Patents

Literature

634 results about "Thin section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In optical mineralogy and petrography, a thin section (or petrographic thin section) is a laboratory preparation of a rock, mineral, soil, pottery, bones, or even metal sample for use with a polarizing petrographic microscope, electron microscope and electron microprobe. A thin sliver of rock is cut from the sample with a diamond saw and ground optically flat. It is then mounted on a glass slide and then ground smooth using progressively finer abrasive grit until the sample is only 30 μm thick. The method involved using the Michel-Lévy interference colour chart. Typically quartz is used as the gauge to determine thickness as it is one of the most abundant minerals.

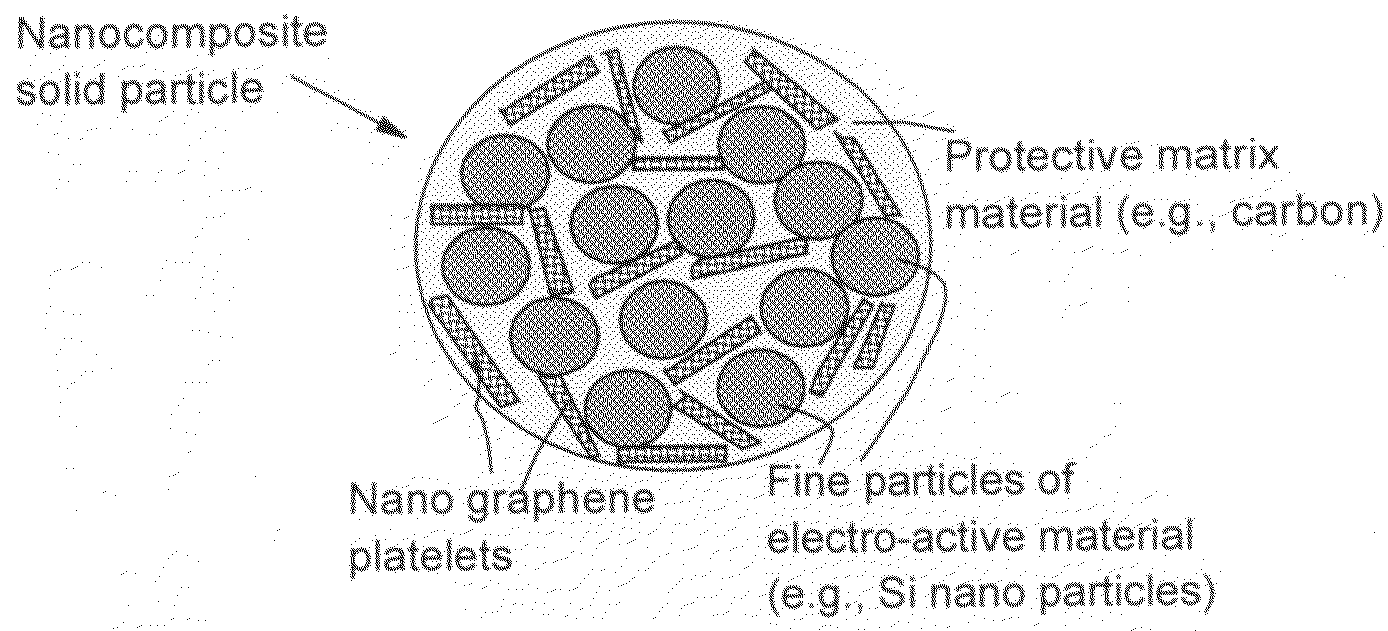

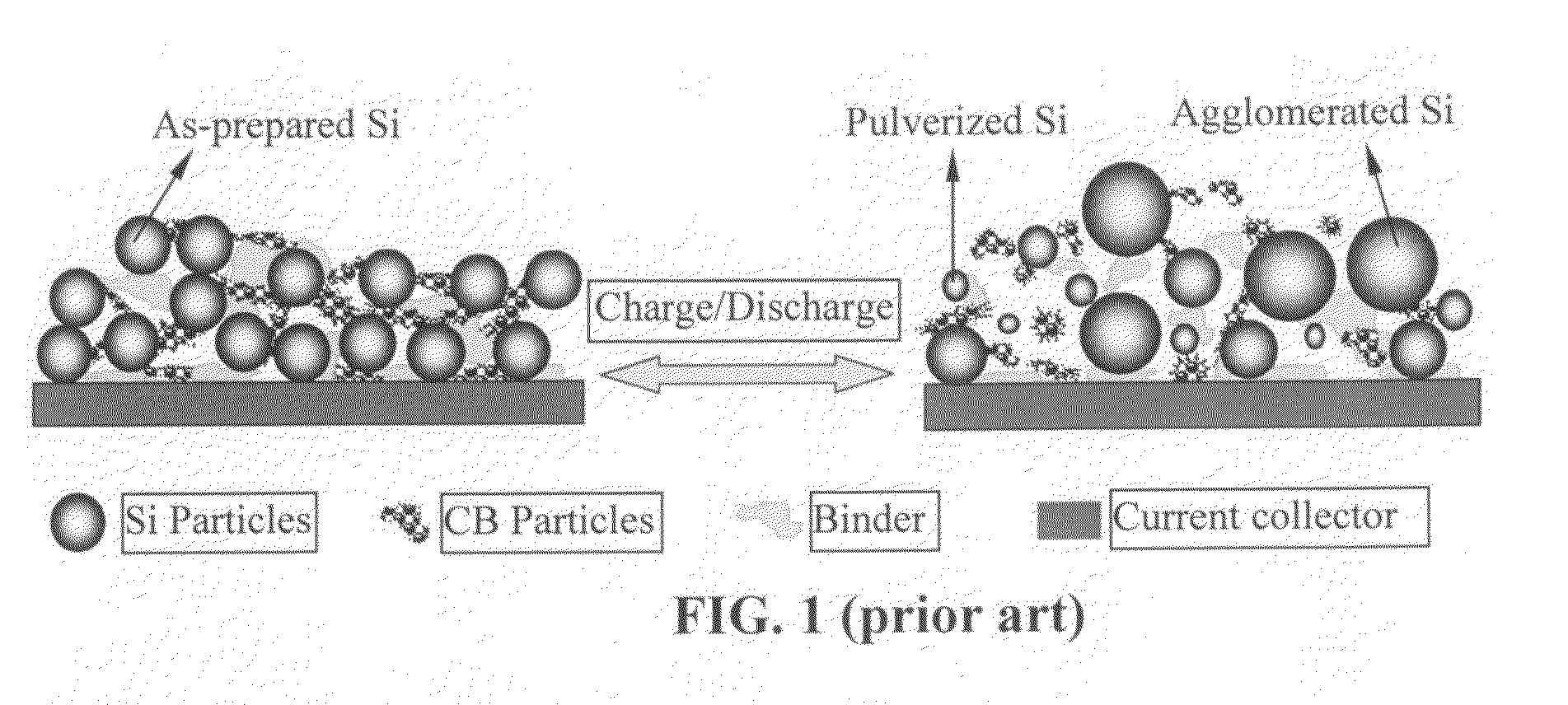

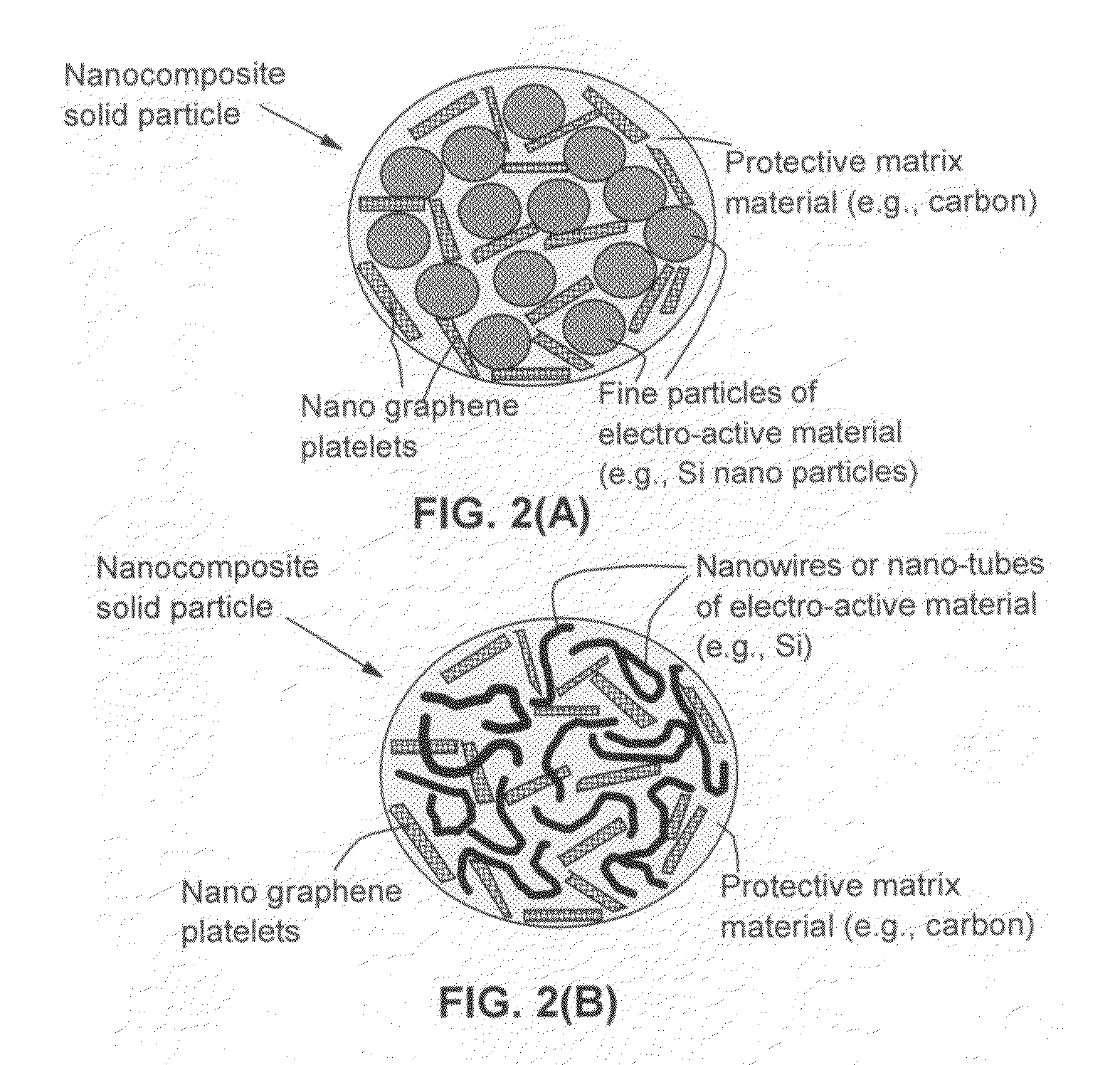

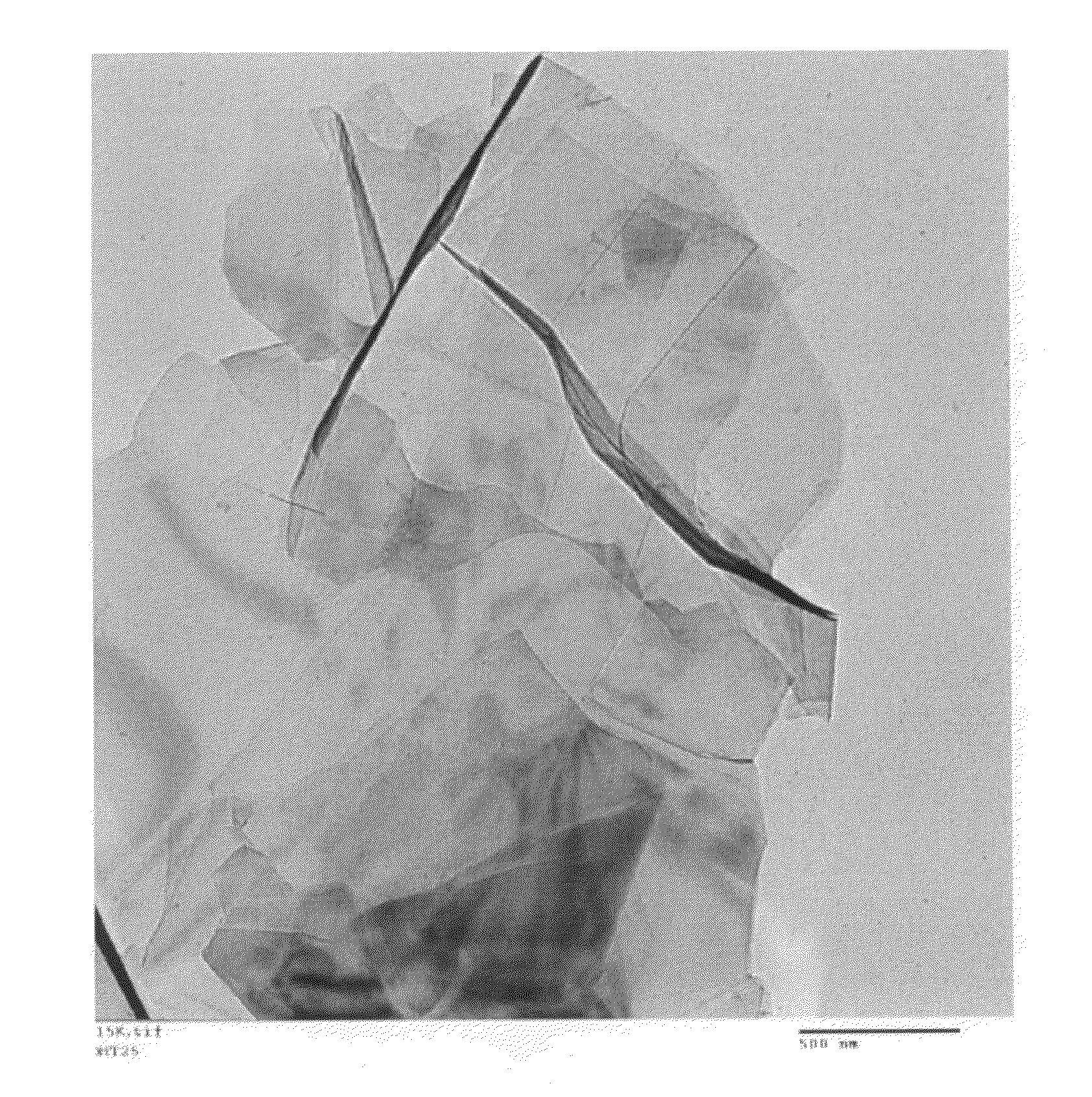

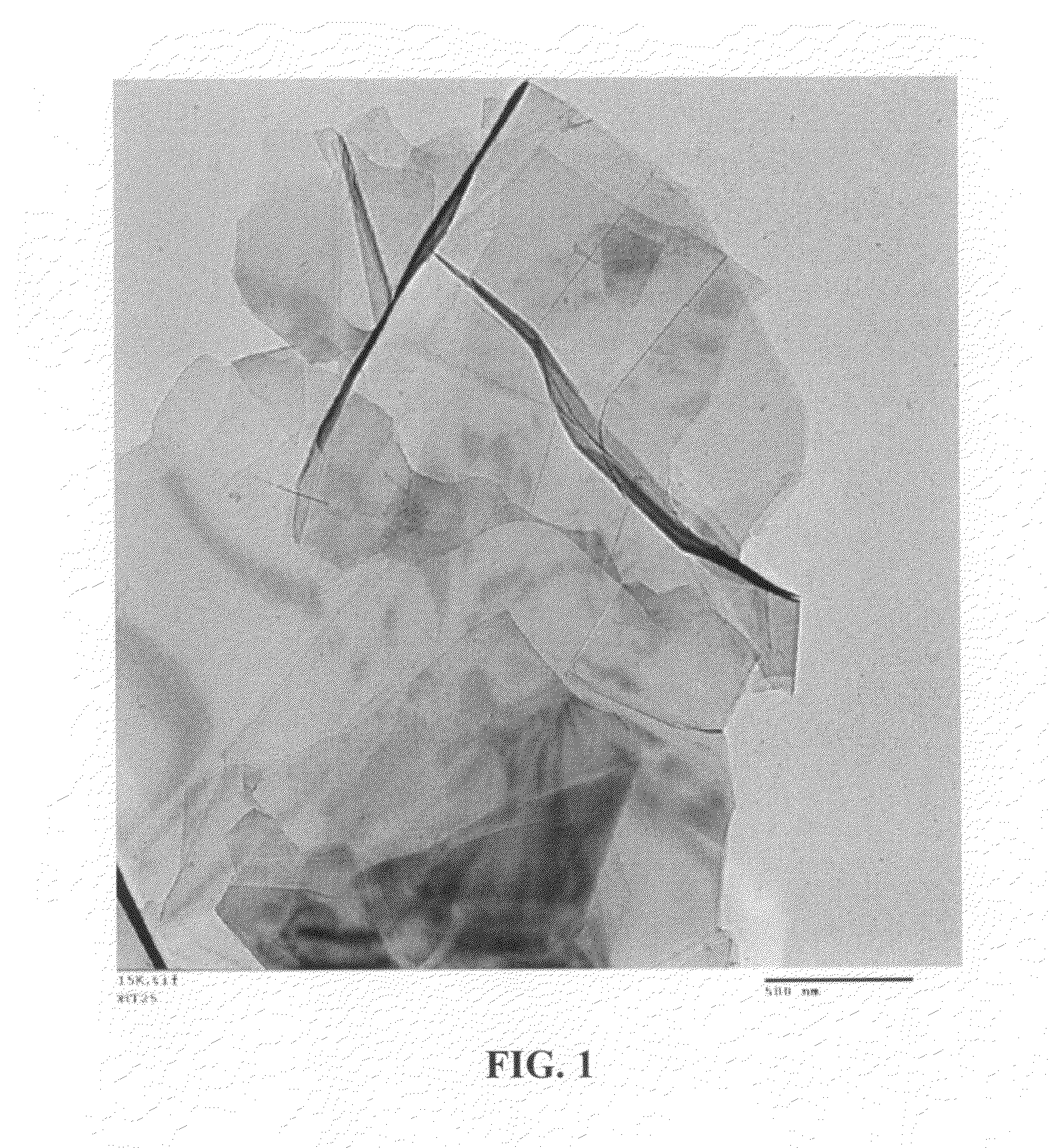

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

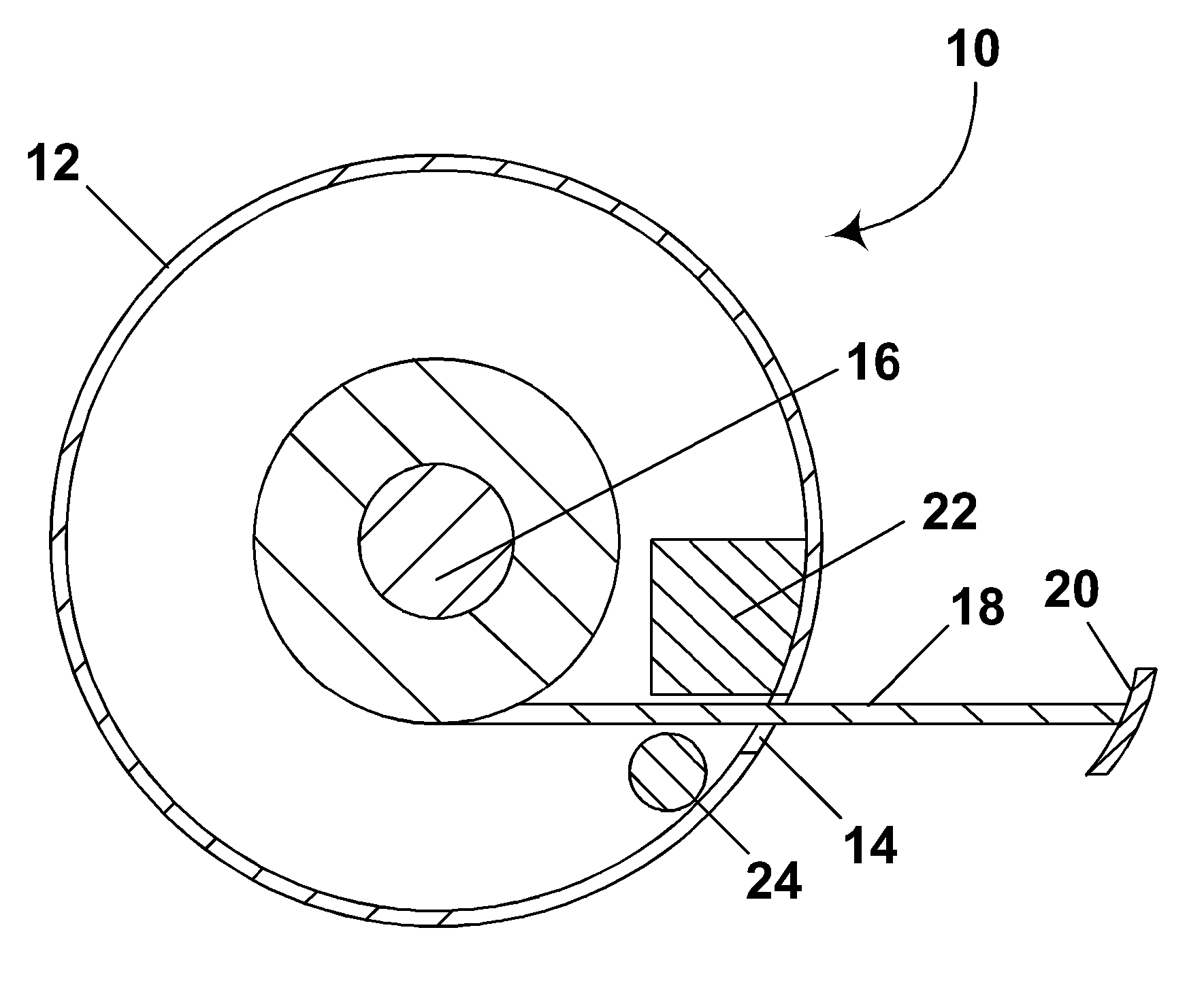

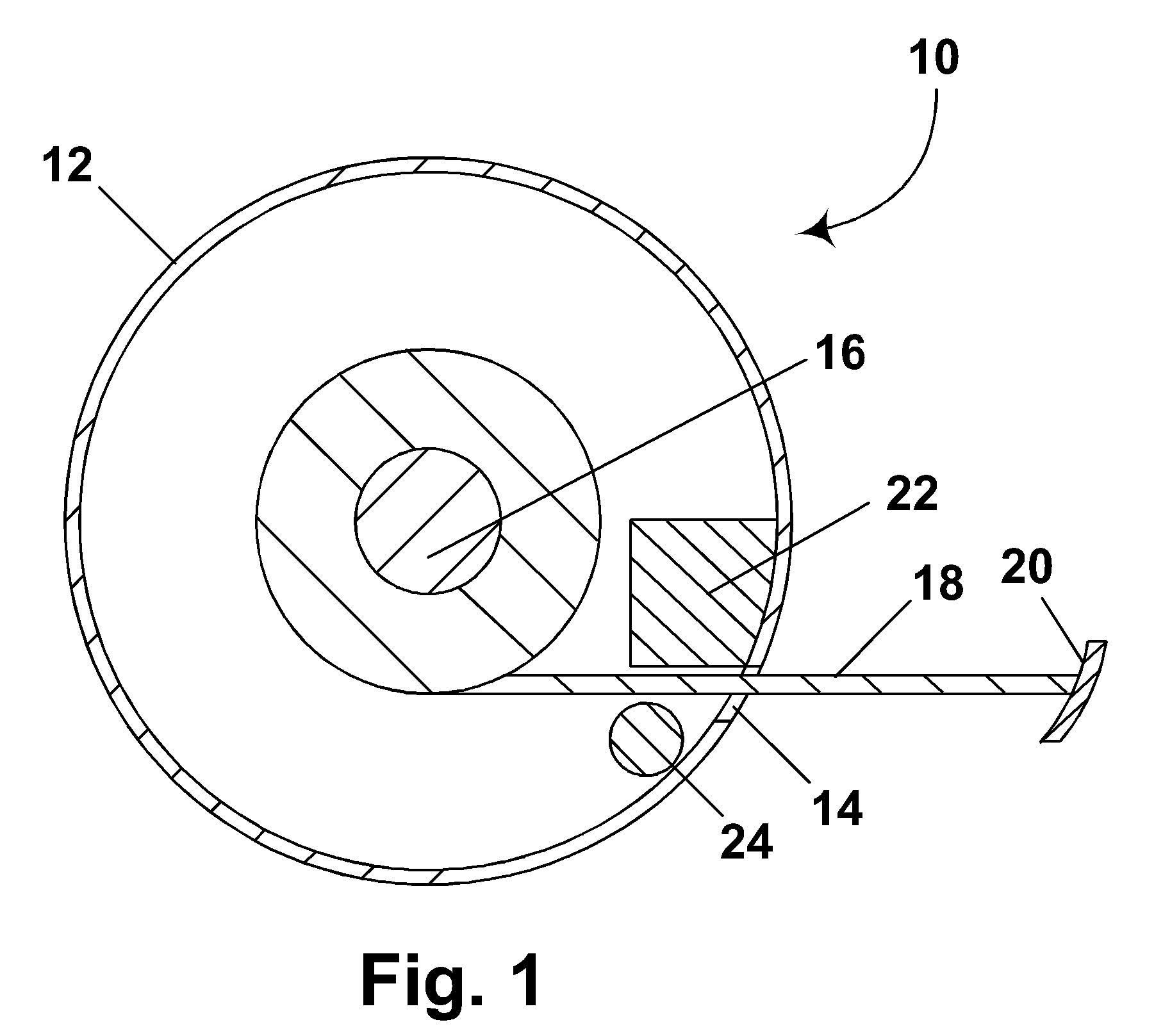

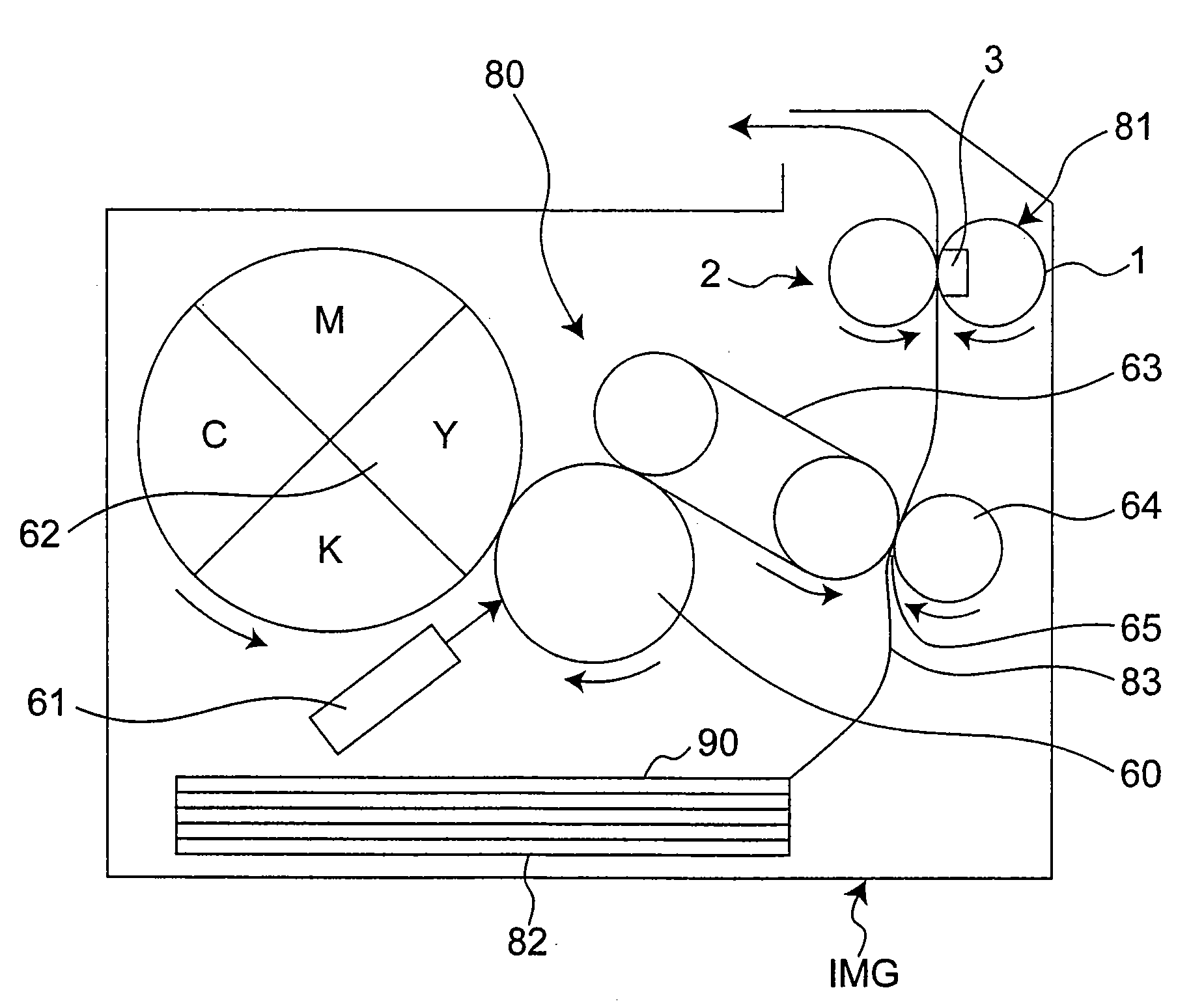

Apparatus For Orienting Magnetic Flakes

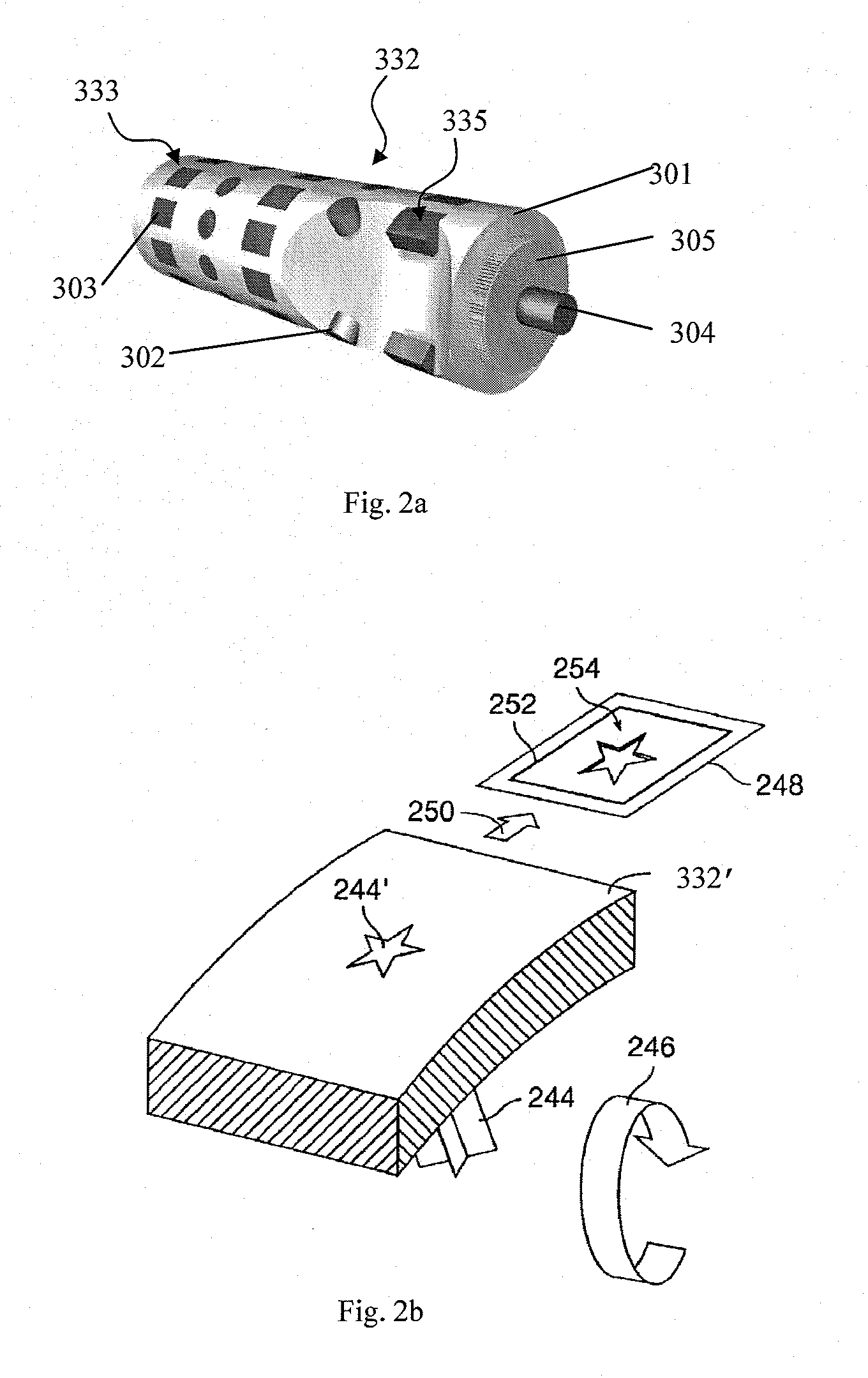

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

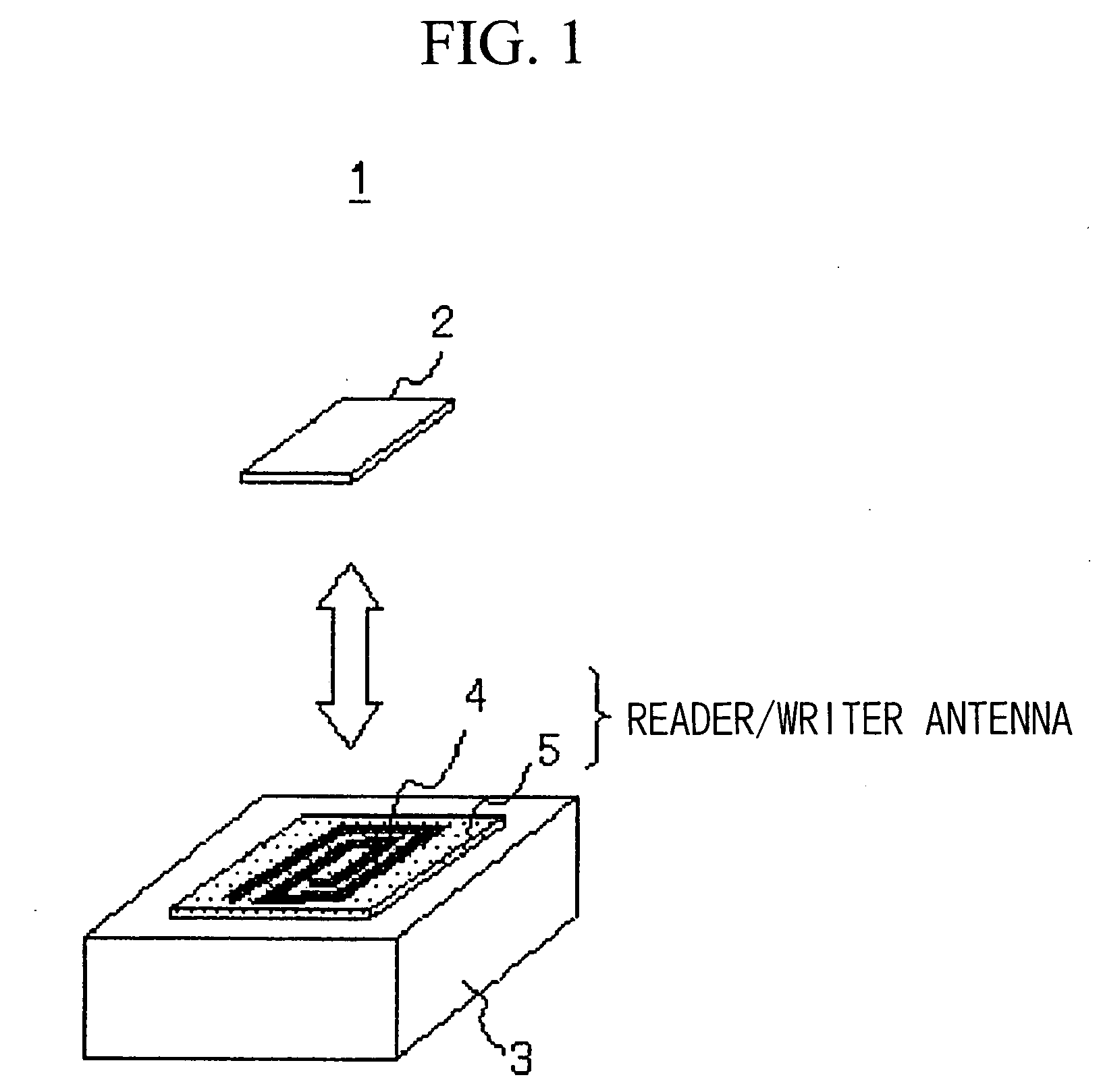

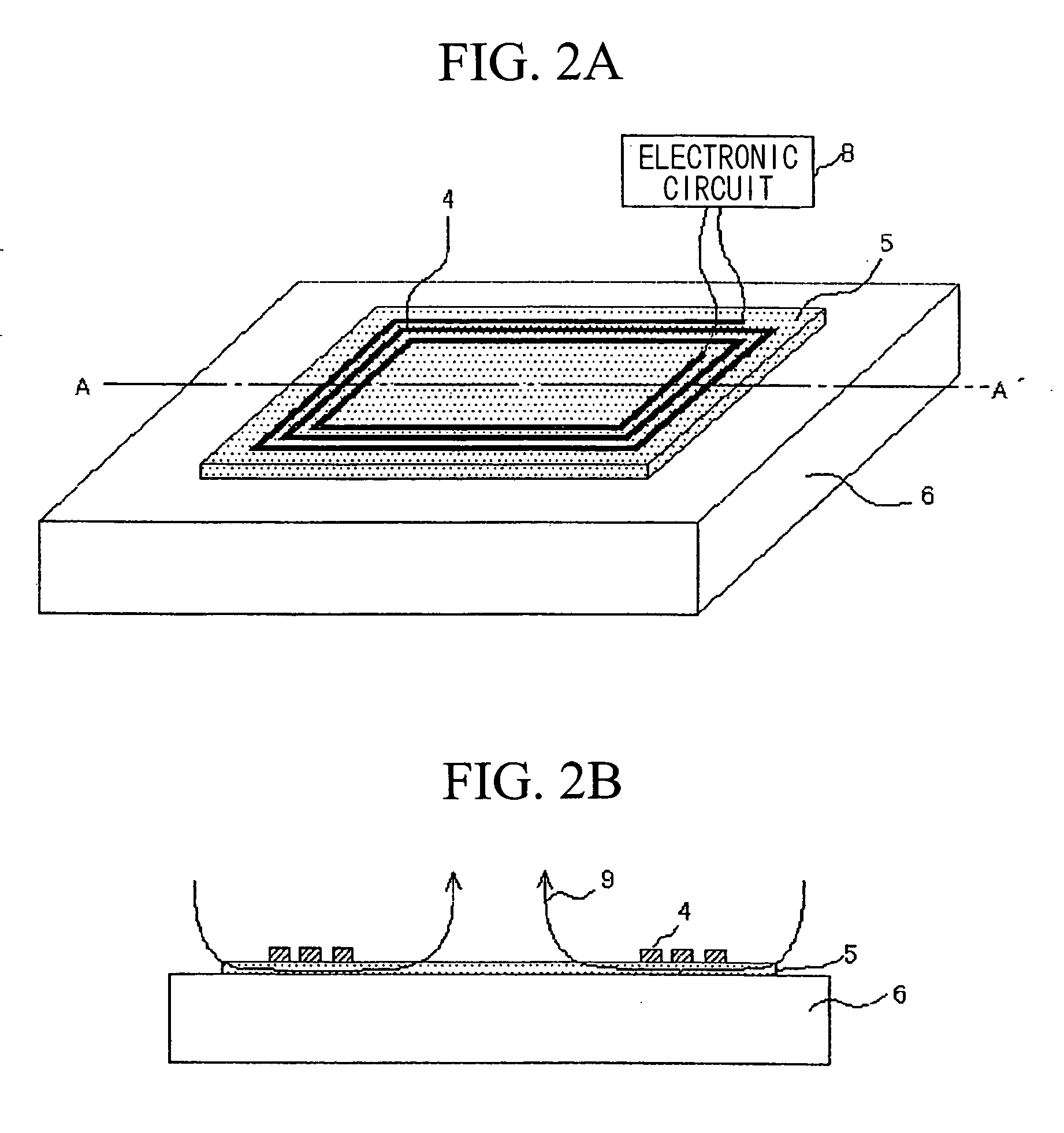

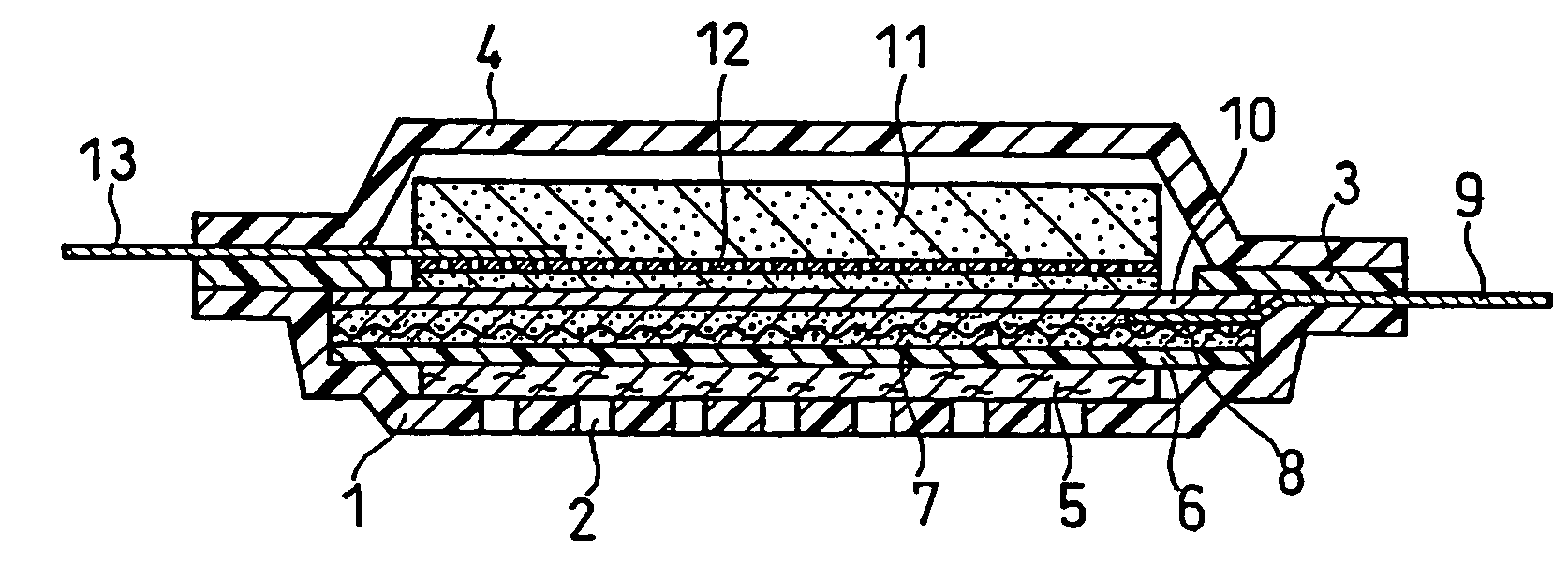

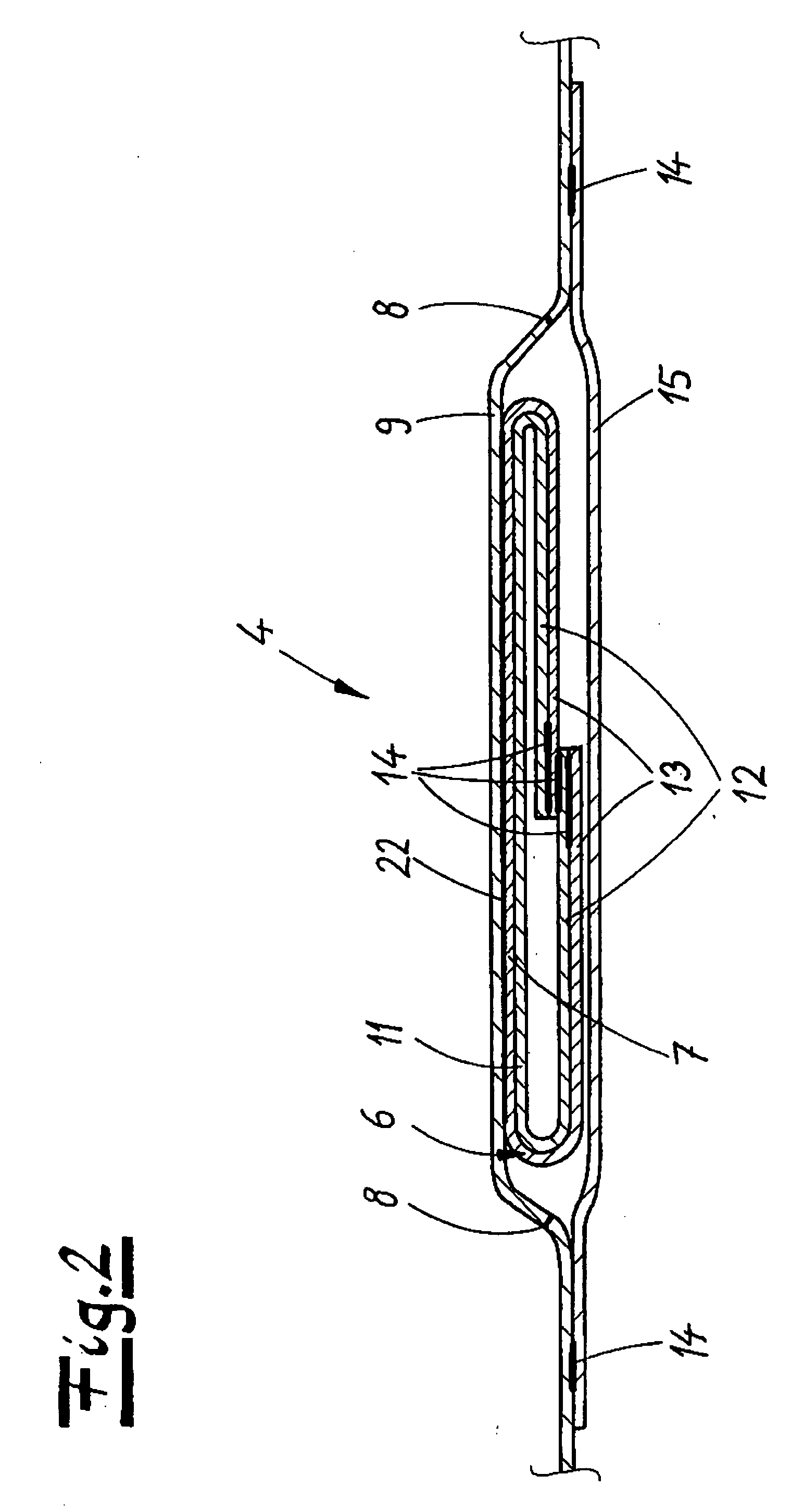

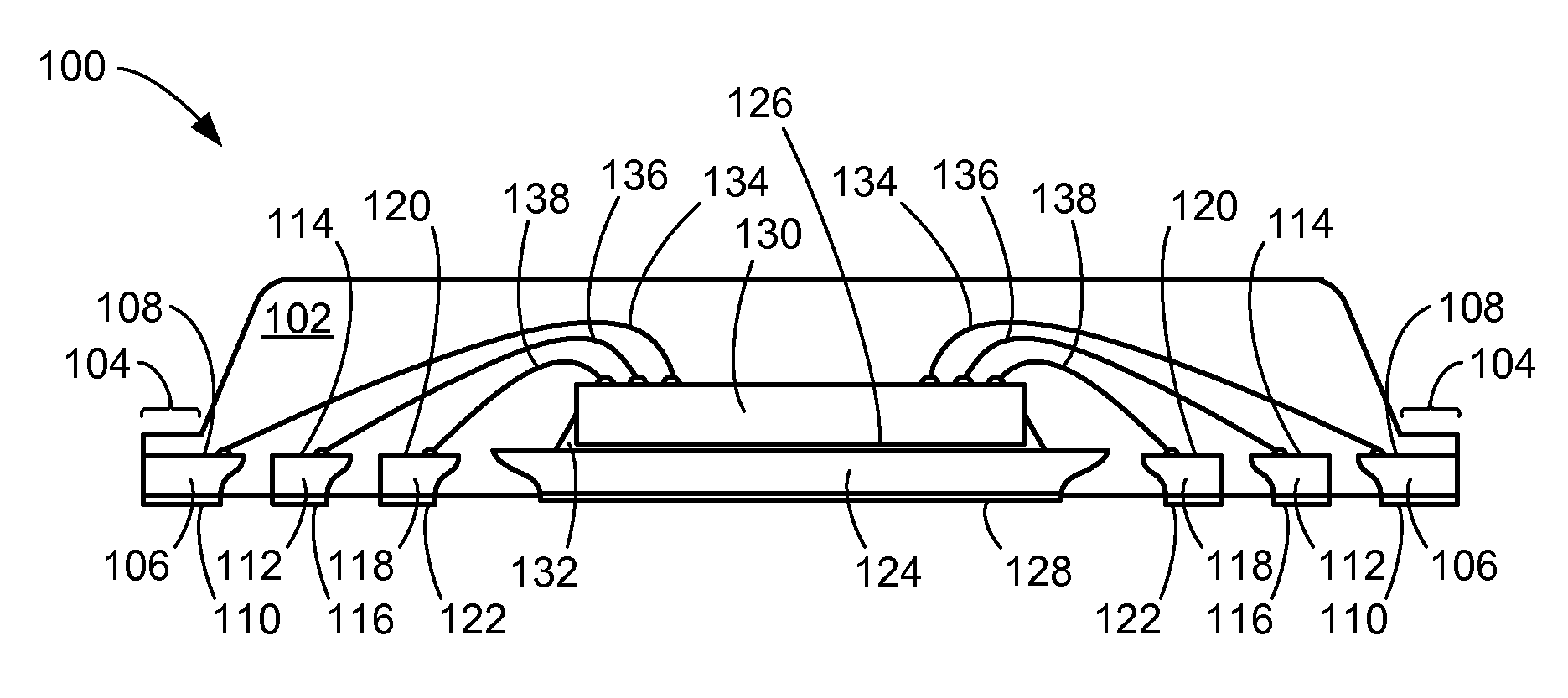

Antenna for reader/writer and reader/writer having the antenna

InactiveUS20050162331A1Limited varianceLoop antennas with ferromagnetic coreAntenna supports/mountingsMagnetic fluxMetal

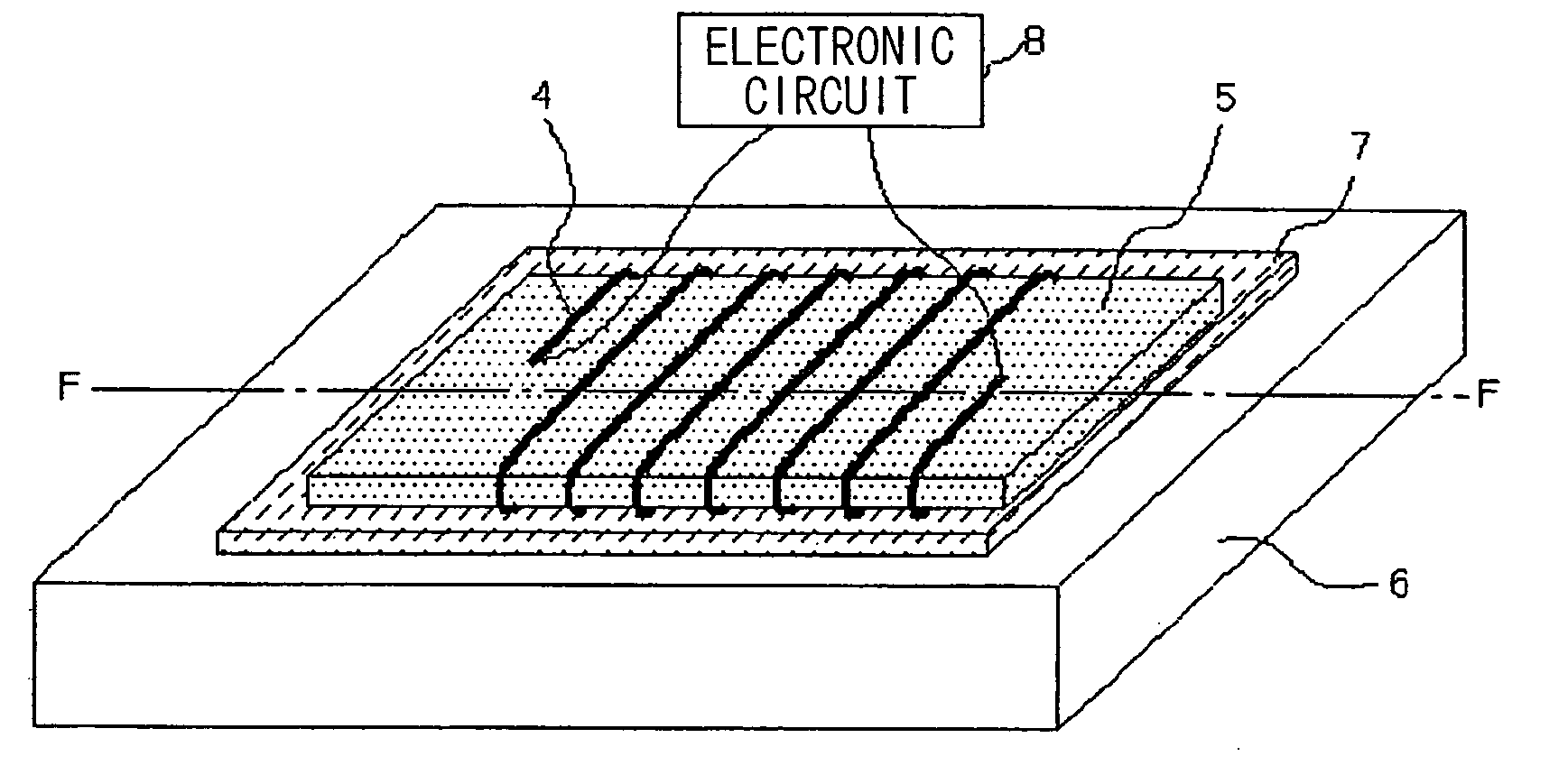

