Embedding method of fiber-shaped sample for axial ultrathin slice

An ultra-thin section, fibrous technology, applied in the field of ultra-thin section, can solve problems such as accurate positioning, achieve the effect of improving the success rate, improving the efficiency of later trimming and the success rate of slicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

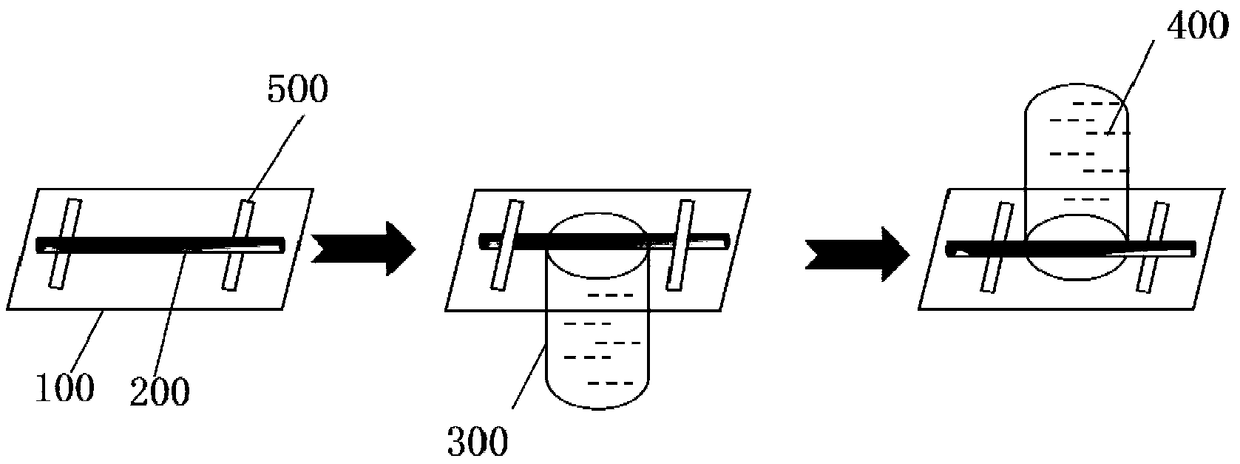

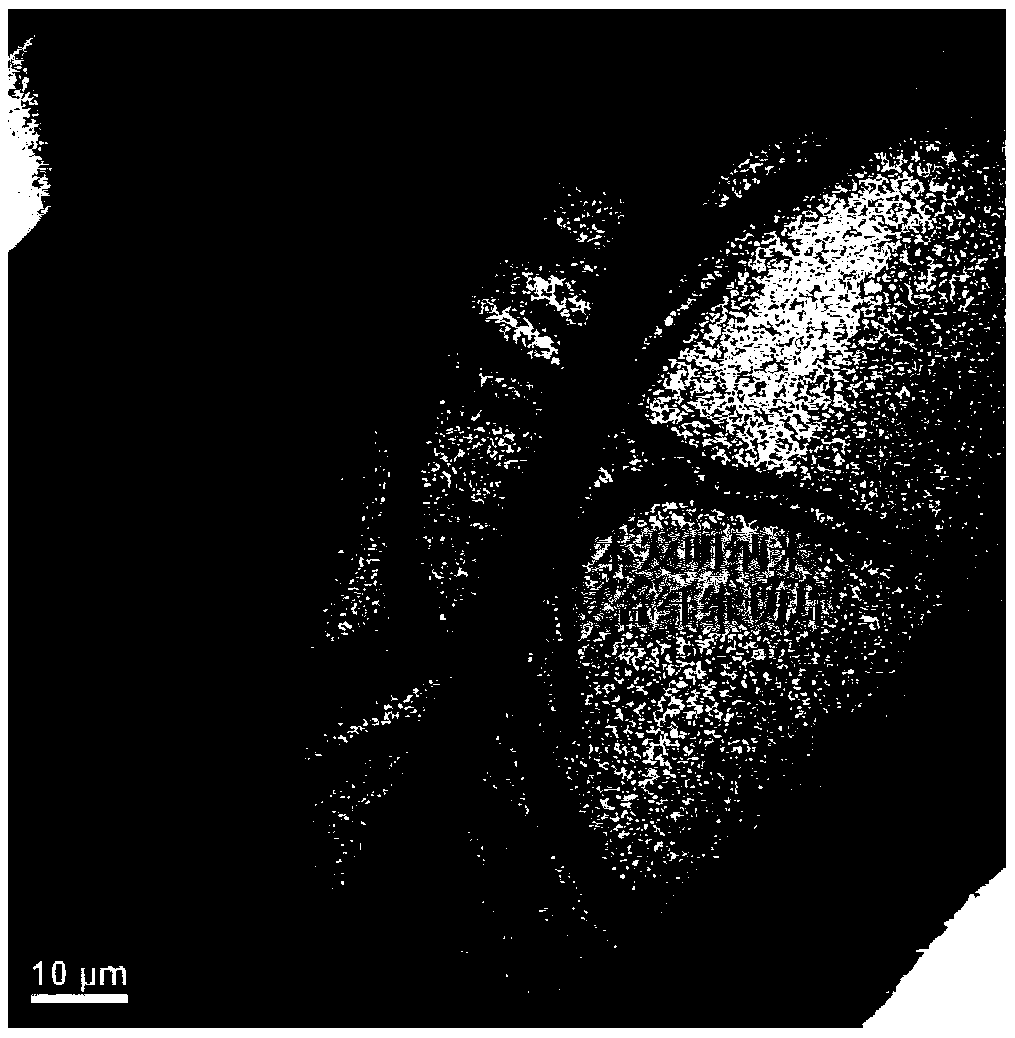

[0052] This embodiment involves using the embedding method of the present application to embed colorless and transparent PET nanocomposite fibers, and then perform ultrathin sectioning and high-resolution TEM photography.

