Patents

Literature

230results about How to "Avoid flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength light foam ceramic plate and manufacturing method thereof

InactiveCN102627469AEasy accessLow priceConstruction waste recoverySolid waste disposalEnvironmental resistanceSodium bicarbonate

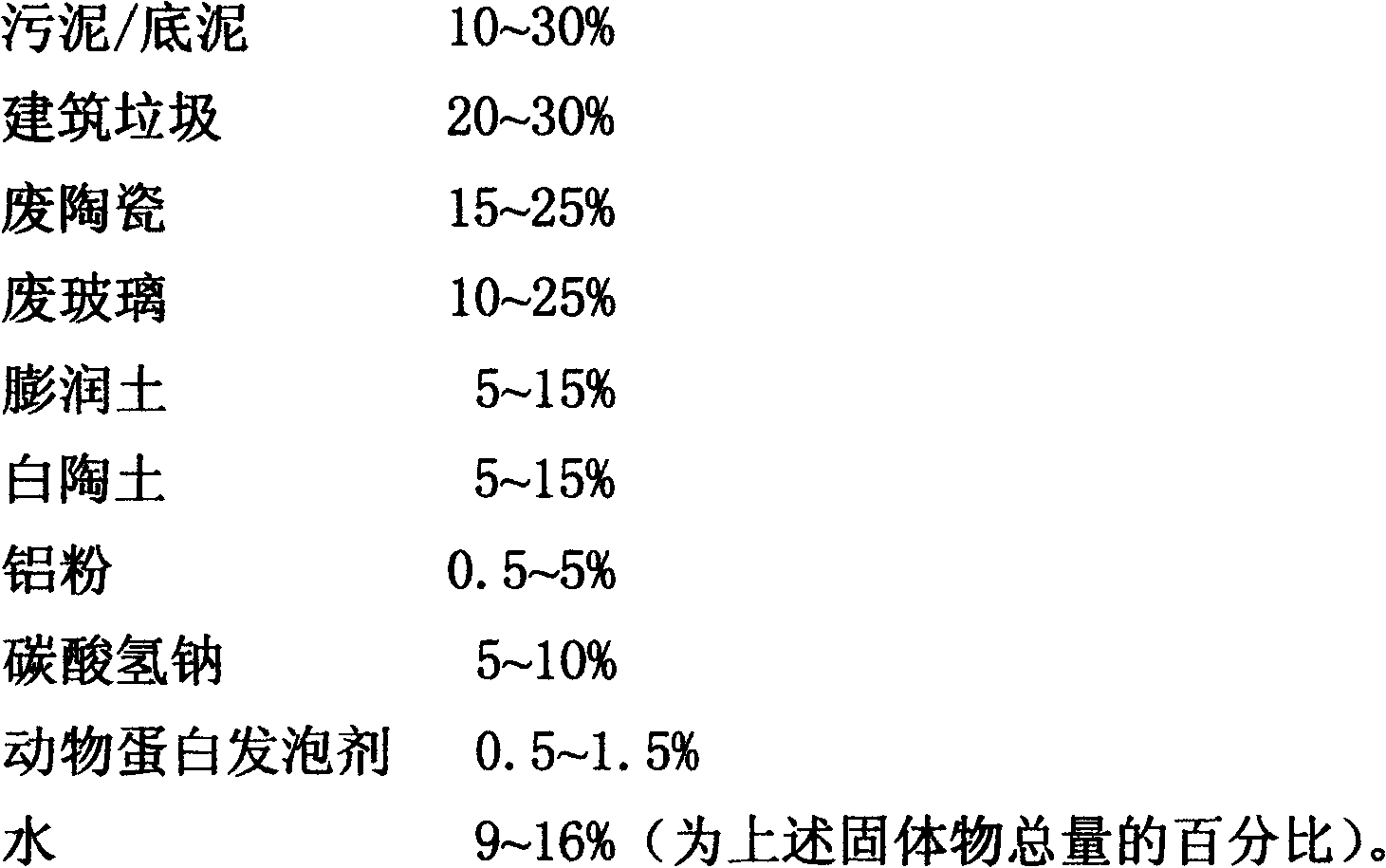

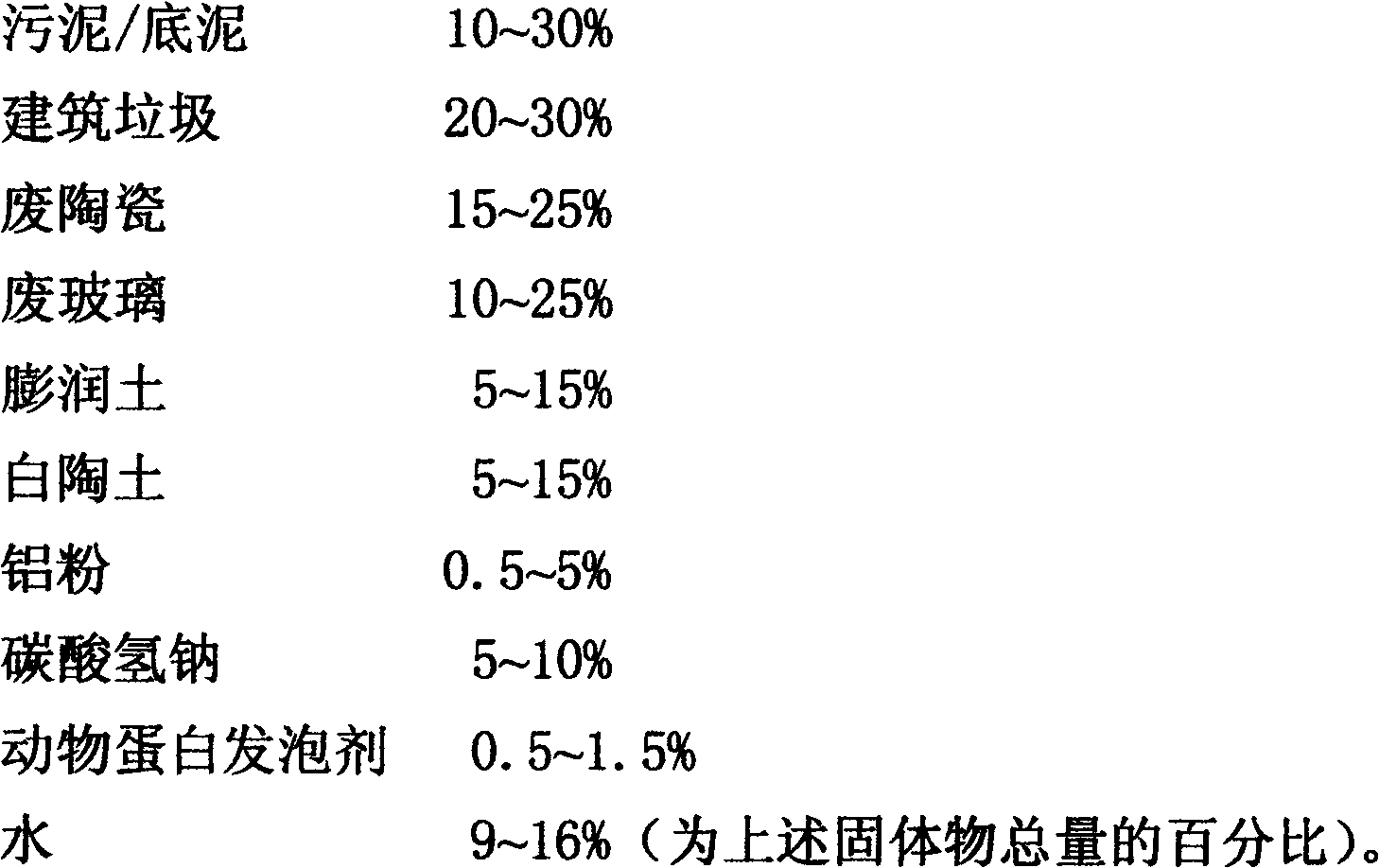

The invention discloses a high-strength light foam ceramic plate and a manufacturing method thereof, and belongs to the field of building material manufacturing. The ceramic plate comprises the following materials in percentage by weight: 10-30 percent of sludge / bottom mud, 20-30 percent of building waste, 15-25 percent of waste ceramic, 10-25 percent of waste glass, 5-15 percent of bentonite, 5-15 percent of kaolin, 0.5-5 percent of aluminum powder, 5-10 percent of sodium bicarbonate, 0.5-1.5 percent of animal albumen foaming agent and 9-16 percent (percentage of total amount of the solid matters) of water. The manufacturing method comprises the following steps of: mixing and crushing the main raw material; adding the animal albumen foaming agent and water; granulating; filling a granular material into a refractory combined mould; leveling; filling in a kiln; firing; and performing cold processing to produce a ceramic plate finished product. The high-strength light foam ceramic plate has the advantages of high product strength, small volume weight, fire proofing, excellent freeze proofing, long-term water proofing, readily available main raw material which basically comes from environmental solid waste, has a wide source and is low in cost and adoption of the animal albumen foaming agent of small using amount and wide source; the manufacturing process has the advantages of simplicity, high efficiency, energy conservation, environmental friendliness, no secondary pollution; and the high-strength light foam ceramic plate can be used as thermal insulation decorative materials, fire barriers and the like of exterior walls of buildings.

Owner:SICHUAN UNIV

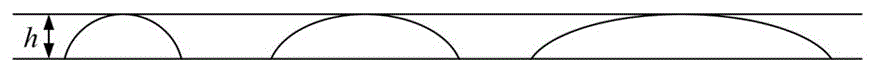

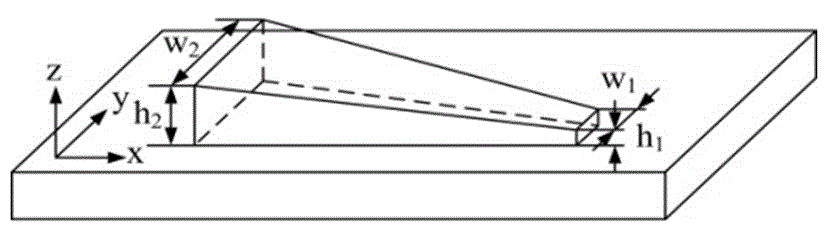

Method for improving precision of stepped components in laser spot-changing direct formation mode

ActiveCN104923784APlay a compensatory roleSolve the problem of inconsistent growth heightAdditive manufacturing apparatusIncreasing energy efficiencyLifting capacitySpray nozzle

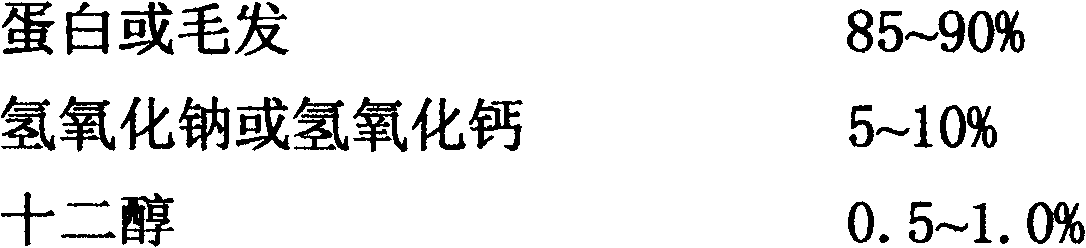

The invention discloses a method for improving precision of stepped components in a laser spot-changing direct formation mode. The method includes the steps that a cladding test is performed firstly, the sectional width and height data of a single-track cladding layer under different technological parameters are obtained, orders of a sectional curve of the cladding layer under different aspect ratios are fitted out, and the function relationship between the orders of the sectional curve of the cladding layer under the different aspect ratios and the height and lifting capacity of the single-track cladding layer is built; then single step-shaped tracks corresponding to the same lifting capacity are built, the technological parameters of the laser spot-changing cladding single tracks are determined according to the single step-shaped tracks, and a highly-smooth cladding layer is formed in a cladding mode through laser spot-changing direct formation; after one cladding layer is completed, a spray nozzle is lifted by a layering height, new fusion tracks are formed in a cladding mode through the single step-shaped tracks, and operations circulate until manufacturing of a three-dimensional part is completed. By means of the method, the highly-smooth cladding layer is obtained, the phenomenon that the top of the cladding layer is not even and portions of small aspect ratios are prone to tension fracture is avoided, and the method improves formation precision and guarantees formation quality.

Owner:KUSN BAOJIN LASER TAILOR WELDED

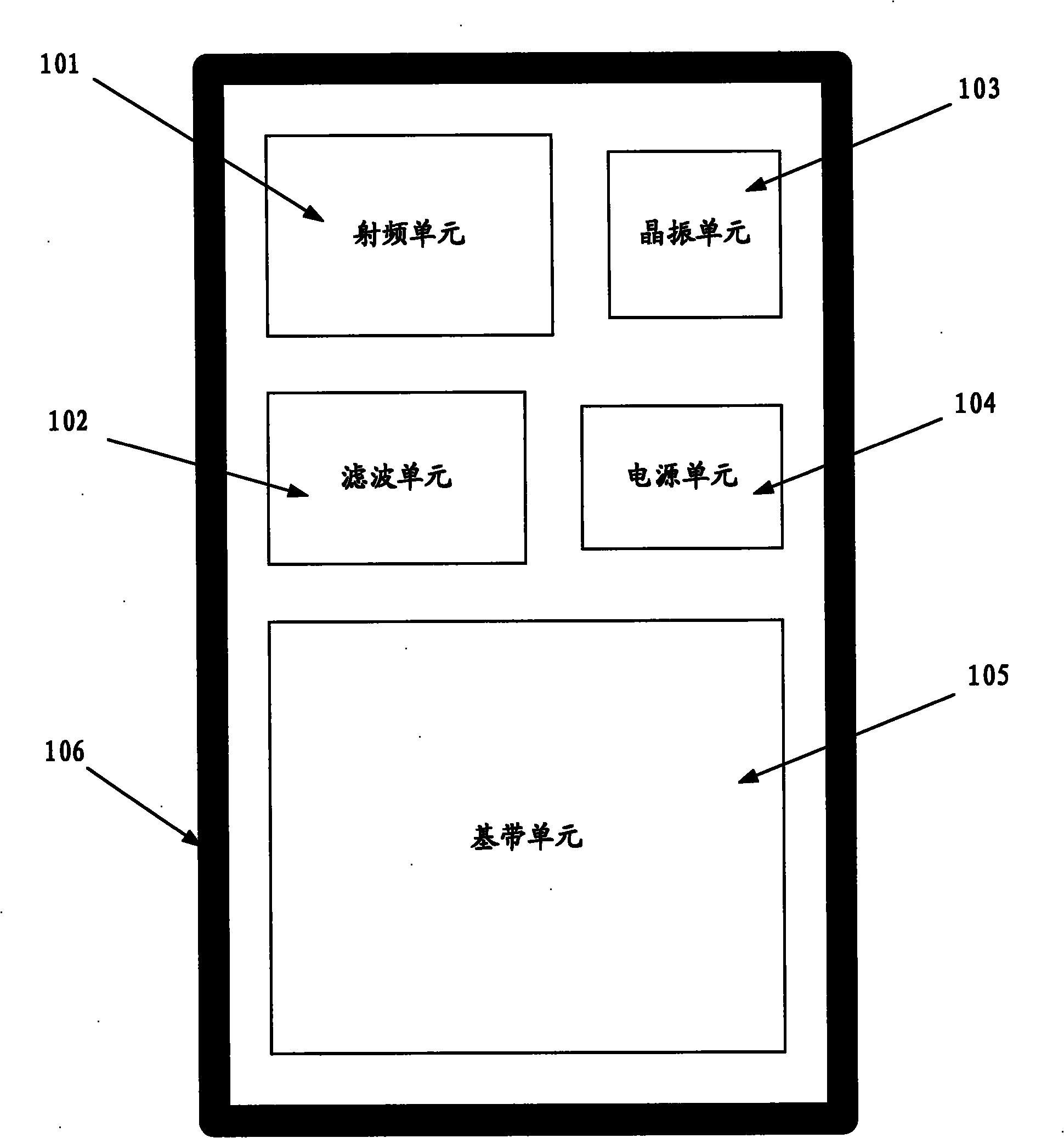

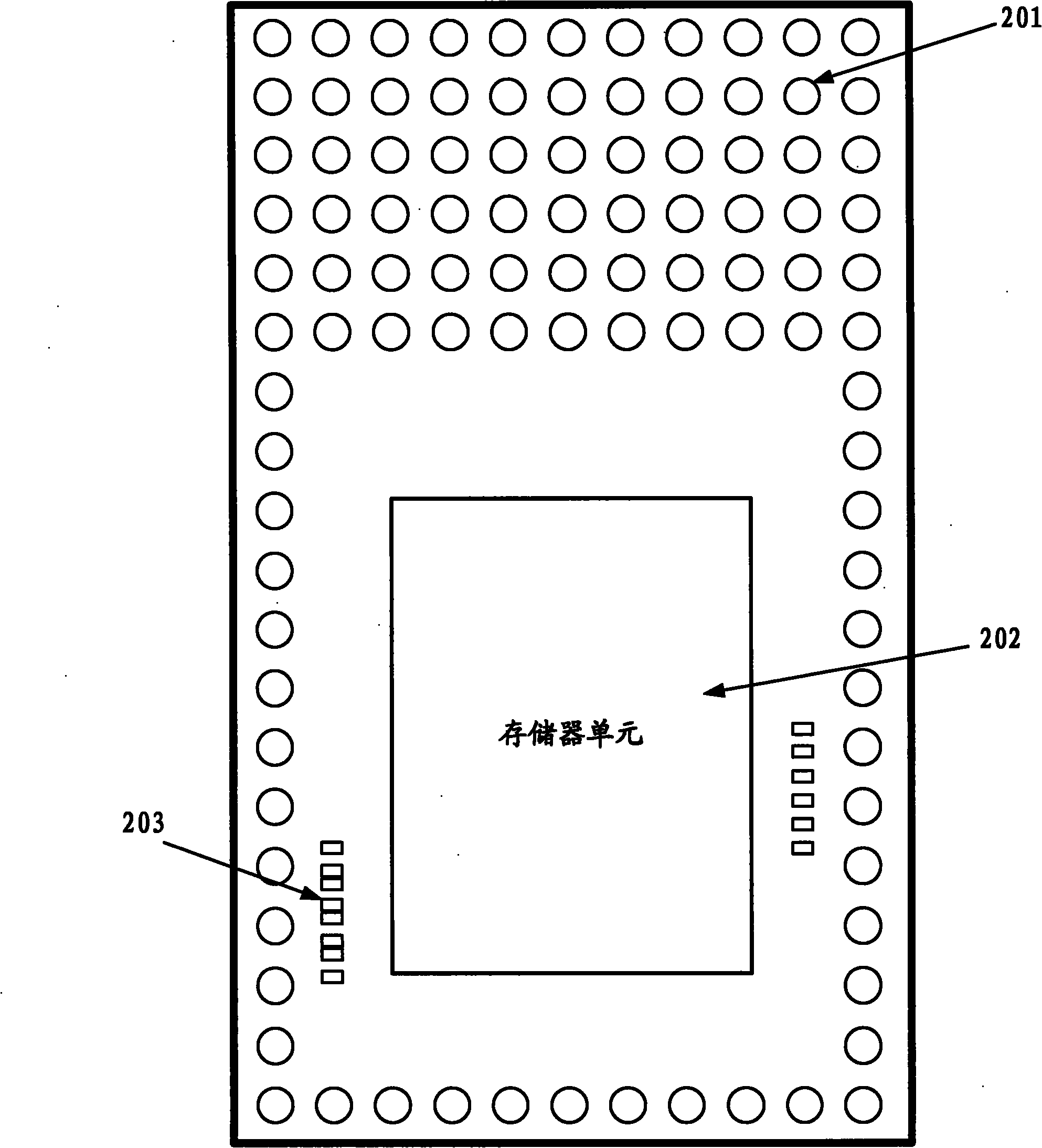

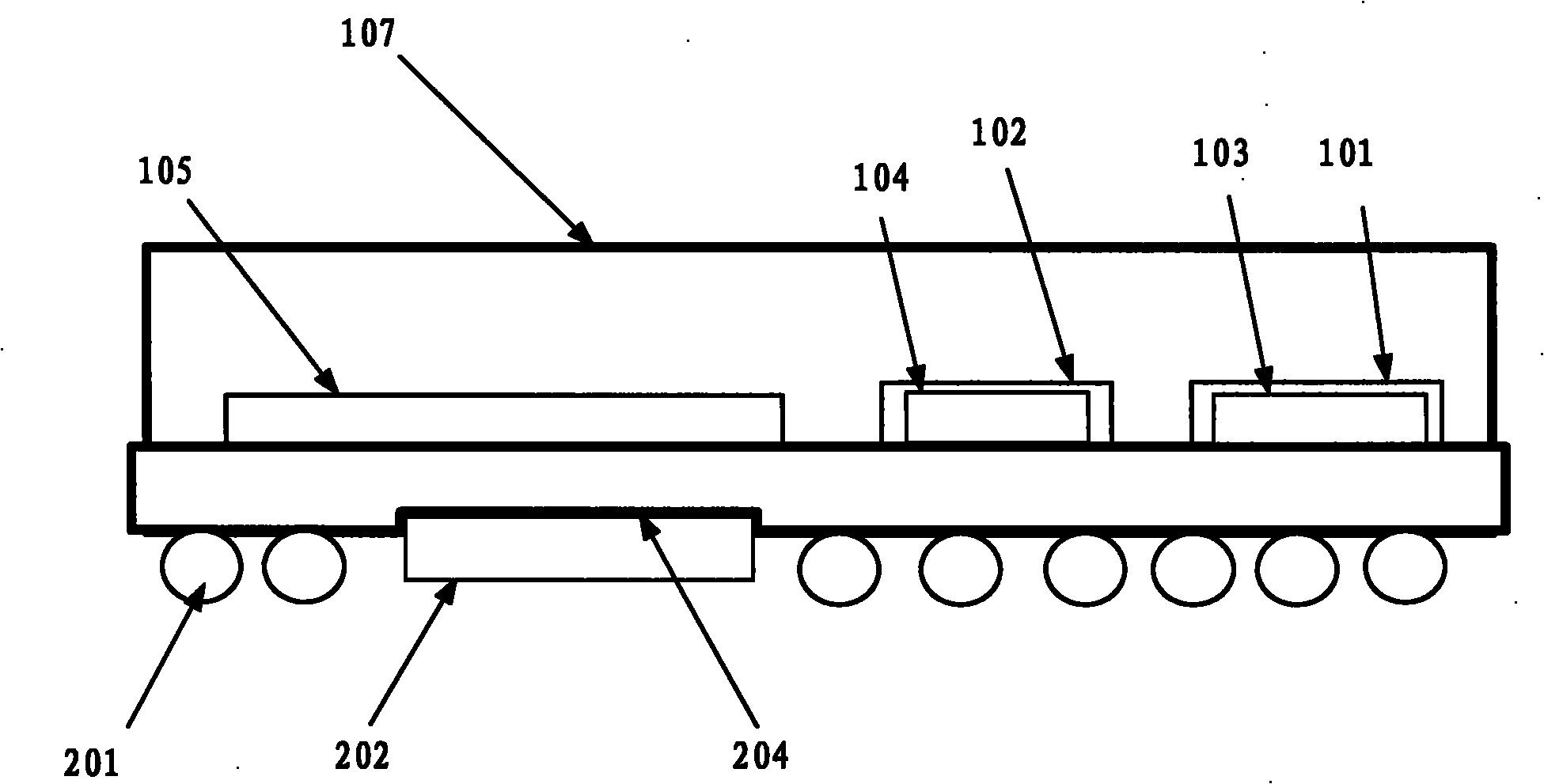

Wireless communication module

InactiveCN102215043AEasy to integrateReduce volumeTransmissionWireless communicationEvolution-Data OptimizedCode division multiple access

The invention belongs to the field of mobile communication, and relates to a wireless communication module, in particular to a high-performance small-sized module of a code division multiple access (CDMA) evolution-data optimized (EV-DO) mobile terminal. The small-sized module is applicable to a third generation (3G) user terminal. The wireless communication module is characterized in that: board-level connection is carried out by ball grid array (BGA) package; the level of integration is high; the size is small; good electrical performance and an external interface function are realized; and requirements of a customer can be well met. The wireless communication module comprises a radio frequency front end, a transmitting and receiving channel, a base band processing part, a memory and a power manager, wherein the base band processing part and the radio frequency front end are placed on a top layer of a circuit board; a shielding cover is arranged on the top layer to guarantee an excellent electromagnetic compatibility function of the module; the memory is placed on a bottom layer of the circuit board; and the bottom layer adopts an advanced BGA technology to guarantee reliable connection during the application of the module.