A soft magnetic member (5) which is formed by a composite of an organic object such as a metal grain powder, a flake, a ferrite grain powder, a ferrite, an amorphous film or a layered member of the amorphous film with 10 mm or lower thickness so as to satisfy a predetermined relationship with an antenna area, a circumference length, and a magnetic transmission ratio and a conductive member (7) which has approximately 10×10−8 Ωm or lower, more preferably 0.005 Ω or lower initial resistance are provided between the an antenna coil which is formed at least one loop and a metal surface (6) of the conductive member such as a metal casing. The magnetic flux which invades into the conductive object is blocked by the soft magnetic member (5) and the conductive member (7) so as to restrict the influence thereof. By doing this, it is possible to provide a reader / writer antenna for an RFID system in which it is possible to restrict a variance of a resonating frequency and an increase in a loss even if it is disposed so as to contact the conductive object such as a metal casing.

Owner:MITSUBISHI MATERIALS CORP

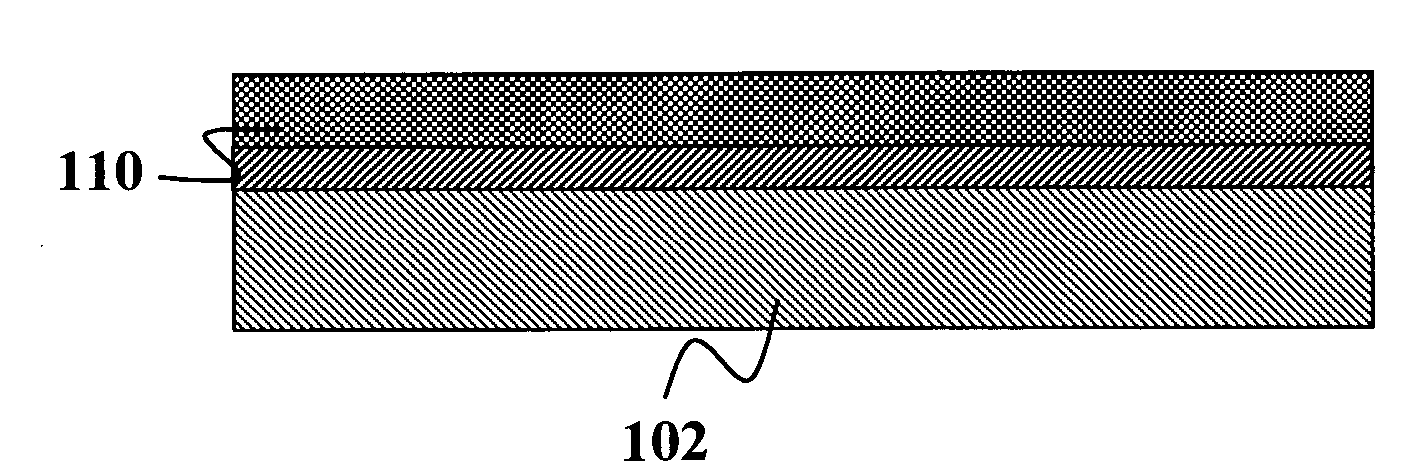

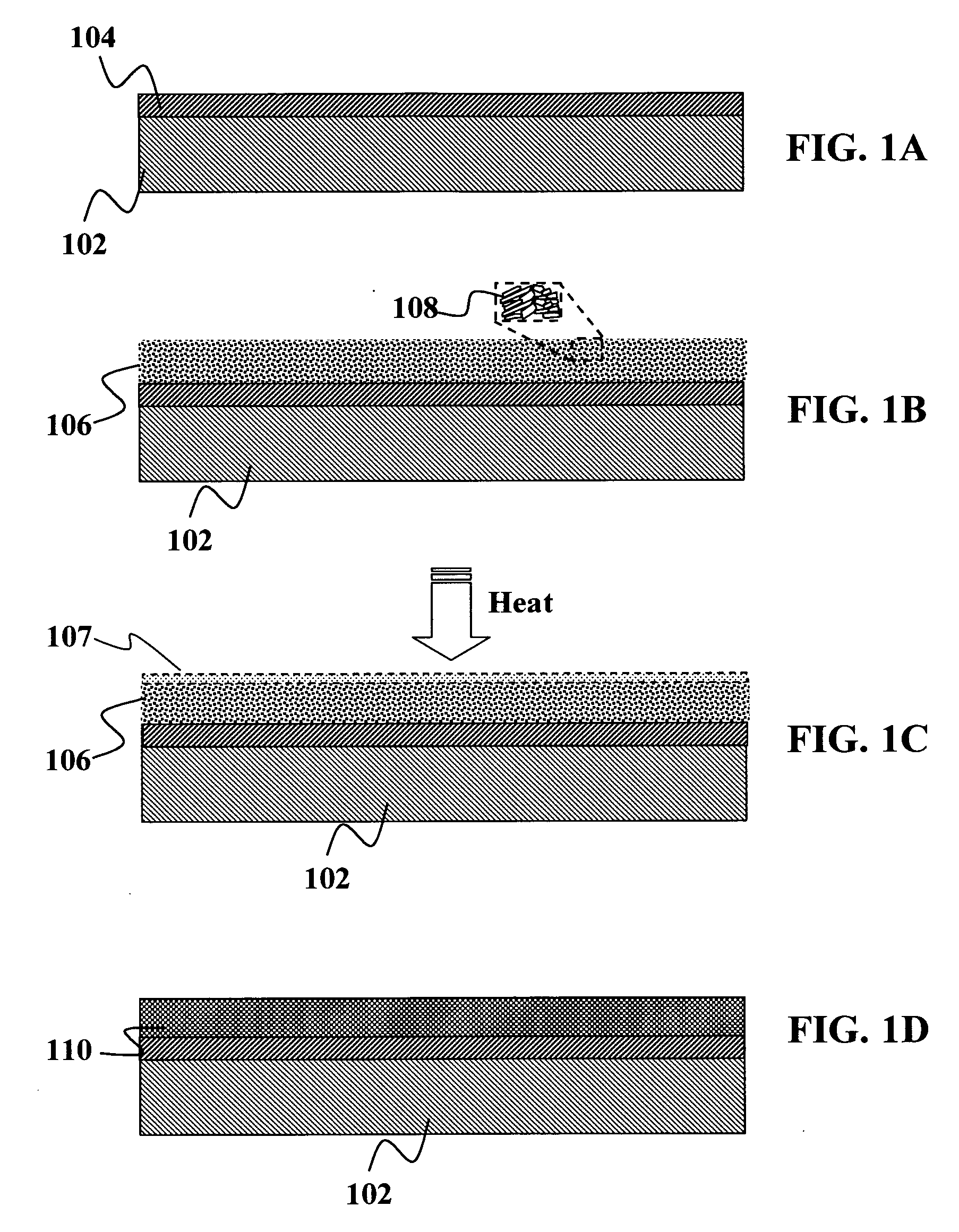

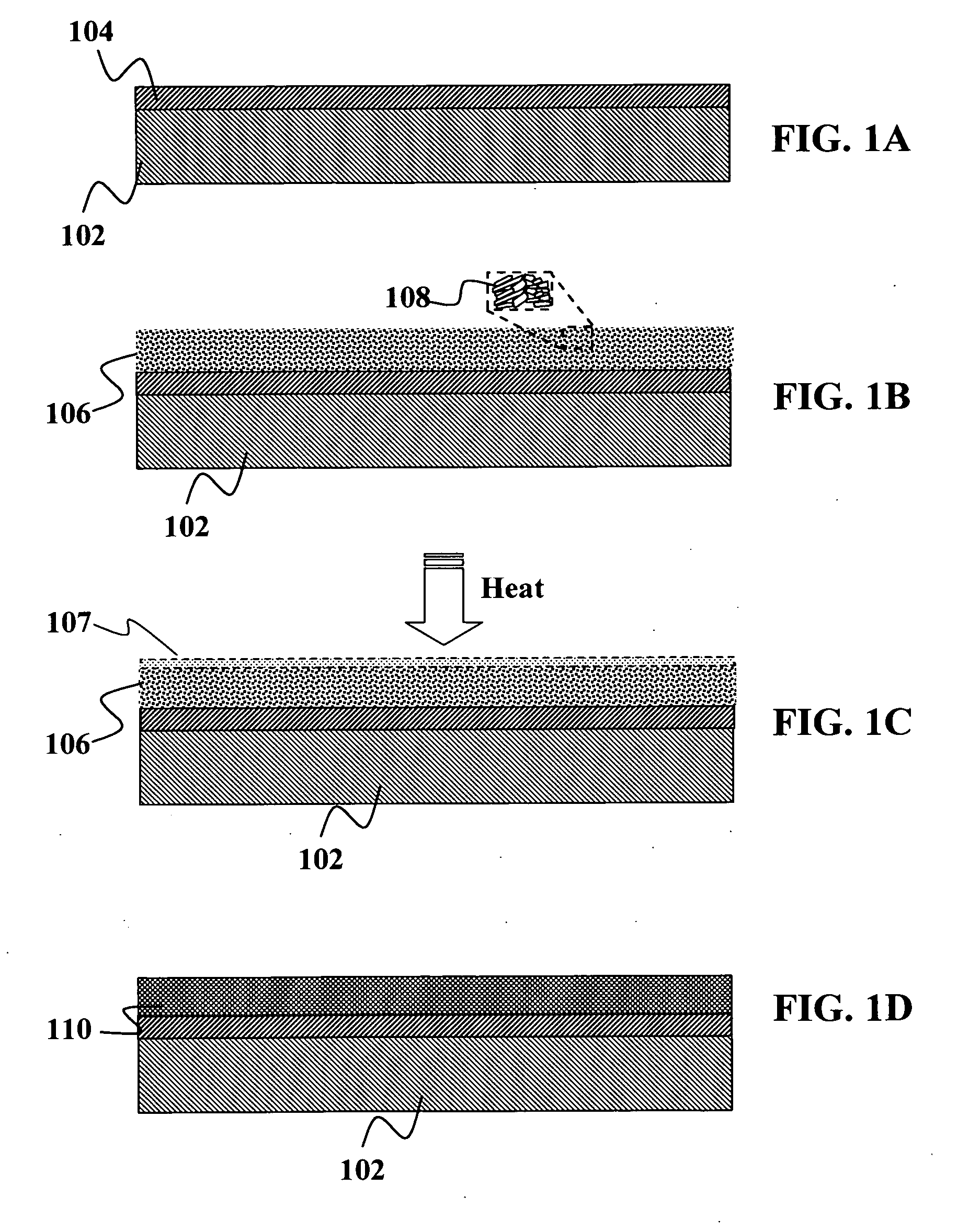

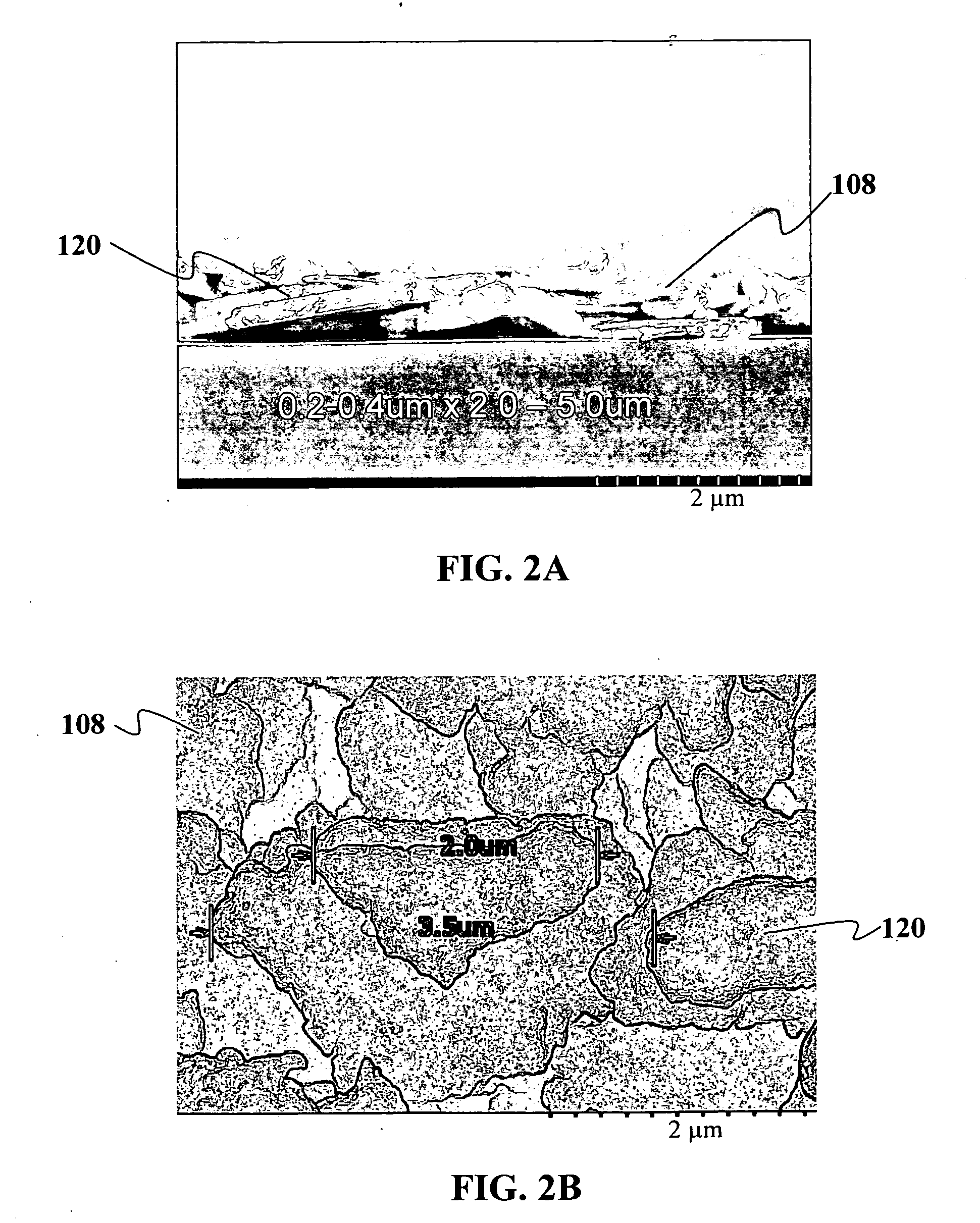

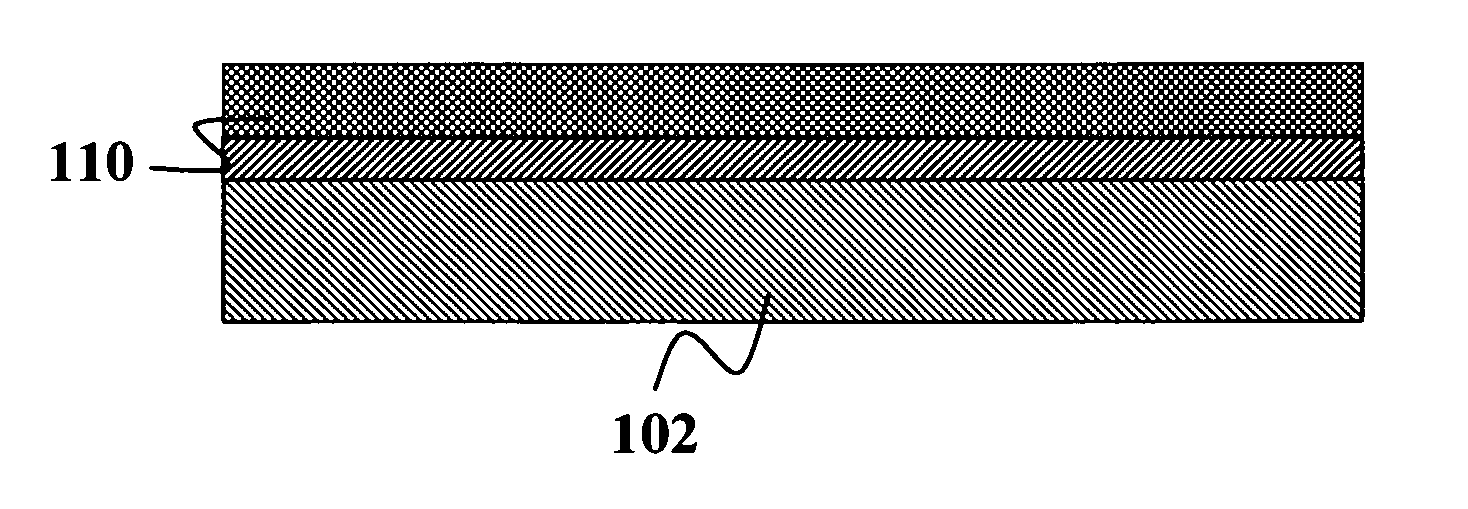

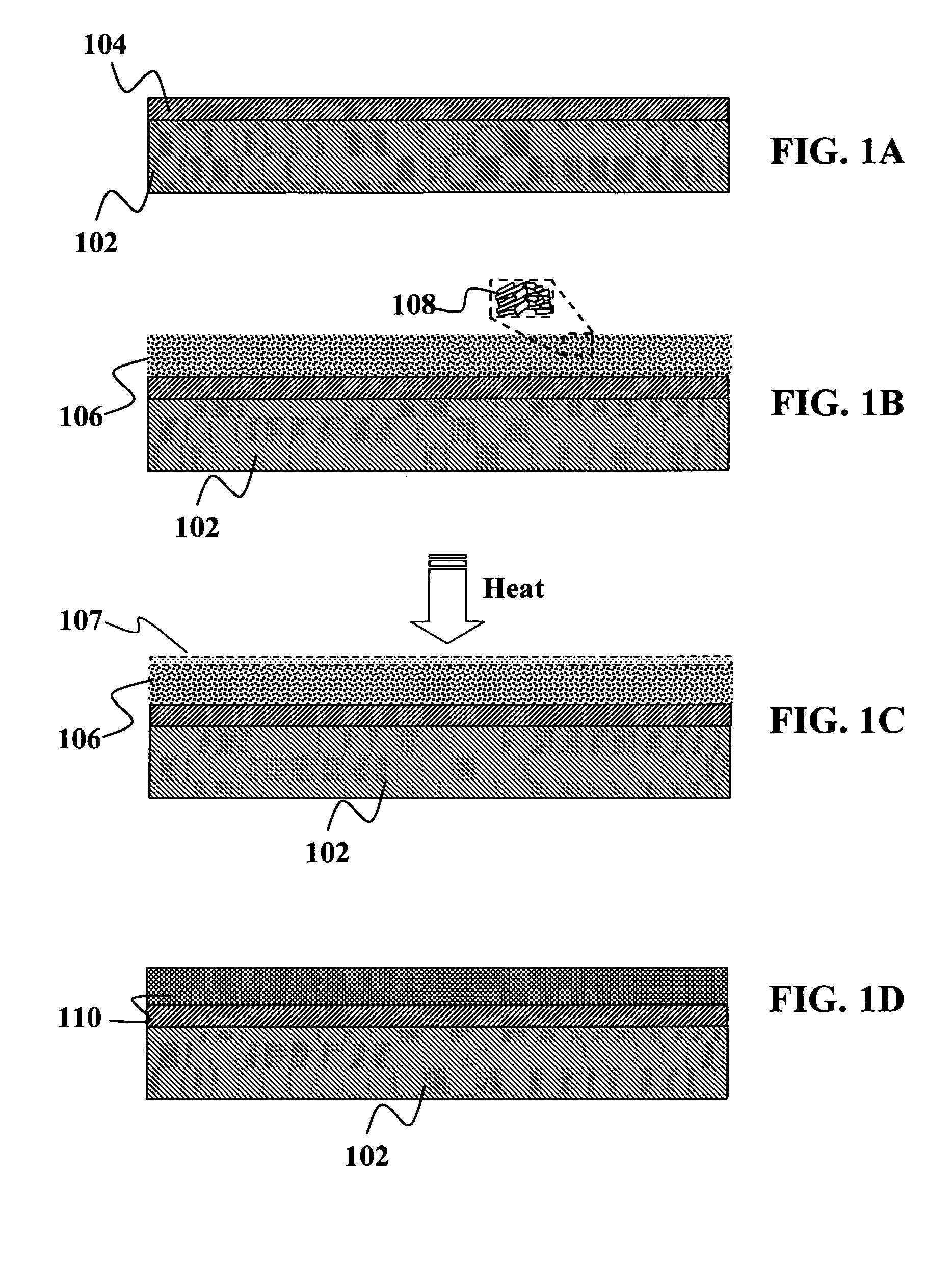

Photovoltaic devices printed from nanostructured particles

InactiveUS20070163638A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingParticle methodSolar cell

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, a solar cell is provided that comprises of a substrate, a back electrode formed over the substrate, a p-type semiconductor thin film formed over the back electrode, an n-type semiconductor thin film formed so as to constitute a pn junction with the p-type semiconductor thin film, and a transparent electrode formed over the n-type semiconductor thin film. The p-type semiconductor thin film results by processing a dense film formed from a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA, wherein the dense film has a void volume of about 26% or less. The dense film may be a substantially void free film.

