Patents

Literature

159results about How to "Improve trimming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

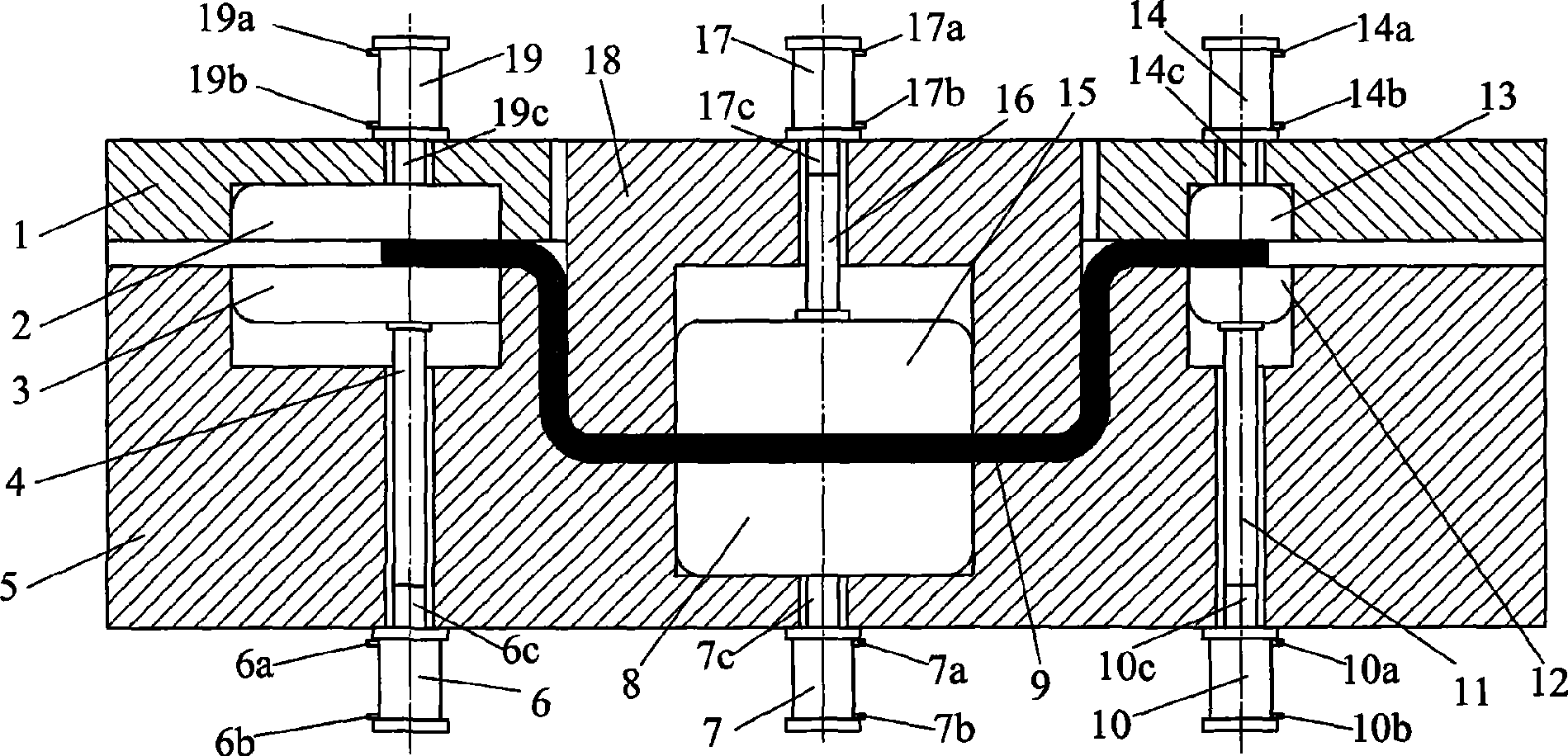

Thermoforming, hole-punching and edge-cutting integrated technique and mold of high-duty steel part

InactiveCN101486061ALess investment in equipmentSmall footprintShaping toolsPerforating toolsSteel platesHot stamping

The invention provides hot-forming, punching and edge-cutting integral technology and a hot-forming, punching and edge-cutting integral die for high strength steel parts. The integral technology comprises the following steps: arranging an edge-cutting and punching tool on a hot-forming die of the high strength steel parts; placing high strength steel plate materials which is heated to be completely austenized into the hot-forming die for punching before hot stamping forming of the high strength steel plate materials; utilizing the edge-cutting and punching tool on the hot-forming die to perform edge-cutting and punching operations on workpieces subjected to stamping after the hot-forming die is closed; cooling the hot-forming die after the operations are over; and utilizing die components which contact formed parts to quench the formed parts. The integral die comprises a forming convex die, a forming concave die, an upper punching tool, a lower punching tool, an upper edge-cutting tool and a lower edge-cutting tool. The integral technology and the integral die reduce the production cost of the hot-formed parts, and shorten the production period of the hot-formed parts; and the hot-formed parts have high edge-cutting and punching quality and high dimension precision and shape precision.