Owner:NATIONZ TECH INC

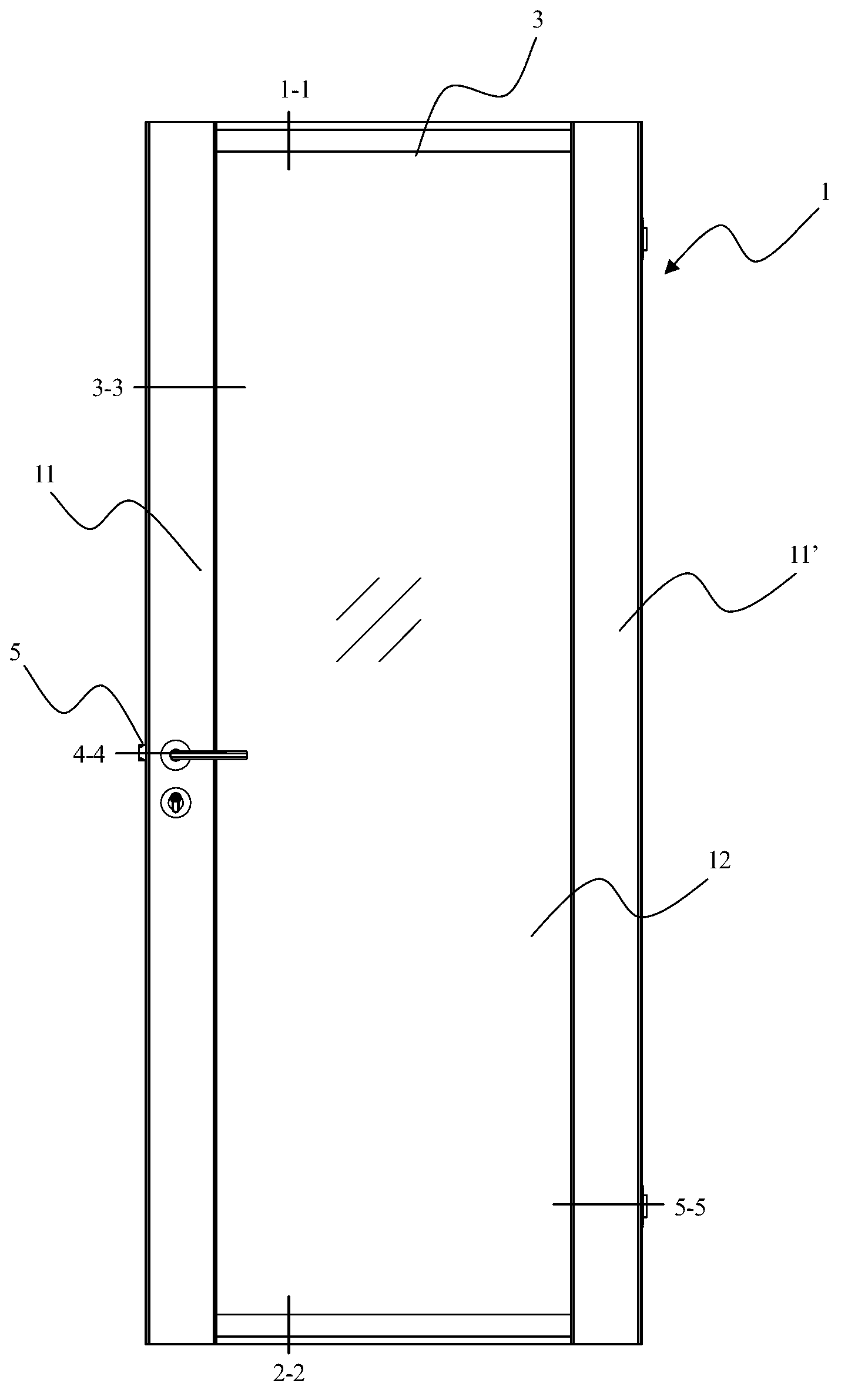

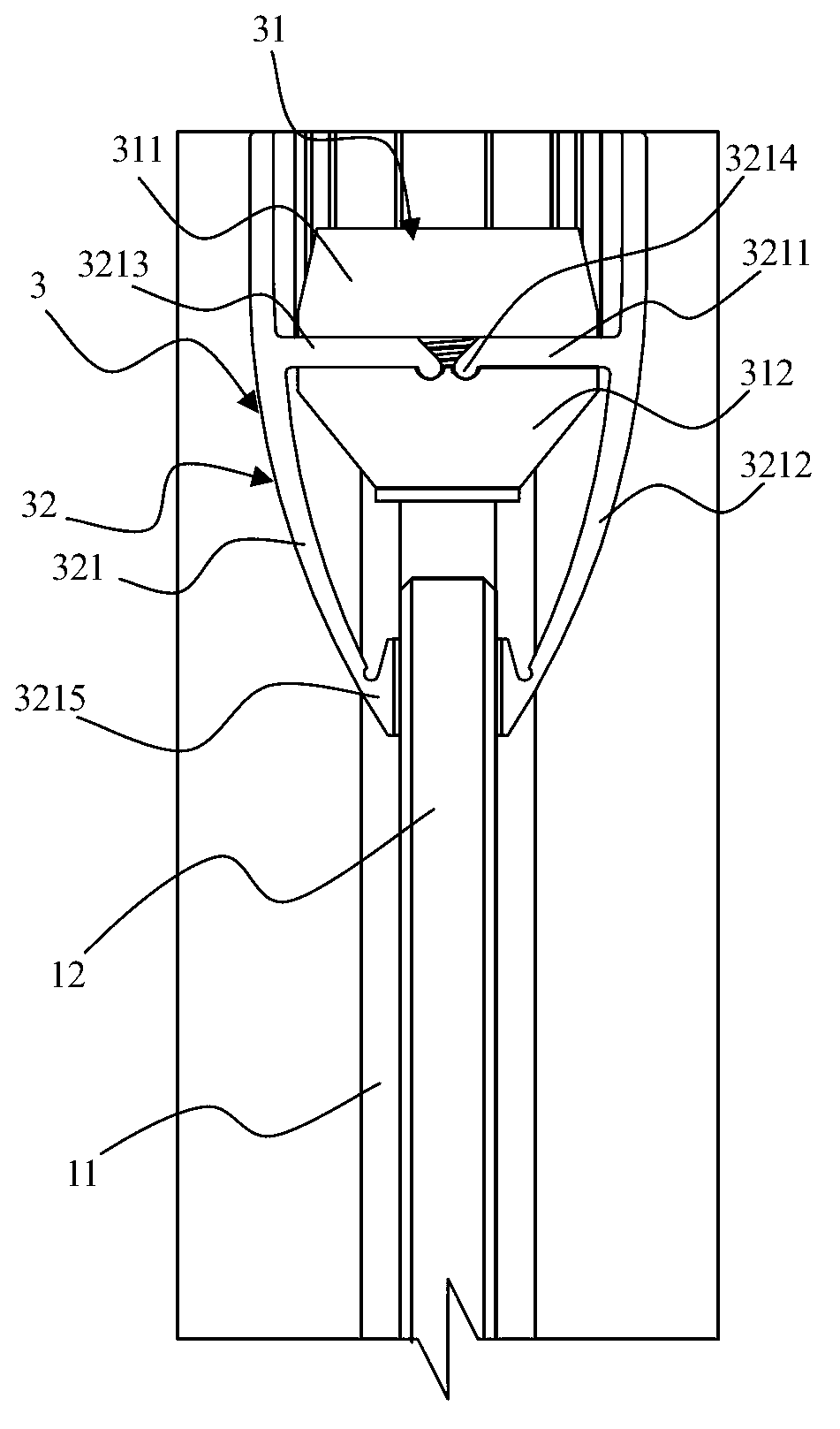

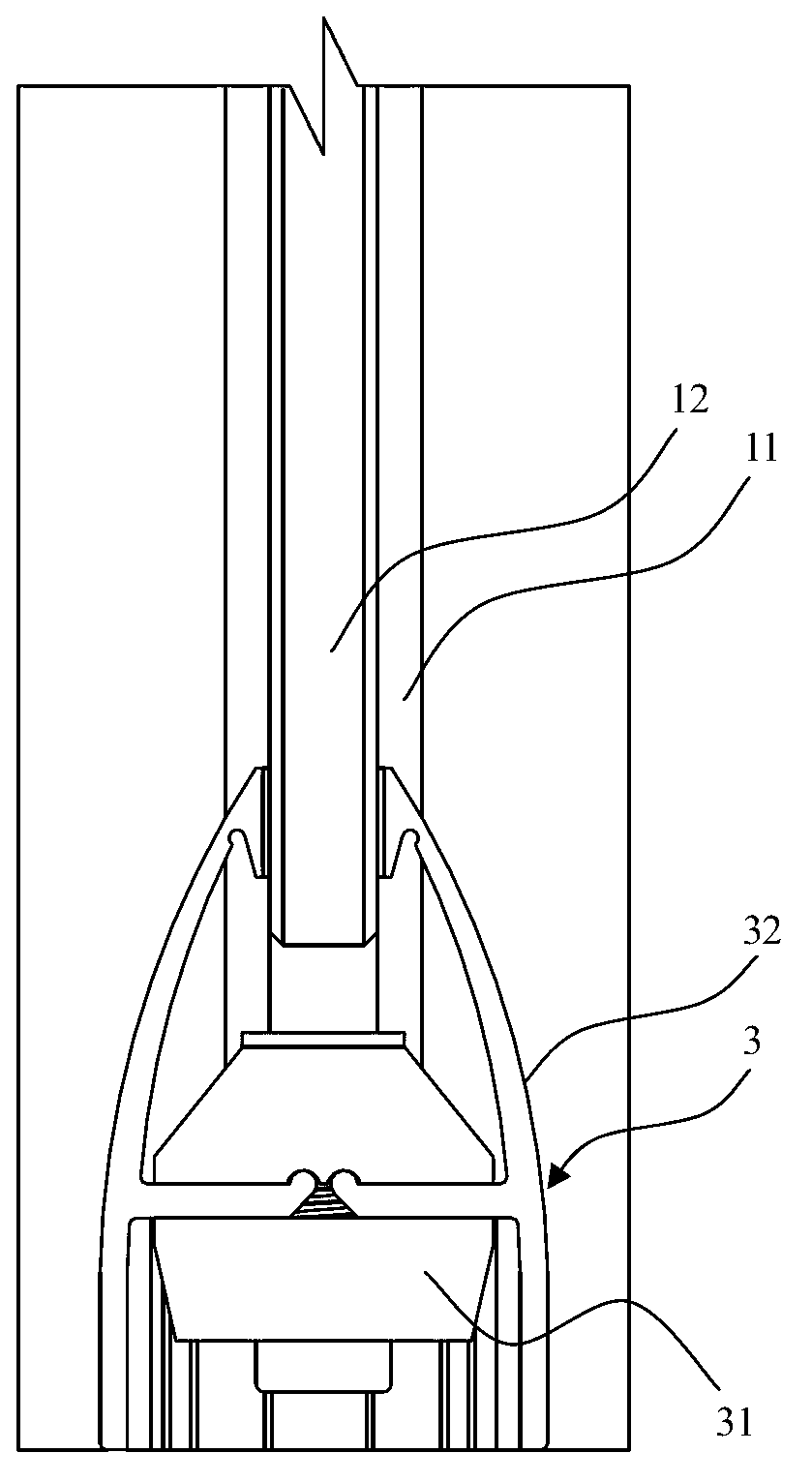

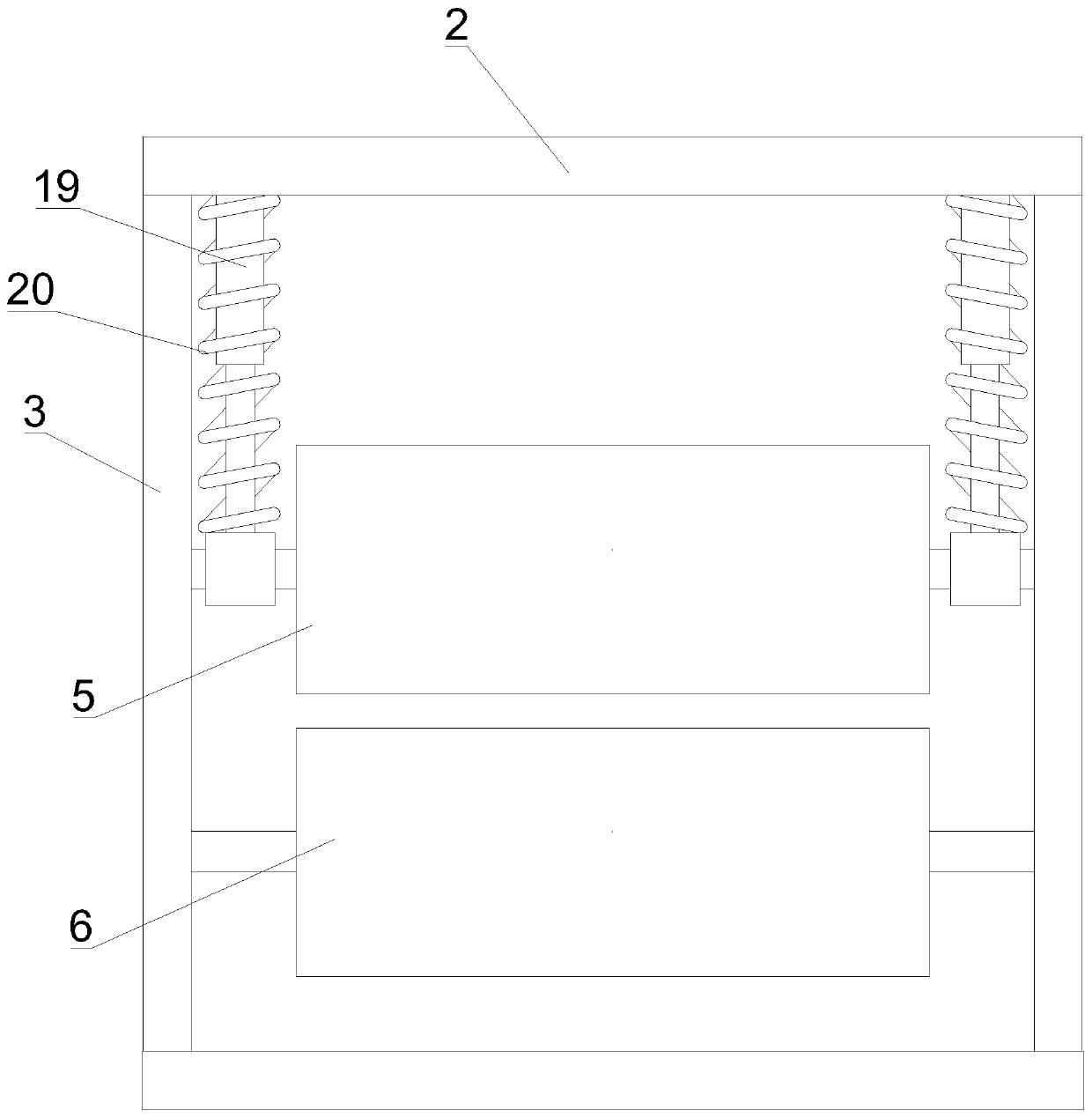

Glazed door window sash and assembly method thereof

ActiveCN103291195ATo achieve fastening effectImprove smoothnessGlass pane fixingDoor leavesEngineeringStructural stability

The invention discloses a glazed door window sash. The glazed door window sash comprises two side frames and a glazed door window sash body, a mounting component is combined at each of the top and the bottom of the glazed door window sash body, the glazed door window sash body is fixed between the two side frames through the mounting components, each mounting component comprises a pressing component and a fastening component, and the pressing components and the glazed door window sash body are matched to press the fastening components to generate prestress and further fasten the glazed door window sash body. The glazed door window sash has the advantages that the glazed door window sash body is fixed with the side frames through the prestress mounting components, and glass and a glazed door window sash frame form a rigid integral rather than an existing rectangular splicing structure, so that structural stability among the glazed door window sash body and the side frames is guaranteed, the problem of deformation of a door window sash connecting structure caused by self weight of the glazed door window sash body can be avoided, the problem of falling resulting from one-sided stress does not exist, and the glazed door window sash is safer in structure and more reasonable in stress.

Owner:山东东成玻璃科技有限公司

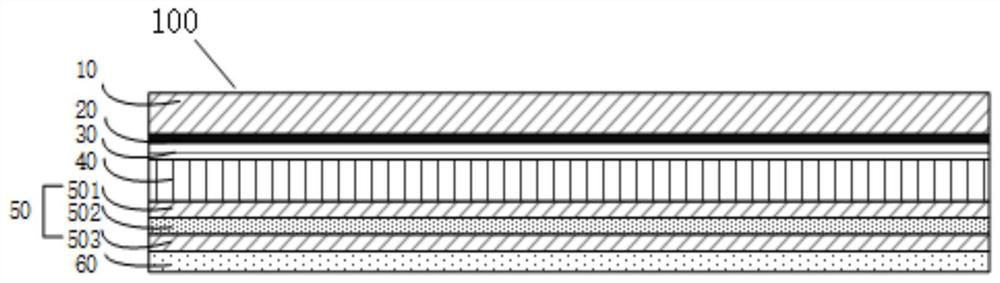

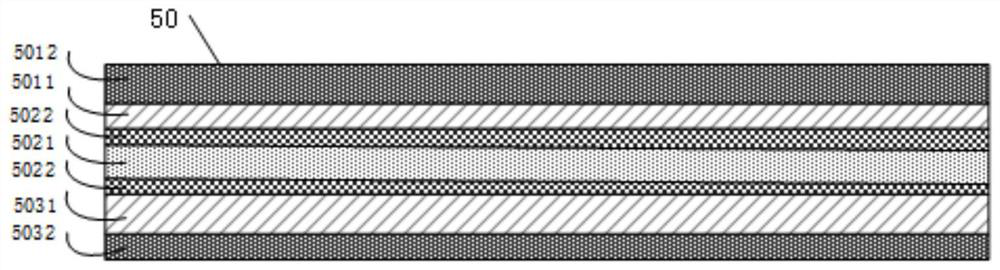

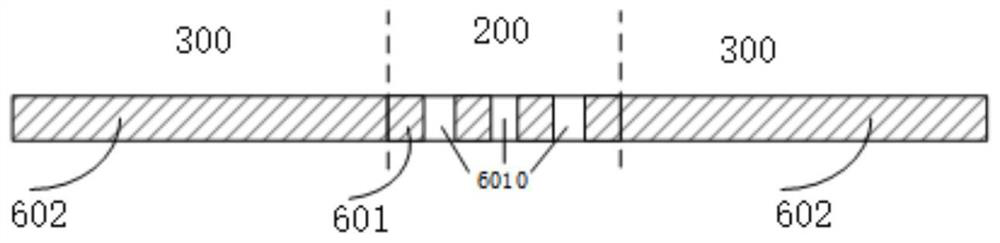

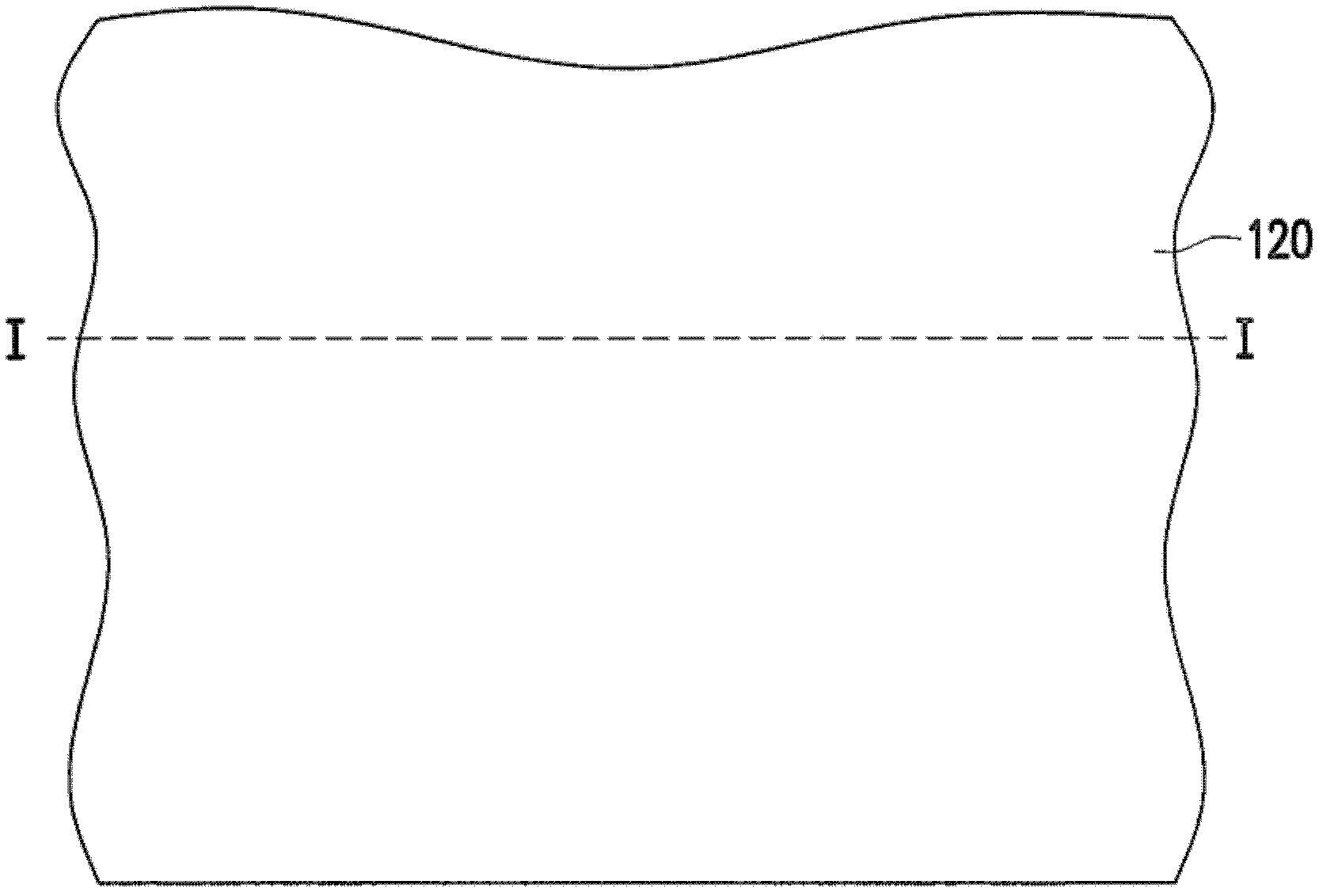

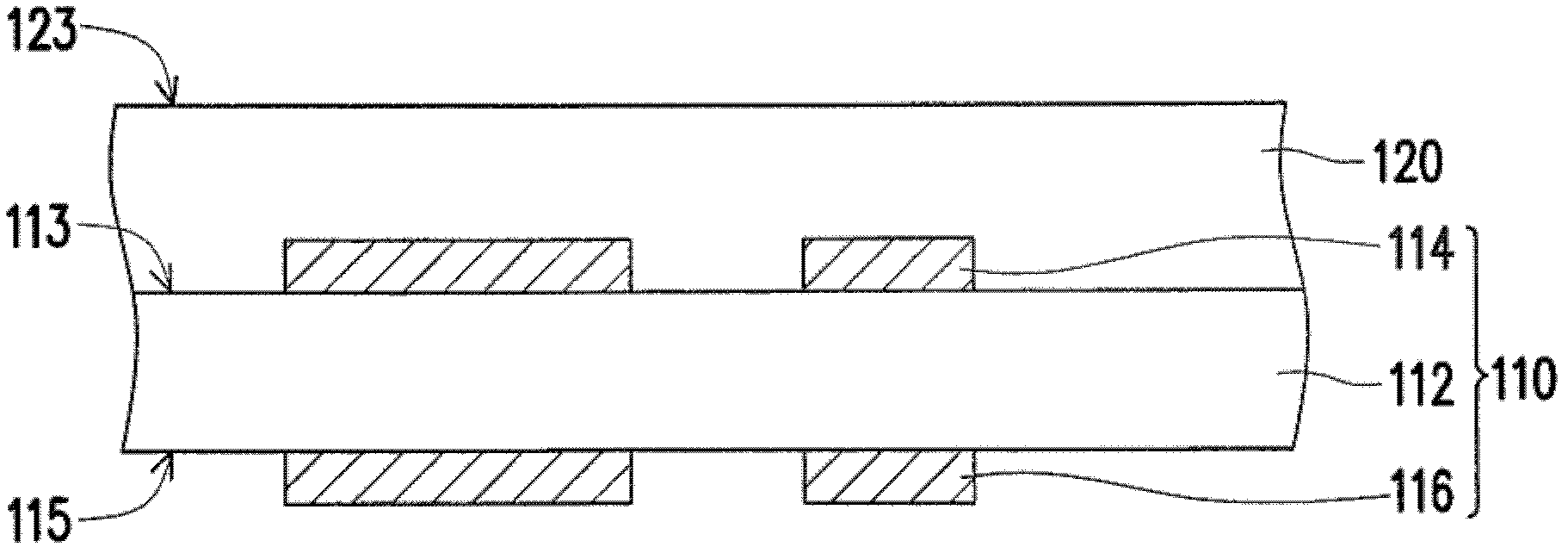

Display panel and display device

PendingCN112967606AAvoid wrinklesAvoid flatnessIdentification meansComputer hardwareComputer graphics (images)

The invention discloses a display panel and a display device. The display panel comprises a display panel main body, a back plate layer which is positioned on one side of the display panel main body, and a supporting layer which is located on the side, away from the display panel body, of the backboard layer, wherein the backboard layer comprises a first backboard located on the side, close to the display panel body, of the supporting layer, a buffer layer located on the side, away from the supporting layer, of the first backboard, and a second backboard located between the buffer layer and the display panel body. The display panel comprises the integrated structure formed by combining the back plate and the buffer layer, and problems of wrinkles and uneven surface caused by multiple times of bending of the display panel are solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

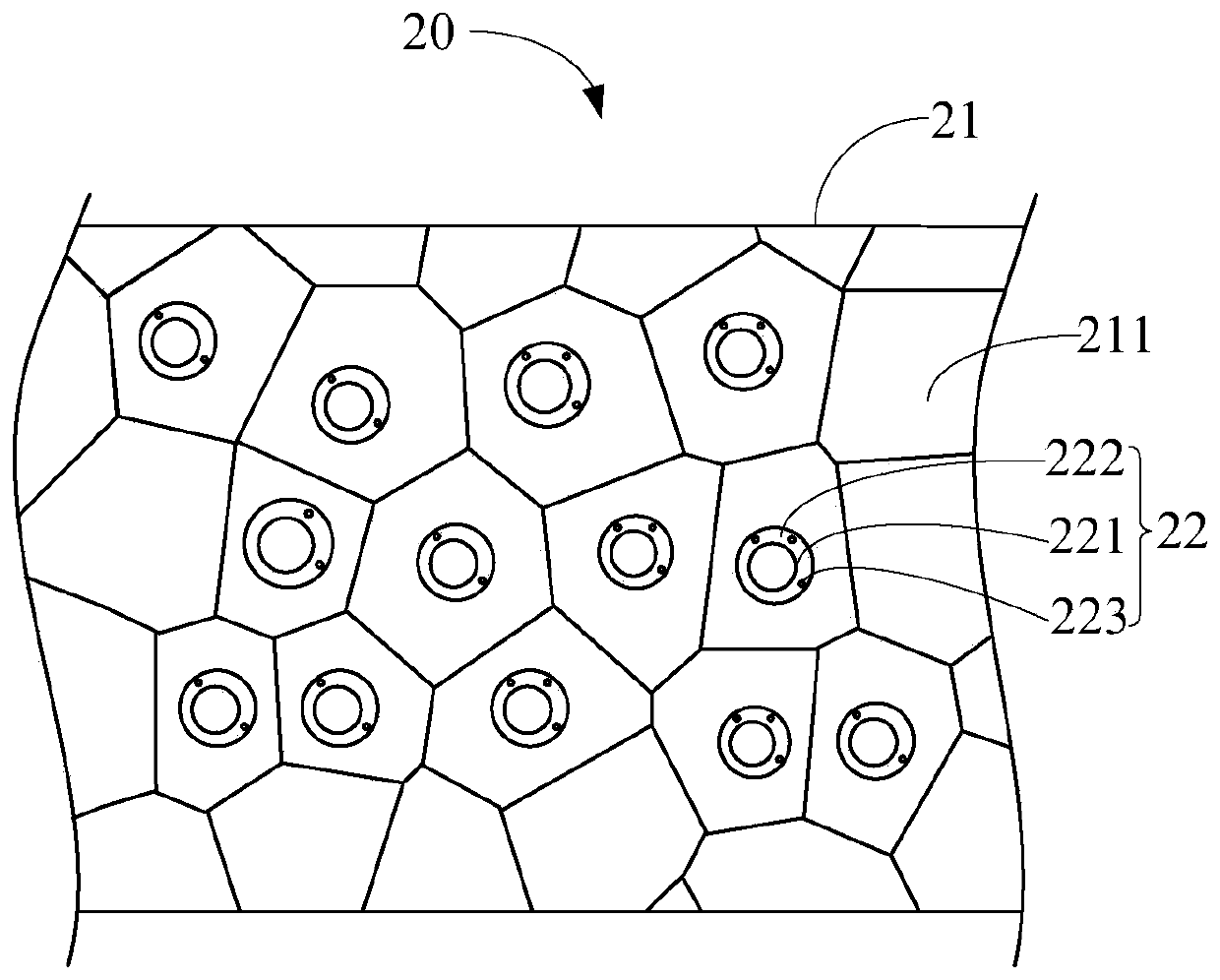

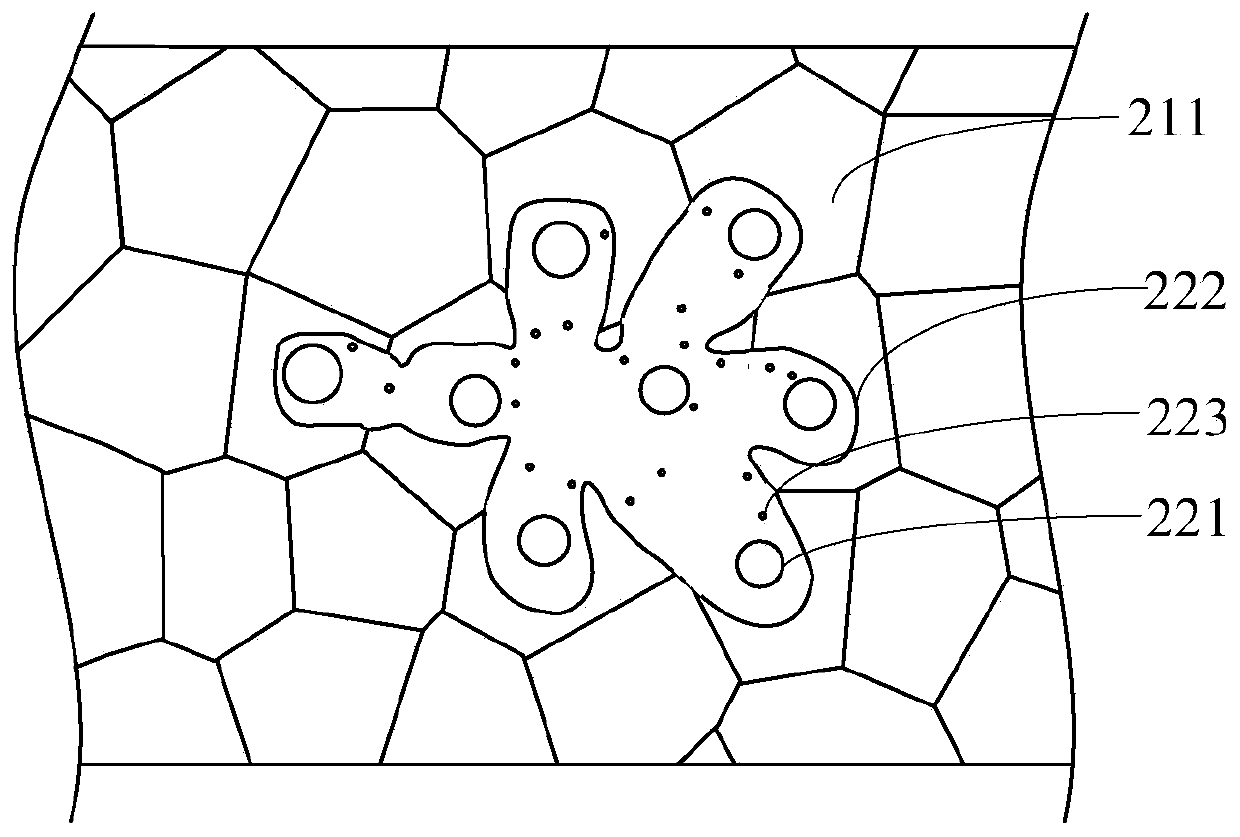

Flexible display module and display device

ActiveCN110288912AHigh hardnessAvoid flatnessDigital data processing detailsIdentification meansDisplay deviceFlexible display