Owner:AERIS CAPITAL SUSTAINABLE IP

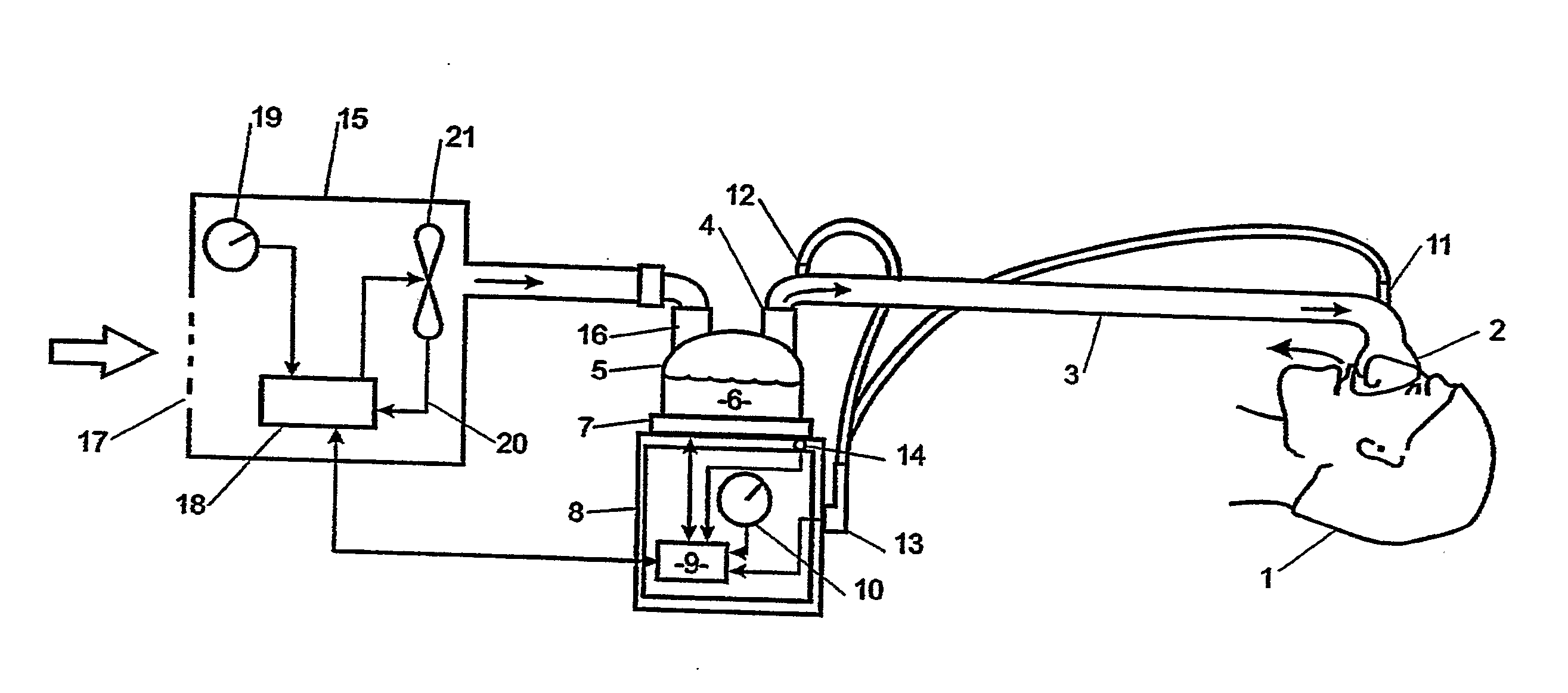

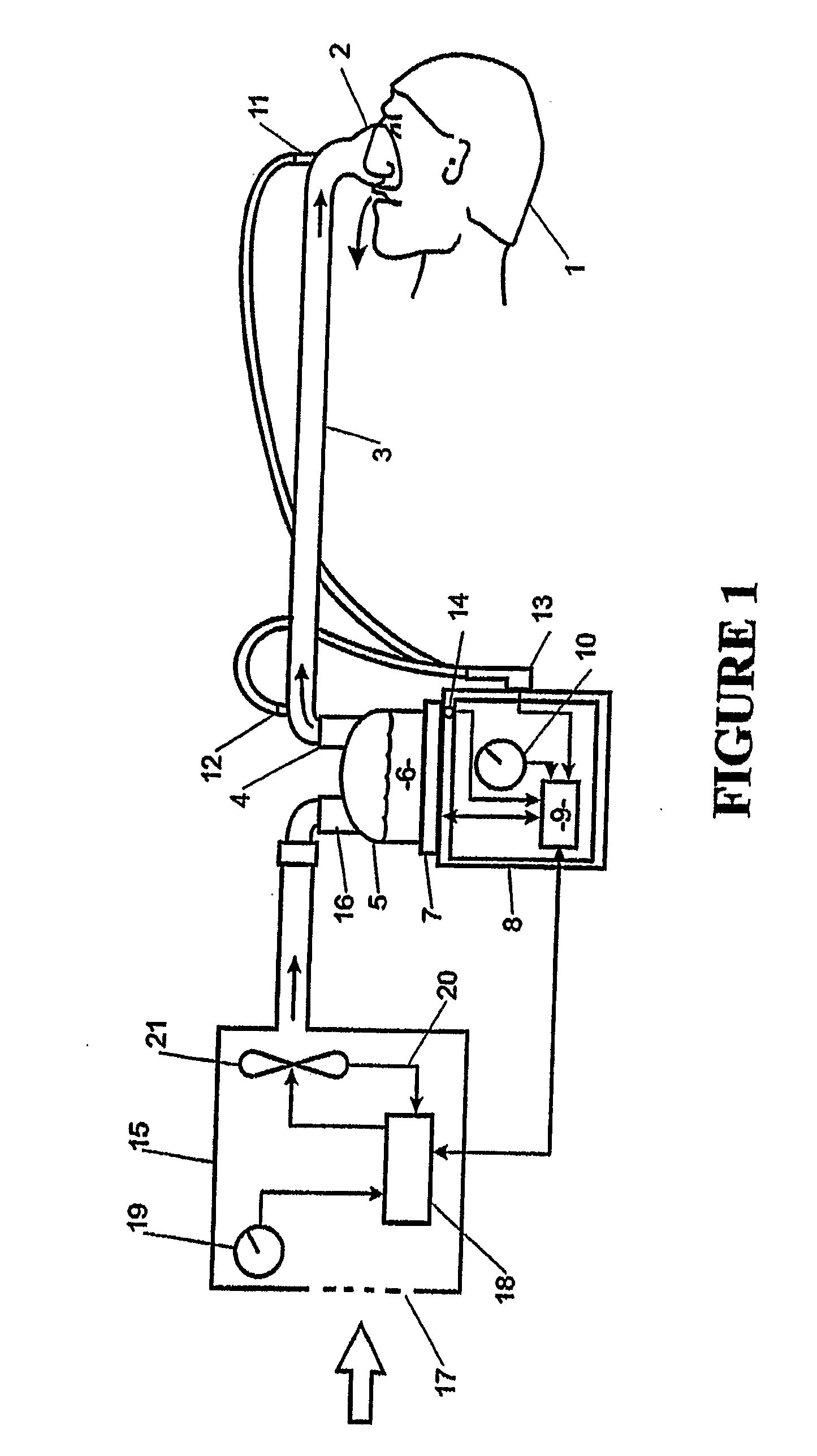

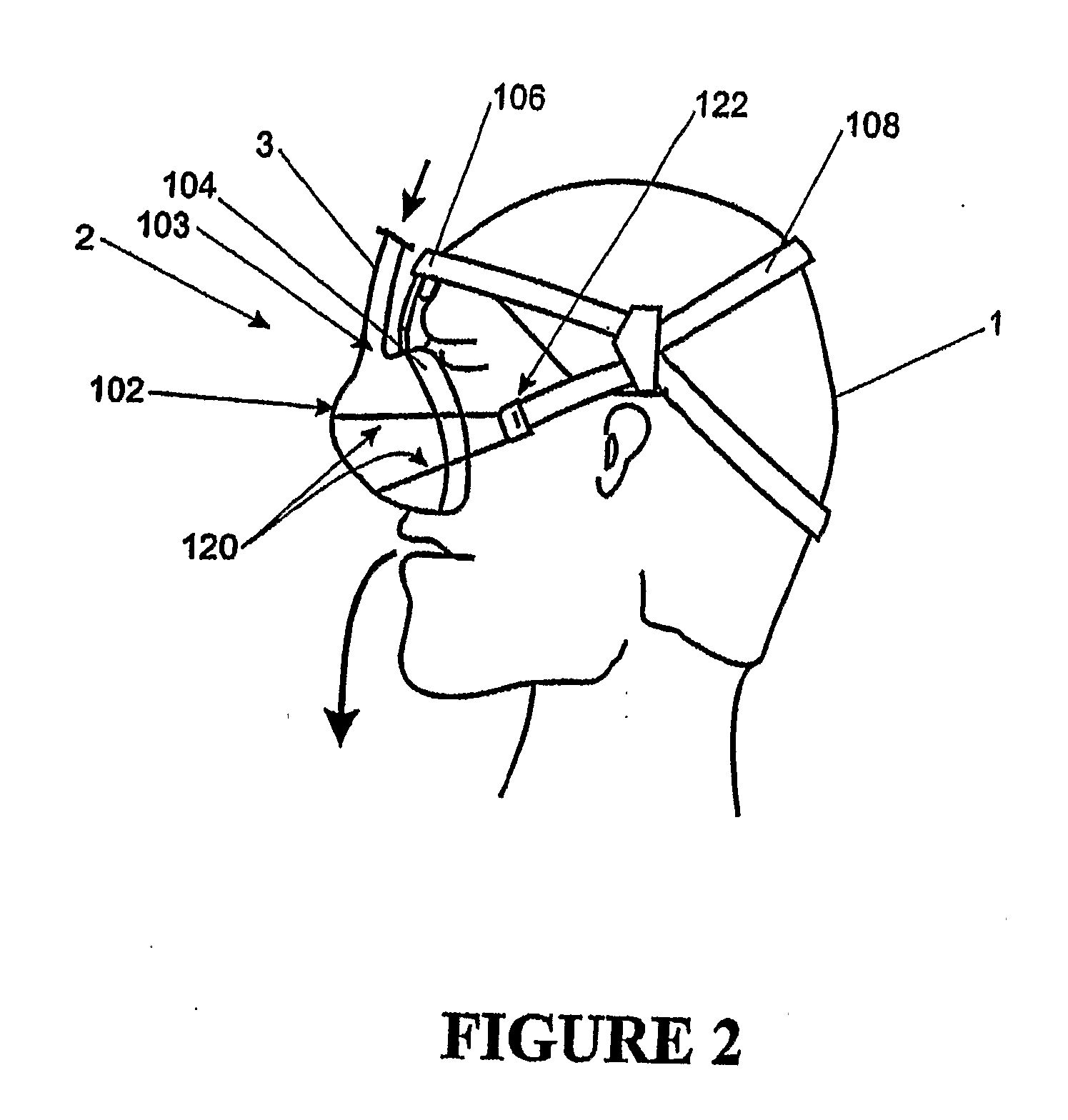

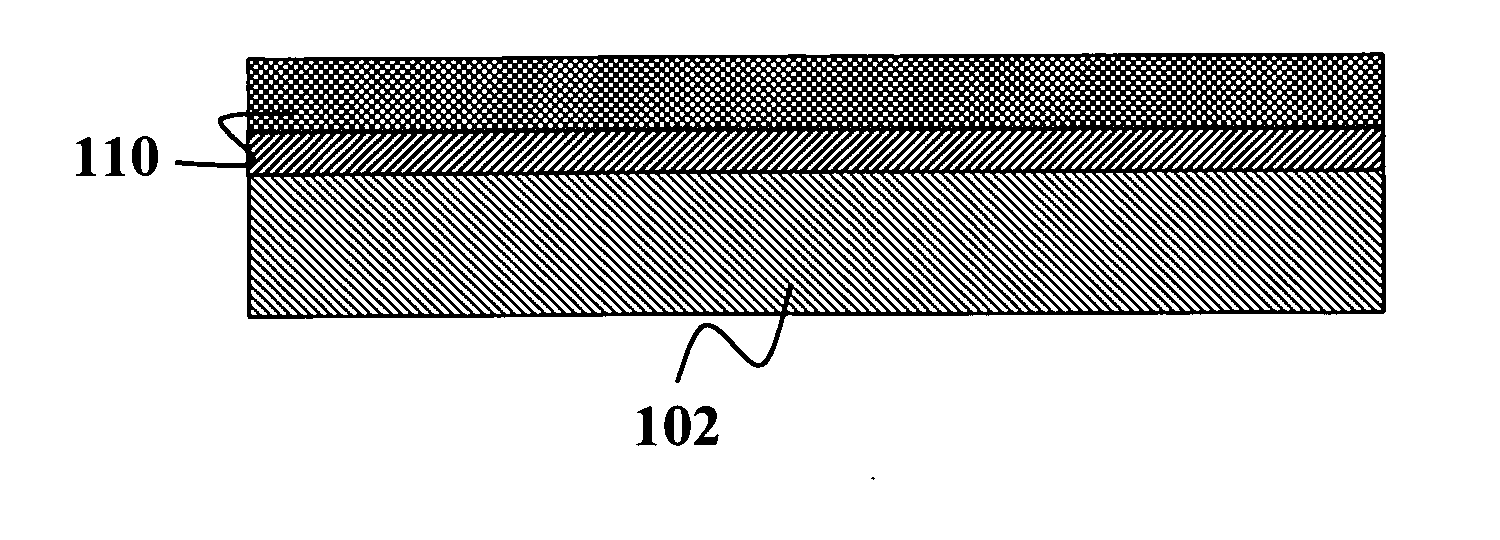

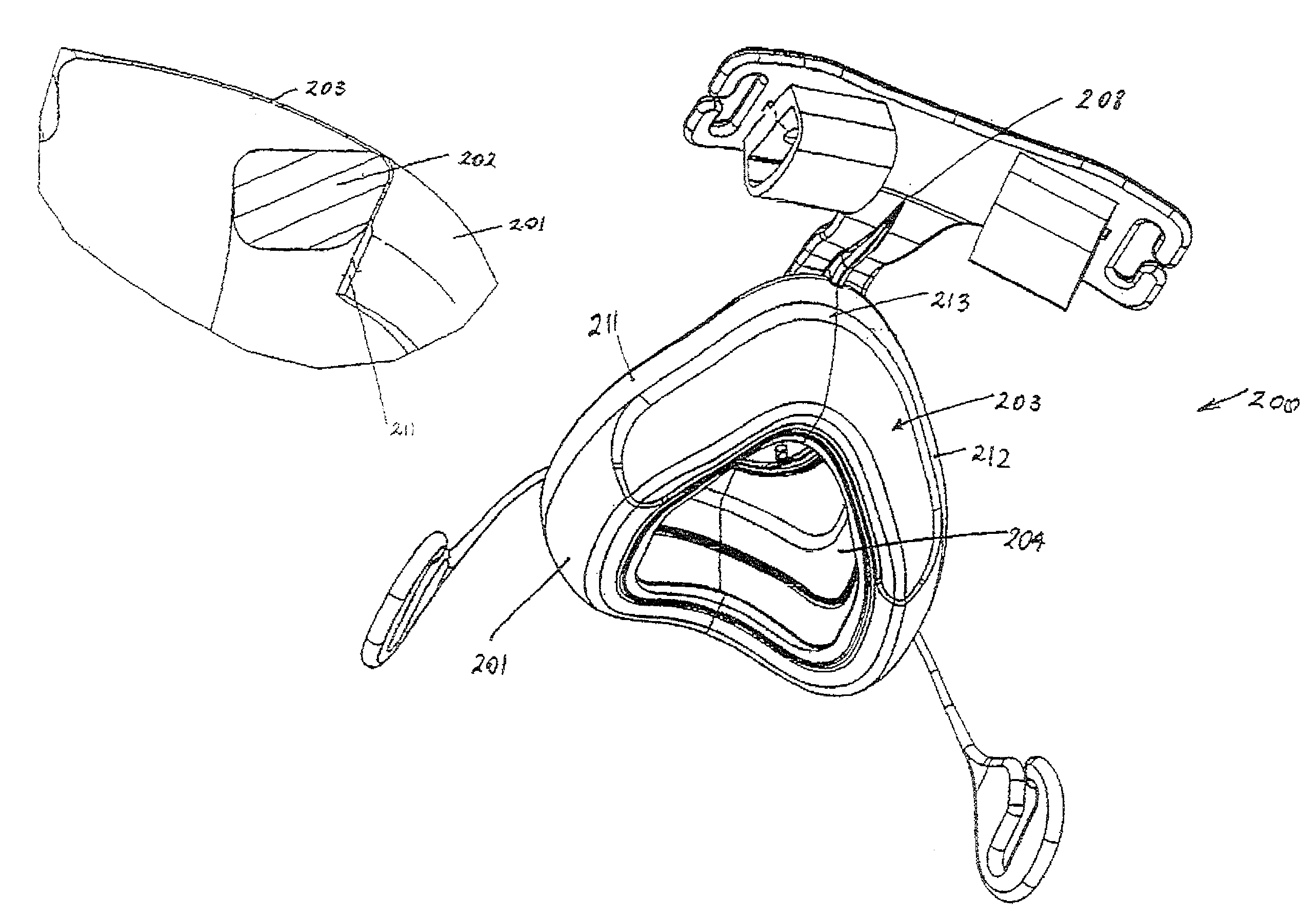

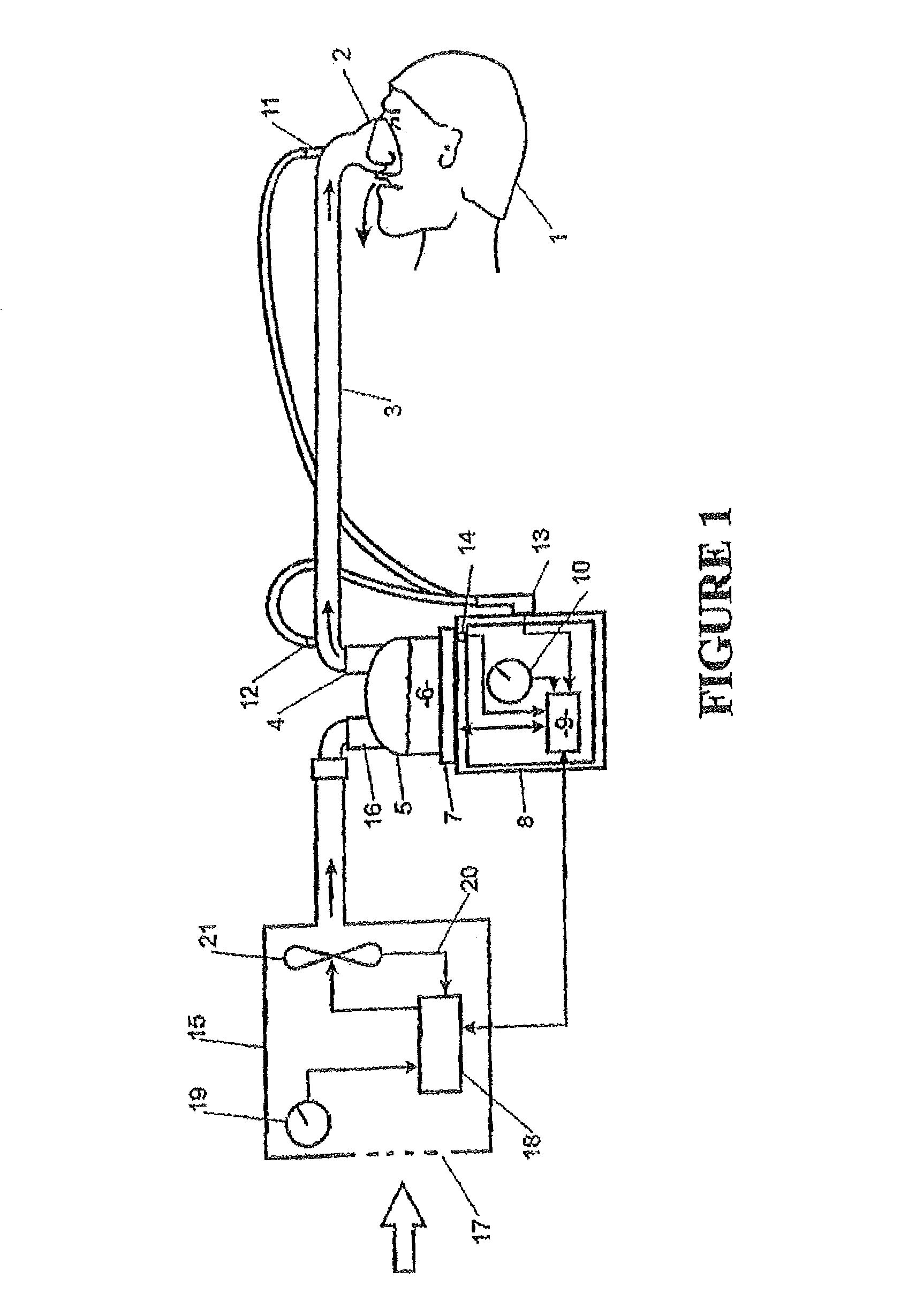

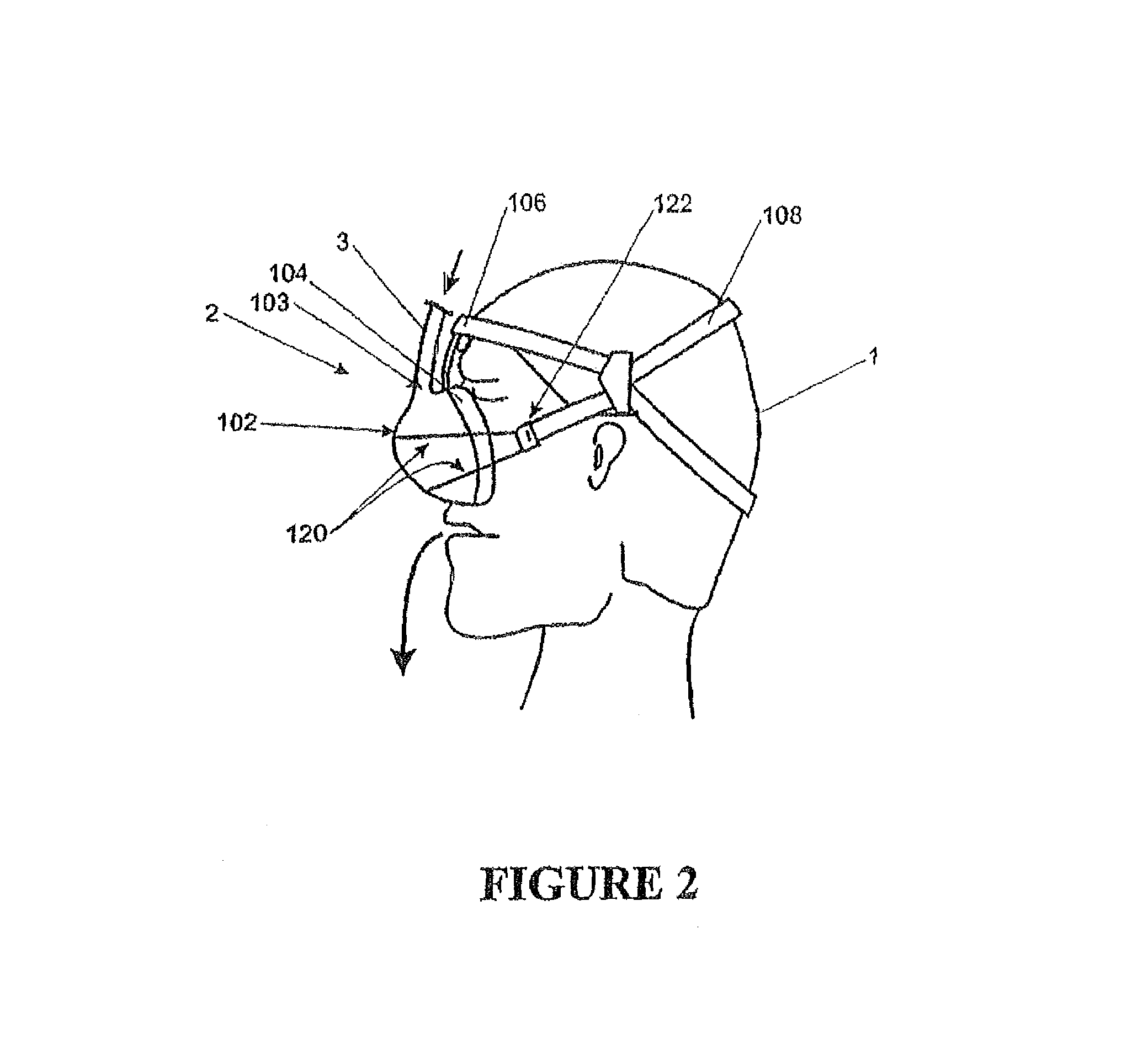

Breathing Assistance Apparatus

A breathing assistance apparatus (200) is disclosed, for use with delivery of respiratory gases to a patient. The breathing assistance apparatus includes a patient interface, having a body section adapted to cover the nose, or nose and mouth of a patient and a sealing interface. The sealing interface includes at least an outer sealing member. The outer sealing member (201) is adapted to attach to the body section in a sealing manner and has a substantially thin section (203) in at least its nasal bridge region. The thin section is substantially thinner than the rest of the outer sealing member.

Owner:FISHER & PAYKEL HEALTHCARE LTD

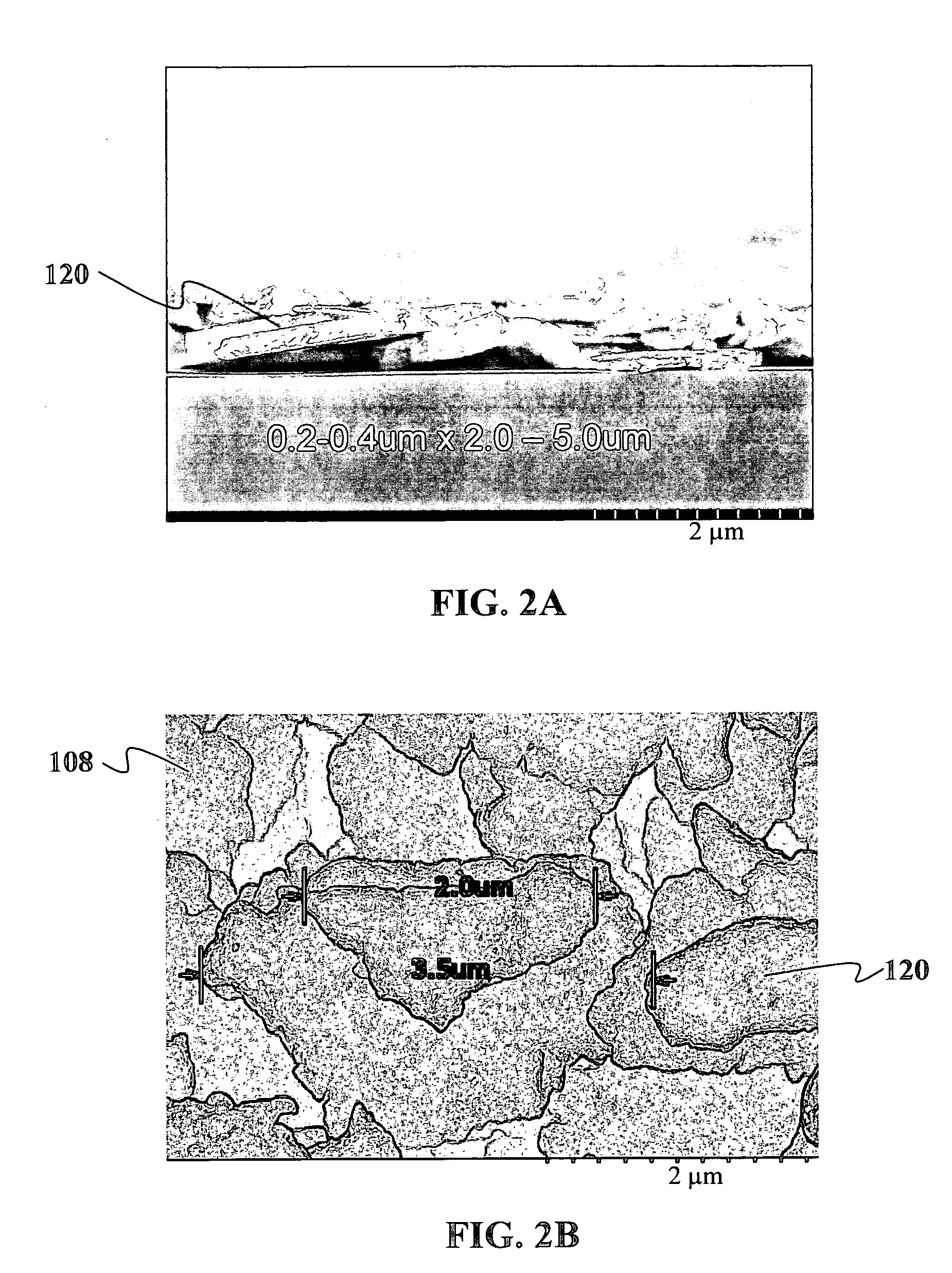

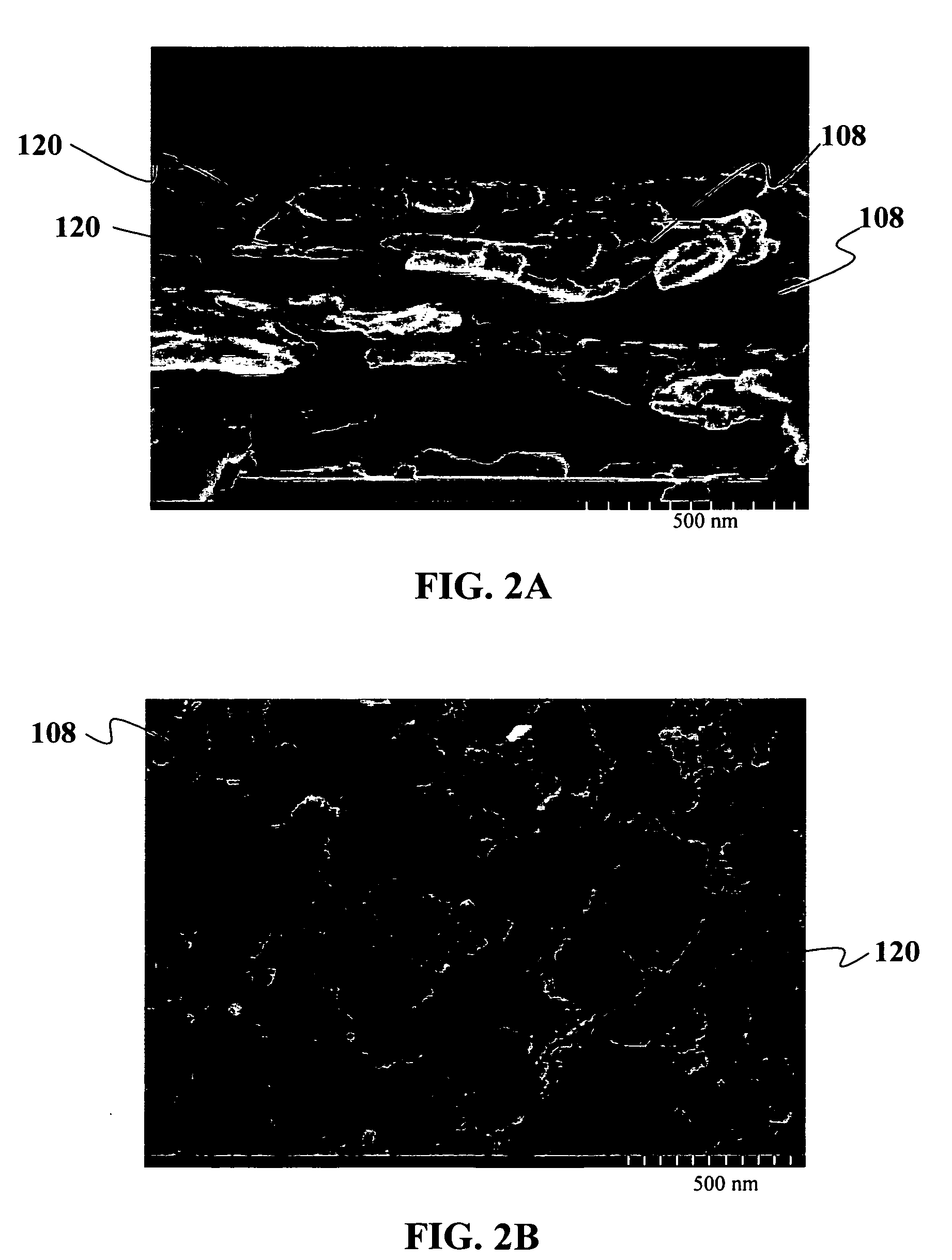

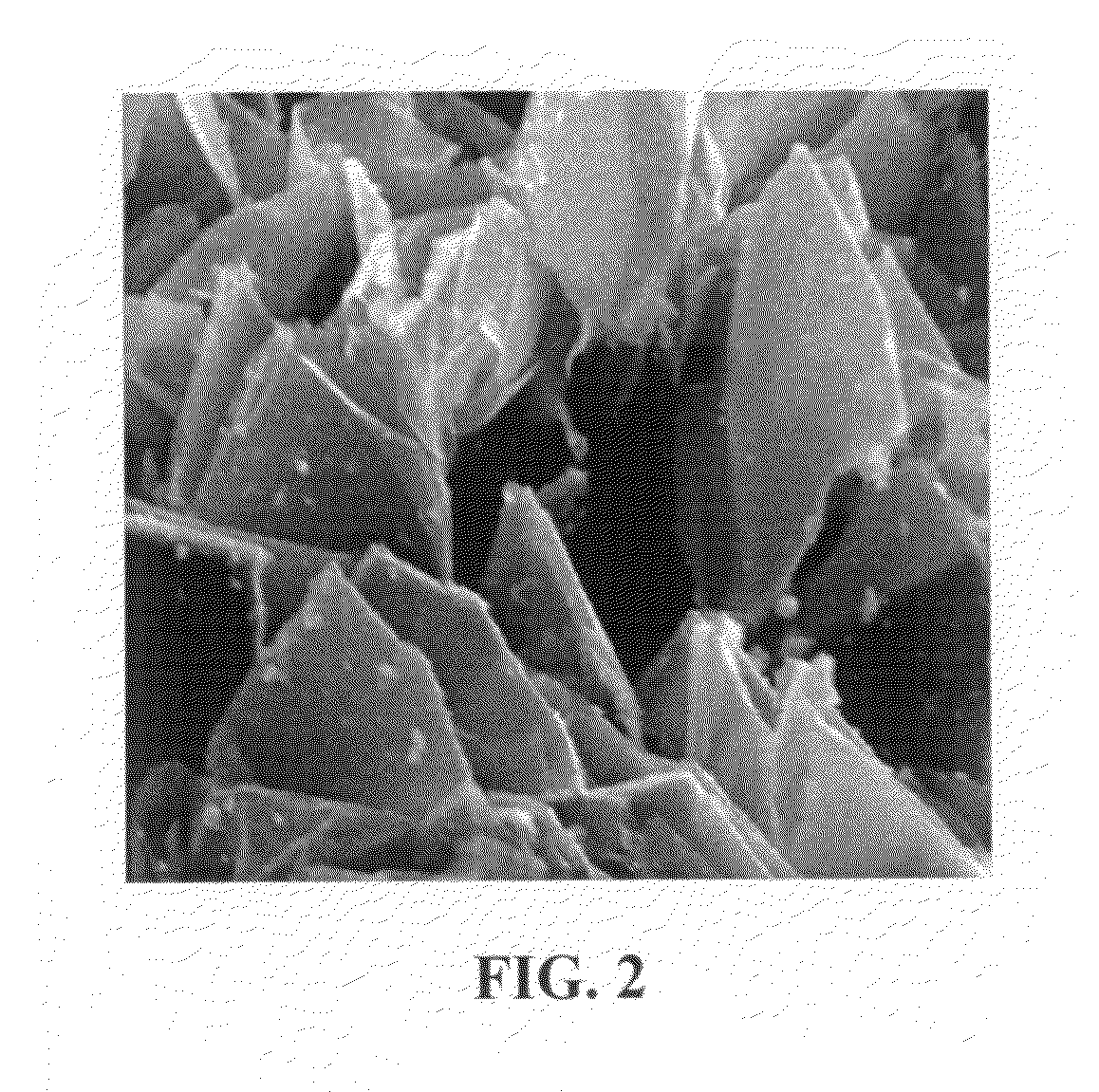

High-throughput printing of semiconductor precursor layer from microflake particles

InactiveUS20070163639A1Efficient and simplified creationIncrease contactMolten spray coatingFinal product manufactureNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