Owner:SHANDONG UNIV

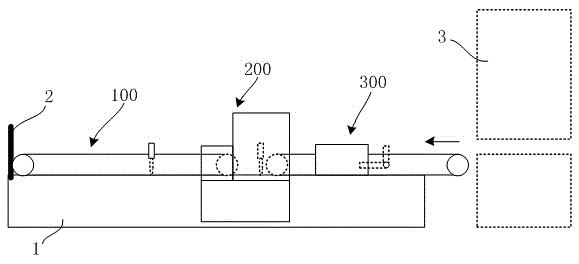

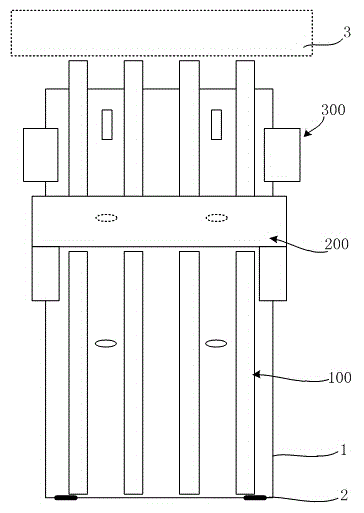

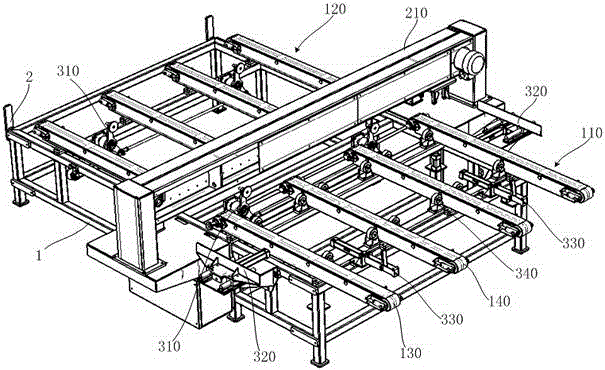

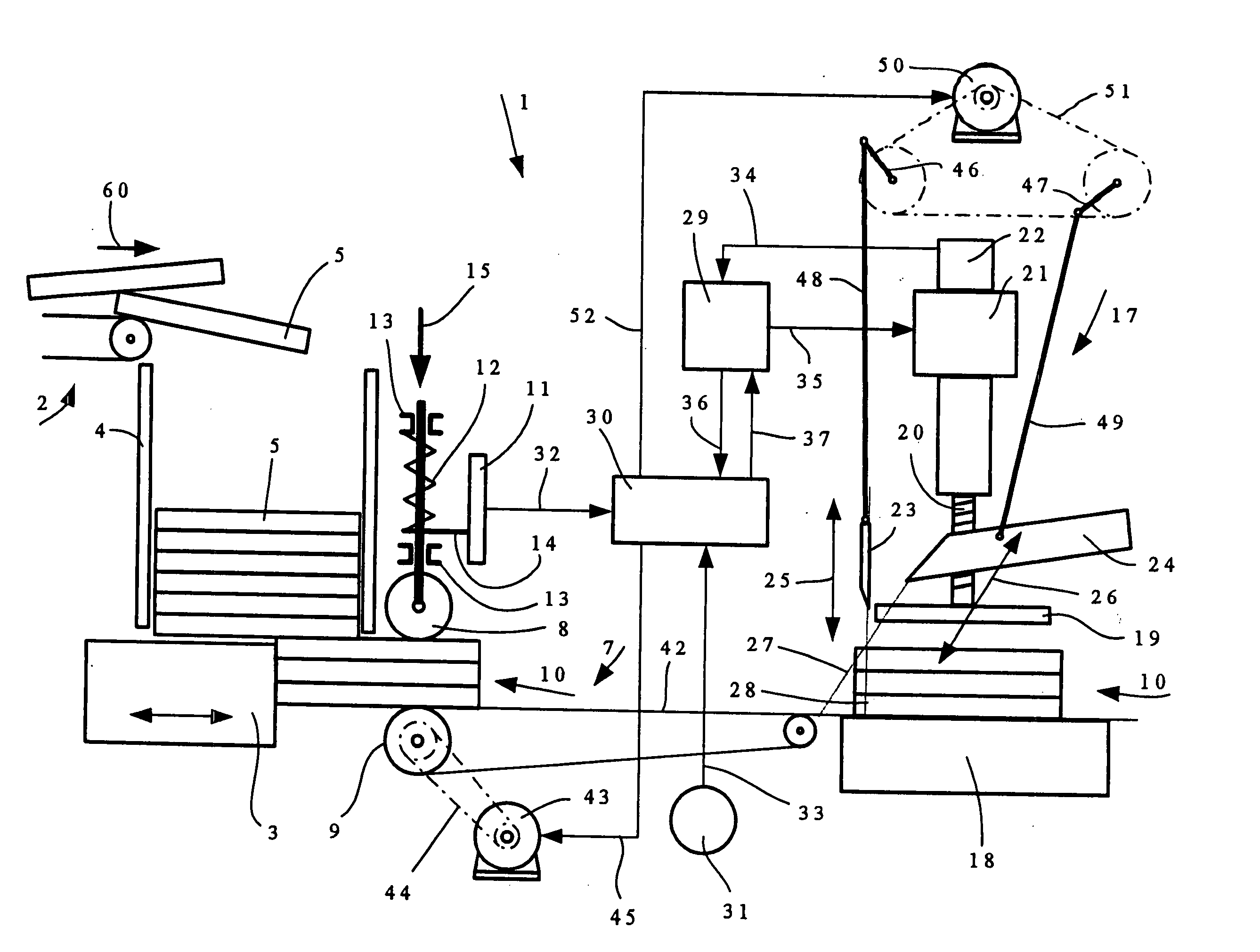

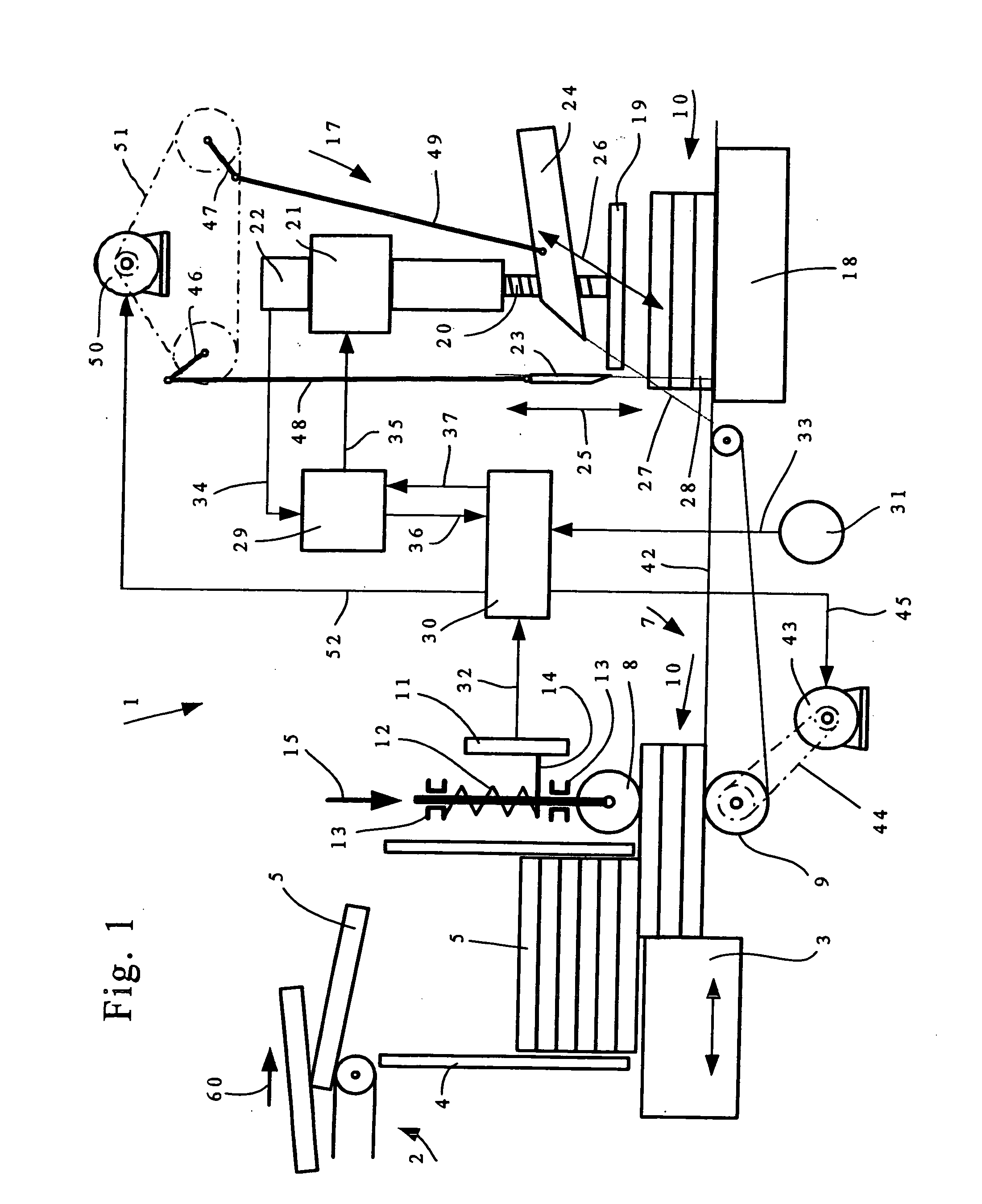

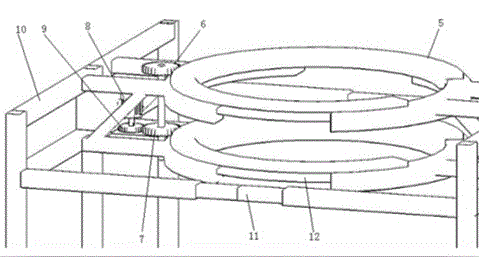

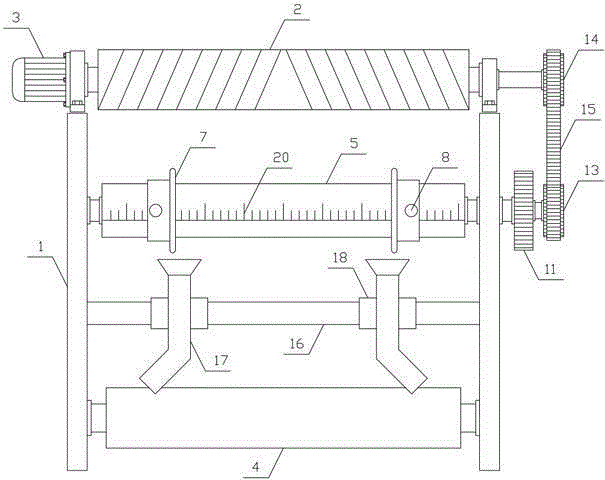

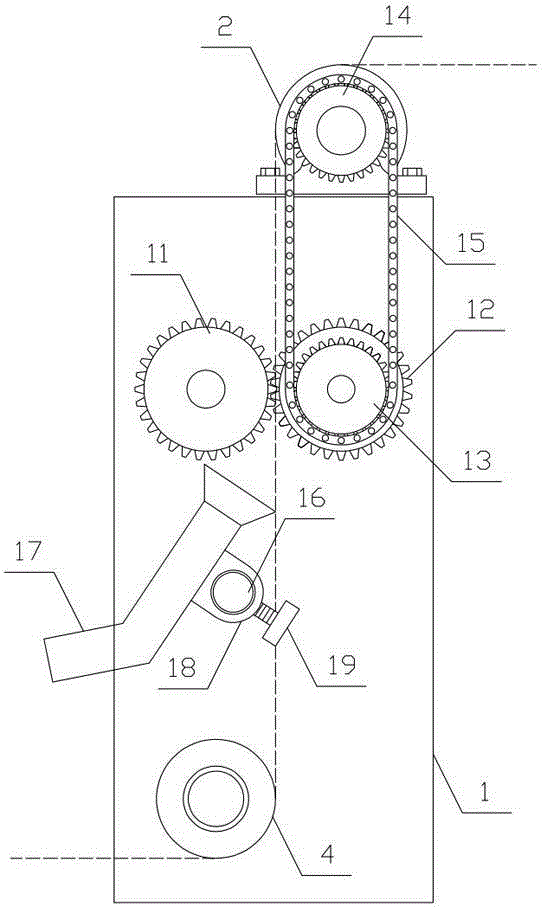

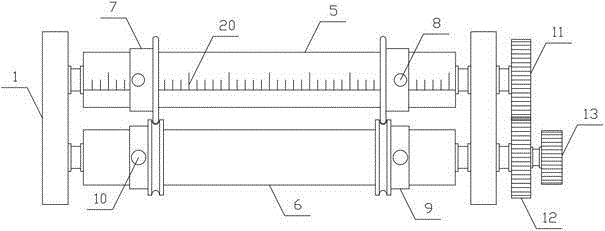

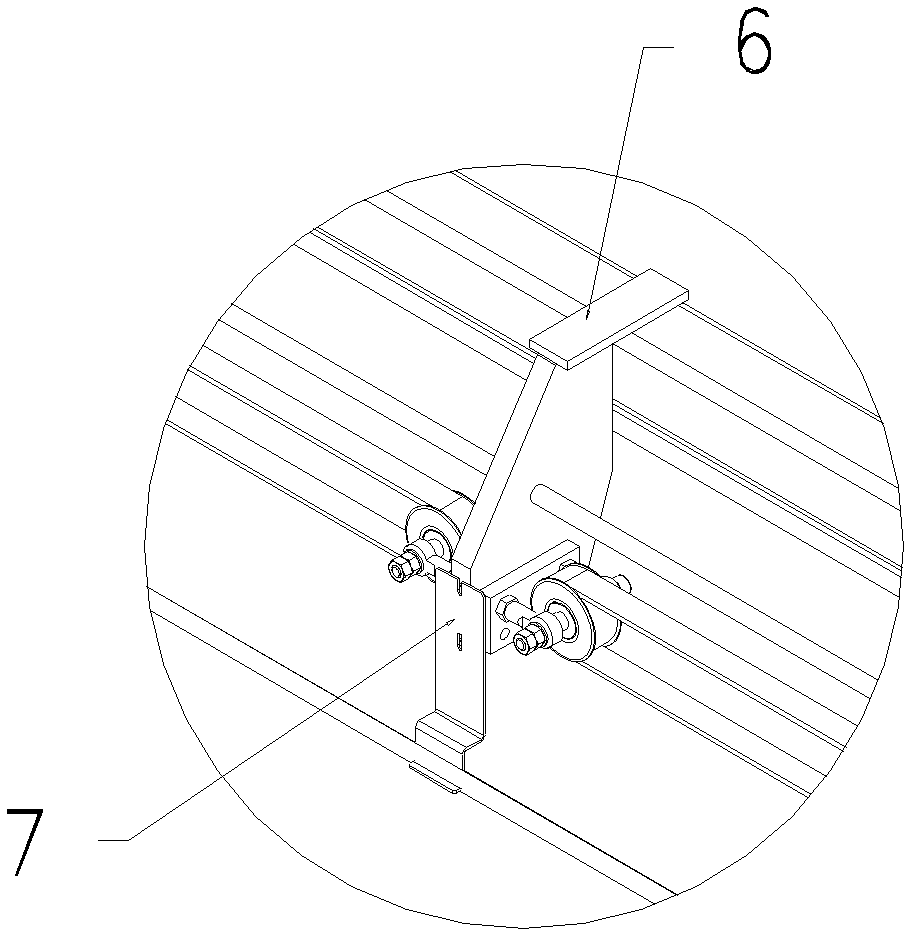

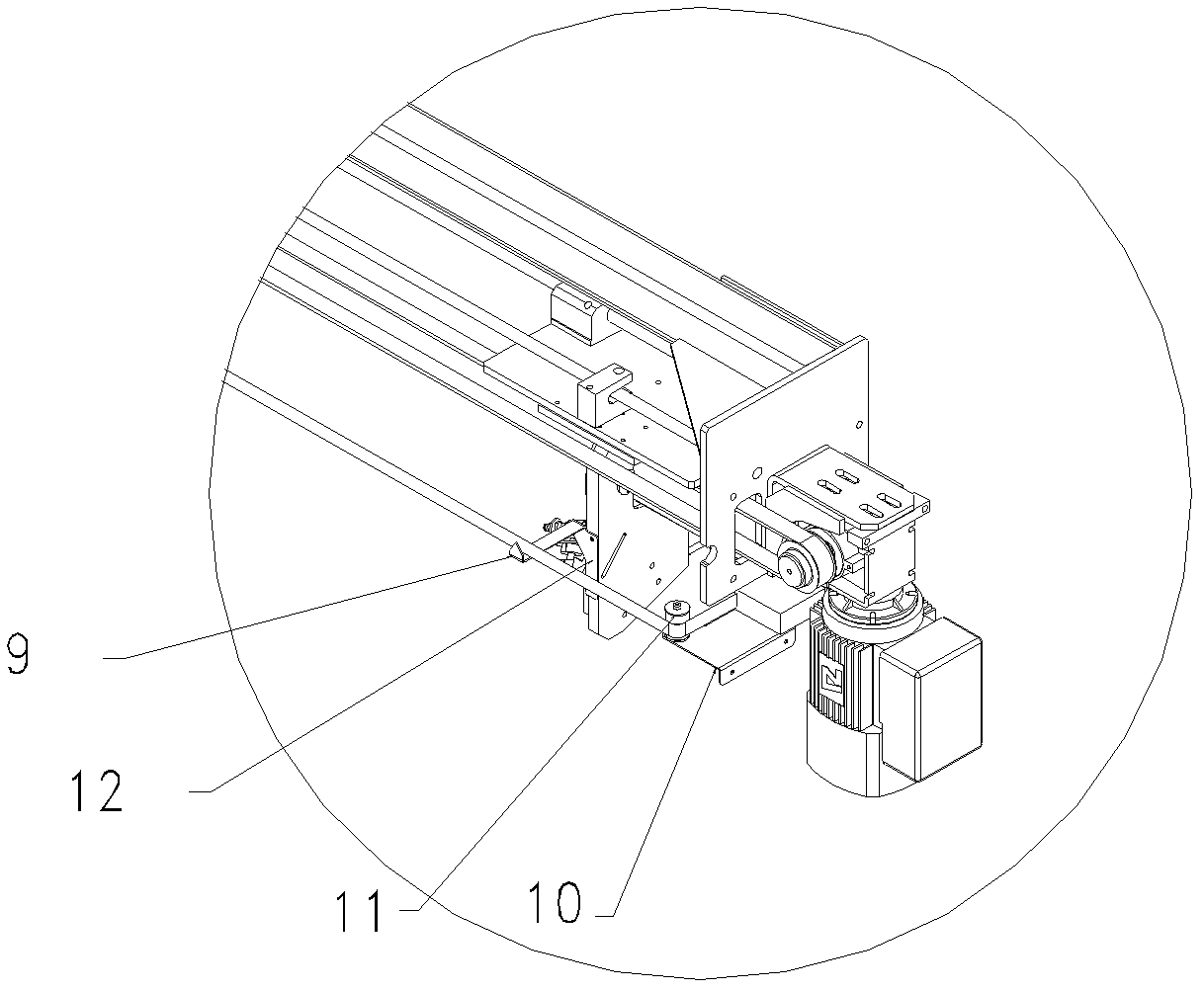

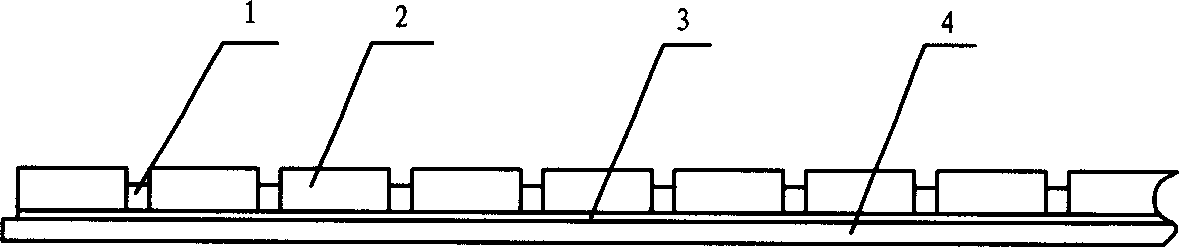

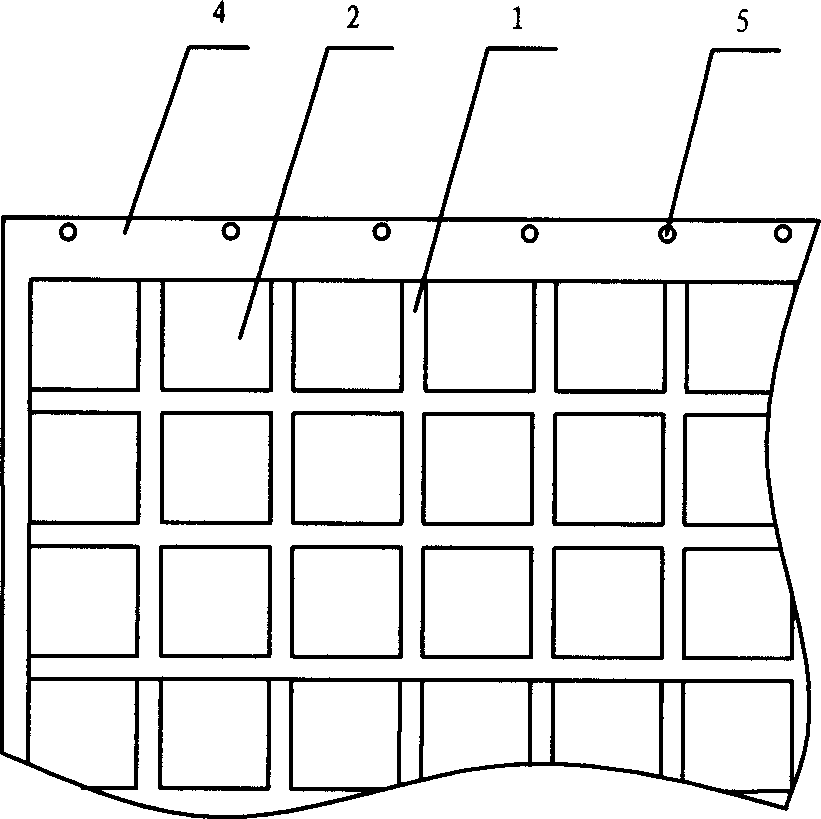

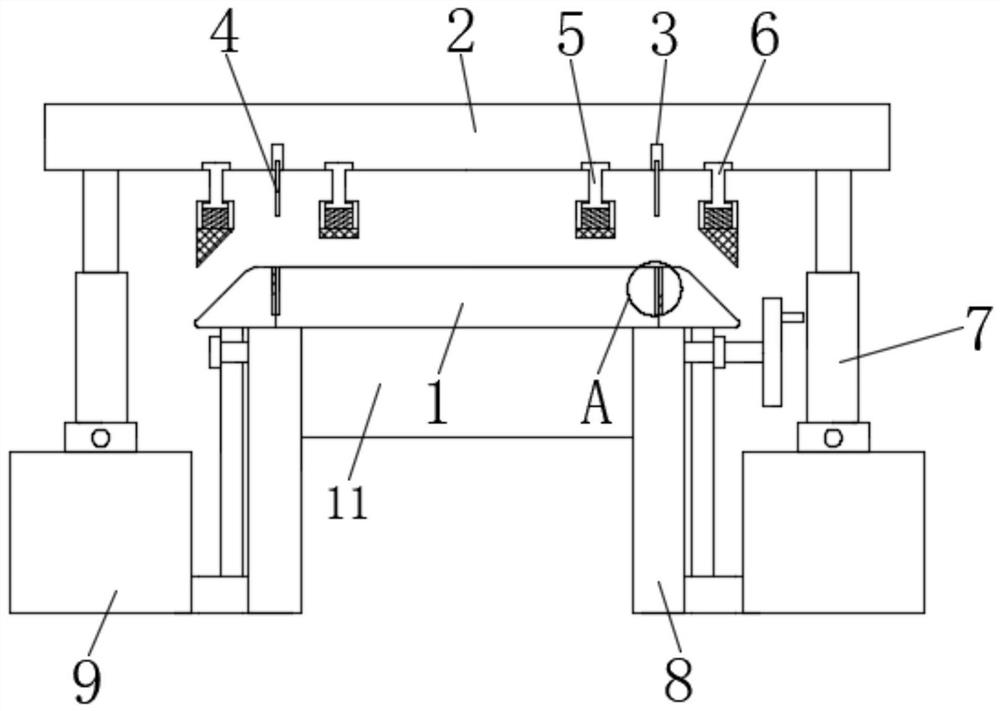

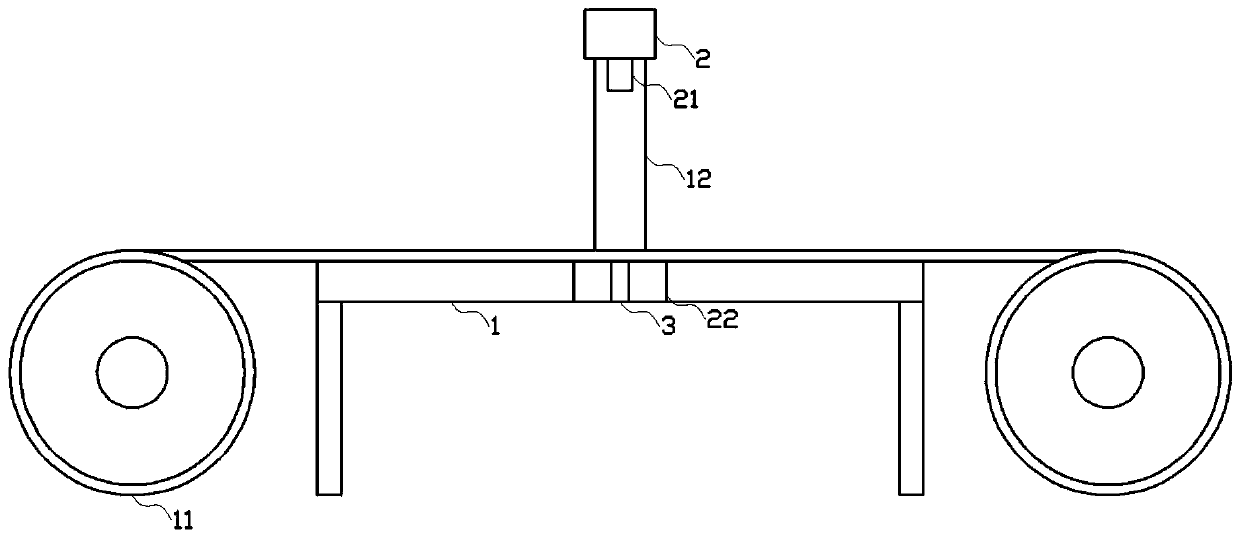

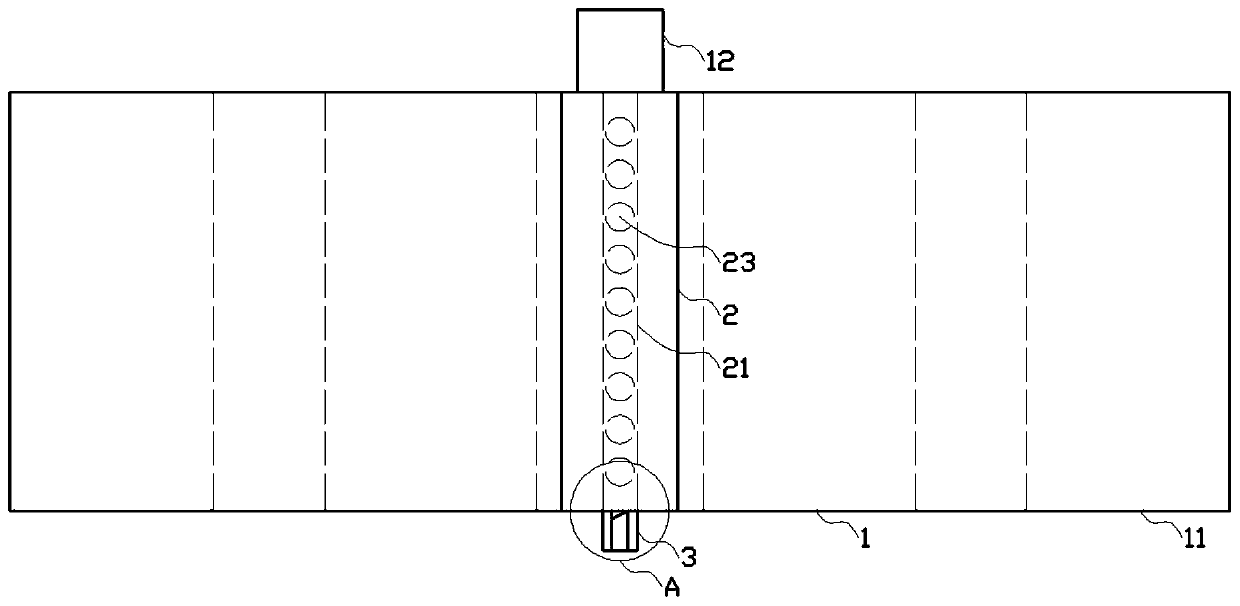

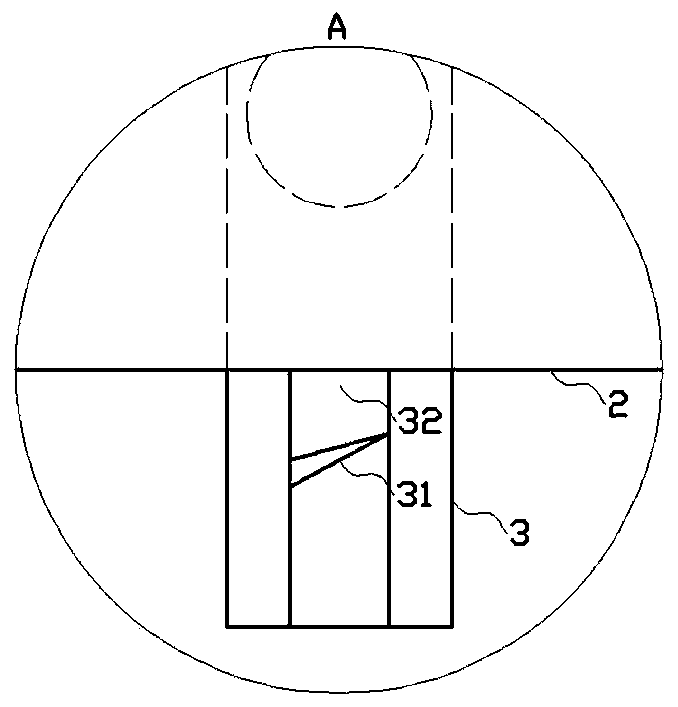

Conveying and trimming assembly used for melamine board, trimming and board discharging assembly and achieving method of conveying and trimming assembly and trimming and board discharging assembly

InactiveCN104444480AReduce labor intensityHigh precisionOther plywood/veneer working apparatusRegistering devicesHeat pressEngineering

The invention discloses a conveying and trimming assembly for a melamine board. The conveying and trimming assembly comprises a bottom frame arranged outside a discharging port of a hot press, a two-section type conveying mechanism arranged on the bottom frame in the discharging direction, a positioning and position adjusting mechanism installed on the bottom frame and used for adjusting the position of a board on the two-section type conveying mechanism to as to conveniently conduct trimming, a trimming mechanism arranged at the sectioned position of the two-section type conveying mechanism in a crossing mode, and a tail-end baffle located at the tail end of the two-section type conveying mechanism. The invention further discloses a trimming and board discharging assembly which comprises the conveying and trimming assembly and a board discharging and carrying mechanism connected with the conveying and trimming assembly. Under the cooperation action of the conveying mechanism and the positioning and position adjusting mechanism, the board obtained after hot pressing is conveyed to a designated position, trimming is conducted on the board through the trimming mechanism, the board is well placed through the board discharging and carrying mechanism, an automatic mechanical device can fully replaced labor force, the labor intensity of workers is greatly lowered, the labor cost is reduced, and the production efficiency is effectively improved.

Owner:李茂华

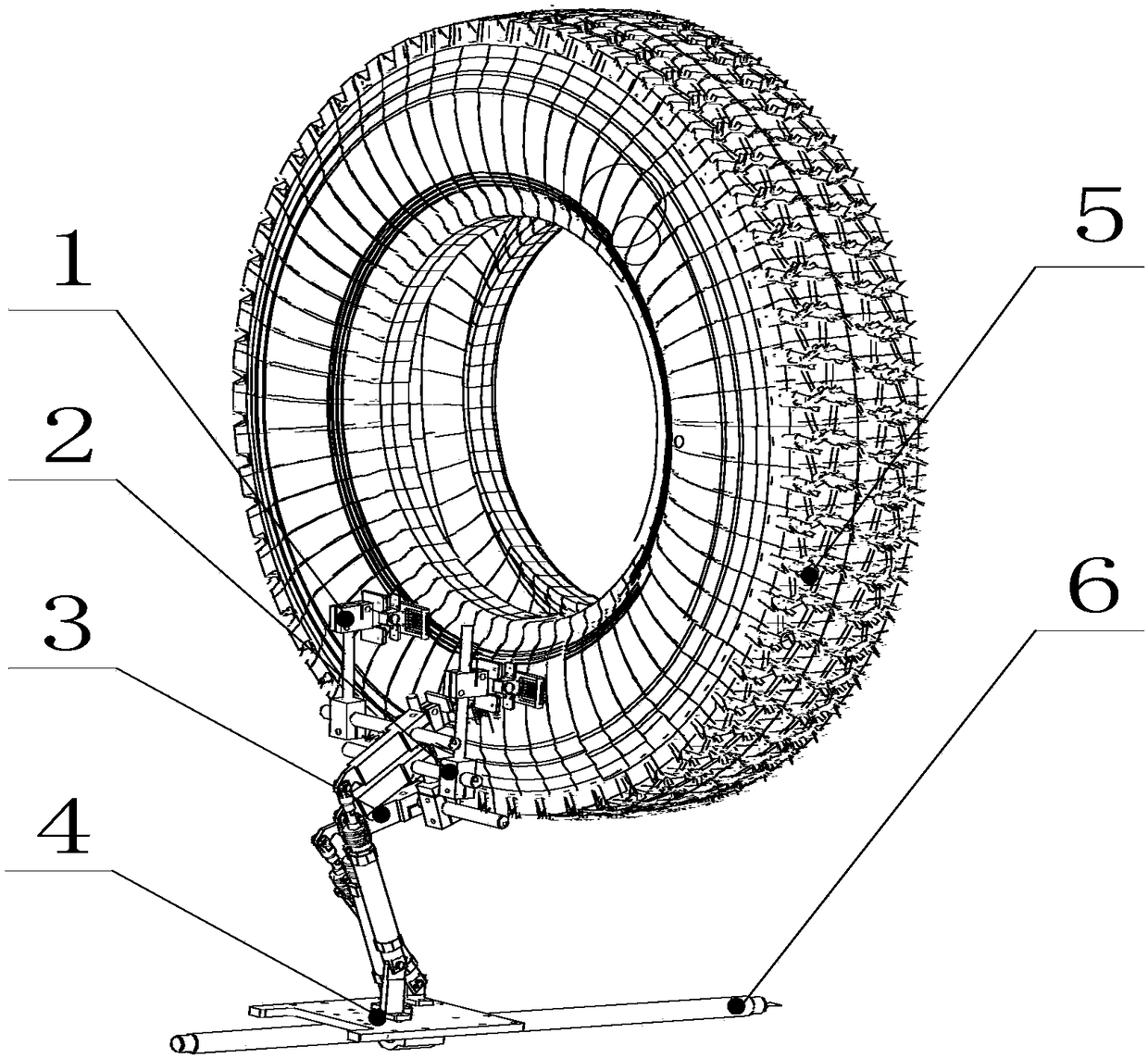

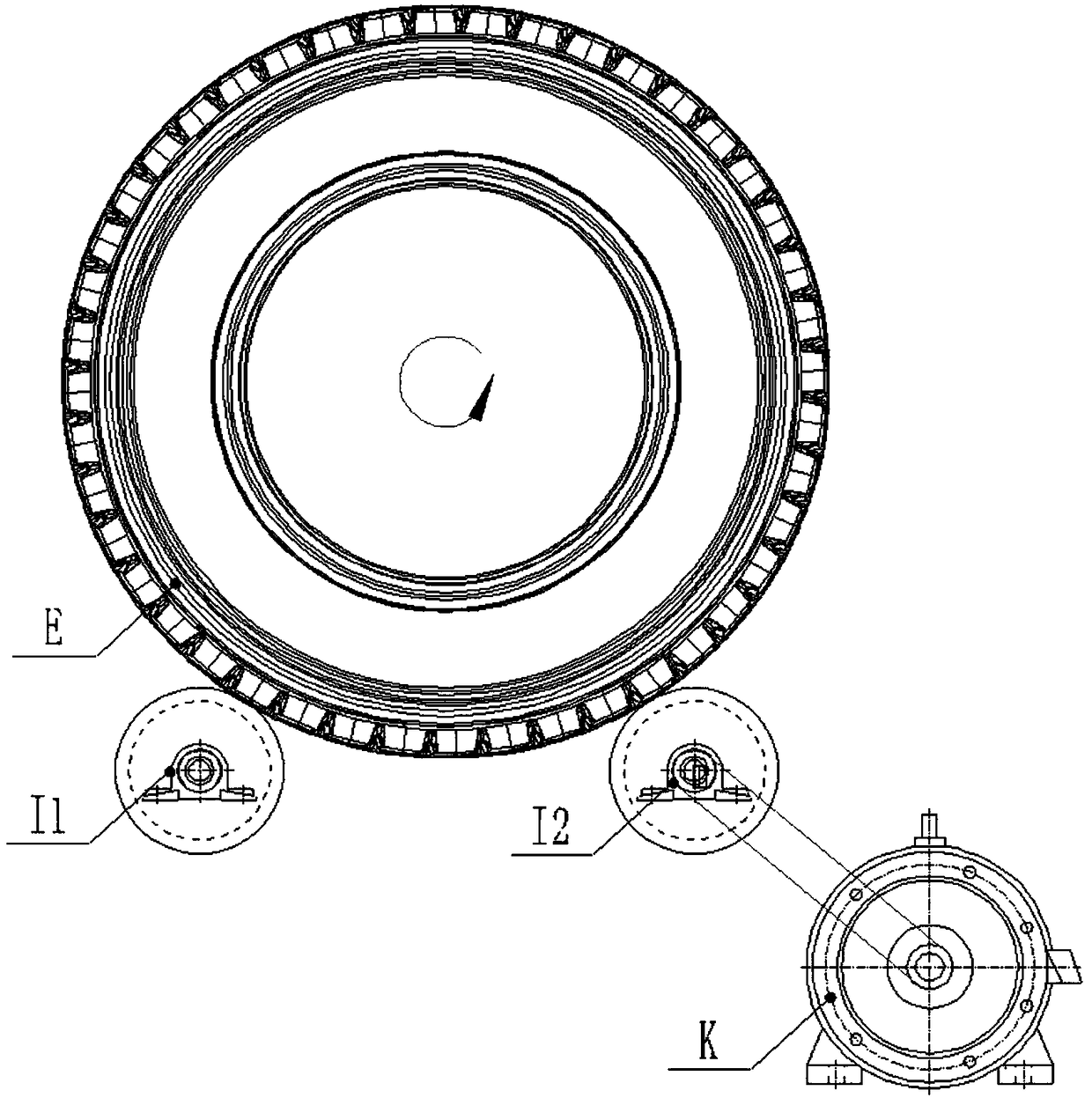

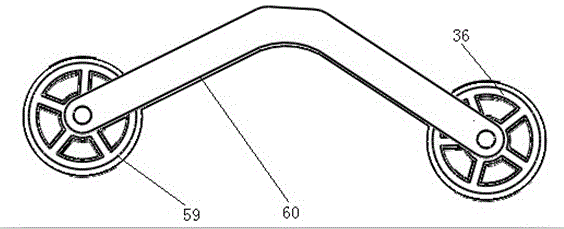

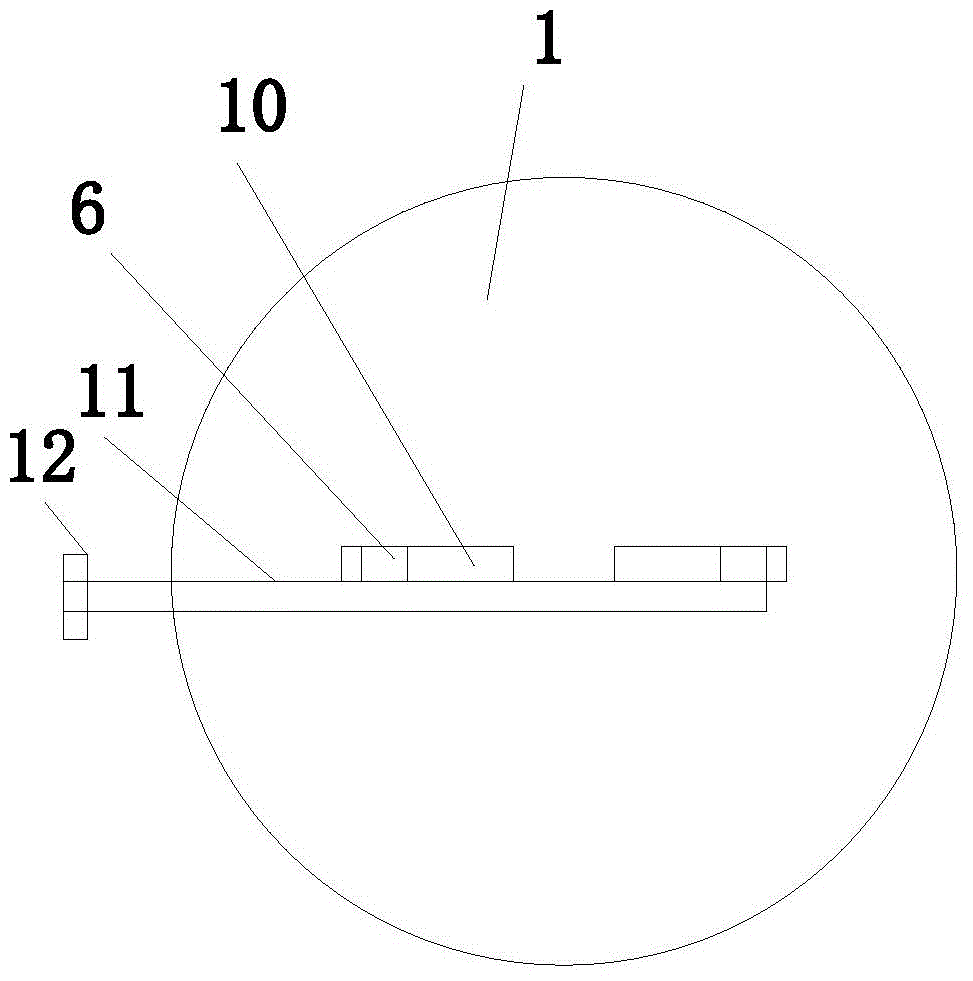

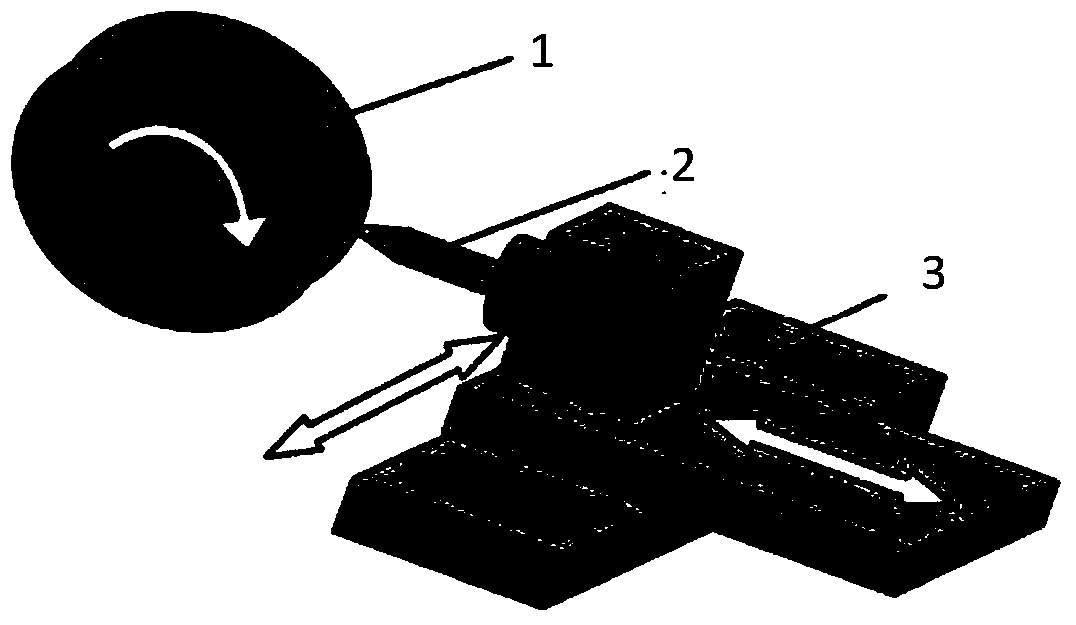

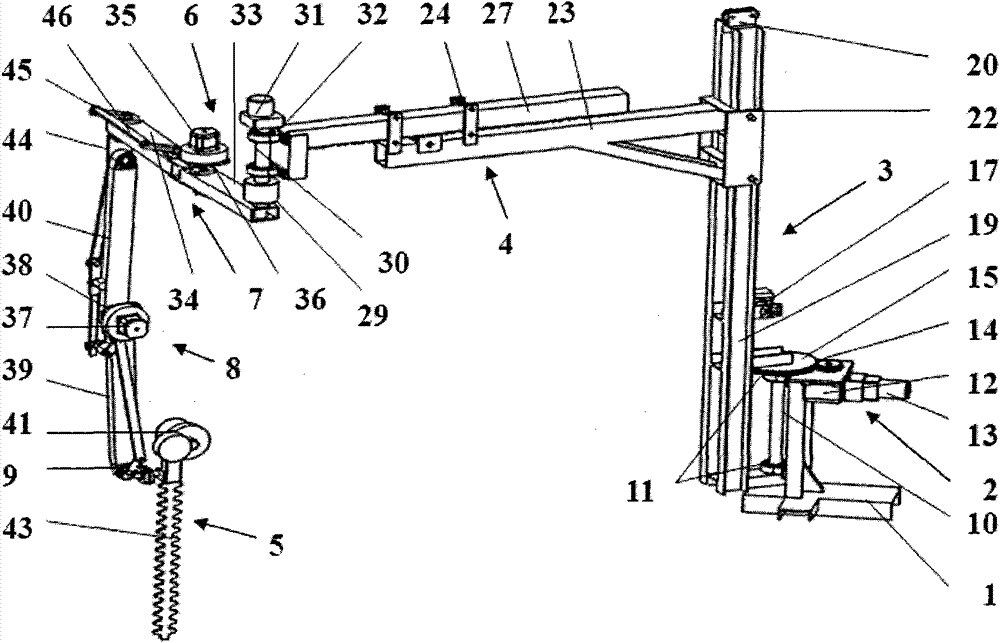

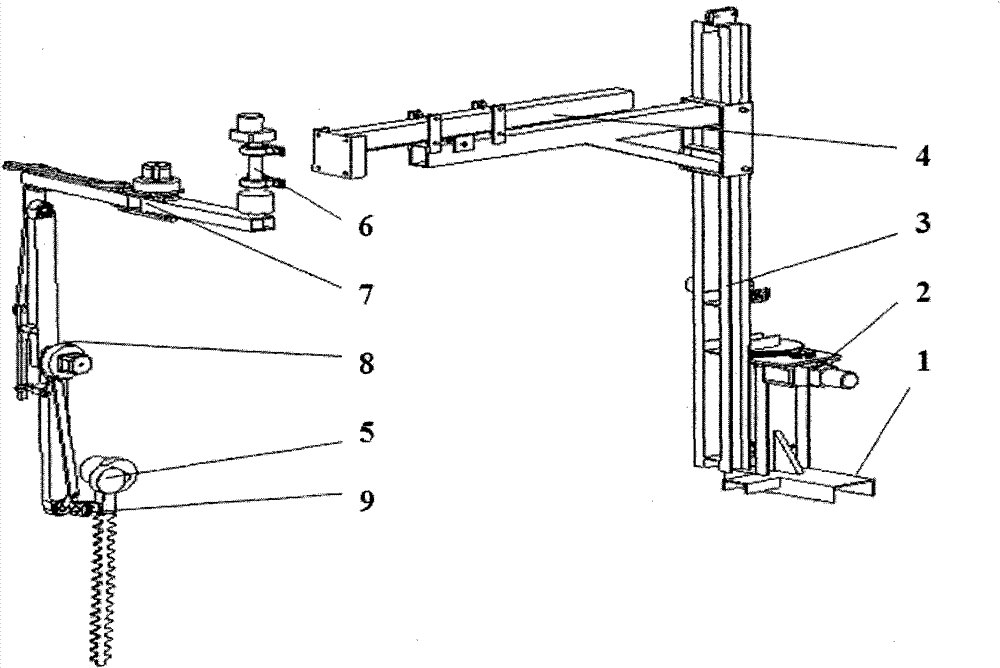

Deburring device for TB tyre side surface

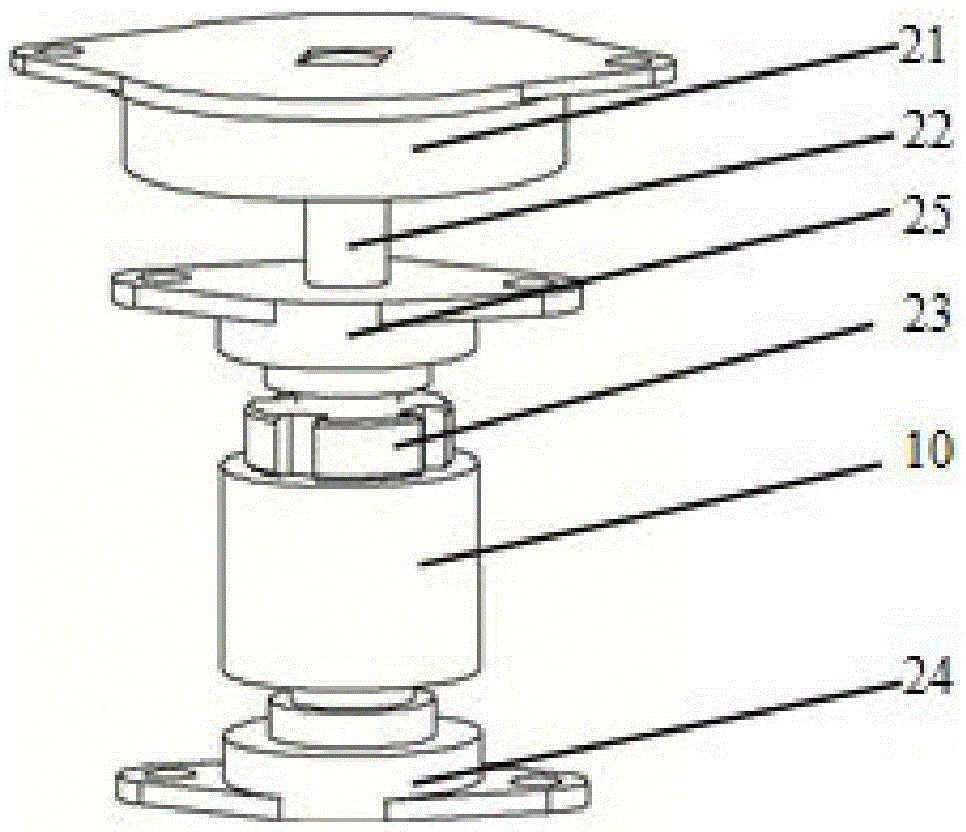

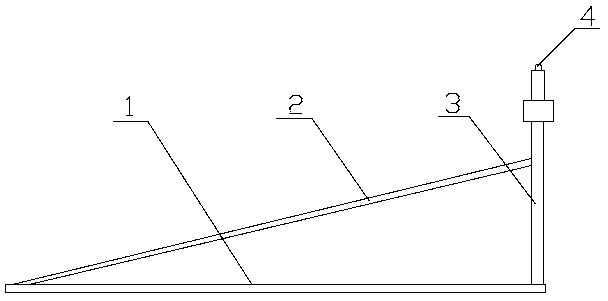

The invention relates to the field of tyre manufacture and particularly relates to a deburring device for a TB tyre side surface. The device includes two sets of cutting tool assemblies that are symmetrical left and right, a rack translation assembly, a tyre and a ball screw. The two sets of cutting tool assemblies are installed on the rack translation assembly and are disposed at both sides of the tyre; opening and closing motion driven by the ball screw is performed on the rack translation assembly to control the distance from the tyre side surface; the tyre is driven by a clamping rotationdevice to perform uniform speed rotary motion, and when the motion is smooth, the cutting tool assemblies are driven by the ball screw to move the tire at a uniform speed on the rack translation assembly, and stop when the cutting tool assemblies move to a suitable distance; at this time, cylinders of cutting tool mechanisms in the cutting tool assemblies perform air inlet work, and cutting toolsare pushed out on a to-be-trimmed tire, and then the cutting assemblies move downward as a whole, and when cutting blades complete trimming deflashing on a tyre surface, the cylinders work at this time, and the cutting tools are recovered; and the cutting tool assemblies are driven by the ball screw to move away from the tyre at the uniform speed until an entire trimming deflashing process is completed.