The invention provides a flexible display module and a display device. The flexible display module comprises a crimpable flexible display panel and a support layer arranged below the flexible display panel, wherein the flexibility of the support layer when the temperature is higher than the specified temperature is smaller than the flexibility of the support layer when the temperature is smaller than or equal to the specified temperature; and when the temperature of the support layer is smaller than or equal to the specified temperature value, the support layer can be curled together with the flexible display panel. The display device comprises the flexible display module.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

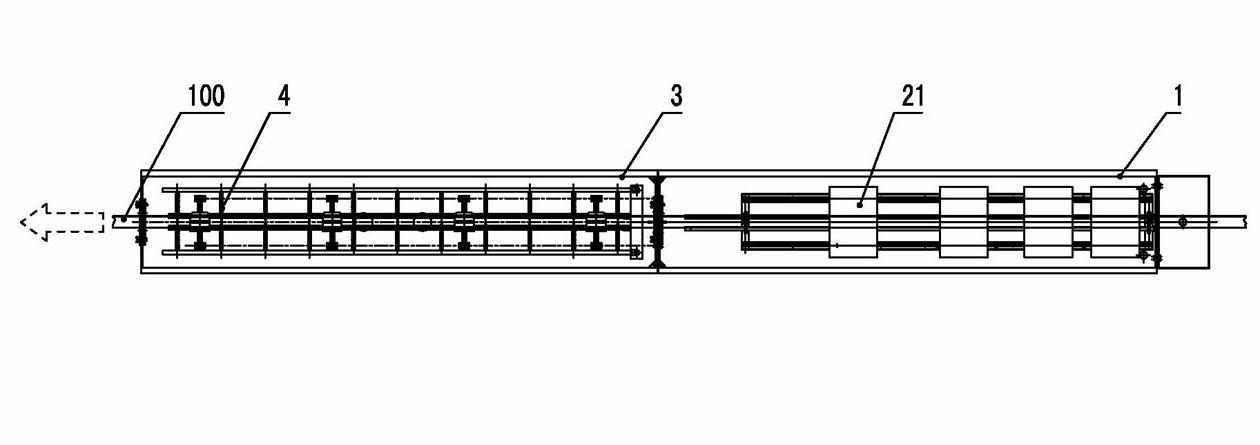

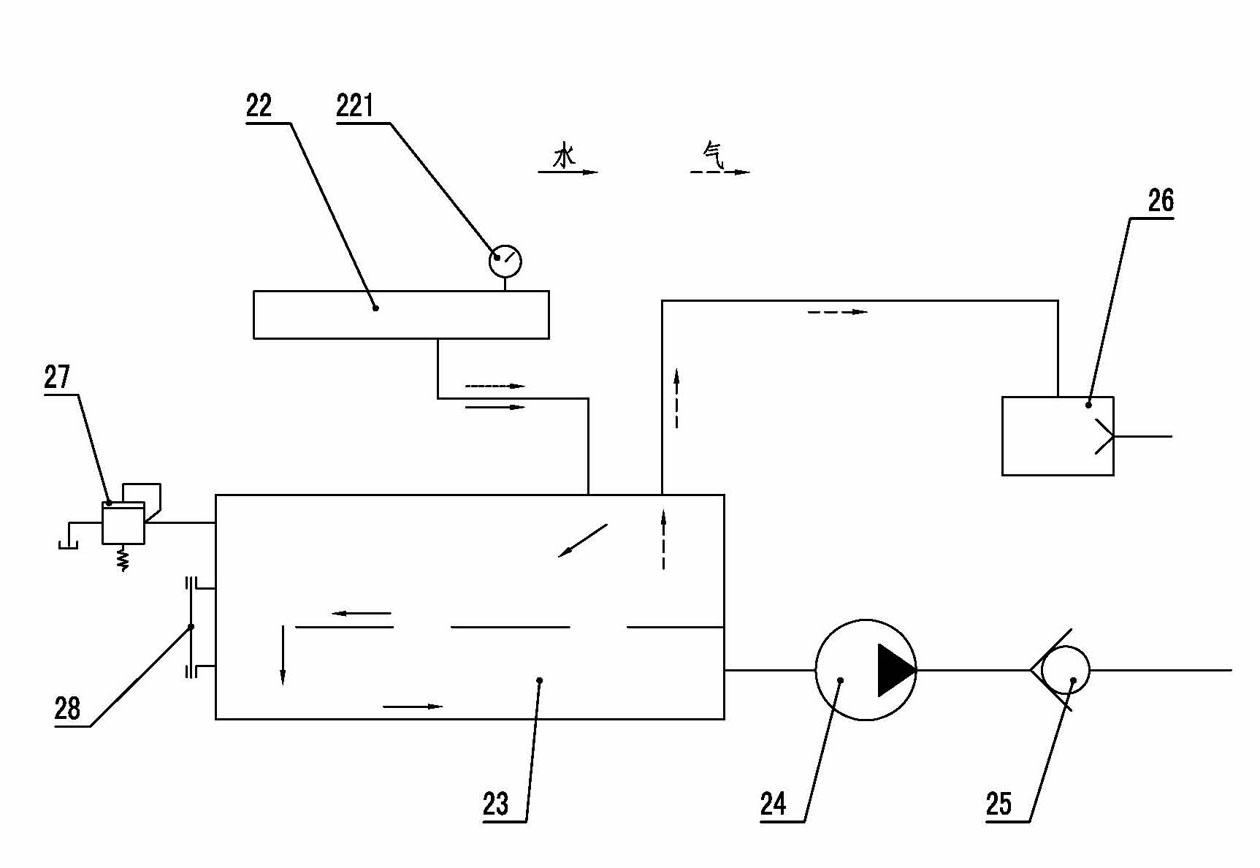

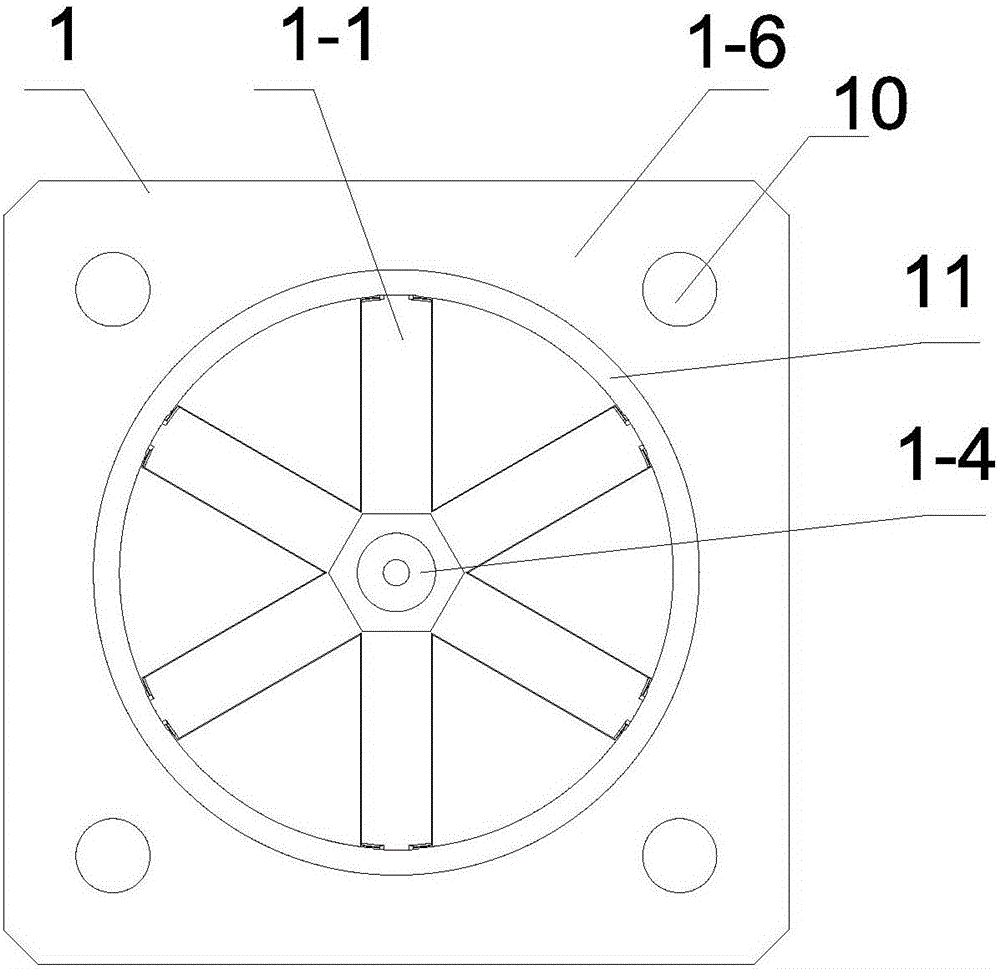

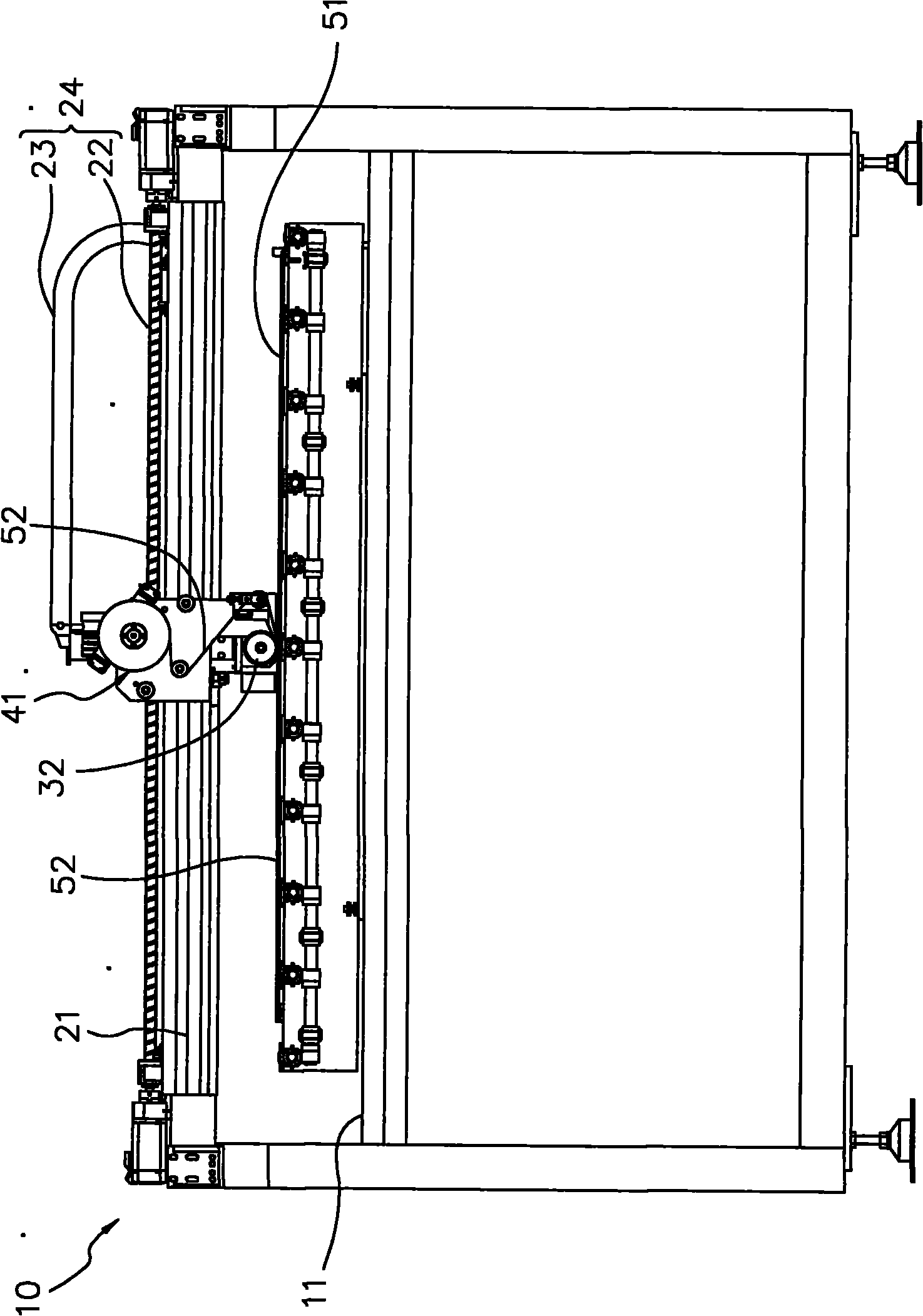

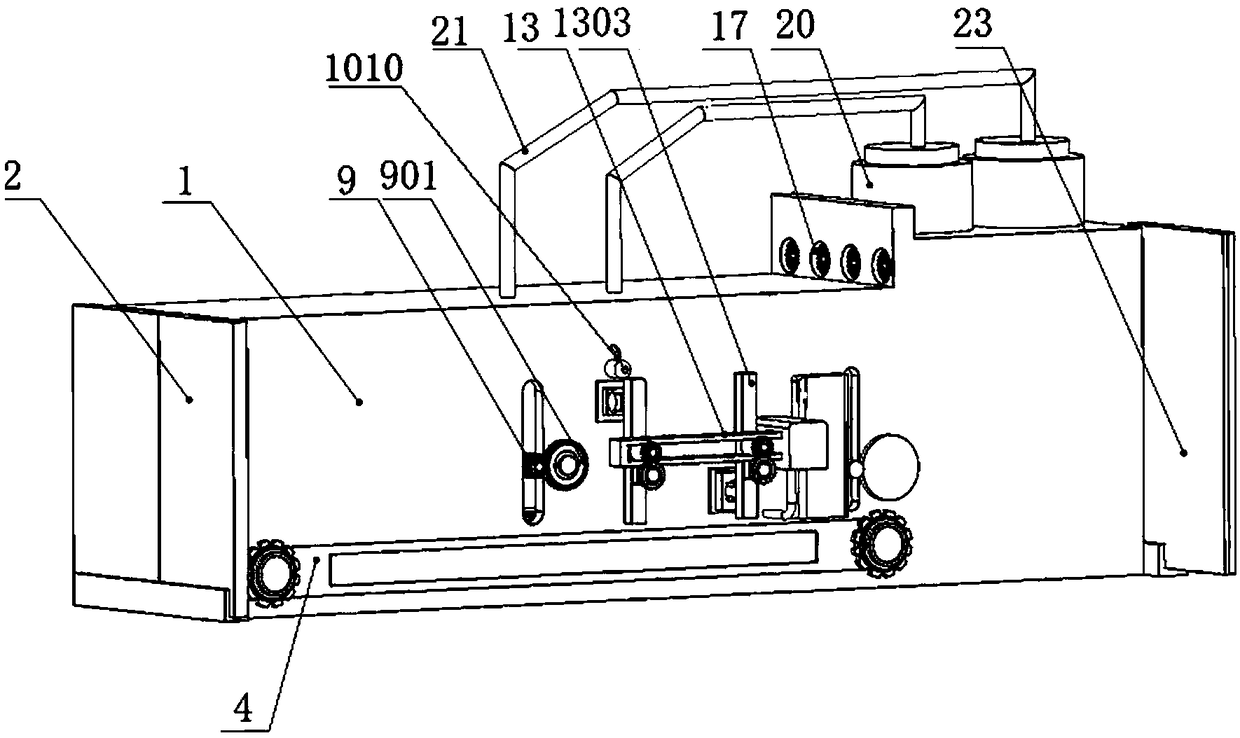

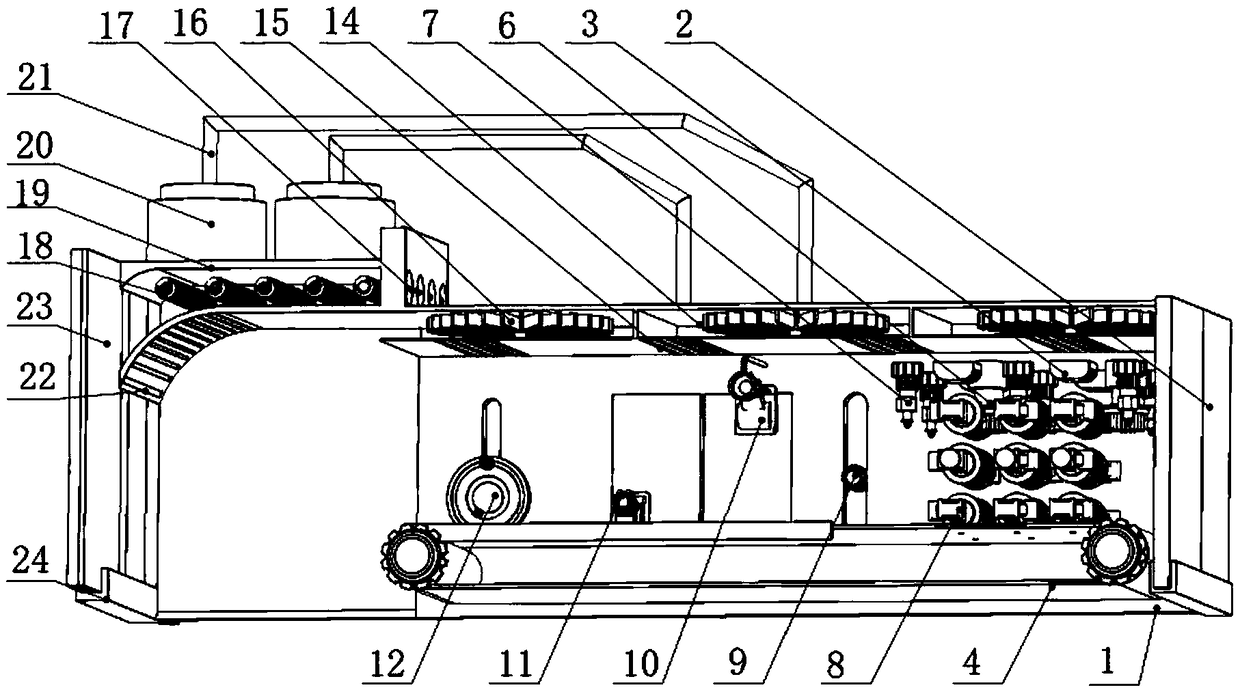

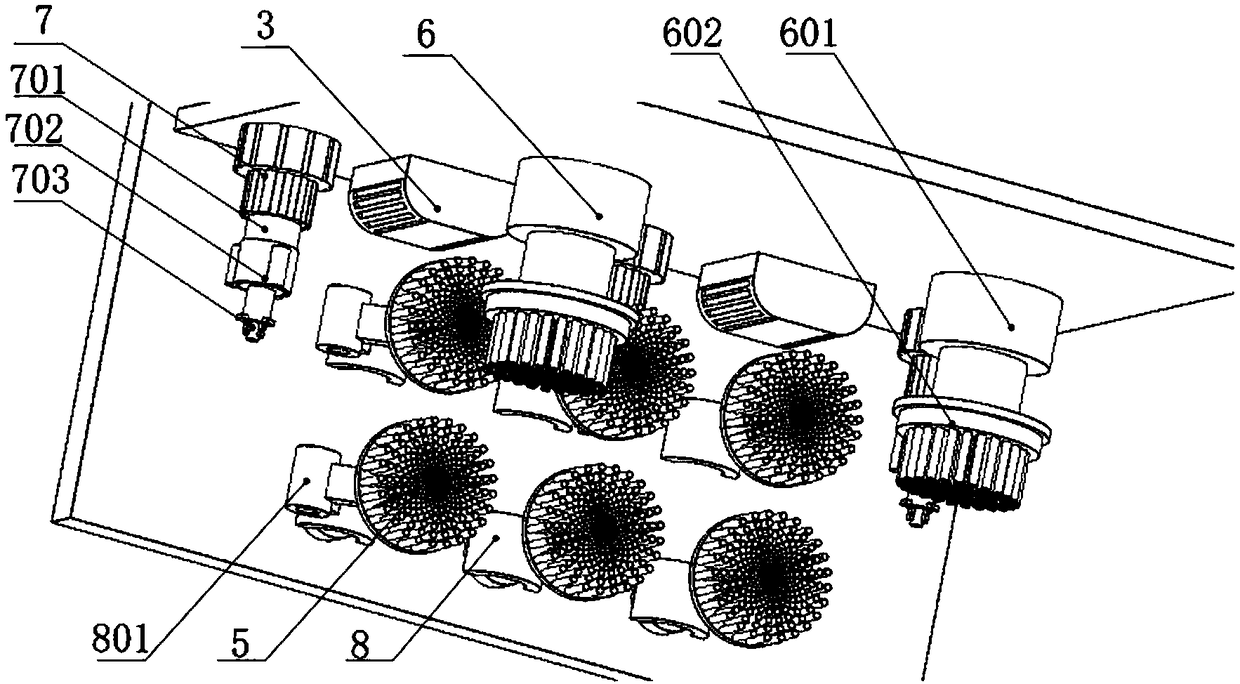

Forming equipment of extruding strip of plastic-steel winding tube

The invention relates to extrusion forming, and in particular relates to forming equipment of an extruding strip of a plastic-steel winding tube in the extrusion forming. The invention provides the forming equipment of the extruding strip of the plastic-steel winding tube, comprising a front water tank and a rear water tank, wherein the front water tank is provided with a vacuum forming mold; therear water tank is suspended with a spraying device; and the vacuum forming mold is connected with a vacuum pumping device. The equipment in the invention has the advantages of improving the cooling efficiency of the strip, and avoiding the deformation and irregular surfaces of the drawn strip.

Owner:HUAHAN SCI & TECH

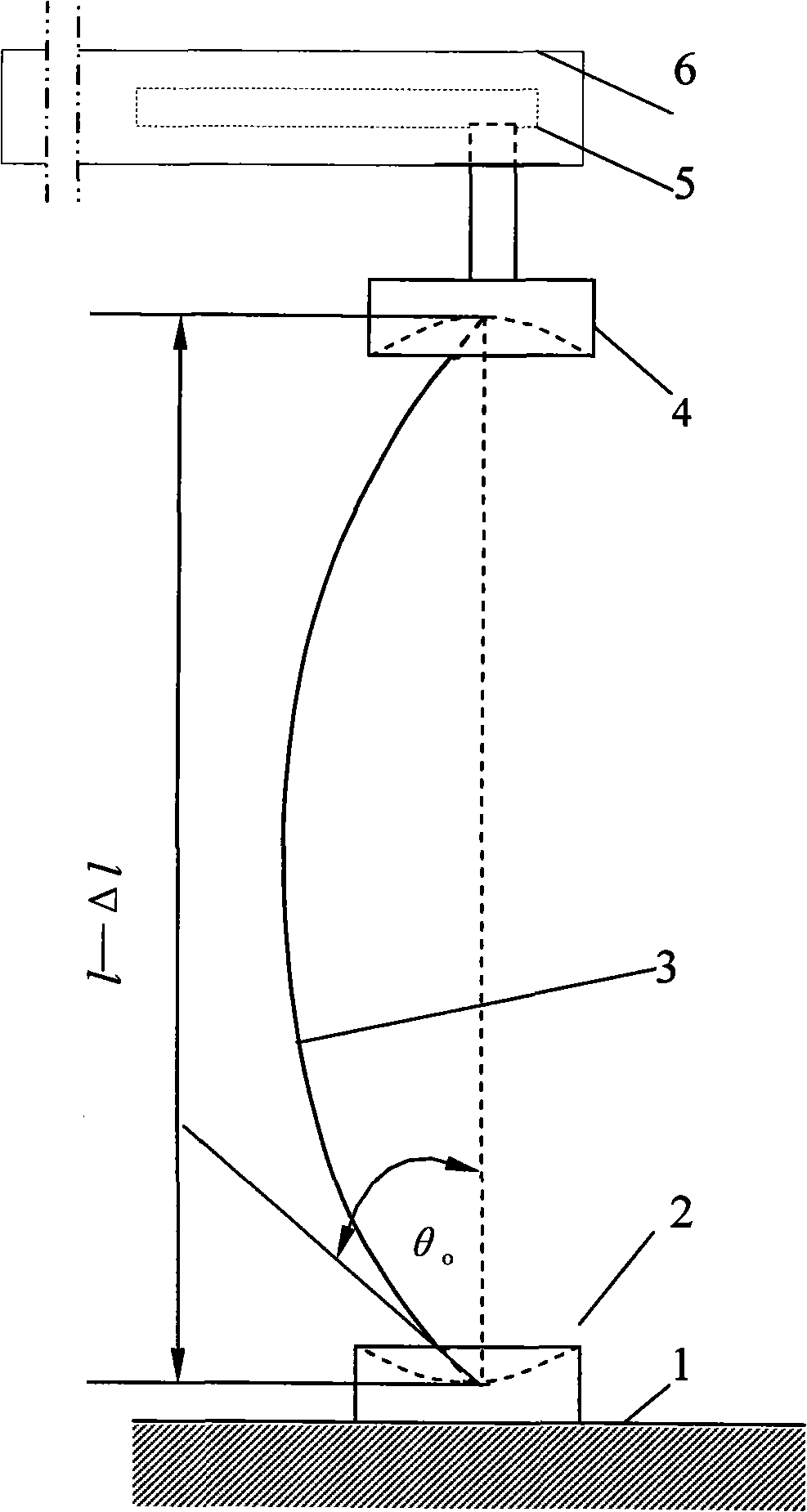

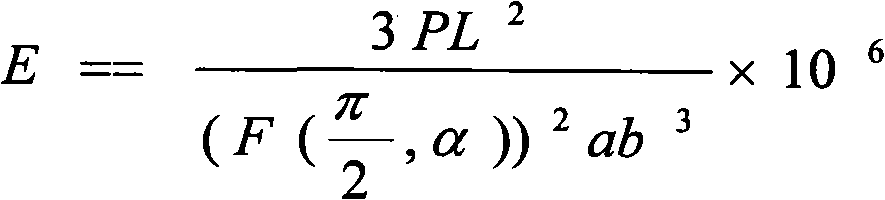

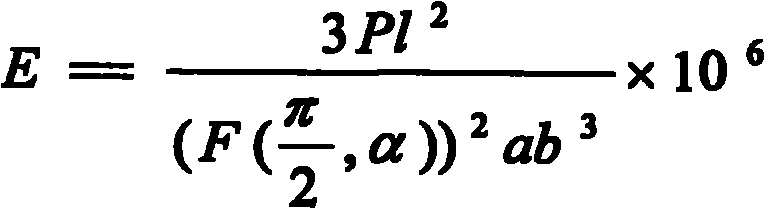

Fine dried noodles elasticity modulus measuring method based on pressure lever post-buckling

InactiveCN101526456AEasy to measureNoodle length is not limitedInvestigating material hardnessMeasurement deviceAxial compression

The invention discloses a fine dried noodle elasticity modulus measuring method based on pressure lever post-buckling. A load measuring device is installed firstly, a static pressure head of the load measuring device is fixed on a base, a force sensor is arranged on a movable arm of the load measuring device, and then a dynamic pressure head is fixedly connected with the force sensor; a certain number of fine dried noodles cut to have corresponding length are respectively arranged between the static pressure head and the dynamic pressure head; and the amount of movement of the dynamic pressure head is determined according to the length of the fine dried noodle and an set intersection angle of the end part of a twisted curve, then the load measuring device is started again, the dynamic pressure head is driven by the load measuring device to load the fine dried noodles in a speed of 0.01mm / s, load corresponding to the amount of movement of the dynamic pressure head is measured by the load measuring device, and at last the fine dried noodle elasticity modulus is counted by a formula relationship. The invention uses pressure lever stability principle and large deflection theory of mechanics of materials to establish the relationship of axial compression, the end part intersection angle and pressure, establishes a counting method of the fine dried noodle elasticity modulus, has simple and convenient measuring method and high precision, and can control the length of the fine dried noodle elasticity modulus to be between 60 mm and 220mm.