Apparatus for displaying drawings

Owner:E INK CORPORATION

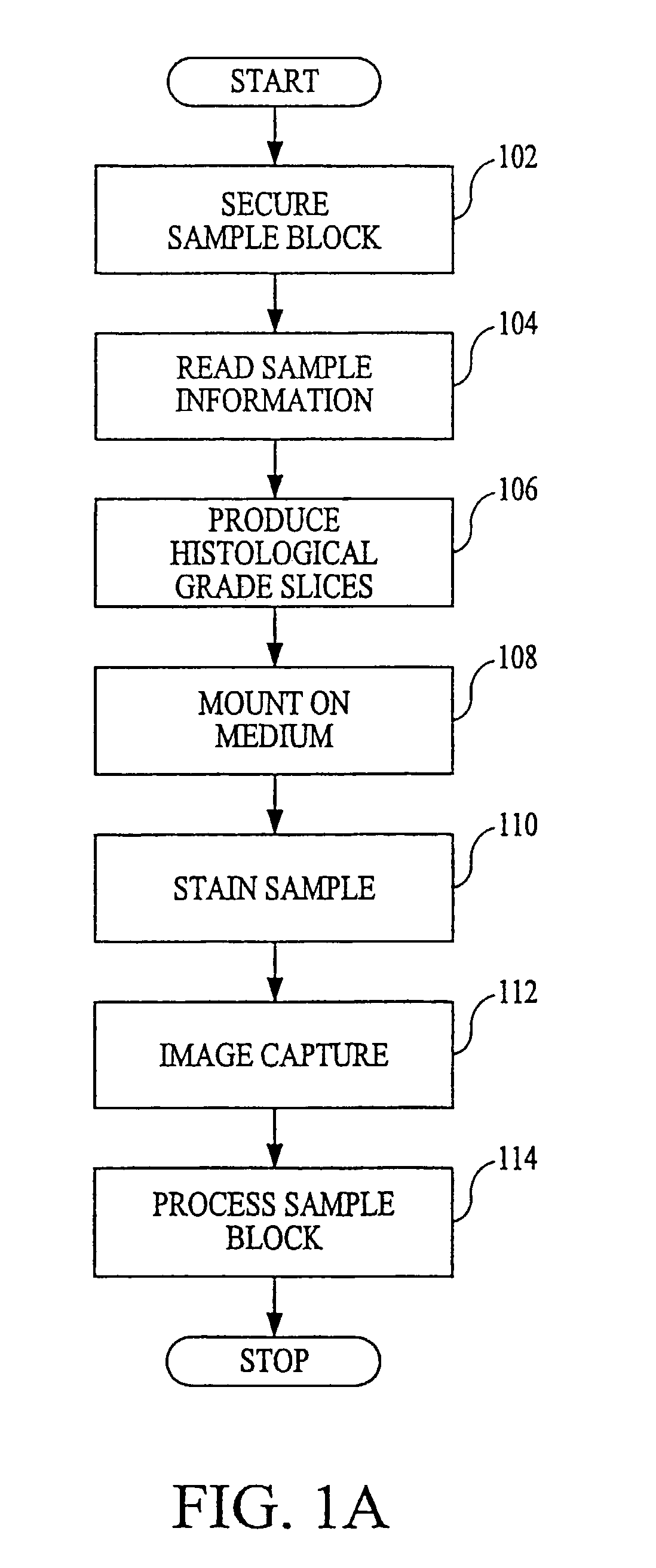

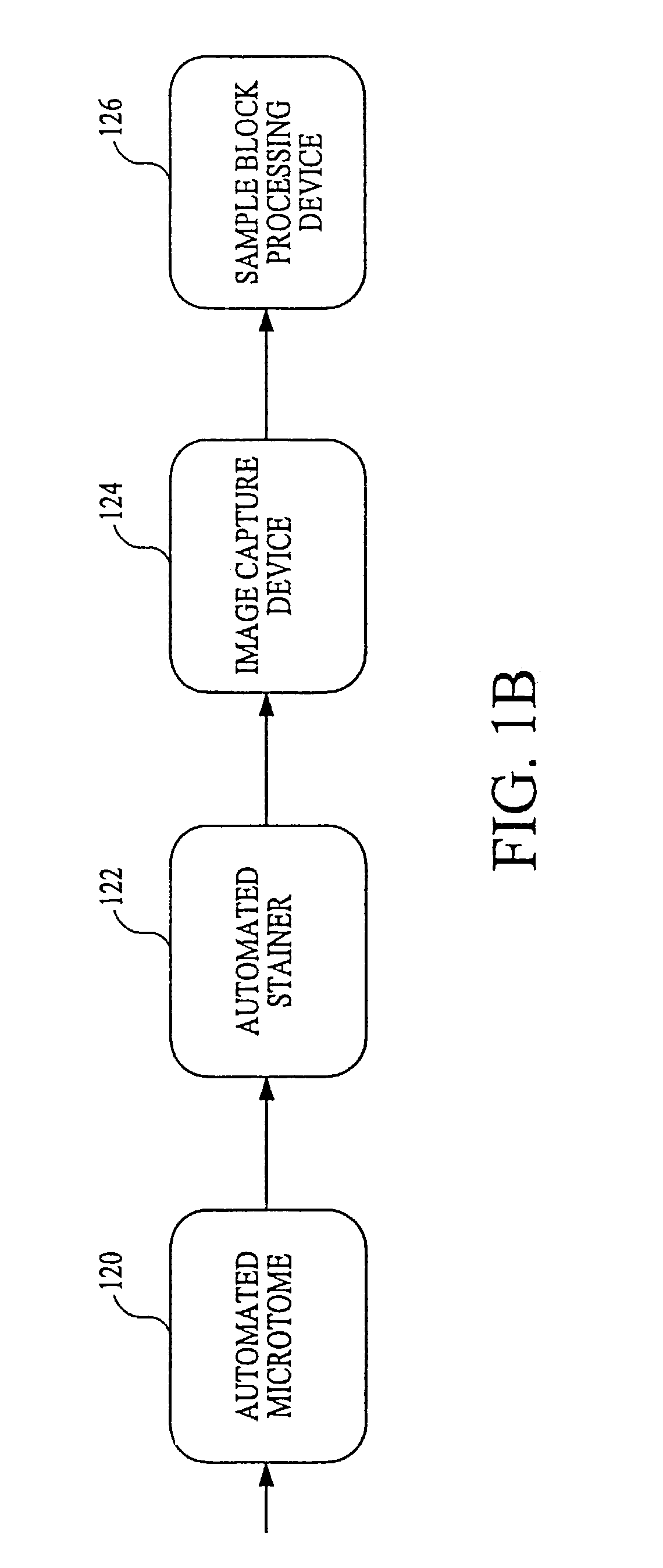

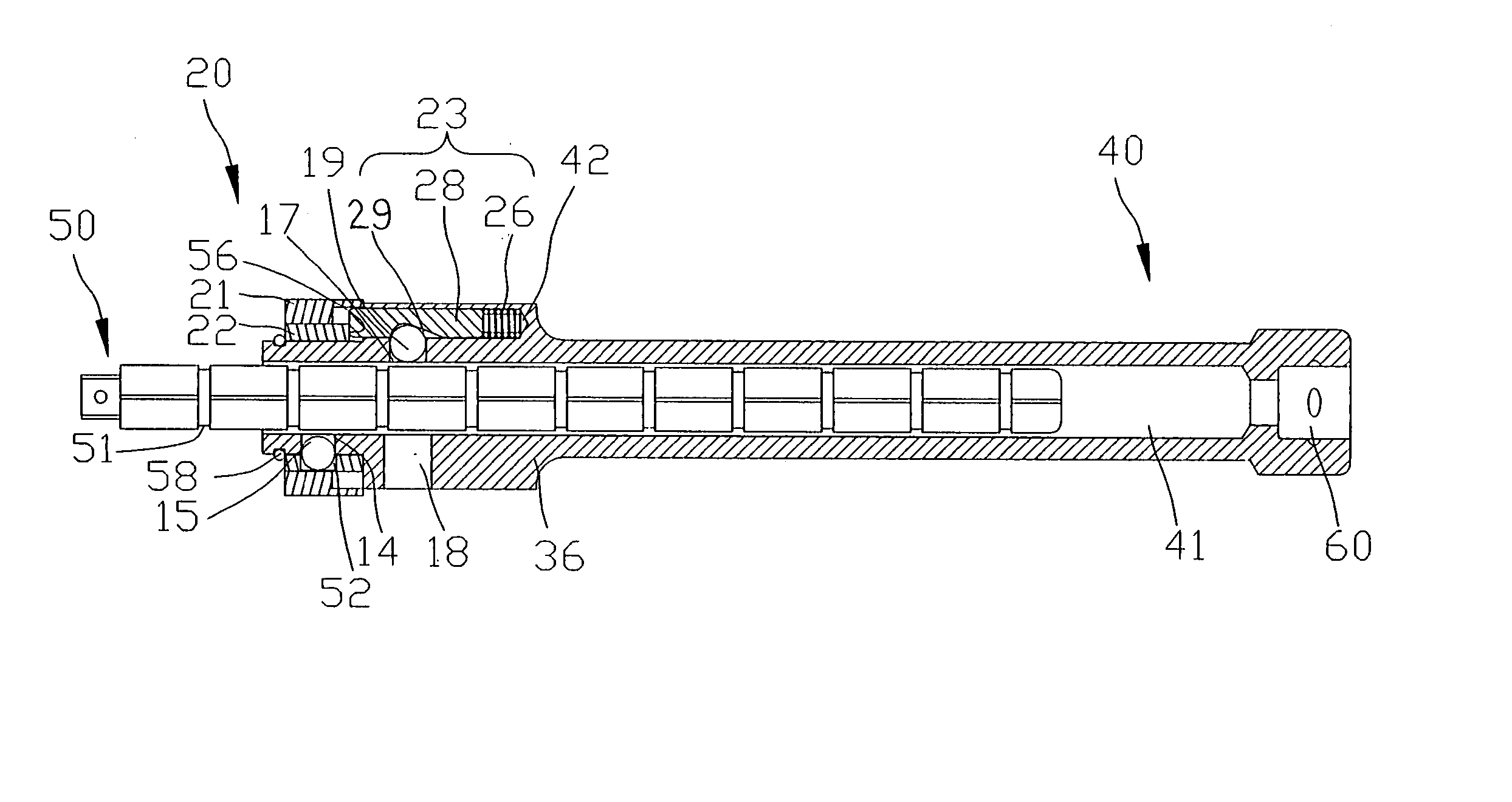

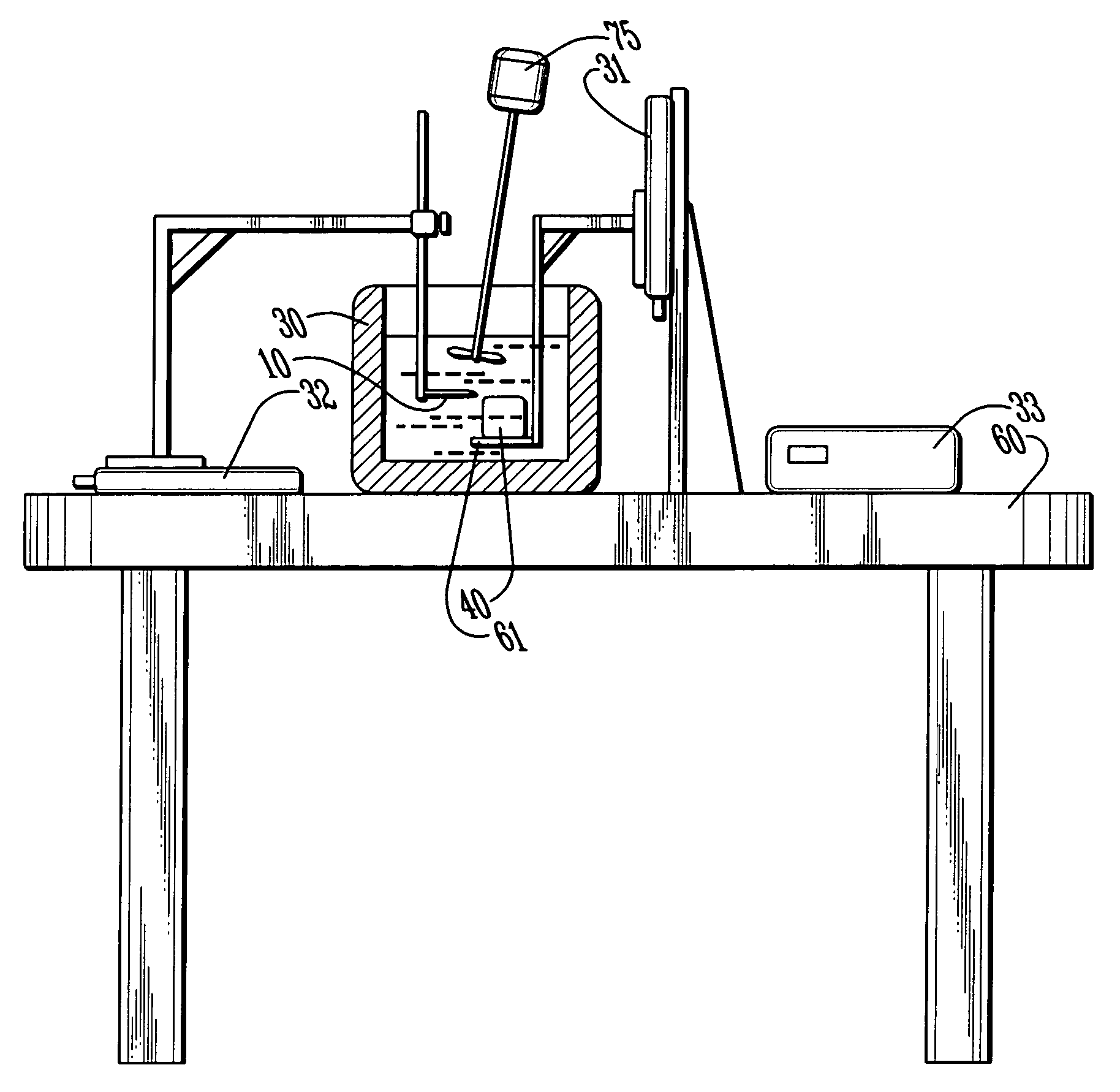

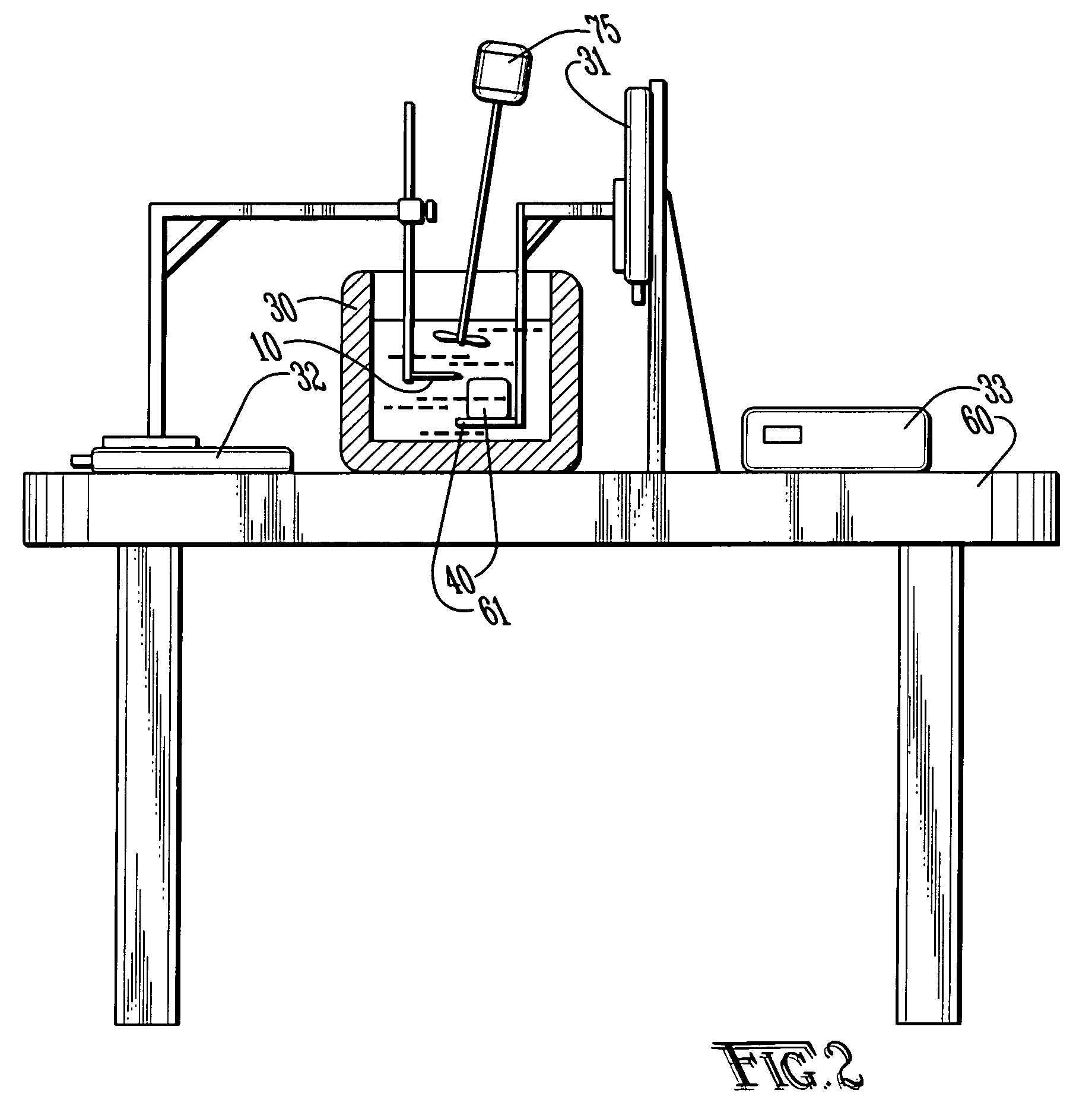

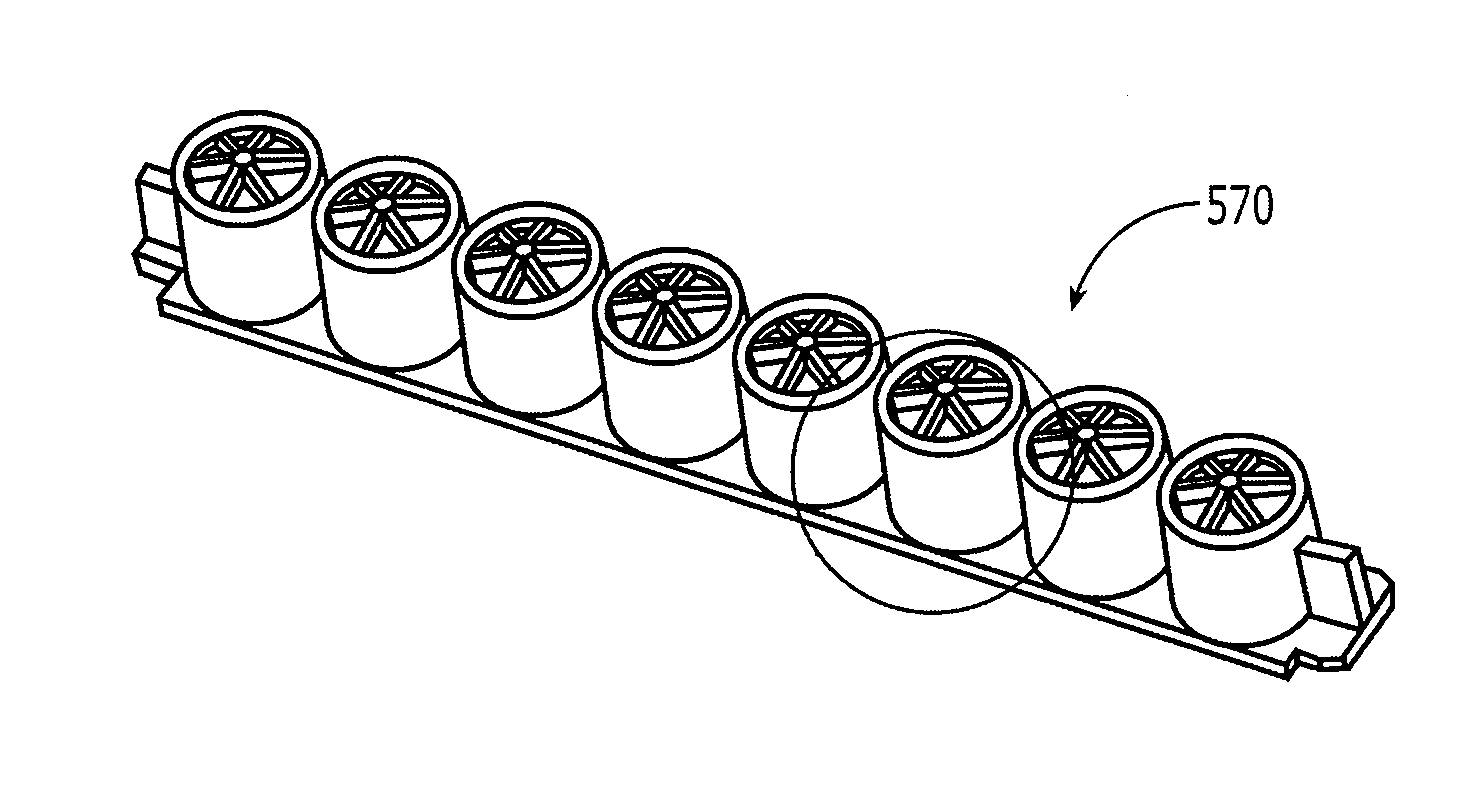

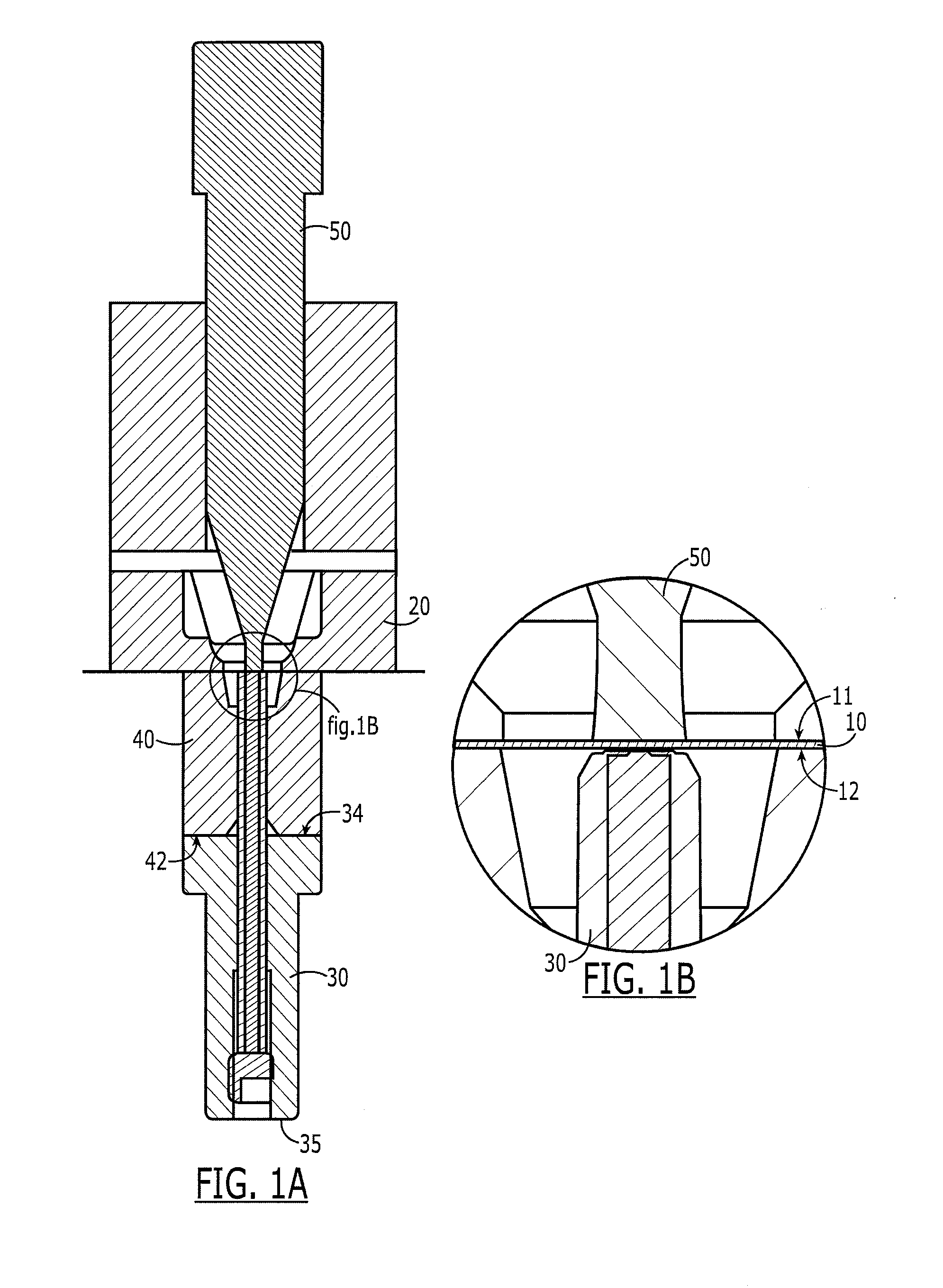

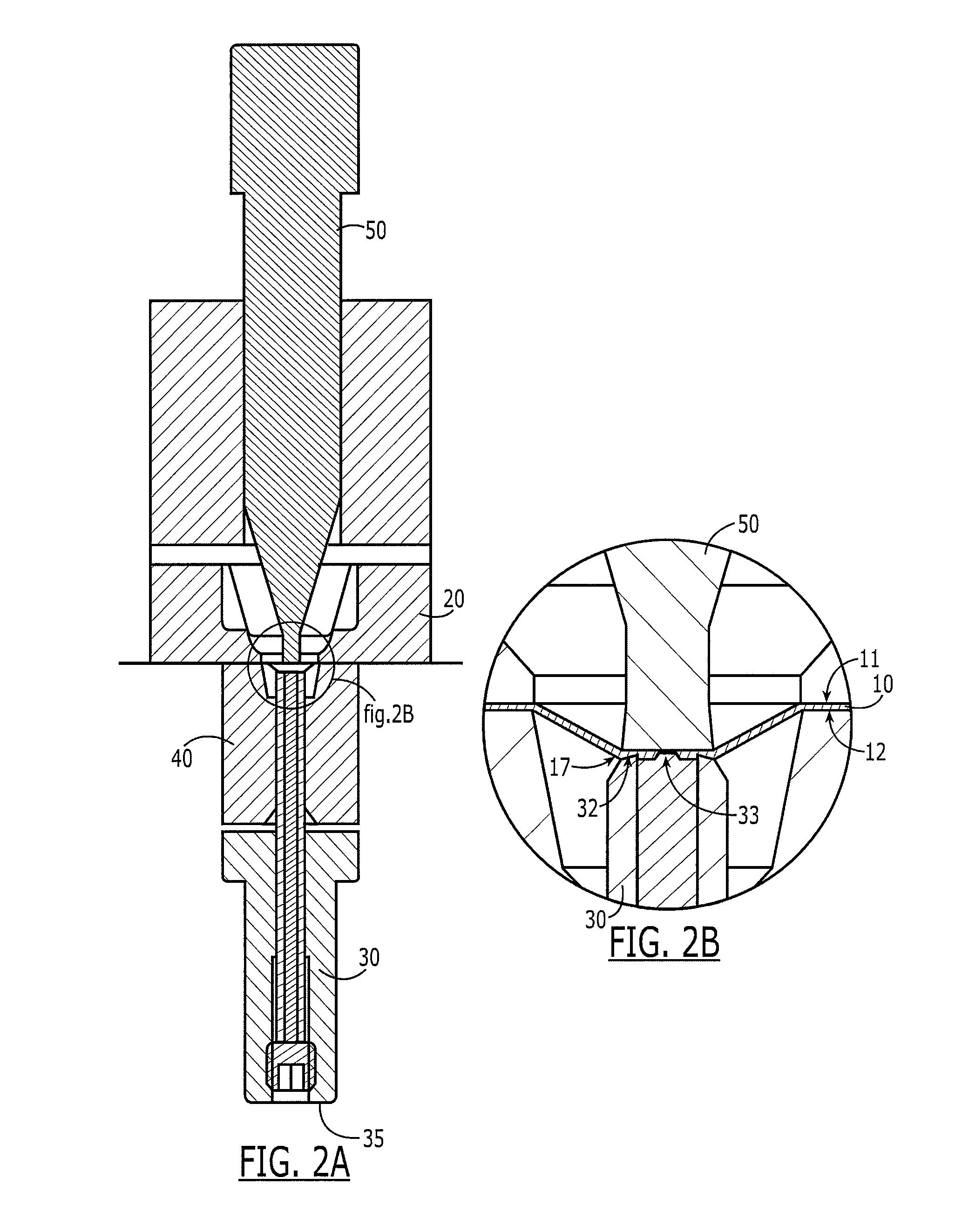

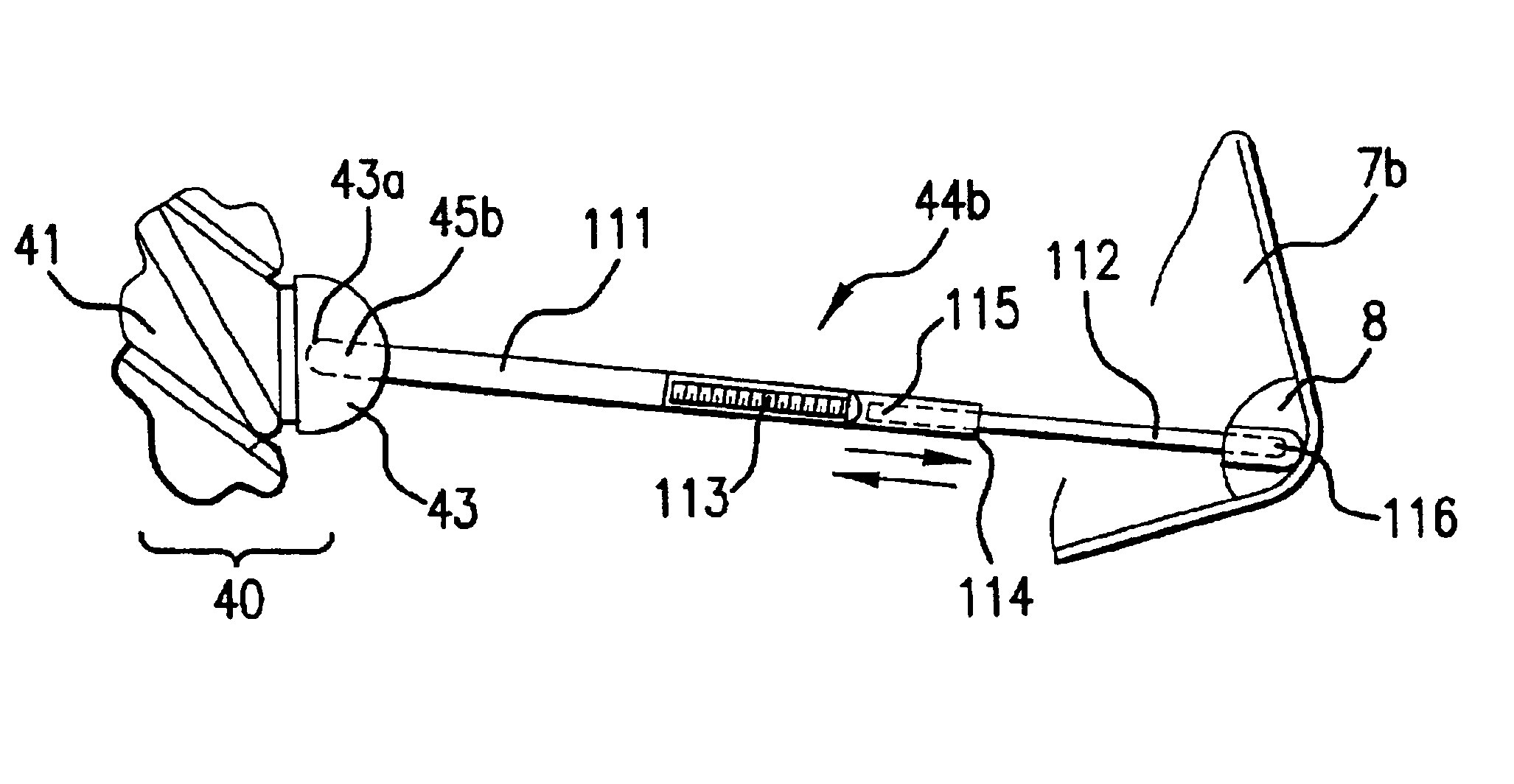

System and method for automatically processing tissue samples

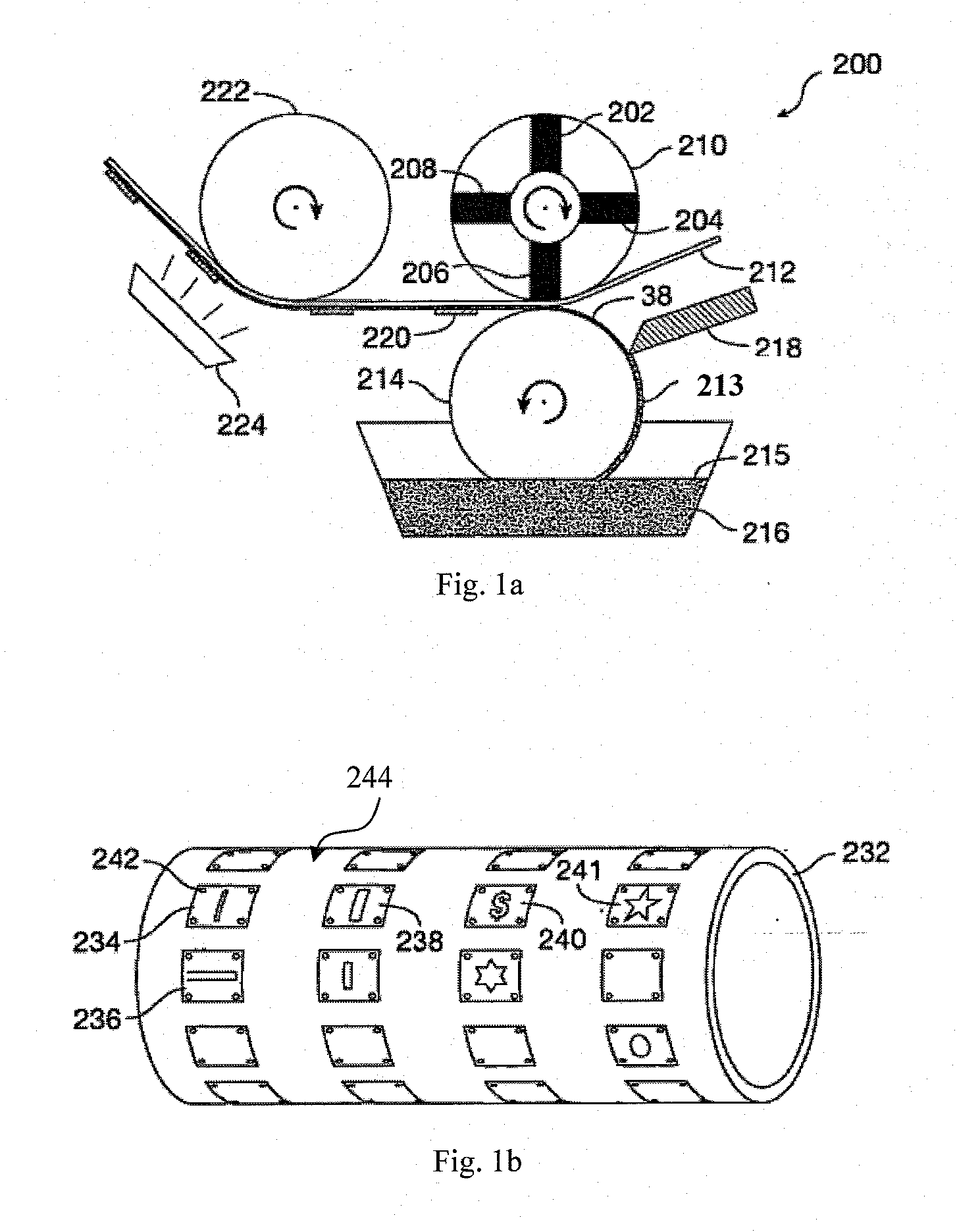

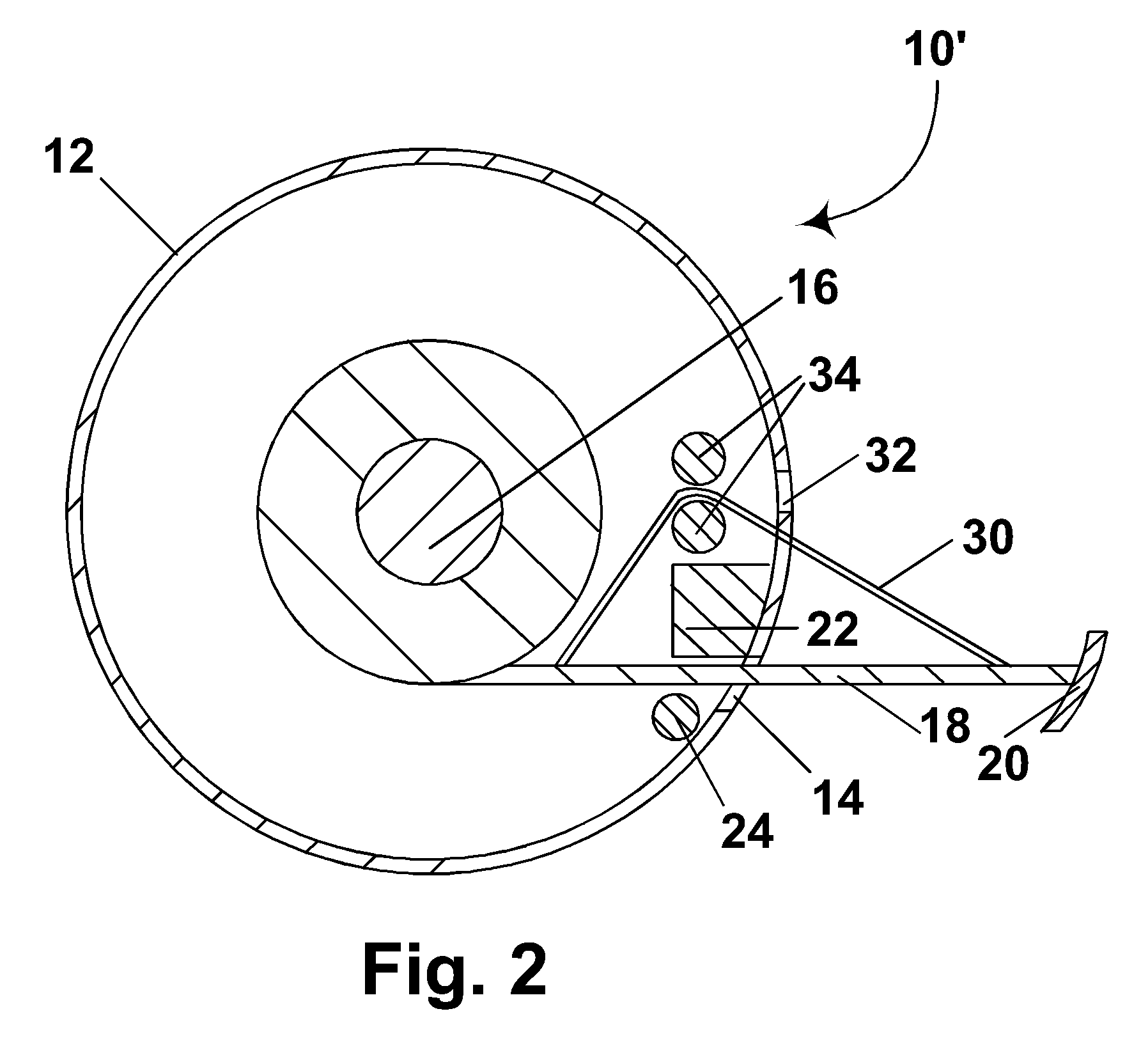

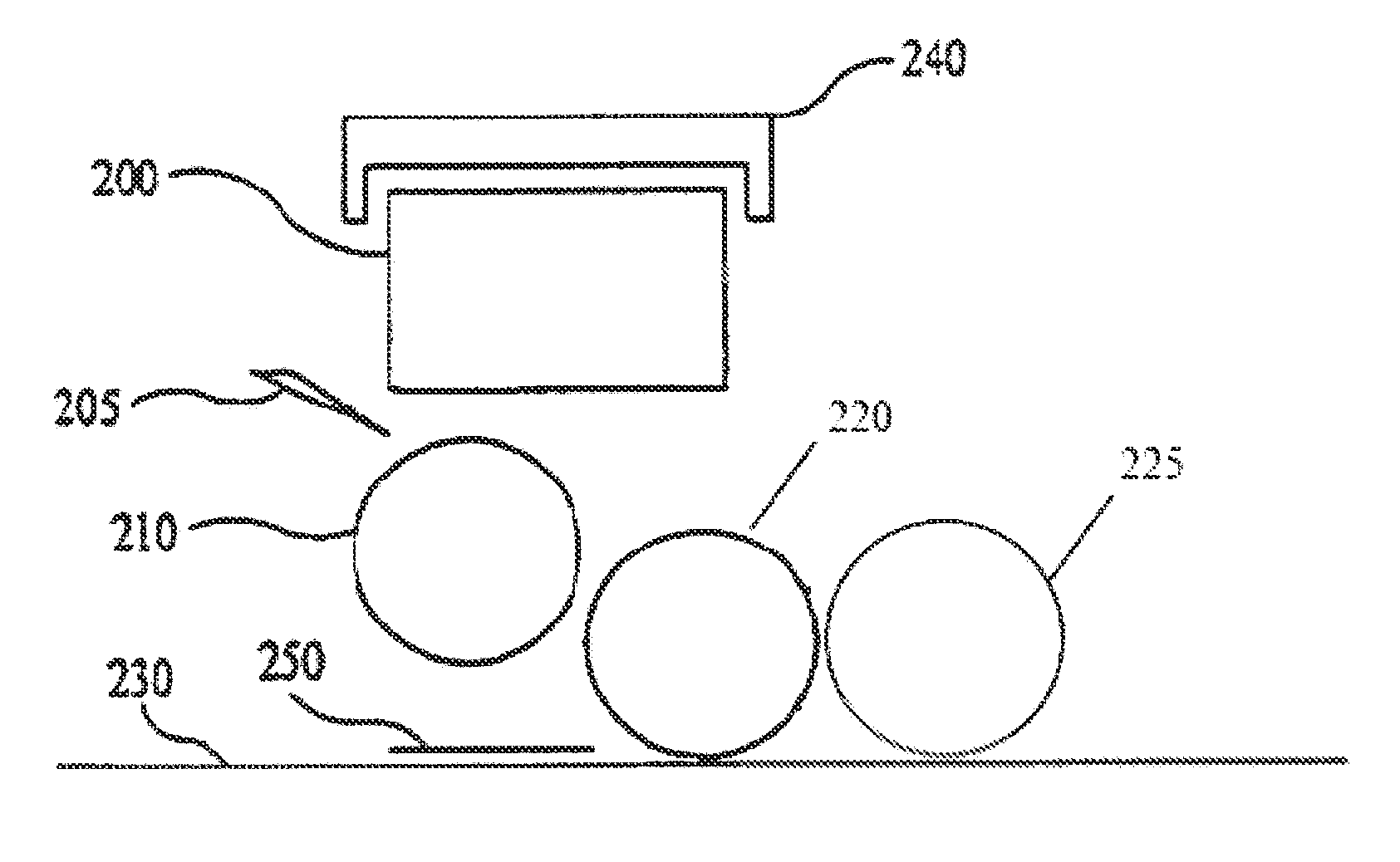

An apparatus and method for producing tissue slides is disclosed. The apparatus includes a holding assembly for manipulating the sample block, a blade assembly for preparing a thin section from the sample block, and a transfer roller mechanism for transferring the thin section to a receiving medium. The apparatus further includes a controller that may track the sample block and thin section. The method includes the steps of first locating a sample embedded within a support medium, which may be paraffin or a similar medium. Next, the embedded sample is oriented in such a way that its working surface is presented. This orientation may entail determining the orientation of the embedded sample with respect to the blade that will produce the largest cross-sectional area. Next, a slice of the sample from said embedded sample is removed and subsequently transferred to a suitable receiving medium, which may include a microscope slide. The slices may be stained, and a representation of the slice may be captured by an image capture device. The sample blocks may be transferred to a holding device, where they may be indexed and stored.

Owner:VONEIFF JOHN +2

High-throughput printing of semiconductor precursor layer from inter-metallic nanoflake particles

InactiveUS20070163641A1Increase contactReduce the temperatureLiquid/solution decomposition chemical coatingPhotovoltaic energy generationNanoparticleParticle method

Methods and devices are provided for transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after selective forces settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be nanoflakes that have a high aspect ratio. The resulting dense films formed from nanoflakes are particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

Breathing assistance apparatus

A breathing assistance apparatus is disclosed, for use with delivery of respiratory gases to a patient. The breathing assistance apparatus includes a patient interface, having a body section adapted to cover the nose, or nose and mouth of a patient and a sealing interface. The sealing interface includes at least an outer sealing member. The outer sealing member is adapted to attach to the body section in a sealing manner and has a substantially thin section in at least its nasal bridge region. The thin section is substantially thinner than the rest of the outer sealing member.The patient interface comprises a mask body and a seal assembly. The seal assembly includes a flexible seal, and a rigid seal clip, the seal assembly being removably attached to the mask body via the rigid seal clip. The mask body and rigid seal clip are profiled to match the contours of a user's face so that the seal has a substantially constant wall depth.