[0053] The embedding method of the fibrous sample that is used for the axial ultrathin section of the present invention comprises the following steps: first, on a piece of clean glass slide, several colorless and transparent PET nanocomposite fibers (diameter is 5mm) ~15 microns) fixed, the PET nano-composite fiber is straightened as far as possible to be linear; then the embedding agent epoxy resin Epon812 is filled in the embedding mold opening plastic capsule until the liquid level of the liquid embedding agent is in line with the opening The upper surface of the container is flush, and air bubbles should be avoided in the sample area during this process; finally, the glass slide fixed with the PET nanocomposite fiber is buckled on the top of the open pla...

Embodiment 2

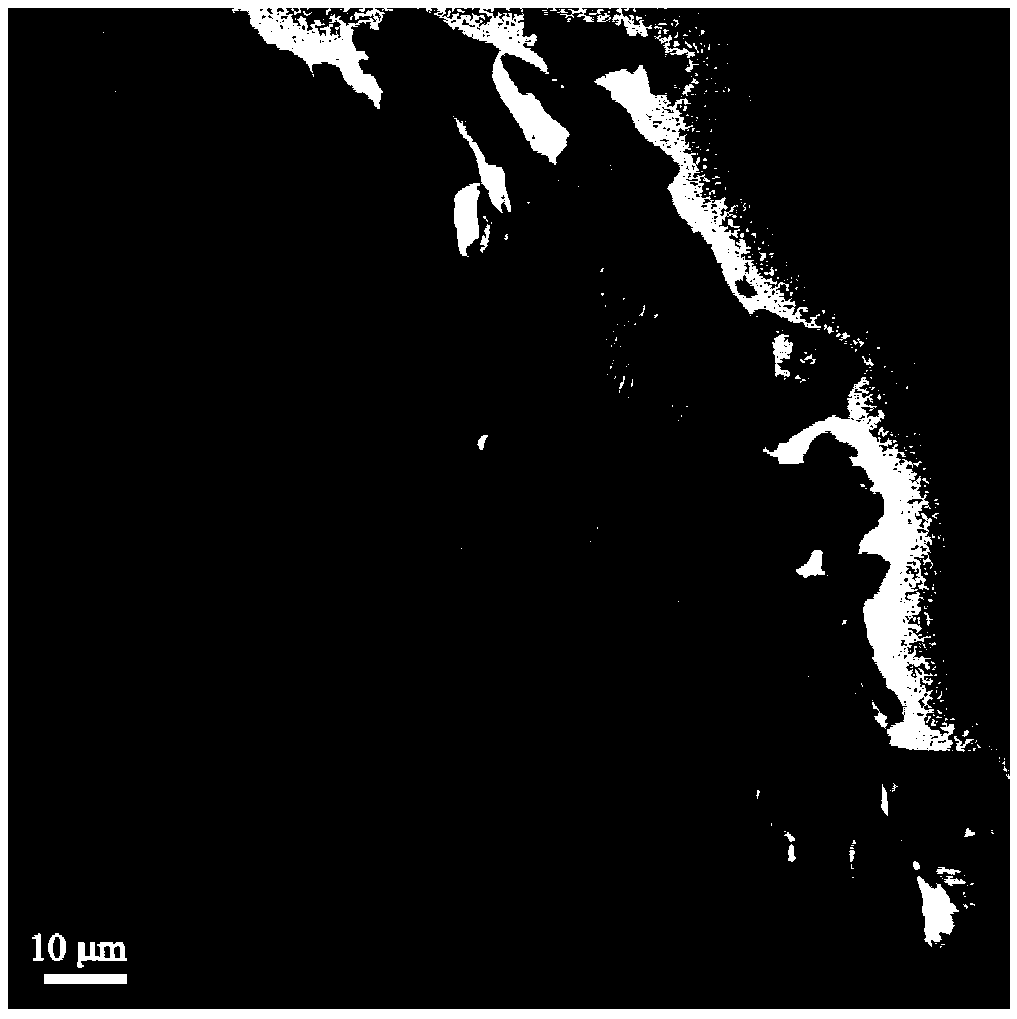

[0056] This embodiment involves embedding hair with the embedding method of the present application, and then performing ultrathin sectioning and high-resolution TEM photography.

[0057] The embedding method of the fibrous sample that is used for axial ultrathin section of the present invention comprises the following steps: at first, hair (diameter 80~90 microns) is fixed with double-sided tape on a piece of clean slide glass, and hair is pulled as far as possible. Straight without bending, 3 to 4 hairs can be arranged in parallel for fixation; then fill the embedding agent epoxy resin Epon812 in the embedding mold opening plastic capsule until the liquid level of the liquid embedding agent meets the open container During this process, air bubbles should be avoided as much as possible in the sample area; finally, the glass slide with the hair fixed is buckled on the top of the open plastic capsule, so that the surface of the glass slide with the hair fixed faces the open plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com