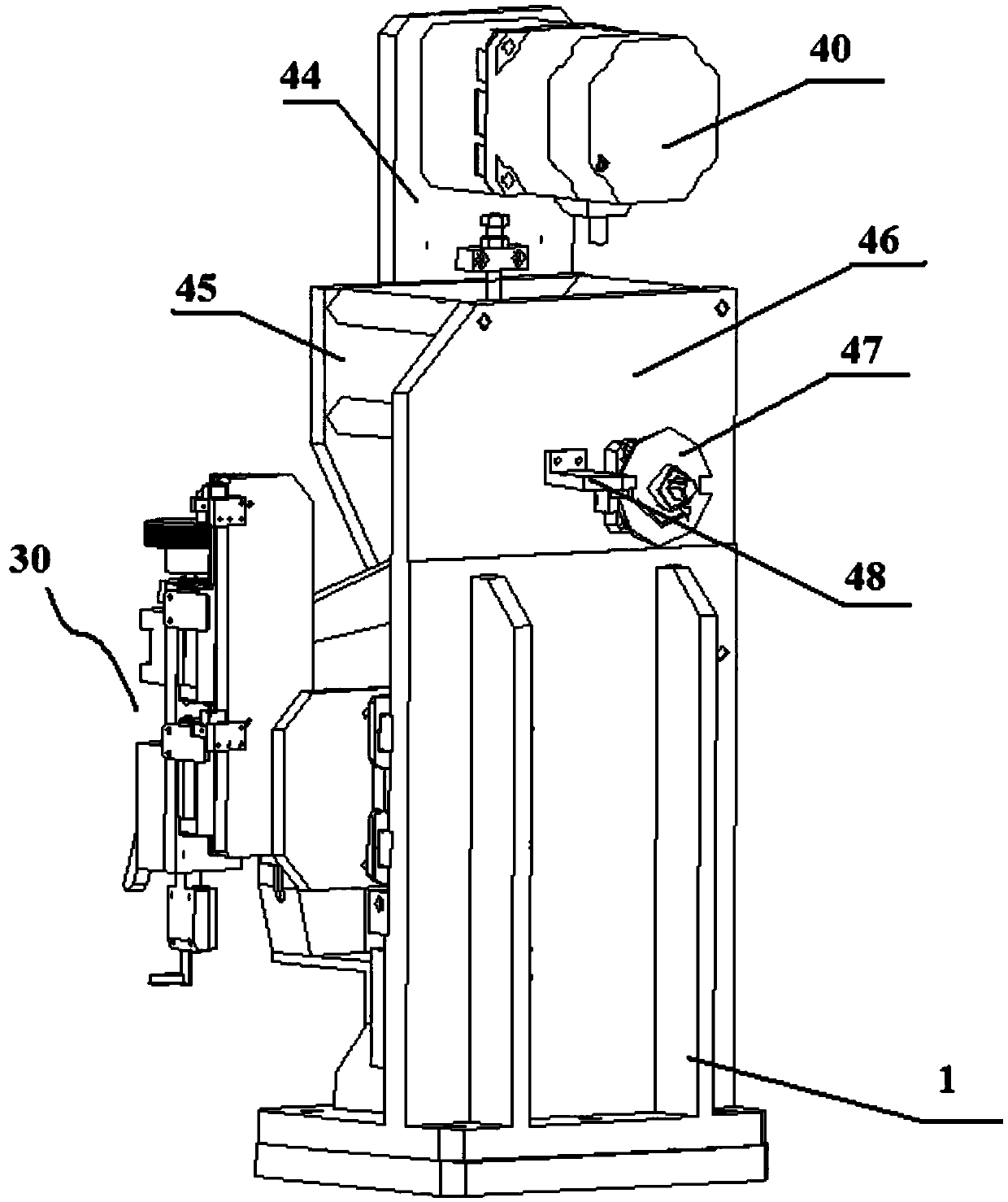

[0027] like Figure 1-3 As shown, this embodiment discloses a trimming device based on a cam structure, which mainly includes: a base assembly 1, an X-axis slide rail 10 and a Z-axis slide rail 20 arranged on the base assembly 1, and a The cutter assembly 30 moves in the X-axis direction along the X-axis slide rail 10 , and the cutter assembly 30 can move in the Z-axis direction along the Z-axis slide rail 20 . In this embodiment, the above-mentioned X-axis direction is a horizontal direction, and the above-mentioned Z-axis direction is a vertical direction.

[0028] The drive unit of above-mentioned trimming device is motor 40, and above-mentioned motor 40 has speed reducer, and the output shaft of above-mentioned speed reducer is sleeved on the driving wheel 41, and above-mentioned driving wheel 41 drives a synchronous wheel 43 to rotate by synchronous belt 42, and above-mentioned synchronous The wheel 43 is connected to the above-mentioned rotating shaft, and the X-axis ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com