Owner:JIANGSU UNIV

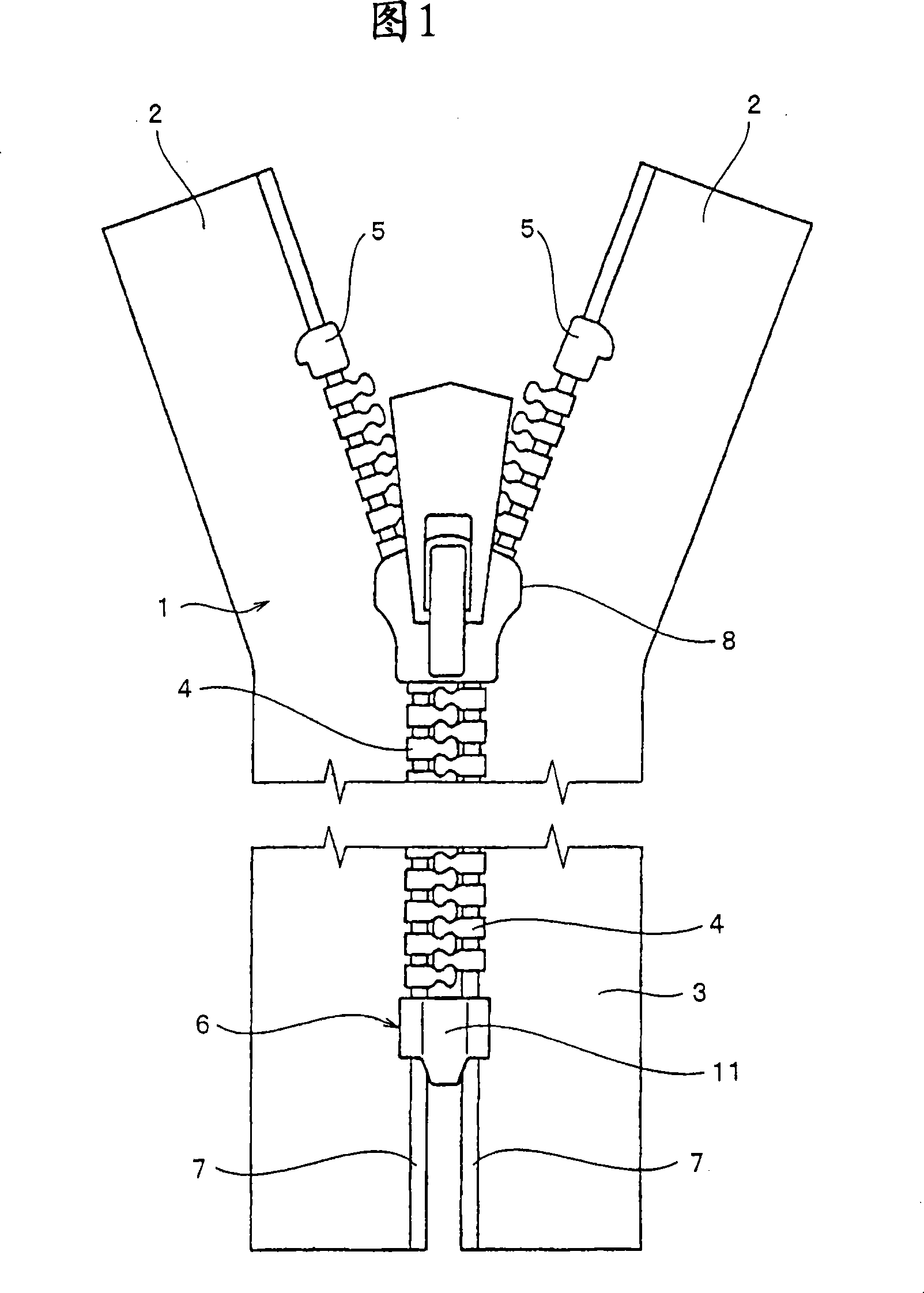

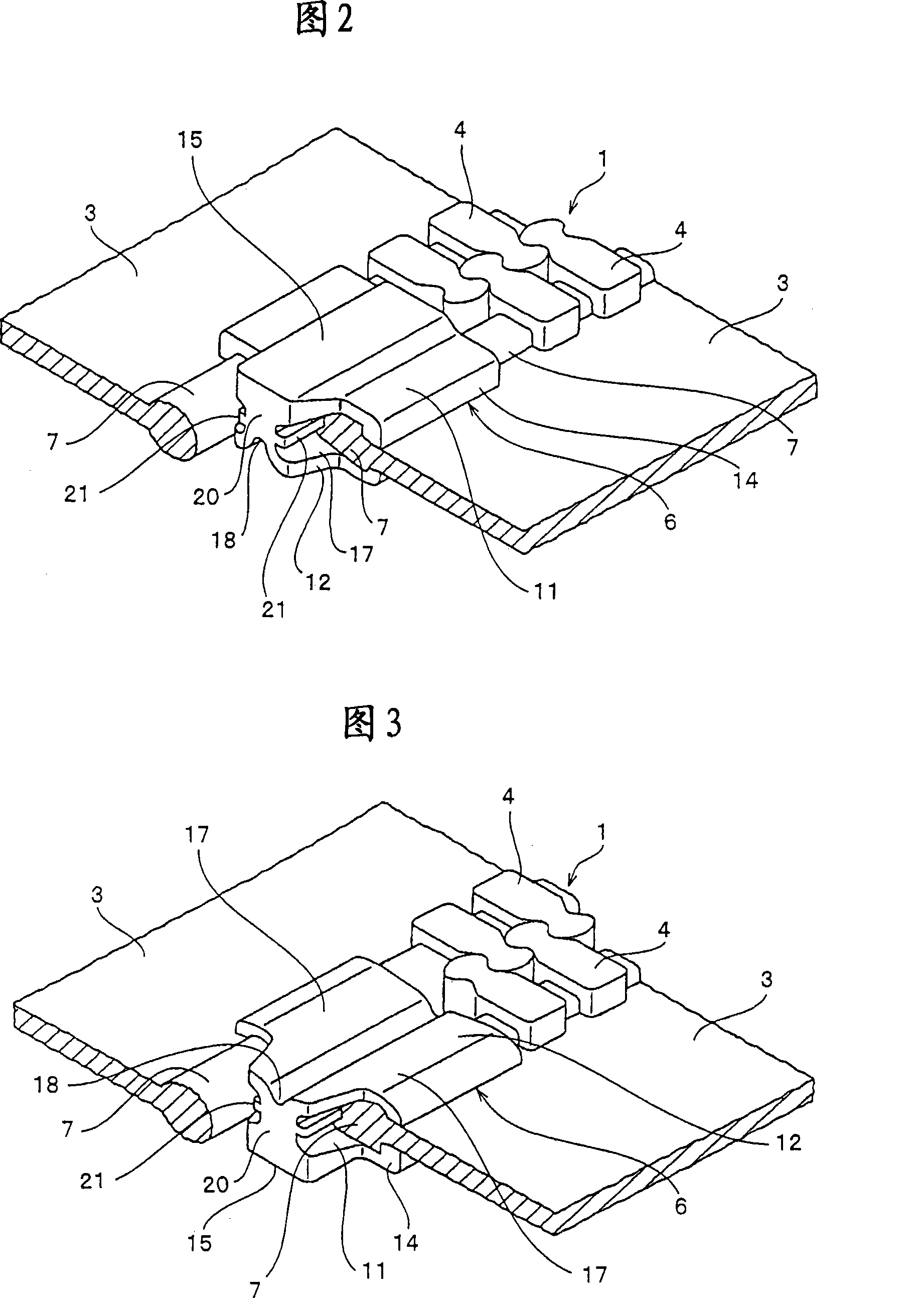

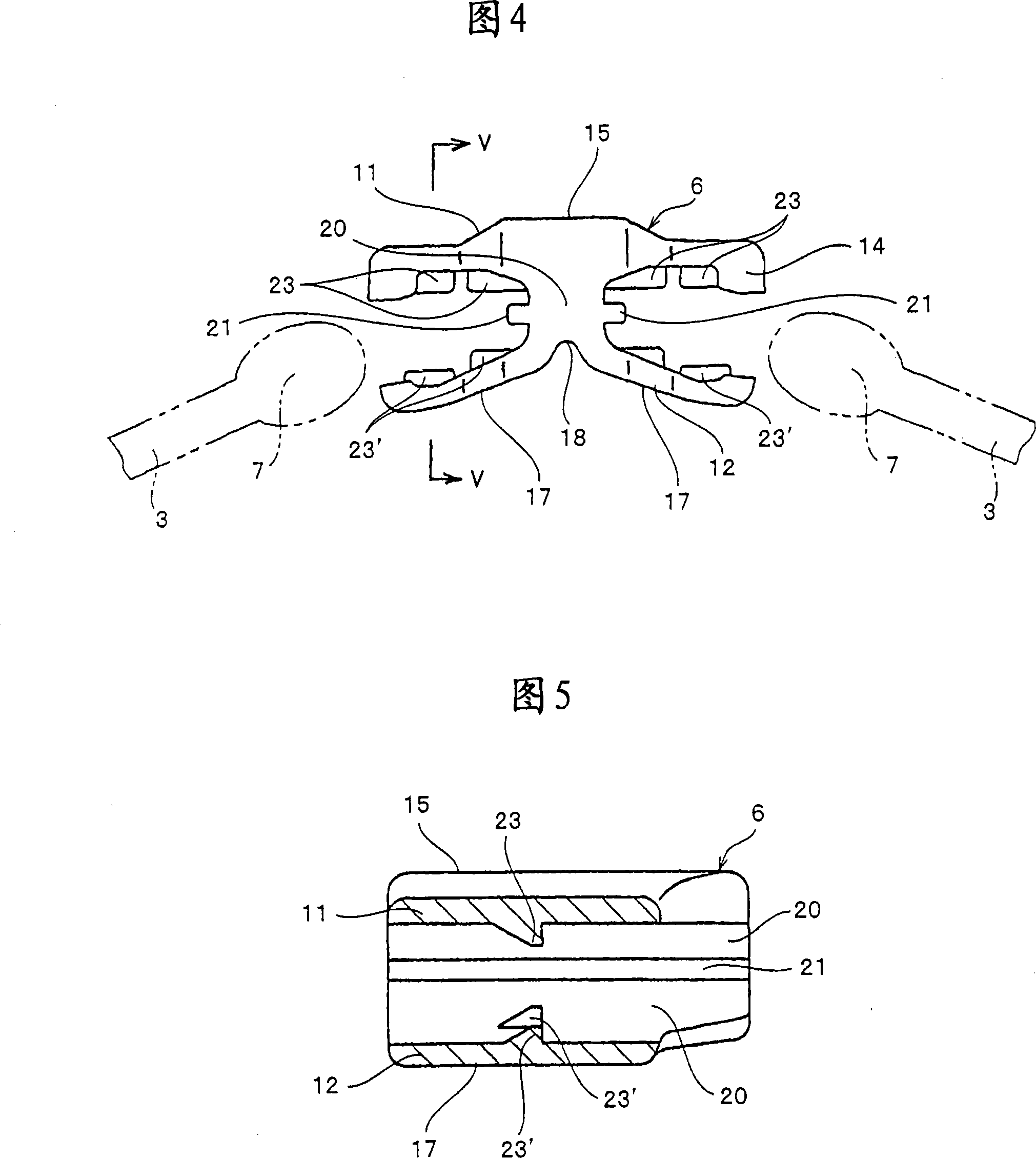

Bottom end stop for slide fastener

Owner:YKK CORP

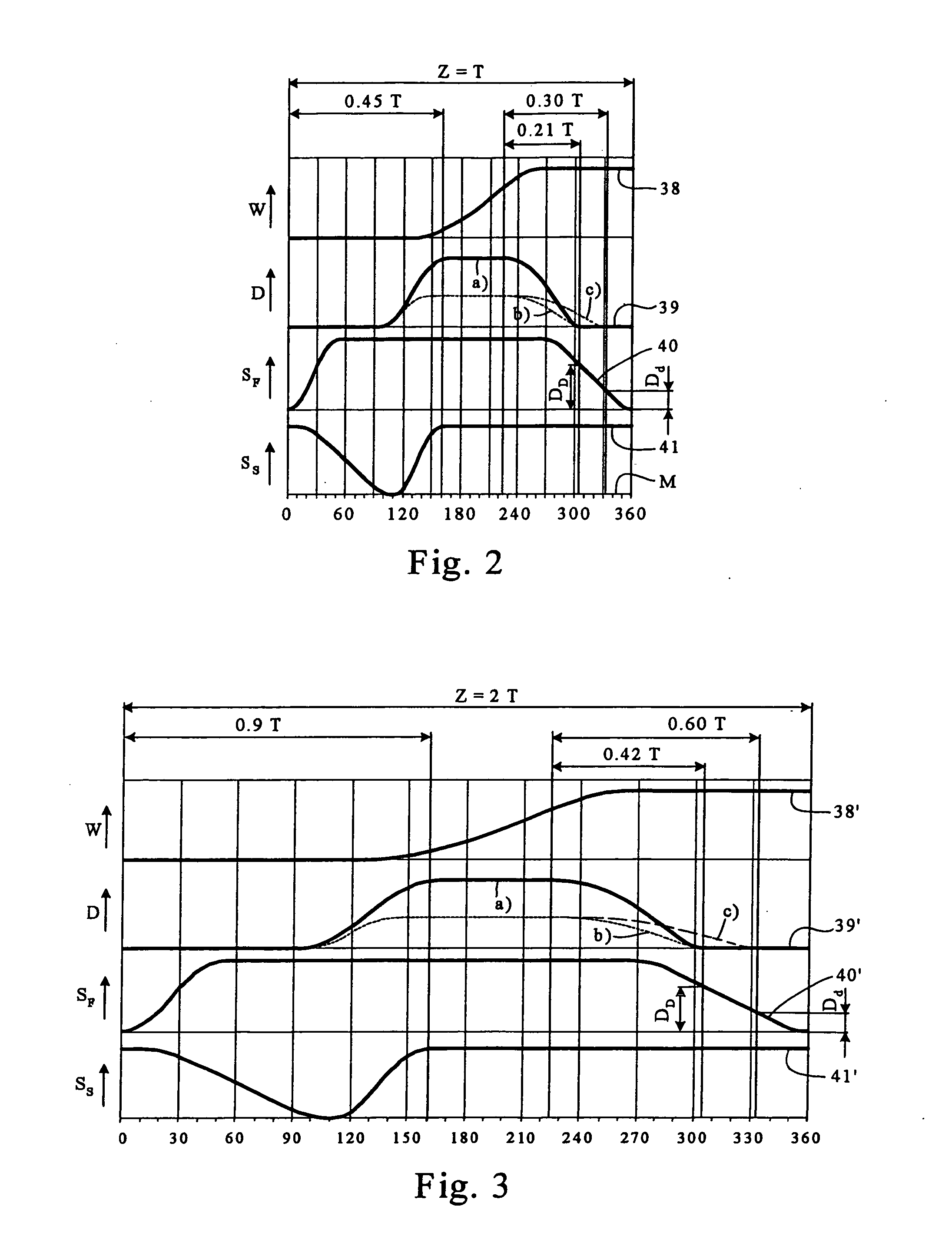

Method for trimming multiple edges of a print product

ActiveUS20060081100A1Improve trimming qualityQuality improvementMetal working apparatusMultiple edgesEngineering

A method for trimming multiple edges of a print product over the course of several processing steps of a processing cycle using a trimming apparatus is disclosed. The method comprises the processing steps of feeding the print product from a stacking device to a trimming device using a feeding device, pressing the print product onto a trimming table using a pressing die, trimming the print product positioned on the trimming table using knives associated with the trimming device, releasing the pressing die from the trimming table, and removing the trimmed print product from the trimming table. The pressing die and the knives are driven by separate drives that are controlled by a control unit. The steps of feeding, pressing down, and releasing are time-variable, while the step of trimming includes a respectively time-constant knife movement for trimming the print product.