Owner:JIANGSU UNIV

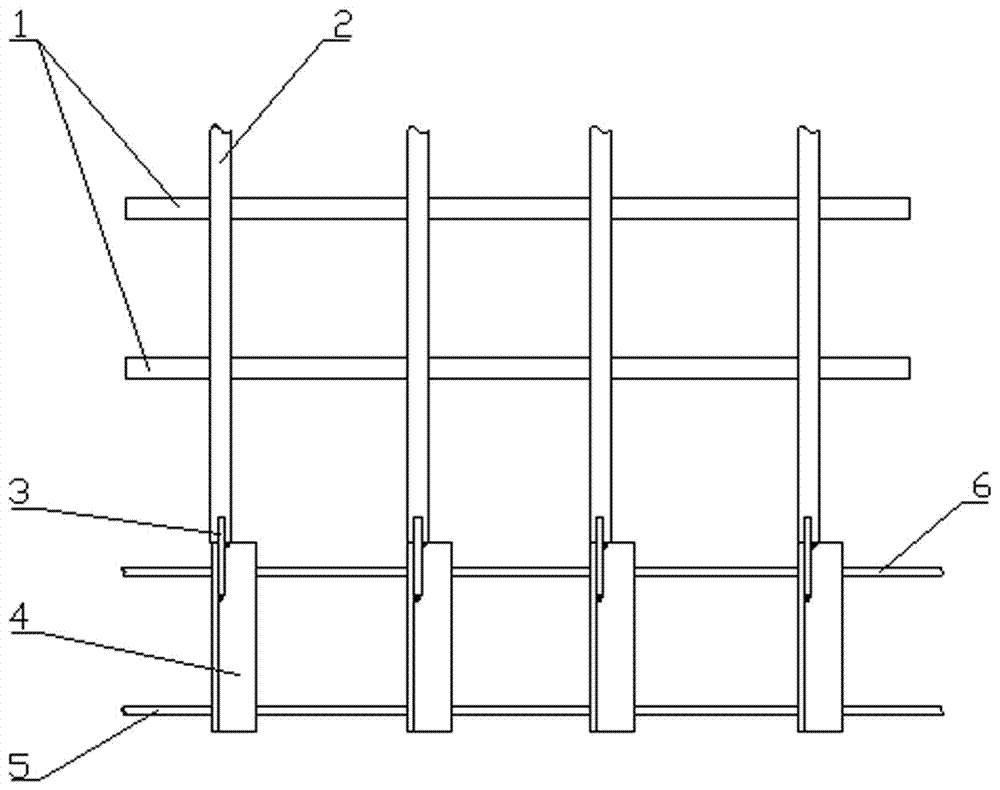

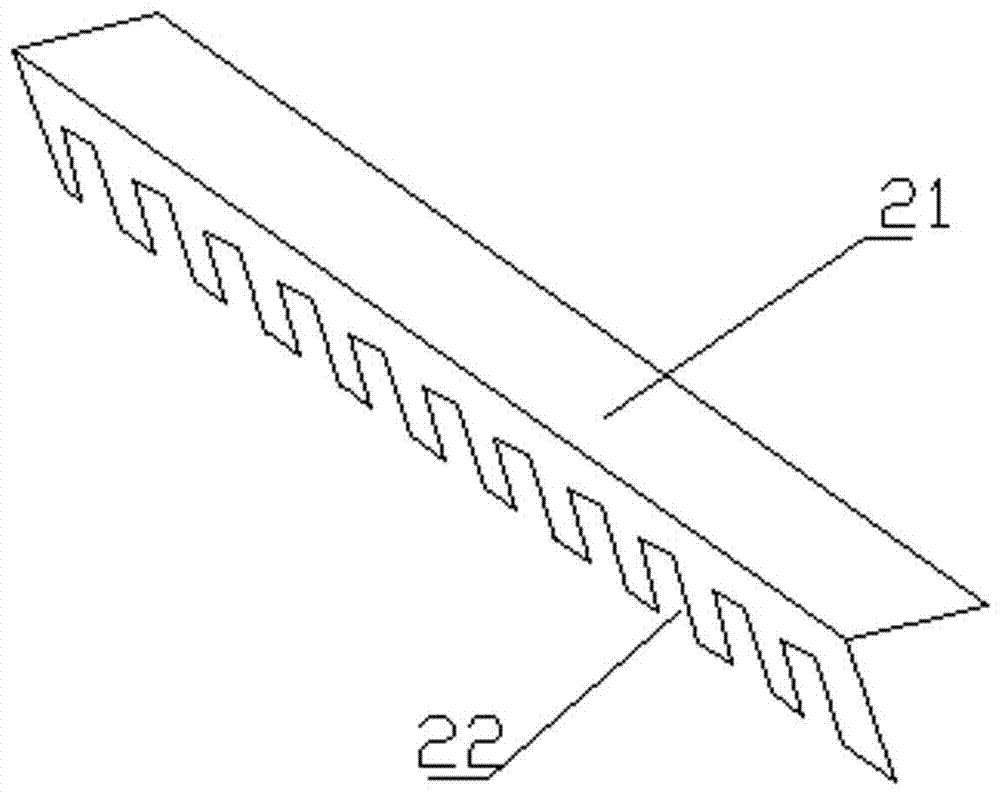

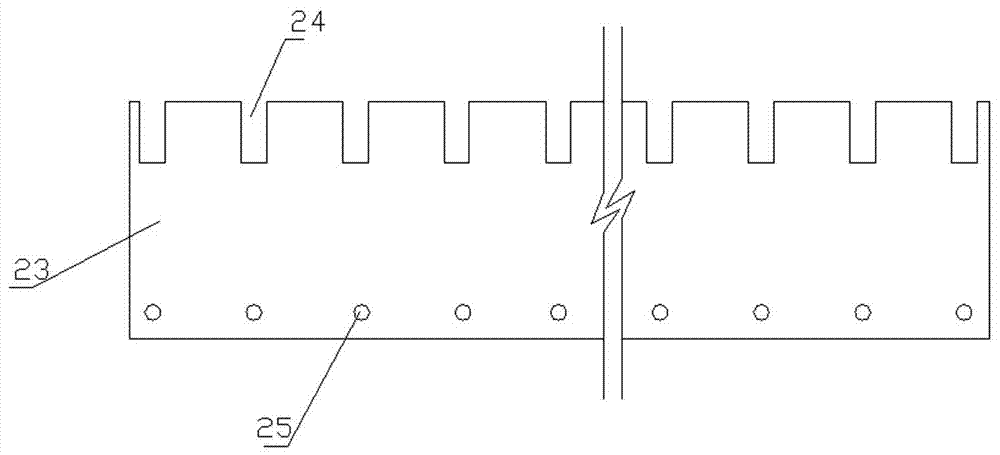

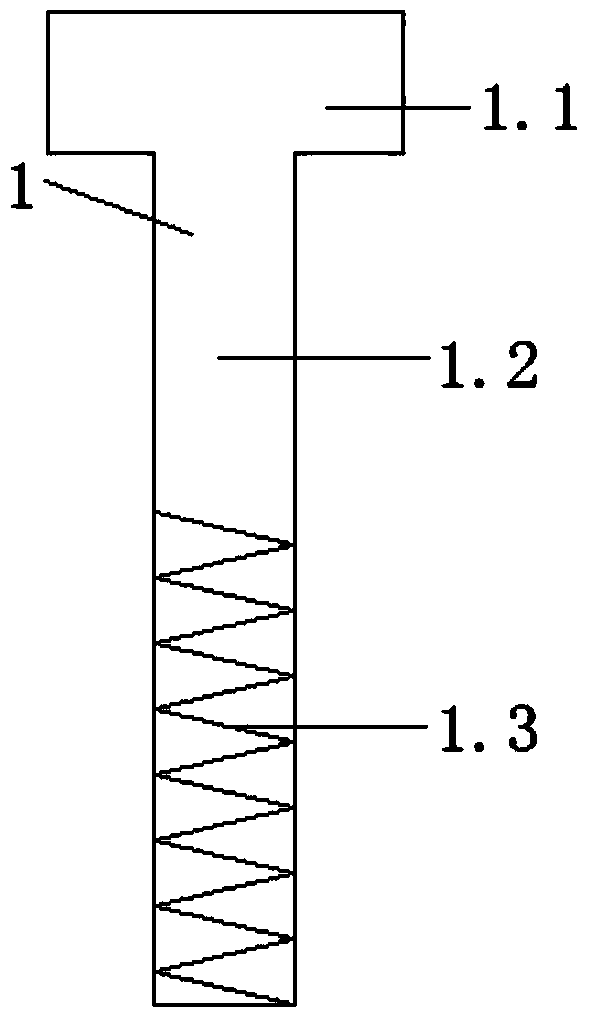

Construction method for strengthening construction quality of 0# block of cast-in-situ beam

PendingCN107574762AGood strengthAvoid flatnessBridge erection/assemblyBridge materialsPre stressContinuous beam

The invention belongs to the field of continuous beam construction, and provides a construction method for strengthening construction quality of a 0# block of a cast-in-situ beam. The problems existedin an existing 0# block construction method are solved. A detachable stiff skeleton is adopted to position a continuous beam bottom plate rebars and support a top plate during construction, and the top and the bottom of a vertical skeleton are detachable; precise positioning of the vertical layer distance and the horizontal distance of vertical rebars and horizontal rebars of the top plate of thecast-in-situ beam segment can be ensured by arranging an longitudinal and transverse angle steel clamping tool; positioning of all prestressed pipes of a section of a continuous beam is achieved by utilizing a position frame; controlling of the mounting angle of an anchor backing plate is achieved by presetting the mounting angle of an upper inclined plane of an anchor box and a vertical pluggingplate, so that the prestressed tensioning effect is improved by controlling an prestressed tendon axis to be perpendicular to the anchor backing plate; and material steel pipes on a construction siteare effectively and reasonably utilized as concrete material distributing channels and vibrating channels, and full in-place of concrete casting and timely in-place of vibrating are achieved by pre-embedding in advance of the channels.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

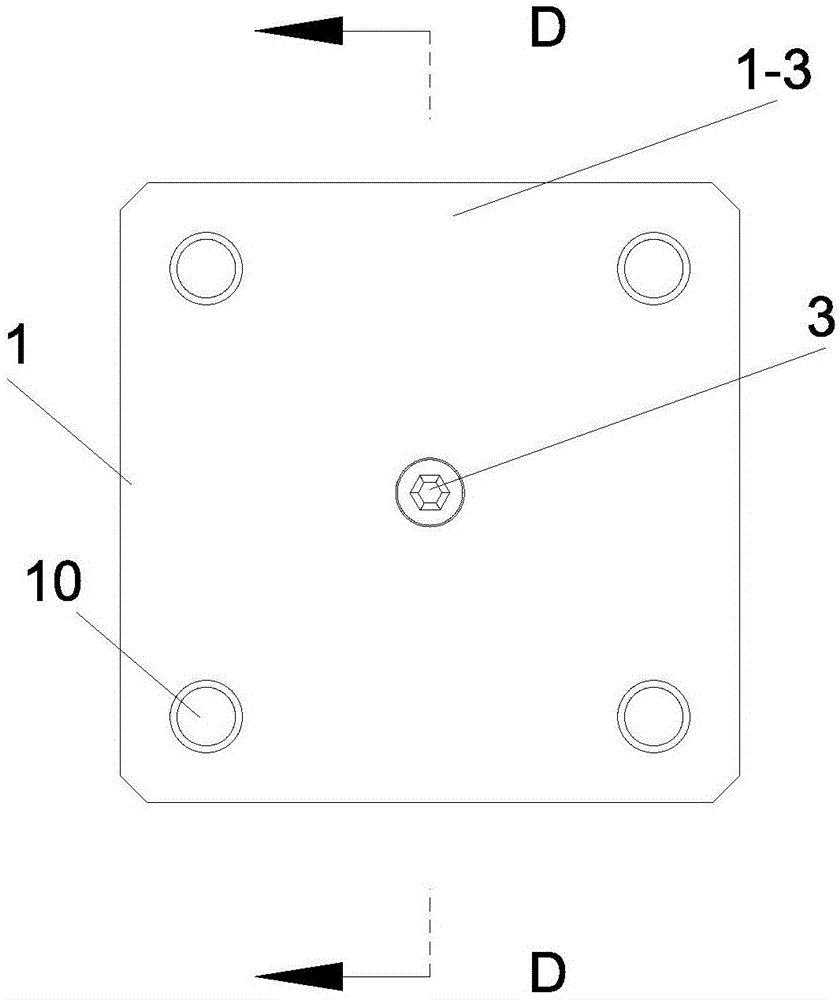

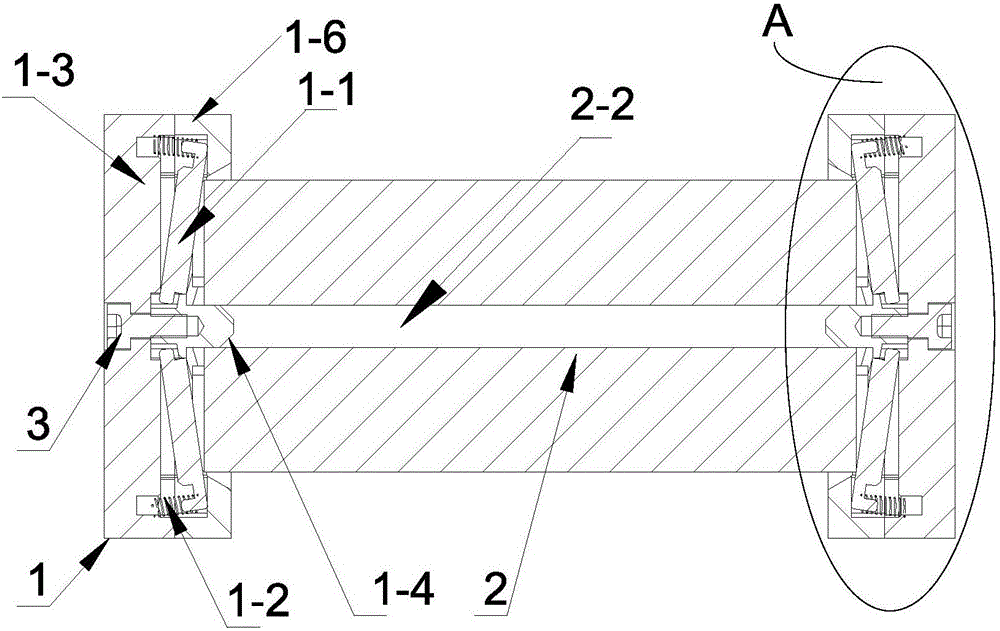

Fastening bolt for shear wall formwork

InactiveCN103993736AAvoid flatnessAvoid quality problemsAuxillary members of forms/shuttering/falseworksChinese charactersSlurry

The invention relates to a fastening bolt for a shear wall formwork. The fastening bolt comprises a pre-buried fastening bolt, a nut, a reinforcing connecting rod and a clamp shaped like a Chinese character 'shan'. The pre-buried fastening bolt comprises a head part and a rod body. Outer threads are arranged at the lower end of the rod body. Inner threads are arranged on the nut. The inner threads are matched with the outer threads at the lower end of the rod body. A nut sleeve pipe is arranged on the outer portion of the nut. The two ends of the reinforcing connecting rod are provided with outer threads. The inner threads of the nut and the outer threads of the reinforcing connecting rod are matched. A thread hole is formed in the middle of the clamp shaped like the Chinese character 'shan'. The size of the thread hole is matched with the outer threads of the reinforcing connecting rod. The fastening bolt has the advantages that the pre-buried fastening bolt is used on an outer wall construction seam part, cost is saved, the common quality problems that outer wall connection portions are not smooth, and slurry leakage happens are effectively avoided, the phenomenon that a support is not arranged on the outer wall formwork during reinforcing through a bottom thread hole is avoided, formwork reinforcing time is saved, and operation is safe and reliable.

Owner:CHINA RAILWAY CONSTR GROUP

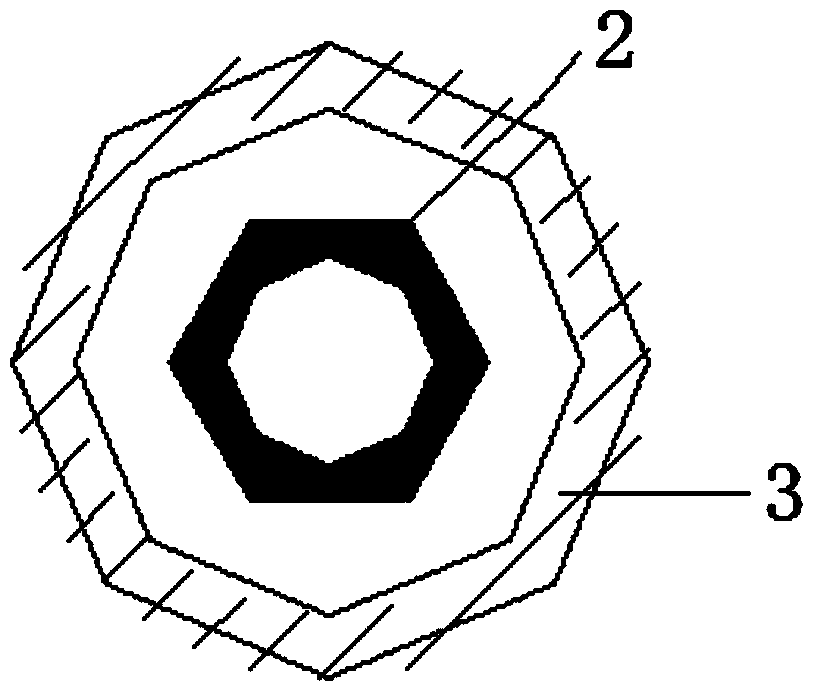

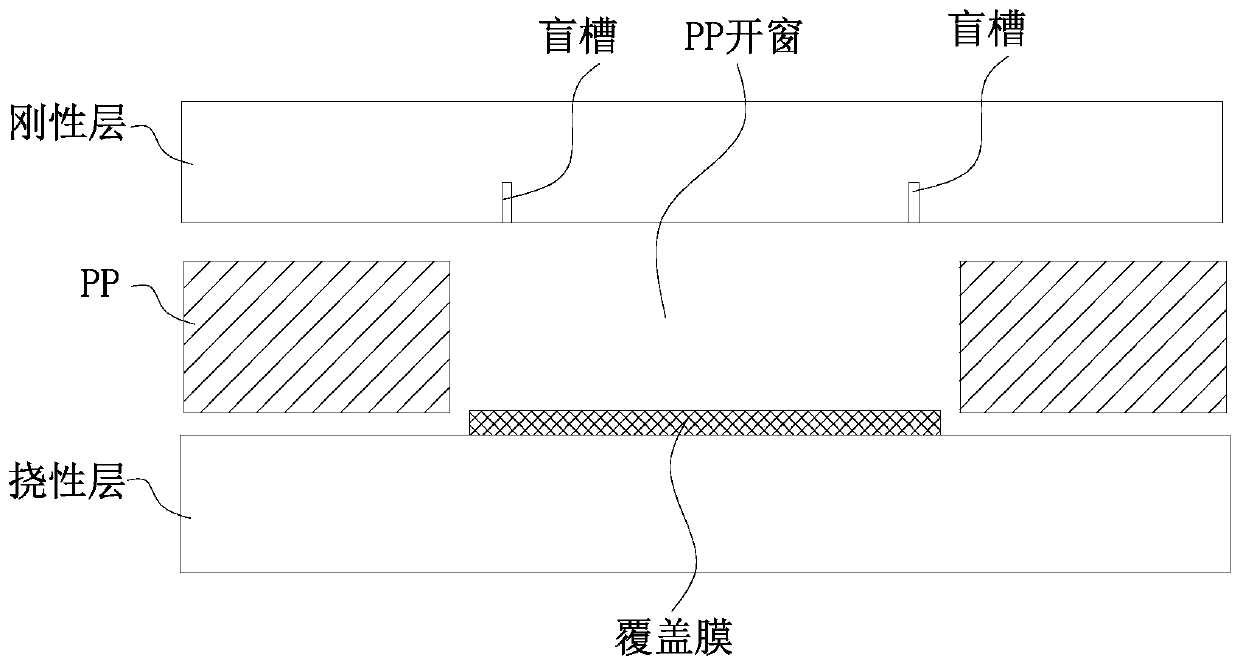

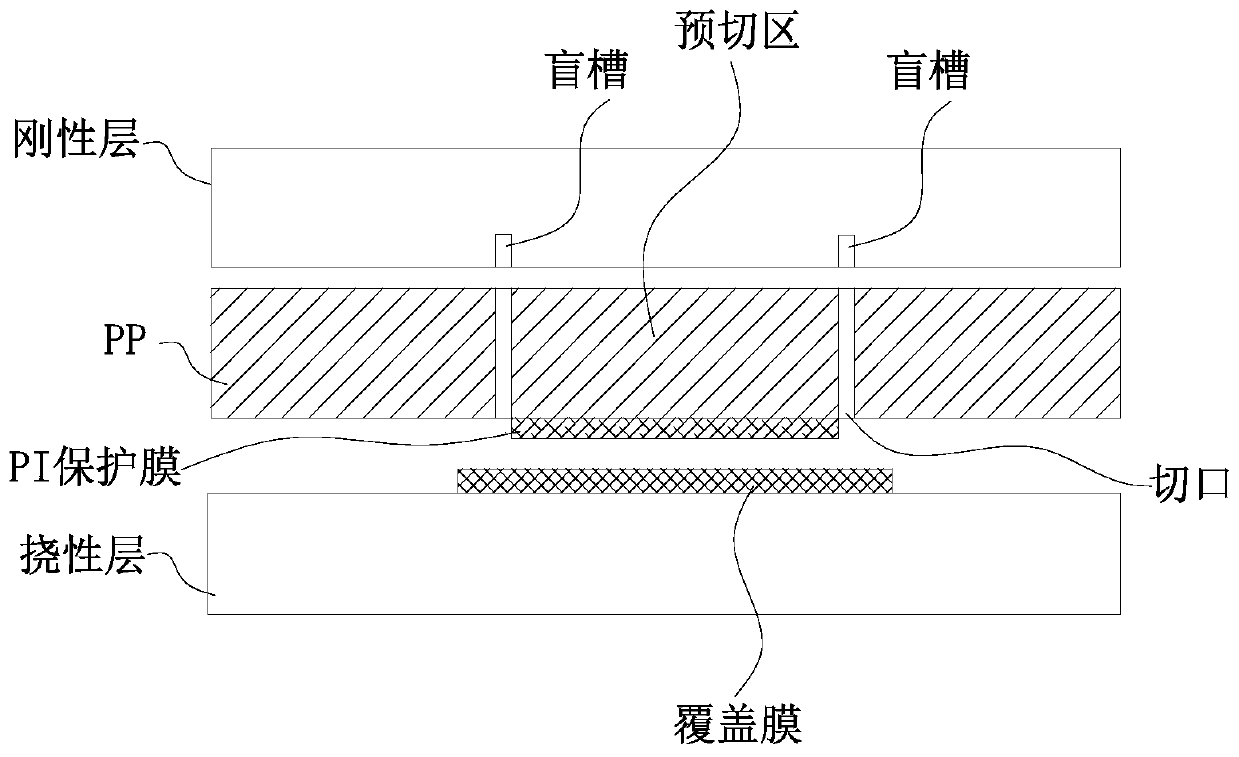

Manufacturing method of rigid-flexible combined board

InactiveCN110678011AGuaranteed binding effectAvoid the formation of protrusions on the pressing surfacePrinted circuit assemblingMultilayer circuit manufactureAdhesiveWindow opening

The invention relates to the technical field of printed circuit boards, in particular to a manufacturing method of a rigid-flexible combined board. According to the invention, the press-fit structureis changed and a pp window does not need to be formed in a prepreg in the press-fit process; a PI protective film is attached to a pre-cutting area. During the press-fit process, the prepreg does notneed to be contracted inwards, so that the sufficient flowing adhesive is provided to ensure the bonding effect of the rigid-flexible layer and a problem of overflowing of the excessive flowing adhesive to the pp window, that is, binding to the flexible area is solved. Besides, with no PP window, a flatness problem of protruding or recession on the press-fit surface due to the window height falling difference caused by the PP window in the prior art is solved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

