Glass materials for optical gain media and infrared optics comprising rare earth oxide glass compositions

a glass composition and optical gain media technology, applied in the field of solid-state lasers, can solve the problem of small conversion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Cast REAl™ Glasses

[0046] The cast REAl™ glasses were prepared from mixtures of fine powders of the constituent pure oxides. The oxides were first melted together in a laser hearth. The product of hearth melting was then pulverized, placed in a platinum crucible, and heated in a Deltech DT31FL high temperature furnace to a temperature of 1920 to 1950K to obtain a homogeneous molten oxide. The platinum crucible was then removed from the furnace and the liquid oxide was cast into a mold to produce the glass products. In some cases the mold was heated to allow in-situ stress relaxation of the as-cast glass by slowly cooling the mold. In other cases the glass was cast into a mold at room temperature and could later be annealed at temperatures up to approximately 1100K. Graphite molds were used for the casting operations. Other mold materials that are commonly used in the art of glass making are within the scope of this invention.

[0047] The process of hearth melting and pulverization of...

example 2

Glasses for Optical Property Investigations

[0050] Several hours are required to complete the procedure of casting a REAl™ glass from a crucible. Small glass samples that are sufficient for optical property investigations can be prepared in a few minutes, by containerless melting techniques. Therefore, many of the compositions of glass that were used to investigate the optical properties of REAl™ glasses as a function of glass composition were prepared by the containerless melting methods.