Owner:MULLER MARTINI HLDG

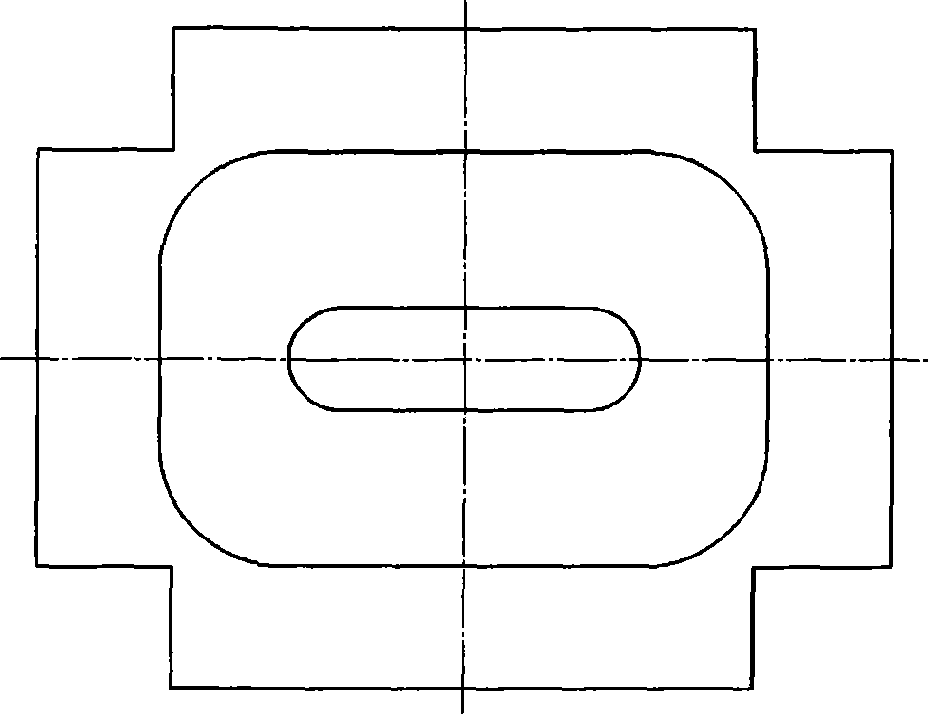

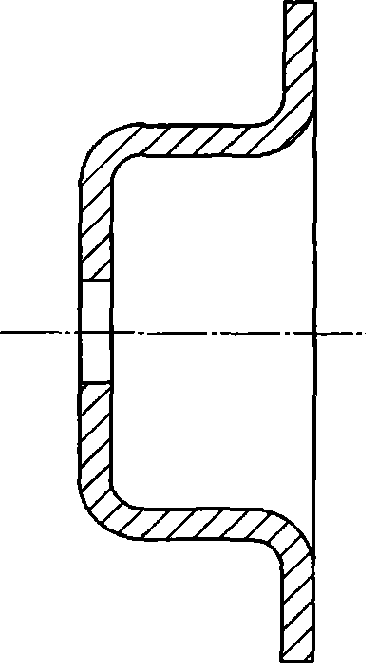

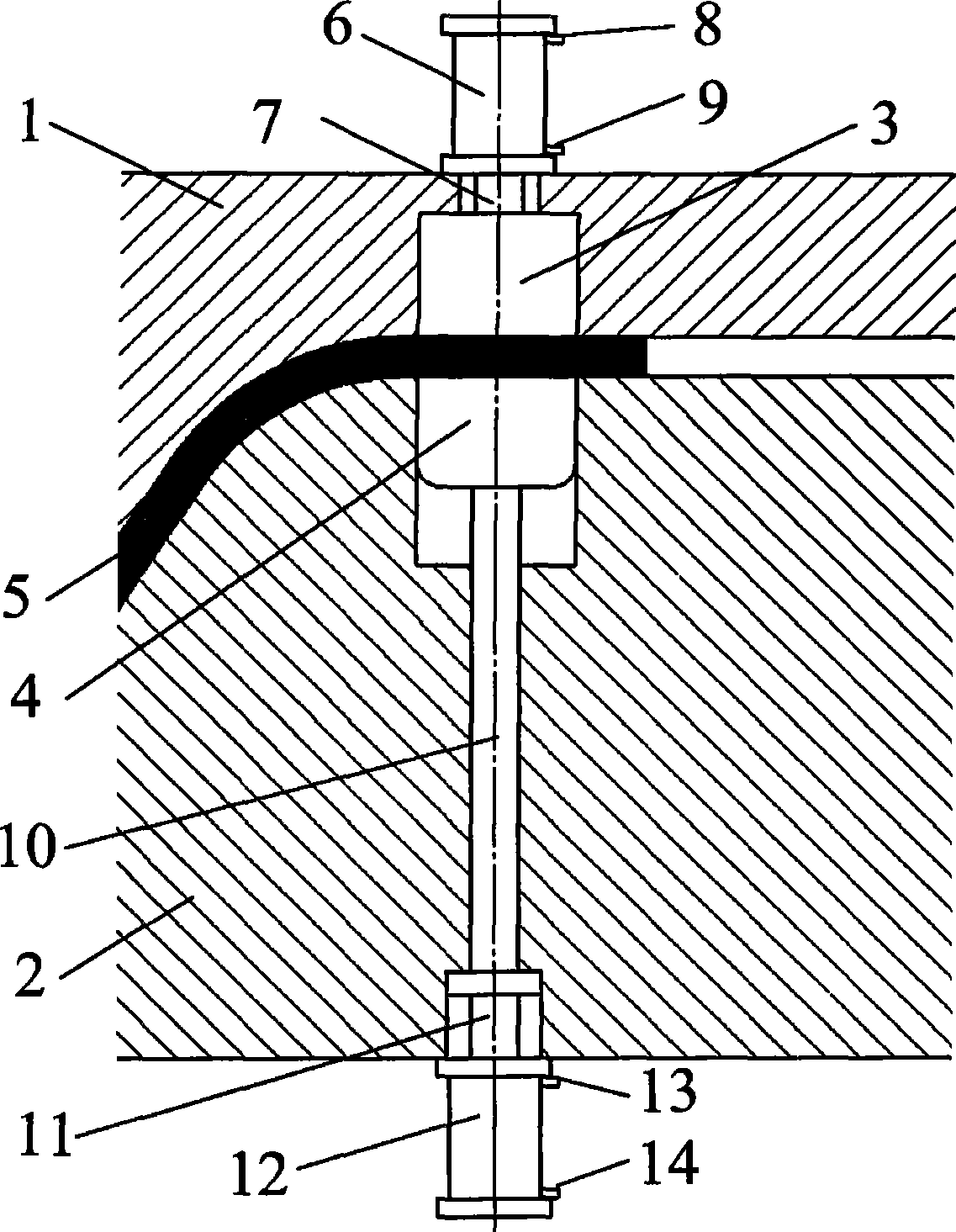

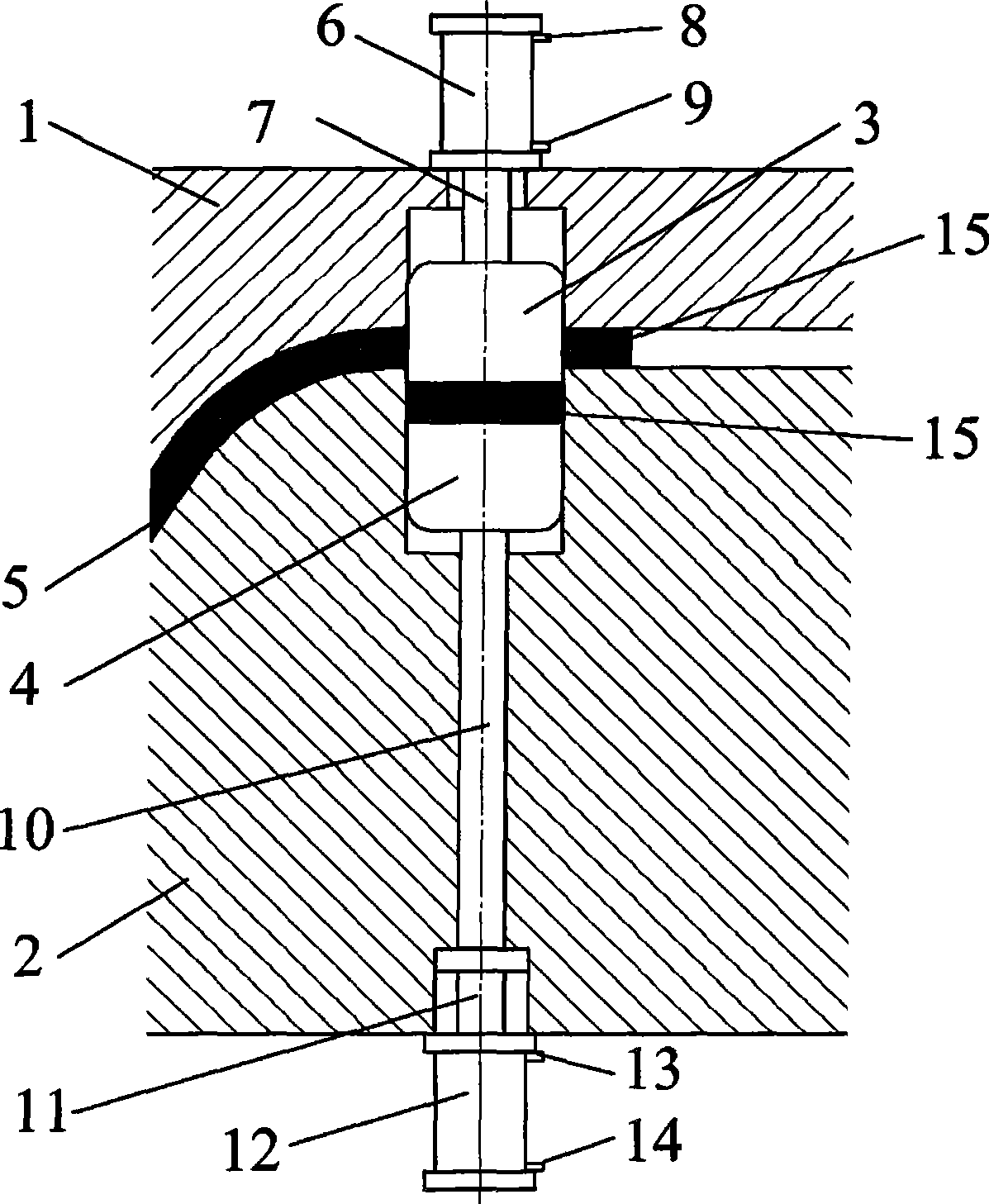

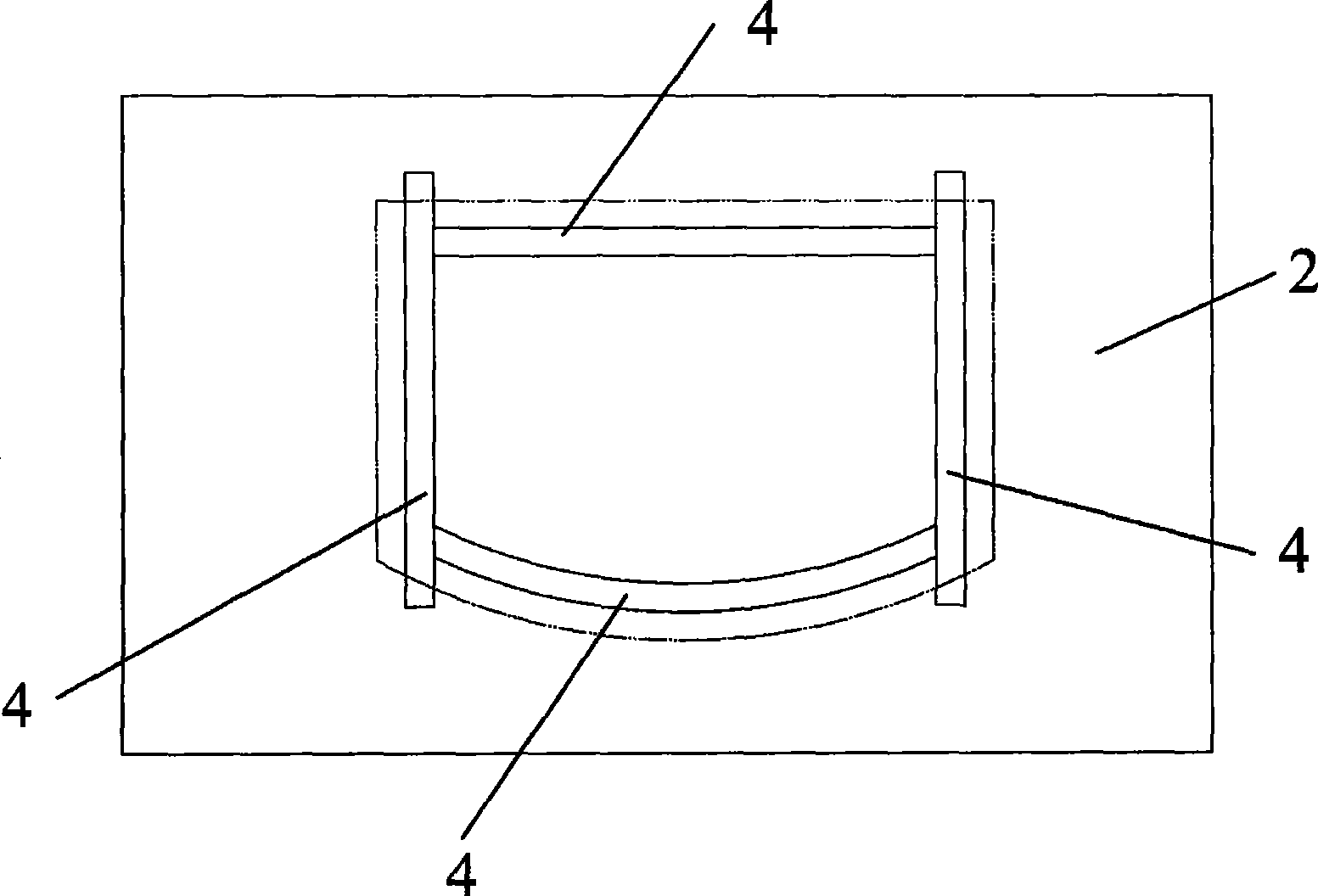

Thermoforming and edge-cutting integrated technique and mold of high-duty steel part

The invention provides hot-forming and edge-cutting integral technology and a hot-forming and edge-cutting integral die for high strength steel parts. The integral technology comprises the following steps: arranging an edge-cutting tool on a hot-forming die of the high strength steel parts; placing high strength steel plate materials which is heated to be completely austenized into the hot-forming die for punching before hot stamping forming of the high strength steel plate materials; and utilizing the edge-cutting tool on the hot-forming die to perform edge-cutting operation on workpieces subjected to stamping after the hot-forming die is closed. The integral die comprises an upper die, a lower die, an upper edge-cutting tool and a lower edge-cutting tool, wherein an upper die oil cylinder is arranged at the upper end of the upper die; a piston rod of the upper die oil cylinder is connected with the upper edge-cutting tool; a lower die oil cylinder is arranged at the bottom of the lower die; and a piston rod of the lower die oil cylinder is connected with the lower end of a mandrel of which the upper end is connected with the lower edge-cutting tool. The hot-forming and edge-cutting integral technology and the hot-forming and edge-cutting integral die for the high strength steel parts reduce the equipment investment and the production cost of hot forming, and shorten the production period; and the parts have high edge-cutting quality and high dimension precision and shape precision.

Owner:SHANDONG UNIV

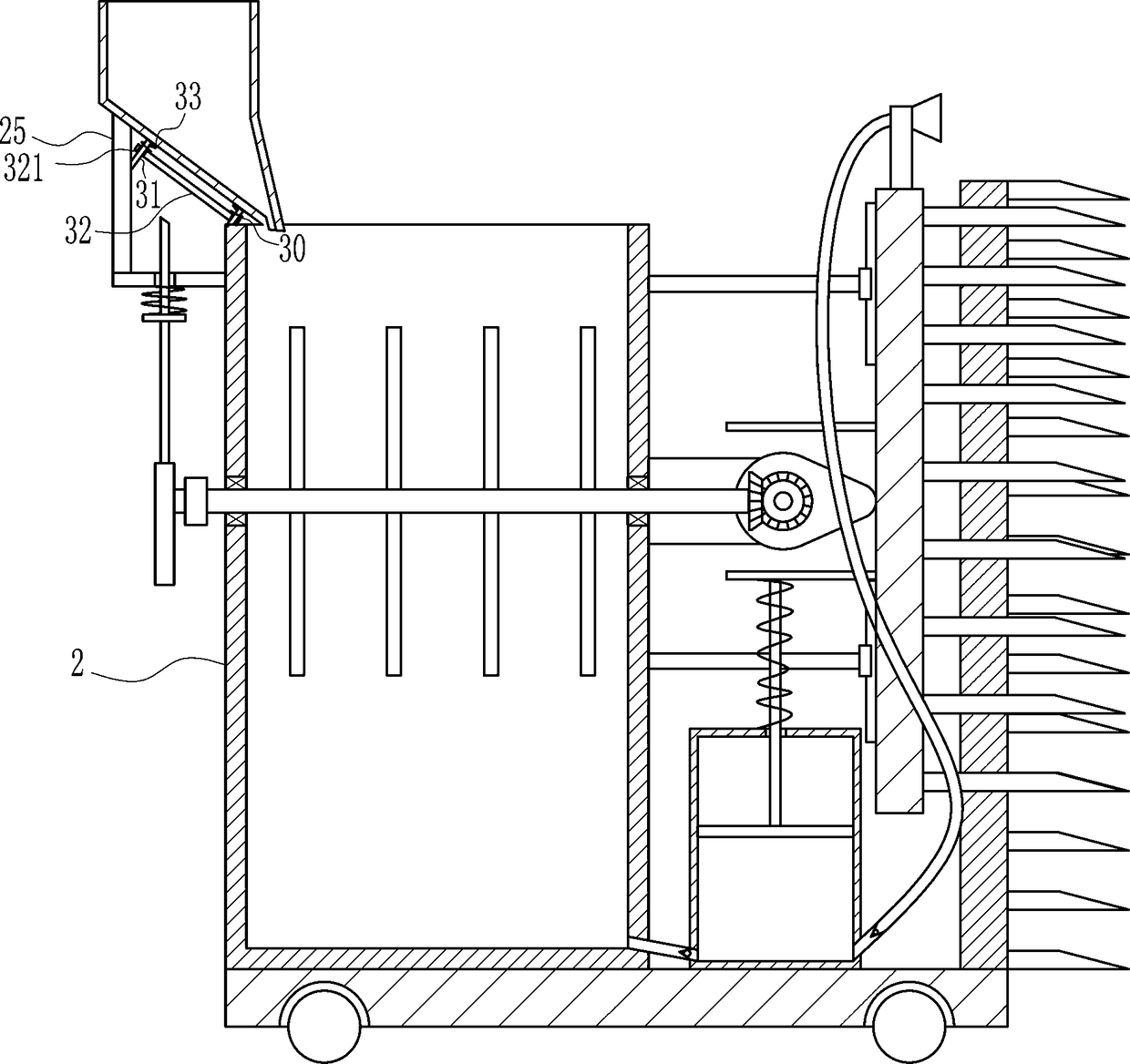

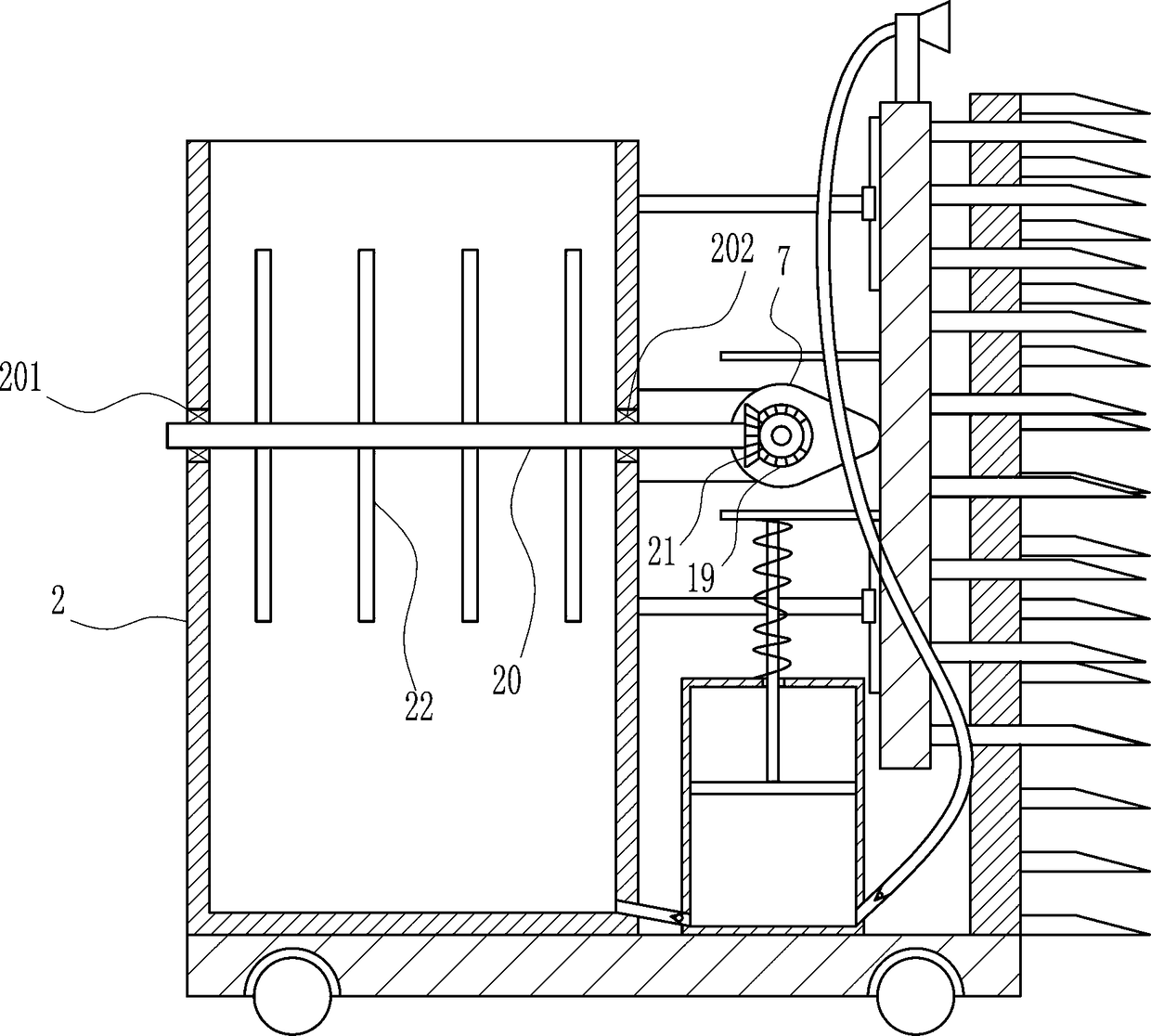

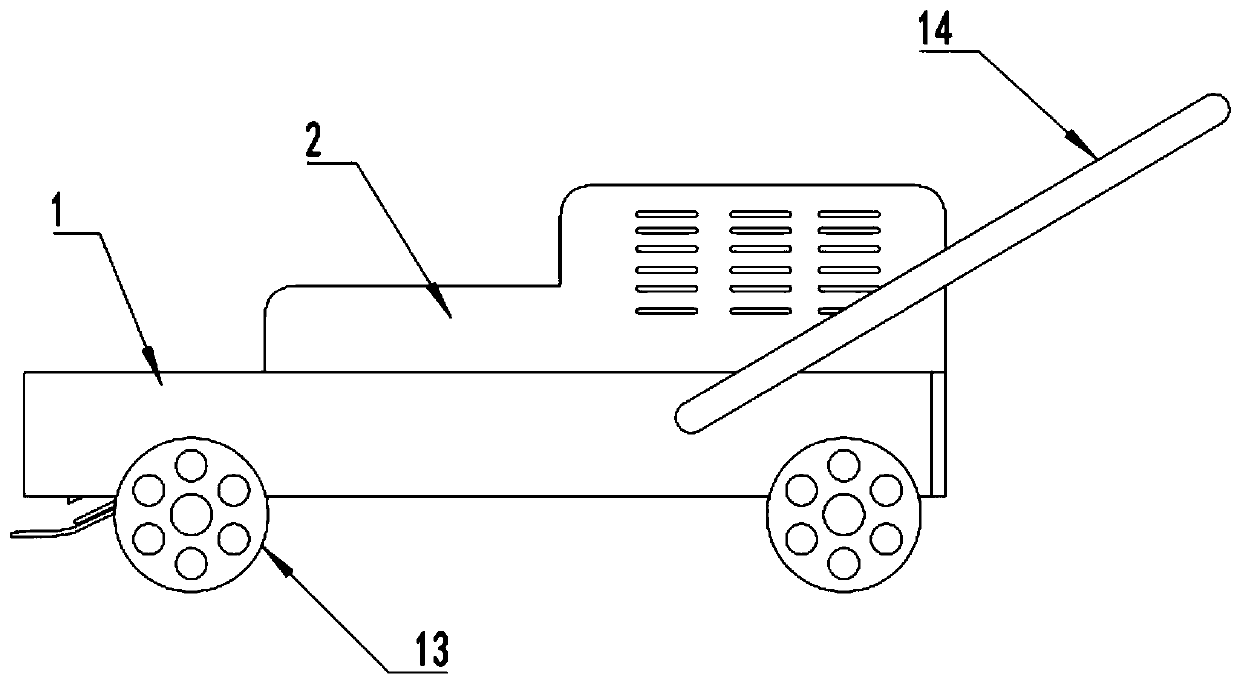

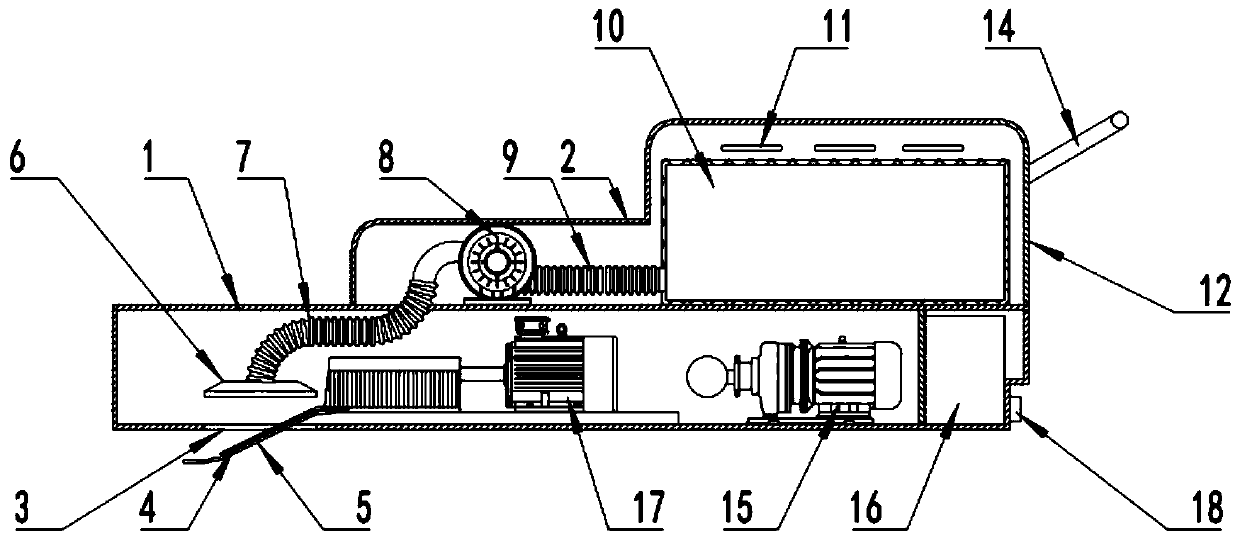

Trolley for pruning shrubs on two sides of municipal road

InactiveCN108235874ASolve the unsafe manual pruningLabor intensiveHedge trimming apparatusWatering devicesVehicle frameLow speed

The invention relates to a trolley for pruning shrubs on two sides of a road, and in particular relates to a trolley for pruning shrubs on two sides of a municipal road. The technical problem to be solved by the invention is to provide the trolley for pruning the shrubs on two sides of the municipal road, wherein the small trolley can automatically prune the shrubs. In order to solve the above technical problem, the invention provides the trolley for pruning the shrubs on two sides of the municipal road. The trolley includes a vehicle frame, a water box, a water absorbing pipe, a first one-wayvalve, a squeeze box, a water outlet pipe, a second one-way valve, a spray nozzle, a fixing plate, a motor, a first cam, a first supporting rod and the like; and the water box is fixedly connected tothe left part of the upper part of the vehicle frame, the water absorbing pipe is arranged at the lower part of the right side of the water box, the squeeze box is fixedly connected to the upper partof the vehicle frame, and the squeeze box is located on the right side of the water box. The trolley provided by the invention has the functions of automatically pruning the shrubs, automatically irrigating the shrubs or automatically spraying an insect repellent and a nutrient solution, and solves the problems that manual pruning has unsafety, a low speed and large labor intensity.

Owner:黄甘霖

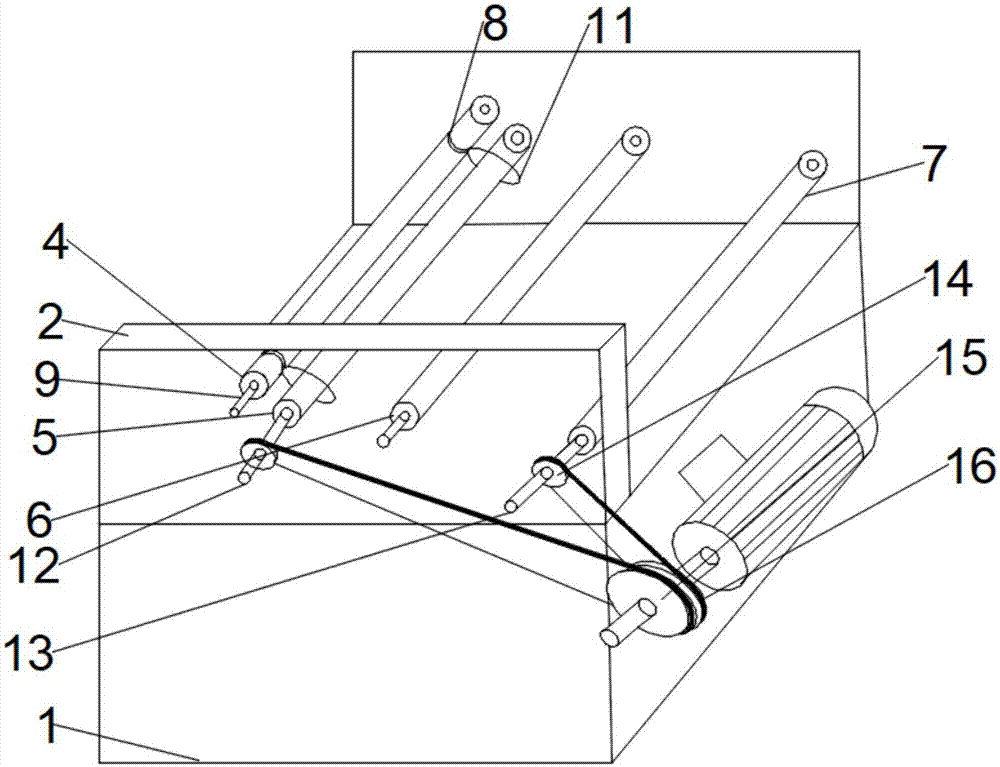

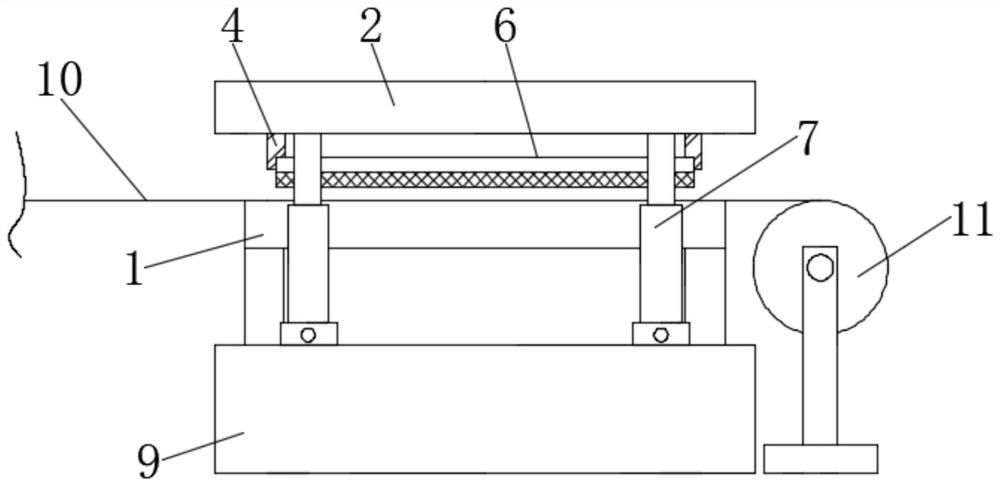

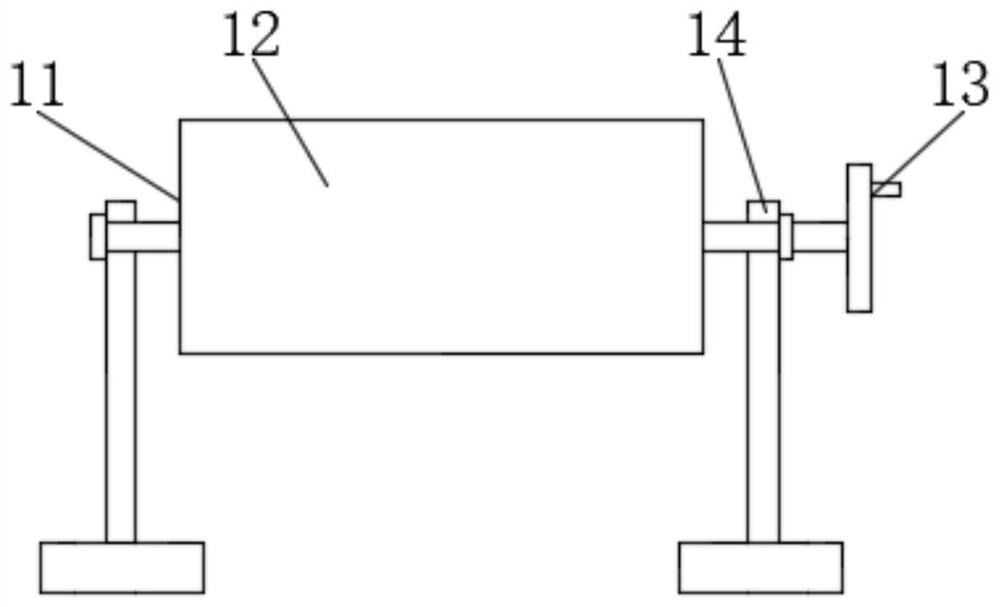

Woven cloth edge cutting device of textile machine

InactiveCN107503103APrevent deviationAvoid flatnessSevering textilesEngineeringMechanical engineering

The invention discloses a woven cloth edge cutting device of a textile machine. The device comprises a support, two mounting plates in parallel are mounted on the top of the support, and a pinch roller, a cloth conveying roller, a supporting roller and a cloth rolling roller are mounted between the two mounting plates from left to right in sequence; grooves are formed in both ends of the side surface of the pinch roller, and annular blades are fixedly mounted on the side surface of both ends of the cloth conveying roller; a first roller shaft and a second roller shaft are fixedly mounted at two ends of the cloth conveying roller and the cloth rolling roller respectively, a first hub is fixedly mounted at one end of the first roller shaft, a motor hub is connected to the first hub through a belt, and a second hub is connected to the motor hub through a belt. Through the design of the two annular blades on the cloth conveying roller, cutting irregularity or cutting incompleteness caused by cloth deflection is prevented, and the efficiency and speed of edge cutting are greatly improved; the height of the pinch roller is adjustable through a height adjusting device, the applicability is wider, the structure is simple, and the production cost of the cloth is reduced.