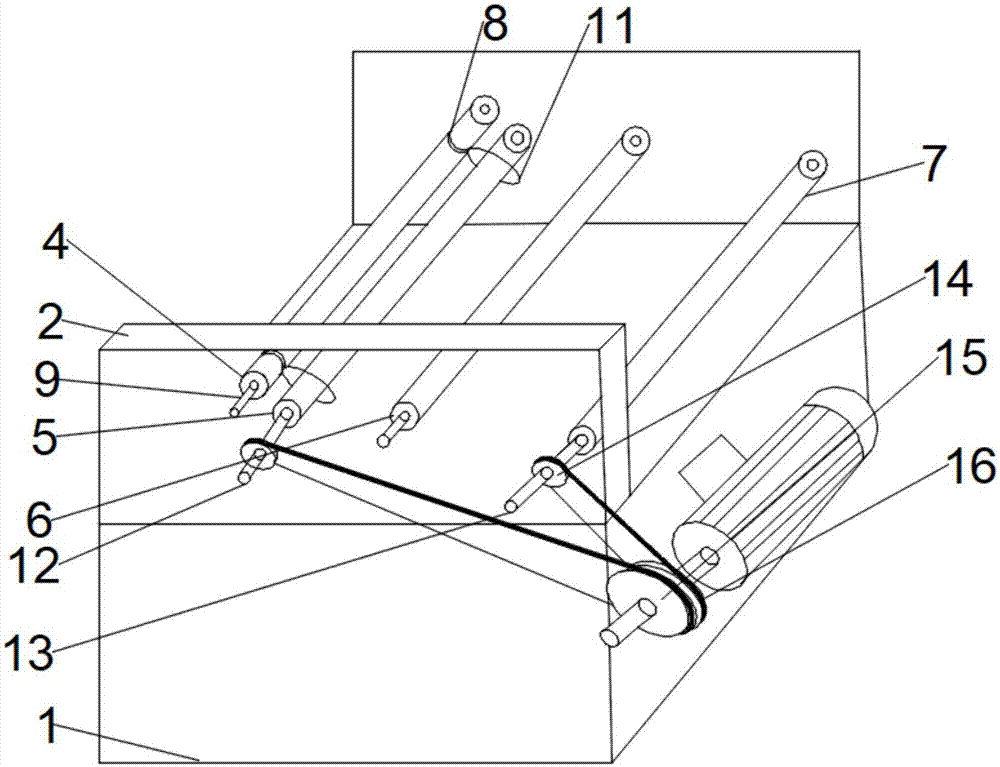

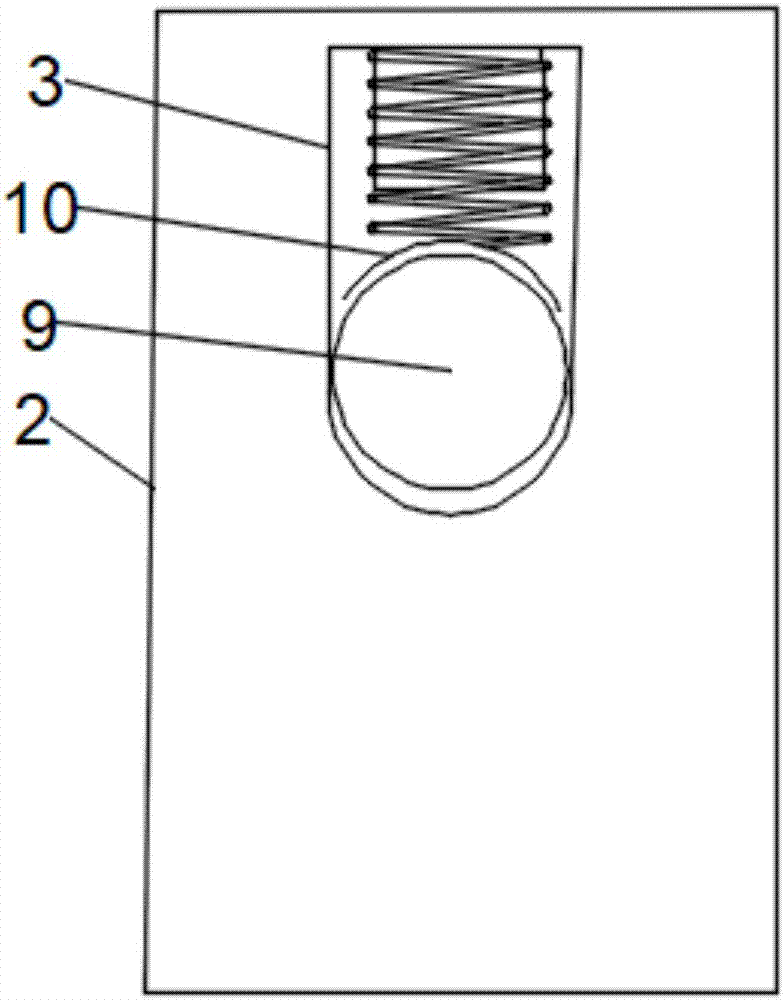

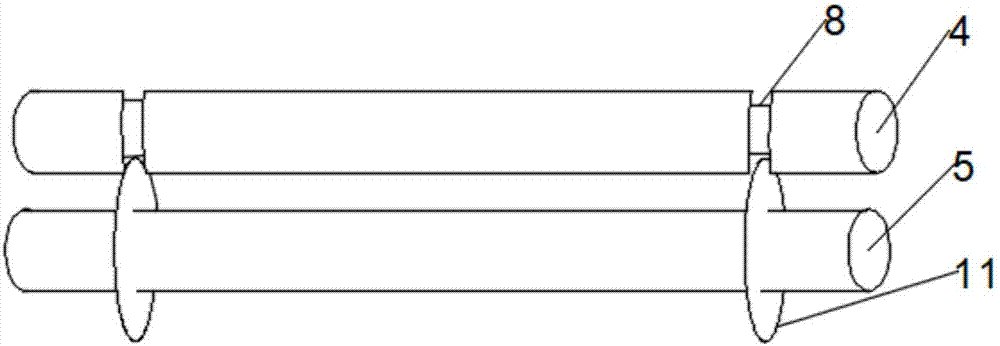

Woven cloth edge cutting device of textile machine

InactiveCN107503103APrevent deviationAvoid flatnessSevering textilesEngineeringMechanical engineering

The invention discloses a woven cloth edge cutting device of a textile machine. The device comprises a support, two mounting plates in parallel are mounted on the top of the support, and a pinch roller, a cloth conveying roller, a supporting roller and a cloth rolling roller are mounted between the two mounting plates from left to right in sequence; grooves are formed in both ends of the side surface of the pinch roller, and annular blades are fixedly mounted on the side surface of both ends of the cloth conveying roller; a first roller shaft and a second roller shaft are fixedly mounted at two ends of the cloth conveying roller and the cloth rolling roller respectively, a first hub is fixedly mounted at one end of the first roller shaft, a motor hub is connected to the first hub through a belt, and a second hub is connected to the motor hub through a belt. Through the design of the two annular blades on the cloth conveying roller, cutting irregularity or cutting incompleteness caused by cloth deflection is prevented, and the efficiency and speed of edge cutting are greatly improved; the height of the pinch roller is adjustable through a height adjusting device, the applicability is wider, the structure is simple, and the production cost of the cloth is reduced.

Owner:安徽嘉利网业织造有限公司

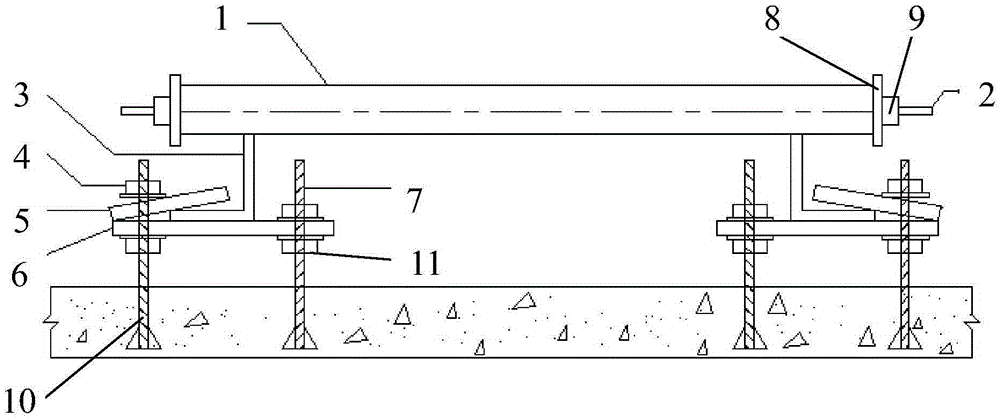

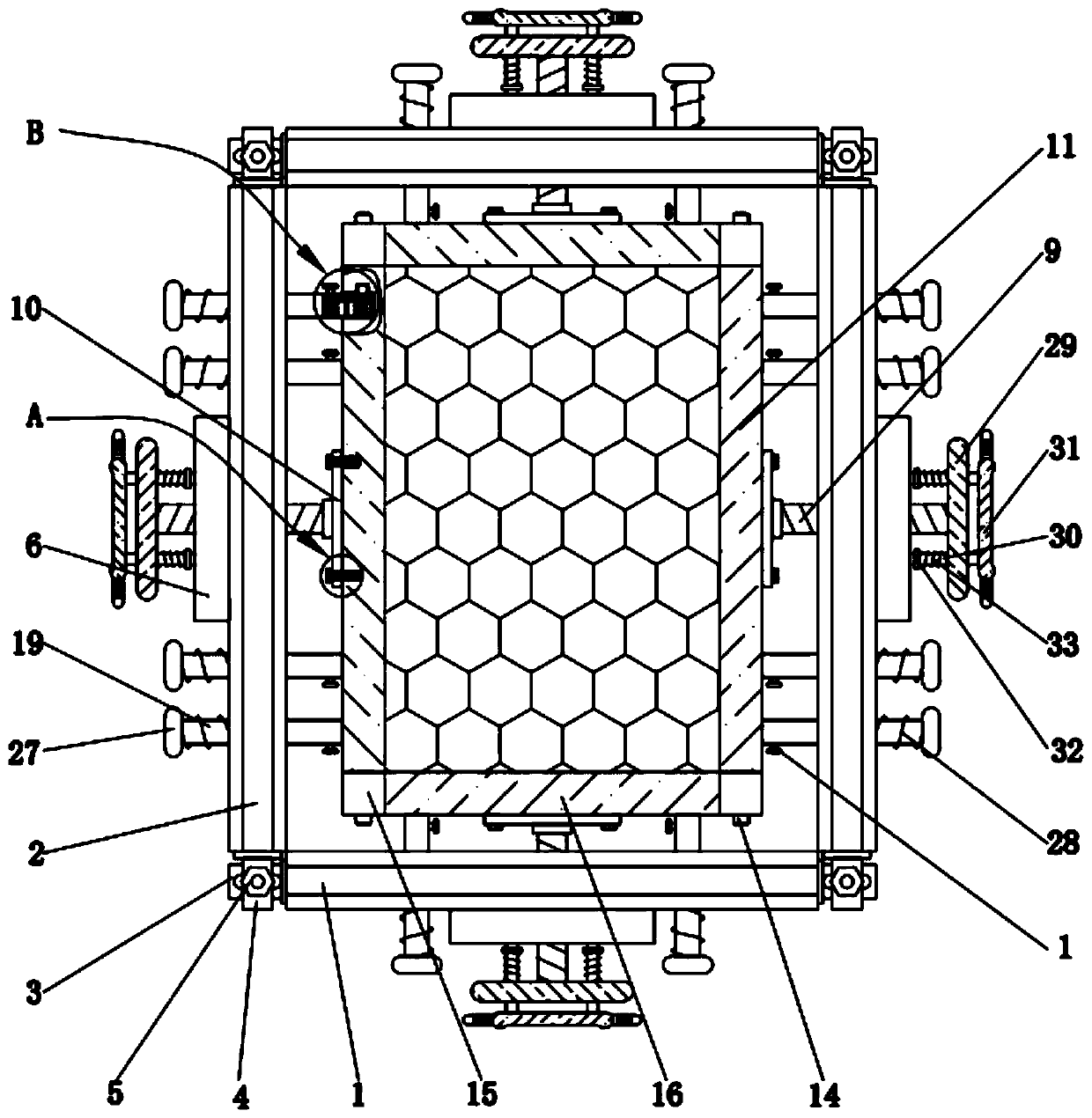

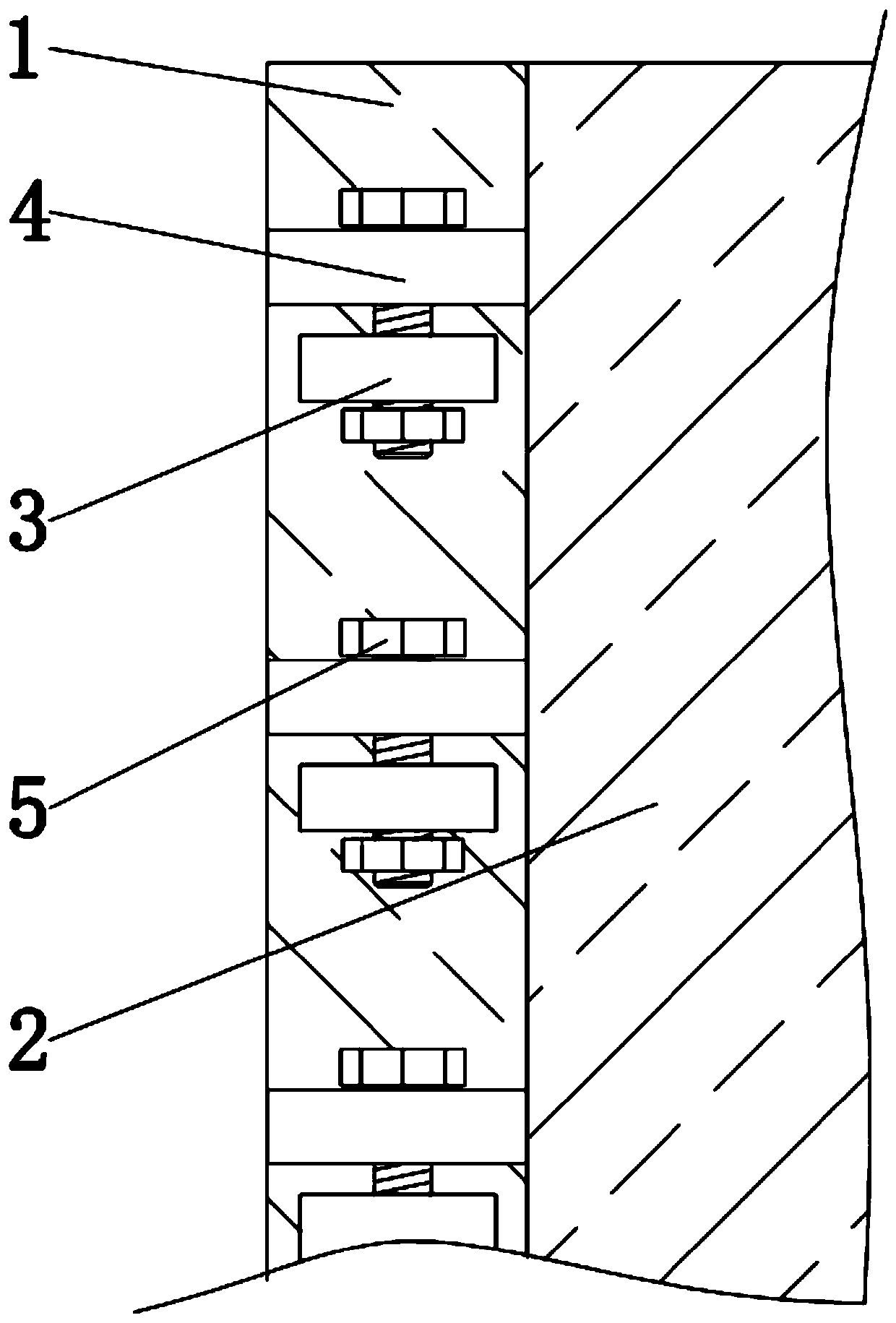

Device for leveling super-flat floor and method for conducting super-flat floor construction through device

ActiveCN105421776AImprove construction qualitySimple structureBuilding material handlingPre stressCushion

The invention discloses a device for leveling a super-flat floor. The device is arranged on a concrete cushion layer of the super-flat floor, the concrete cushion layer is divided into multiple bar-shaped areas, and the device comprises prestress darby slickers, angle bars, backing plates, pressing plates and multiple pairs of bolts with the height adjustable; a pair of holes which are formed in a spaced mode are formed in each side of each bar-shaped area at the interval of 1.5-2.0 m, a pair of the bolts with the height adjustable are fixedly installed in each pair of holes respectively, each backing plate is fixedly installed on the corresponding bolt at each side of each bar-shaped area, each backing plate is fixedly provided with the corresponding angle bar, the length of each backing plate and the length of each angle bar are equivalent to the length of the concrete cushion layer, and the two ends of each prestress darby slicker are placed on the angle bars at the two sides of the corresponding bar-shaped area. The invention further discloses a method for constructing a super-flat floor through the device. The device is simple in structure and convenient to manufacture, the high flatness of the floor can be guaranteed in the floor construction process, and floor construction quality is improved.

Owner:MCC TIANGONG GROUP

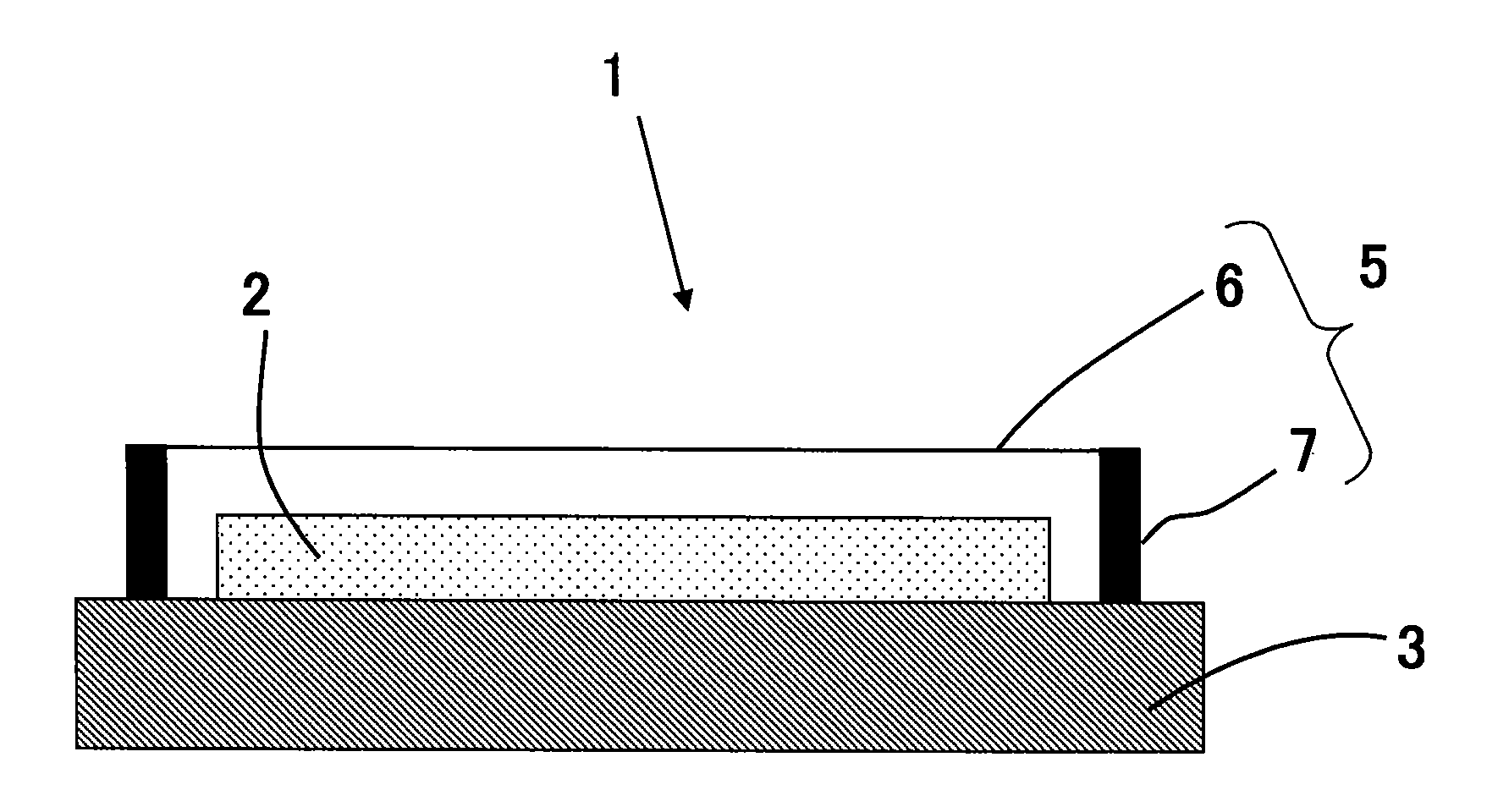

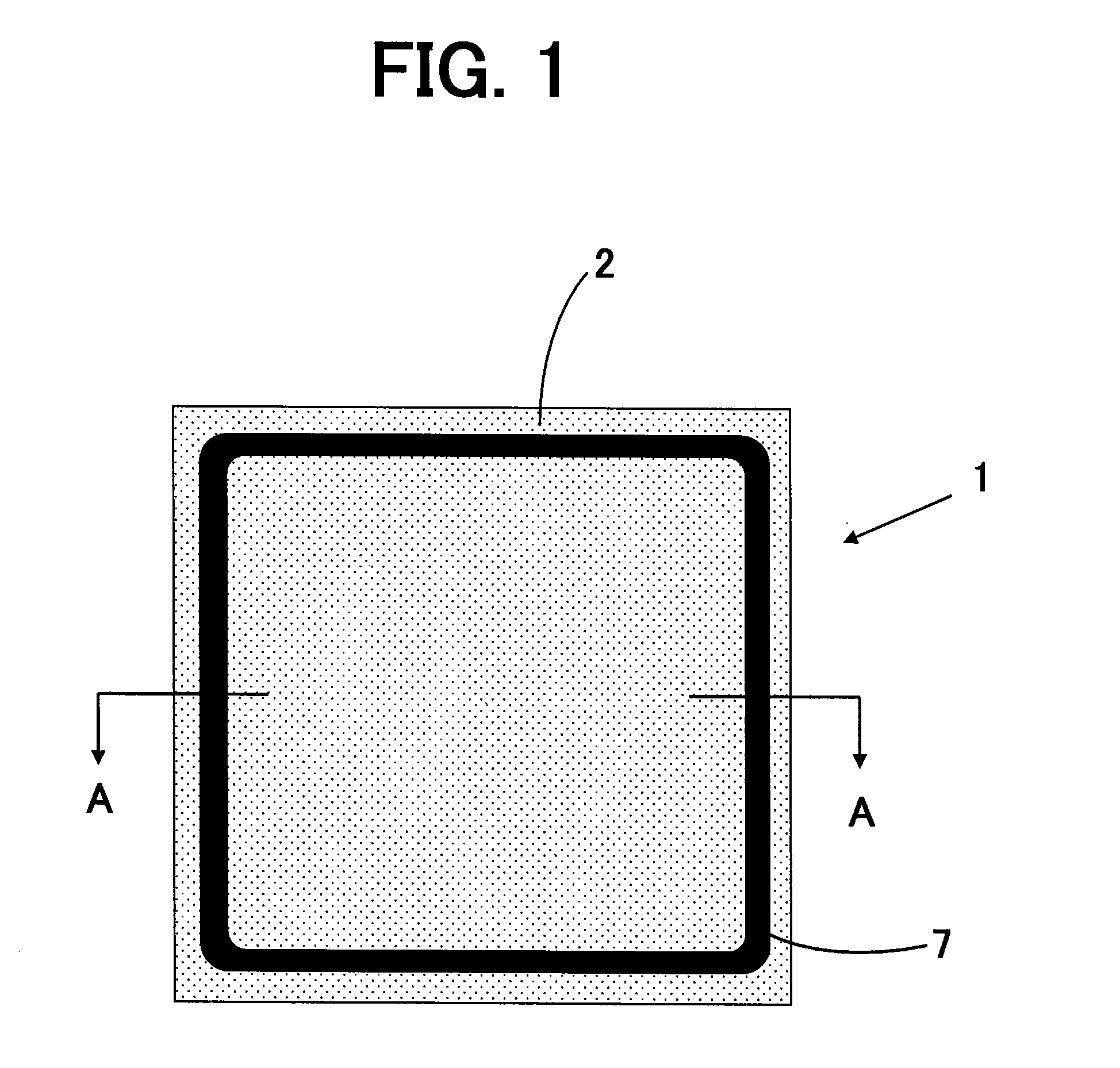

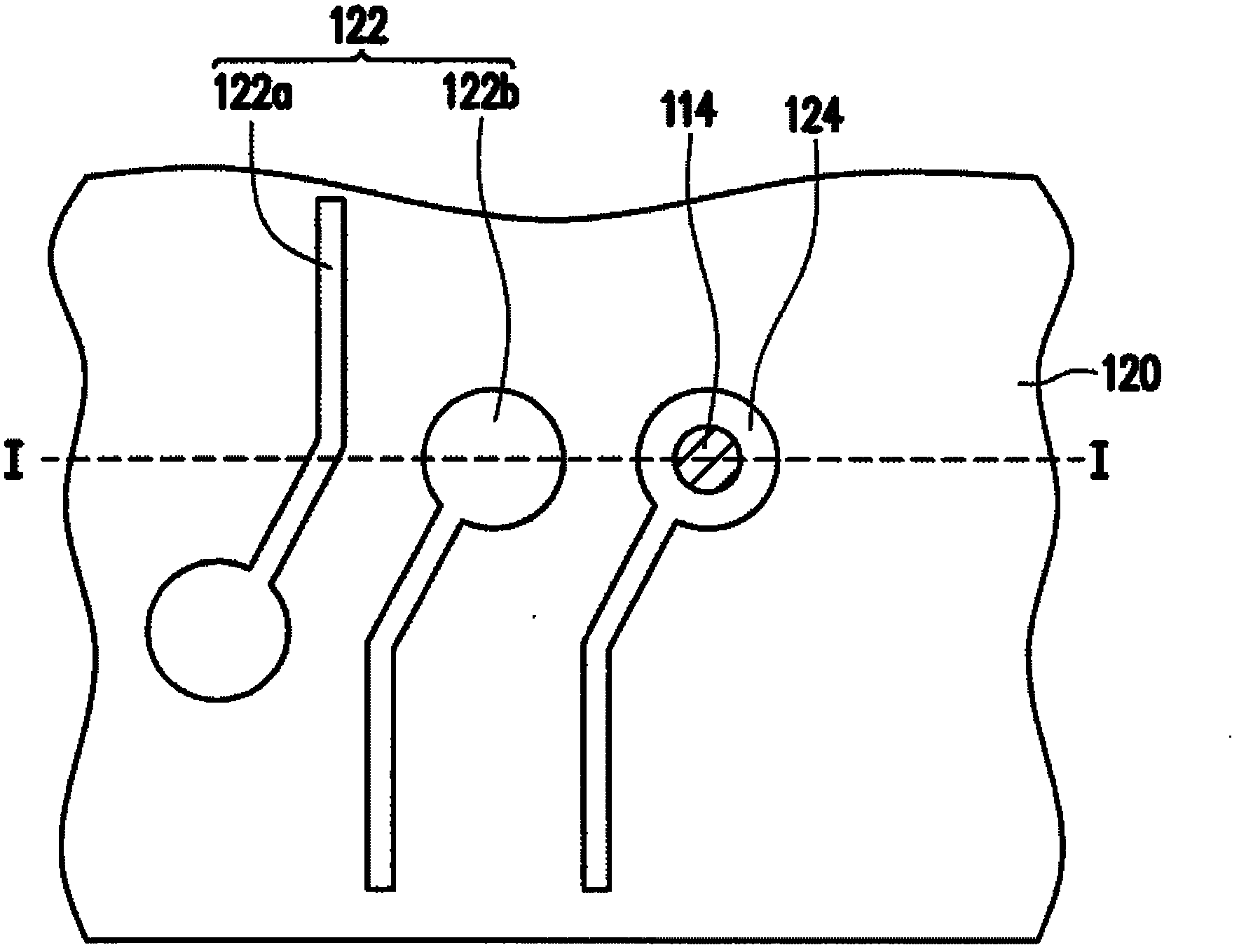

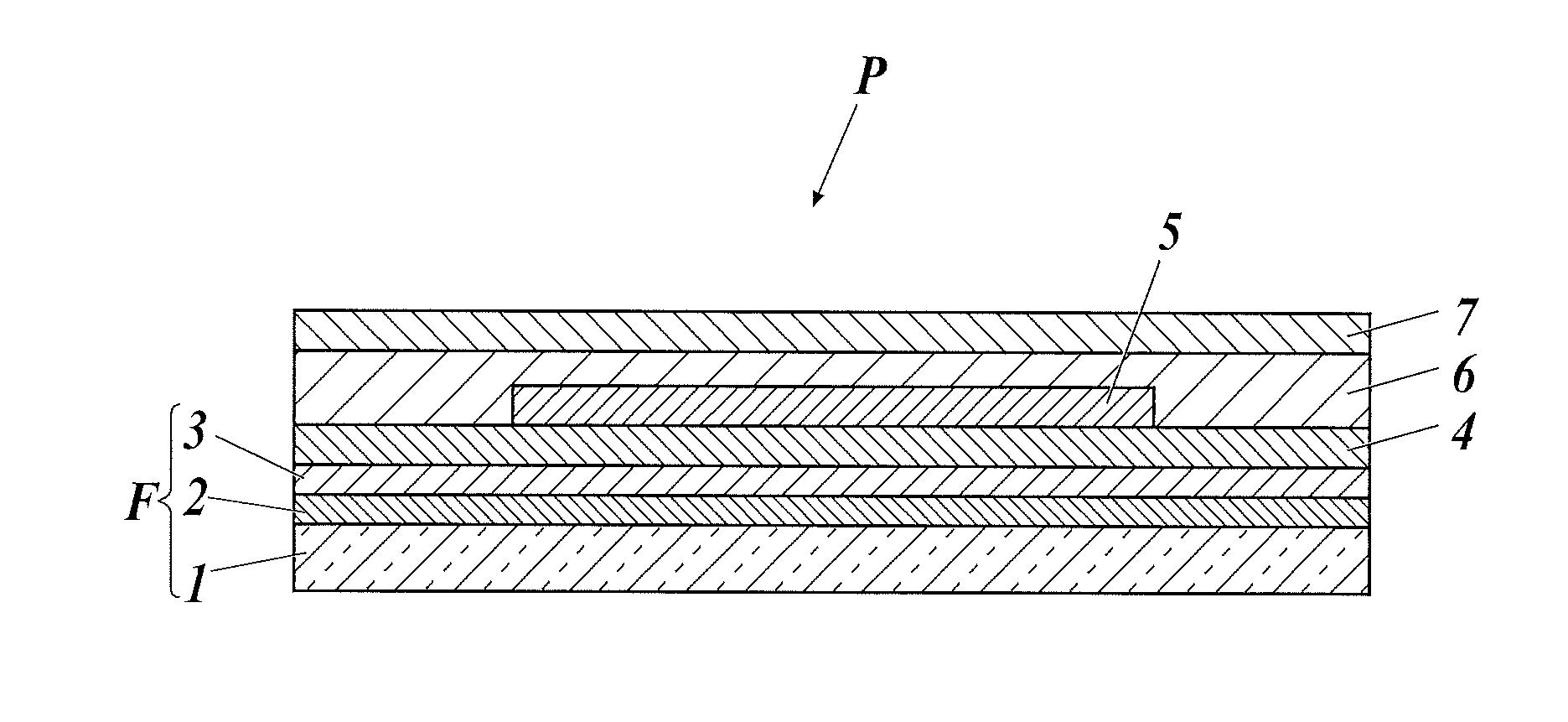

Photo mask unit comprising a photomask and a pellicle and a method for manufacturing the same

InactiveUS20130003036A1Avoid flatnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistEngineering

It is an object of the present invention to provide a photomask unit suitable for forming a microscopic pattern of 32 nm or smaller on a photoresist film using the EUV exposure technique and being able to reliably prevent the flatness of a photomask from being lowered. The photomask unit 1 according to the present invention includes a pellicle membrane 6, a pellicle frame 7 onto one surface of which a region of the pellicle membrane 6 in the vicinity of side portions of the pellicle membrane 6 is fixed, a photomask 2 and a stage 3 onto one surface of which the photomask 2 and the pellicle frame 7 are fixed, and the pellicle frame 7 is fixed onto the stage 3 at a region outside of a region of the stage 3 onto which the photomask 2 is fixed.

