Patents

Literature

150 results about "Styrene ethylene butadiene styrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SEBS (styrene-ethylene-butylene-styrene) SEBS is actually a form of thermoplastic elastomer (TPE) with styrene added. Green Peace lists SEBS as an acceptable alternative to PVC in toys.

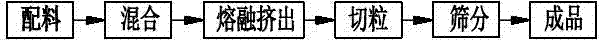

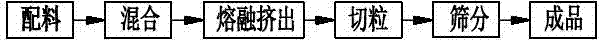

Hot-melt adhesive for steel-plastic composite pipe

ActiveCN102190984AImprove performanceExtended service lifeNatural rubber adhesivesNon-macromolecular adhesive additivesPolyolefinRare earth

The invention discloses a hot-melt adhesive for a steel-plastic composite pipe, which is prepared by blending and extruding the following components in percentage by weight by a parallel double screw extruder: 5-40% of binding resin master batch, 50-80% of polyolefin resin, 5-25% of tackifying resin and 0.02-5% of inorganic rare-earth oxide, wherein the binding resin is prepared by carrying out graft modification on polyethylene and / or ethylene copolymer, which is / are used as the matrix resin, and initiator (accounting for 0.01-0.2 wt% of the binding resin master batch) and unsaturated polar monomer (accounting for 0.1-5 wt% of the binding resin master batch); the polyolefin resin is used for adjusting the consumption of the binding resin master batch and the comprehensive properties of the hot-melt adhesive; and the tackifying resin is one or combination of SBS (styrene-butadiene-styrene), SEBS (styrene-ethylene-butadiene-styrene), SIS (styrene-isoprene-styrene), cis-1,4-polybutadiene rubber, nitrile-butadiene rubber and natural rubber. Since the rare-earth oxide is added, the grafting ratio of the binding resin master batch in the hot-melt adhesive is increased, thereby obviously enhancing the initial viscosity, enduring viscosity, binding strength and other properties.

Owner:河北金天塑胶新材料有限公司

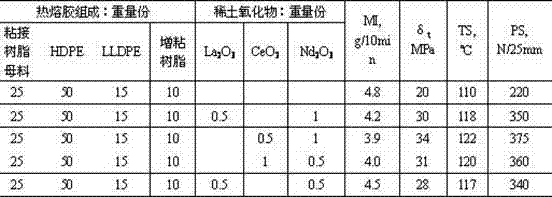

High-softness high-wear-resistance rubber-plastic injection foam material

The invention relates to a high-softness high-wear-resistance rubber-plastic injection foam material which is prepared from the following raw materials in percentage by weight: 45-48% of ethylene-vinyl acetate (EVA) copolymer with the VA (vinyl acetate) content of 22-28%, 20-24% of EVA copolymer with the VA content of 36-40%, 10-15% of ethylene-octylene copolymer, 13-15% of ethylene propylene diene monomer rubber, 12-15% of styrene-ethylene-butadiene-styrene (SEBS), 10-13% of anti-wear agent, 0.8-1.0% of bridging agent and 2.1-2.4% of foaming agent. The foam material has the advantages of high softness, rubber feeling, high elasticity and favorable physical properties, can improve the plastic feeling and elasticity of the EVA foam product, is suitable for casual living shoes for nonprofessional sports, enhances the wear comfort of the product, and satisfies the demands for casual living of urban people.