Owner:安徽嘉利网业织造有限公司

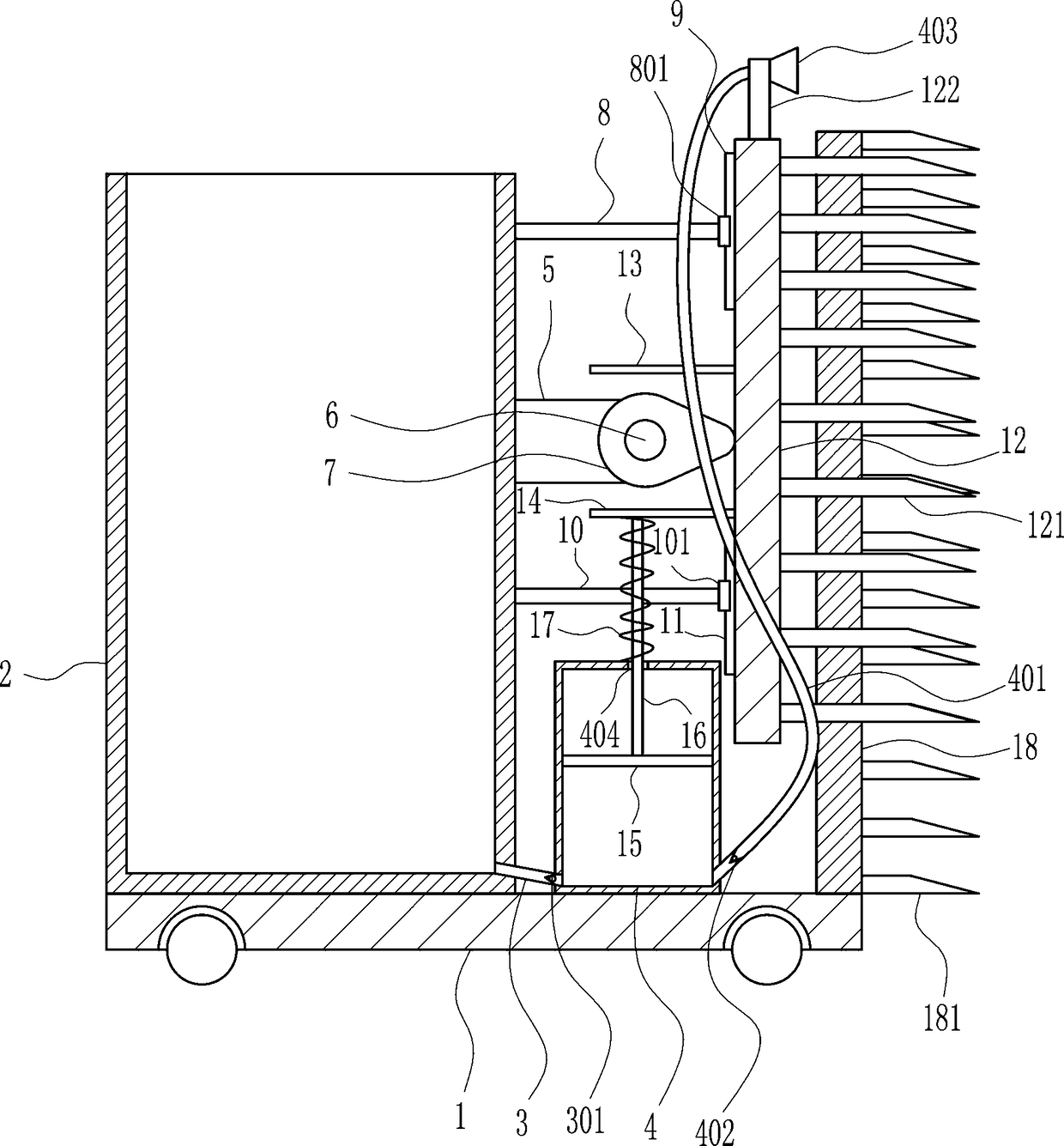

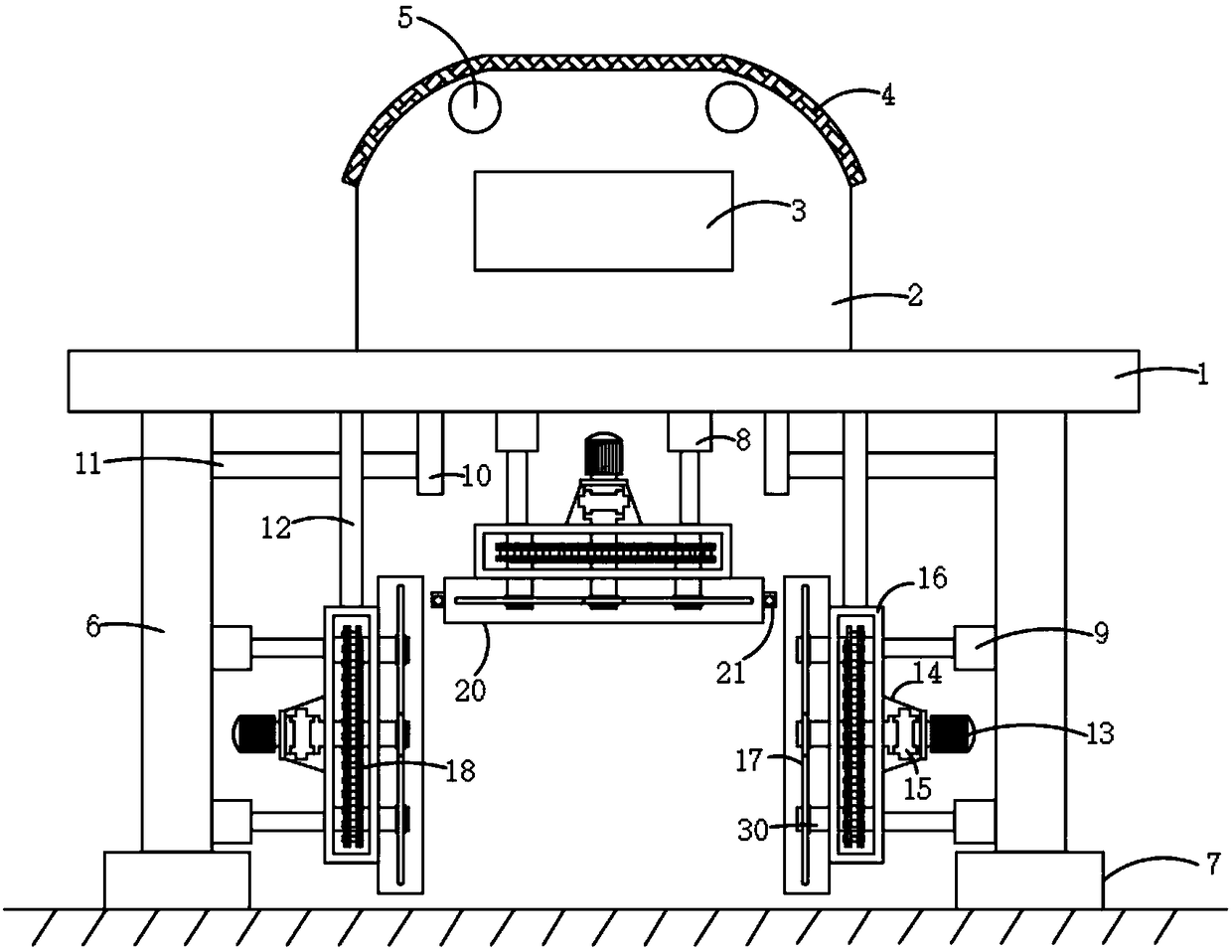

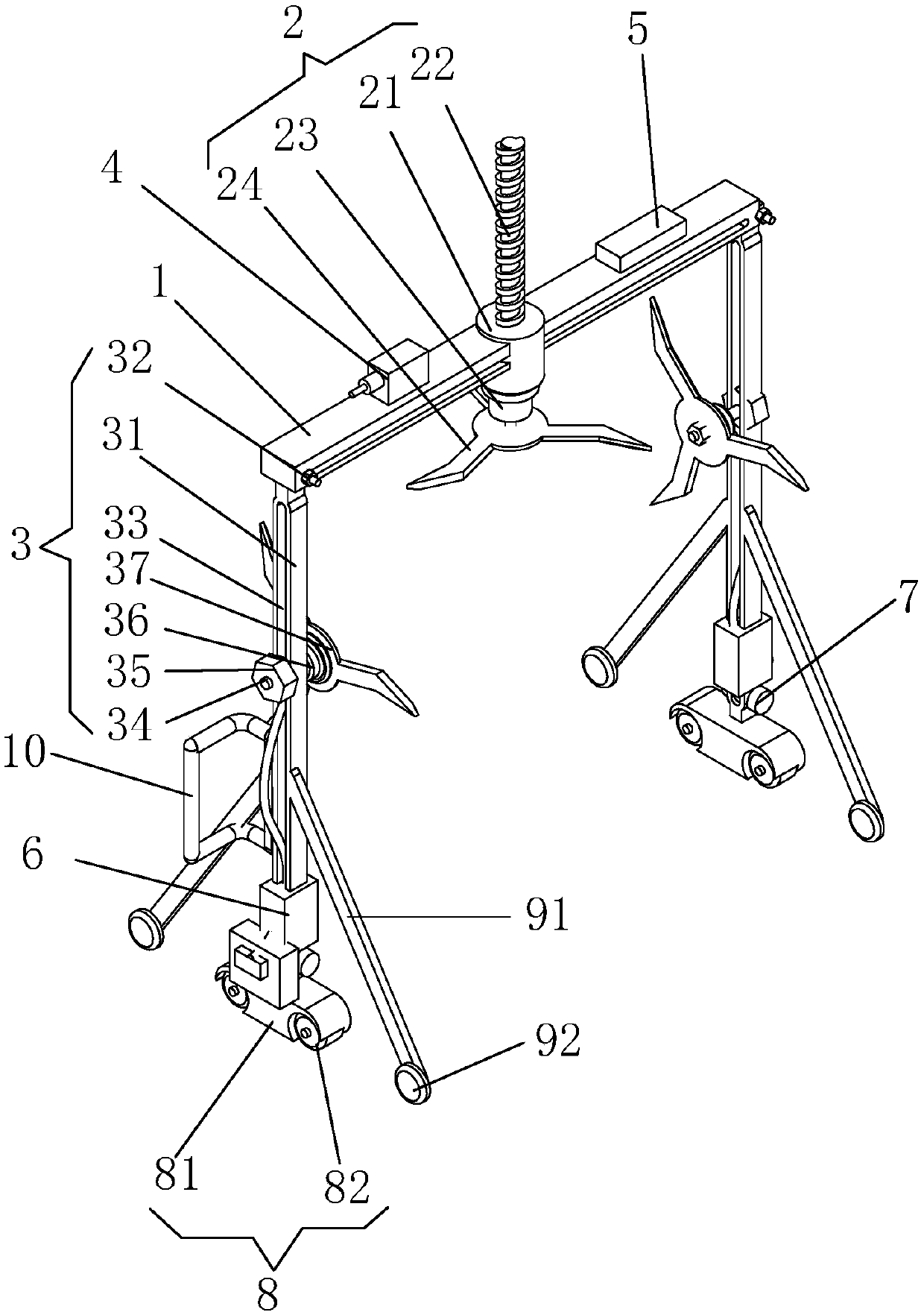

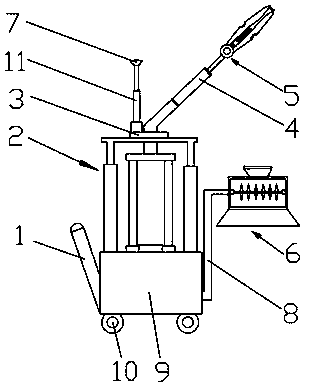

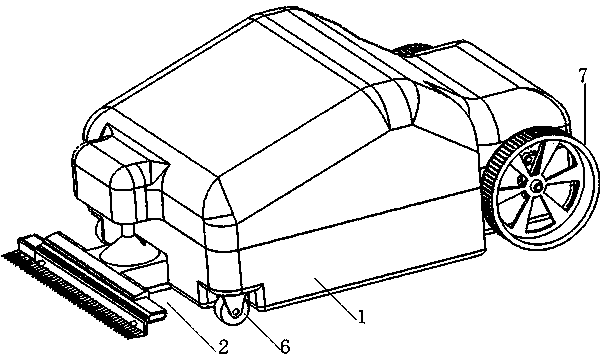

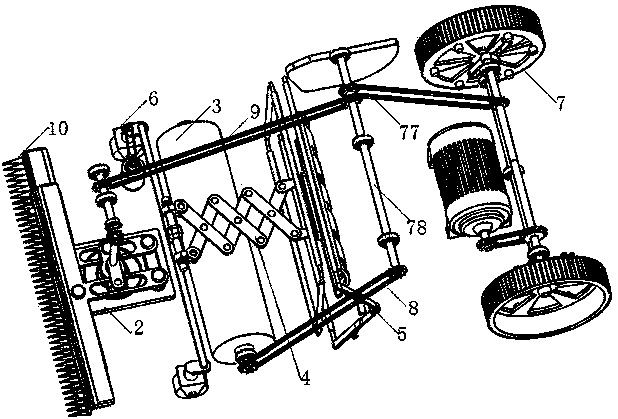

Multifunctional integrated smart highway pruning machine

InactiveCN104429654AAchieving Adaptive WalkingRealize the function of overcoming obstaclesHedge trimming apparatusCuttersDrive wheelEngineering

The invention discloses a multifunctional integrated smart highway pruning machine and relates to the field of vegetation pruning machinery. The multifunctional integrated smart highway pruning machine comprises four main modules, namely a pruning module, a spraying module, an obstacle-surmounting module and a travelling module and realizes functions of mechanical cutting, pruning, spraying and travelling. The pruning module is composed of a main cutter mechanism and a side cutter mechanism which can cooperatively complete pruning of different shapes; the spraying module is provided with a liquid level sensor which is capable of monitoring pesticide allowance in real time; the obstacle-surmounting module steps over obstacles of a central partition by applying incomplete gear rings and an electromagnetic valve; the travelling module comprises a driving wheel, universal wheels and built-in guide wheels, and the machinery travelling along the central partition can be guaranteed. Compared with a traditional machine, the multifunctional integrated smart highway pruning machine has the advantages that vegetation of different shapes can be pruned, pruning quality is improved, labor intensity of pruning personnel and pruning cost are reduced, and potential safety hazard existing in manual pruning is reduced.

Owner:胡镔

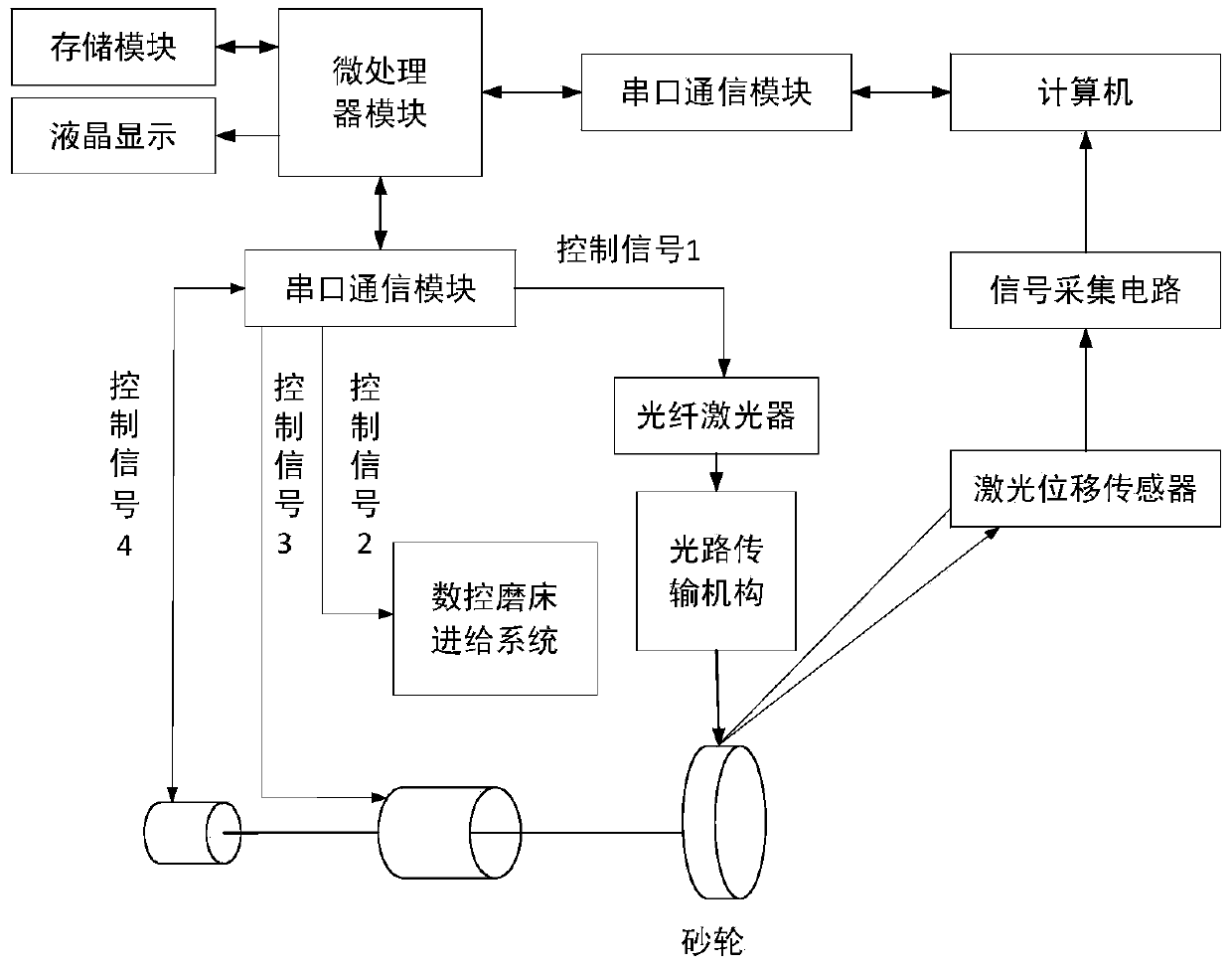

Method for assisting on-line trimming diamond grinding wheel based on discharging in air

InactiveCN1557608ADressing force reducedReduce wearAbrasive surface conditioning devicesEngineeringCooling fluid

The present invention is air discharge method for auxiliary in-situ trimming of grinding diamond wheel and belongs to the field of precise machining technology. The present invention includes three steps of establishing spark discharge temperature field in air, trimming with diamond pen under air discharge and controlling the sustained air discharge. In the first step, the discharge between electrode and grinding wheel in the air establishes temperature field to soften adhering metal material in grinding diamond wheel; in the second step, the grinding wheel rotates and the trimming diamond pen reciprocates in the surface of the grinding wheel to trim the softened binding agent material mechanically; and in the third step, the measuring link, control link and executing link complete the control for sustained discharge. The present invention realizes the in-situ trimming of grinding diamond wheel at high efficiency, high precision and low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

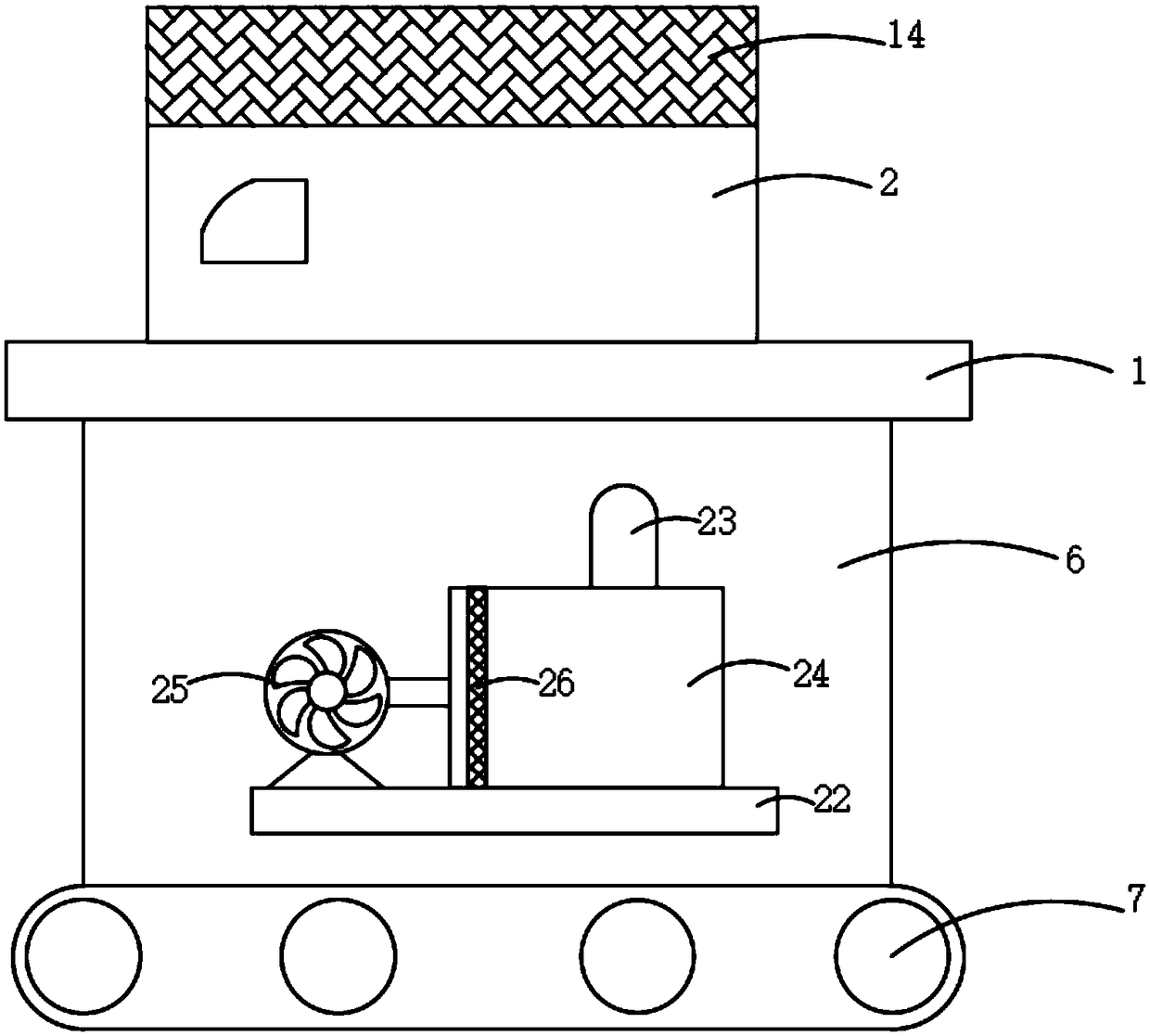

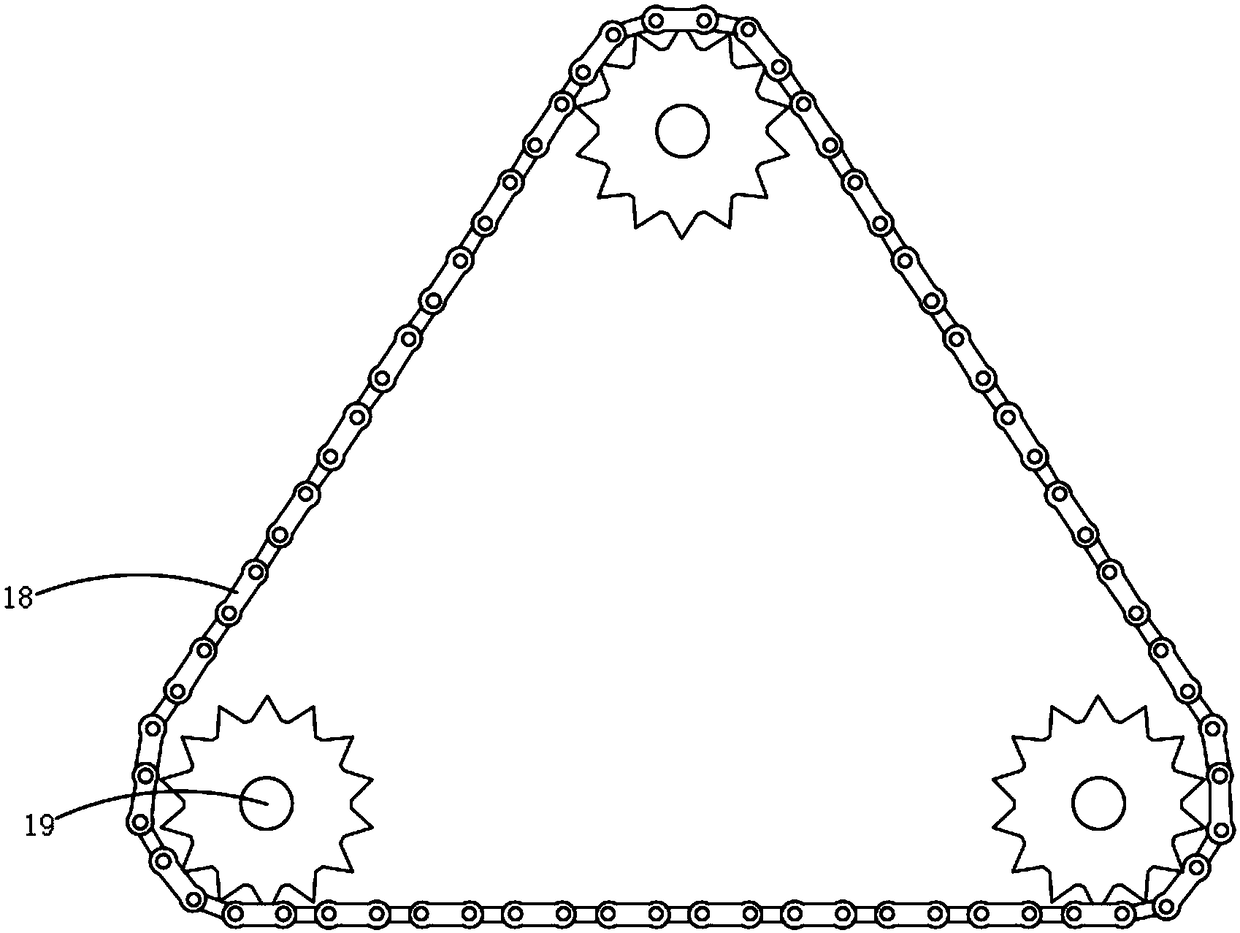

Shrub trimmer for urban road

ActiveCN108651044AAvoid Cleaning SituationsFast trimmingHedge trimming apparatusCuttersHydraulic cylinderControl room

The invention discloses a shrub trimmer for an urban road. The shrub trimmer comprises an operation platform, the upper end of the operation platform is fixedly connected with a driving control room,a solar cell panel is fitly mounted at the upper end of the driving control room, and a driving mechanism, a control mechanism and a power mechanism are arranged in the driving control room. Accordingto the shrub trimmer, the distance between a trimming cutter and a shrub is adjusted through a vertical hydraulic cylinder and a horizontal hydraulic cylinder, a rotary motor rotates a rotary shaft,a chain wheel transmission chain drives other rotary shafts to rotate, the trimming cutter trims the shrub, the trimming speed is high, trimming can be carried out by one person, and a large amount oflabor cost is reduced. The trimmed position is in a negative pressure environment through a negative-pressure fan, the trimmed shrub enters a shrub collecting box to be collected under the negative pressure condition, the situation that the road needs to be cleaned after trimming is carried out is avoided, time and labor are saved, and the trimming efficiency and the trimming quality are improved.

Owner:ZHEJIANG ZOMAX GARDEN MACHINERY

Plant trimming equipment

ActiveCN107691006AImprove trimming qualityFast trimmingCuttersCutting implementsControl engineeringFine-tuning

Disclosed plant trimming equipment is characterized in that a transverse bar is arranged, a transverse trimming device is connected to the transverse bar, vertical trimming devices are vertically arranged at two ends of the transverse bar, a control chip and a horizontal detector are installed on the transverse trimming device, a movable device is arranged at the lower end of each vertical trimming device, and a rotating part is arranged between each movable device and one corresponding vertical trimming device, and a height fine tuning telescopic motor is arranged between ends of each rotating part and one corresponding vertical trimming device. When trimming plants, the plant trimming equipment can automatically trim plants fitly, and can also trim plants fitly in a situation of uneven ground, so that the trimming quality is greatly increased. Also, the plant trimming equipment is fast in trimming speed, saves time, brings convenience to people, and is simple in structure and convenient to use.