Owner:SHIN ETSU CHEM IND CO LTD

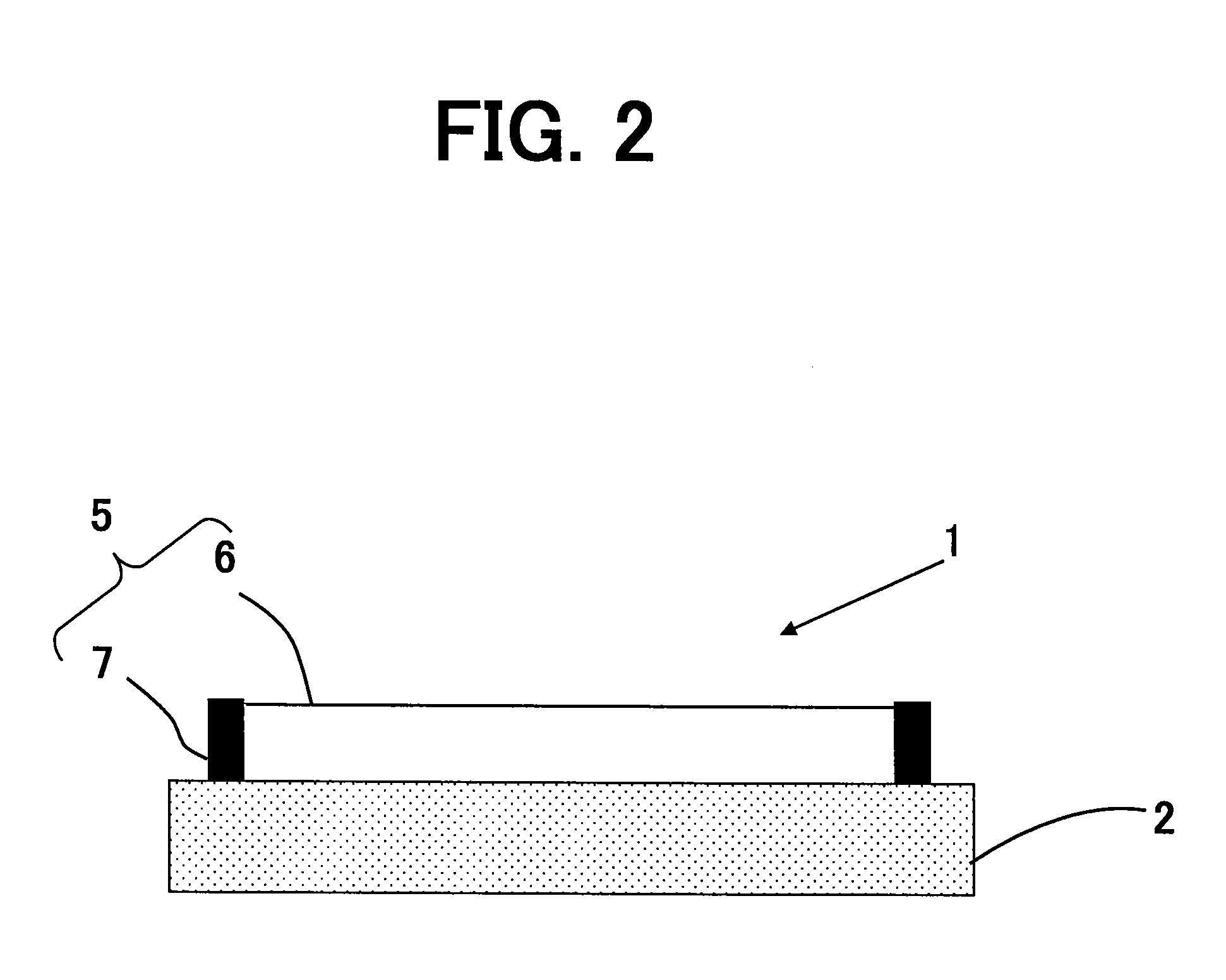

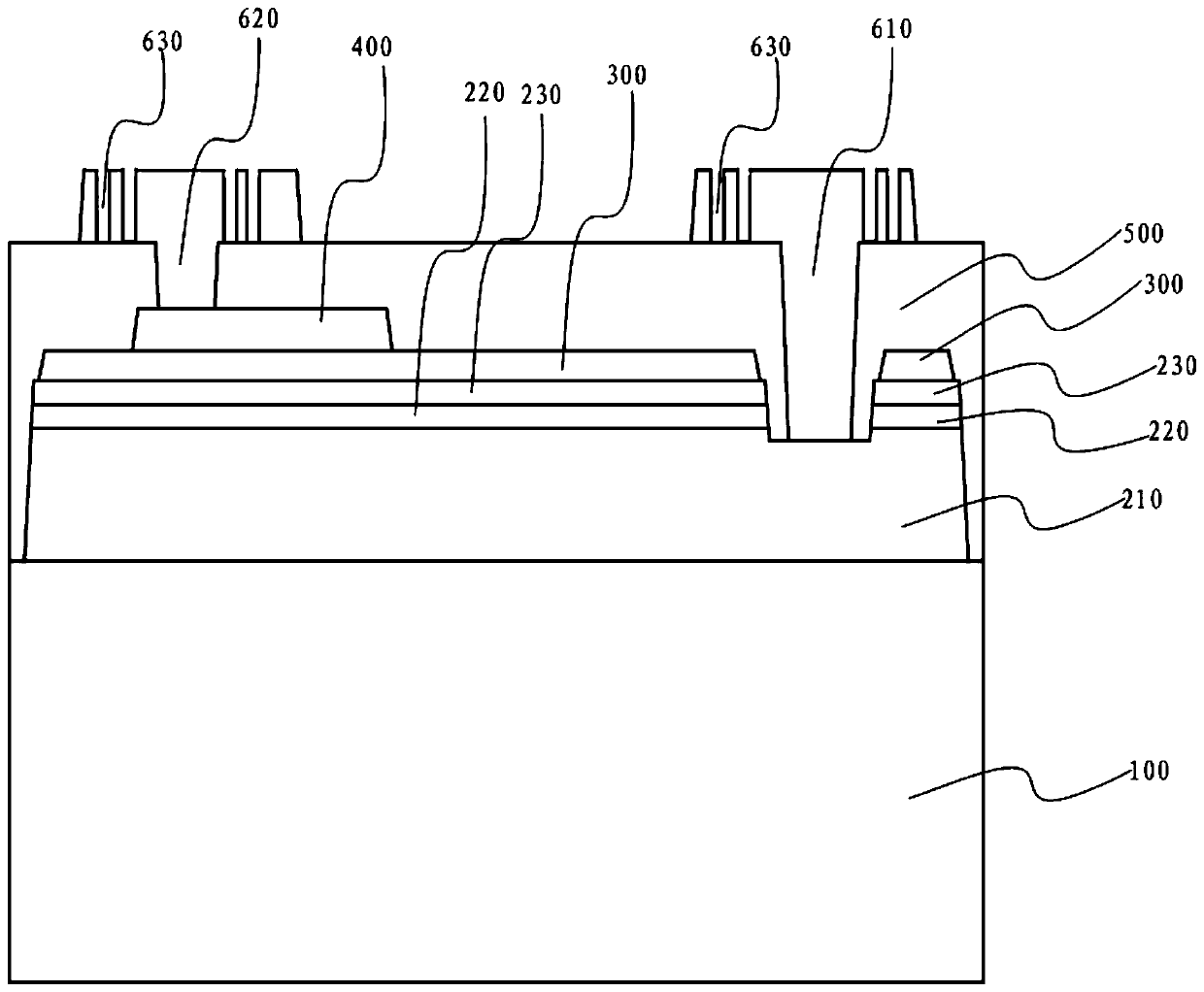

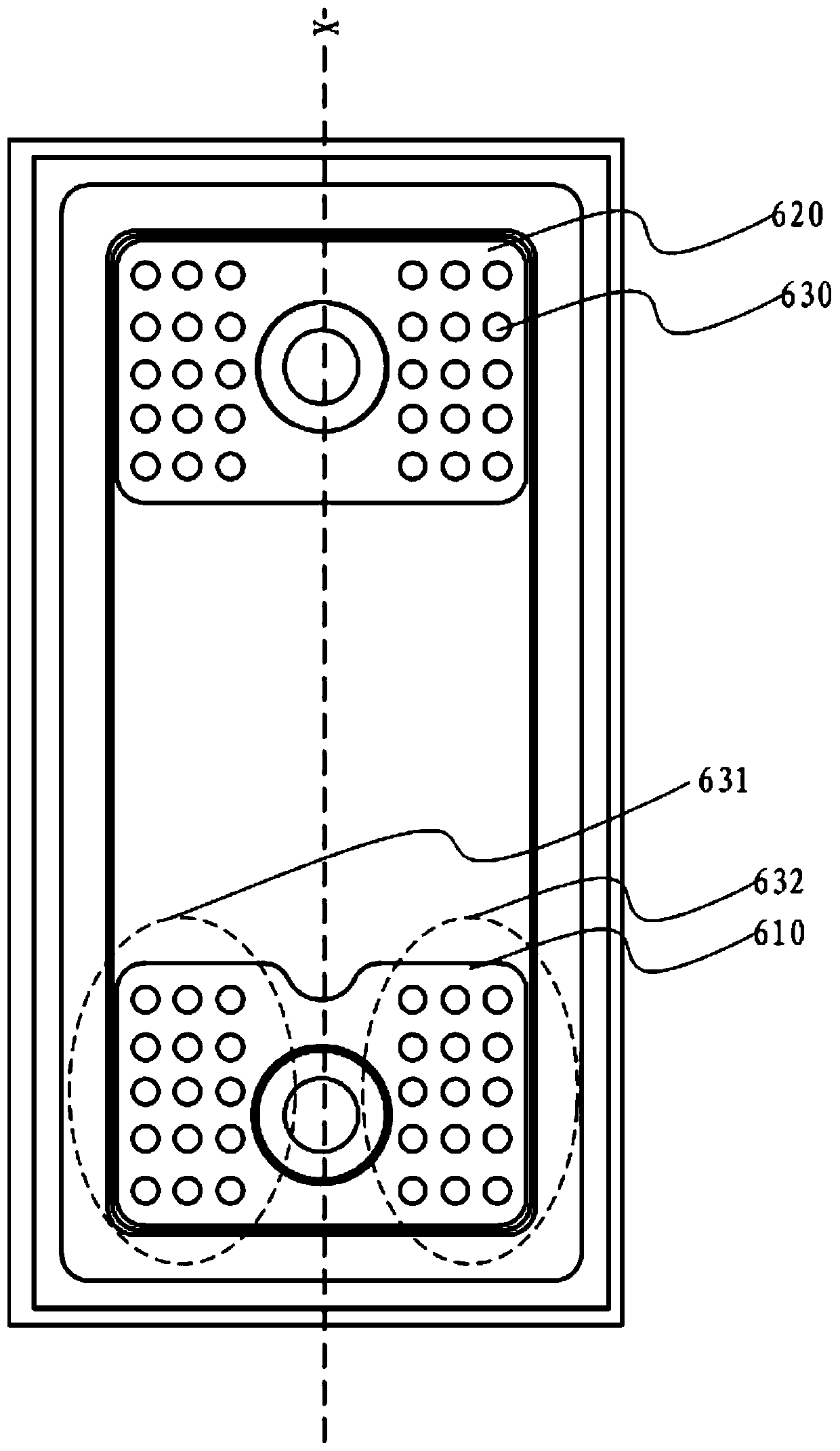

Mini LED chip and manufacturing method thereof

InactiveCN110931620AAvoid footprint issuesIncrease the areaSemiconductor devicesPhysical chemistryEngineering

The invention provides a Mini LED chip and a manufacturing method thereof. The first auxiliary extension electrodes are located between the first type semiconductor layer and the first bonding electrodes and are not connected through the corresponding auxiliary extension electrodes. That is to say, no auxiliary extension electrode is manufactured on the surface of the exposed first-type semiconductor layer at the electrode contact hollowed-out part, so that the problem that the area occupied by the electrode contact hollowed-out part is enlarged due to the existence of the auxiliary extensionelectrode is avoided, the area of a light-emitting region is large, and the light-emitting efficiency of the Mini LED chip is improved. Further, according to the technical scheme provided by the invention, an auxiliary extension electrode does not need to be manufactured; therefore, the problems that the flatness of the prepared first bonding electrode is poor and the coverage effect of the insulation isolation reflection layer is poor due to the existence of the auxiliary expansion electrode are avoided, the reliability of the Mini LED chip is improved, and the light-emitting angle of the Mini LED chip is ensured to achieve an expected effect at the same time.

Owner:XIAMEN CHANGELIGHT CO LTD

Construction method with supports and templates in single side of arc shear wall

ActiveCN109208790ASide pressure ensuresGuarantee molding qualityWallsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a construction method with supports and templates in the single side of an arc shear wall, and belongs to the technical field of architectural engineering. The method comprisesthe steps of measurement and line layering, steel bar installation, manufacturing the templates of the arc shear wall, assembling and fixing the templates, fixing the bottoms of the templates in theouter sides, erecting supports, concrete pouring and dismounting the templates and supports. The large templates are used to reduce splicing seams of the templates, reduce template assembling time andaccelerate construction; the customized arc templates of a steel and plastic combined template system are used to reduce the deviation of arc degree and verticality, and the engineering quality is improved; the bottom is fixed by split bolts and compressed by square strips in the lower, the template stability is improved, template displacement is reduced, and conditions including slurry leakage,surface unevenness, template expansion and staggering of the bottom of the exterior wall are avoided; a triangular steel pipe truss system of the wall uses steel pipes, fasteners and template steel bar back ribs for fixation, inclination of the templates is controlled and the safety is improved; and the large steel-plastic templates and the triangular steel pipe truss system are used repeatedly sothat energy is saved, the environment is protected and the cost is reduced.

Owner:WENZHOU CONSTR GROUP

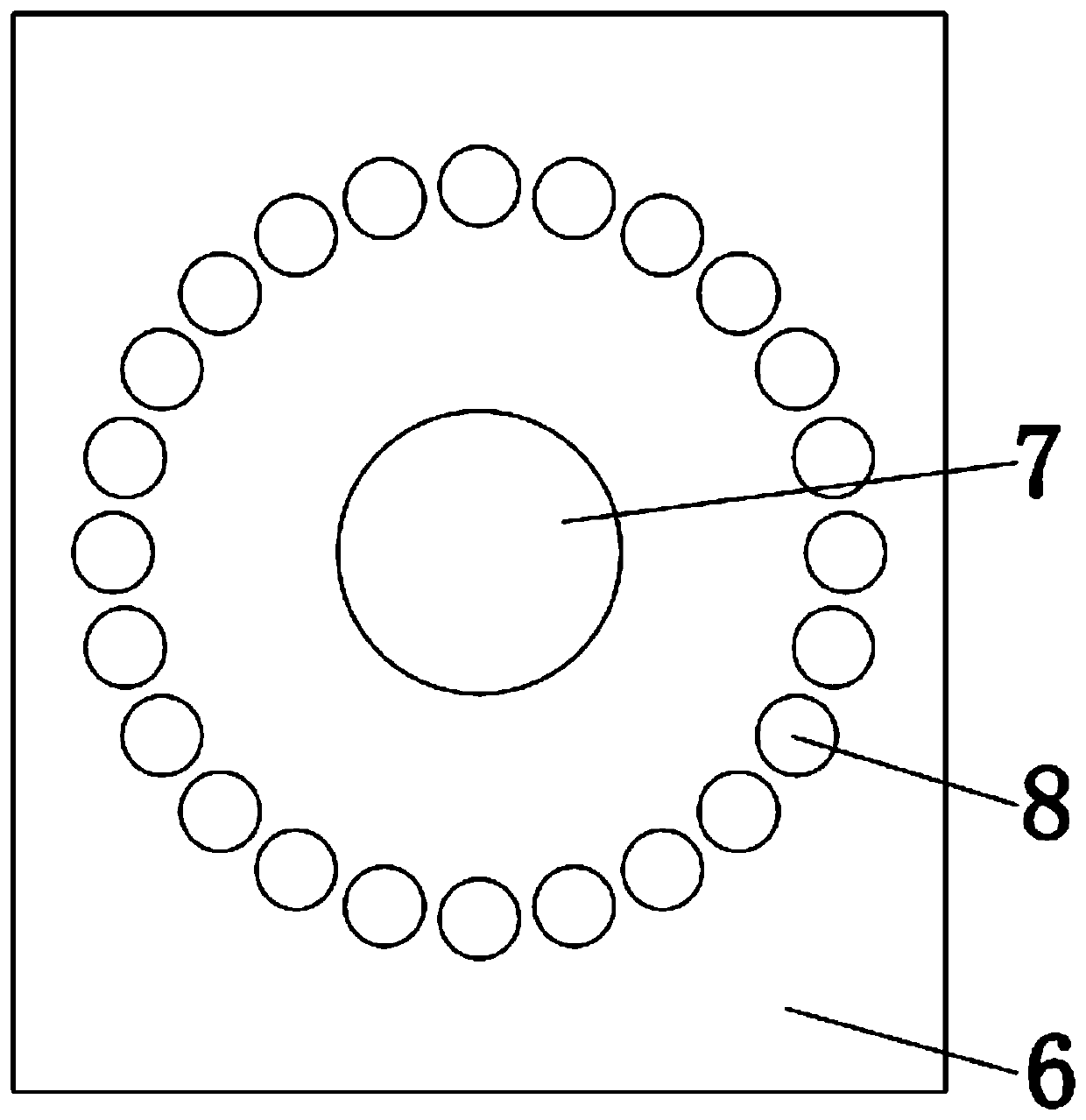

Bonding encapsulation structure and method suitable for radio frequency MEMS and method

PendingCN107814351AFlat distributionIncrease the effective bonding areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEtchingRadio frequency

The invention relates to a bonding encapsulation structure and method suitable for radio frequency MEMS. The method comprises the steps that organic materials are spin-coated on an encapsulation coverplate and patterned, then Cr and Au are sputtered, and an encapsulation cover plate with the uniformly distributed organic materials and cavities is obtained by using a method that the cavities are etched with a TMHA solution. The cover plate full of the cavities is made from a high-resistance silicon material, and the cavities are obtained through wet etching by using the TMAH solution. By meansof the encapsulation method, the organic materials can be smoothly distributed in a bonding area, the effective bonding area of wafer-level bonding is increased, and then the airtightness, the reliability and other performance of the product obtained after bonding are improved. A low-temperature bonding technology is adopted to conduct low-temperature encapsulation of a radio frequency device, and while good mechanical strength and airtightness are achieved, the requirements for encapsulating the RF MEMS device which is sensitive to temperature are met.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