Owner:GUIRENNIAO CO LTD

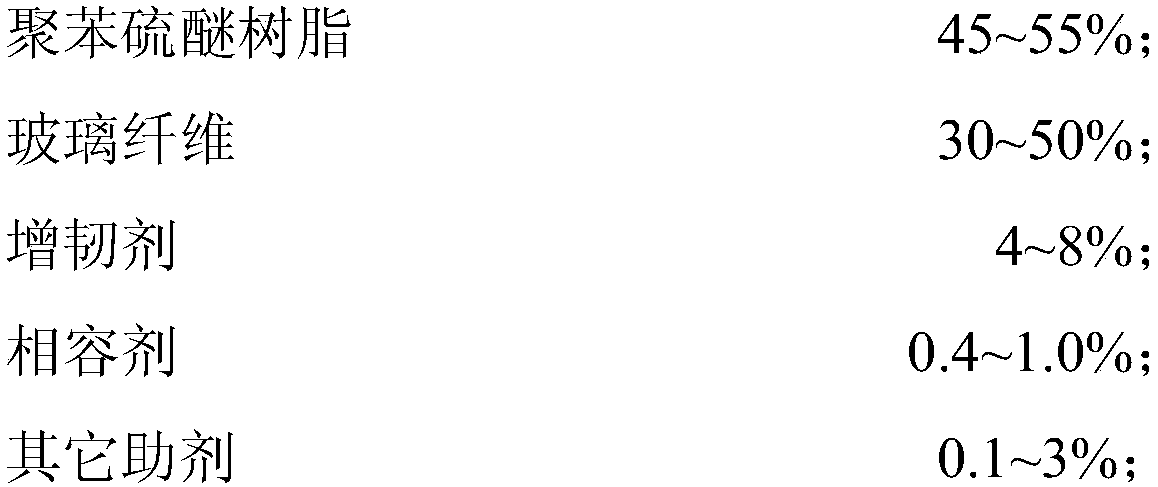

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

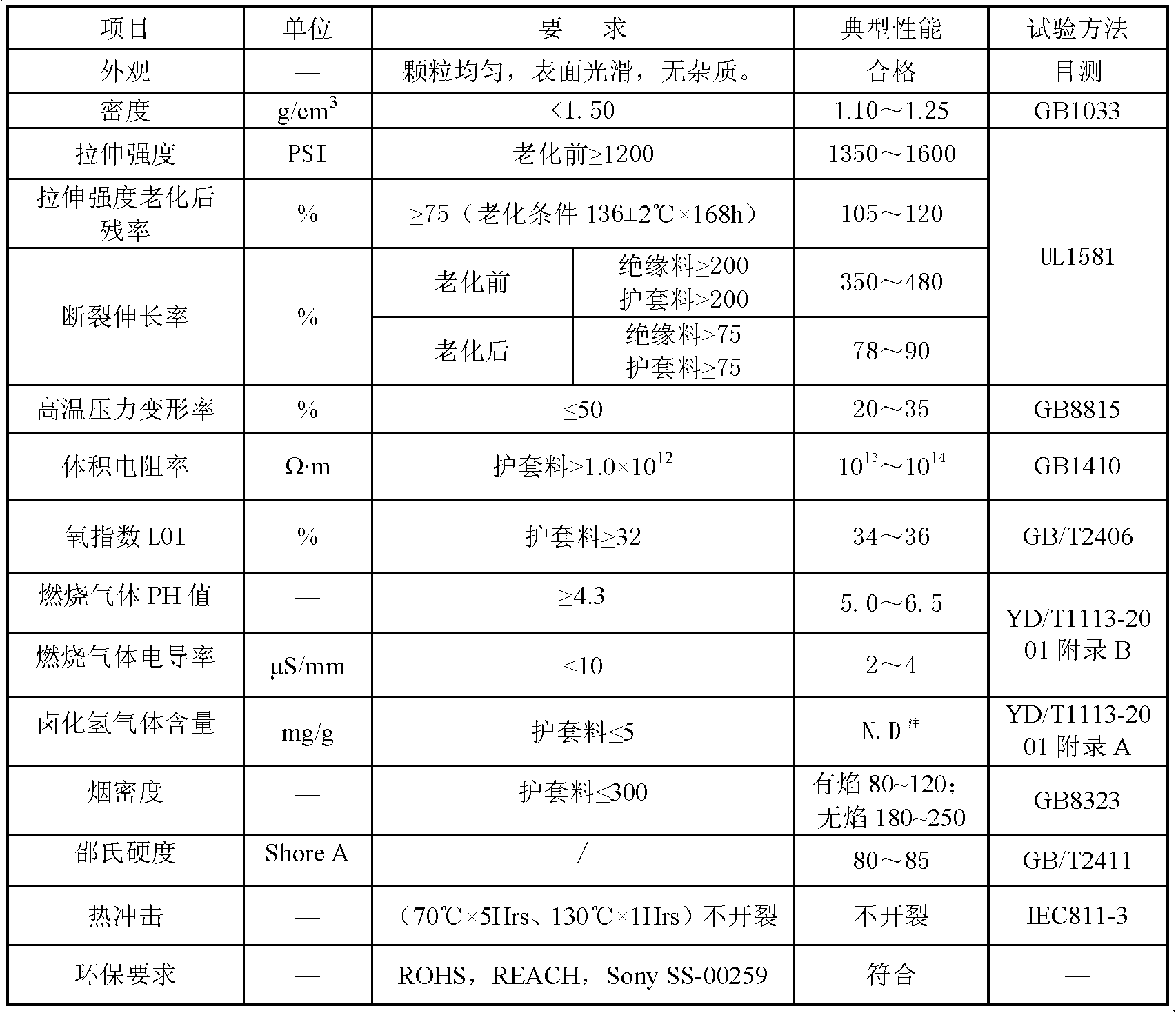

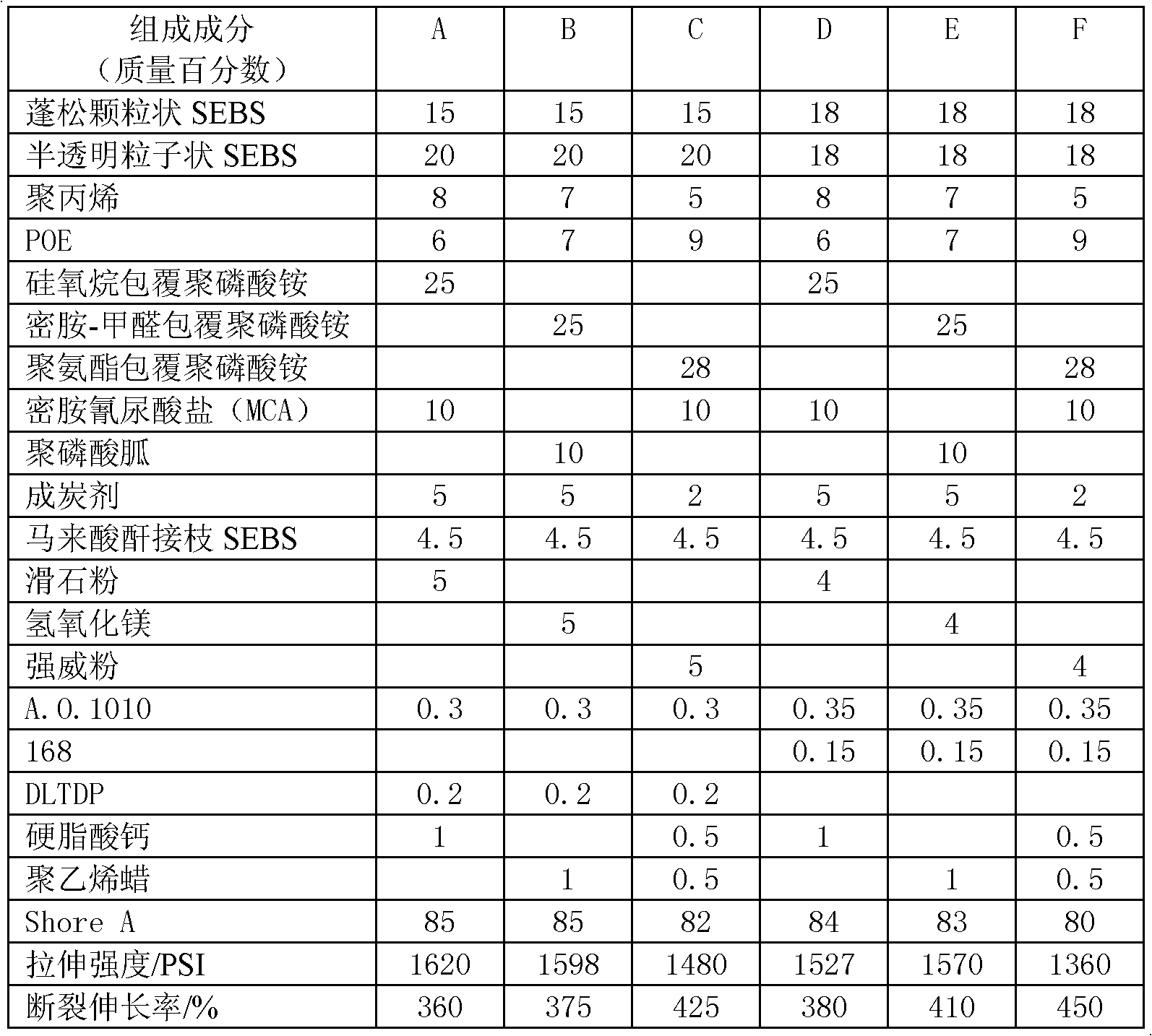

Cable thermoplastic elastomer composition and preparation method thereof

InactiveCN101955626AImprove high flame retardant performanceImprove flame retardant performancePlastic/resin/waxes insulatorsElastomerPolyolefin

