Automatic battery box production equipment

A technology for production equipment and battery boxes, which is applied in the field of automatic production equipment for battery boxes, can solve the problems that battery boxes do not have automatic trimming, detection and rejection functions, the quality of battery boxes is difficult to guarantee, and the reliability is poor. good quality, reliable quality, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

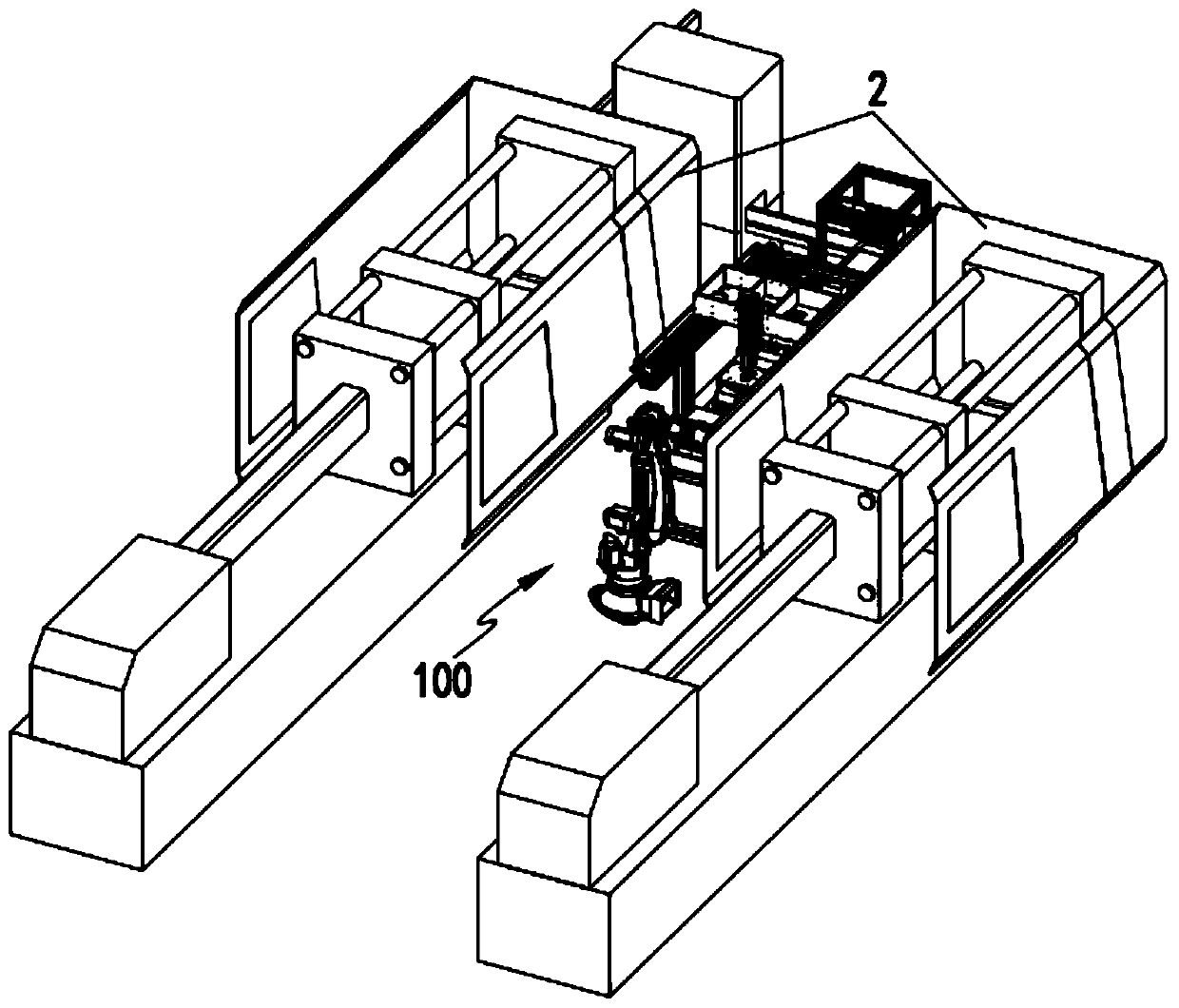

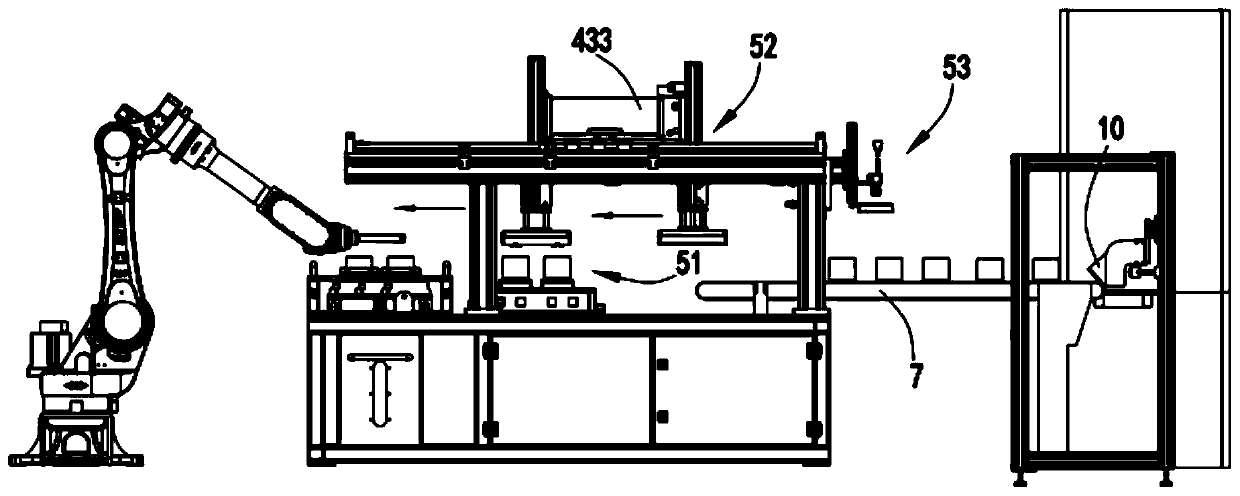

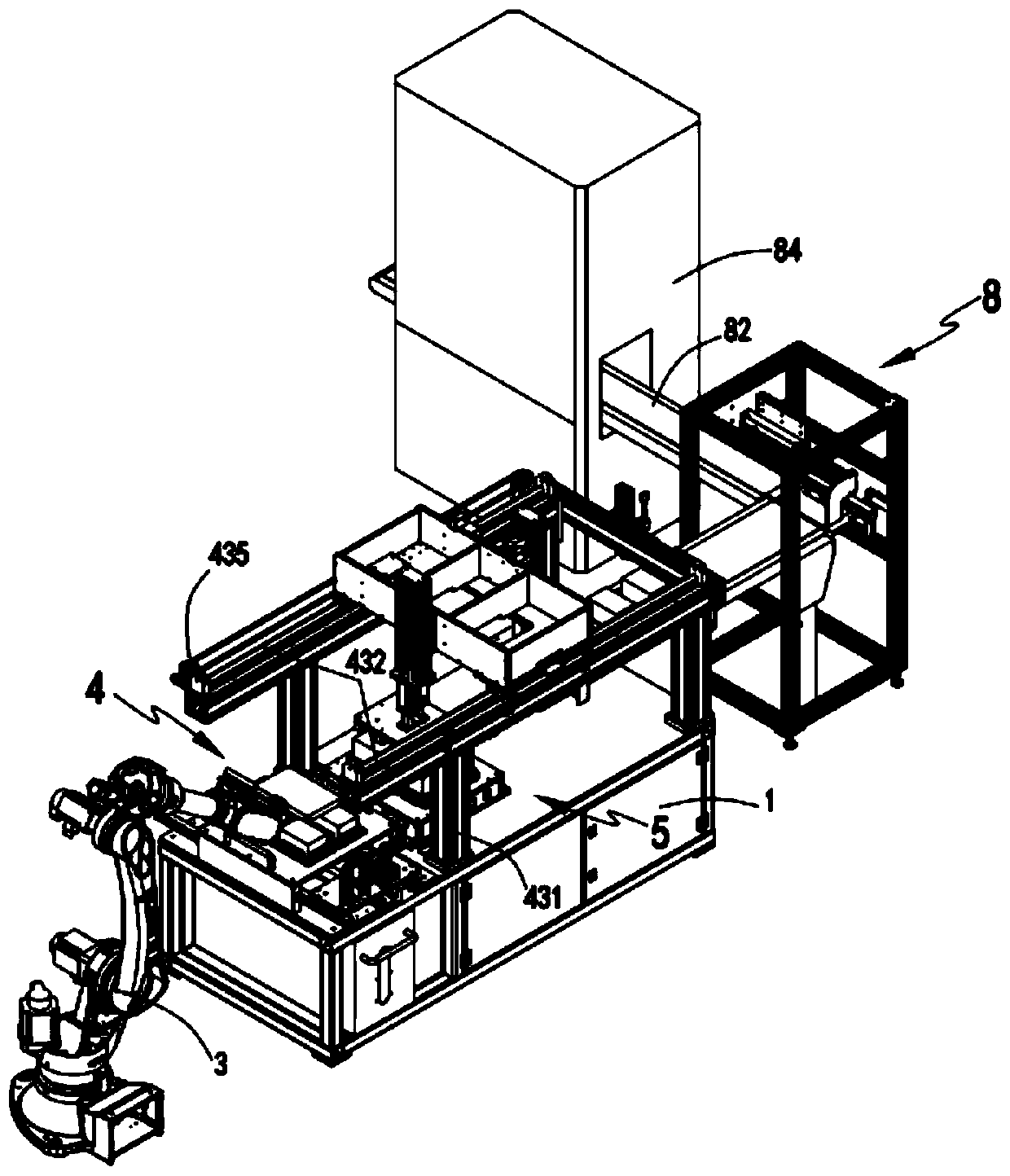

[0048] Such as Figure 1 to Figure 10 As shown, an automatic battery box production equipment includes an injection molding machine 2 for automatic injection molding of a battery box 10, a battery box post-processing line 100, and a manipulator 3. The battery box 10 formed on the injection molding machine 2 is passed through the manipulator. 3 Take it out to the post-processing line 100 of the battery box to perform automatic trimming at the edge of the opening, internal airtightness testing, and waste rejection in sequence;

[0049] The post-processing line 100 transfers the trimmed battery case 10 at the trimming station to the inspection station through the transfer mechanism 43 , and at the same time transfers the battery case 10 inspected at the inspection station to the rejecting station.

[0050] Further, the battery box post-processing line 100 includes a support table 1, on which a trimming device 4, a detection device 5 and a rejecting device 6 are sequentially arran...

Embodiment 2

[0072] Such as Figure 5 and Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment lies in that the four corners of the positioning groove 413 are provided with arc-shaped through grooves 415 , and the upper ends of the four sides are provided with guiding and limiting blocks 416 .

[0073] In this embodiment, arc-shaped through grooves 415 are provided at the four corners of the positioning groove 413 so that the four corners of the battery box and the positioning groove 413 can be avoided in the process of putting the battery box into the positioning groove 413. The friction and collision of the inner wall can further ensure the quality of the battery box.

[0074] The working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com