Glass fiber reinforced plastic centralizer

A technology of glass fiber reinforced plastics and centralizers, which is applied to drilling equipment, earthwork drilling, drill pipes, etc., and can solve problems such as inability to match fiberglass steel casings, oil pipes, and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

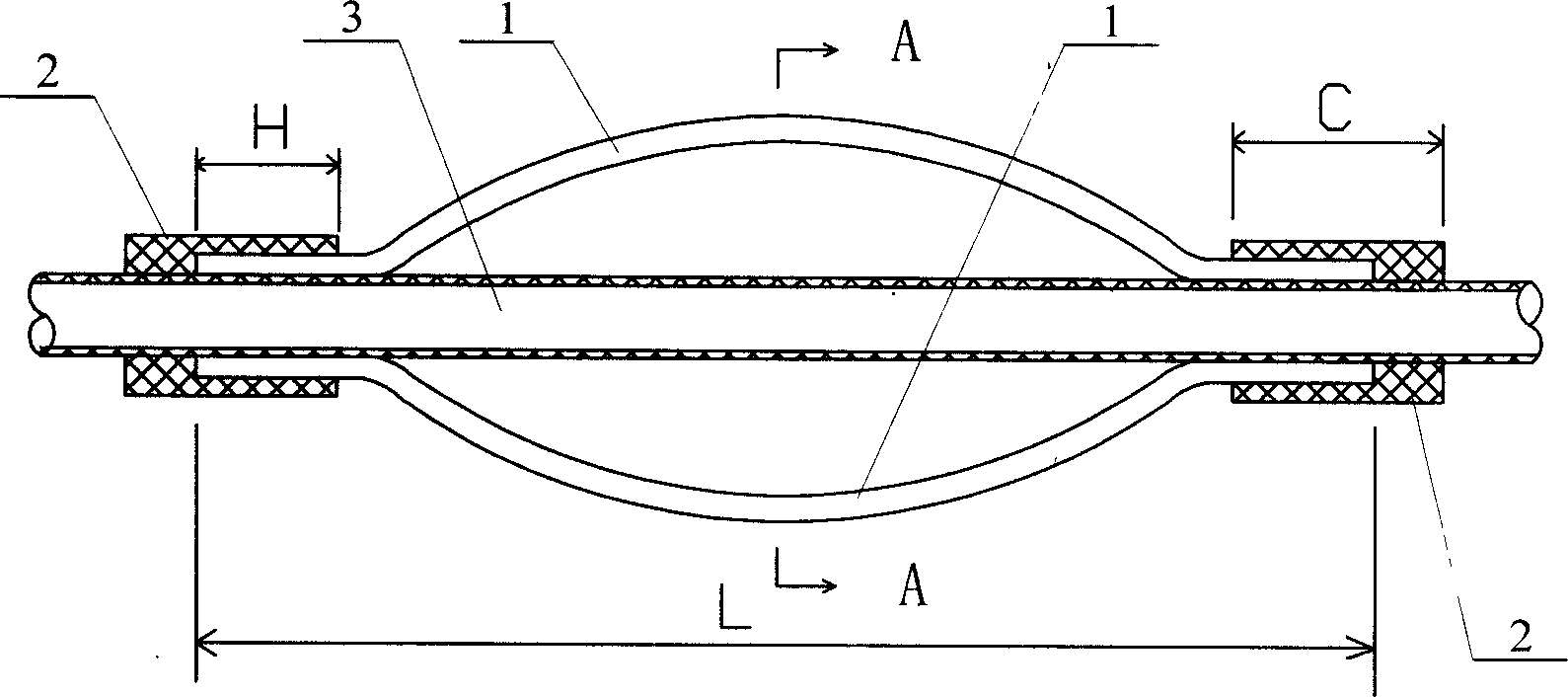

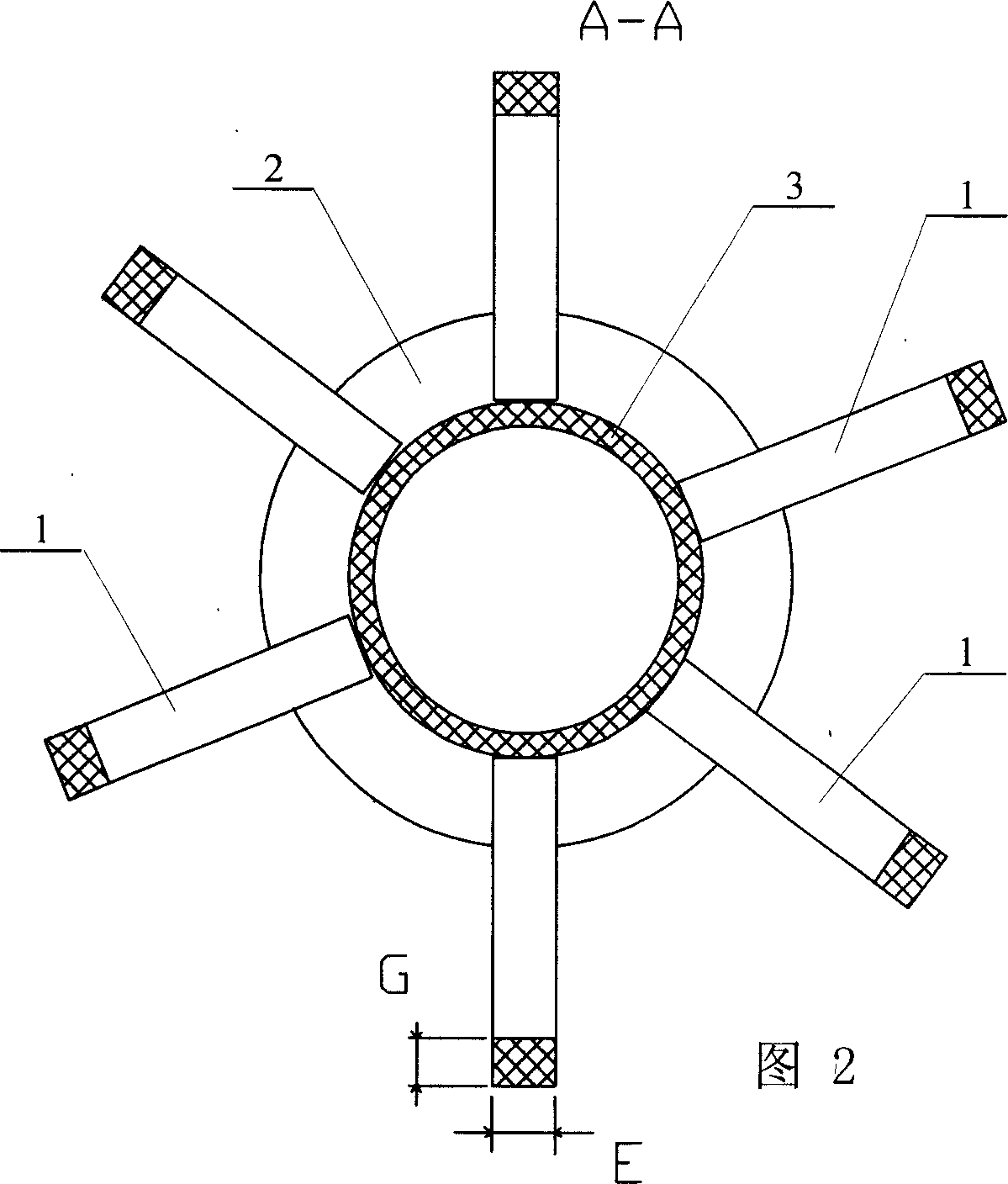

[0005] Specific implementation mode one: (see figure 1 , Fig. 2) The FRP centralizer of the present embodiment is composed of four to twelve FRP bow bars 1 and two FRP fixing rings 2, and the two FRP fixing rings 2 are respectively fixed on the two ends of four to twelve FRP bow bars 1 . The manufacturing method of the FRP centralizer of this embodiment is: the arched back of the FRP bow 1 faces outward, and is radially fixed on the surface of the mold at equal distances, and the two ends of the FRP bow 1 are impregnated with thermosetting resin. The continuous glass fiber is wound on the pipe body, so that the wound glass fiber forms the FRP fixing ring 2, and the FRP bow strip 1 and the FRP fixing ring 2 are fixed together by curing, and the resin system is cured and released from the mold to become a complete FRP centralizer . There is another method in this embodiment, which is to directly solidify the FRP centralizer on the FRP casing or FRP oil pipe according to the ab...

specific Embodiment approach 2

[0006] Specific embodiment two: (refer to Fig. 2) the FRP arch bar 1 of this embodiment consists of six components. The other components, connections and manufacturing methods are the same as those in the first embodiment.

specific Embodiment approach 3

[0007] Specific Embodiment Three: The FRP arch bar 1 of this embodiment consists of eight pieces. The other components, connections and manufacturing methods are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com