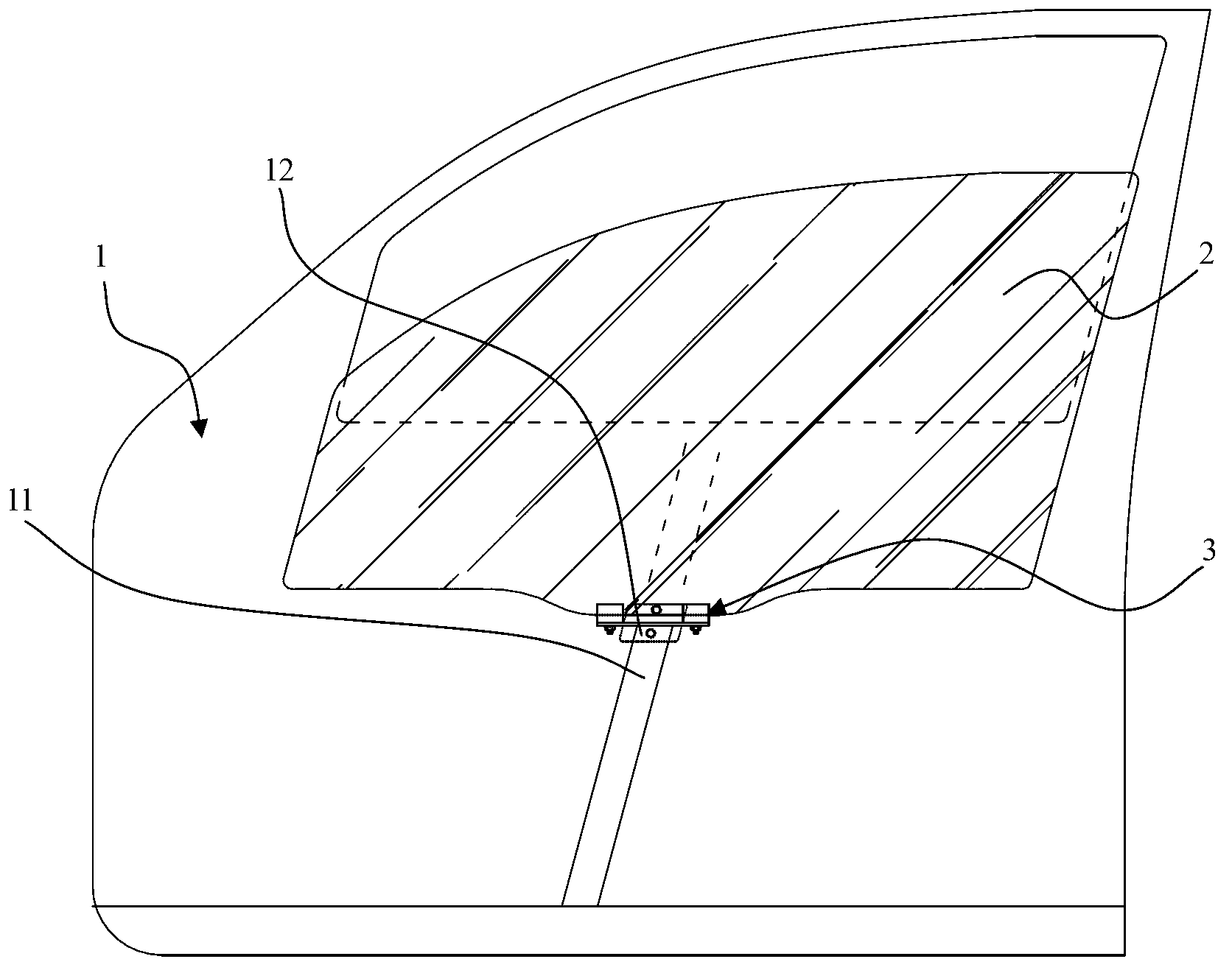

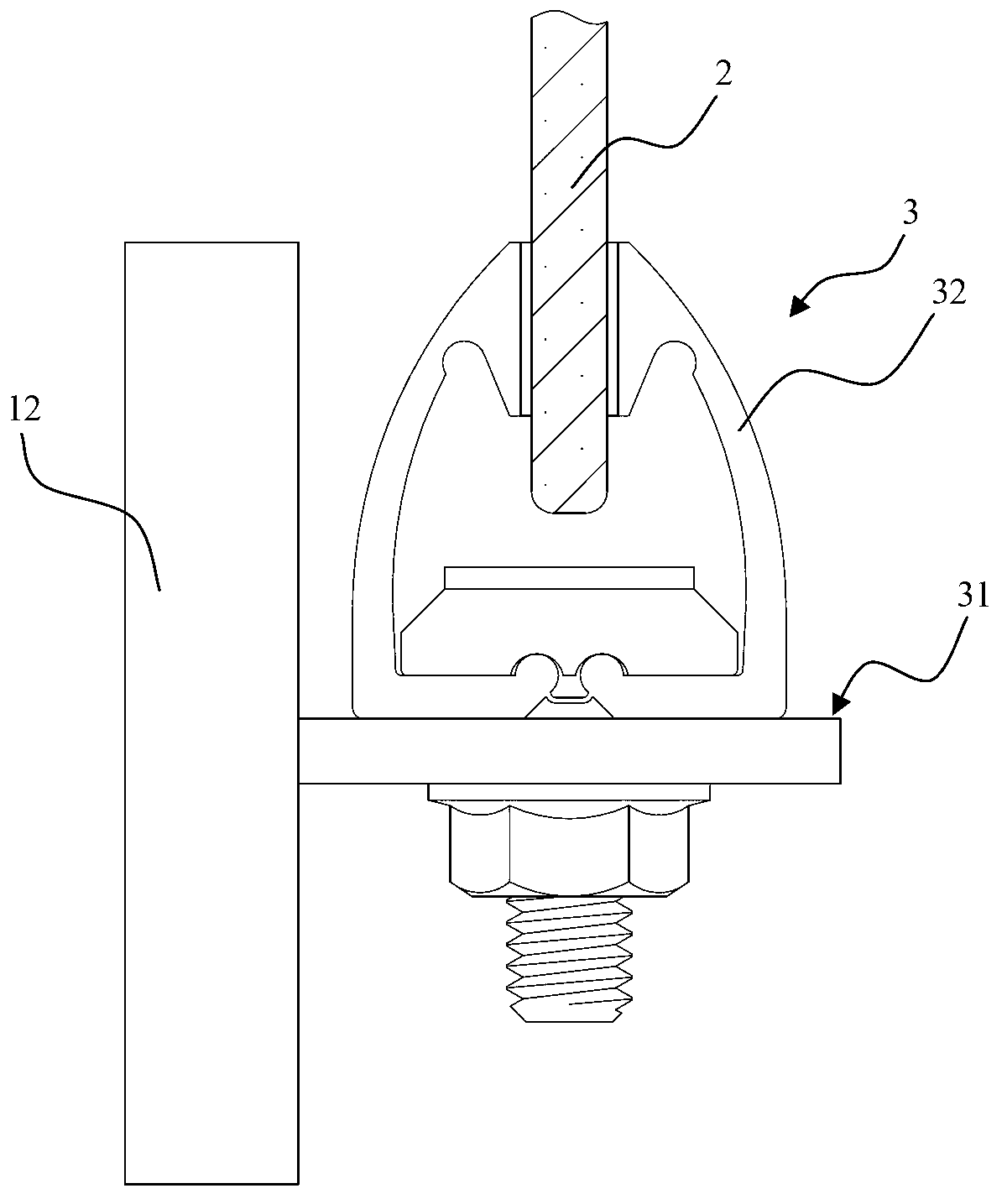

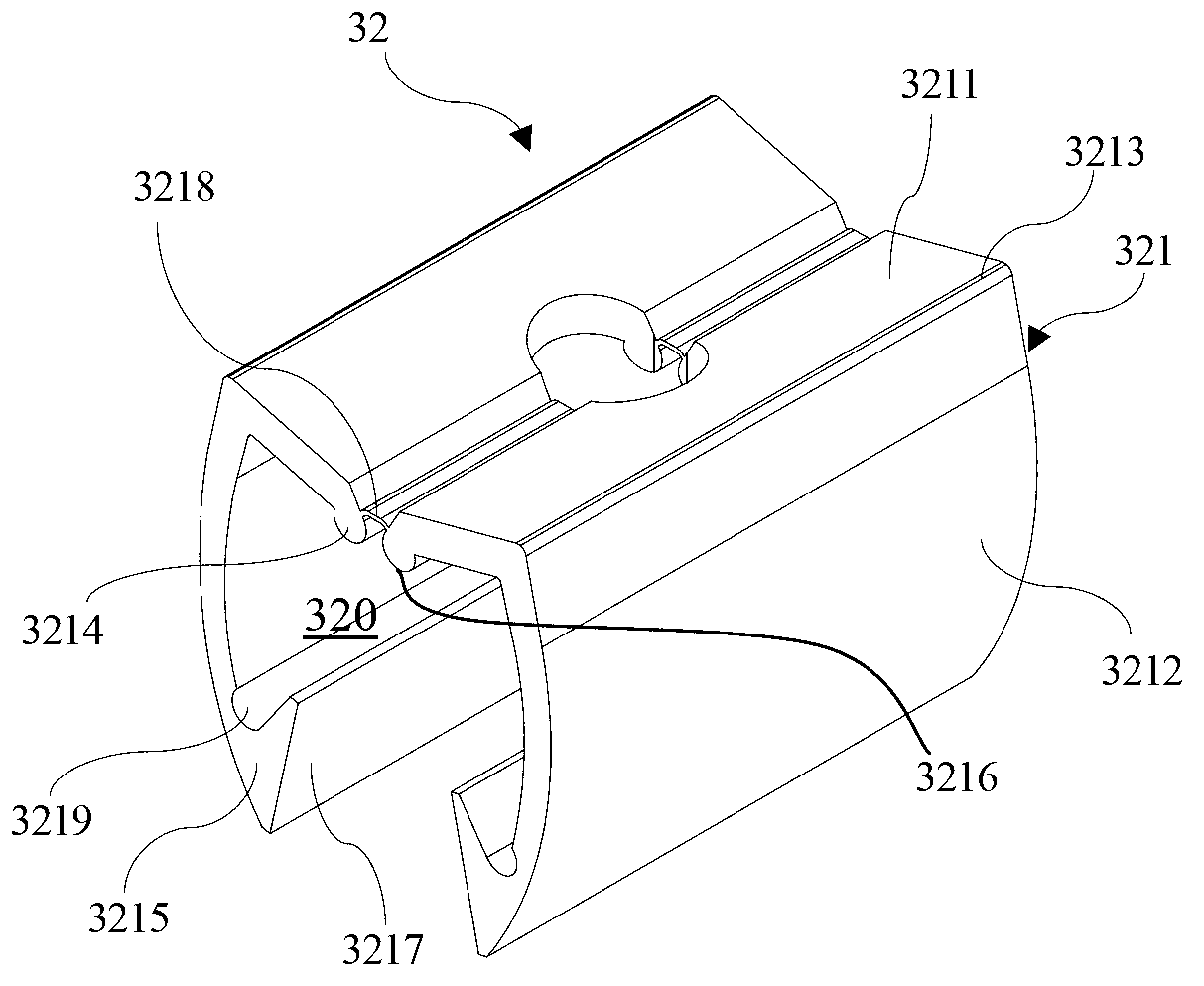

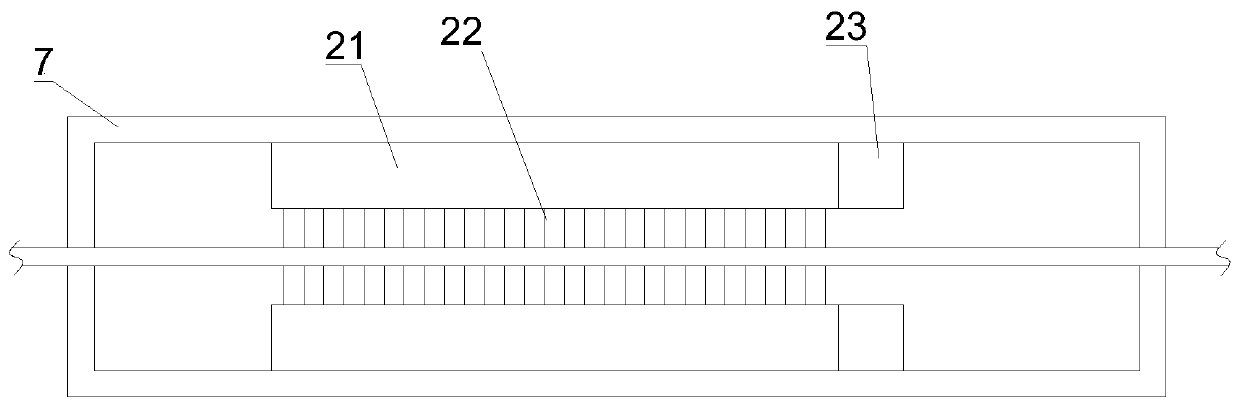

Mounting structure for car door glass tightening and method for mounting car door glass

ActiveCN103303105ATo achieve fastening effectImprove smoothnessWindowsWindscreensPre stressPre stressing

The invention discloses a mounting structure for car door glass tightening, which comprises a car door glass body, wherein the car door glass is movably arranged on a car door through a moving device on a car window track; the car door glass body is fixed on the moving device through a tightening system; the tightening system comprises an oppressing component and a plurality of tightening components; and the tightening components are oppressed through the match of the oppressing component with the car door glass body to generate a pre-stressing force to tighten the car door glass body. In the mounting structure for the car door glass tightening provided by the invention, the tightening components are oppressed through the match of the oppressing component with the car door glass body together to generate the pre-stressing force; the car door glass body becomes a main control element to generate the pre-stressing force; the tightening components are made of elastic materials; and under the action of external forces, a stable pre-stressing force is formed at the inner part of the materials and stored to form a stable pre-stressing force system with the car door glass body and the oppressing component together.

Owner:WM MOTOR TECH GRP CO LTD

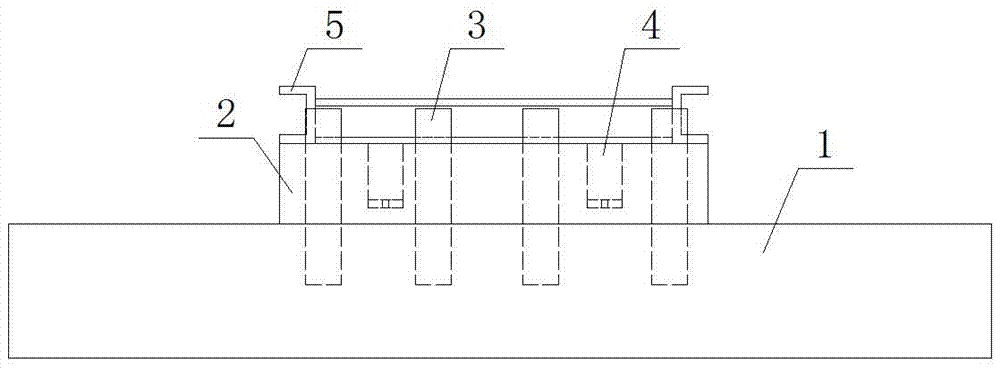

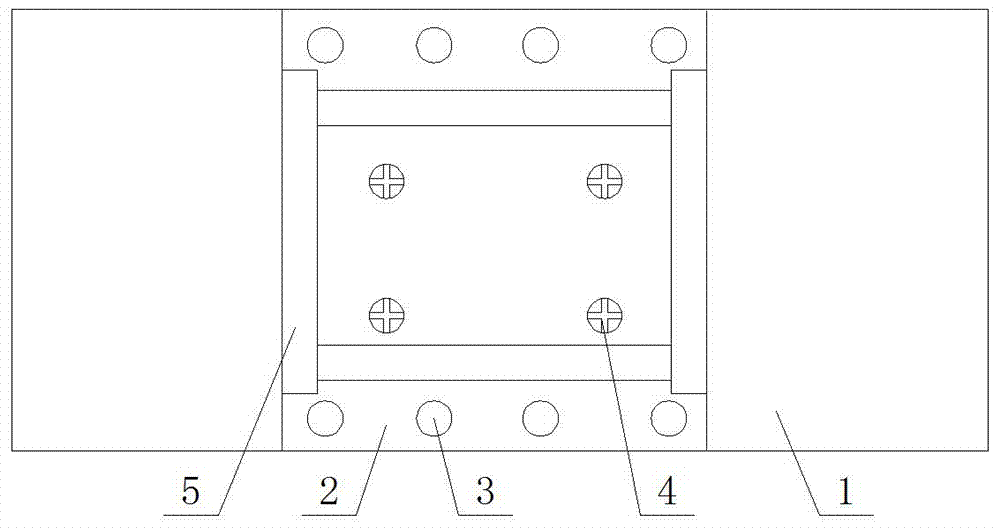

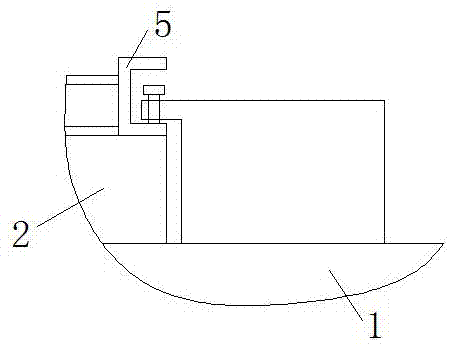

Precise locating and fixing device of prefabricated part embedded parts and using method of locating and fixing device

ActiveCN107503521APrecise positioningPrevent slippingBuilding material handlingStructural engineeringAluminium

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

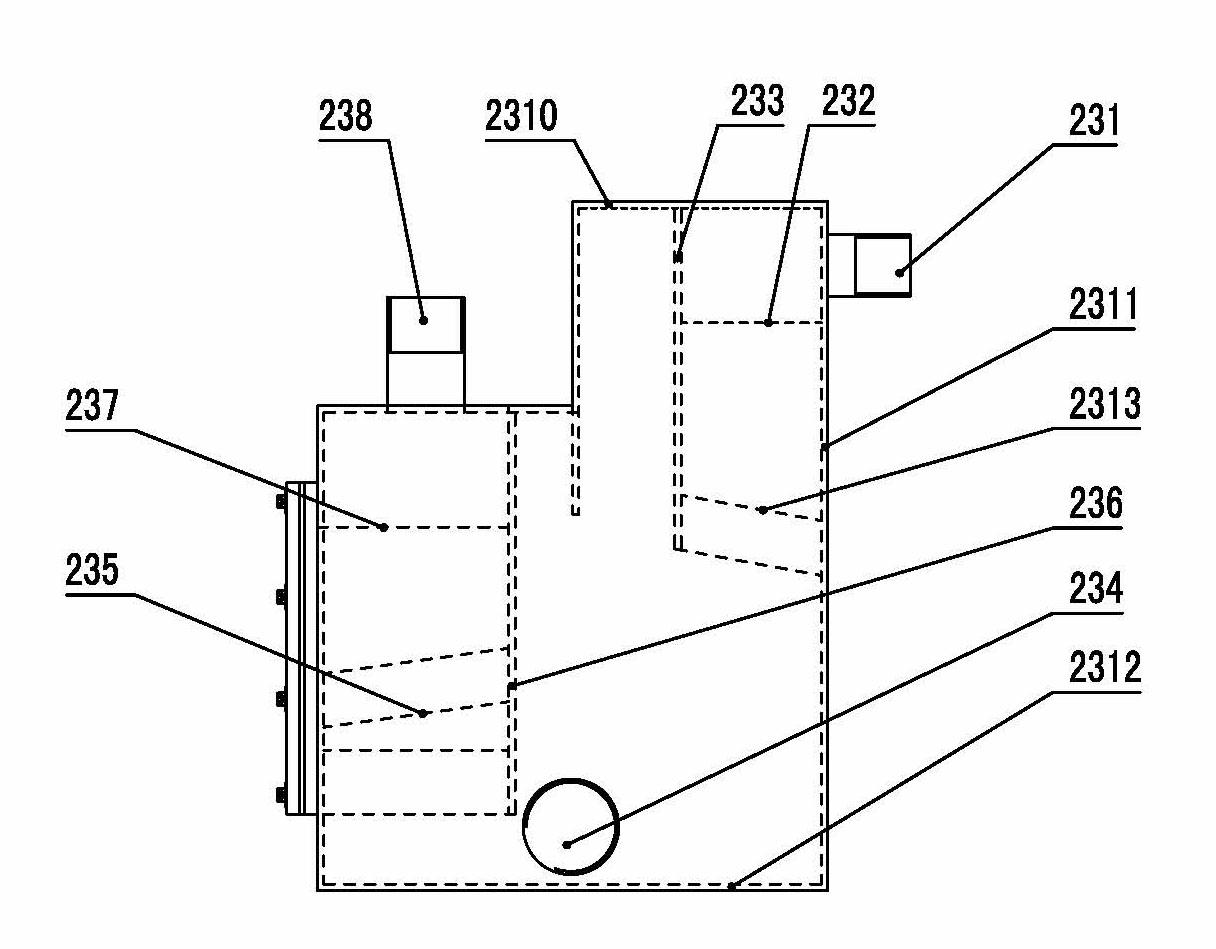

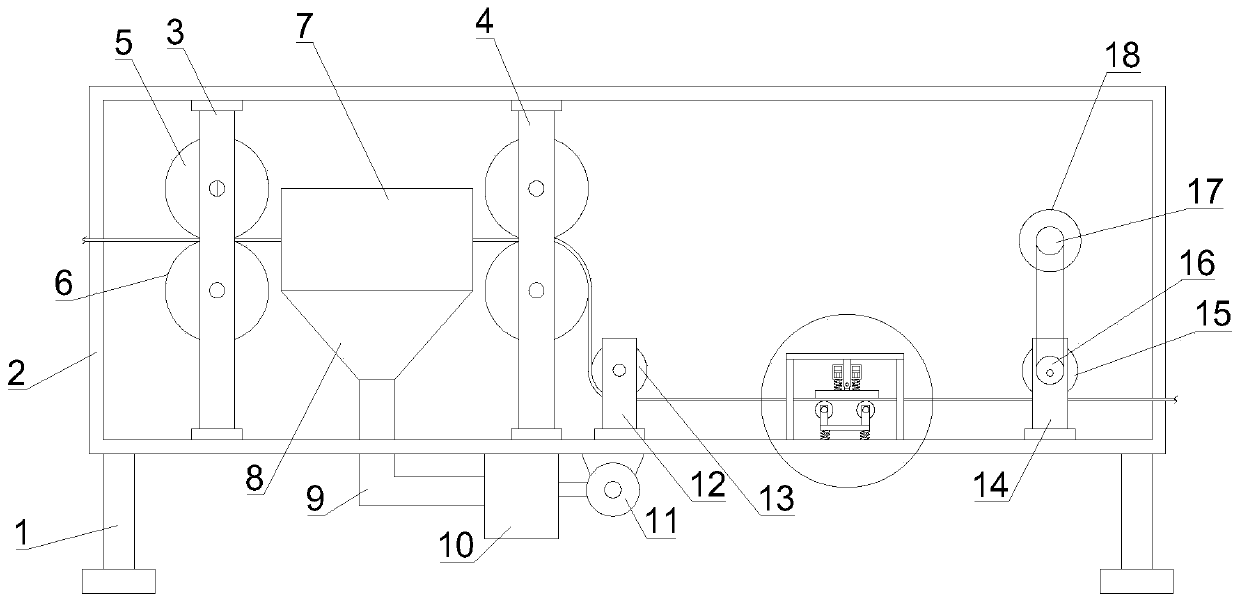

Blended yarn impurity removal and transporting mechanism

The invention discloses a blended yarn impurity removal and transporting mechanism which comprises a box body, a transporting mechanism body and an impurity removal mechanism, wherein landing legs are arranged at the bottom of the box body; the transporting mechanism body and the impurity removal mechanism are arranged in the box body; a first support plate and a second support plate are in sliding fit with a yarn feeding press roller through a first connecting shaft; a sleeve is arranged on the first connecting shaft in a sleeving manner; the sleeve is connected with the bottom end of a telescopic rod; the top end of the telescopic rod is connected with the top surface of the box body; a first spring is arranged on the telescopic rod in a sleeving manner; the first support plate and the second support plate are rotatably connected with a yarn feeding rotary roller through a second connecting shaft; the yarn feeding press roller is right above the yarn feeding rotary roller; a third support plate is rotatably connected with a yarn guiding rotary roller through a third connecting shaft; and a fourth support plate is rotatably connected with a driving rotary roller through a fourth connecting shaft. The blended yarn impurity removal and transporting mechanism can compress and transport blended yarn to enable the blended yarn to be fully unfolded during the transporting process and ensure the transporting broad width of the blended yarn, is cleaner and more comprehensive in blended yarn impurity removal and higher in efficiency.

Owner:徐州嘉搏纺织股份有限公司

Method for making circuit structure

InactiveCN103052268AInhibition thicknessAvoid flatnessConductive pattern formationElectricityEngineering

The invention discloses a method for making a circuit structure. The method comprises the following steps: a dielectric layer with a second surface is laminated on a first surface of a circuit substrate and a first patterned circuit layer; at least one blind hole and an engraved pattern are formed, and the blind hole extends from the second surface to the first patterned circuit layer; a patterned photoresist layer is formed on the second surface and provided with at least one opening, and the blind hole and the engraved pattern are exposed by the opening; a region where the patterned photoresist layer is positioned is defined as a first region, and a region outside the first region is defined as a second region; an activating layer is formed in the first region and the second region; the patterned photoresist layer and the activating layer in the first region are removed so as to leave the activating layer in the second region; an electricity conducting material is formed on the activating layer in the second region; and partial electricity conducting material and partial activating layer in the second region are removed.

Owner:UNIMICRON TECH CORP

Casting mold plate device capable of easily and conveniently disassembling and demolding

InactiveCN109707163AHigh precisionLabor savingAuxillary members of forms/shuttering/falseworksForm treatmentEngineeringCasting mold

The invention provides a casting mold plate device capable of easily and conveniently disassembling and demolding. The casting mold plate device capable of easily and conveniently disassembling and demolding comprises horizontal plates and vertical plates, a plurality of first connecting blocks, a plurality of second connecting blocks, and auxiliary plates, wherein the multiple first connecting blocks are evenly arranged on the two sides of the horizontal plates; the multiple second connecting blocks are evenly arranged on one sides of the vertical plates and the other sides of the vertical plates; and the right sides of the auxiliary plates are fixed to left threaded rods of the vertical plates, and the threaded rods are arranged on the left sides of the auxiliary plates. According to thecasting mold plate device capable of easily and conveniently disassembling and demolding, the accuracy of rotation of the threaded rods is improved, disassembly and assembly of mold plates are more convenient and lightweight, meanwhile, a great deal of labor force is saved, operation is easy and convenient, stability of movement and installation of the mold plates is improved, tidiness and stability of casting are ensured, thus disassembly of the mold plates is programmed, stability of the mold plates after being installed is ensured, and meanwhile, the convenience of removal of the mold plates is improved.

Owner:ZHONGHANG CONSTR ENG CO LTD

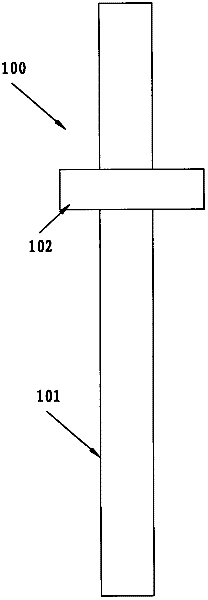

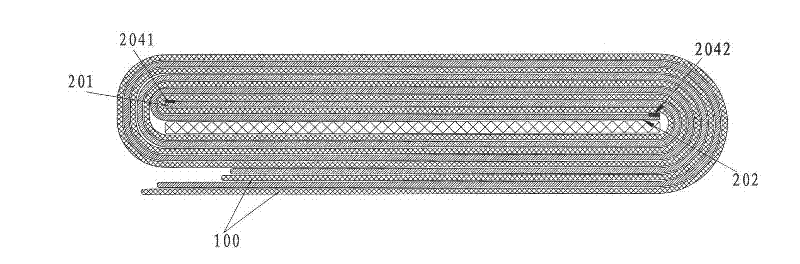

Lug, rolled lithium ion cell and soft-package rolled lithium ion battery

InactiveCN102332552AGuaranteed shape consistencyGood shape consistencyFinal product manufactureSecondary cellsAdhesivePhysical chemistry

The invention relates to the field of lithium ion battery designs, and discloses a lug, a rolled lithium ion cell and a soft-package rolled lithium ion battery. The lug comprises a foil and lug adhesive, the foil consists of a lathy section and a rectangular section, wherein the width of the rectangular section is larger than the width of the lathy section; and the lug adhesive is stuck on both surfaces of one predetermined section of the lathy section, and is a predetermined distance away from the rectangular section. The lug applied in the soft-package rolled lithium ion battery can help to improve the smoothness of the surfaces of the rolled cell and the soft-package rolled lithium ion battery and increase the convenience of production.

Owner:SHENZHEN GREPOW BATTERY CO LTD

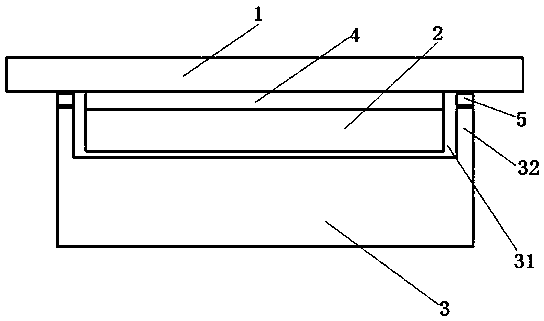

Backlight assembling structure of vehicle-mounted display screen

Owner:HUIZHOU DESAY SV AUTOMOTIVE

Refractory ceramic product and manufacturing technology thereof

InactiveCN106866107AReduce manufacturing costMaintain ecological balanceClaywaresManufacturing technologyHardness

The invention provides a refractory ceramic product and a manufacturing technology thereof and relates to the technical field of ceramics. The refractory ceramic product comprises 200-350 weight parts of blanks, 50-100 weight parts of glazes and 20-40 weight parts of auxiliaries. The raw material composition and the manufacturing technology of the refractory ceramic product provided by the invention are both strictly controlled; at the aspect of the raw materials, blanks, glazes and auxiliaries are reasonably prepared, so that the roasted ceramic product has excellent high temperature resistance, chemical stability, hardness and toughness; at the aspect of the technology, an once-firing manner is adopted for roasting the ceramic, so that the shovel strength is increased and the cost is lowered; besides, a method for gradually increasing temperature and roasting in stages is adopted for roasting, so that the cracking and uneven surface caused by the rapid loss of the ceramic water can be avoided, the yield of the product can be greatly increased and the refractory ceramic product is worthy of popularization in the market.

