Preparation method of carbon fiber and fiberglass-combined reinforced composite

A technology for reinforcing composite materials and glass fibers, applied in the field of composite materials, can solve problems such as poor cost performance, and achieve the effects of high specific modulus, weight reduction, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

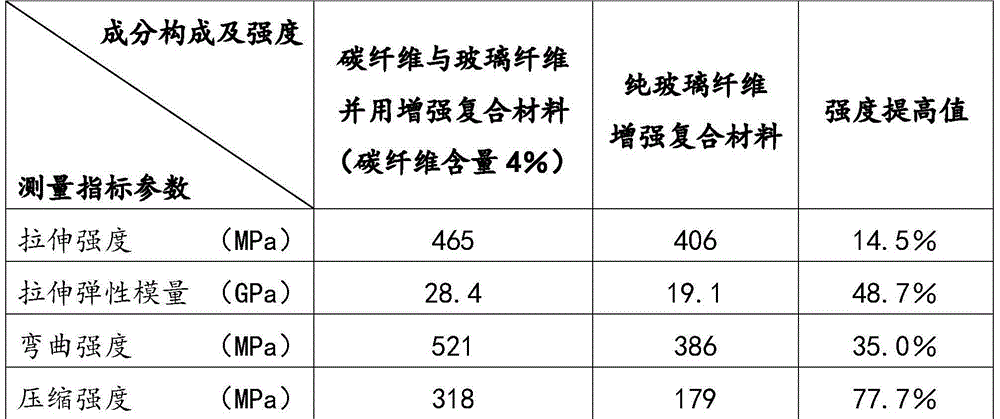

[0016] When reinforcing resin-based composite materials, tensile strength, tensile modulus of elasticity, flexural strength, and compressive strength are the main technical indicators to be considered. The above four indicators of the reinforced composite material with carbon fiber and glass fiber were also tested. The relevant conditions of the test are as follows:

[0017] Test method: According to the measurement methods in the national standard of the four technical indicators of tensile strength, tensile elastic modulus, flexural strength, and compressive strength.

[0018] Parameter setting: In the case of pure glass fiber reinforced resin composite material, the weight part of glass fiber is 55%, and the weight part of resin material is 45%. Enter the following table; the above-mentioned four indicators of the reinforced composite material with carbon fiber and glass fiber are also tested, wherein the weight part of glass fiber is 51%, the weight part of resin material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com