Zero-point positioning system, method and device for joint of robot

A robot joint and zero point positioning technology, applied in the field of robots, can solve problems such as complex circuits, and achieve the effect of simplifying the system structure and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

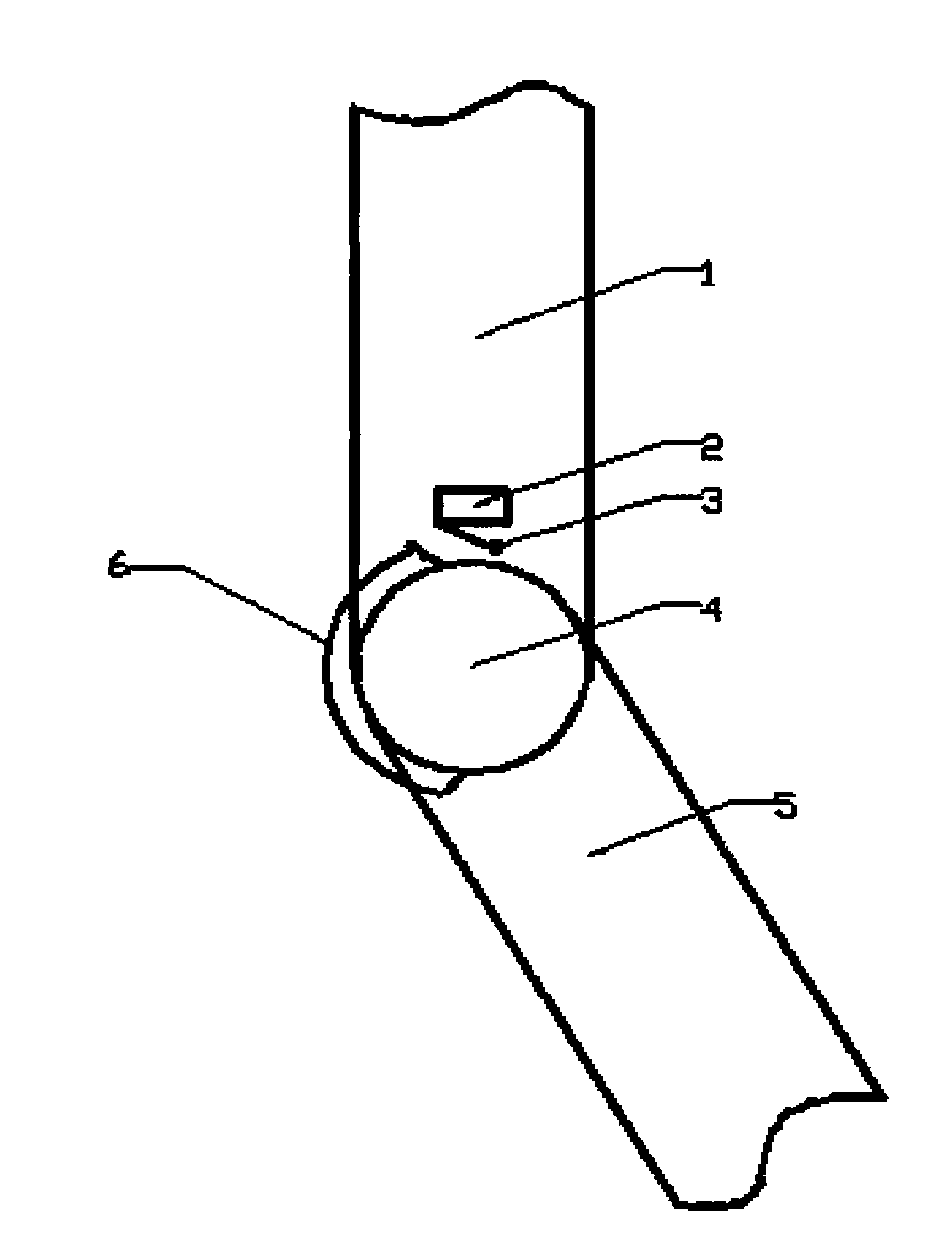

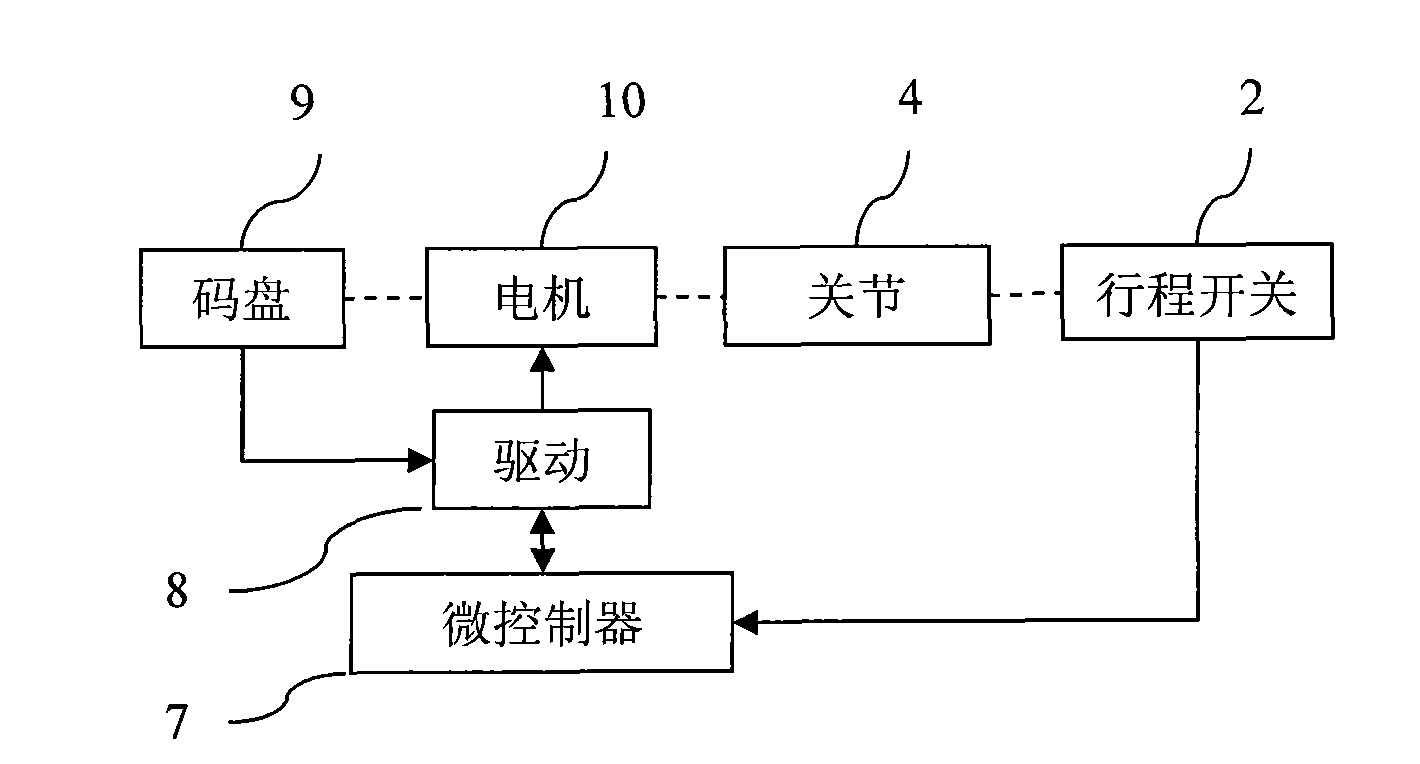

[0045] An embodiment of the present invention provides a robot joint zero point positioning system, figure 1 It is a schematic diagram (front view) of the mechanical structure of the robot joint equipped with the zero point positioning system. Wherein, the robot rod A1 and the robot rod B5 are respectively connected with the robot joint 4 and can rotate clockwise or counterclockwise around the robot joint 4 . In the embodiment of the present invention, in order to perform zero-point positioning on the robot joints, a travel switch 2 is fixed on the joint side of the robot rod A1. At one end of limit switch 2. The zero stop 6 of the robot rod B5 is made of a thin sheet bent into an arc shape, and is fixed on the joint side of the robot rod B5, and is used to touch or stay away from the travel switch of the travel switch 102 when the rod B105 rotates. link. The zero stopper 6 can be made of thin sheets such as metal sheets and plastic sheets, and its center of circle can be l...