The invention relates to insulated plastic, in particular to a cable thermoplastic elastomer composition and a preparation method thereof. The cable thermoplastic elastomer composition comprises the following components: 30 to 65 weight percent of styrene-ethylene-butadiene-styrene (SEBS), 5 to 20 weight percent of polypropylene, 5 to 15 weight percent of polyolefin elastomer (POE), 13 to 40 weight percent of fire retardant, 2 to 10 weight percent of charring gent, 0.5 to 5 weight percent of fire retarding assistant, 0.1 to 6 weight percent of compatilizer, 0.1 to 2 weight percent of antioxygen and 0.01 to 2 weight percent of processing assistant. The invention provides a formula technique and a production method of a halogen-free TPE-S thermoplastic elastomer composition with proper hardness (Shore A of 80 to 85), high-temperature resistance and high fire retarding resistance for wire and cable protective sleeves and insulation layers.

Owner:江苏安格特新材料科技有限公司 +1

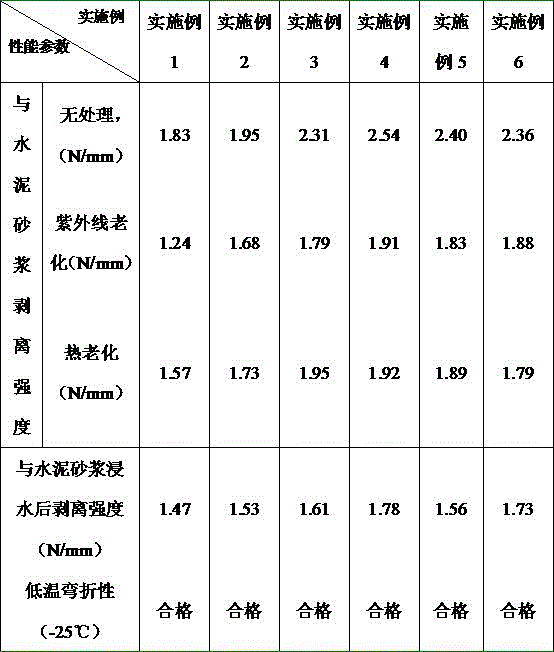

High-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN105694776AImprove heat aging resistanceAccelerated agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerButadiene-styrene rubber

The invention discloses a high-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by mass: 30-200 parts of elastomer composition, 40-100 parts of tackifying resin, 20-70 parts of plasticizer, 0.3-5 parts of stabilizer and 0.1-3 parts of additive. The elastomer composition is selected from SIS (styrene-isoprene-styrene) / SEPS (styrene-ethylene / propylene-styrene), SIS / SBS (styrene-butadiene-styrene), and / or SBS / SEBS (styrene-ethylene-butadiene-styrene). The mass ratio of the two components in the elastic composition is 1-20; the styrene in the SIS in the elastic composition accounts for 15-30 wt%, the styrene in the SEPS accounts for 10-30 wt%, the styrene in the SBS accounts for 20-50 wt%, and the styrene in the SEBS accounts for 10-40 wt%. The hot-melt pressure-sensitive adhesive has the characteristics of excellent ultraviolet aging resistance, favorable thermal aging resistance, high peel strength, simple technique and low cost.