Owner:嘉兴厚亿纺织股份有限公司

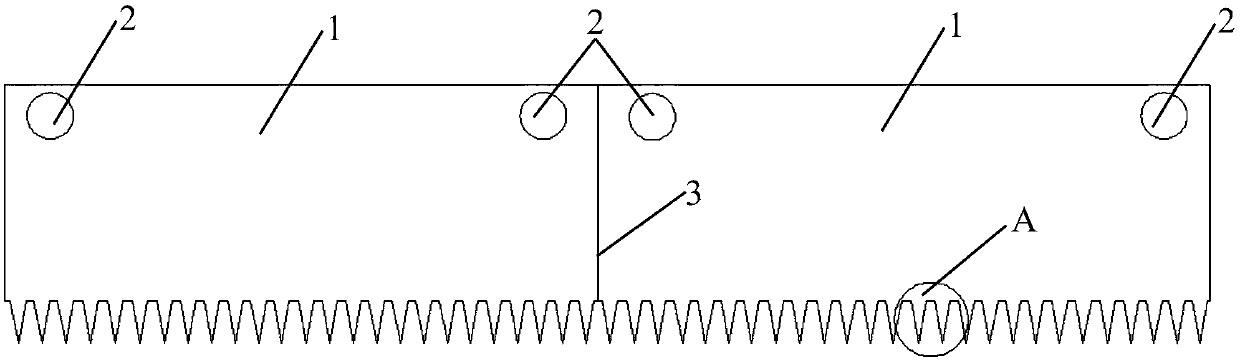

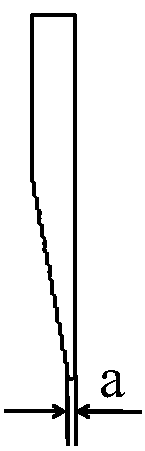

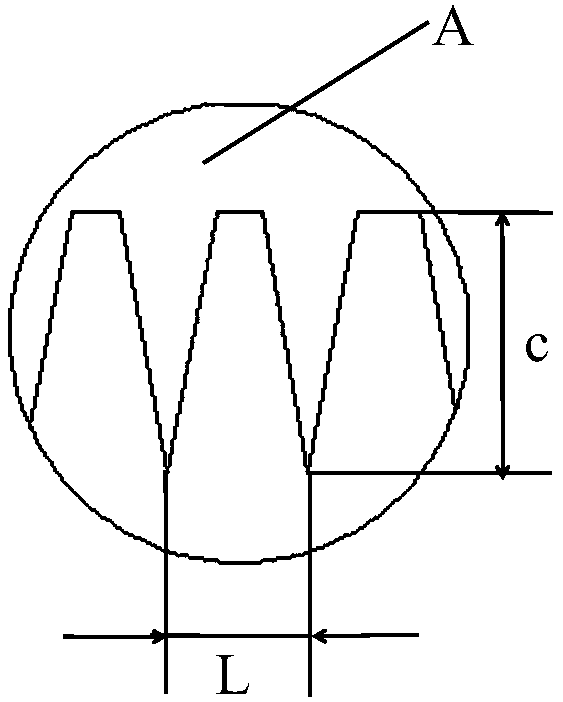

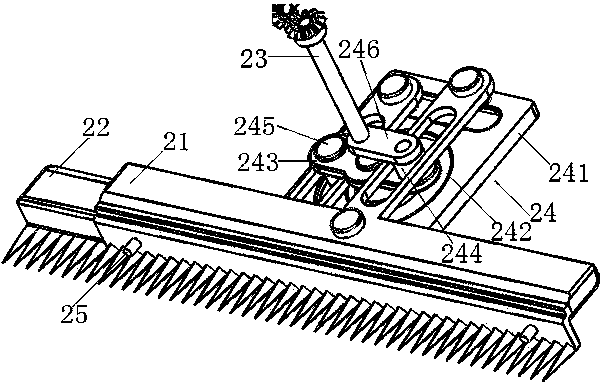

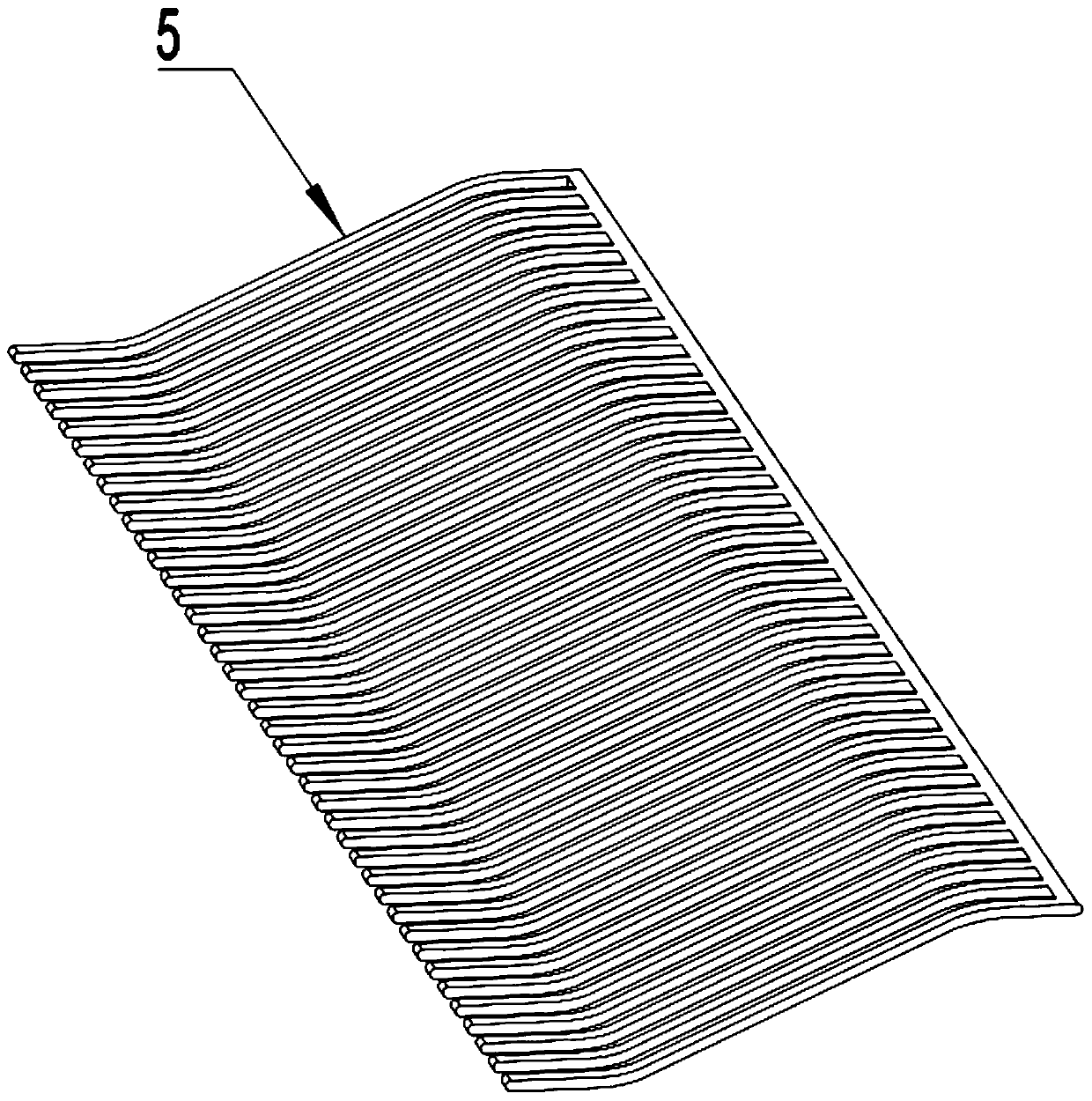

Serrated knife for high-speed carpet textile machine and machining method thereof

The invention discloses a serrated knife for a high-speed carpet textile machine. The serrated knife comprises a knife rest and a blade component, wherein the blade component comprises a plurality ofblade bodies; a plurality of sawteeth are arranged on one side of each blade body; the plurality of sawteeth are arranged at equal intervals; a plurality of mounting holes are formed in one side, farfrom the sawteeth, of each blade body; the plurality of blade bodies are detachably connected with the knife rest through the plurality of mounting holes; the end parts of the plurality of blade bodies are correspondingly spliced with one another; splicing lines are formed in spliced positions; the splicing lines are positioned at the roots of the sawteeth, so that the phenomena that the splicinglines have cracks at cutting edges of the splicing lines and the shearing quality of carpet fabric is reduced are avoided; meanwhile, the invention further discloses a machining method of the serratedknife. The serrated knife machined through the method is high in quality, sharp in cutting edges and long in service life, and improves the shearing efficiency of the carpet fabric.

Owner:昆山立达纺织实业有限公司

Sweet-scented osmanthus pruning equipment

The invention discloses sweet-scented osmanthus pruning equipment. The equipment comprises a vehicle bucket, a lifting air cylinder is connected to the upper end of the vehicle bucket, and a rotatingdisc is installed at the upper end of the lifting air cylinder and provided with a telescopic rod with a pruning device; a crushing device is connected to the right side of the vehicle bucket througha connecting rod and comprises a crushing box, a horizontal rotating shaft driven by a motor to rotate is installed in the crushing box, crushing blades are evenly distributed on the rotating shaft, and a collecting box and a storage box which are detachable are connected to the upper and lower ends of the crushing box respectively. The equipment can safely and quickly prune branches on the premise of not damaging the sweet-scented osmanthus branches and improve the pruning quality while ensuring the attractiveness of the tree shape.

Owner:浦江县顺光科技有限公司

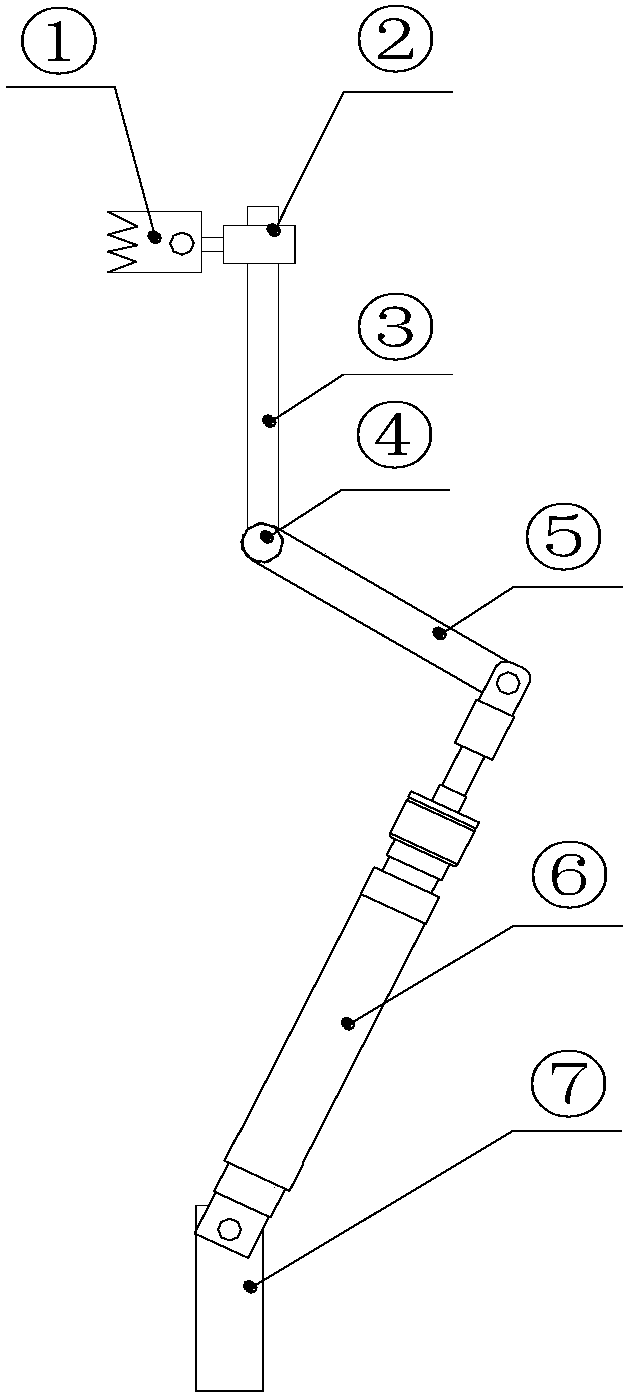

Arm type hedgerow trimmer

The invention discloses an arm type hedgerow trimmer. The arm type hedgerow trimmer comprises a fixing plate, a supporting arm, a trimming saw head, a connecting seat and an adjusting hydraulic rod, wherein the supporting arm comprises a vertical arm, an angle adjusting arm, a telescopic outer arm and a movable arm; the lower end of the vertical arm is arranged on the fixing plate; the upper end of the vertical arm is hinged to the lower end of the angle adjusting arm; the upper end of the angle adjusting arm is hinged to one end of the telescopic outer arm; the other end of the telescopic outer arm is hinged to one end of the movable arm; the connecting seat is arranged at the other end of the movable arm; the trimming saw head is arranged on the connecting seat; the adjusting hydraulic rod comprises a lower hydraulic rod, an upper hydraulic rod and a top hydraulic rod; the lower hydraulic rod is arranged between the vertical arm and the angle adjusting arm; the upper hydraulic rod isarranged between the angle adjusting arm and the telescopic outer arm; and the top hydraulic rod is arranged between the telescopic outer arm and the movable arm. Trimming operation is facilitated, and the trimming quality and efficiency are greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Edge cutting mechanism for airbrushed fabric

ActiveCN104960966AImprove trimming efficiencyImprove trimming qualityUnfolding thin materialsArticle deliveryMotor driveEngineering

The invention discloses an edge cutting mechanism for airbrushed fabric, and belongs to the field of advertisement processing mechanical equipment. The edge cutting mechanism comprises a main support, an unfolding roller, a transmission motor, a fabric sending roller, an edge cutting mechanism and a material guiding mechanism; the unfolding roller rotates horizontally to be connected to the upper side of the main support, the transmission motor drives the unfolding roller, the fabric sending roller rotates horizontally to be connected to the lower side of the main support, and the edge cutting mechanism is arranged on the main support horizontally; the edge cutting mechanism comprises an edge cutting roller and a fabric bearing roller which rotate horizontally to be connected to the main support respectively, two sides of the edge cutting roller are provided with edge cutting knives respectively and symmetrically, and two sides of the fabric bearing roller are provided with limiting knife grooves matched with the edge cutting knives respectively and symmetrically; the material guiding mechanism comprises translation rods and material guiding pipes, two sides of the translation rods are horizontally provided with translation sleeves matched with the translation rods respectively, and the material guiding pipes are arranged on one sides of the translation sleeves. According to the edge cutting mechanism, the structure is simple, transmission and edge cutting can be rapidly, efficiently and conveniently carried out on the airbrushed fabric, and requirements for producing and machining are met.

Owner:徐州辰耀针织有限公司

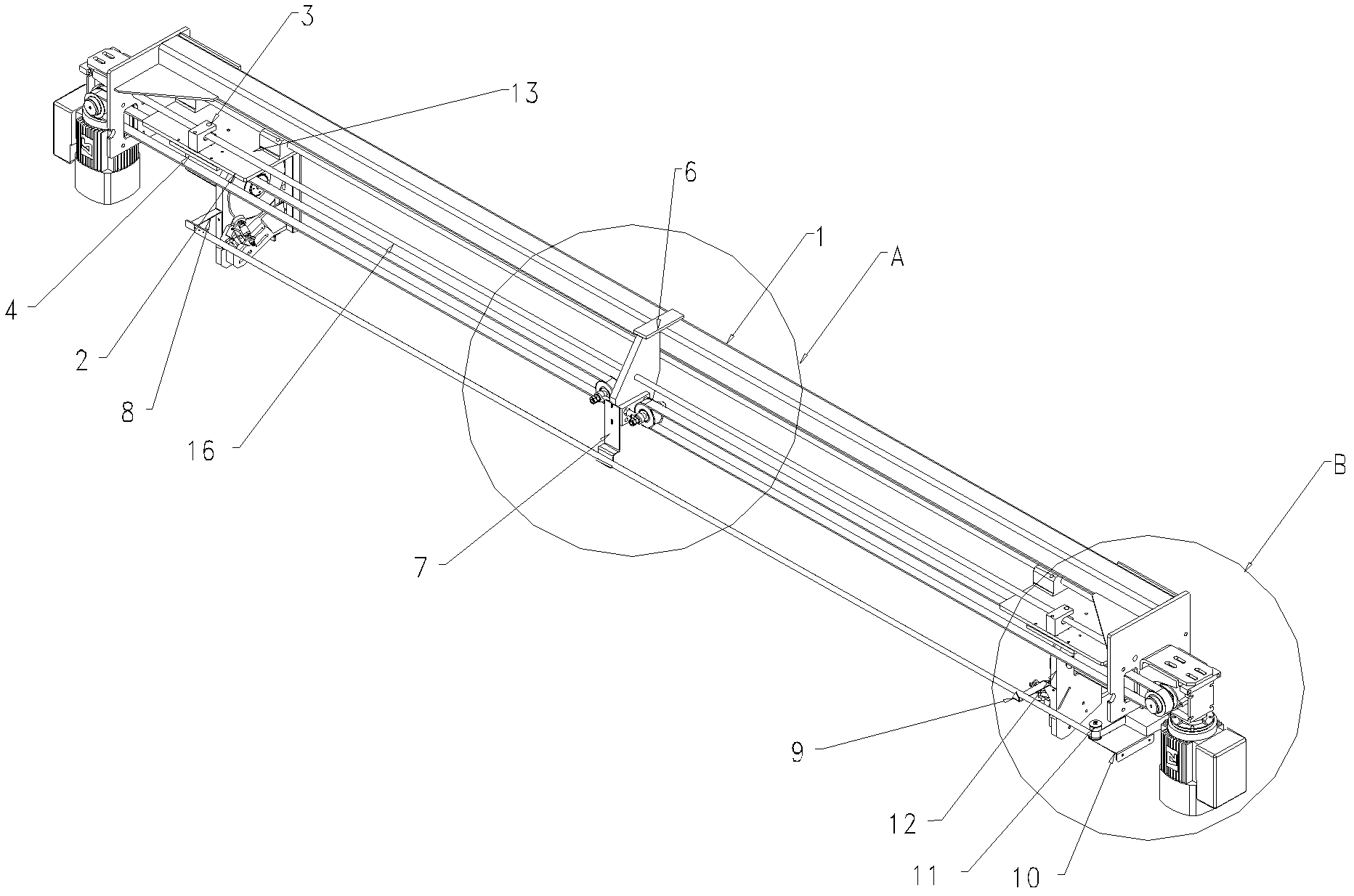

Automatic moving device for vertical cutting of cutting machine

ActiveCN102995385AImprove cutting accuracyEasy to convert cutting sizeSevering textilesProgrammable logic controllerOptical axis

The invention discloses an automatic moving device for vertical cutting of a cutting machine. The automatic moving device comprises a vertical cutting rack, a left vertical cutting component, a right vertical cutting component and a driving device. A middle installation plate is fixedly arranged in the middle of the vertical cutting rack. The left vertical cutting component and the right vertical cutting component are respectively are arranged on the vertical cutting rack through polished shaft sliding block structures, can slide leftwards and rightwards and are respectively arranged on the two sides of the middle installation plate. The driving device comprises motors which are fixedly installed at the two ends of the vertical cutting rack, motor belt pulleys which are fixedly arranged on the output shafts of the motors, middle belt pulleys which are rotatably arranged on the two sides of the middle installation plate, and synchronous belts which are sheathed on the motor belt pulleys and the middle belt pulleys on the corresponding side, wherein the synchronous belts are fixedly connected with vertical cutting sliding plates through belt pressing blocks. The automatic moving device for vertical cutting of the cutting machine has the advantages that the cutting precision of the vertical cutting machine is high, the cutting specification is convenient to change, the production efficiency is high and the speed is fast; and since the automatic moving device for vertical cutting of the cutting machine is controlled by using a PLC (programmable logic controller), the entire machine is more intelligent and automatic, and the automation degree of equipment is improved.

Owner:上工富怡智能制造(天津)有限公司

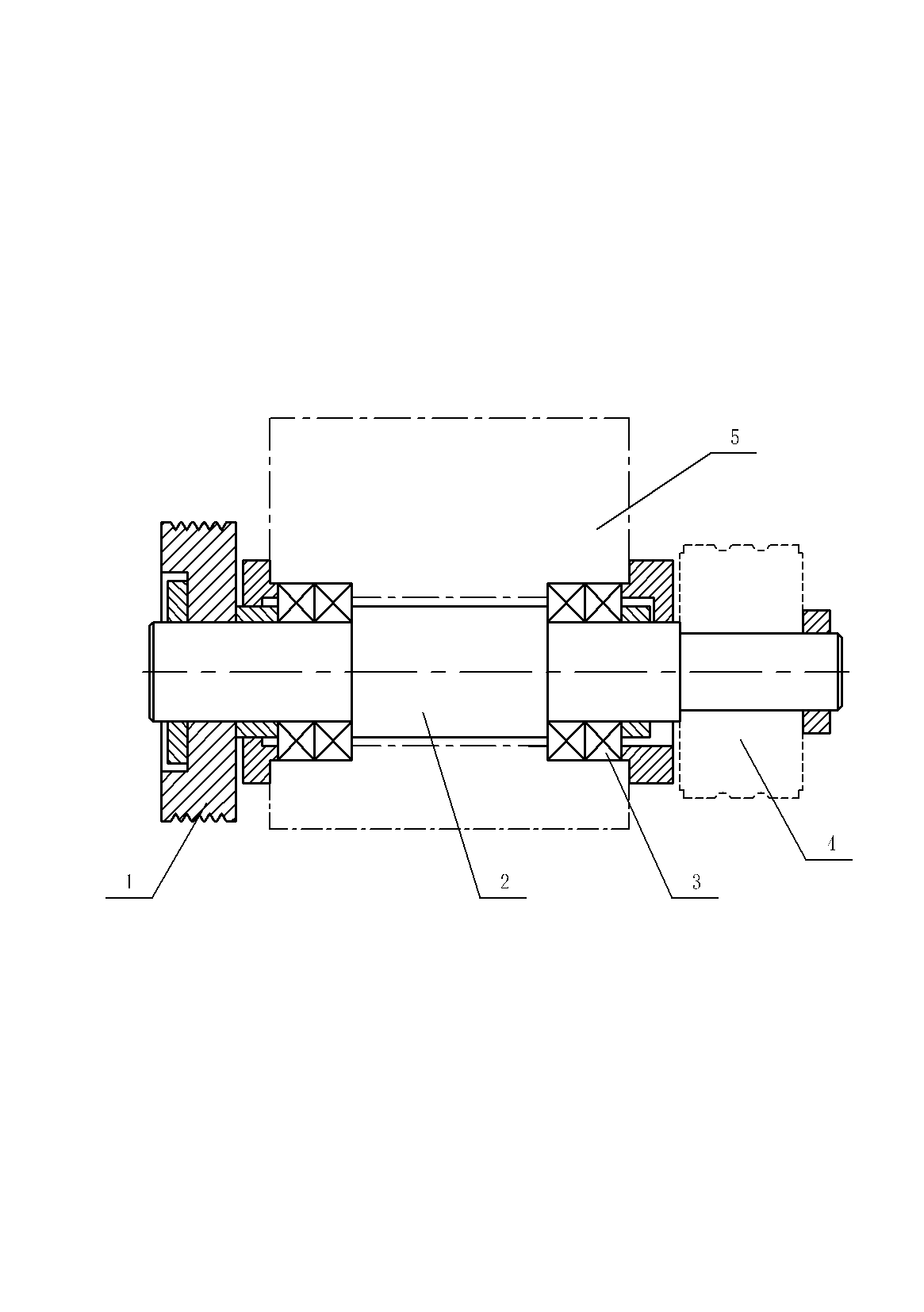

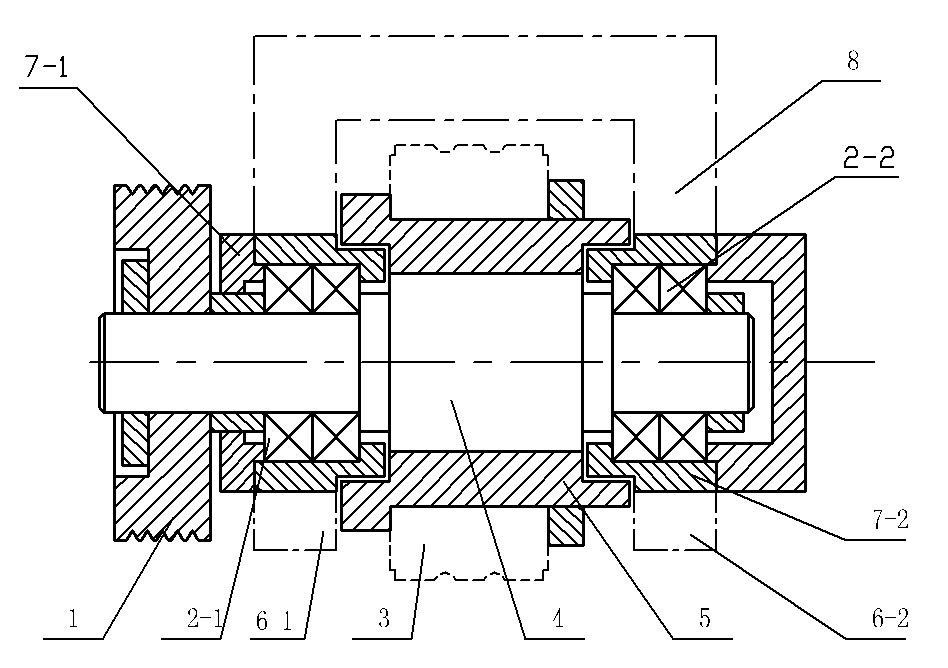

Improved diamond idler wheel trimmer

InactiveCN102001043AEven by forceExtended service lifeAbrasive surface conditioning devicesInterference fitEngineering

The invention provides an improved diamond idler wheel trimmer which comprises a shell fixing device and a trimming rotary device, wherein the trimming rotary device comprises a main shaft, the main shaft is rotatably arranged on the shell fixing device through two gears of bearings and a bearing block, and one end of the main shaft is connected with a belt wheel. The improved diamond idler wheel trimmer is characterized in that the shell fixing device comprises a support and a shell, wherein the main shaft is embedded in an idler wheel bushing in an interference fit manner, the outer diameter of the idler wheel bushing is more than that of the bearing block, the idler wheel bushing is positioned between the two gears of bearings, and a diamond idler wheel is arranged on the idler wheel bushing. Because two ends of the diamond idler wheel are supported by adopting the two gears of bearings, the bearings at two sides have uniform stress during the rotation, the service lives of the bearings are effectively prolonged, the rigidity during trimming a sand wheel is increased, and the sand wheel trimming quality is improved, thus the grinding property of a machine tool is ensured.