Owner:玉林龙升建筑装饰工程有限公司

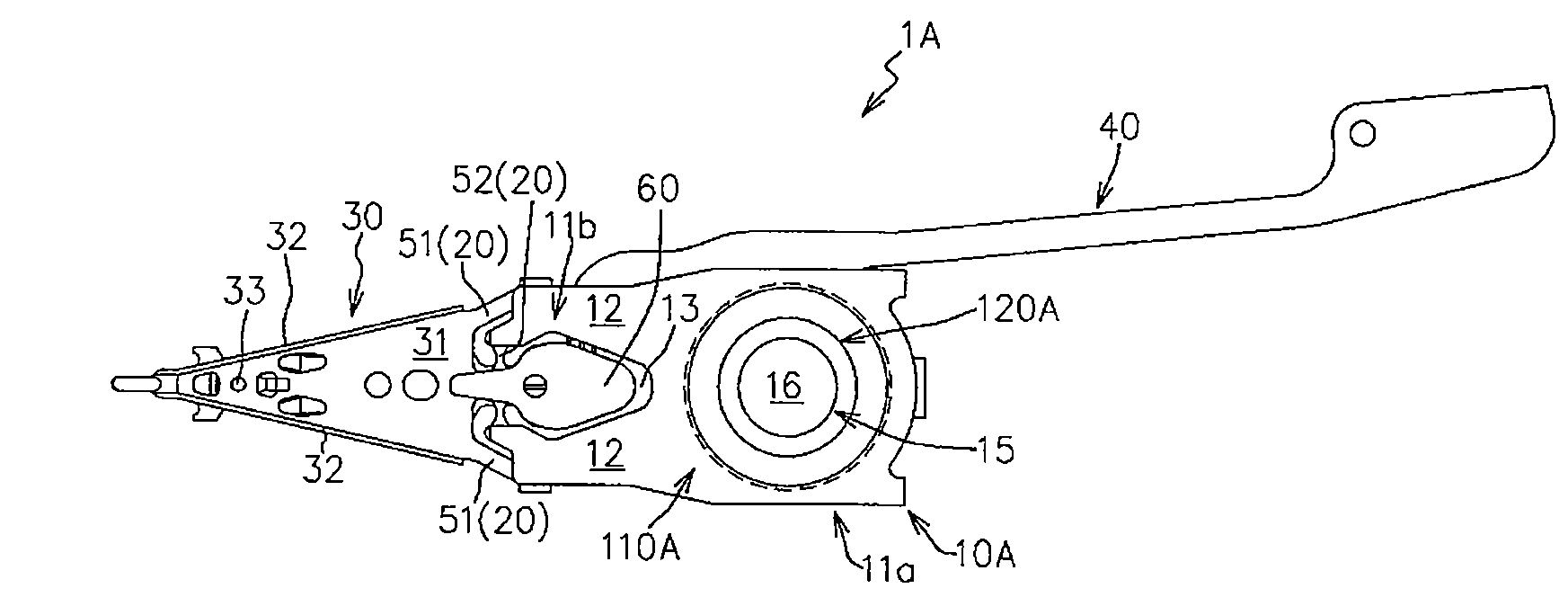

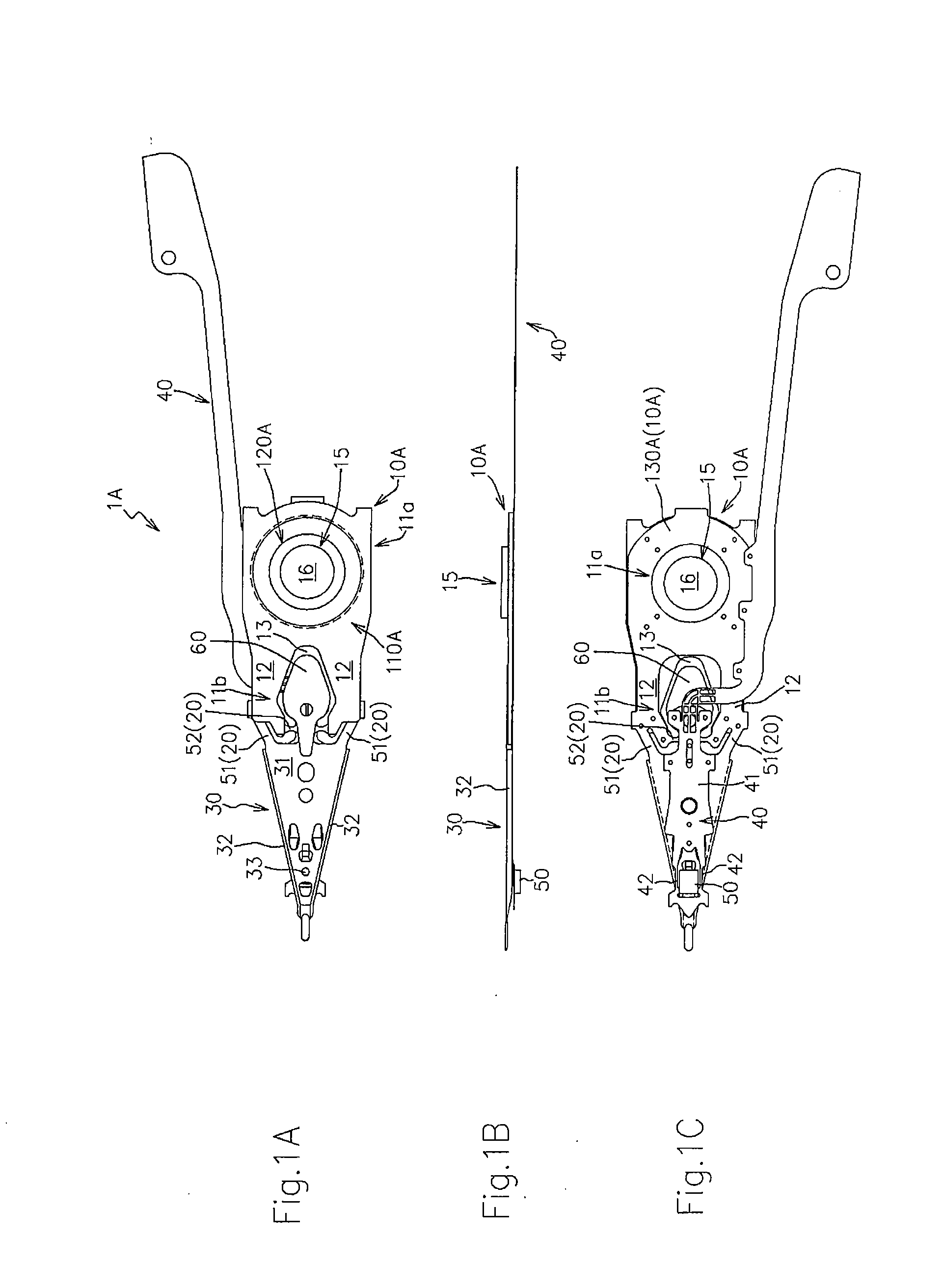

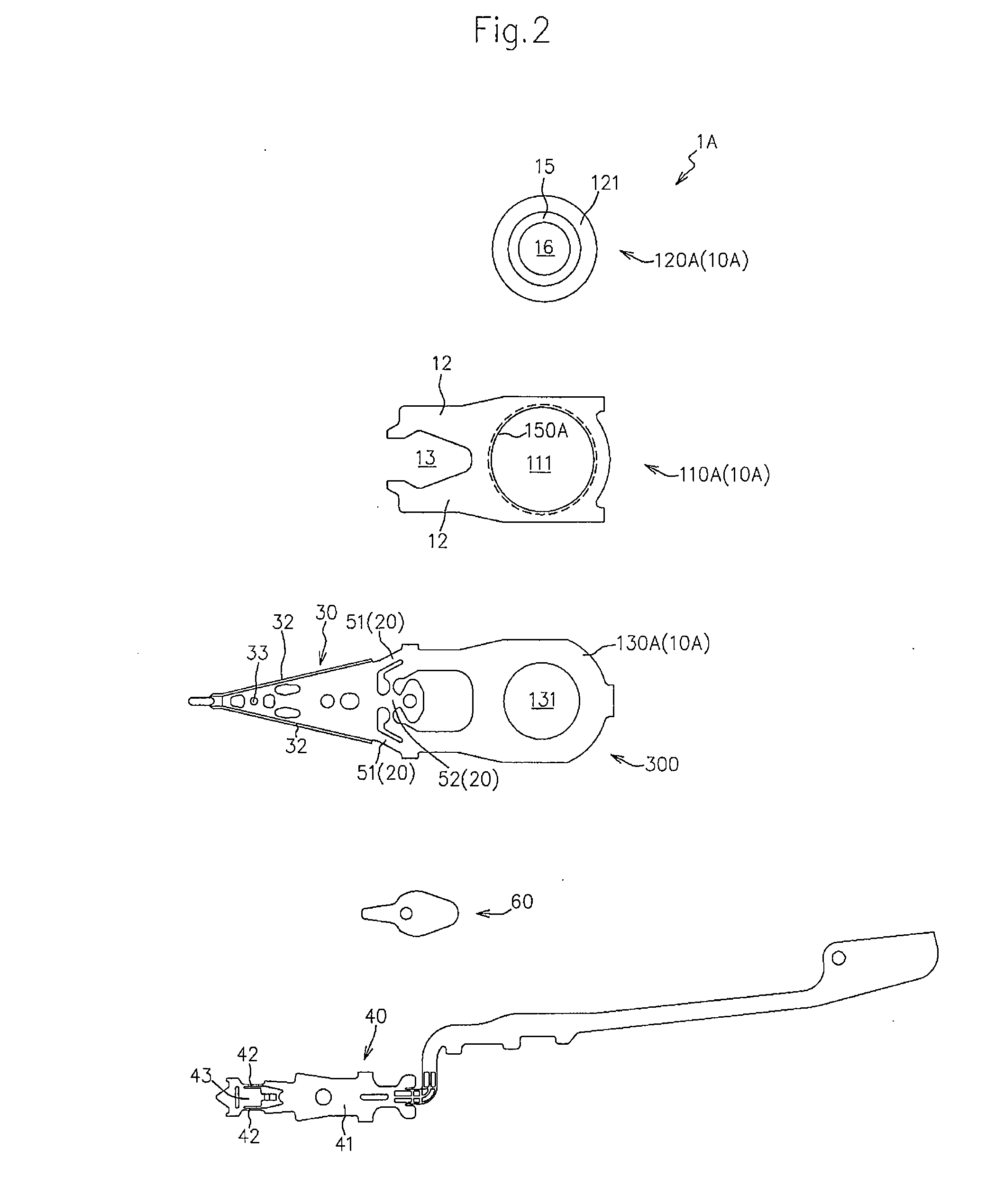

Magnetic Head Suspension

ActiveUS20100202087A1Reduce thicknessReduce supportRecord information storageStructure of arm assemblyEngineeringBody region

It is an object to achieve prevention of lowering resonant frequency and improved production efficiency while achieving reduction in weight of a supporting part with a boss portion and reduction in thickness at area at which the boss portion is located. In the present invention, the supporting part includes a first supporting member with which a load bending part is connected, and a second supporting member with the boss portion and a main body region extended radially outward from the boss portion. At least one of the inner periphery of the mount hole and the outer periphery of the main body region is integrally provided with a rib region. The first and second supporting members are connected to each other by a restoring force of the rib region that has been elastically and / or plastically deformed by the other one of the inner periphery of the mount hole and the outer periphery of the main body region with the main body region being located at least partially in the mount hole in a through-thickness direction.

Owner:SANCALL CORP

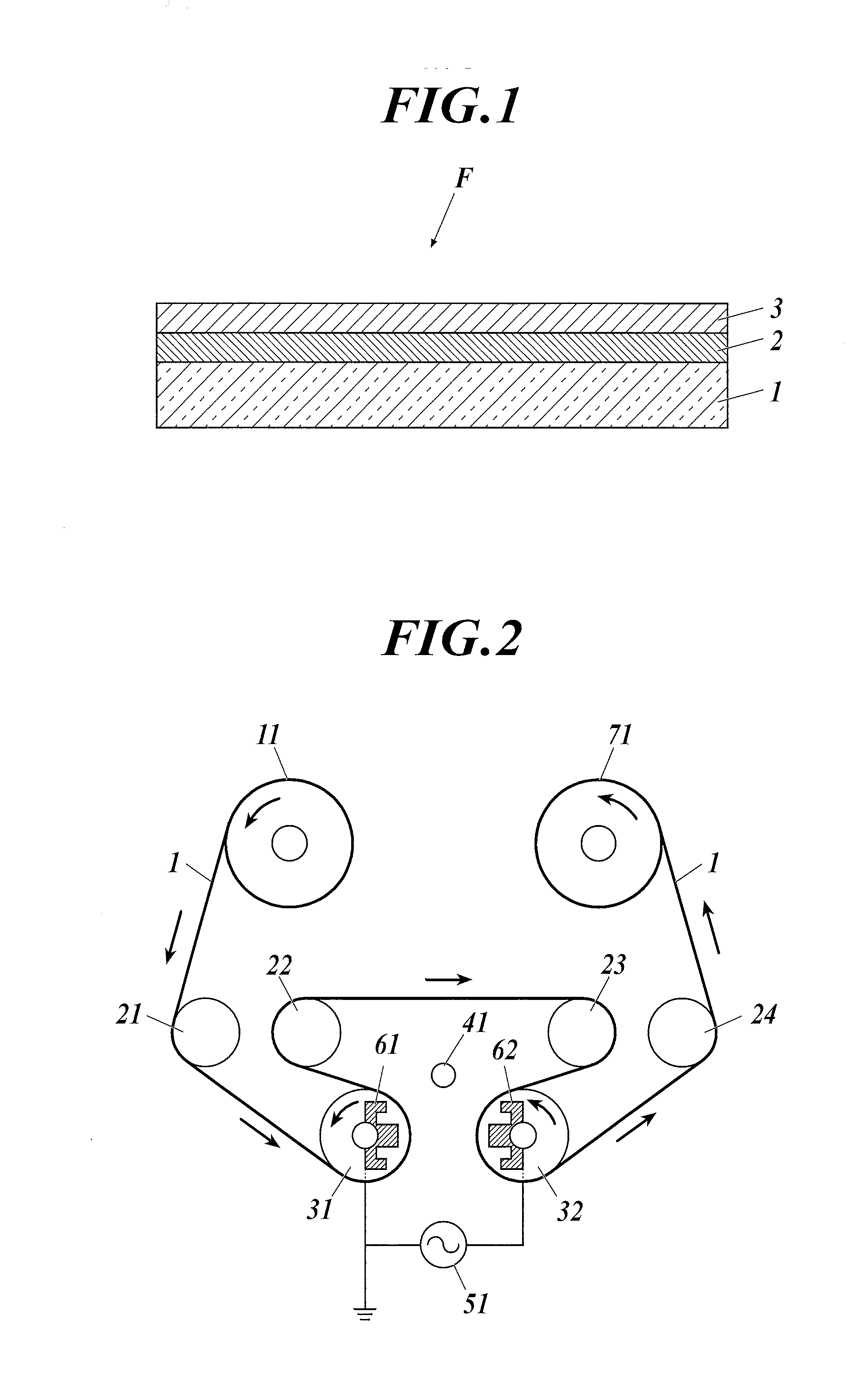

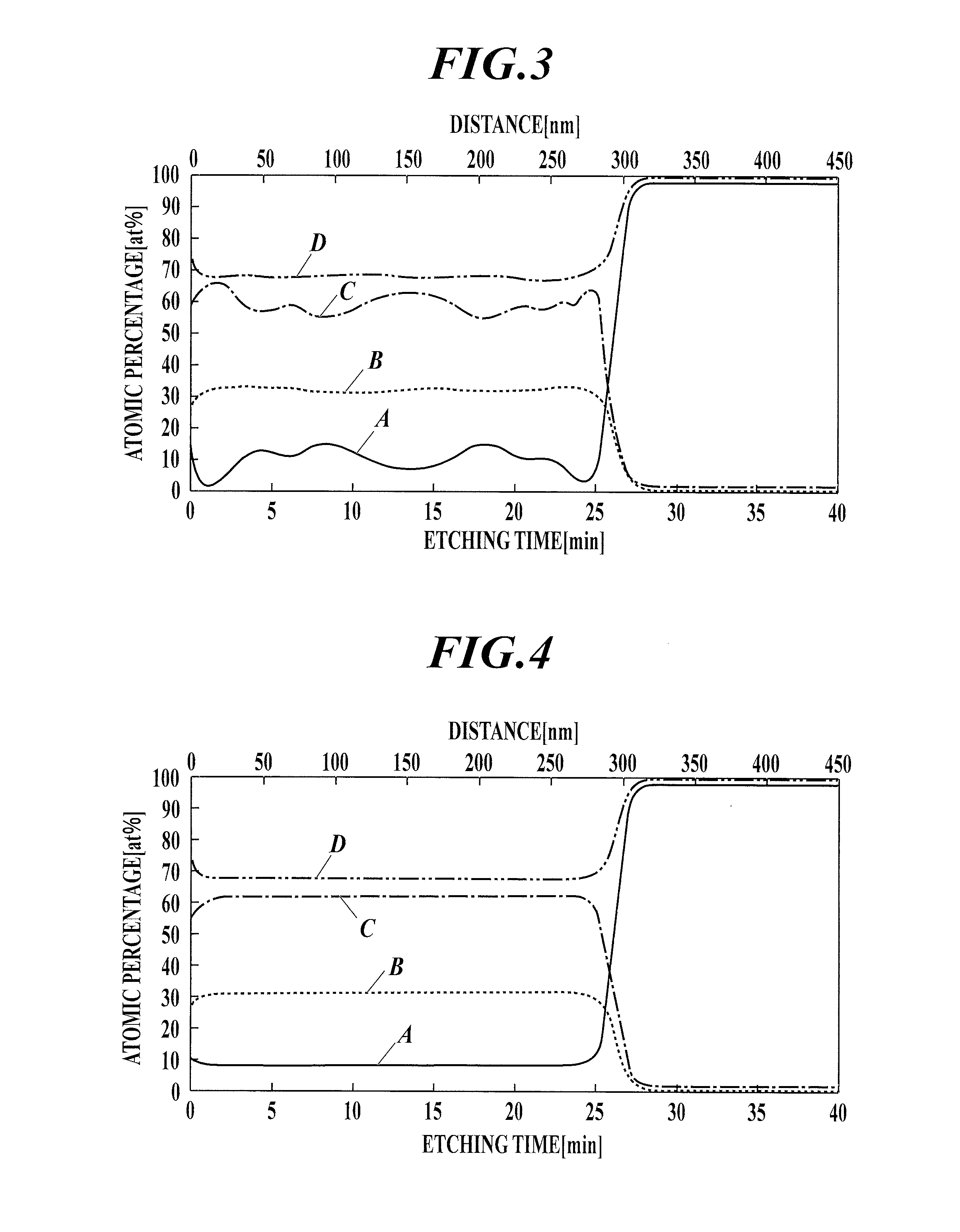

Electronic device and gas barrier film manufacturing method

InactiveUS20150284844A1Good effectIncreased durabilityFilm/foil adhesivesSynthetic resin layered productsDark spotElectron

An electronic device may be provided which is superior in gas barrier performance and robustness (flatness and dark spot resistance), and a gas barrier film fabrication method may be provided.

Owner:KONICA MINOLTA INC

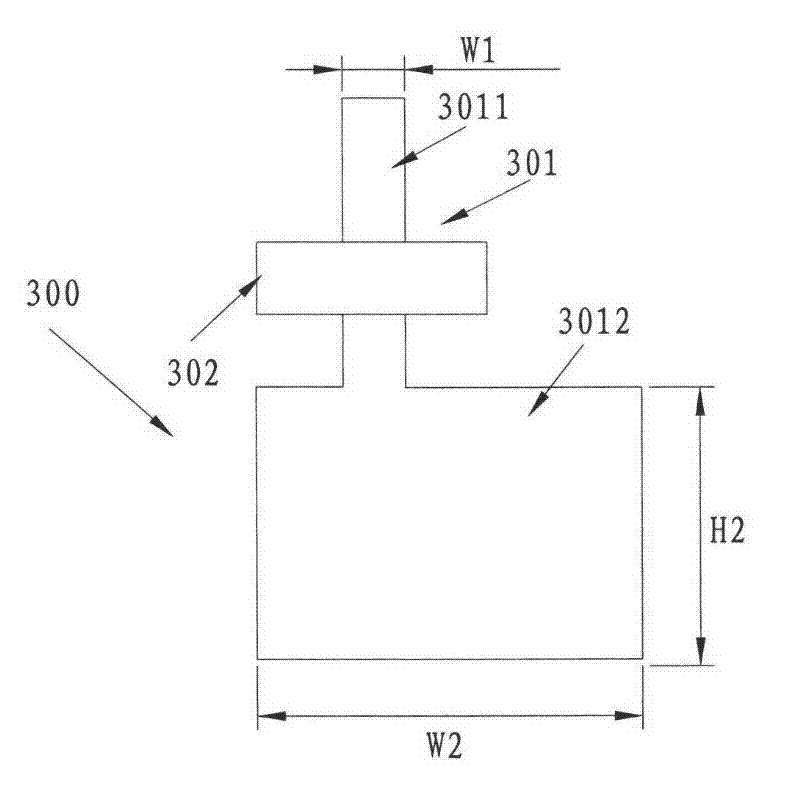

Lug bending structure and battery cell reshaping device with lug bending structure

PendingCN106711397AAvoid consistencyAvoid flatnessElectrode manufacturing processesFinal product manufactureEngineeringExtrusion

The invention provides a lug bending structure and a battery cell reshaping device with the lug bending structure. The lug bending structure is used for bending lugs on two ends of a battery cell, and comprises a main body, and an extrusion part arranged on the main body, wherein the extrusion part is characterized in that when the lug bending structure is used for bending, an inner side of a radial direction or an outer side of the radial direction of the extrusion part firstly press against the end part of a radial direction of the battery cell, and the extrusion part can press the lugs from one side of the radial direction to the other side of the radial direction along the radial direction of the battery cell on the end part of the battery cell. According to the lug bending structure provided by the invention, the extrusion part sequentially presses the lugs from one side to the other side along the radial direction on the end part of the battery cell, so that the problems of inconformity in felling directions of the lugs and poor smoothness after the battery cell is reshaped are effectively solved, and a follow-up welding process has no insufficient welding, reduced internal resistance and low overcurrent temperature.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

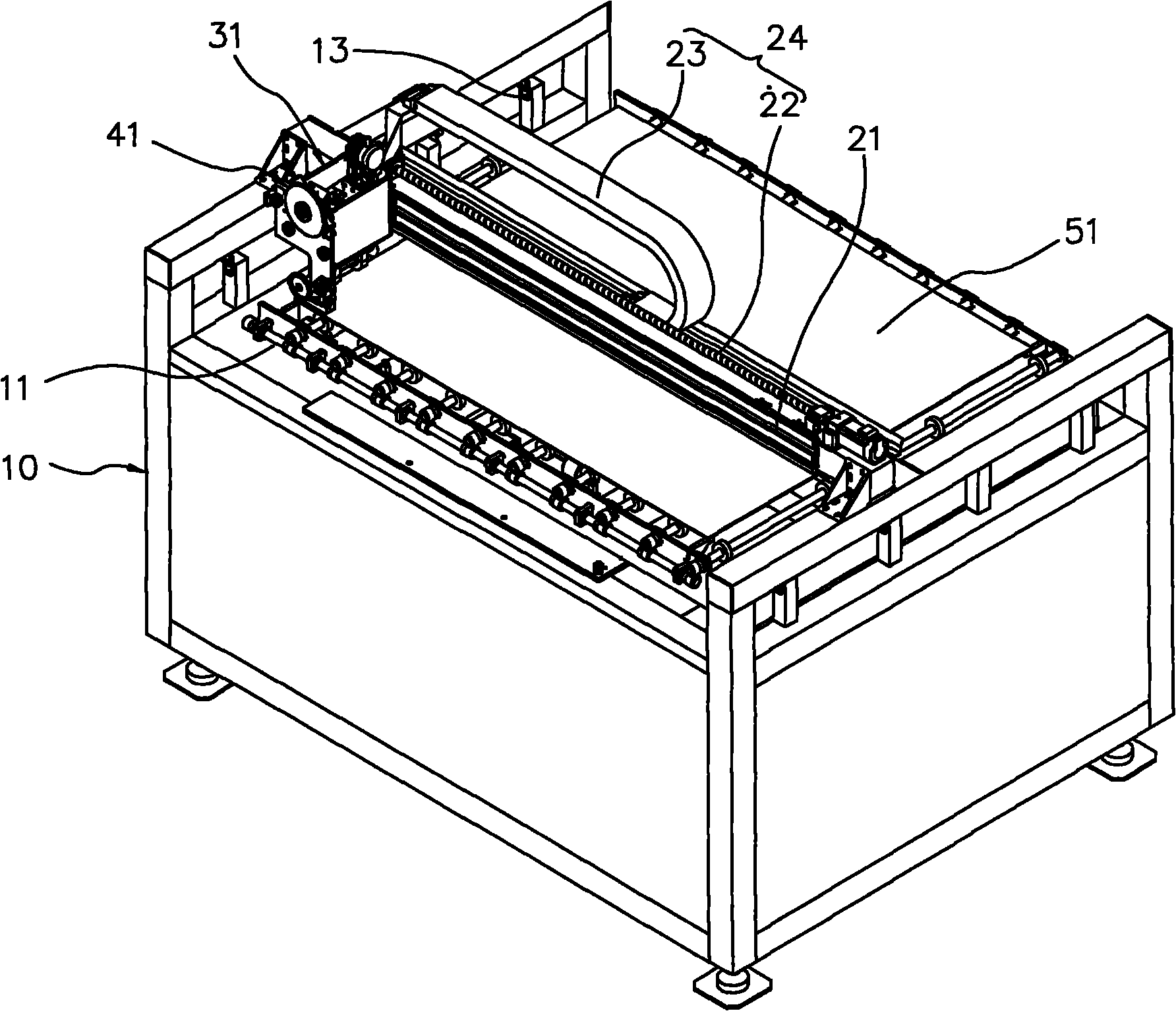

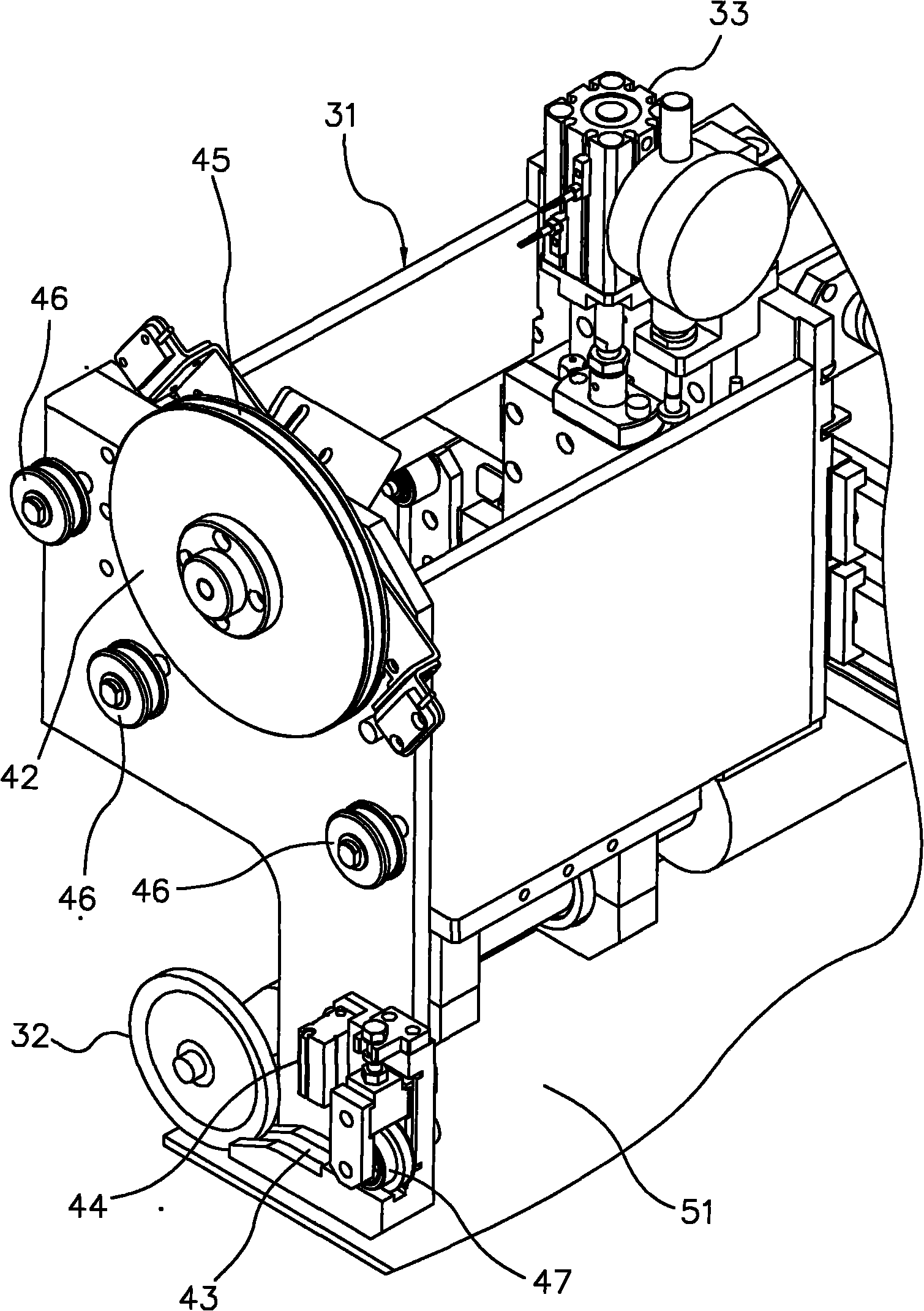

Ultrasonic roll welding stand

InactiveCN101920394AAvoid flatnessImprove processing qualityNon-electric welding apparatusShort axisUltrasonic welding

The invention relates to an ultrasonic roll welding stand which comprises a platform, a bearing arm, an ultrasonic roll welding device and a metal band supply device, wherein the platform is rectangular, the short axis of the platform is parallel with the X axis, and the long axis of the platform is parallel with the Y axis; the bearing arm is parallel with the Y axis and has a preset distance to the platform; the ultrasonic roll welding device is arranged on the bearing arm near the front end of the platform, and the ultrasonic roll welding device is provided with a lifting unit and a disc type ultrasonic welding head; and the metal band supply device can supply a metal band to the disc type ultrasonic welding head, the metal band supply device is provided with a spacing groove, the spacing groove is arranged at the back end of the disc type ultrasonic welding head, the metal band is arranged in the spacing groove, and the front section of the metal band protrudes out of the spacing groove and is clamped between the disc type ultrasonic welding head and the platform. Thus, the metal band can be quickly welded onto one substrate without deviation to be used for improving the processing quality and increasing the product yield.

Owner:CONTREL TECH CO LTD

Vehicle paint surface spraying and repairing device

InactiveCN108906459AImprove repair effectRestore the effect of car paintPretreated surfacesCoatingsElectrophoresisEngineering

The invention discloses a vehicle paint surface spraying and repairing device, and belongs to the technical field of vehicle paint repairing technologies. The vehicle paint surface spraying and repairing device comprises a shell and sealing doors, and the sealing doors are arranged at the two ends of the shell to form a closed shell with a mounting space inside. A conveying device used for conveying a vehicle is arranged at the bottom of the inner side of the shell, and the inner part of the shell is sequentially provided with a grinding area, a phosphorization area, an electrophoresis area, aspraying area and a drying area in the conveying direction of the conveying device. The grinding area is provided with a grinding mechanism, the phosphorization area is provided with a phosphorization mechanism, an electrophoresis part is arranged in the electrophoresis area, a spraying part is arranged in the spraying area, and a drying mechanism is arranged in the drying area. By arranging multiple repairing mechanisms, car paint repairing can be carried out in a sealed dust-free environment, and the paint spraying and repairing effects of a vehicle paint surface are enhanced so that the vehicle can recover the paint spraying effect obtained when the vehicle leaves a factory. The conveying device and the like are arranged, so that the repairing work is more intelligent, and the work efficiency is improved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com