Manufacturing method of rigid-flexible combined board

A technology of rigid-flex board and manufacturing method, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc. It can solve problems such as easy to be torn, affect product flex performance, and sag, so as to avoid window opening The effect of high drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

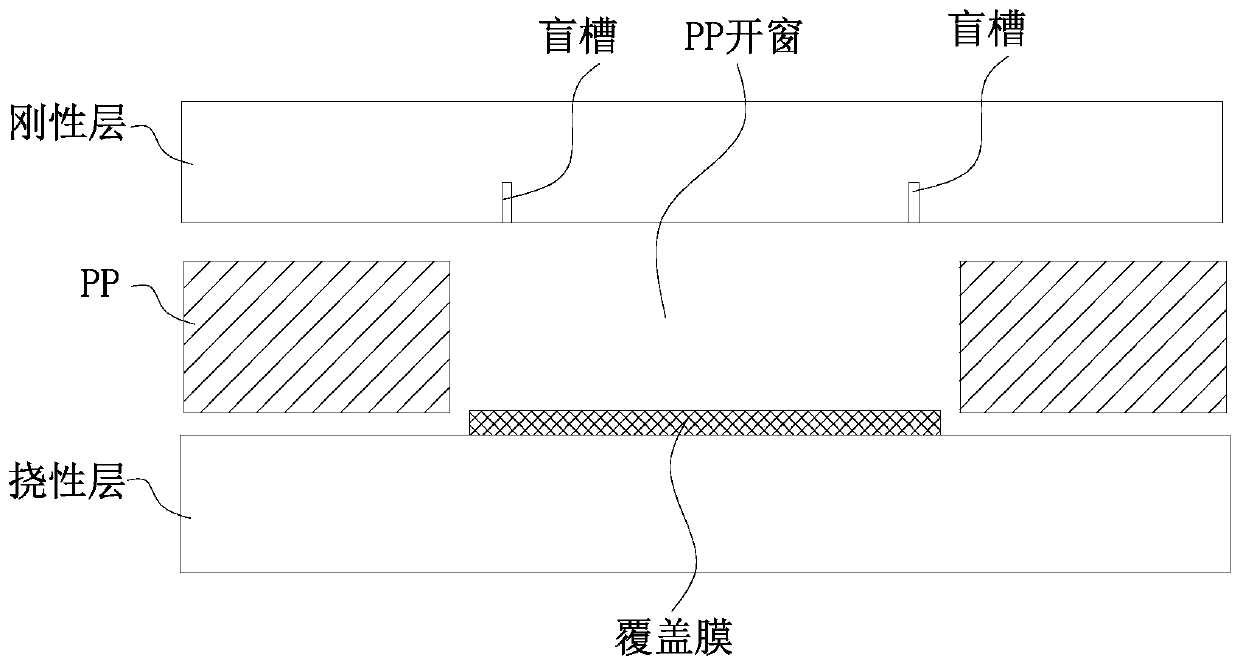

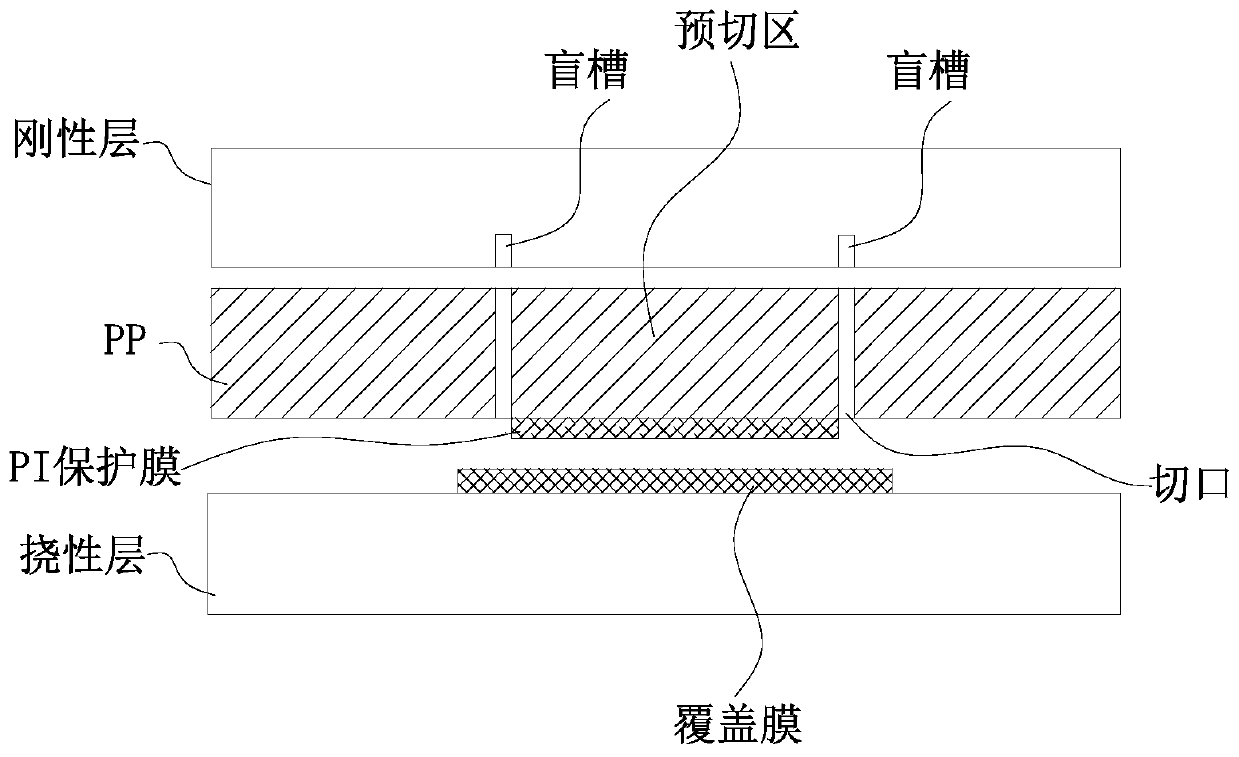

[0029] This embodiment provides a method for manufacturing a rigid-flex board, including the following steps:

[0030] (1) Make rigid layer, flexible layer and bonding layer respectively

[0031] Making the rigid layer: as in the production process of the PCB in the prior art, the raw materials of the PCB are cut to obtain the rigid core board of the required size. Through the processes of film coating, exposure, development, etching and film stripping in sequence, the inner layer circuit is made on the rigid core board. Carry out OPE punching processing and AOI inspection of the inner layer of the rigid core board, and the qualified products enter the next process, that is, blind grooves around the edge of the cut-off area on the rigid core board, and the opening of the blind groove is set On the side opposite the flex board, the rigid core board is then browned.

[0032] Making the flexible layer: Like the production process of the flexible circuit board (FPC) in the prior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com