Owner:无锡市长鹰机床制造有限公司

Stepping full-automatic weeding machine

The invention discloses a stepping full-automatic weeding machine. The weeding machine comprises a machine shell; a weed cutting device is arranged at the front part of the machine shell; a weed collecting device, a weed compressing device and a weed packing device are arranged inside the machine shell; and turning wheel devices and motor wheel devices are arranged at the lower part of the machineshell. After the weed cutting device trims weeds, the weeds are collected through the weed collecting device, and packaging is carried out through the weed compressing device and the weed packing device; the weeding machine is driven by the motor wheel devices to move forward; the weed collecting device is driven to work through a third-stage conveying belt; the weed cutting device is driven to work through a second-stage conveying belt; and the direction is adjusted through the turning wheel devices. The weeding machine provided by the invention effectively solves the problem that certain operation experience is needed and potential safety hazards exist in a use process of a conventional weeding device, and effectively solves the problem that weeds need to be cleaned, packed and conveyedafter trimming by using a conventional weeding device and thus the workload is increased.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

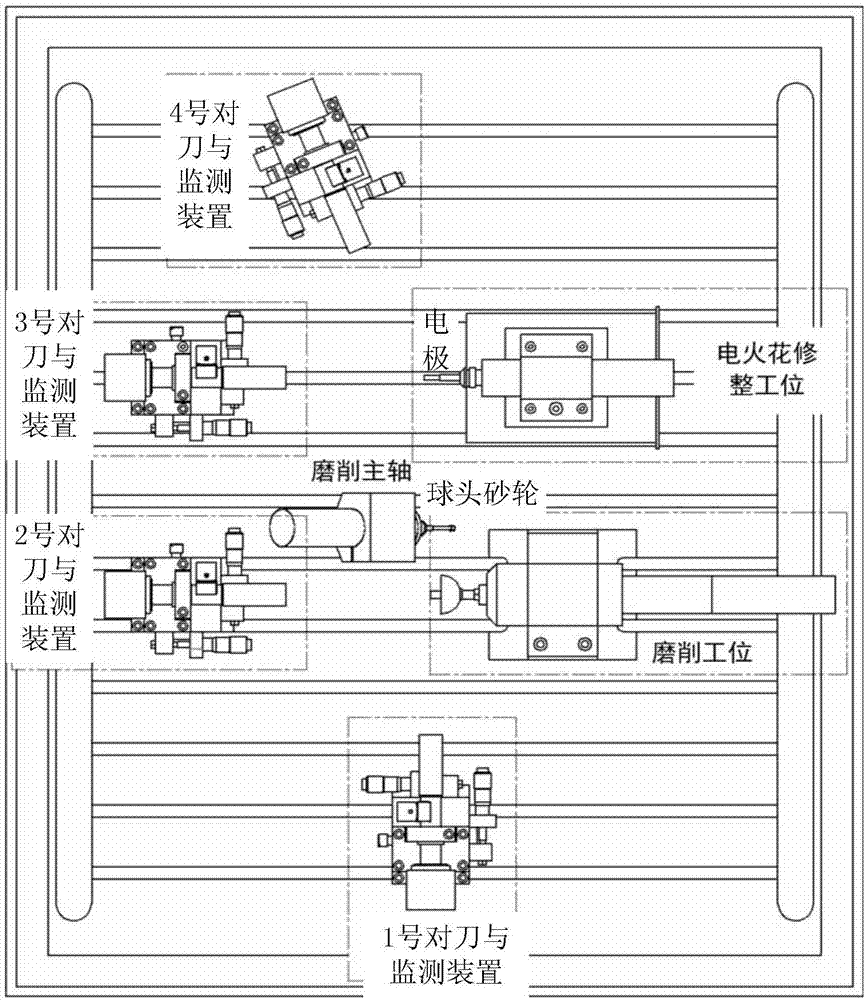

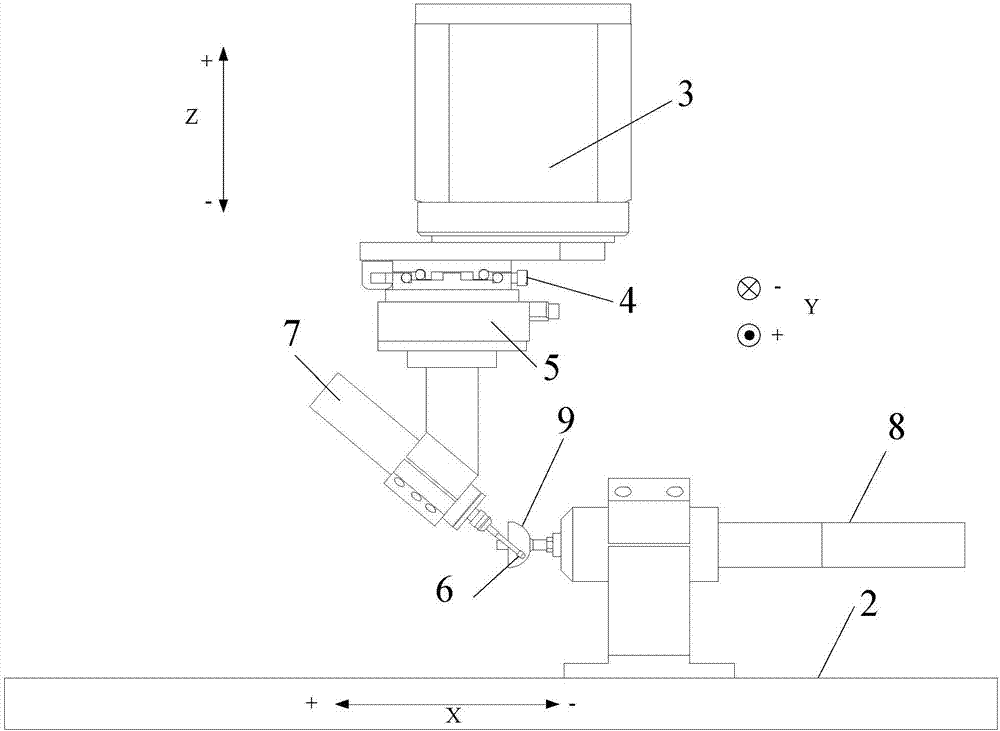

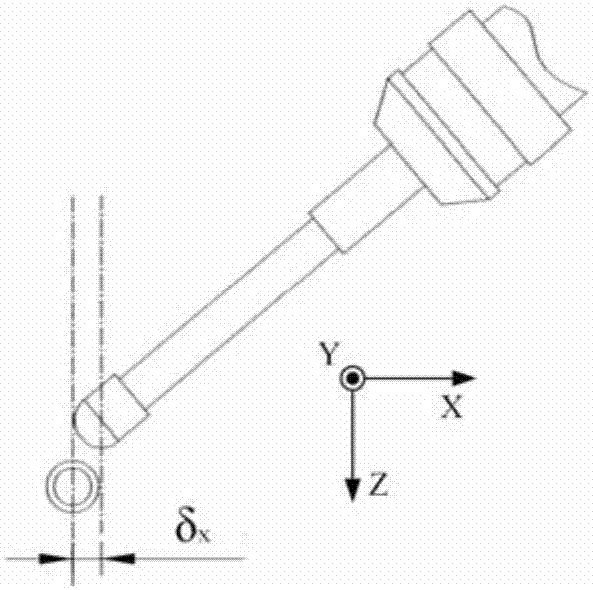

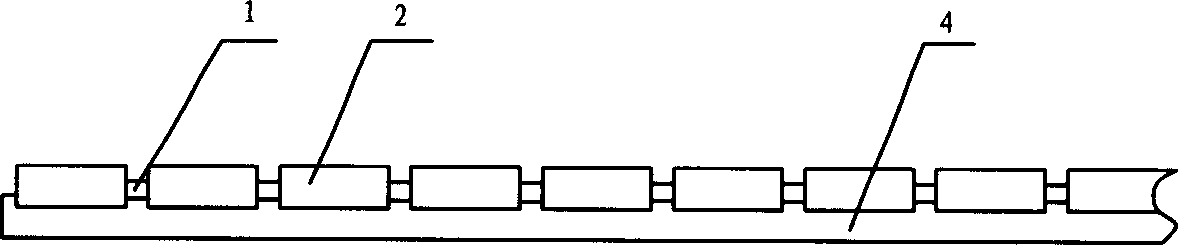

On-position dressing method for ball head grinding wheel during ultra-precision grinding of special-shaped thin-wall structural member

ActiveCN107263323AGuarantee the quality of in-situ trimmingConvenient and fast on-site monitoringAbrasive surface conditioning devicesElectrode locationGrinding wheel

The invention provides an on-position dressing method for a ball head grinding wheel during ultra-precision grinding of a special-shaped thin-wall structural member to realize easy operation and a convenient and rapid tool-setting process without need of repeated dressing and grinding and ensure the higher dressing quality of the grinding wheel, and relates to a processing technology. First, a third tool-setting and monitoring device and a fourth tool-setting and monitoring device are utilized to calibrate ball center coordinates and dressing electrode location coordinates when the ball head grinding wheel is at a dressing station; and the location coordinates of the distance from the ball head grinding wheel to a first tool-setting and monitoring device are calibrated; during the ultra-precision grinding process, the ball head grinding wheel is monitored and the abrasion status of the grinding wheel is judged; ultra-precision grinding is suspended so as to conduct on-position dressing on the ball head grinding wheel, the fourth tool-setting and monitoring device is adopted to monitor the electric spark discharging status and the dressing quality of the ball head grinding wheel; and the ball center position of the grinding wheel is adjusted after dressing, and procedure origin during grinding machining is searched to continue the unfinished ultra-precision grinding processing.

Owner:HARBIN INST OF TECH

Integrated mosaic decoration plate and its processing and mounting method

InactiveCN1807810AFast constructionRealize factory productionCovering/liningsLaminationAgricultural engineeringBuilding construction

The invention relates to an integrated mosaic ornament plate and relative method. It comprises a waterproof or humid-resistant basic plate on which the mosaic blocks are fixed. Wherein, said basic plate is made from thermosol material, which can directly adhere the mosaic blocks at one temperature and fix them after be cooled. The invention can apply the industry batch production to reduce the on-site workload, while it can improve the construction speed with high quality.

Owner:任建国

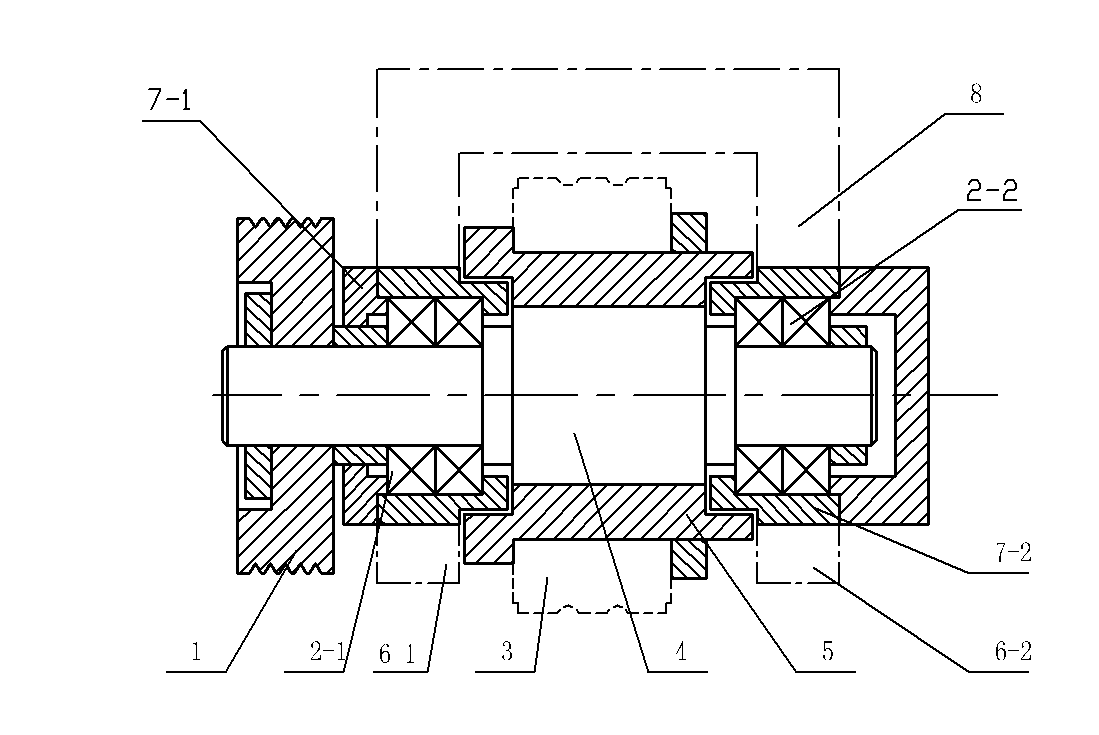

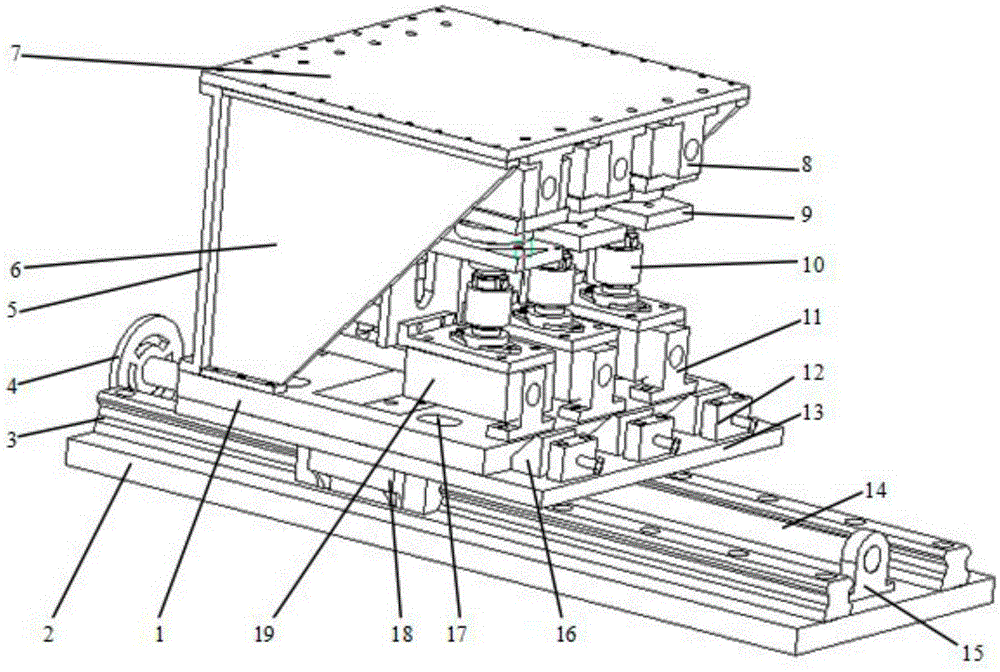

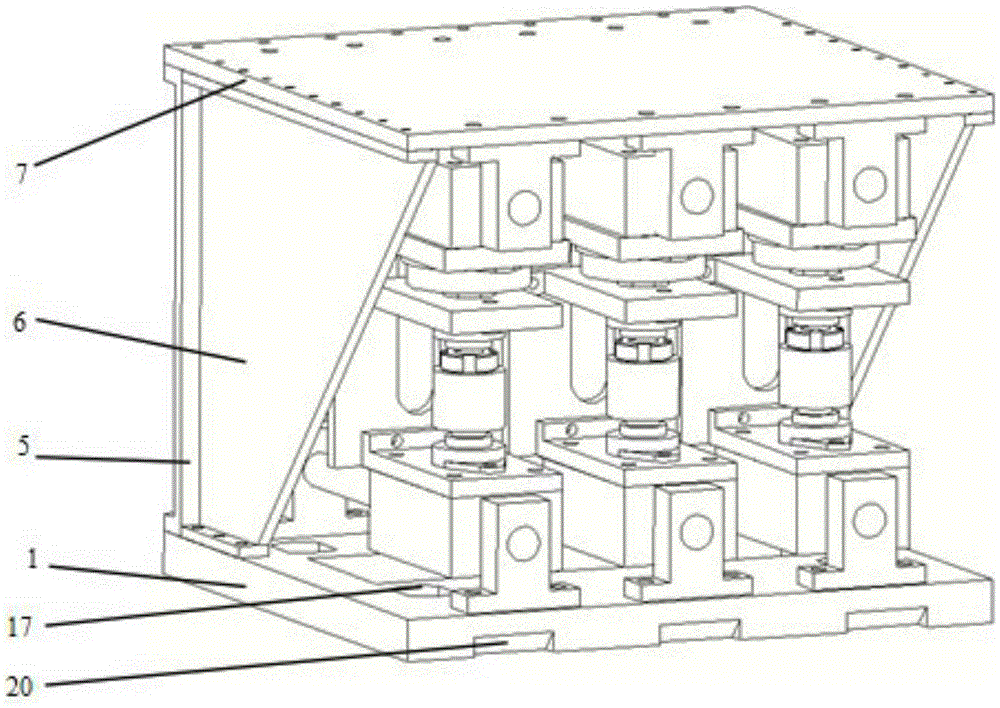

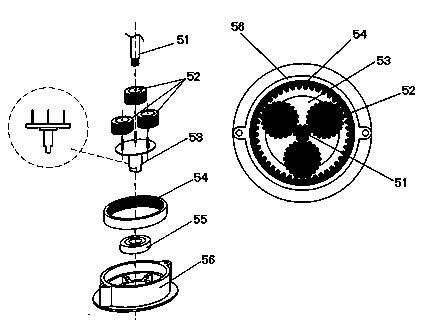

Passive-type strip steel edge grinding device suitable for finishing machine set

InactiveCN105415125AImprove trimming qualitySolve process problemsEdge grinding machinesGrinding drivesEngineeringStrip steel

The invention provides a passive-type strip steel edge grinding device suitable for a finishing machine set. The passive-type strip steel edge grinding device comprises a box body framework, grinding mechanisms, follow-up mechanisms and a feeding mechanism. Three to six sets of the grinding mechanisms and the follow-up mechanisms are arranged inside the box body framework in a linear mode. A box body bottom plate of the box body framework is fixed to a feeding bottom plate of the feeding mechanism. The feeding bottom plate is fixed to a sliding block which is arranged on a feeding guide rail fixed to the bottom of the device. According to the passive-type strip steel edge grinding device suitable for the finishing machine set, the design is delicate, the occupied space is small, the grinding force is adjustable, and the device can be adapted to the specification changes of strip steel and specially grinds strip steel edge tearing zones; on the premise that equipment interference and process interference are not introduced, burrs of the strip steel edge tearing zones can be ground simultaneously, so that the quality of strip steel edges is improved, the technology problems caused by the quality of strip steel edges is solved for downstream customers, and benefits are brought to enterprises.

Owner:唐山扬邦钢铁技术研究院有限公司

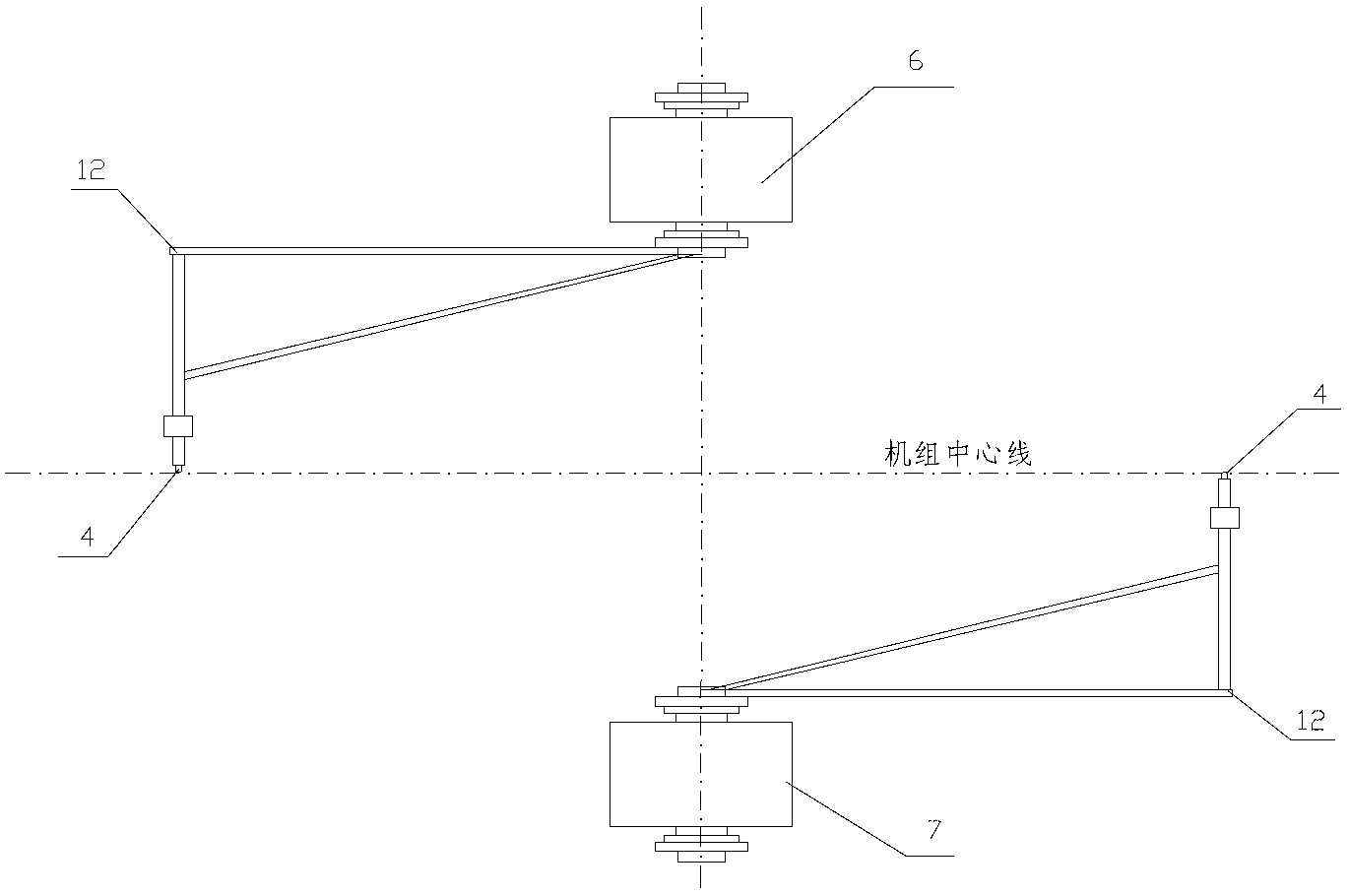

Method for adjusting horn mouth of circle shears by applying orthogonal method

ActiveCN102706240AAccurate and fast measurementAccurate and fast adjustabilityMechanical measuring arrangementsCircular discOrthogonal method

The invention provides a method for adjusting a horn mouth of circle shears by applying an orthogonal method. The method comprises the following steps of: building a central line of a unit; leading two vertical lines from the central line; making an oscillating bar; fixing the oscillating bar at one side of a shear blade shaft of a left circle shear; fixing an inside micrometer at an upper end of a vertical rod of the oscillating bar; rotating the shear blade shaft of the circle shears to measure; reading and recording reading value of the inside micrometer; measuring the other side of the shear blade shaft of the circle shears and the shear blade shaft of another circle shear according to the steps; and comparing read and recorded reading values, if the reading value error of the inside micrometer is larger than a range, repeatedly measuring and adjusting until a standard error requirement is reached. By the method, a horn mouth state of two circle shears can be accurately and rapidly measured and adjusted, the problems of accurate measurement and accurate adjustment on the horn mouth state of a shear blade of a double-head circle shear are effectively solved, the shear blade is prevented from being damaged, the shearing edge quality is improved, and waste quantity and quality problem of products are reduced.

Owner:ANGANG STEEL CO LTD

Corner trimming device for non-woven fabric production

PendingCN112323443AGuaranteed pruning positionReduce scrap rateSevering textilesWoven fabricStructural engineering

The invention belongs to the technical field of non-woven fabric production, and discloses a corner trimming device for non-woven fabric production. The corner trimming device comprises a workbench and a first supporting plate. The first supporting plate is arranged above the workbench, a collecting roller is arranged at one end of the workbench, and a non-woven fabric capable of being driven is placed at the top of the workbench. One end of the non-woven fabric is connected with the collecting roller, two cutter grooves are symmetrically formed in the top of the workbench, and two first cutters are symmetrically installed at the bottom of the first supporting plate. According to the corner trimming device for the non-woven fabric production, a first pressing seat and a second pressing seat are arranged, before trimming of the first cutters, the first pressing seat and the second pressing seat firstly press the non-woven fabric on the workbench, the non-woven fabric is prevented from displacing under the impact of the first cutters in the cutting process, it is ensured that the trimming positions of the corners of the non-woven fabric are proper, and the rejection rate of the non-woven fabric is reduced; and meanwhile, the bottom of the second pressing seat and the two side edges of the workbench are obliquely arranged by 45 degrees, so that automatic falling of trimmed leftover materials is facilitated.

Owner:江门市粤新化纤有限公司

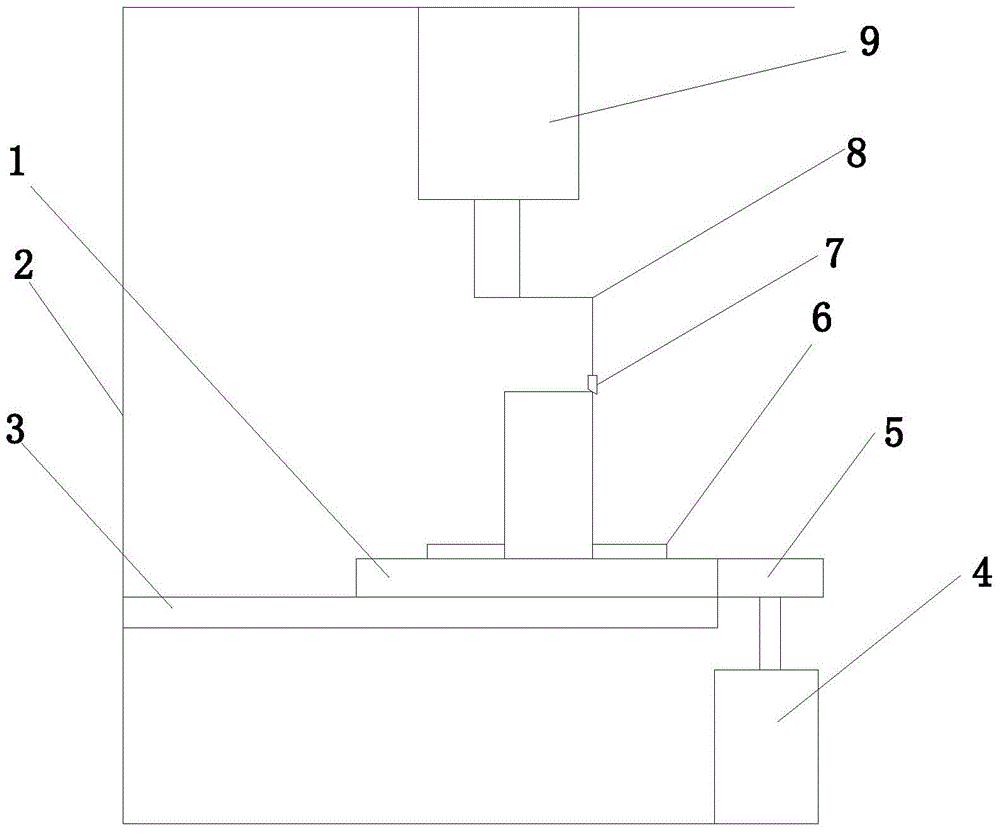

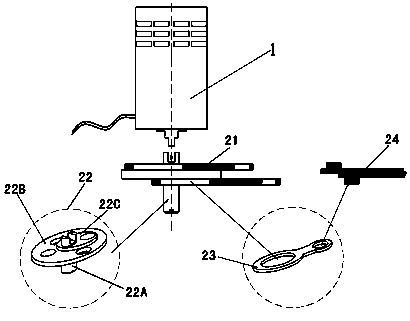

Method and device for cleaning bottom of plastic cup

The invention discloses a method and a device for cleaning the bottom of a plastic cup. The method is as follows: placing and fixing the plastic cup upside down on a rotary base, wherein a rotary blade is fixed above the base, and the rotating direction of the blade is enabled to be opposite to that of the base, so that the blade can clear burrs at the bottom of the plastic cup. The device provided by the invention includes a rack, wherein an operation platform is arranged on the rack; a base gear is arranged on the operation platform; two strip-shaped holes are formed in the base gear; a fixing device is arranged in the holes; a rotary gear is arranged on the side surface of the base gear; a gear motor is arranged at the lower part of the rotary gear; a cutting motor is arranged above the operation platform; a frame is connected with the cutting motor; the blade is arranged on the frame. According to the invention, the operations are simple, the working efficiency can be improved, the edge trimming quality is stable, and the cutting edge is uniform.

