Flat edge-trimming machine

A technology of edge trimmer and flat mouth, which is applied in metal processing and other directions, can solve the problems of low operating efficiency of the whole machine, low power transmission efficiency, and inconspicuous guiding effect, and achieve low production accuracy requirements, low production cost, Fix easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

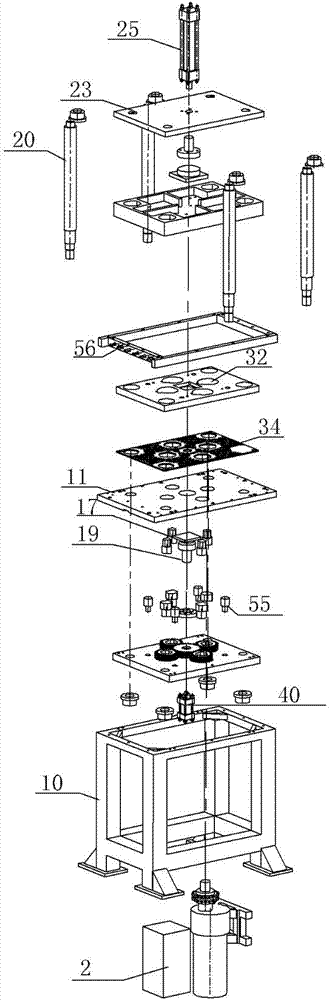

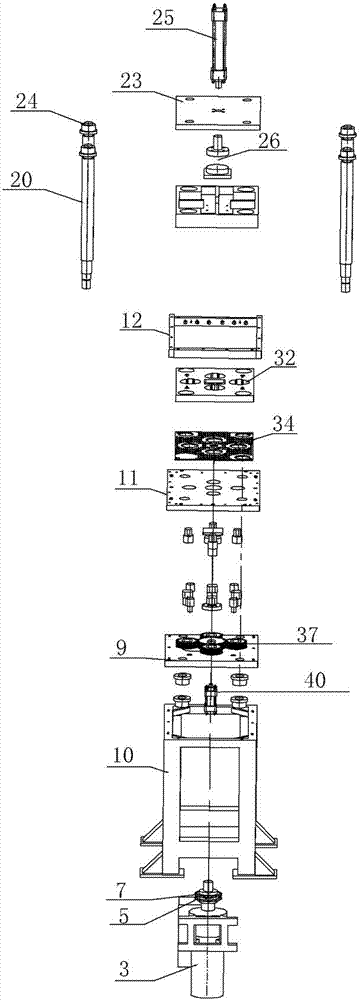

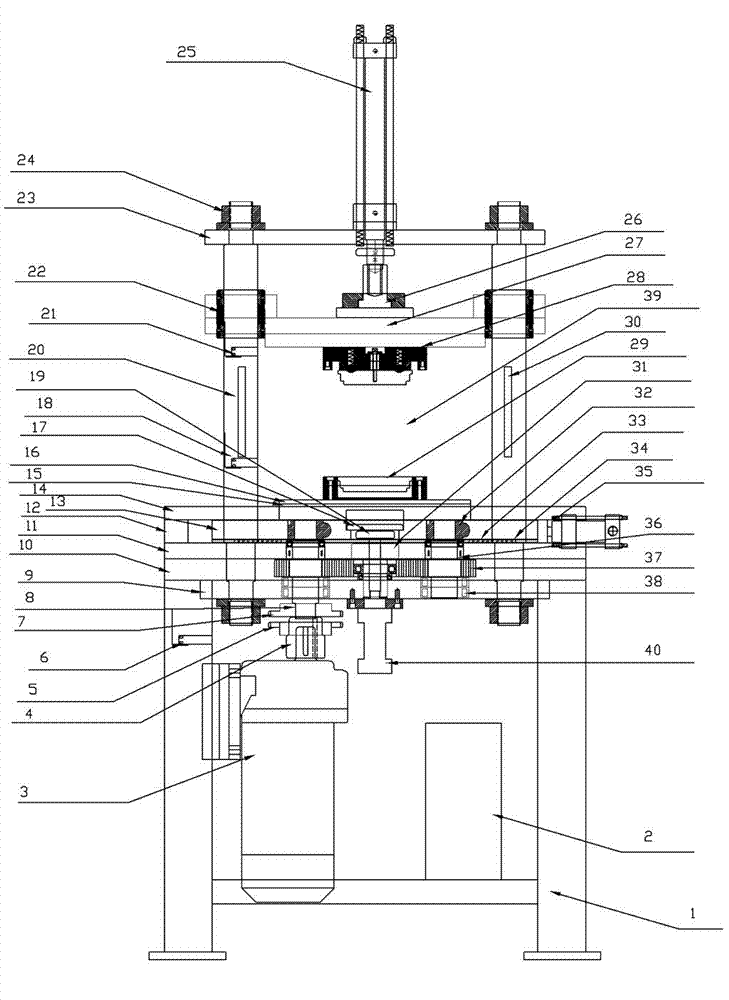

[0031] see Figure 1-3 , a flat edge trimming machine, mainly comprising: a frame 1, an electrical control box 2 placed in the frame 1 and a brake motor 3, an oil cylinder or an air cylinder device installed on the top of the frame 1, and a mold divided into upper and lower parts Assembly 39, which transmits the power of the brake motor 3 to the transmission part of the lower part of the mold assembly 39; the main shaft 8 in the transmission part is directly connected with the brake motor shaft 4 on the brake motor 3 through a sprocket; the brake motor The power of 3 is transmitted to the main shaft 8 after the brake motor shaft single row sprocket 5 on the brake motor shaft 4 engages with the main shaft single row sprocket 7 on the main shaft 8 . As another embodiment of the present invention, the brake motor shaft 4 of the brake motor 3 can be directly nested in the main shaft 8 in the transmission part, such as Figure 4 As shown, the brake motor 3 is an automatic brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com