Embodiment 2

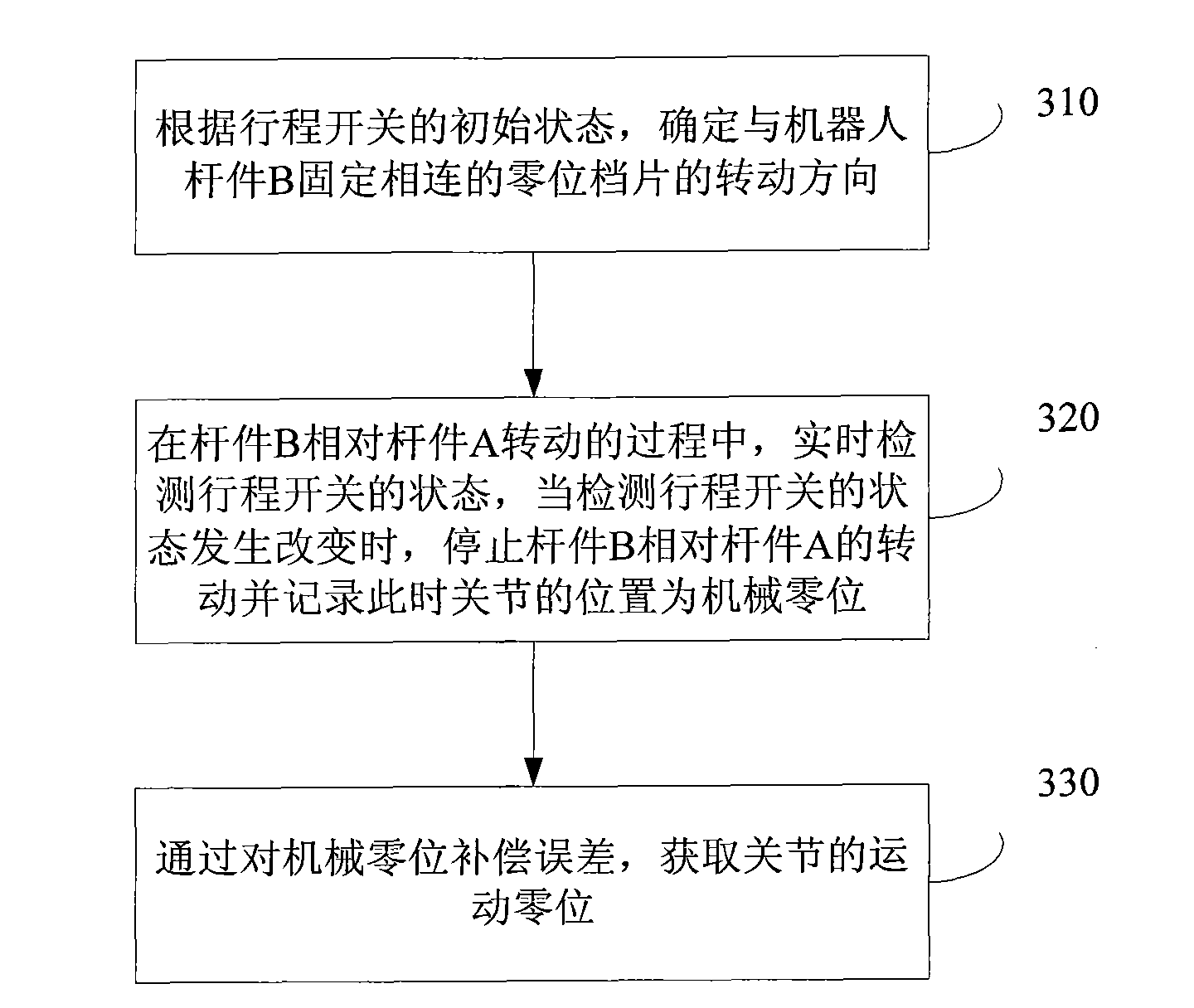

[0059] An embodiment of the present invention provides a robot joint zero point positioning method, such as image 3 shown, including the following steps:

[0060] 310: According to the initial state of the limit switch, determine the rotation direction of the zero stop fixedly connected with the robot bar B, wherein the limit switch is fixedly arranged on the joint side of the robot bar A.

[0061] see figure 1 , the rod A1 is connected with the rod B5 through the joint 4, and can rotate clockwise or counterclockwise around the joint 4 of the robot. The zero stopper 6 is a sheet bent into an arc shape, and is fixed on the joint side of the robot rod B5. The zero stopper 6 can be made of sheet materials such as metal sheets and plastic sheets, and its center of circle is located at the joint 4 vertical to the central axis of the paper. In this embodiment, the central angle of the zero stopper 6 may be about 130 degrees.

[0062] Further, in step 310, according to the initi...

Embodiment 3

[0075] An embodiment of the present invention provides a robot joint zero point positioning device, see Figure 4 ,include:

[0076] The judging module 401 is used to determine the rotation direction of the zero stop fixedly connected to the robot rod B according to the initial state of the travel switch, wherein the travel switch is fixed on the joint side of the robot rod A.

[0077] Judgment module 401 includes:

[0078] The judging unit is used to determine the initial state of the travel switch, and the travel switch is fixed on the joint side of the rod A of the robot. For a specific method of determining the initial state of the travel switch, refer to the descriptions in Embodiments 1 and 2.

[0079] The execution unit is used to rotate the zero position plate fixedly connected with the robot bar B to the direction away from the travel switch connecting rod of the travel switch if the travel switch is initially in the closed state; if the travel switch is initially i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com