Owner:FISHER & PAYKEL HEALTHCARE LTD

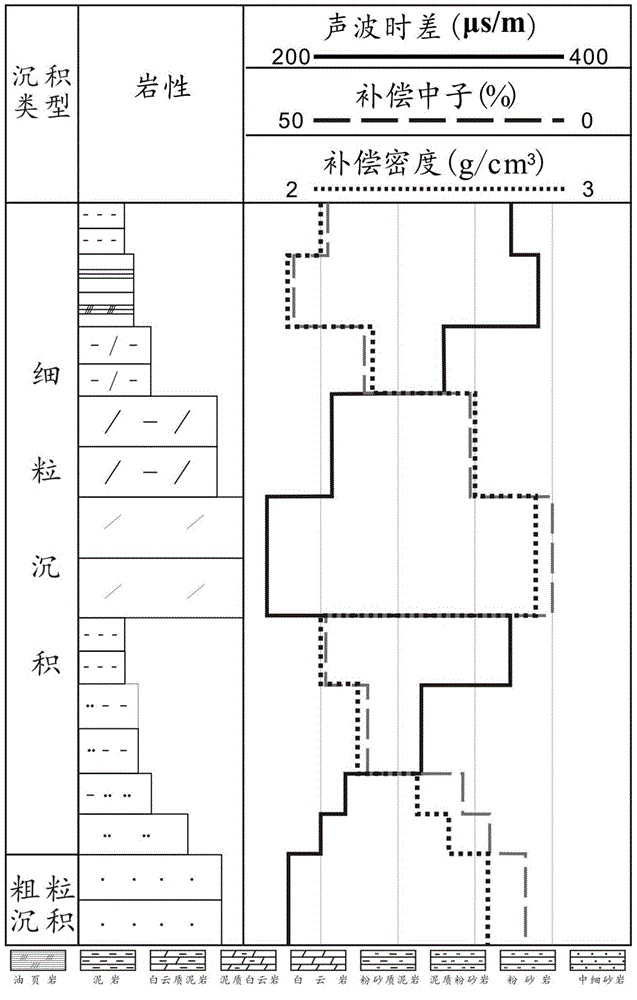

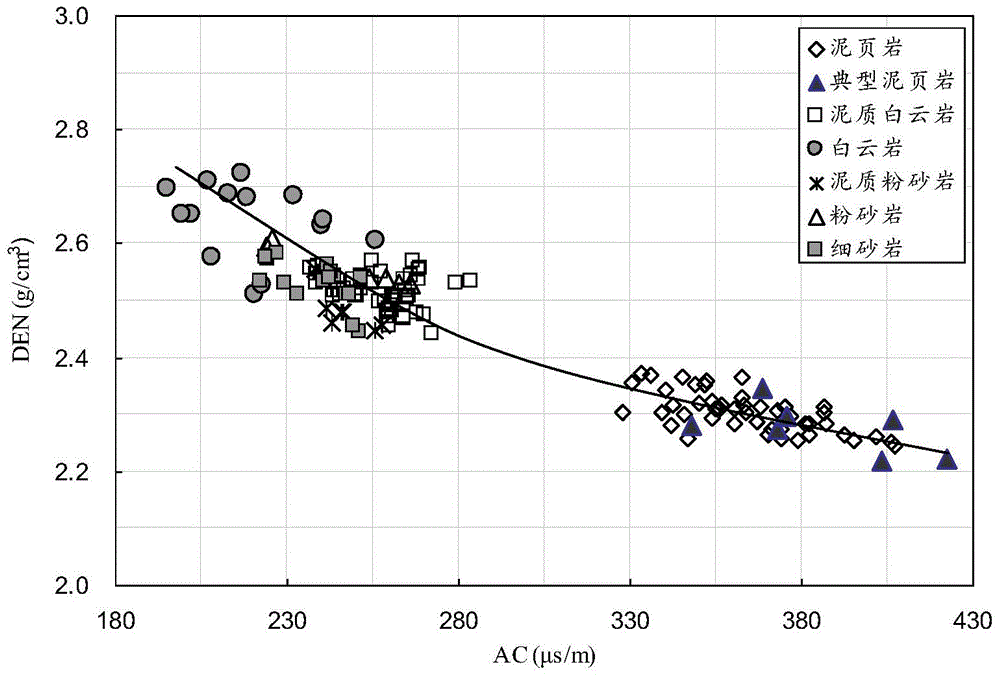

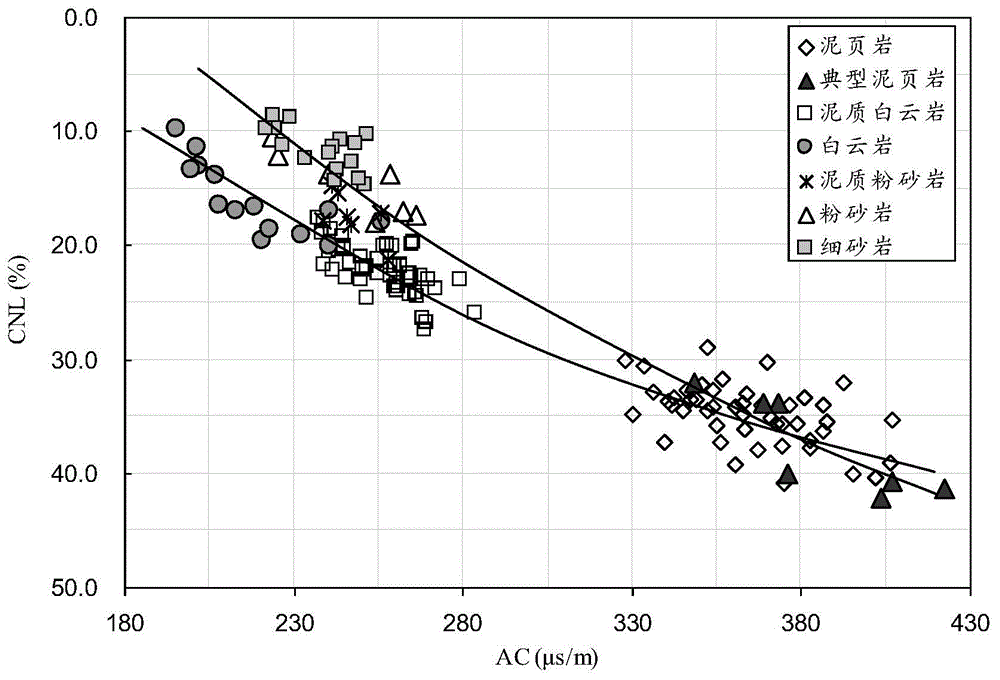

Lithology identification method

ActiveCN104989392ALithology Identification ContinuousMeet the evaluationBorehole/well accessoriesLithologyPorosity

The invention discloses a lithology identification method. The lithology identification method comprises the steps that firstly, conventional three-porosity (sound waves, density and neutrons) logging measured values of N rock core samples are obtained through the steps of thin section authentication, X-ray diffraction analysis, rock core true depth determination and the like; secondly, the relative distance between two parameters of conventional three-porosity logging is obtained, and the quantitative relation between the relative distance of the two parameters and primary mineral components obtained through X-ray diffraction total rock analysis is obtained according to the relative distance of the two parameters and the mineral components of the N rock core samples; thirdly, rock classification based on the relative distance of the two parameters is established and can be applied to lithology identification of fine grain sedimentary facies area logging, and continuous lithology identification can be carried out on well stratums without core sampled.

Owner:PETROCHINA CO LTD

Powder coating containing aerogel particles and preparing method thereof

InactiveCN101143981AImprove insulation performanceImprove sound insulationPolyurea/polyurethane coatingsPowdery paintsInsulation layerMixed materials

A powder coating containing aerogel particles and a method for preparing the same relates to a powder coating and a preparation method, which solves the problem that the existing heat insulating composite material containing aerogel is not suitable for making thinner heat insulation material and spraying insulation layer on the component surface, and the aqueous coating has high water content, long construction period and low heat insulation property. The coating of the invention is prepared by 5-80 percent of aerogel particles and 20-95 percent of powderedd resin by volume percentage, and the method includes the following steps: firstly, aerogel, resin and additive are mixed by volume percentage; secondly, the mixed materials are delivered into a melting-extruder melt and extrude; thirdly, the extrudate is pressed into thin sections; fourthly, the thin sections are ground into small pieces by roller machine; fifthly, the small pieces are conveyed into an air staged milling equipment to grind, so as to obtain the powder coating. The powder coating containing aerogel of the invention has advantages of environmental protection, clearness, economy, high efficiency, and good heat insulation property, sound insulation property and surface hydrophobicity.

Owner:HARBIN INST OF TECH

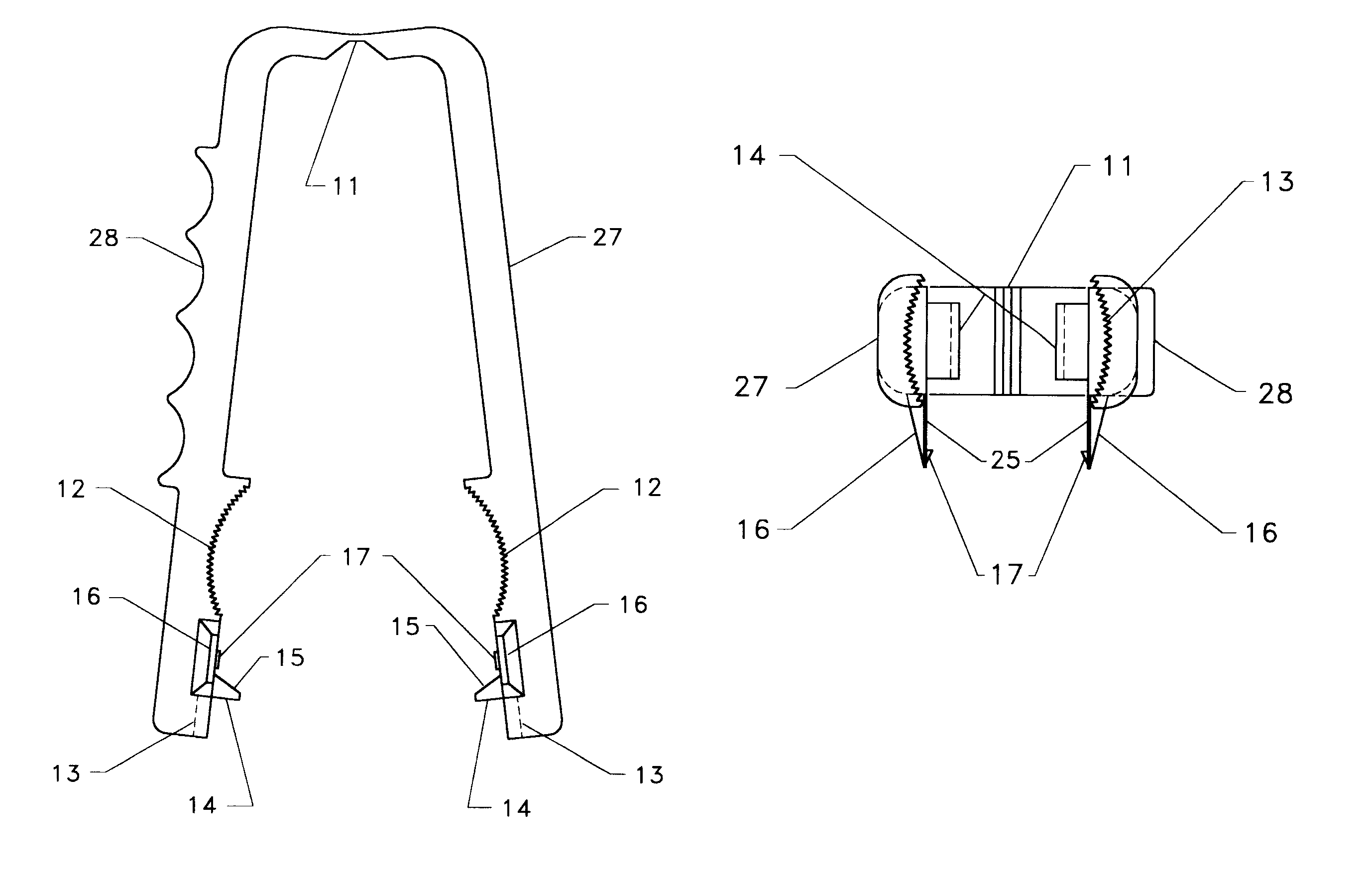

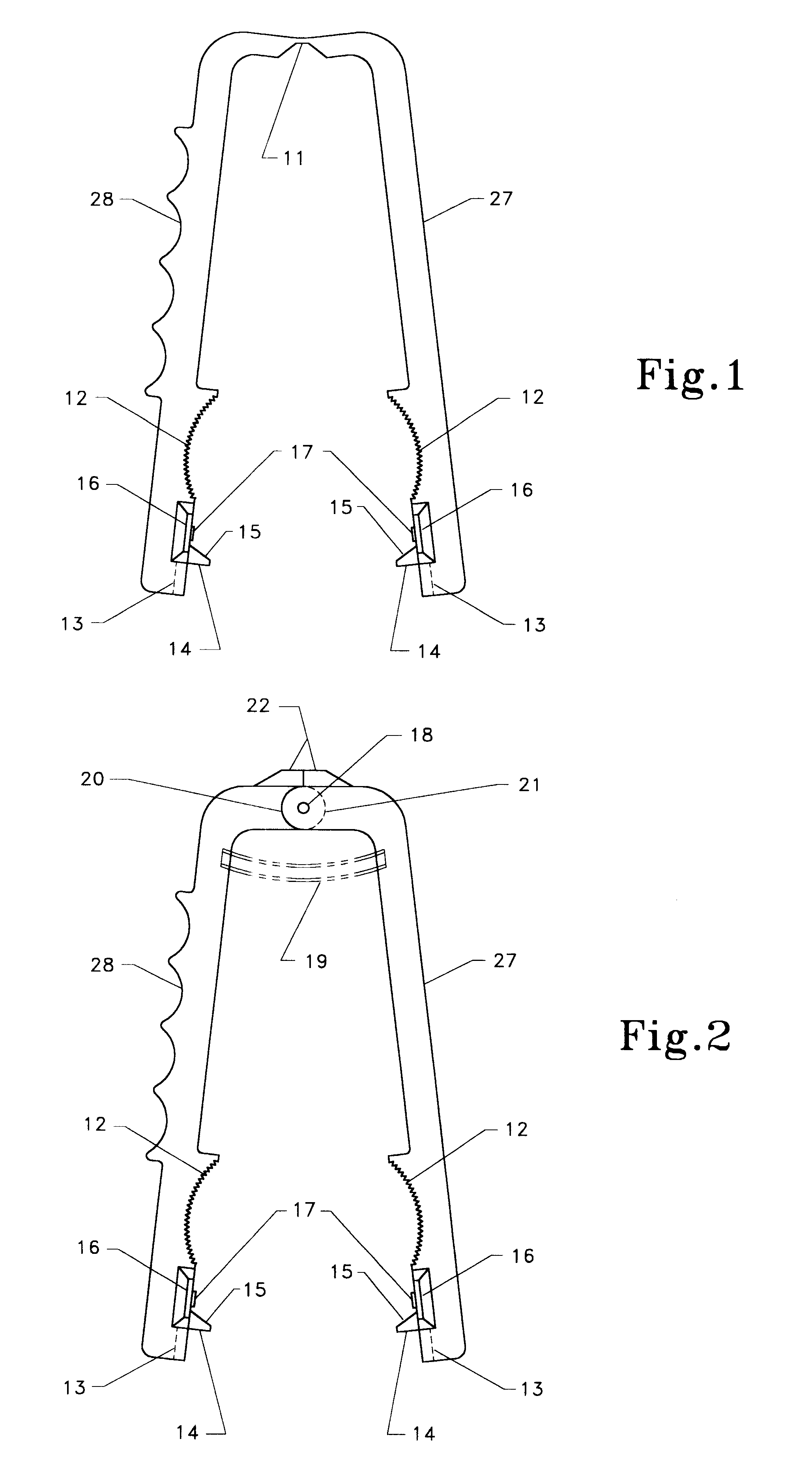

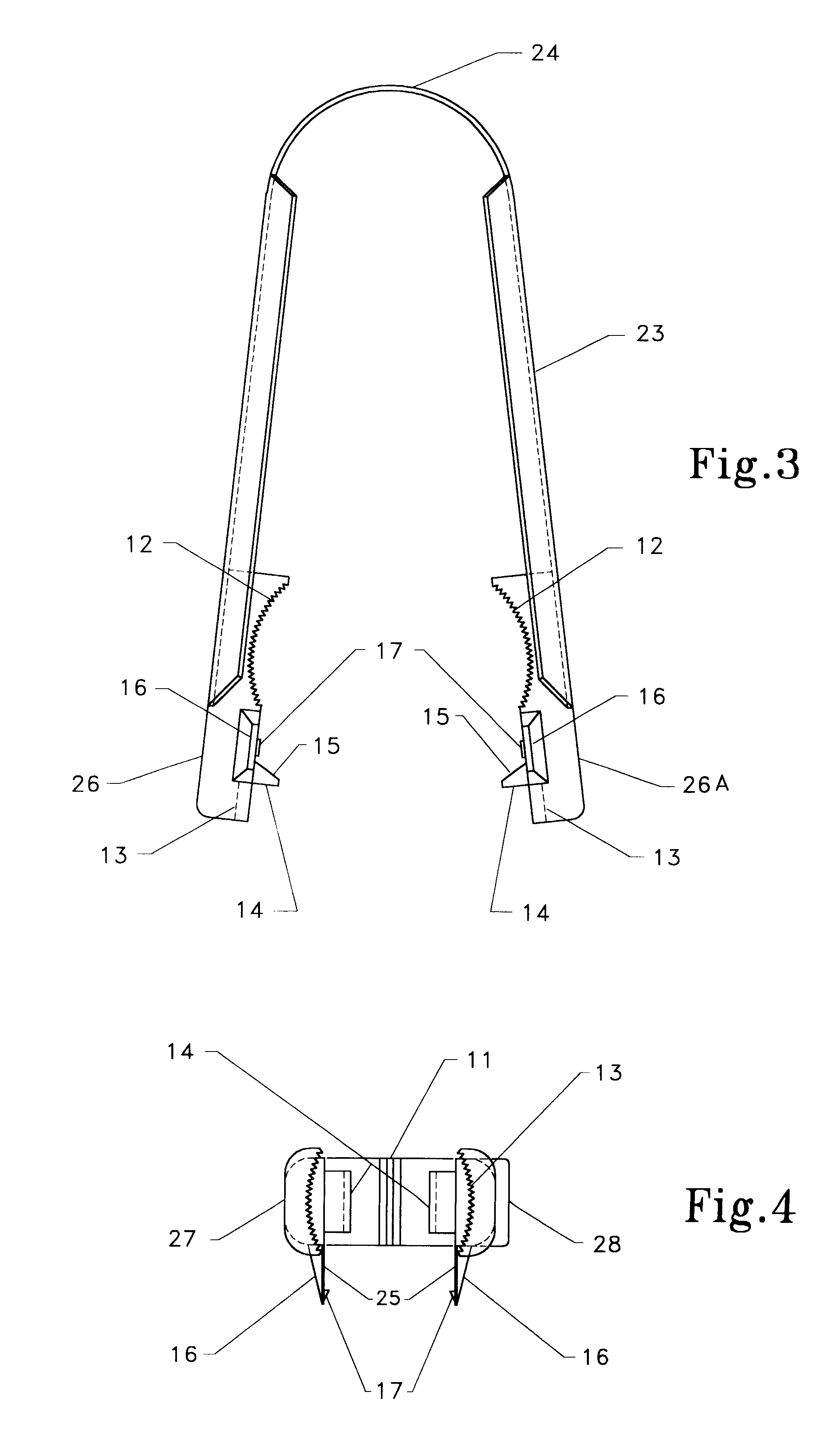

Pill bottle opener

An opener for several different types of pill bottle caps and closures. In the preferred embodiment, the opener is molded as one piece of strong, flexible plastic material that can be repeatedly bent without failing. The opener has the shape of an arch, with a thin section at the top of this arch that acts as a hinge and return spring for the two legs of the arch, which are thicker in section and act as handles to react the forces applied by the user's band. The inside of each handle has a curved surface with teeth on its inside face to grip the outside of a bottle cap. The inside surface of each handle also has a triangular shaped lug that applies a downward force on the top of a bottle cap, and also applies an upward wedge force to pry a bottle cap free. At the bottom of each handle is a second curved surface, as viewed from below, which also has teeth for gripping the outside of a bottle cap. The side of each handle has a thin section blade which can cut and pry loose the seals on pill bottles, as well as pull the cotton packing from pill bottles.

Owner:RYDER JOHN C

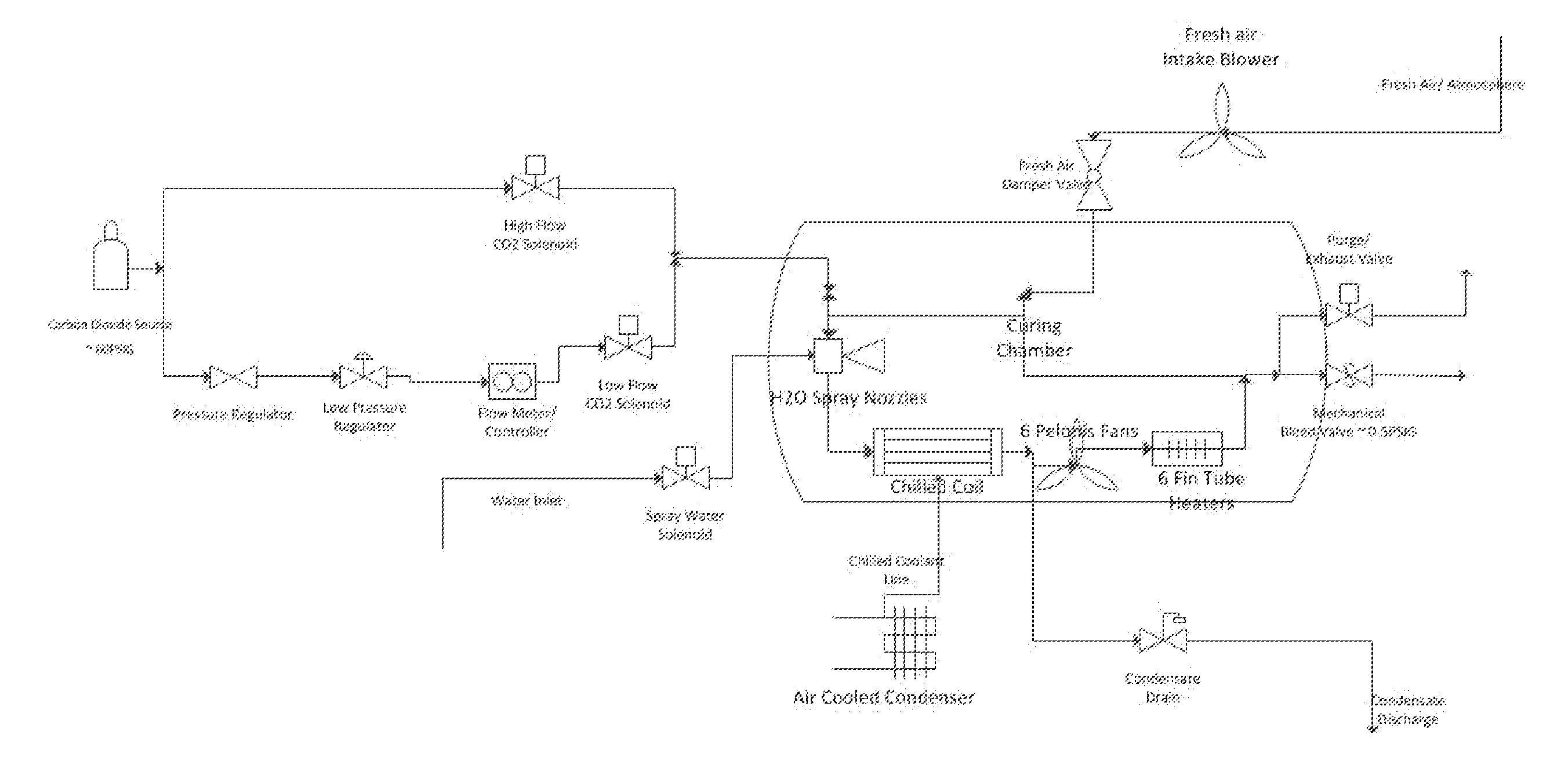

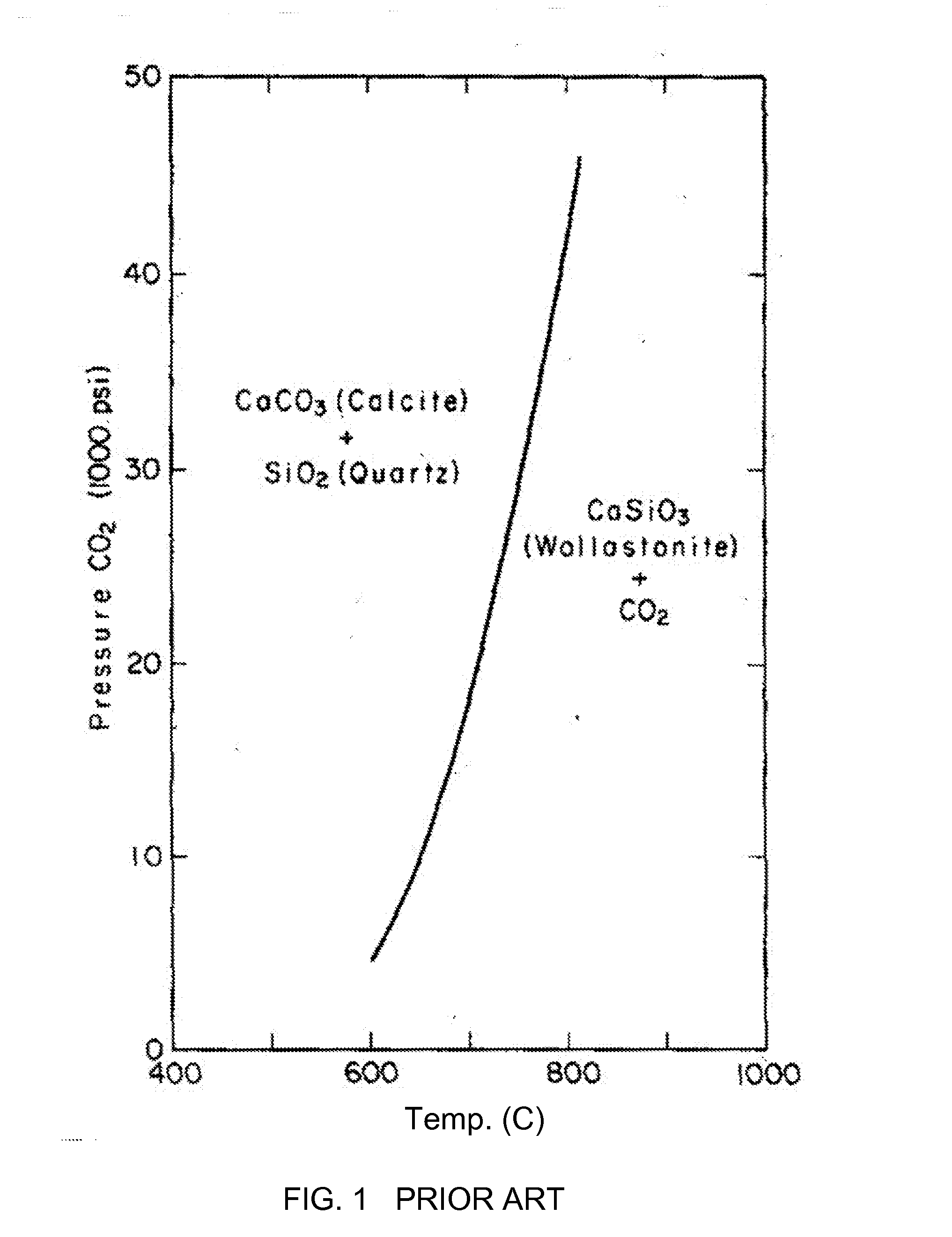

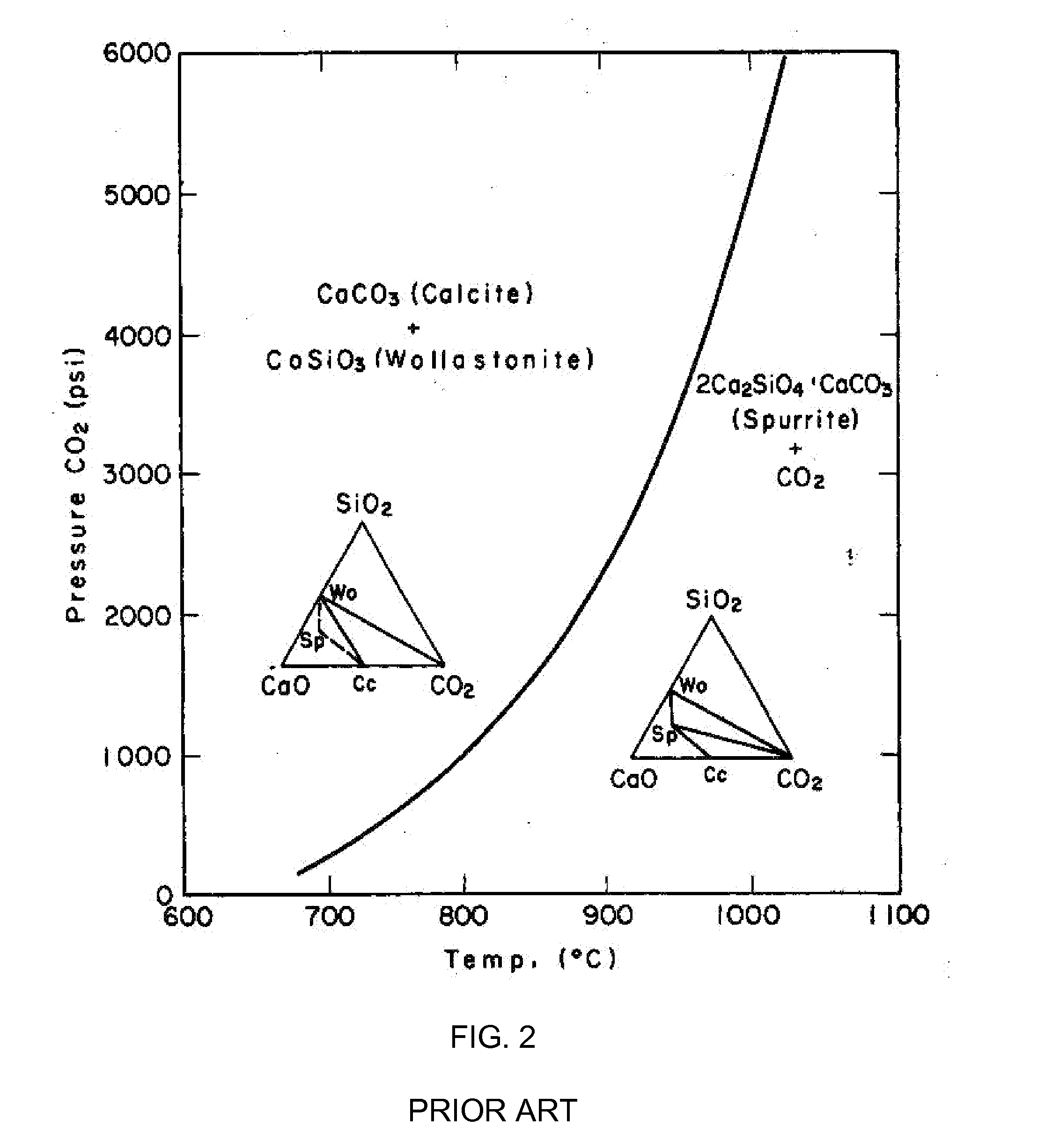

Rapid curing of thin composite material sections

A method of preparing and rapidly curing a composite material having a thin cross section. The composite material includes a mixture of solid particles, at least some of which are a material that reacts with CO2, such as a silicate, for example Wollastonite. The green material is prepared by mixing the solid components with a liquid such as water to form a slurry, and forming green bodies by placing the slurry in forms. The green bodies are reacted with CO2 to form cured composite materials having thin sections, in the range of 10 to 15 mm. Curing in periods of 6 hours has been demonstrated.

Owner:SOLIDIA TECH

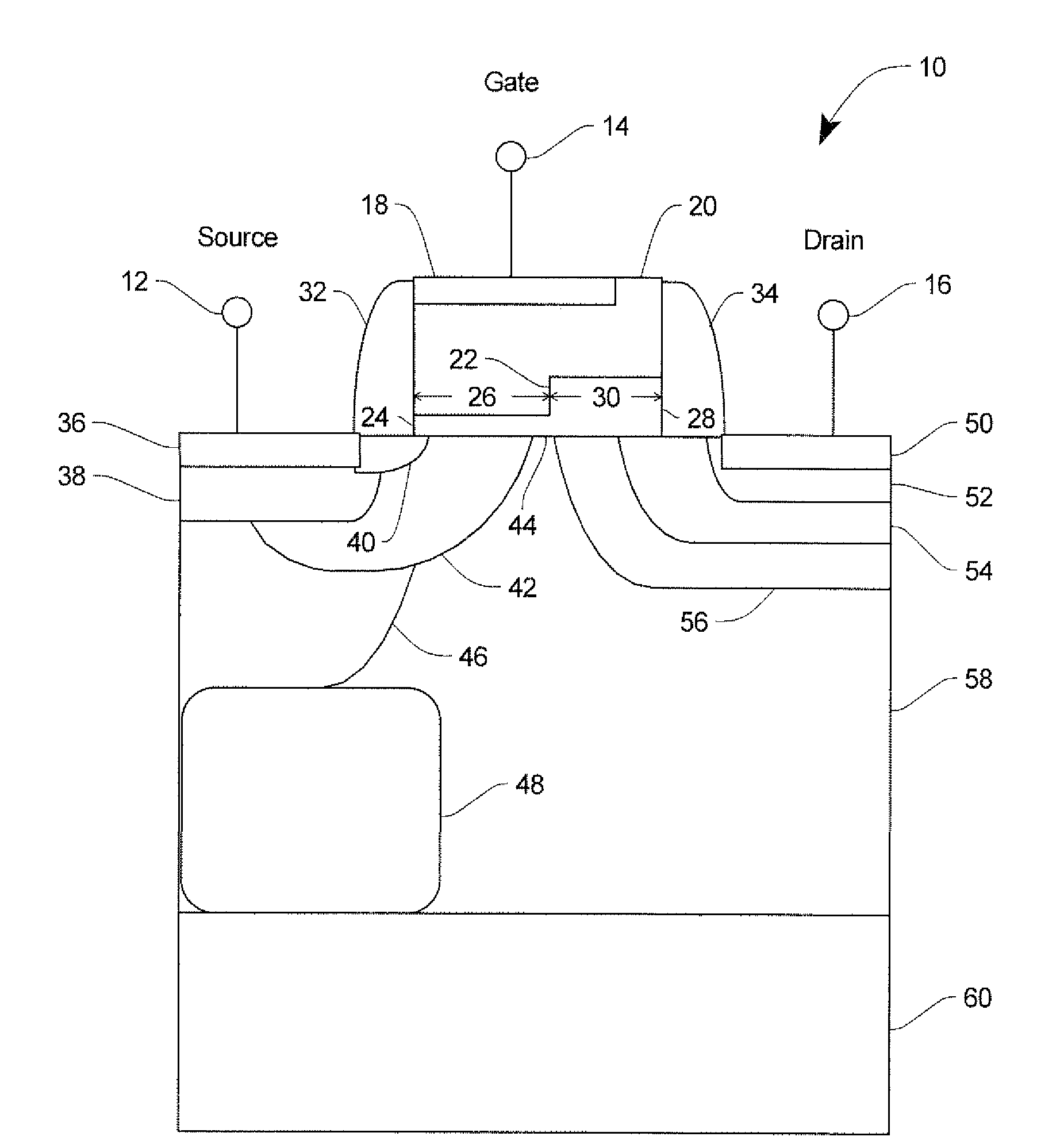

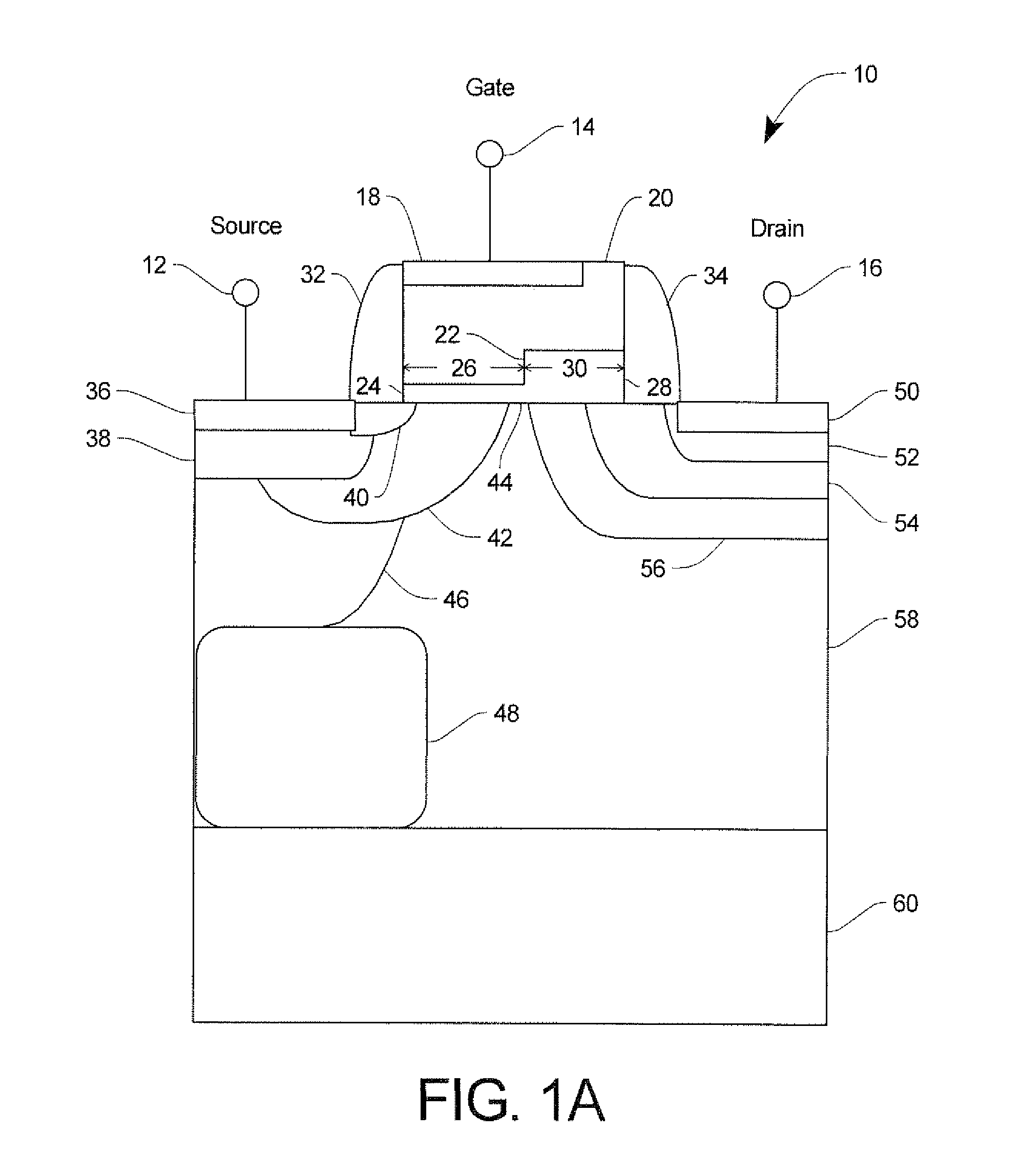

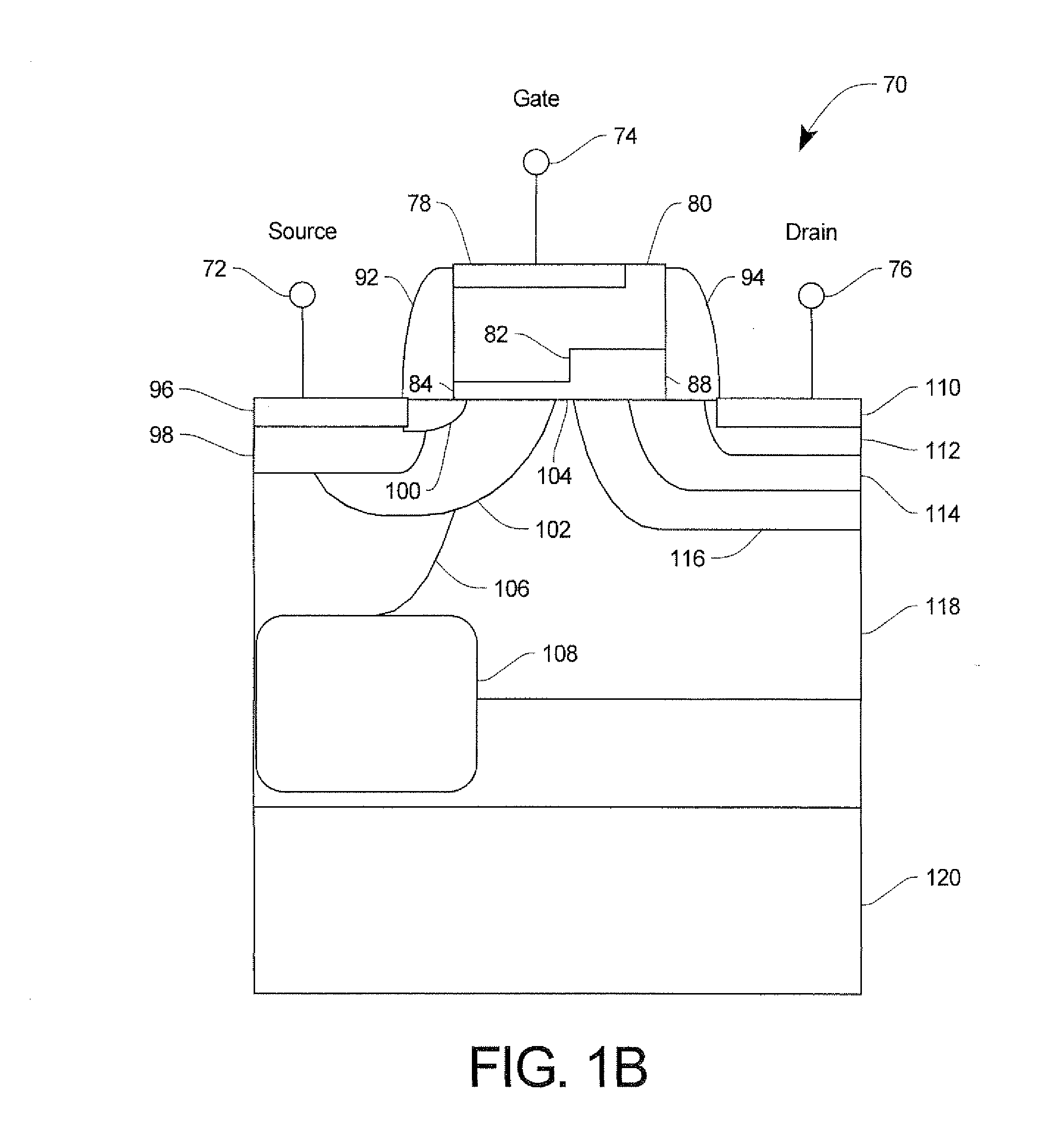

Integrated complementary low voltage rf-ldmos

InactiveUS20080164537A1Semiconductor/solid-state device manufacturingSemiconductor devicesLDMOSLow voltage

Complementary RF LDMOS transistors have gate electrodes over split gate oxides. A source spacer of a second conductivity type extends laterally from the source tap of a first conductivity type to approximately the edge of the gate electrode above the thinnest gate oxide. A body of a first conductivity type extends from approximately the bottom center of the source tap to the substrate surface and lies under most of the thin section of the split gate oxide. The source spacer is approximately the length of the gate sidewall oxide and is self aligned with gate electrode. The body is also self aligned with gate electrode. The drain is surrounded by at least one buffer region which is self aligned to the other edge of the gate electrode above the thickest gate oxide and extends to the below the drain and extends laterally under the thickest gate oxide. Both the source tap and drain are self aligned with the gate side wall oxides and are thereby spaced apart laterally from the gate electrode.