Owner:HUIZHOU NENGHUI CHEM CO LTD

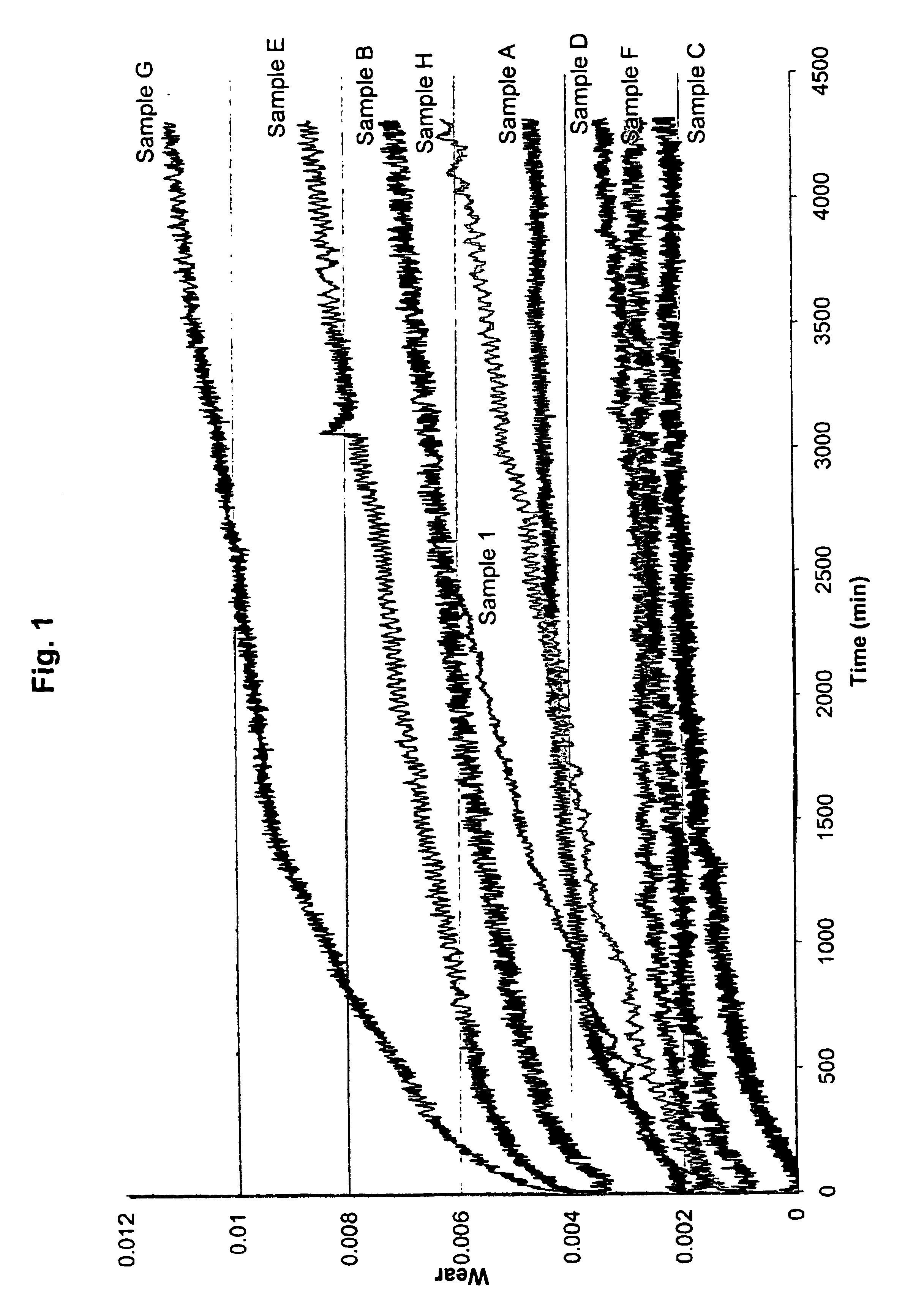

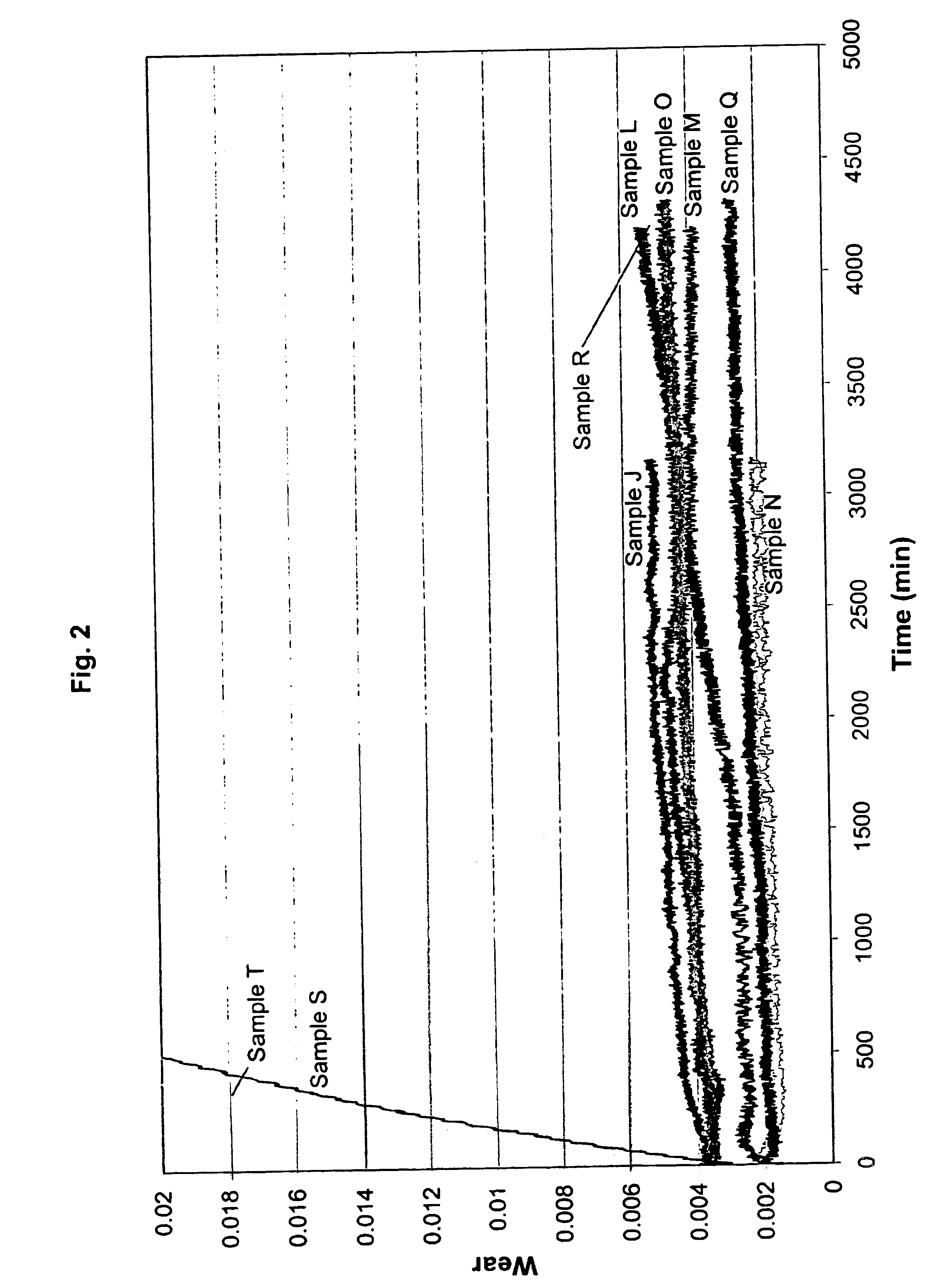

Compositions containing polyphenylene ether and/or polystyrene having improved tribological properties and methods for improving tribological properties of polyphenylene ether and/or polystyrene compositions

InactiveUS6887938B2Improve tribological propertiesImprove wear resistanceSpecial tyresOrganic dyesLinear low-density polyethylenePolystyrene

Internally lubricated polymer compositions containing a styrene- and / or polyphenylene ether-containing polymer, an olefin-containing polymer, and a compatibilizer are provided. The olefin-containing polymer, which is present in the compositions in about 3 to about 30 weight percent, provides internal lubrication and improves the tribological properties of the compositions compared with the styrene- or polyphenylene ether-containing polymer alone, as determined by wear measurements. Preferred compositions exhibit wear factors less than about 130×10−11n mm5 / Pa-m. A preferred composition includes a blend of polystyrene / polyphenylene ether, linear low density polyethylene, and styrene-ethylene-butadiene-styrene. Methods are also provided for improving tribological properties of styrene- and / or polyphenylene ether-containing base polymers by incorporating into the base polymers at least one olefin-containing polymer and at least one compatibilizer, or by incorporating at least one substantially halogen-free internal lubricant.