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

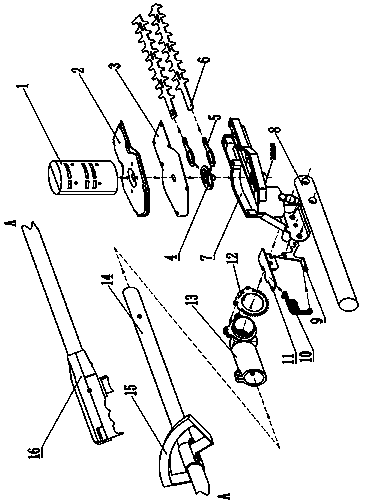

Electric grape branch pruner

InactiveCN104186221AQuick trimReduce labor intensityCuttersCutting implementsCrankshaftPower transmission

The invention relates to an electric grape branch pruner. The electric grape branch pruner is characterized in that the lower end of a center shaft of a double-crankshaft disk of a power transmission mechanism is inserted into a positioning hole of a shell, a protruding eccentric boss is arranged on the upper surface of a circular base disk of the double-crankshaft disk as well as one on the lower surface of the circular base disk, the circular center of the protruding eccentric boss of the upper surface and the circular center of the protruding eccentric boss of the lower surface are arranged on the same diameter line of the circular base disk (22B), one end of an upper connecting rod is sleeved with the boss on the upper surface, and the other end of the upper connecting rod is sleeved with a boss at a root end of a double-edge blade. A spline of an end of an output shaft of a motor penetrates an upper cover of the shell and a press plate through hole to be inserted into a notch of the upper end of a mandrel in the double-crankshaft disk. A gear change mechanism and a motor structure are integrated, total weight of the electric grape branch pruner is reduced, the edges of the blade are lengthened and broadened, pruning quality and efficiency are improved, labor intensity of operators is alleviated, and the electric grape branch pruner with a 12V 20-ampere-hour lithium battery can work continuously for 8-10 hours.

Owner:侯巧生

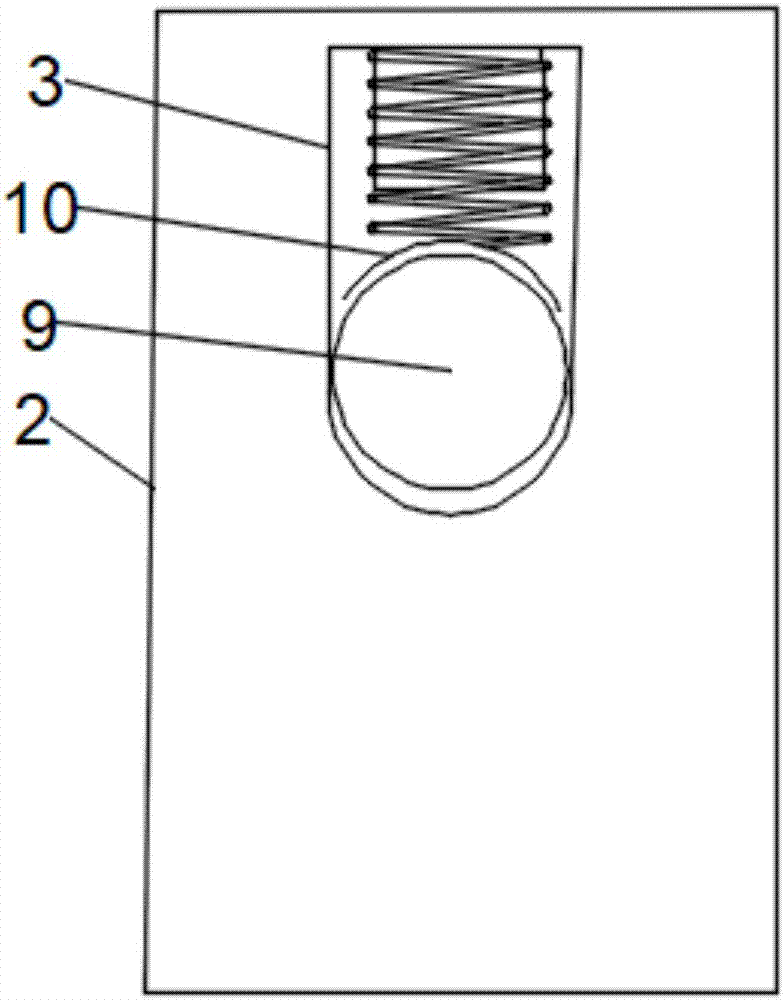

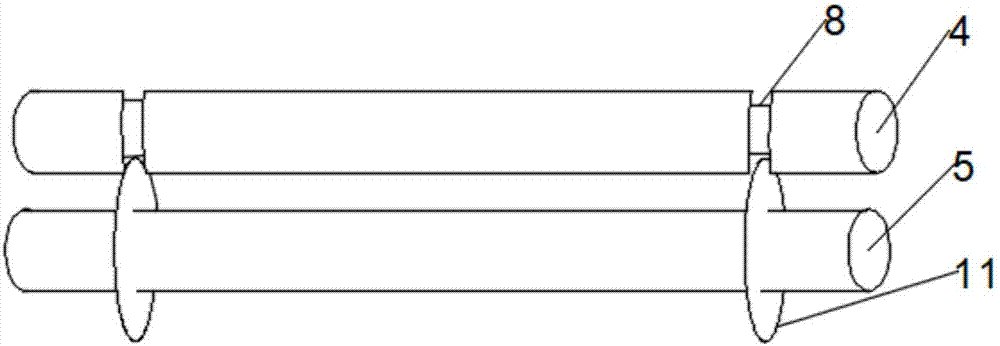

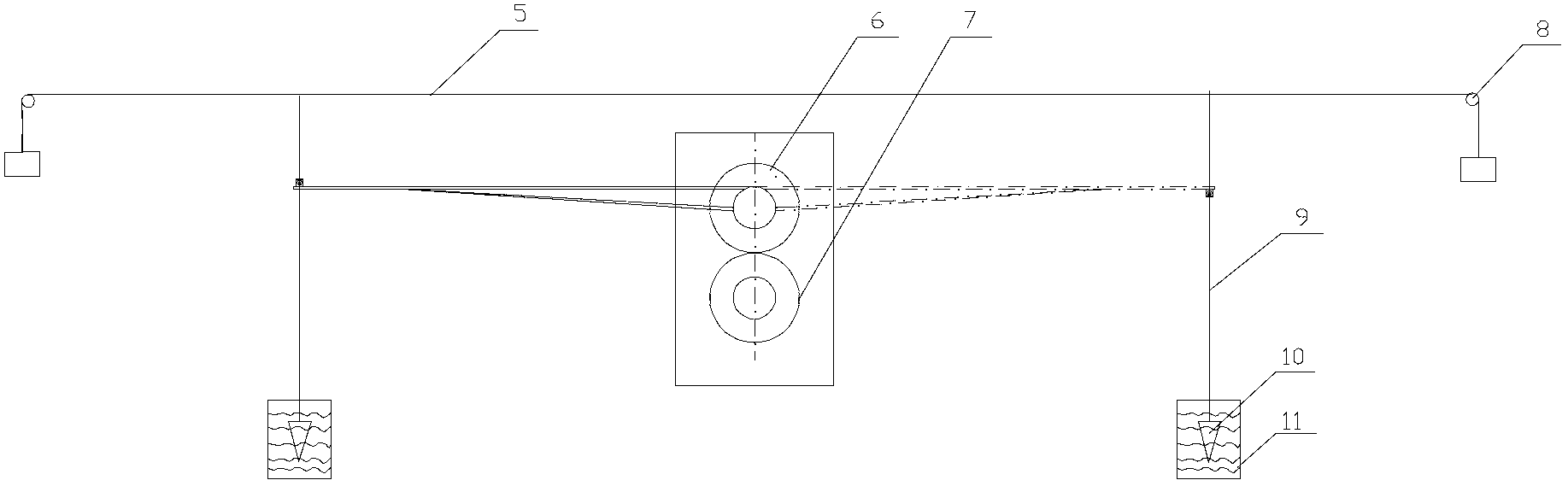

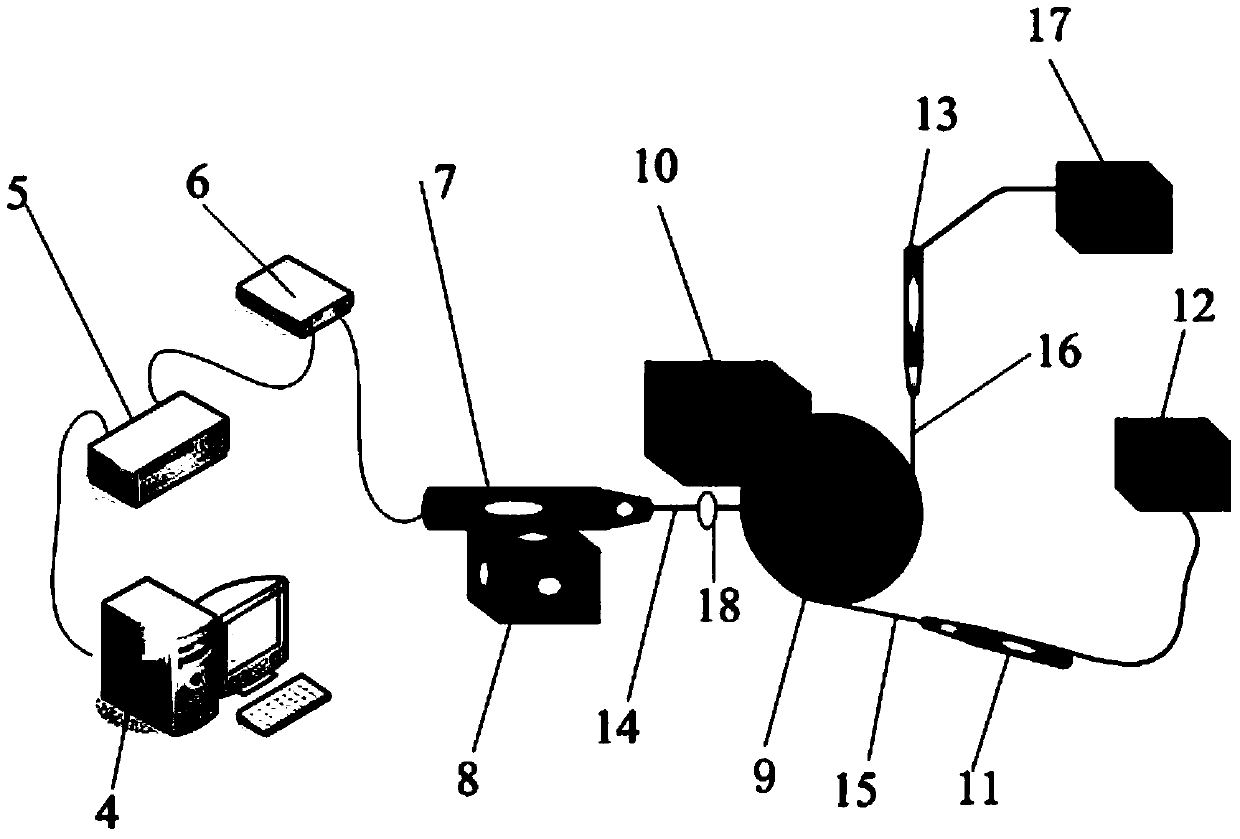

Laser grinding wheel trimming device with double tangential liquid column flows and trimming method thereof

ActiveCN103802025AAvoid defectsImprove trimming qualityAbrasive surface conditioning devicesEnergy balancingEvaporation

The invention relates to a laser grinding wheel trimming device with double tangential liquid column flows. The laser grinding wheel trimming device comprises computer control equipment (4), a control operating platform (5), a fiber laser device (6), a laser ablation head (7), a three-dimensional moving platform (8), an ultrahard abrasive grinding wheel (9), a grinder (10), a lower tangential thin water pipe (11), a lower tangential liquid column pressure controller (12), a right tangential thin water pipe (13), a laser beam (14), the lower tangential liquid column flow (15), the right tangential liquid column flow (16), a right tangential liquid column pressure controller (17) and a focusing lens (18). The auxiliary double-tangential-liquid-column-flow device is provided, so that the energy accumulation effect is suppressed, and energy balance in the trimming process is improved. In addition, a liquid film is formed on the surface of a grinding wheel, so that heat loss of an evaporation effect is reduced, the use ratio of laser is improved, and surface quality of the trimmed grinding wheel is improved.

Owner:HUNAN UNIV

Automatic quality detection and trimming device for gray cloth

ActiveCN110438788AImprove efficiency and qualityImprove trimming efficiencyMarking textilesInspecting textilesEngineering

The invention provides an automatic quality detection and trimming device for gray cloth. The automatic quality detection and trimming device for the gray cloth comprises a conveying module, a detection module and a trimming module; a support plate is arranged on the conveying frame, and transmission rollers are arranged at two ends of the support plate; a support rod is vertically fixed on the support plate, and a detection module is arranged at the top of the support rod; the detection module comprises an infrared emitting device; the detection module comprises an infrared receiving device;the trimming module comprises a trimming knife; and the trimming module comprises an electric sliding block. According to the automatic quality detection and trimming device for the gray cloth, the edge of the gray cloth is detected through infrared rays, the position of a trimming cutter is adjusted timely, and waste of the cloth is avoided under the condition of ensuring the purpose of trimming;and meanwhile, defects of the gray cloth can be automatically detected through infrared monitoring and are marked, and by the device, the defect detection efficiency and accuracy are greatly improved.

Owner:江西天达纺织有限公司

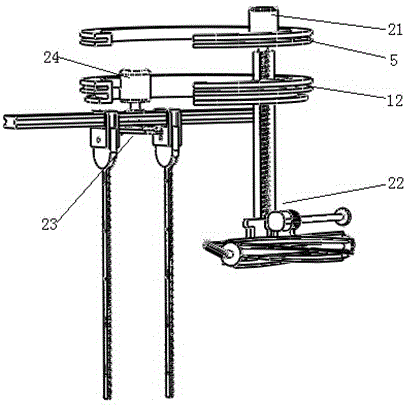

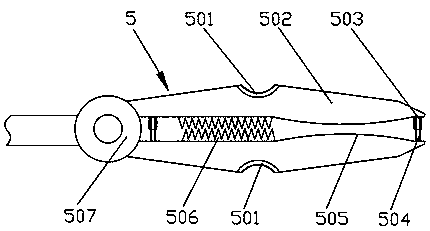

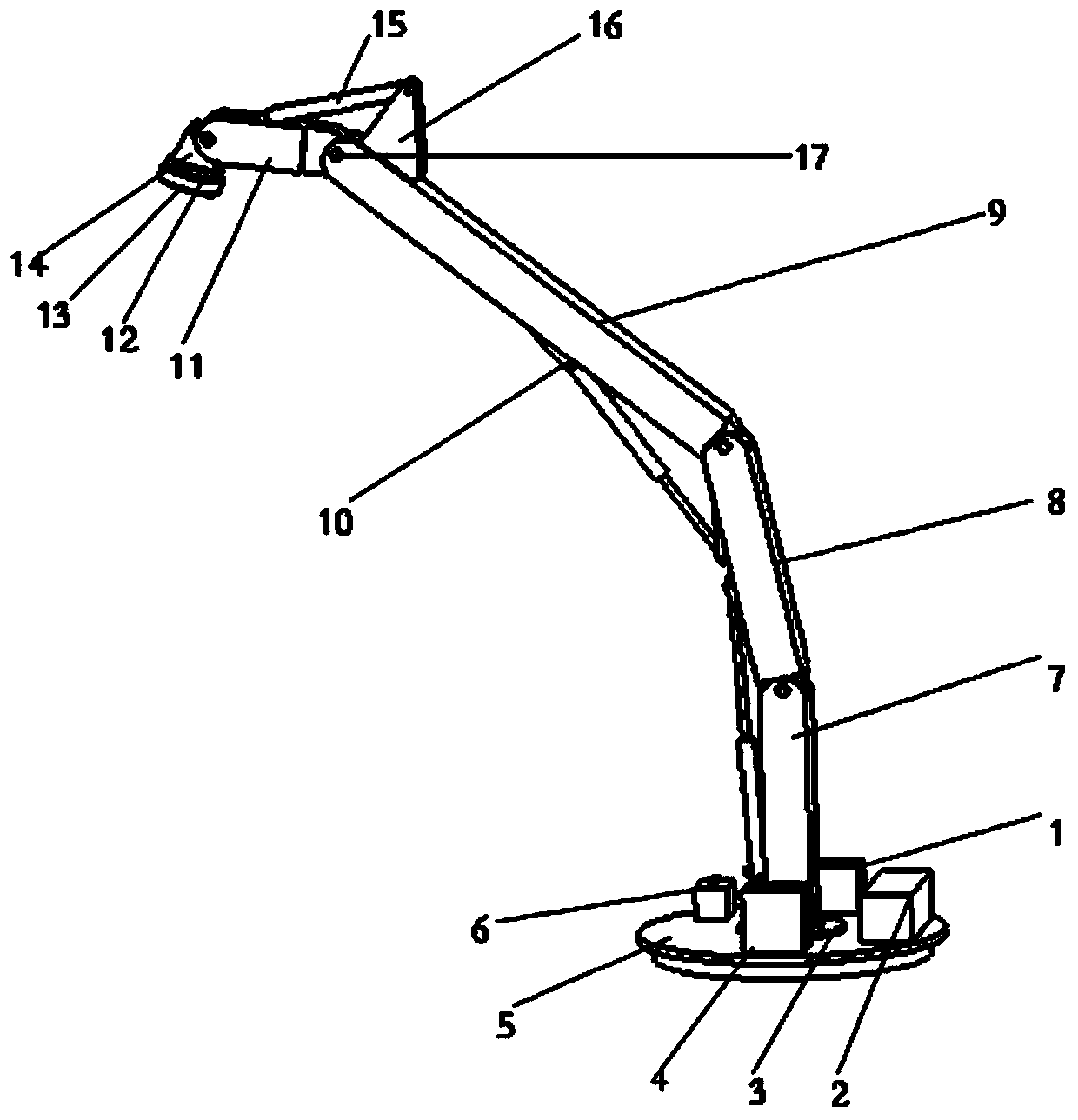

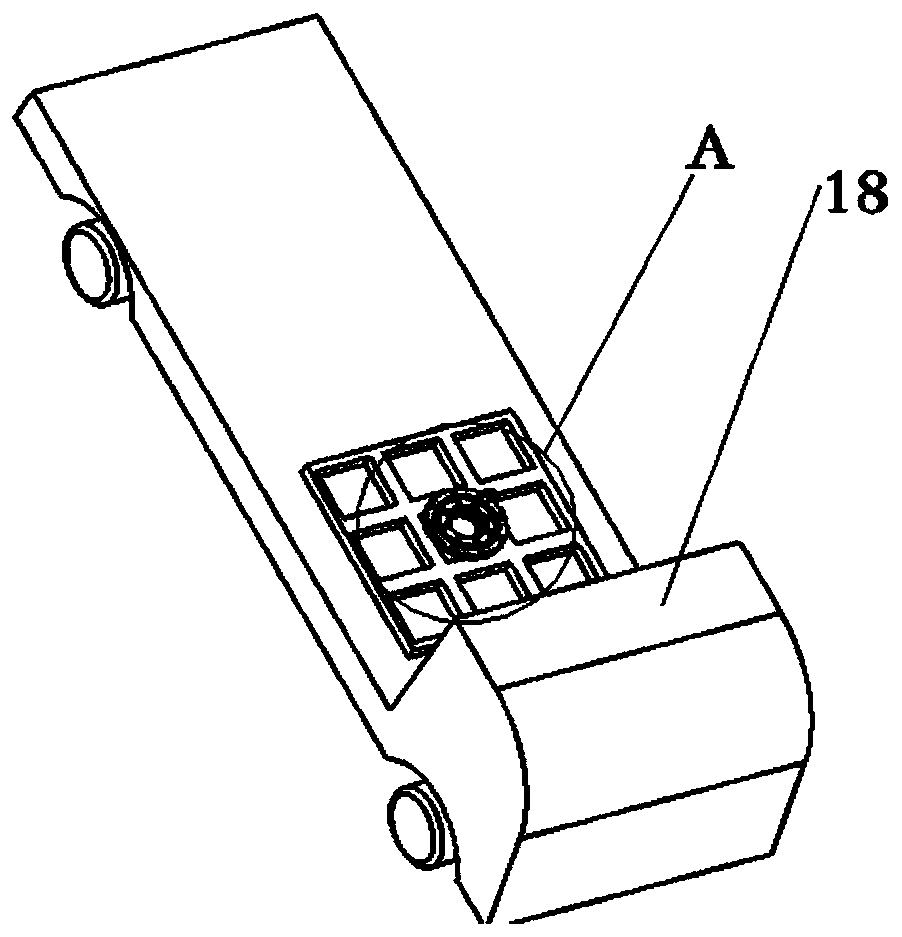

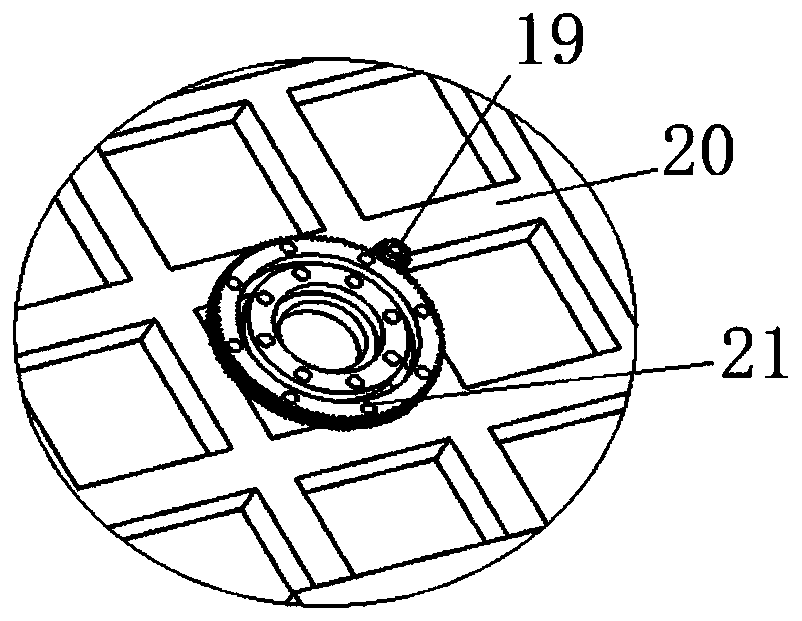

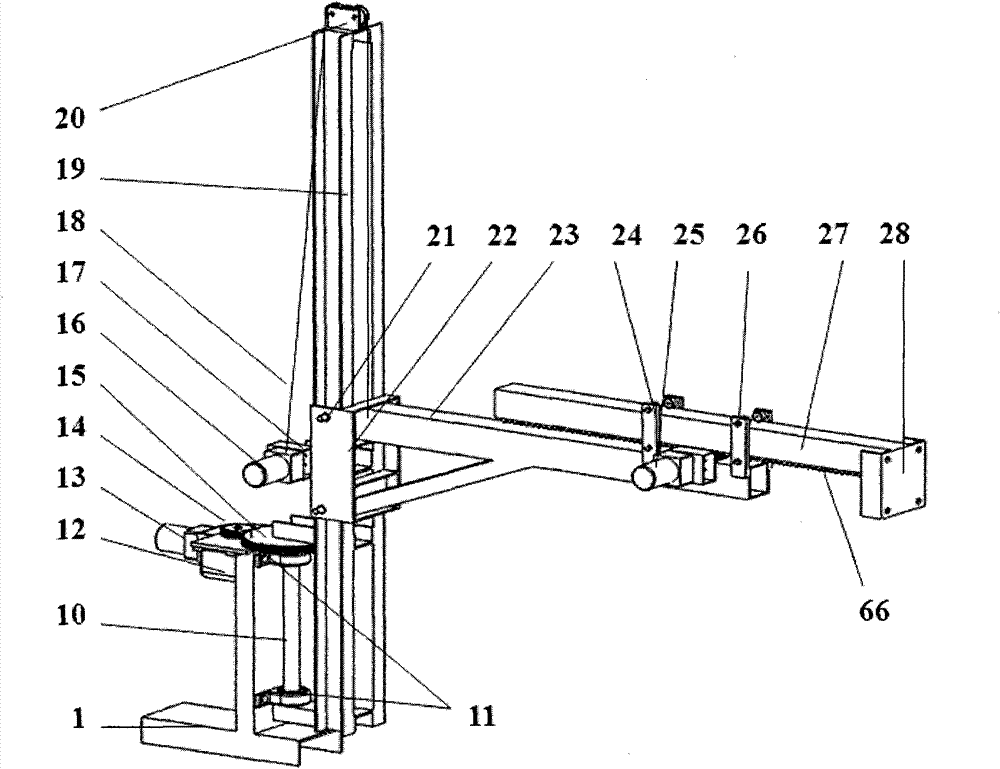

Hedgerow pruning manipulator with six degrees of freedom (DOP)

ActiveCN101982051BHigh degree of automationImprove work efficiencyHedge trimming apparatusAutomatic controlControl system

The invention discloses a hedgerow pruning manipulator with six degrees of freedom (DOP). The manipulator comprises a main swing mechanism, a pruning knife assembly and a supporting mechanism, wherein the supporting mechanism is fixed on a dragging vehicle, and consists of a base, a rotary component, a lifting component and a telescopic component; the front end of the supporting mechanism is fixedly provided with the main swing mechanism capable of doing gyroscopic motion; the output shaft end of the main swing mechanism is fixedly connected with a horizontal mechanical arm the front end of which is connected with a vertical mechanical arm, and the front end of the vertical mechanical arm is provided with a wrist joint; the output end of the wrist joint is fixedly provided with the pruning knife assembly; and a control system utilizes a control module which takes ARM series processors as the core to automatically control the joint operation of the horizontal mechanical arm, the vertical mechanical arm, the wrist joint and the main swing mechanism, so that the pruning knife can be operated along various tracks in space, thus realizing pruning operation of various form such as a spherical shape, a conical shape, a cylindrical shape, a plane, an inclined face, a wavy face and the like. The pruning manipulator has the characteristics of high automaticity, wide adaptability, energyconservation, environmental protection and the like, and is convenient to popularize and use.

Owner:GUANGXI UNIV

Lawn mowing device for landscape design

InactiveCN109699282AUniform amount of grassImprove trimming qualityHops/wine cultivationMowersLandscape designKnife blades

The invention discloses a lawn mowing device for landscape design. The lawn mowing device includes a vehicle body, walking wheels and a walking motor. The bottom of the vehicle body is provided with aplurality of walking wheels, the walking wheels are driven by the walking motor to rotate, the surface, opposite to the ground, of the bottom of the vehicle body is further provided with a movable blade and a fixed blade which adhere to each other tightly, the movable blade is driven by a driving mechanism to swing relative to the fixed blade, the fixed blade includes a base part, cutting parts and a separation part which are integrally formed, the cutting parts inclined to the ground are arranged on the base part, and the movable blade is tightly attached with the cutting part. The device has the advantages that during pruning, grass firstly enters from the separation part and then is separated, grass, dead leaves, garbage and the like are sucked upwards by a fan and a suction hood in the process, grass can stretch under the action of wind force and is then cut by the fixed blade moving relatively when moving to the cutting part, and grass can be automatically separated before pruning.

Owner:HEFEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com