Owner:SEMICON COMPONENTS IND LLC

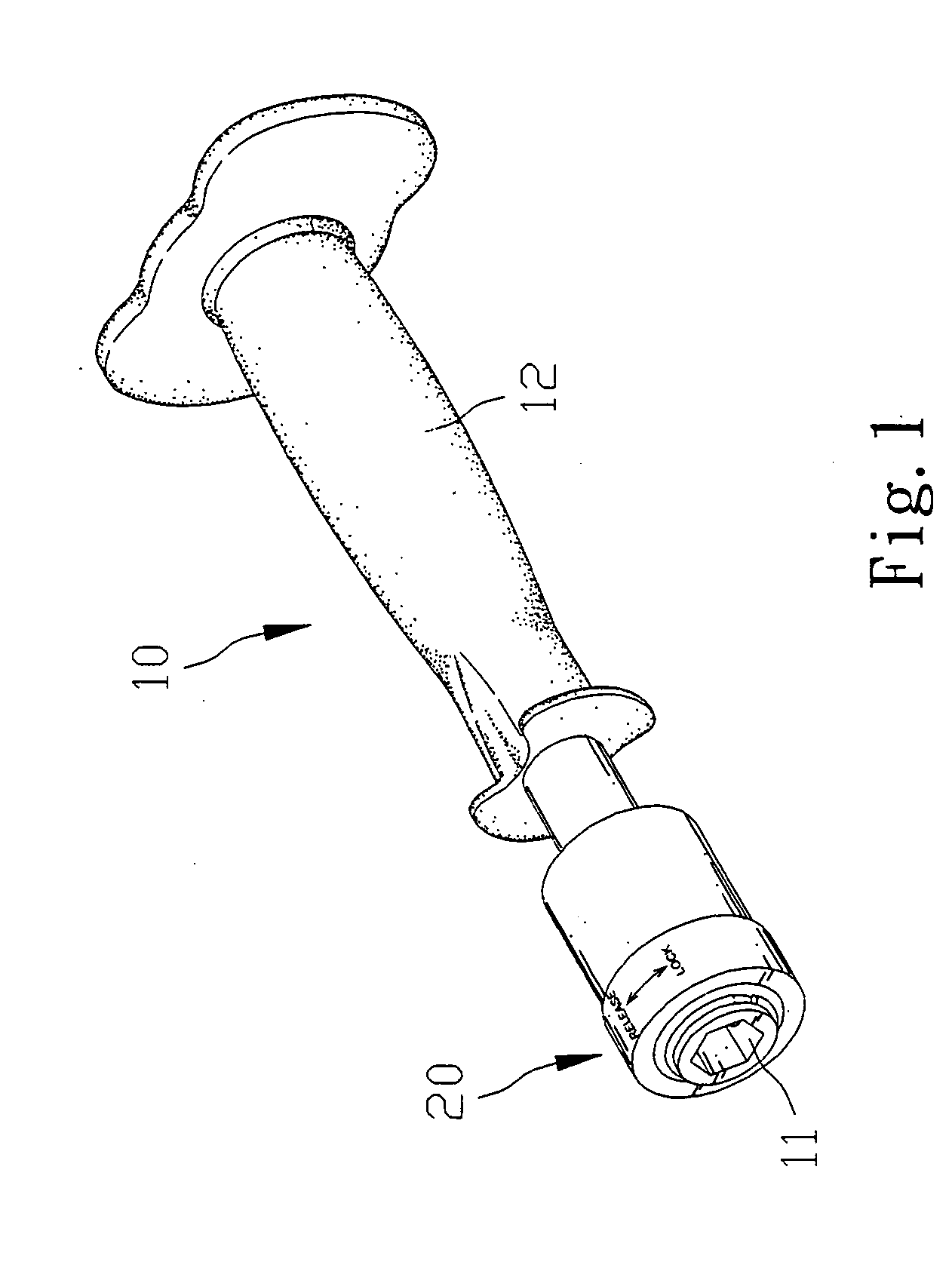

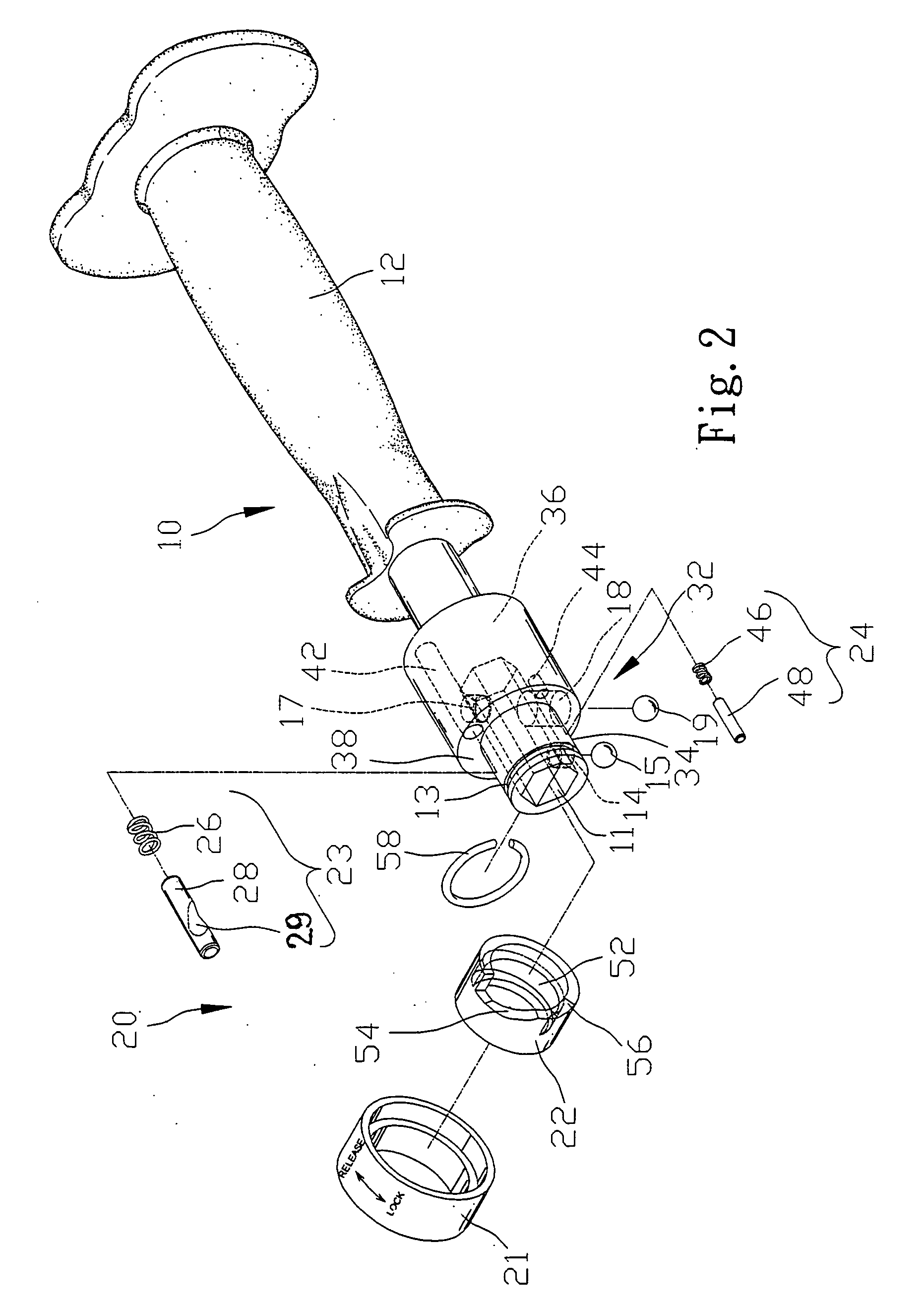

Tool including bit and handle

A handle is provided for use with a bit or extensive rod. The handle includes a socket. The socket includes a thin section, a thick section, an annular face between the thin and thick sections, an axial cavity and a radial aperture communicated with the axial cavity in the thin section. A detent is put in the radial aperture. A chuck is put on the socket for control over the detent.

Owner:LIOU MOU TANG

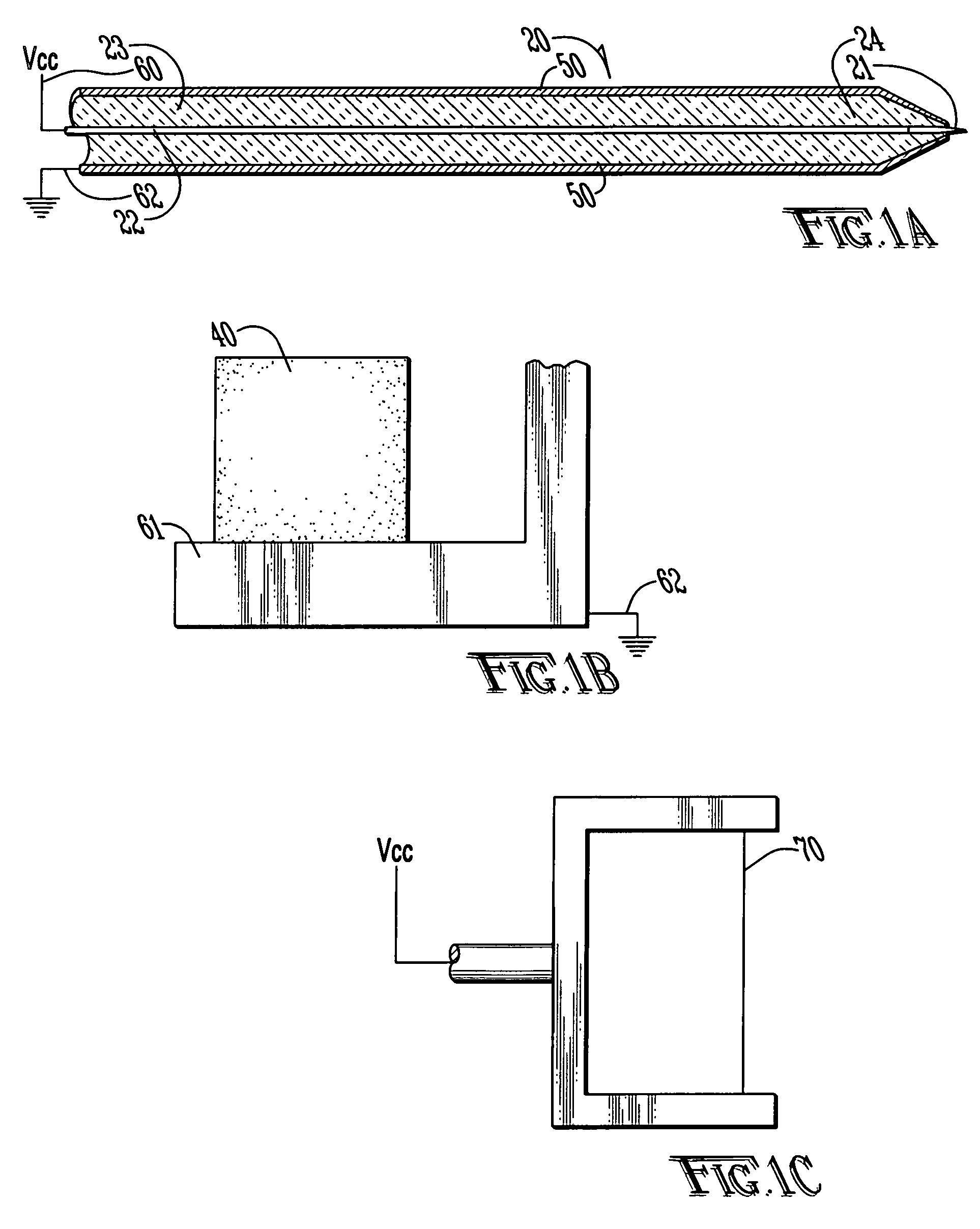

Tissue electro-sectioning apparatus

InactiveUS20050220674A1Increase the sectionIntense and localized fieldAutomatic control devicesAnalysis using chemical indicatorsFresh TissueGene and protein expression

An apparatus for sectioning fresh unfixed tissue into very thin layers with preserved tissue architecture, antigenicity, mRNA content, and amenable to 3-D computer reconstruction without mechanical or thermal damage by employing a sectioning tool having an electrode with an intense focused electrical field at an edge. A computer controlled x-y-z translation stage moves the sectioning tool through the tissue as defined by a predetermined program. The sectioning tool produces consecutive thin sections of fresh tissue for immunohistochemical and nucleic acids analyses without mechanical or thermal damage, ultimately allowing high-resolution volumetric reconstruction of gene and protein expression patterns of large tissue specimens. The geometry of the sectioning tool is selected so as to produce a spatially localized electrical field of sufficient intensity to sever molecular bonds or propagate flaws in tissue without mechanical cutting.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

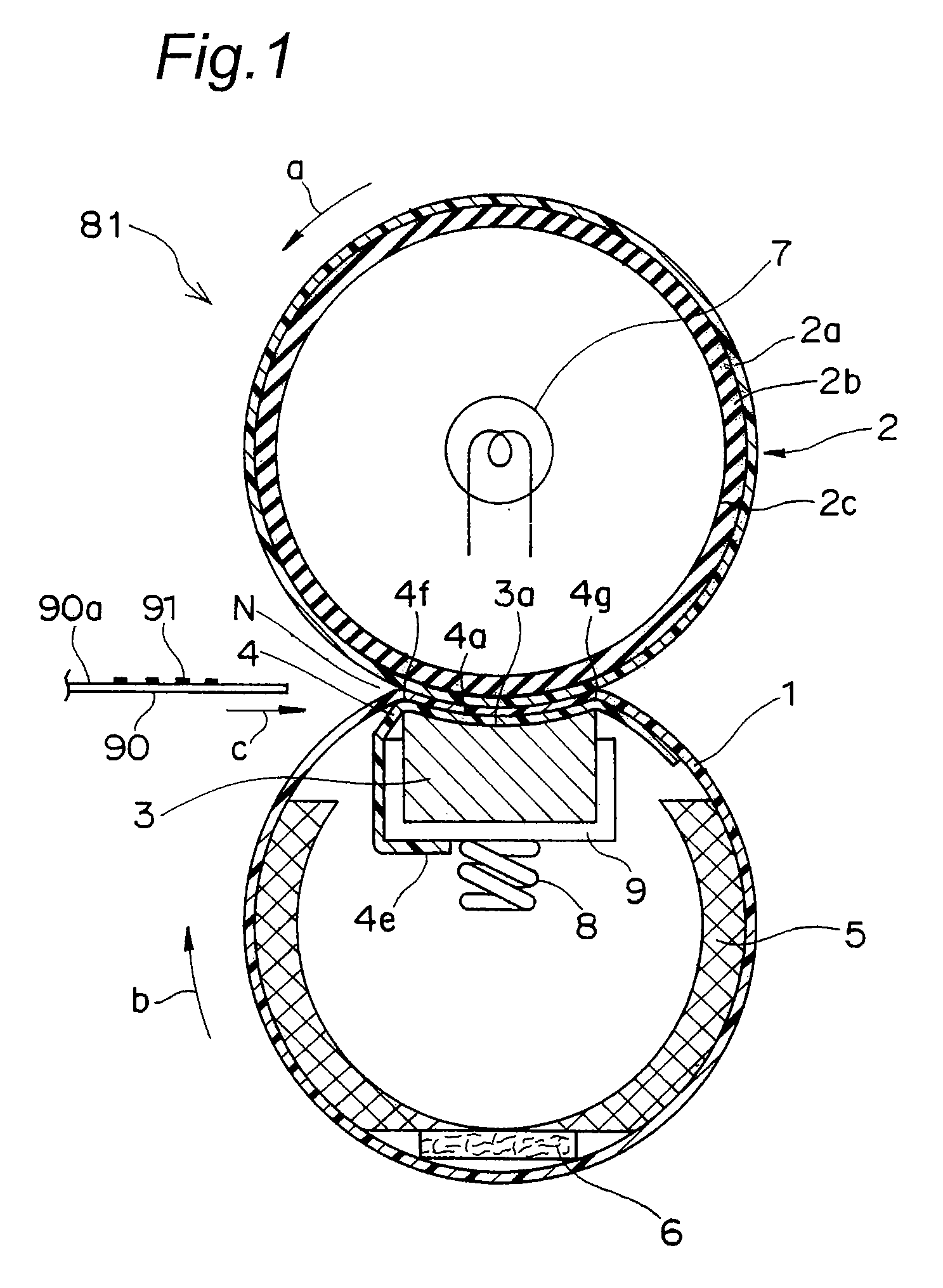

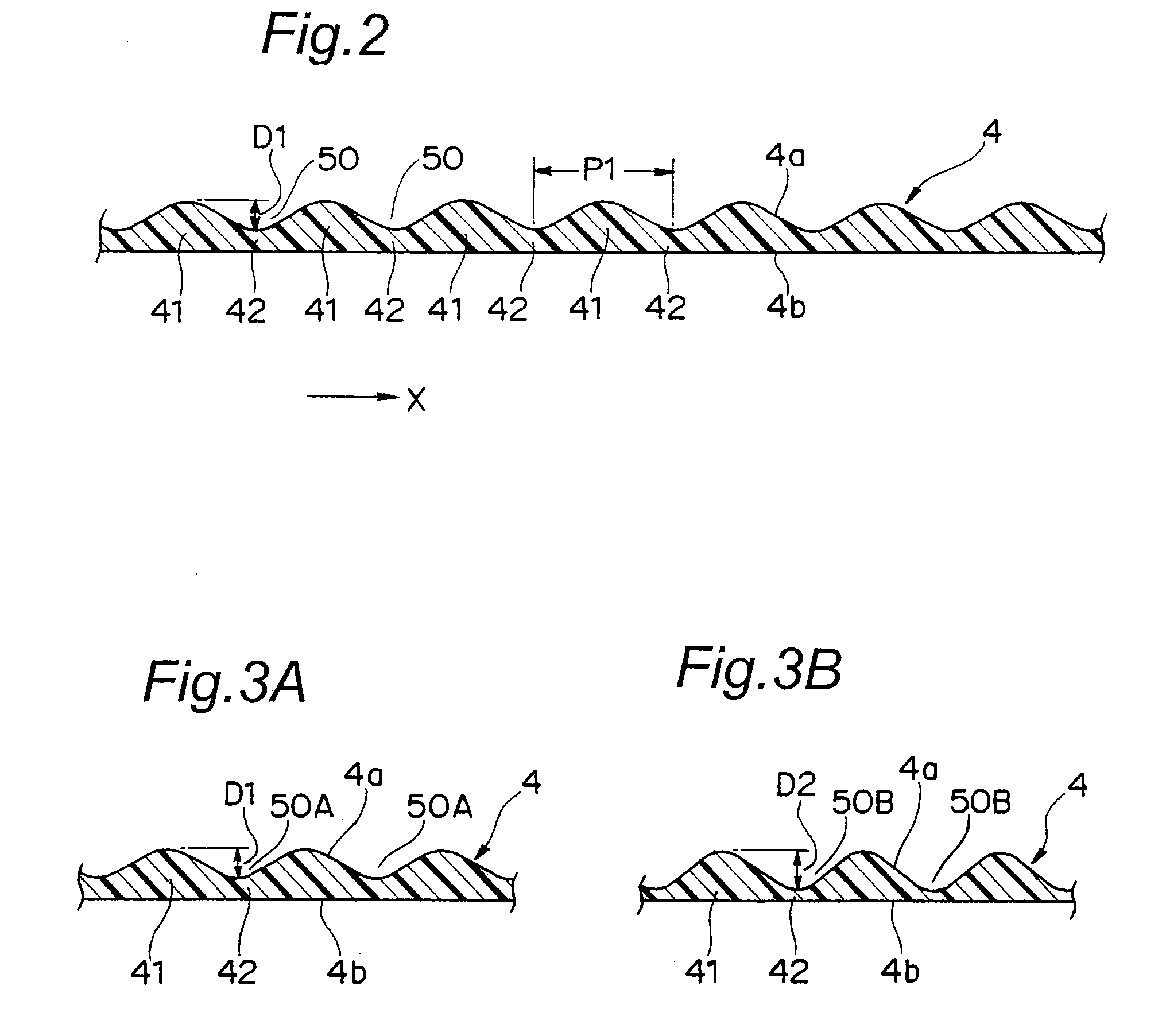

Sliding sheet for fixing devices, manufacturing method for same, fixing device, and image forming apparatus

ActiveUS20090014942A1Reduce manufacturing costShape stableElectrographic process apparatusRotary pressesEngineeringThin section

A sliding sheet for fixing devices in the present invention is inserted in between an endless belt constituting one member out of two members which form a nip section for fixing operation and a pressure member for pressing the endless belt from an inner surface side toward the other member out of the two members. The sliding sheet, which is made of a single resin, repeatedly has a thick section and a thin section at least with respect to a sliding direction of the endless belt due to substantial difference in resin amount per unit area corresponding to positions within a sheet surface.

Owner:KONICA MINOLTA BUSINESS TECH INC

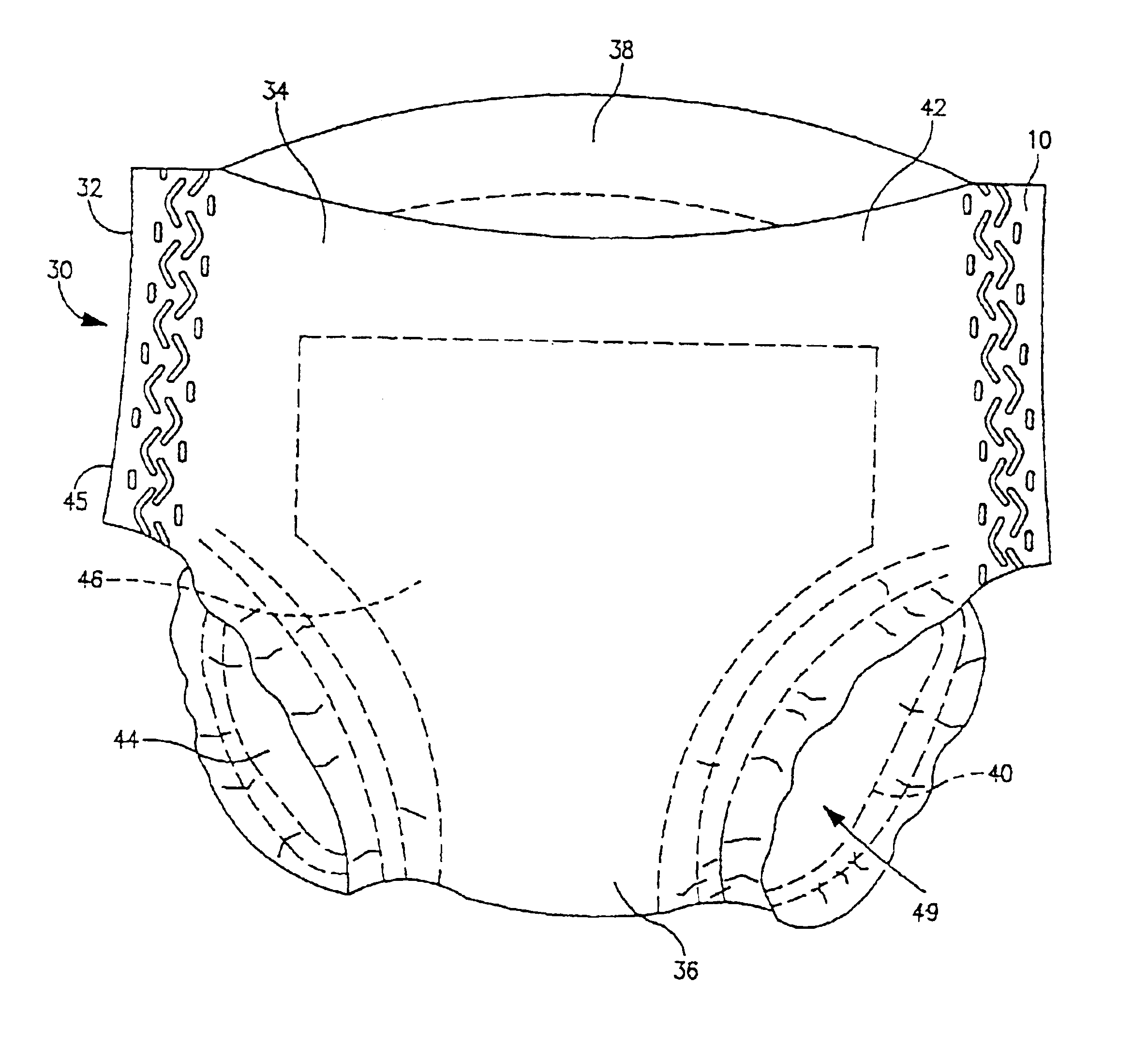

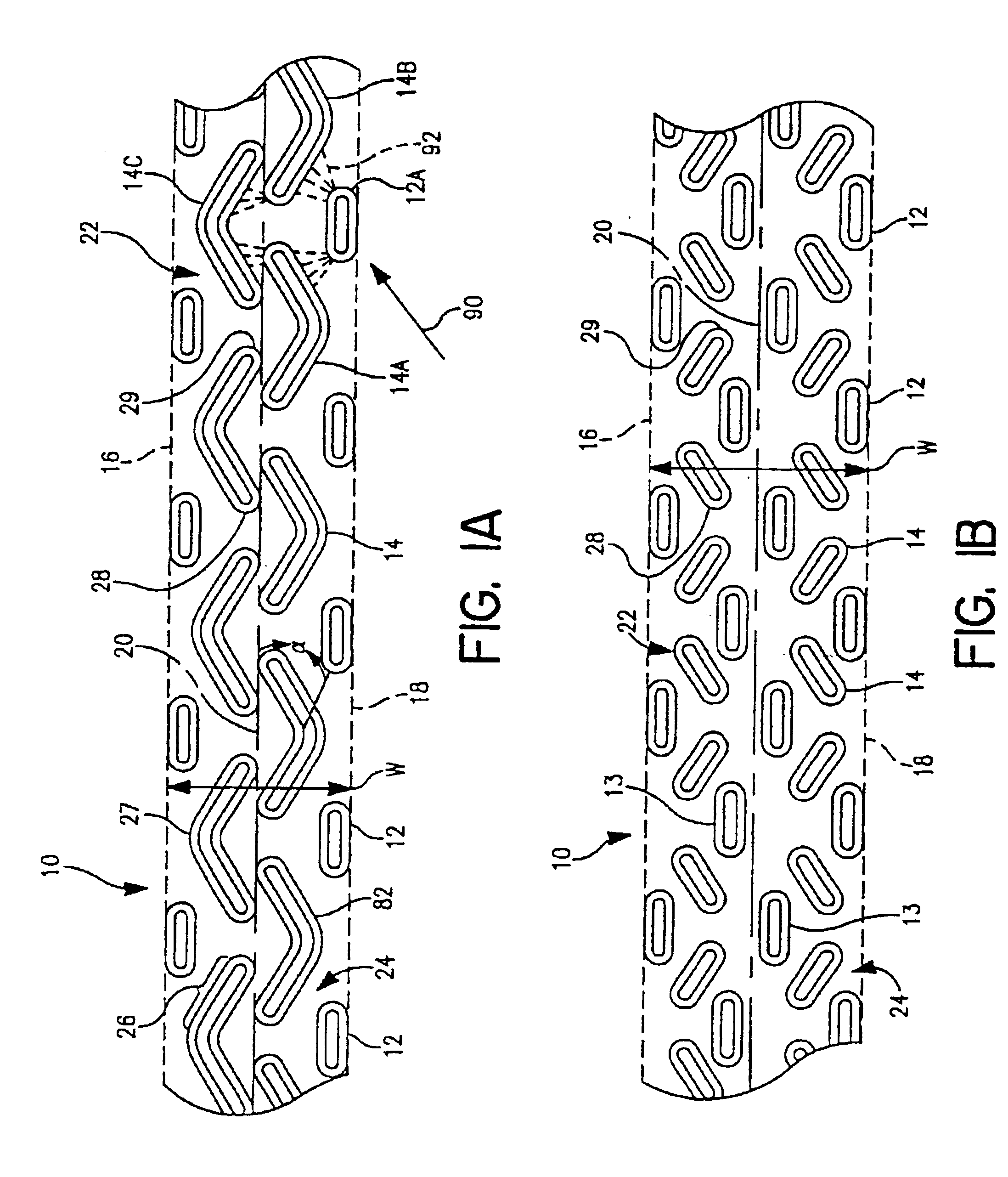

Method of making tear-resistant adhesive/combination bond pattern

Bonded composites, absorbent articles comprising such bonded composites, and processes for bonding thin-section elements. The bonded composite has first and second thin-section elements bonded to each other, at least in part by bond elements and at least in part by adherent material. The adherent material is disposed between the first and second thin-section elements proximate and about the bond elements. The adherent material, at least in part, bonds the thin-section elements to each other at loci of the adherent material. The bond patterns are arranged and configured to preferentially direct stresses imposed on the bond pattern, inwardly into the interior of the bond pattern for distribution, dissipation, and termination.

Owner:KIMBERLY-CLARK WORLDWIDE INC

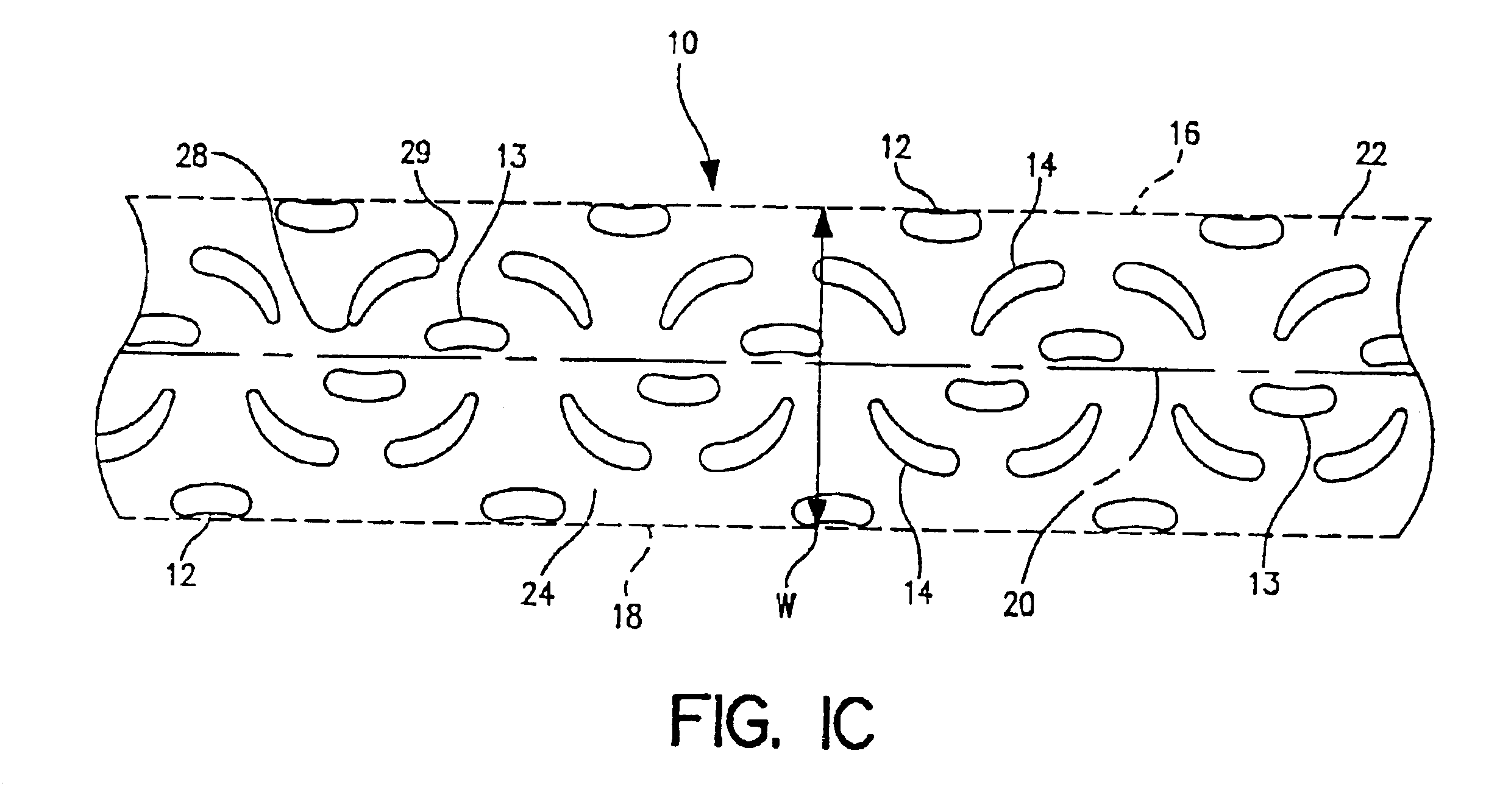

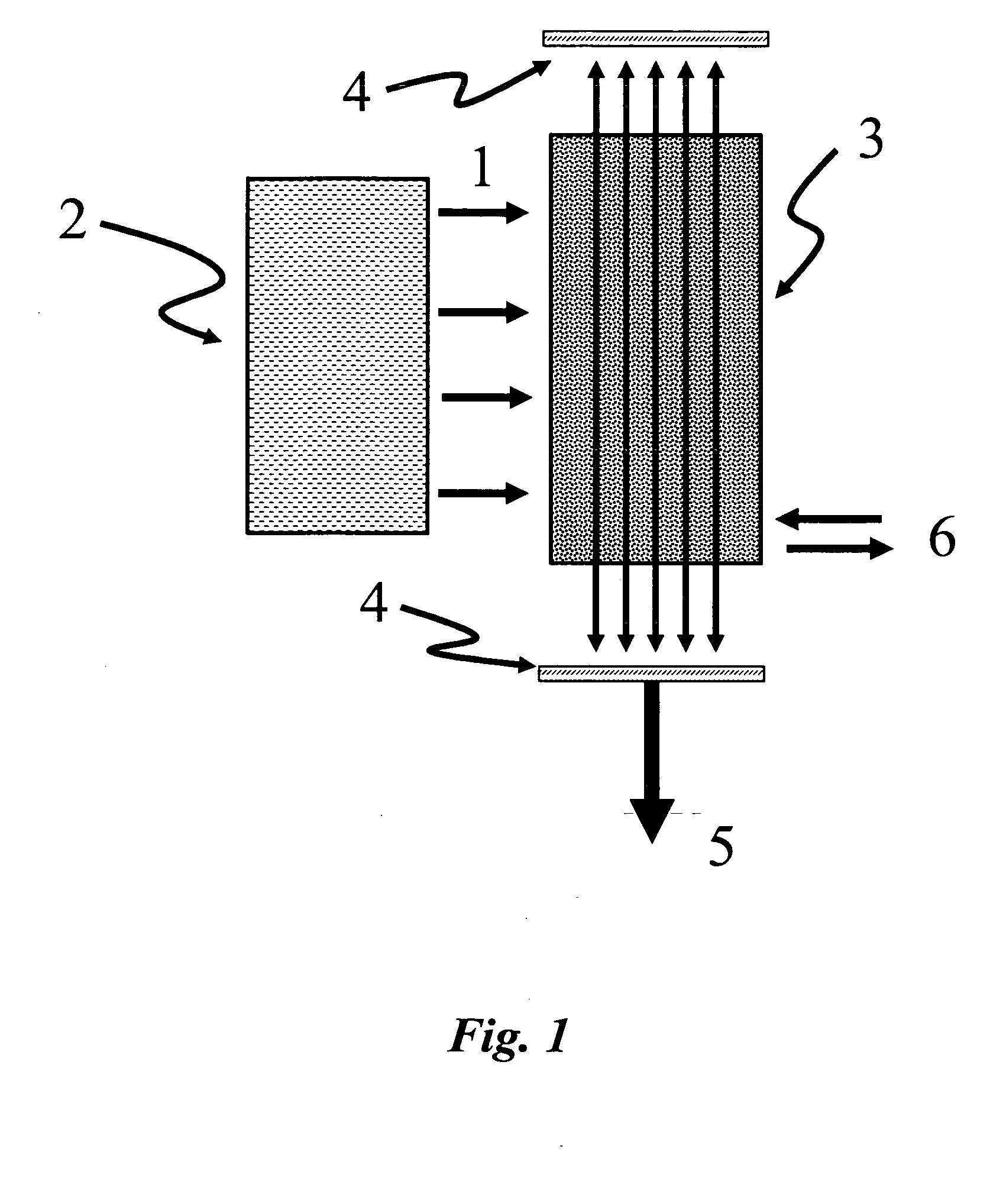

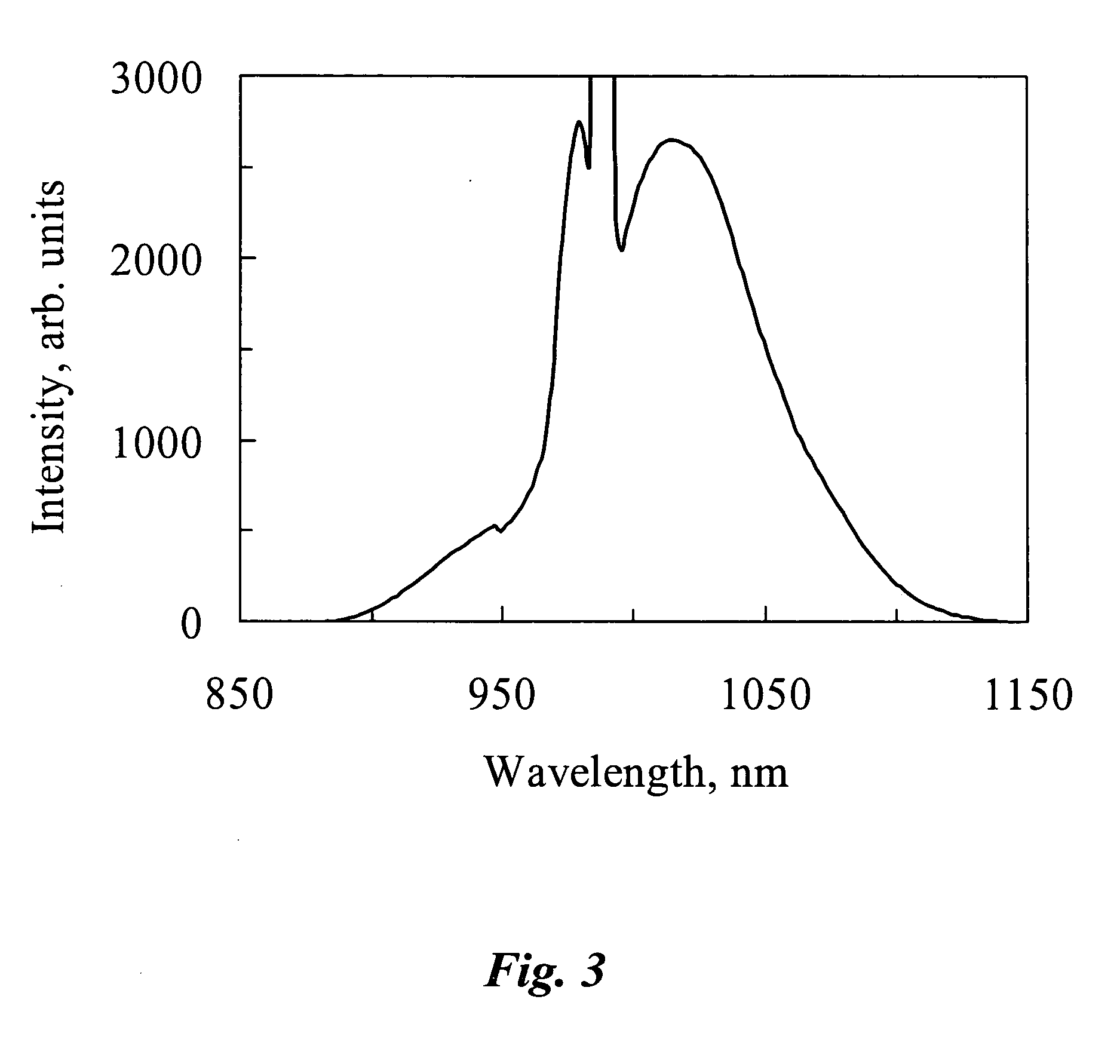

Glass materials for optical gain media and infrared optics comprising rare earth oxide glass compositions

This invention relates to the use of novel glass materials comprising rare earth aluminate glasses (REAl™ glasses) in the gain medium of solid state laser devices that produce light at infrared wavelengths, typically in the range 1000 to 3000 nm and for infrared optics with transmission to approximately 5000 nm in thin sections. The novel glass materials provide stable hosts for trivalent ytterbium (Yb3+) ions and other optically active species or combinations of optically active species that exhibit fluorescence and that can be optically excited by the application of light. The glass gain medium can be configured as a waveguide or placed in an external laser cavity, or otherwise arranged to achieve gain in the laser waveband and so produce laser action.

