PPS composite material for nanometer injection molding and preparation process thereof

A technology of nano-injection molding and composite materials, applied in the field of PPS composite materials for nano-injection molding and its preparation process, to achieve the effects of good compatibility, improved heat resistance, and high specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

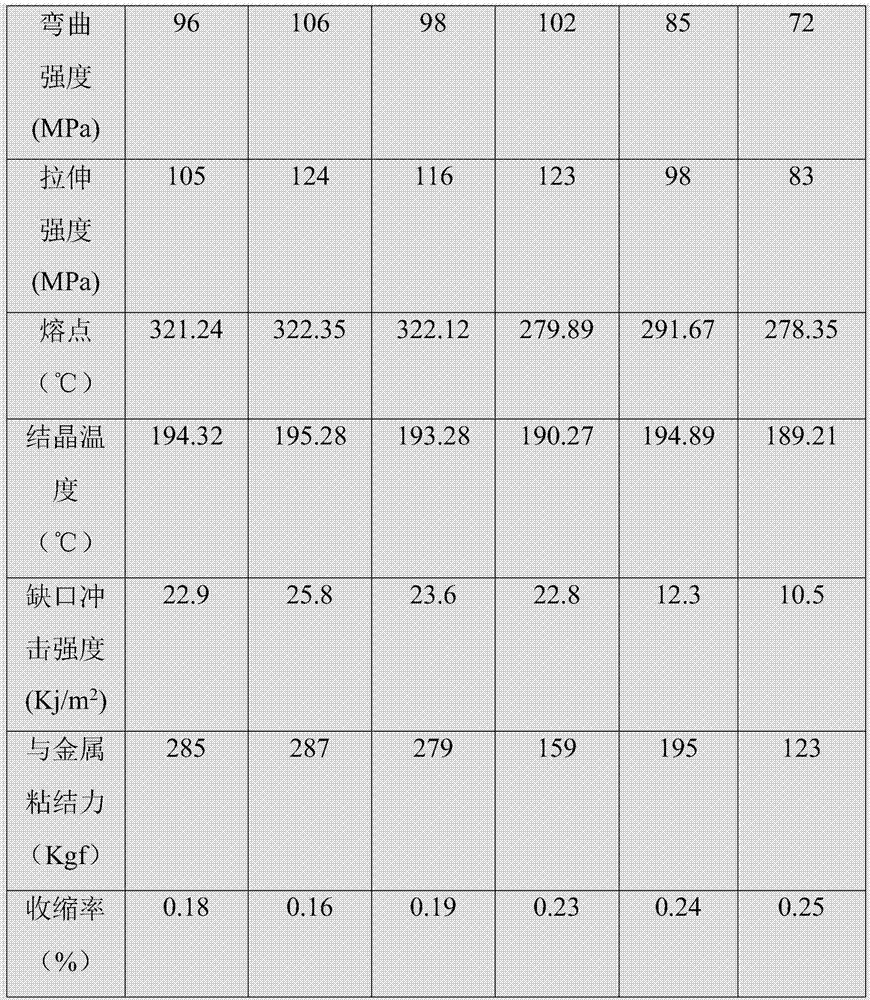

specific Embodiment 1

[0025] PPS composite material for nano injection molding, including the following components in parts by weight, 58.5 parts of PPS resin, 30 parts of continuous long carbon fiber, 5 parts of silicon dioxide, 3 parts of toughening agent, 0.5 part of antioxidant, 2 parts of coupling agent , lubricant 1 part.

[0026] Among them, the toughening agent is maleic anhydride grafted styrene-ethylene-butadiene-styrene; the continuous long carbon fiber is pitch-based carbon fiber filament; the weight average molecular weight of PPS resin is 45000; the coupling agent is silane coupling agent; the antioxidant is a mixture of hindered phenol and phosphite in a mass ratio of 1:1; the lubricant is composed of silicones and amide compounds.

specific Embodiment 2

[0028] PPS composite material for nano injection molding, including the following components in parts by weight, 67 parts of PPS resin, 18 parts of continuous long carbon fiber, 7 parts of silicon dioxide, 5 parts of toughening agent, 0.5 part of antioxidant, 1.5 parts of coupling agent , lubricant 1 part.

[0029] Among them, the toughening agent is maleic anhydride grafted styrene-ethylene-butadiene-styrene; the continuous long carbon fiber is pitch-based carbon fiber filament; the weight average molecular weight of PPS resin is 45000; the coupling agent is silane coupling agent; the antioxidant is a mixture of hindered phenol and phosphite in a mass ratio of 1:1; the lubricant is composed of silicones and amide compounds.

specific Embodiment 3

[0031]PPS composite material for nano injection molding, including the following components in parts by weight, 73 parts of PPS resin, 7 parts of continuous long carbon fiber, 9 parts of silicon dioxide, 8 parts of toughening agent, 1 part of antioxidant, 1 part of coupling agent , lubricant 1 part.

[0032] Among them, the toughening agent is maleic anhydride grafted styrene-ethylene-butadiene-styrene; the continuous long carbon fiber is pitch-based carbon fiber filament; the weight average molecular weight of PPS resin is 45000; the coupling agent is silane coupling agent; the antioxidant is a mixture of hindered phenol and phosphite in a mass ratio of 1:1; the lubricant is composed of silicones and amide compounds.

[0033] Control group 1: no silica was added to the composite system

[0034] The PPS composite material for nano injection molding includes the following components in parts by weight: 69 parts of PPS resin, 22 parts of continuous long carbon fiber, 5 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com