Owner:SHPP GLOBAL TECH BV

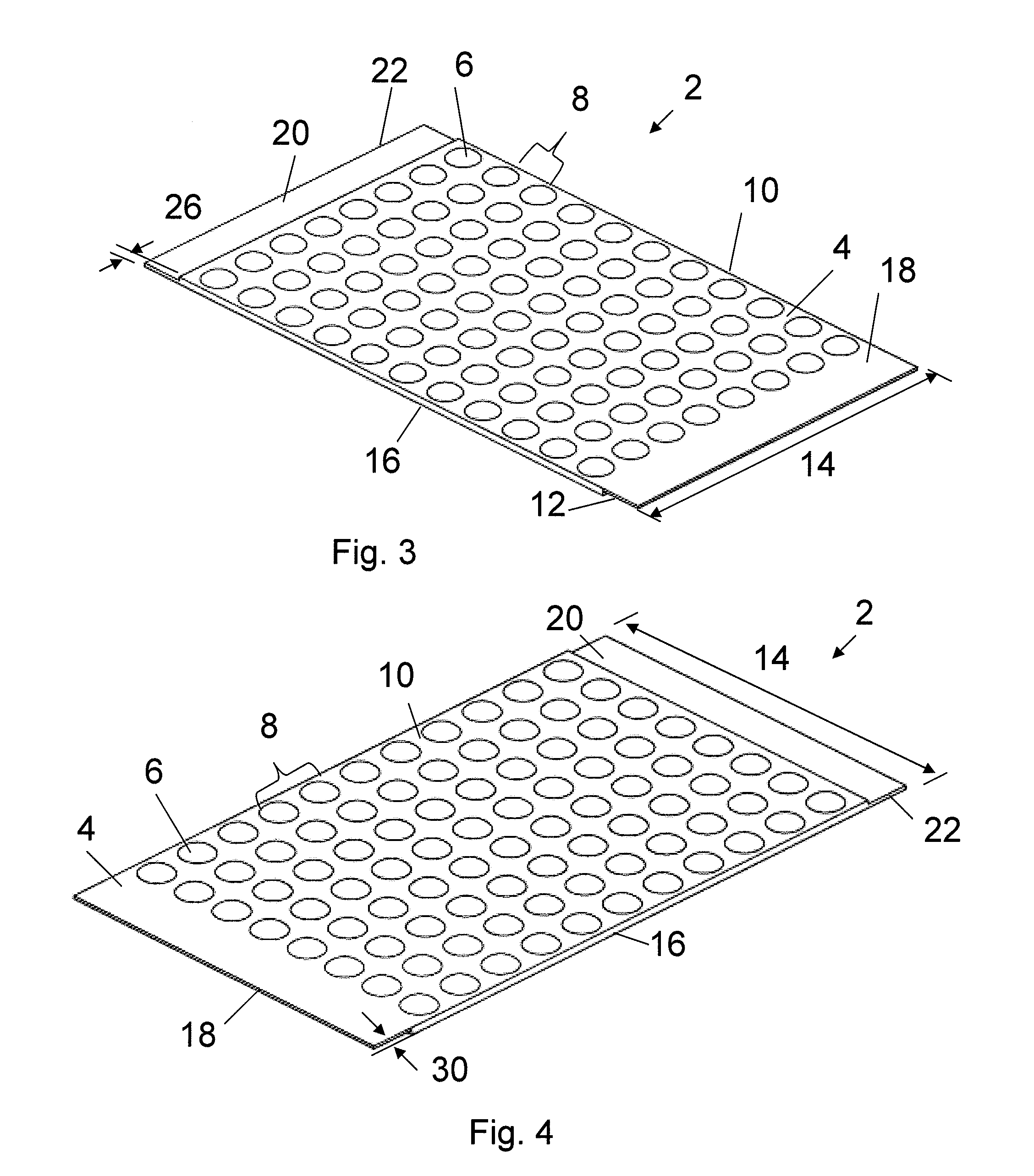

Antimicrobial colloidal silver and gold products and method of making same

Gelatinous foam, coated paper, fabric, and polymer materials combined with the Colloidal Silver or Gold additive to formulate products with antimicrobial surfaces. Some embodiments of the present invention can include gelatinous materials selected from a group consisting of thermosetting polymer, Styrene-Ethylene-Butadiene-Styrene polymer (SEBS), Thermoplastic Elastomer (TPE), and Polyurethane (PU) gelatin with and without a raised geometry on an outer surface and in any shape. The various embodiments include coated polymer sheets, polymer trays, bamboo and / or cotton towels and fabric, polymer foam, or polymer mats containing nano-silver or nano-gold in an scheduled and organized manner (with input / requests from the customer) to create permanent or semi-permanent anti-microbial surfaces.