Owner:3M INNOVATIVE PROPERTIES CO

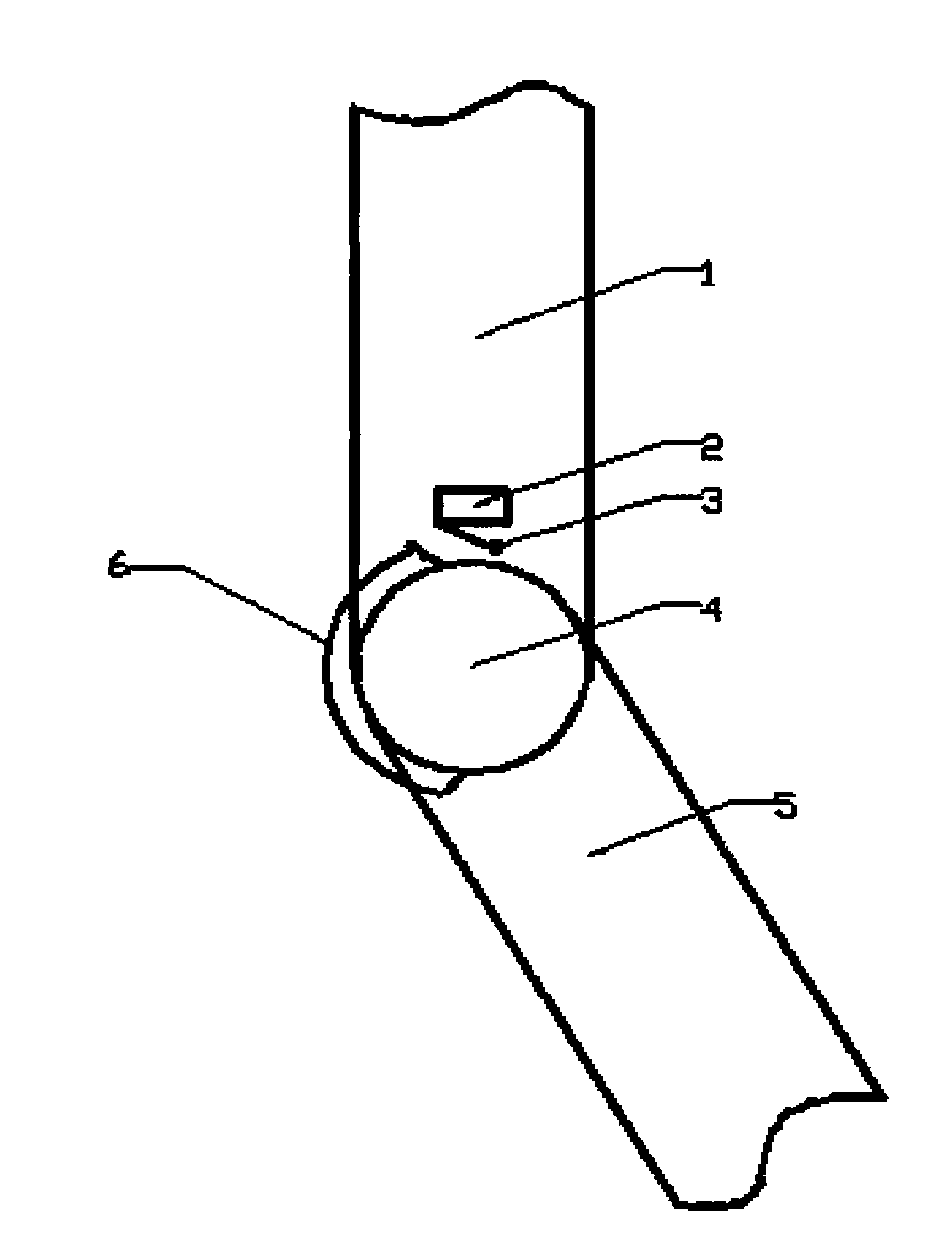

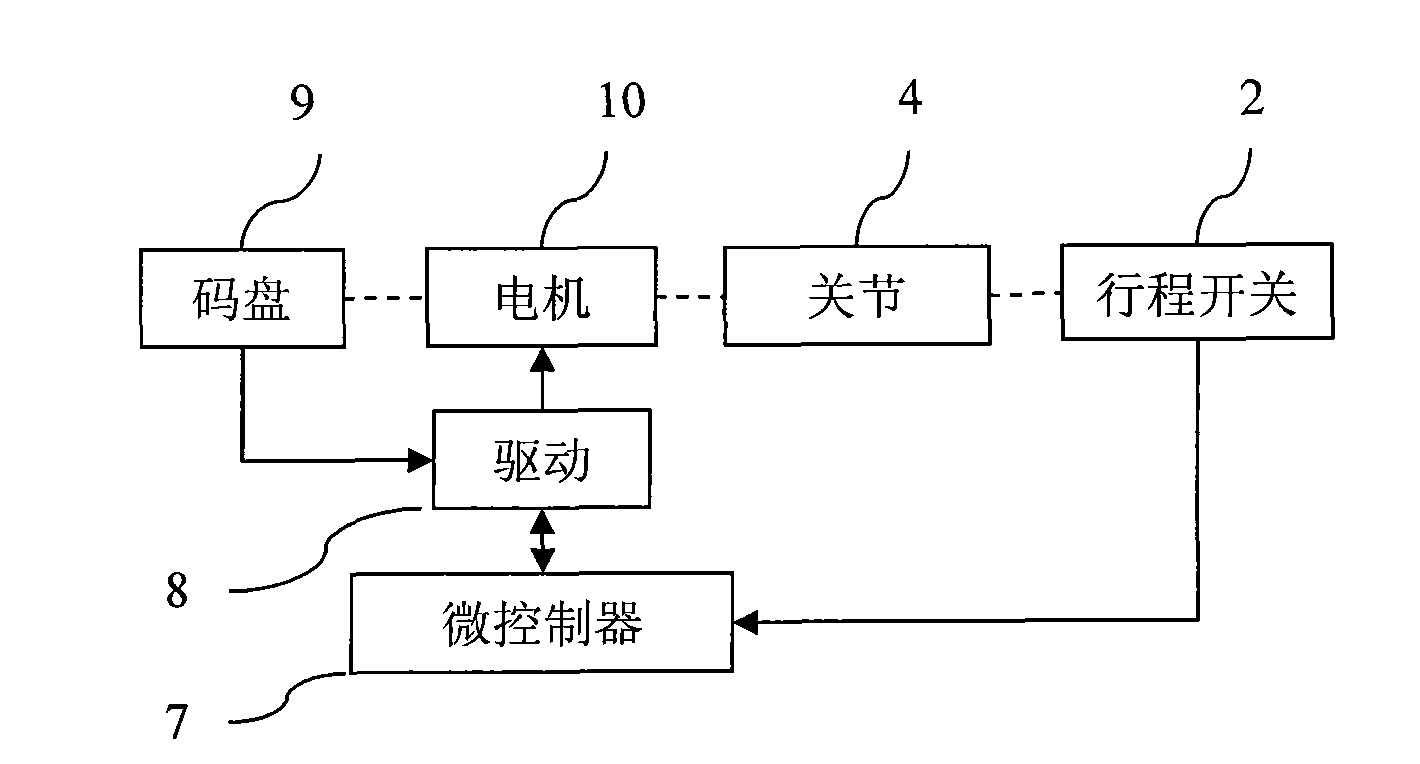

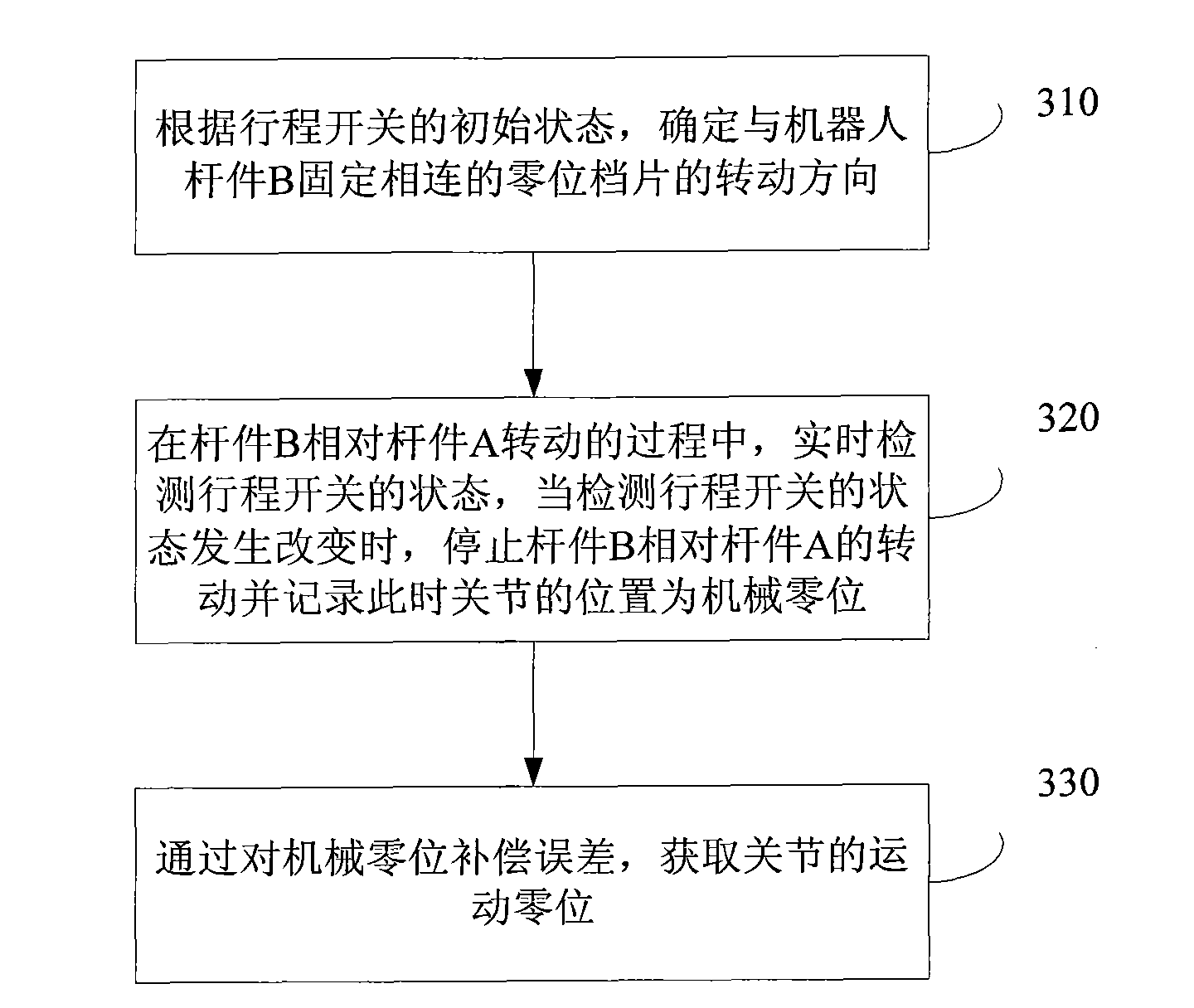

Zero-point positioning system, method and device for joint of robot

The invention discloses a zero-point positioning system for joint of robot and a method and a device thereof, and belongs to the technical field of robot. The system comprises a travel switch, a rotation direction detecting device, a microcontroller and a zero-position stopping piece, wherein the travel switch is fixedly arranged at the joint side of a robot rod piece A; the rotation direction detecting device is connected with an electric motor; the microcontroller is connected with the travel switch and simultaneously is driven to be connected with the electric motor and the rotation direction detecting device; the zero-position stopping piece is formed by bending a thin section into a circular arc shape and is fixedly arranged at the joint side of a robot rod piece B; and the rod piece A and the rod piece B are connected with each other by a joint. The method includes: determining the rotation direction of the zero-position stopping piece according to the initial state of the travel switch; and stopping the rotation and recording the position of the joint at the moment as mechanical zero position when the state of the travel switch is changed. The device comprises a judge module and a mechanical zero-position acquisition module. The invention simplifies the system structure and reduces the cost.

Owner:BEIJING HUAKAIHUI INFORMATION TECH

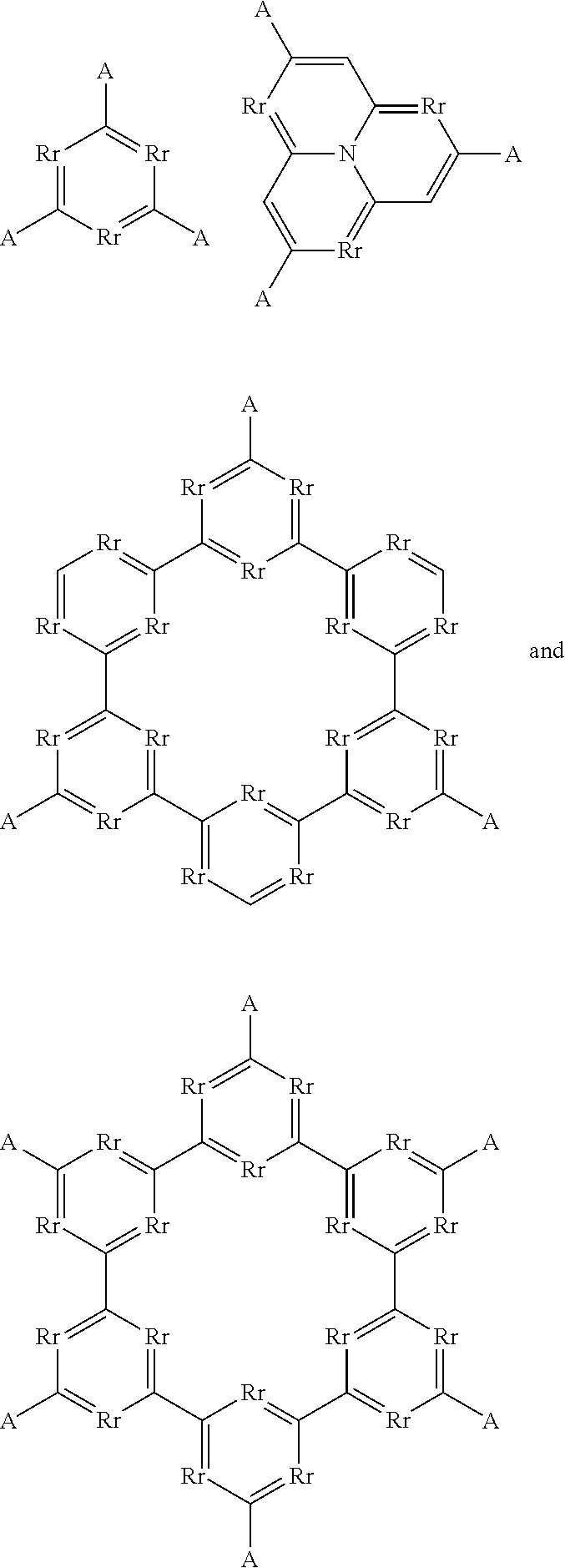

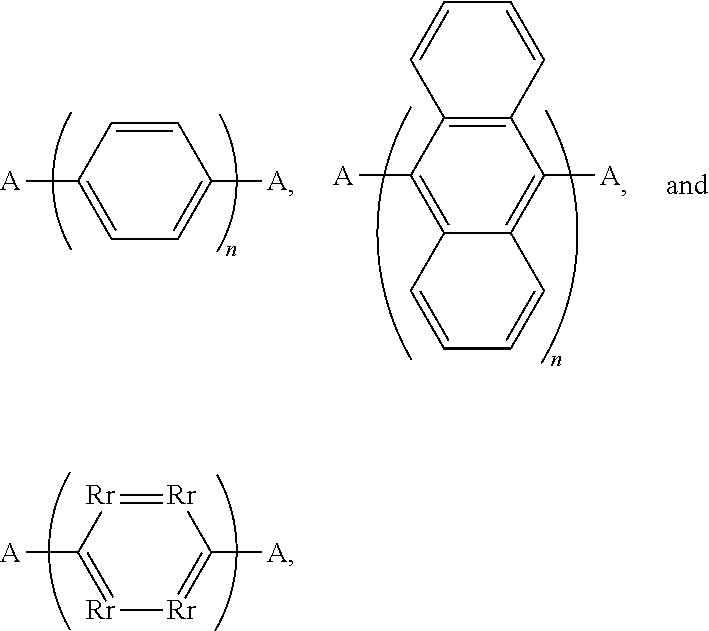

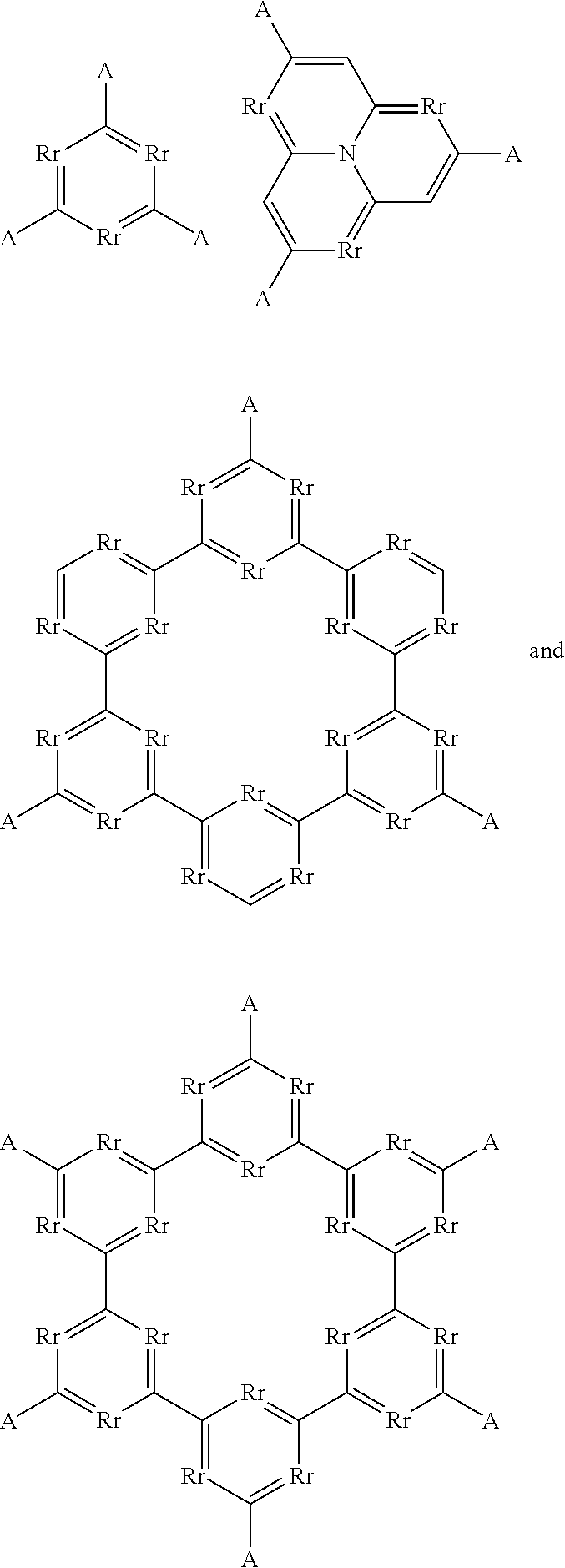

Method for forming perforated graphene with uniform aperture size

A method of forming a filter with uniform pore sizes includes synthesizing a moiety so as to form a plurality of like platelets having a precisely sized pore extending therethrough, distributing the plurality of like platelets about a membrane having apertures therethrough, and bonding the plurality of platelets around the apertures to form precisely sized pores through the membrane. A filtration membrane is also disclosed which provides a porous membrane having a plurality of apertures therethrough, and a plurality of platelets, wherein each platelet has a pore therethrough. The platelets are positioned over or in the apertures.

Owner:LOCKHEED MARTIN CORP

Small volume unitary molded filters and supports for adsorbent beds

InactiveUS20080128346A1Less squeezeMaintain permeabilityButtonsLaboratory glasswaresAnalyteFiltration

Methods and devices are provided for preparing and separating biological analytes. In one embodiment, one or more filtration devices or filter plate wells can be formed by clamping a filter sheet between first and second plates having at least one connecting cavity. First and second moveable core pins positioned on opposed sides of the sheet can be moved to remove portions of the sheet. A molten plastic can be injected to fill the volume between the cores and cavities and to form a liquid-impermeable sleeve wall or walls, each being separately sealed at the bottom to the perimeter of the sheet portion, each having liquid permeable regions of said removed and sealed sheet portion, and each remaining open at the top. Various exemplary configurations for filtration devices or filter plate wells are also disclosed.

Owner:ORBITAL BIOSCI

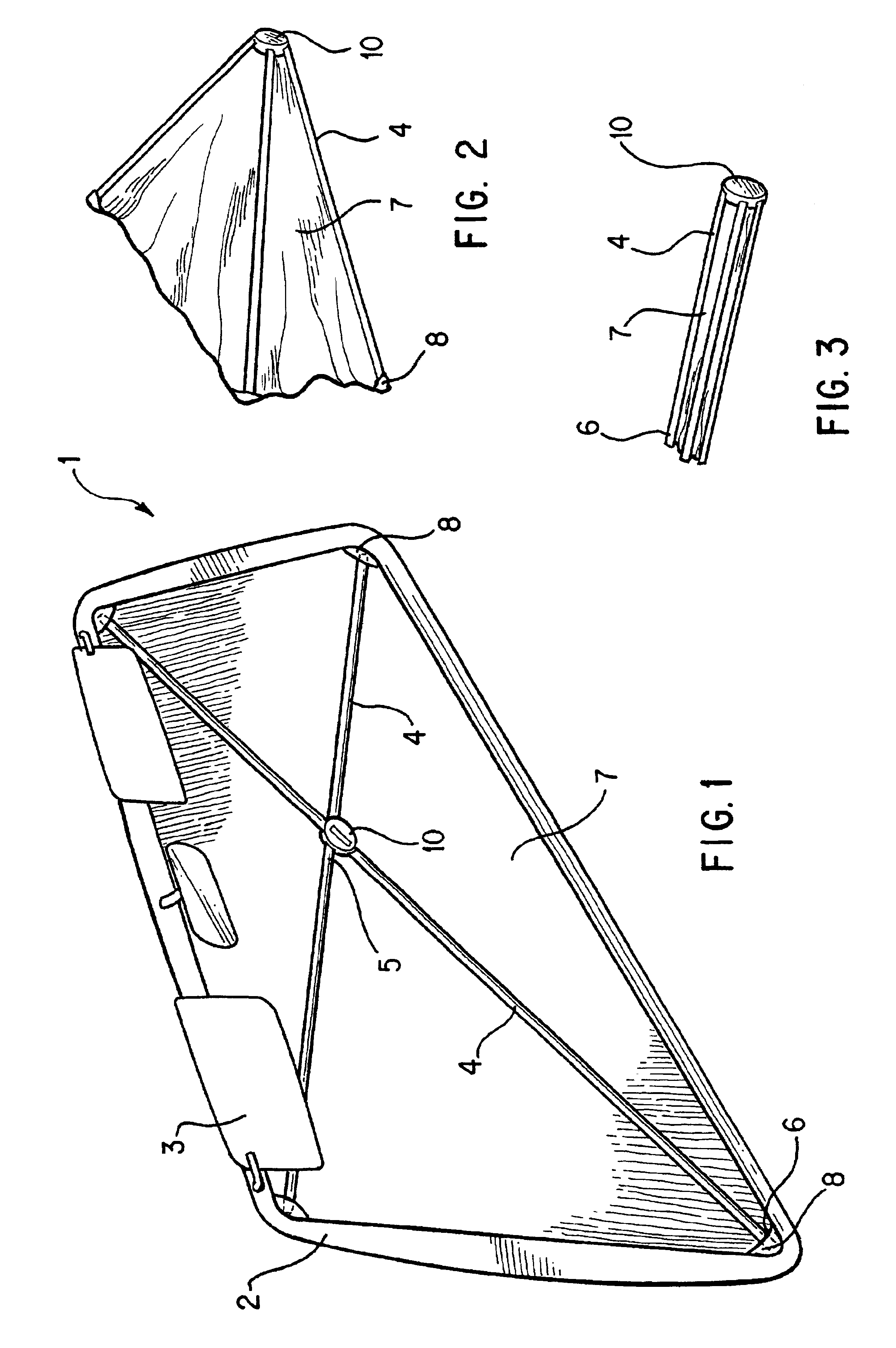

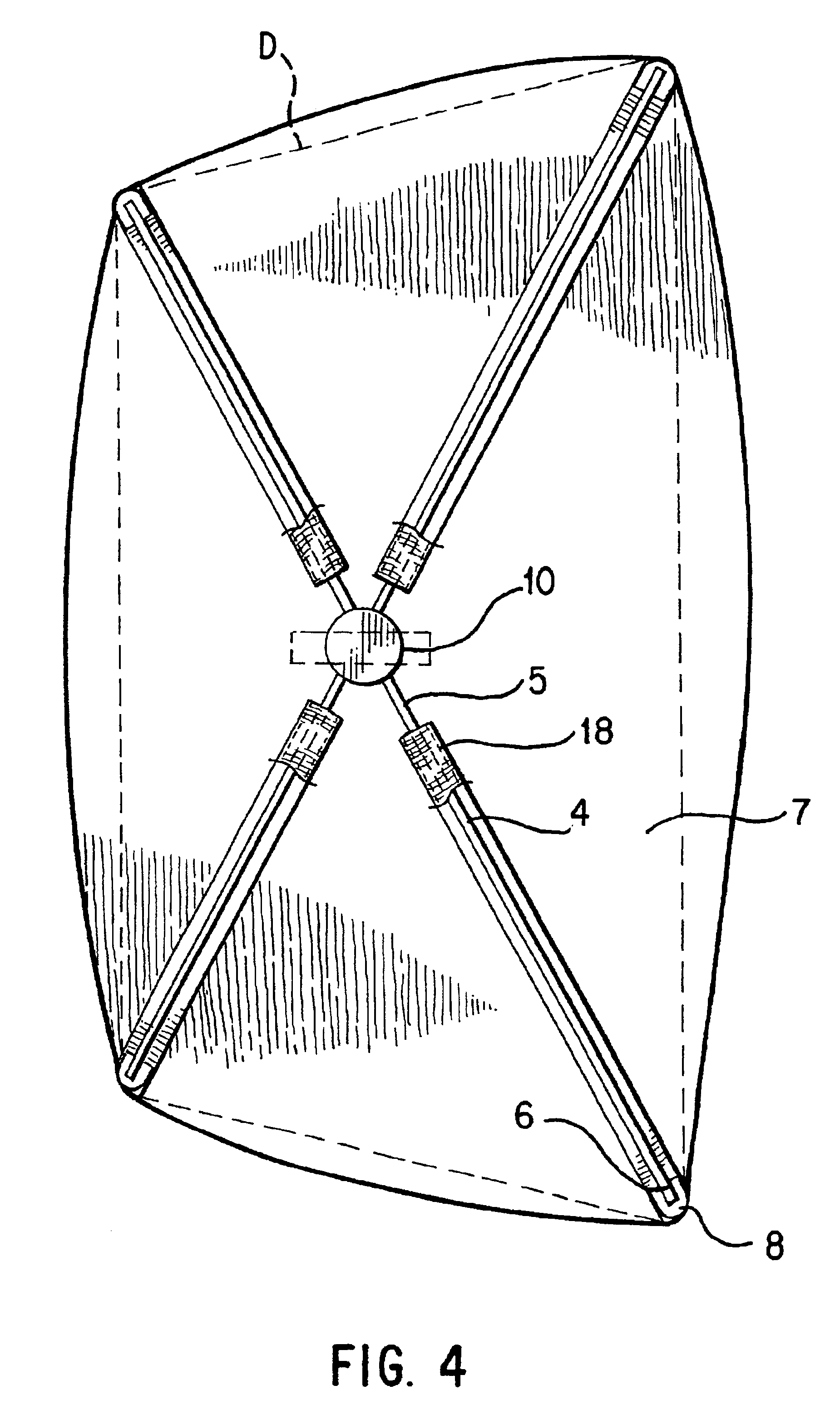

Sunshade

A sunshade has a shade and at least two supports, with each support having a second end that is coupled to the shade at spaced-apart locations thereof. The sunshade also has a connector coupled to the first end of each support, the connector having a central portion that has a groove, and a leaf for coupling the first end of each support. The leaf is hingedly connected to the central portion by an integral thin section and has a locking member fitted inside the groove to hold the leaf at a fixed position with respect to the central portion. Each support of the sunshade can also have an adjustable length.

Owner:QUANTUM AUTO HONG KONG

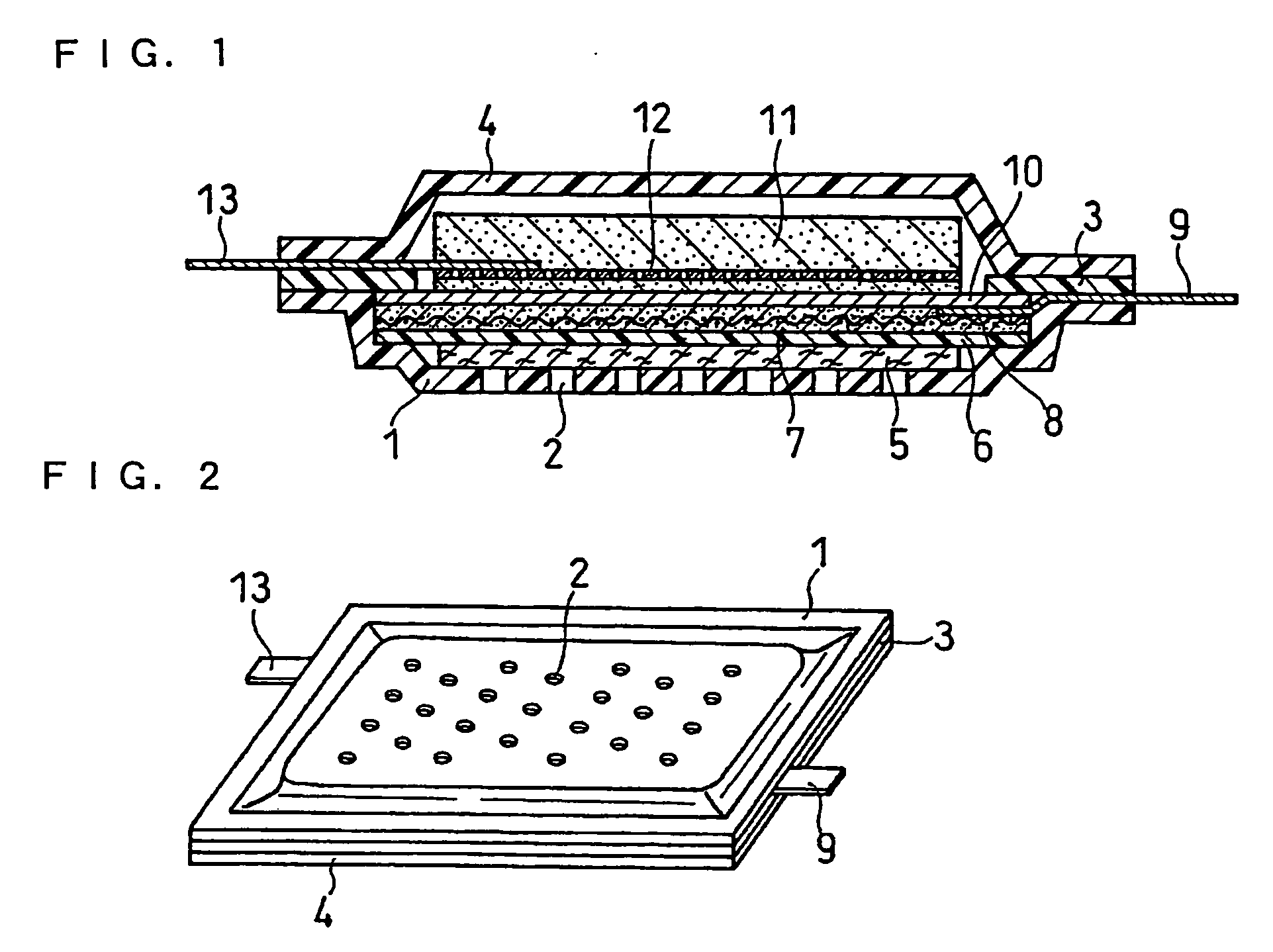

Thin film for package of alkaline battery and thin air battery using the same

InactiveUS20070077485A1Improve long-term reliabilityExpansion can be suppressedFuel and primary cellsSpecific condition cell workingHydrogenHigh energy

There is provided a thin air battery comprising a power-generating element including air diffusion paper and a water repellent film, the power-generating element sealed in a package composed of first and third sheet layers that cover the air electrode side and negative electrode side of the power-generating element, and a second sheet layer disposed in the peripheral portion between the two sheet layers and joined to the two sheet layers. The sheet layers are each composed of a thin film formed by stacking an alkali resistant polymer film having hydrogen gas permeability and a polymer film having gas barrier properties, and in each of the first and third sheet layers, the polymer film having hydrogen gas permeability is disposed on the internal surface side. According to the present invention, a thin air battery that has high energy density and has excellent long-term reliability is provided.

