Construction method for strengthening construction quality of 0# block of cast-in-situ beam

A technology of construction quality and construction method, applied in the direction of bridges, bridge materials, bridge construction, etc., to achieve the effect of good beam force, improved installation efficiency, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

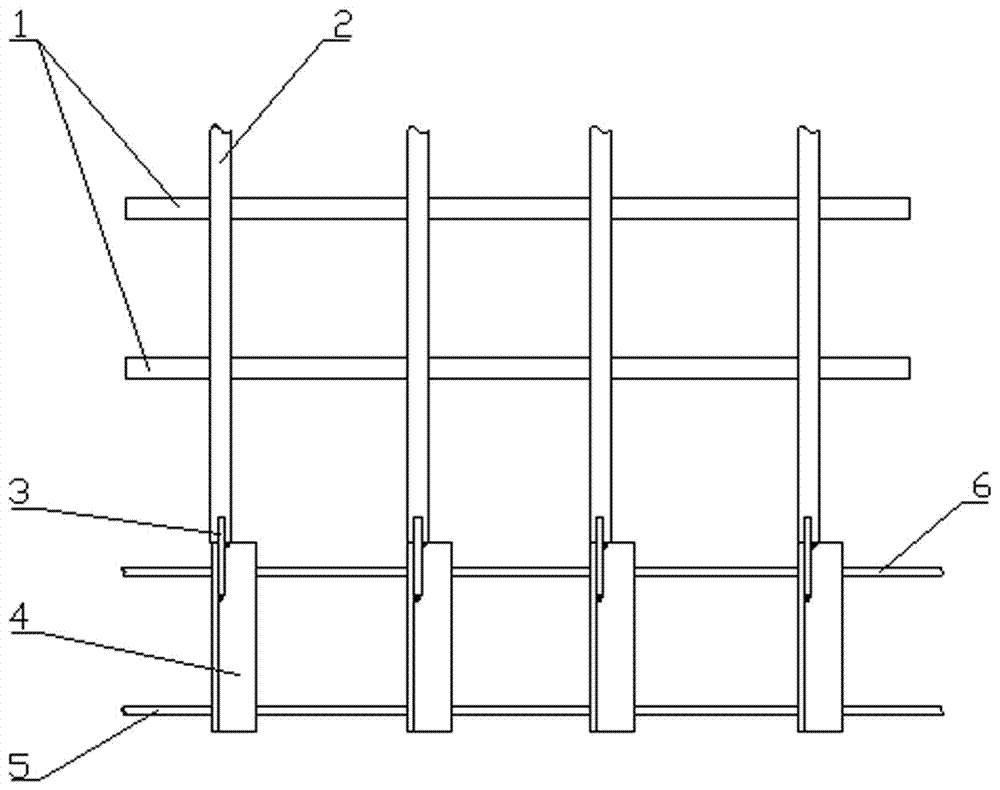

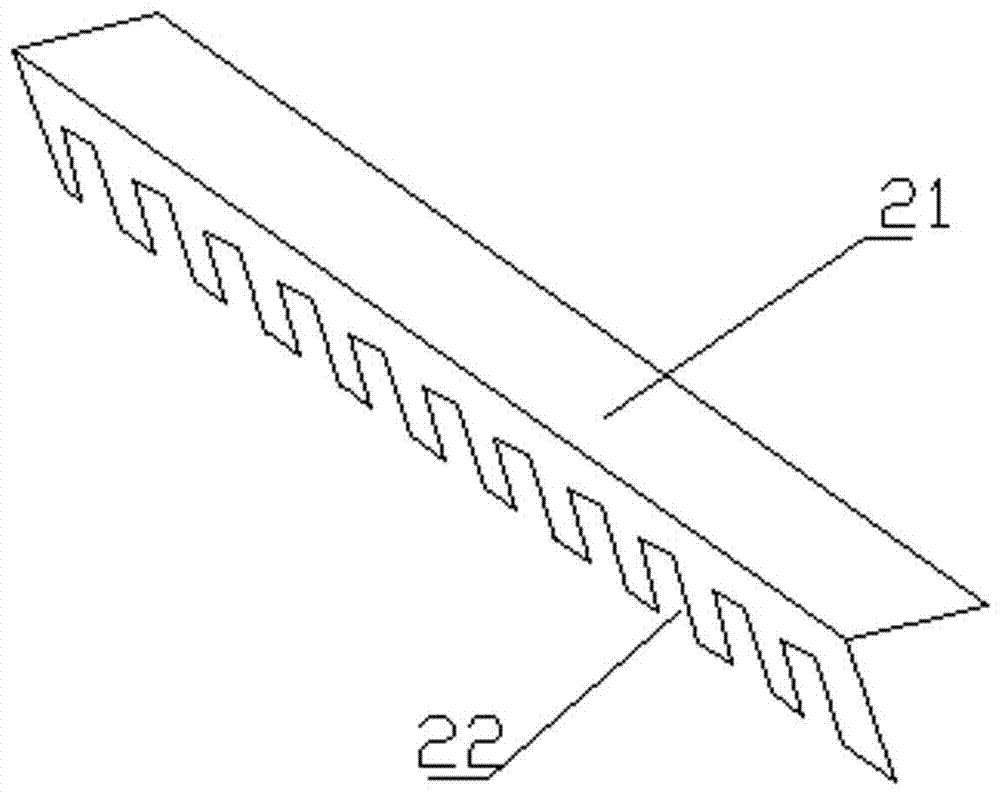

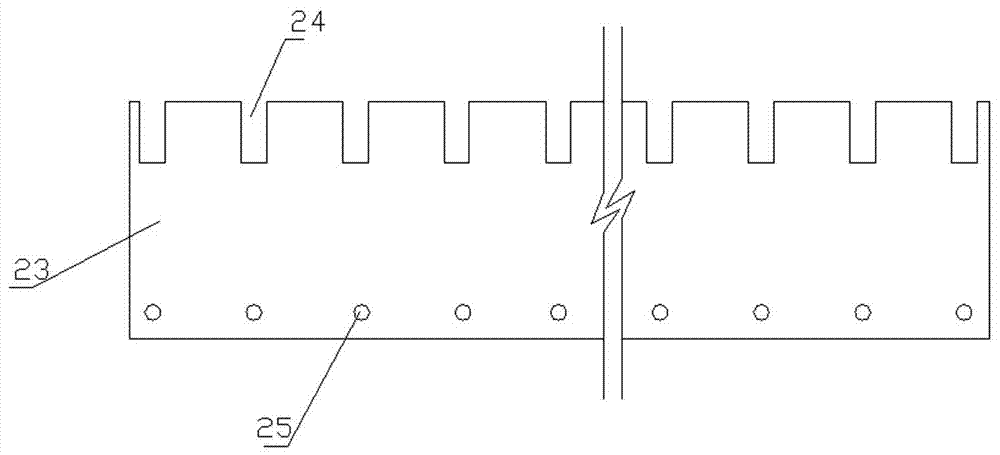

[0043] Taking a certain engineering continuous bridge as an example, the specific embodiment of the present invention is described as follows:

[0044] During the construction of the cantilever pouring beam, in order to bear the weight of the T-beam and the unbalanced moment generated during the cantilever construction, the design drawings provide temporary consolidation measures for the pier beam, and the cantilever box girder is temporarily anchored on the top of the main pier through the temporary consolidation of the pier beam , The pier beam temporary consolidation reinforcement (HRB400Φ32 thread) is pre-embedded in the main pier to set the 1m position, and the upper end 1m is poured in the 0# block together. C50 concrete temporary supports are cast in place on both sides of the top pad stones of 615# and 616# main piers respectively. m.

[0045] Removal of temporary consolidation: The temporary consolidation is removed after the mid-span is closed, and the air compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com