example 3

Yb Optical Properties in REAl™ Glass

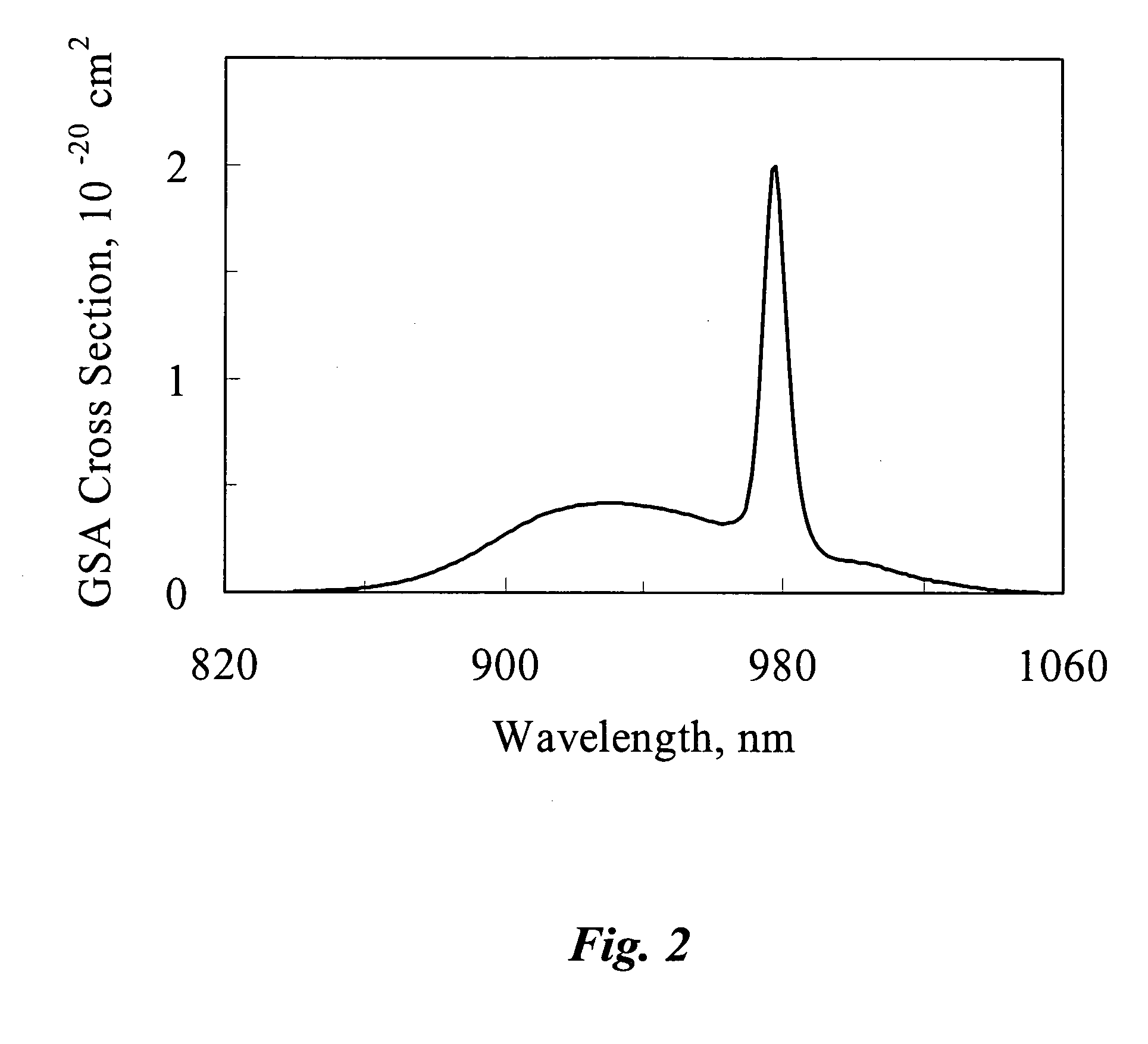

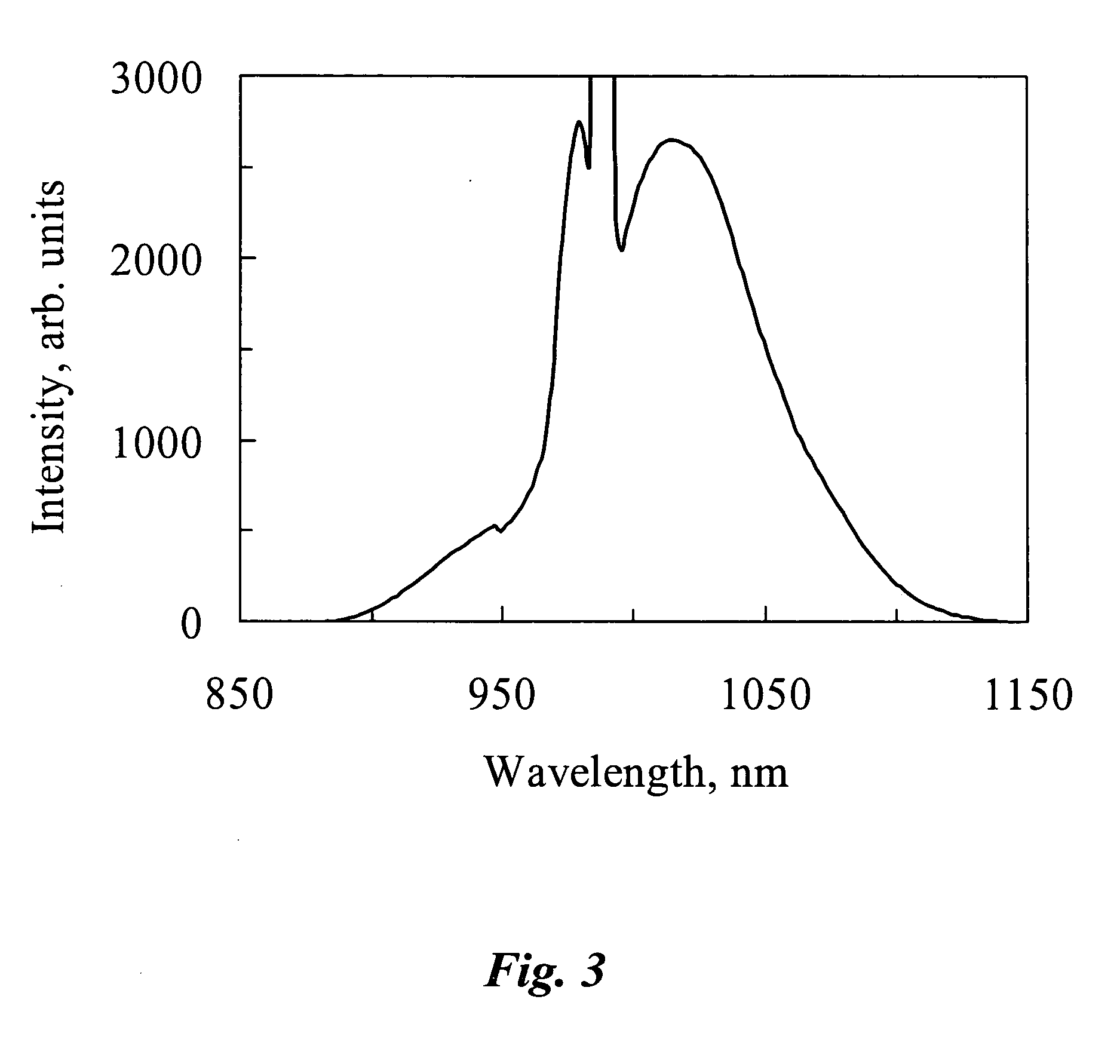

[0051]FIGS. 2-5 illustrate various optical properties of Yb3+ ions in REAl™ glass. The ground state absorption spectrum of Yb3+ is shown in FIG. 2. The peak absorption cross section is approximately 2×10−20 cm2, at a wavelength of 980 nm. The absorption peak is quite narrow in a crystalline host material, such as the yttrium aluminum garnet crystals that are used in prior art Yb:YAG lasers. The absorption peak is broadened in a glass material, which facilitates laser pumping by increasing the pump laser waveband that can be used. Thus, Yb:YAG lasers typically use a pump laser operating at approximately 940 nm where a relatively narrow absorption peak occurs, with a much smaller absorption cross section than at the 980 nm peak in REAl™ glasses. The broadened 980 nm absorption peak of Yb3+ ions in a REAl™ glass host have the benefits, relative to prior art Yb:YAG lasers, including that (i) more efficient laser pumping is possible, (ii) inexpensive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength range | aaaaa | aaaaa |

| wavelength range | aaaaa | aaaaa |

| wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com