Owner:PANASONIC CORP

Spacer-modified nano graphene electrodes for supercapacitors

ActiveUS8315039B2Increase surface areaMaterial nanotechnologyLiquid electrolytic capacitorsCapacitancePlatelet

Owner:NANOTEK INSTR GRP LLC

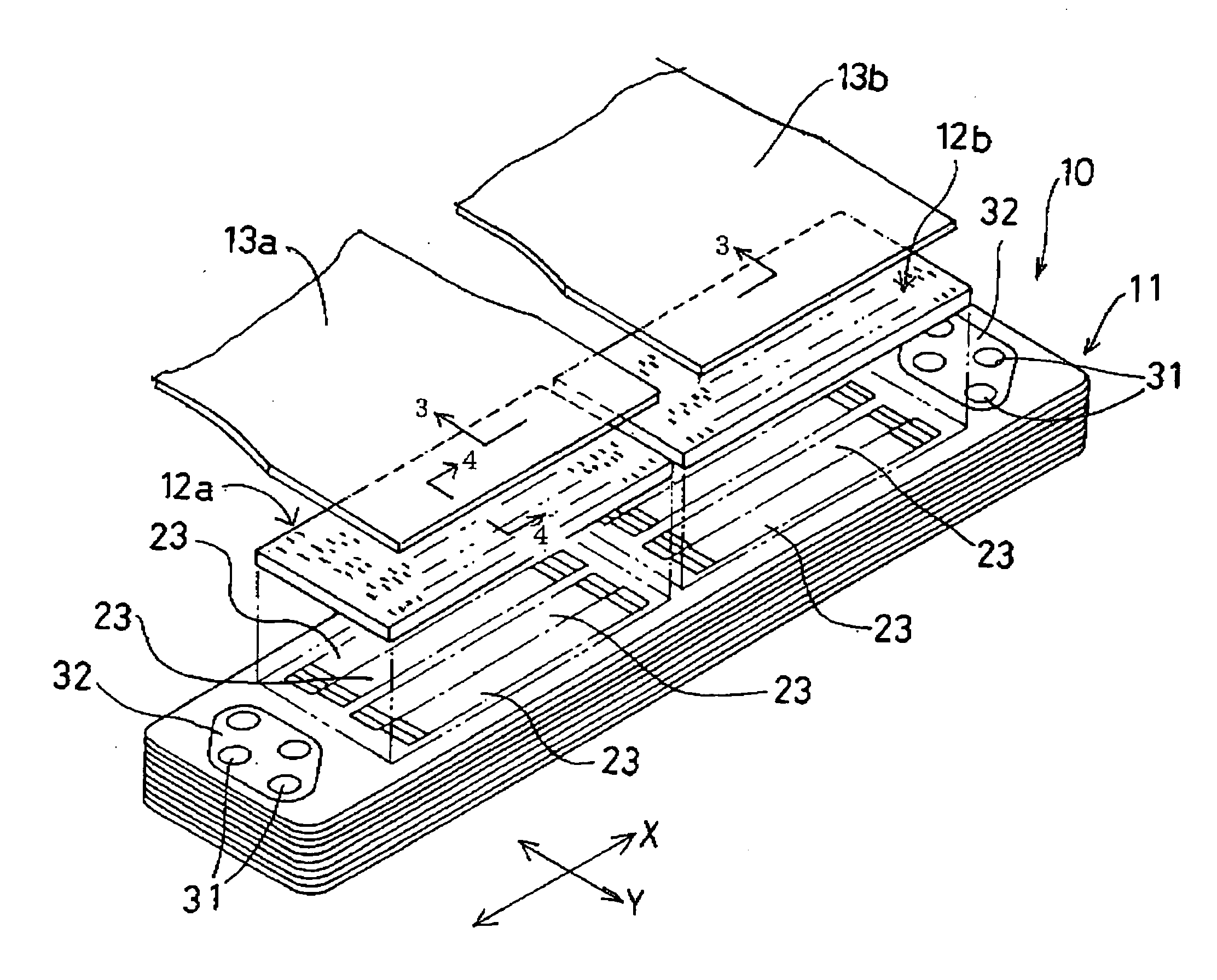

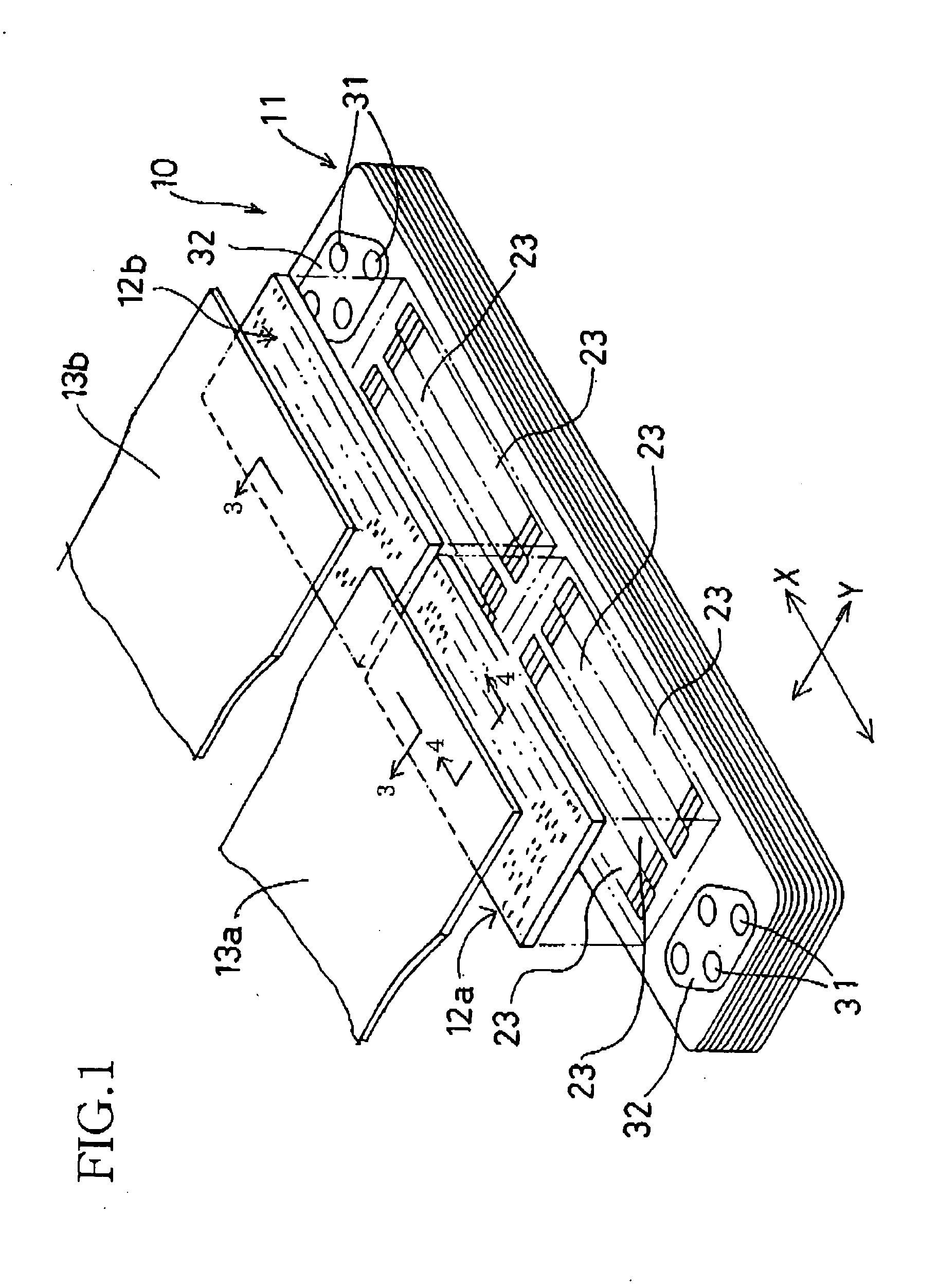

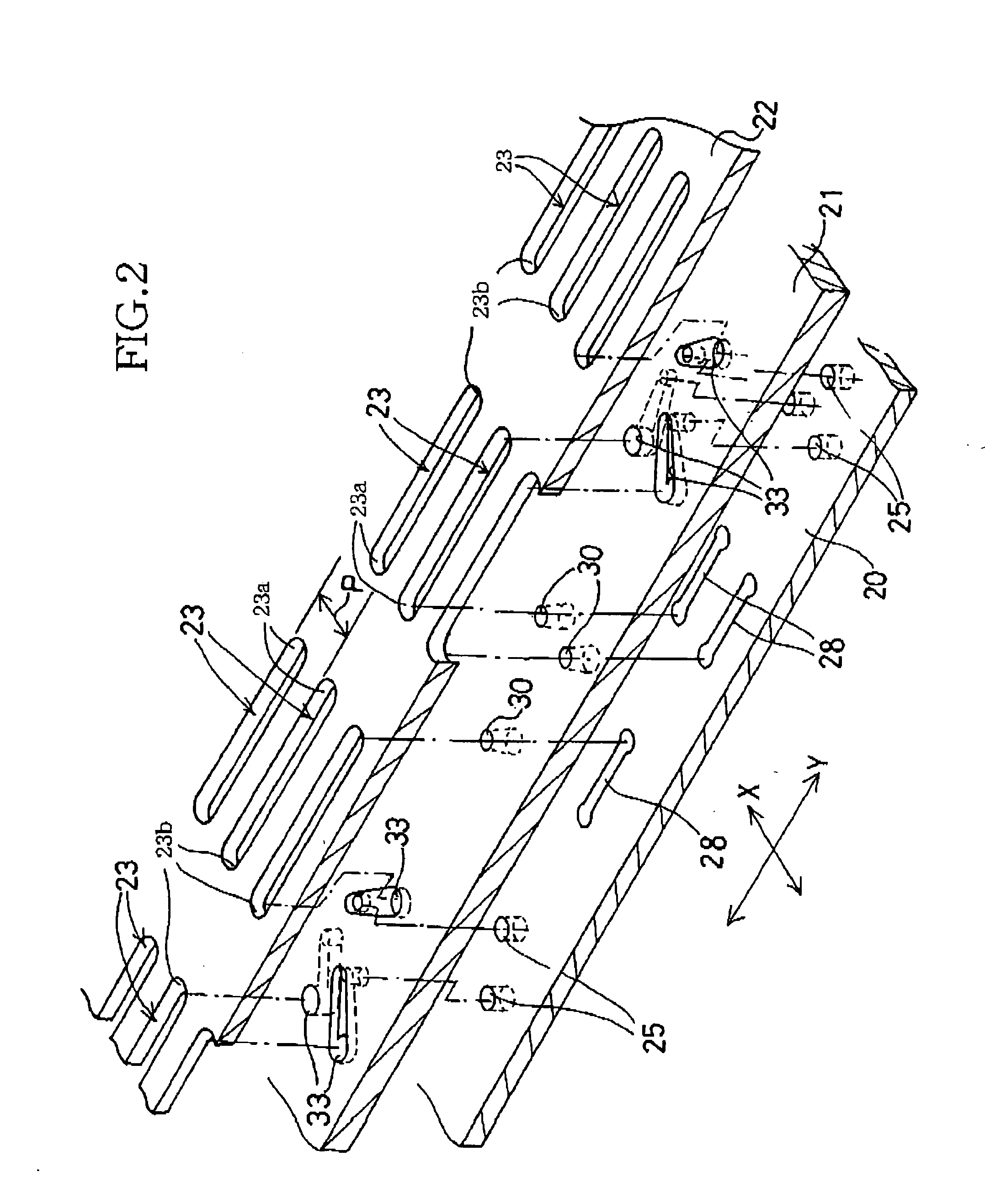

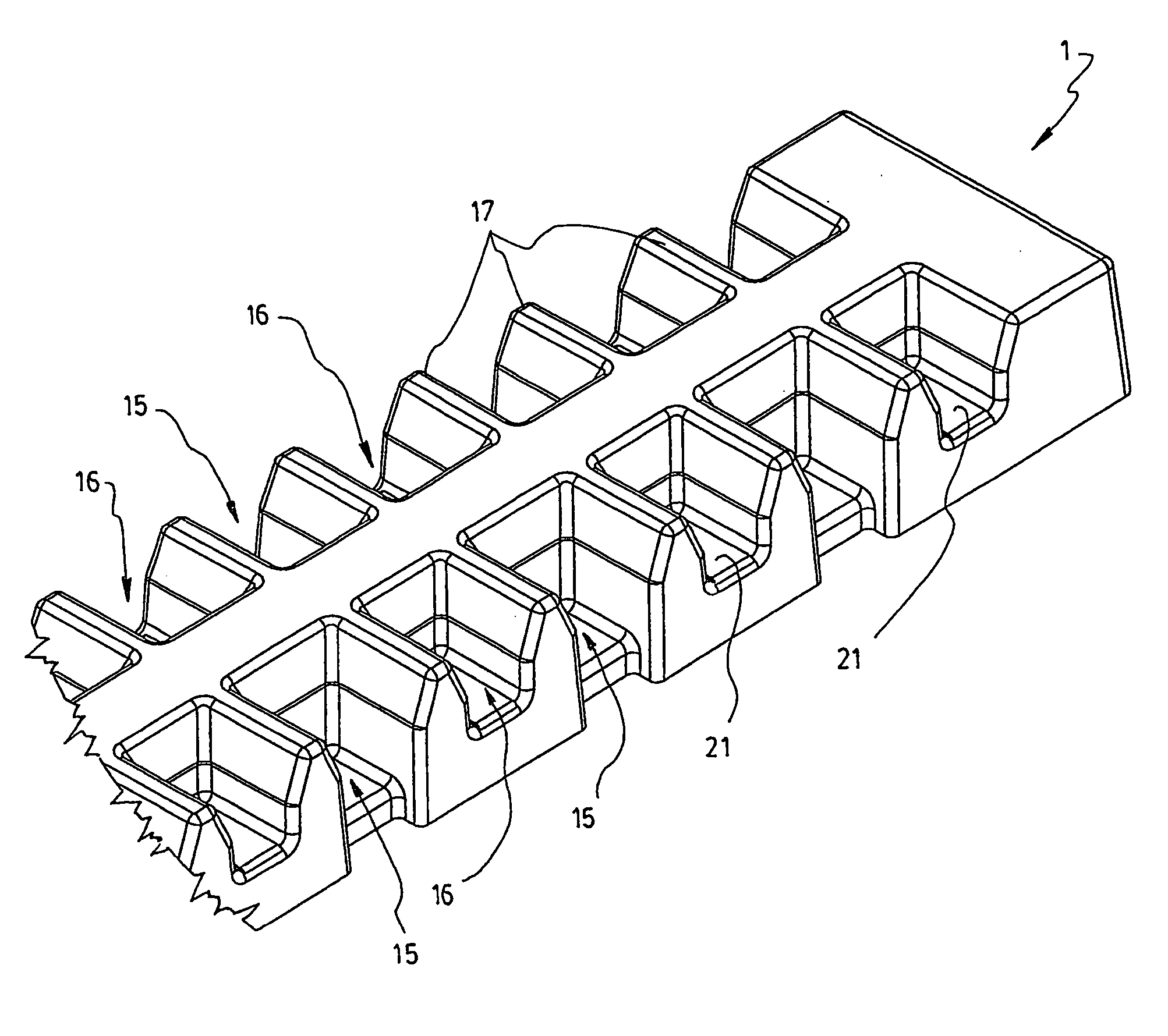

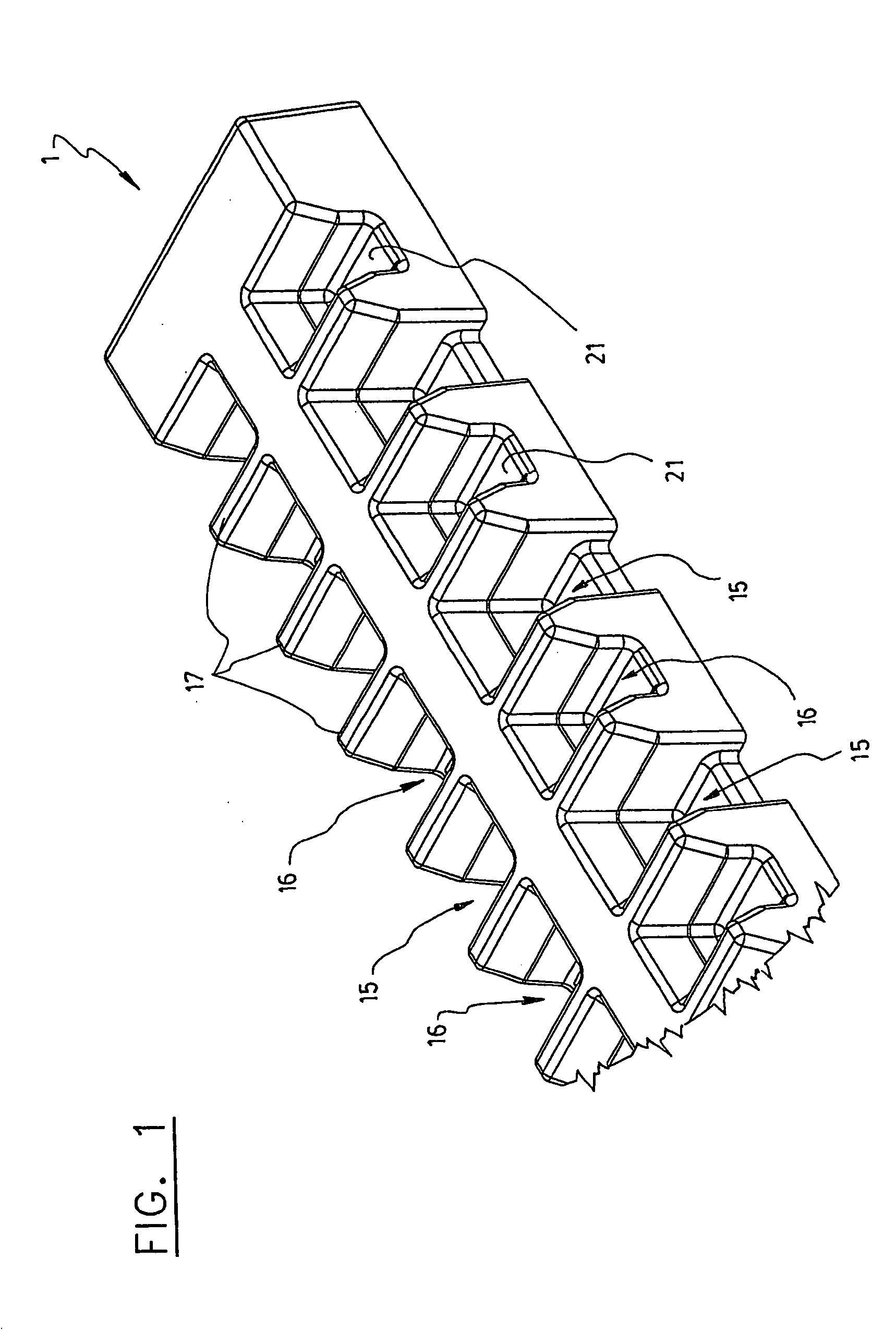

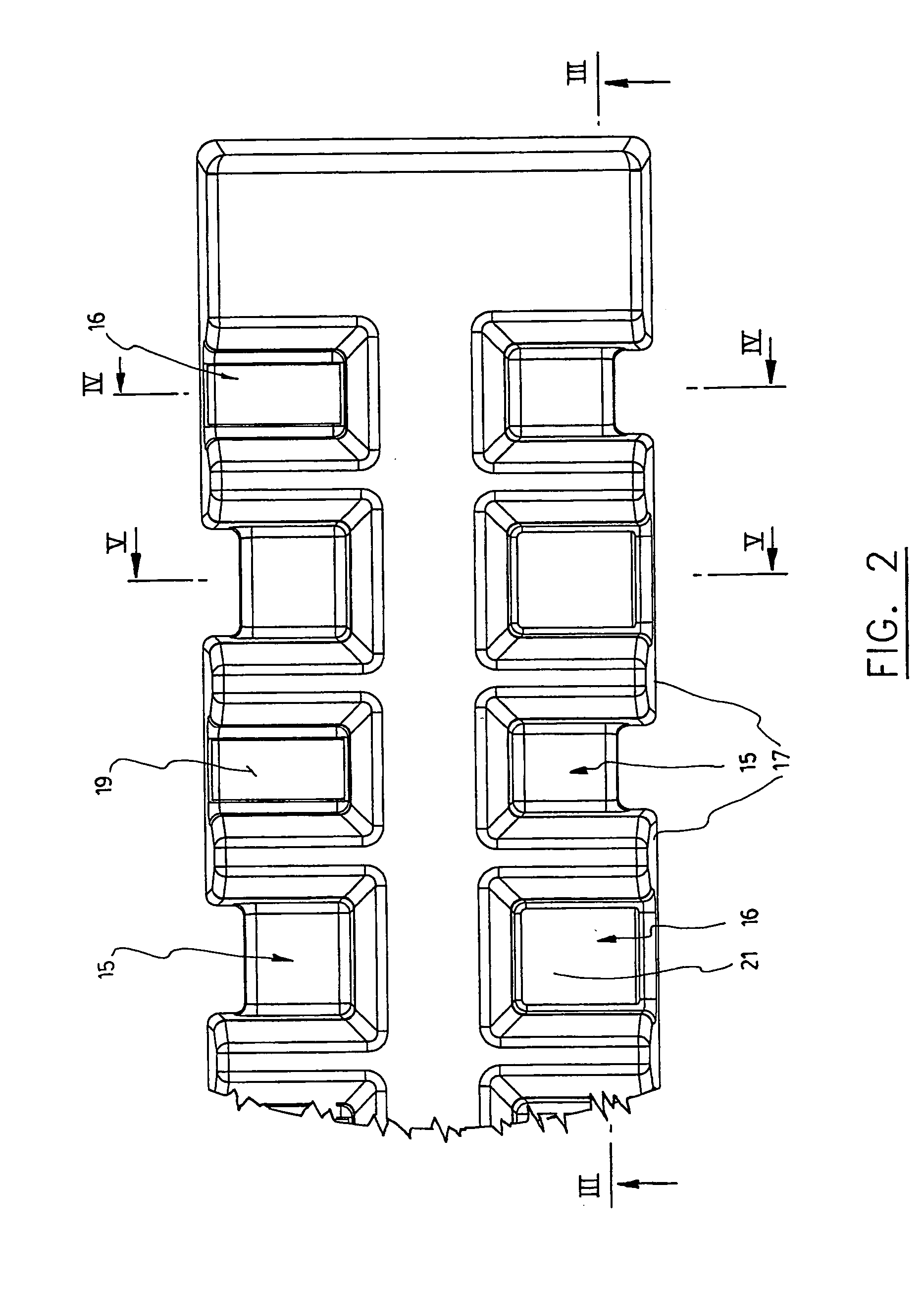

Sheet-member stacked structure, lead frame, lead-frame stacked structure, sheet-member stacked and adhered structure, and ink jet printer head

ActiveUS20050040581A1Low costRecord an image with accuracyPrintingArticle feedersAdhesiveEngineering

A sheet-member stacked structure produced by a method including one or more of the following steps: stacking lead frames on each other, and stacking sheet members of one lead frame on sheet members of another or other lead frame or frames, each lead frame including a frame portion, the sheet members, first groups of bridge portions, and second groups of bridge portions each group of which connect two opposite sides of a corresponding one of the sheet members, to an inner peripheral portion of the frame portion and one of two opposite sides of its adjacent sheet member, or to respective one sides of its two adjacent sheet members; stacking sheet members on each other via an adhesive, a contact surface of one of each pair of adjacent sheet members having a relief groove formed along a location where the adhesive is applied, each of the stacked sheet members except for one of the two opposite, outermost sheet members having a relief hole communicating with the relief groove and formed through a thickness of the each sheet member, at least a portion of the relief hole of the other outermost sheet member having a cross-section area greater than a cross-section area of the relief hole of each of the other sheet members; and stacking sheet members on each other, the sheet members including a liquid-chamber sheet member formed of a rolled metal sheet and having liquid chambers arranged, separately from each other, in a direction perpendicular to a direction of rolling of the metal sheet.

Owner:BROTHER KOGYO KK

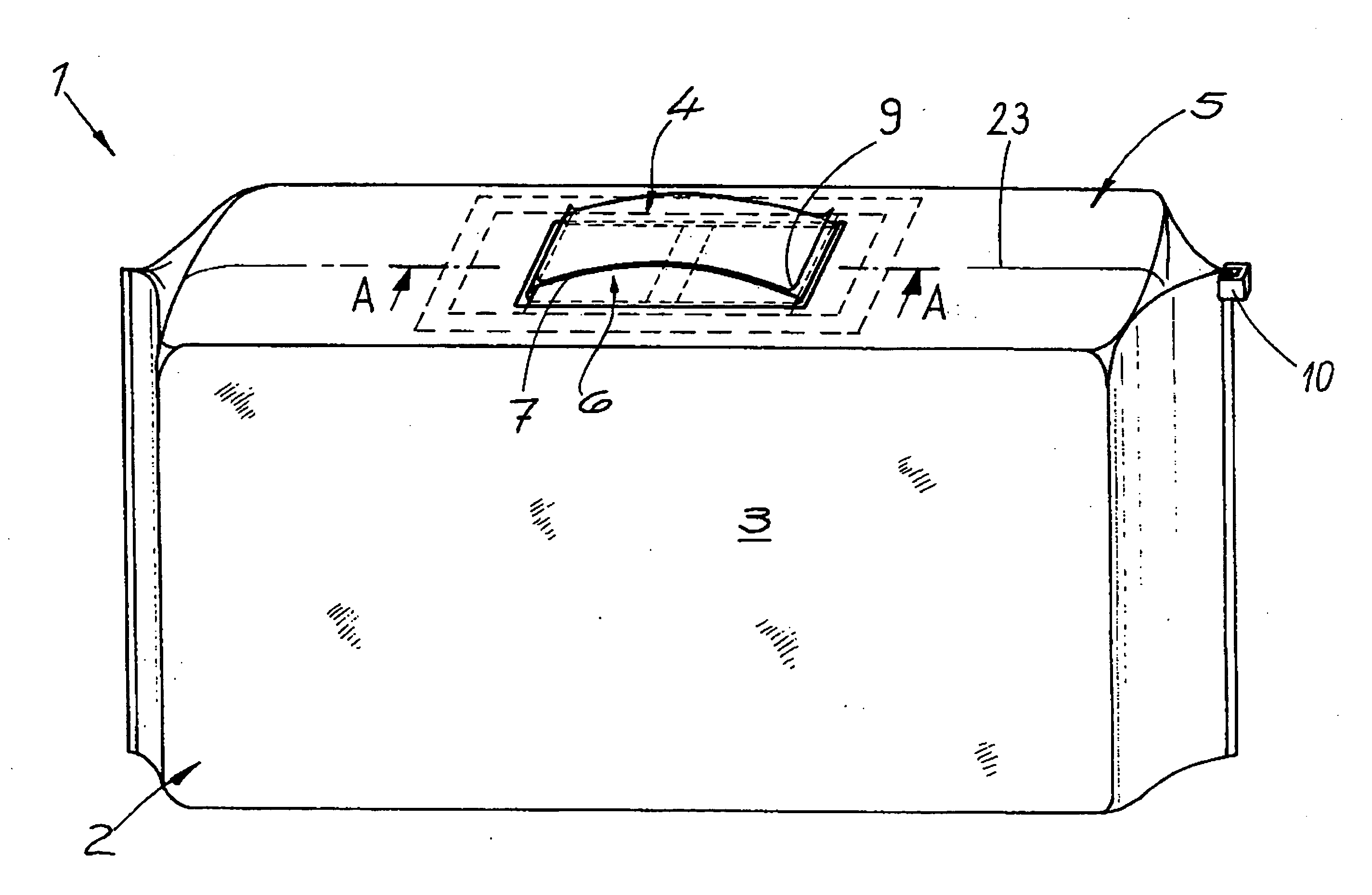

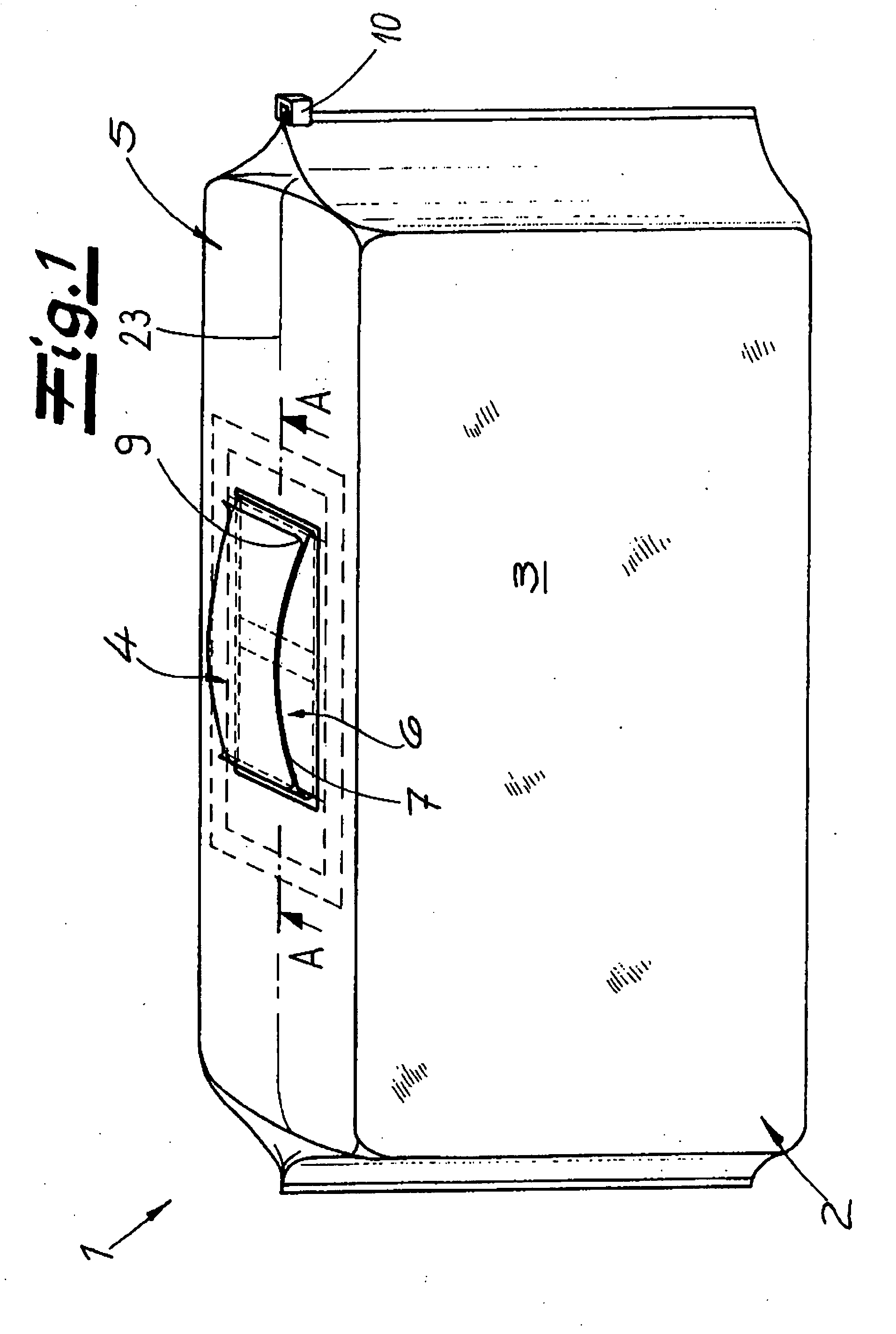

Film packaging bag

ActiveUS20080080794A1Easy and precise foldingGood machine handlingEnvelopes/bags making machineryBag making operationsThin membraneInternal connection

A film packaging bag has bag surfaces formed by a bag film and a carrying handle disposed on one of the bag surfaces, whereby the carrying handle has a film strip having a handle segment that is accessible via an opening in the bag film, during use. The film strip is disposed on a carrier sheet, whereby the film strip surrounds the carrier sheet with folded strip ends that follow the handle segment, which sheet is wider than the film strip. The film strip is attached to the bag film by way of the carrier sheet, whereby the carrier sheet is connected with the inside of the bag to the side of the film strip, directly or indirectly.

Owner:NORDENIA DEUTLAND HALLE

Capping board with at least one sheet of electrically conductive material embedded therein

ActiveUS20050121319A1Heat dissipation fastImprove distributionCellsMachining electrodesConductive materialsEngineering

Disclosed is a capping board for use to support anodes and cathodes within adjacent electrolytic cells, which has a plurality of individual seats positioned in spaced apart relationship all along its length to receive and support hanging legs projecting from these anodes and cathodes. This capping board is improved in that it has at least one sheet or wire of electrically conductive material embedded therein. This sheet or wire extends over the length of the board and is shaped and positioned so that part of its extends externally within at least some of the seats so as to allow electrical contact of the legs of either the anodes or the cathodes and to allow fast dissipation of heat in the case of a short circuit.

Owner:PULTRUSION TECHN

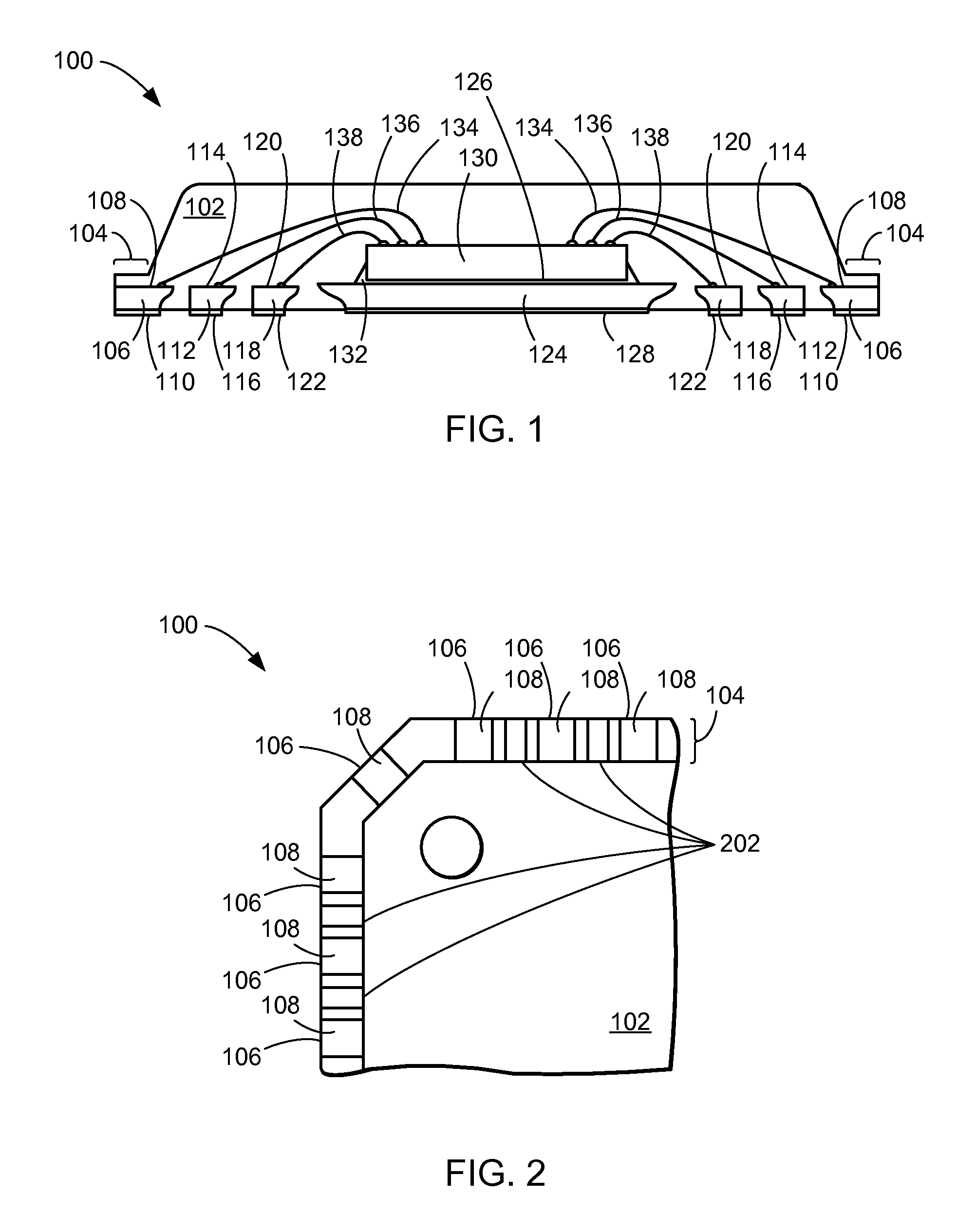

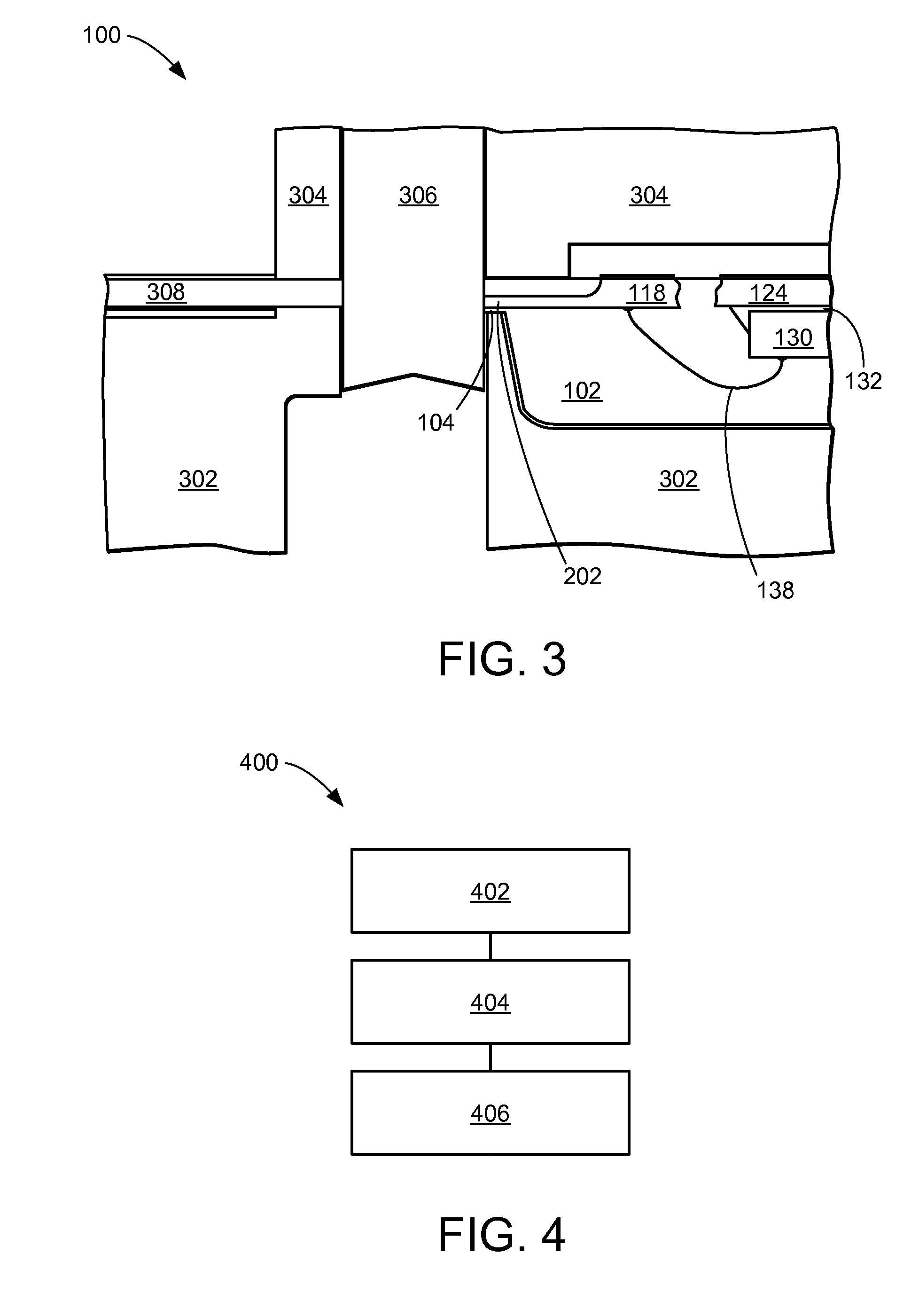

Integrated circuit leadless package system

An integrated circuit leadless package system includes forming a lead, attaching an integrated circuit die to the lead, and applying an encapsulant including a thin encapsulant region with a thinner section over the lead than a section over the integrated circuit die.

Owner:STATS CHIPPAC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com