Owner:ECO PROD GROUP

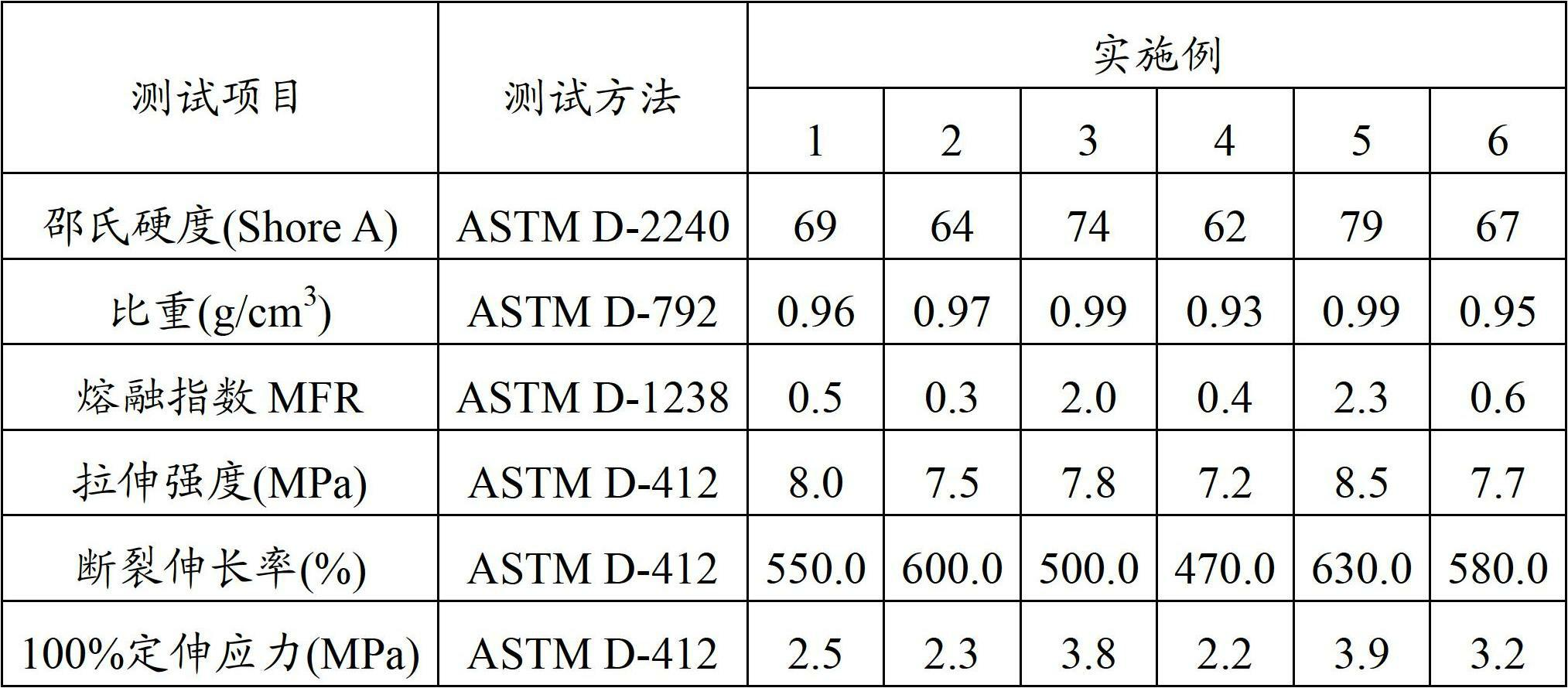

TPE (thermoplastic elastomer) material applicable to automobile interior decorations and preparation method thereof

The invention relates to a TPE (thermoplastic elastomer) material applicable to automobile interior decorations and a preparation method thereof. The material comprises the following components in parts by weight: 100-200 parts of SEBS (styrene-ethylene-butadiene-styrene), 100-200 parts of white oil, 20-80 parts of polypropylene, 30-100 parts of filler and 0.2-0.4 part of stabilizer. The method comprises the following steps: slowly mixing the SEBS and white oil in a stirrer at 50-80 DEG C for 20-30 minutes, mixing with the other raw materials and assistants for 20-30 minutes, and adding into a double screw extruder; meanwhile, adding a liquid azeotrope former into first three regions of a vacuum zone by using a melt measuring pump; and carrying out vacuum exhaust until the liquid azeotrope former is thoroughly discharged. The TPE material has the advantages of low smell, high / low-temperature resistance, low atomization value, wear resistance and excellent stretching resistance, is especially suitable for automobile interior decoration materials, has the characteristics of wide application range, high practicality and simple production technique, is more environment-friendly and durable than the existing TPE material, and is worthy of widespread popularization.

Owner:大韩道恩高分子材料(上海)有限公司

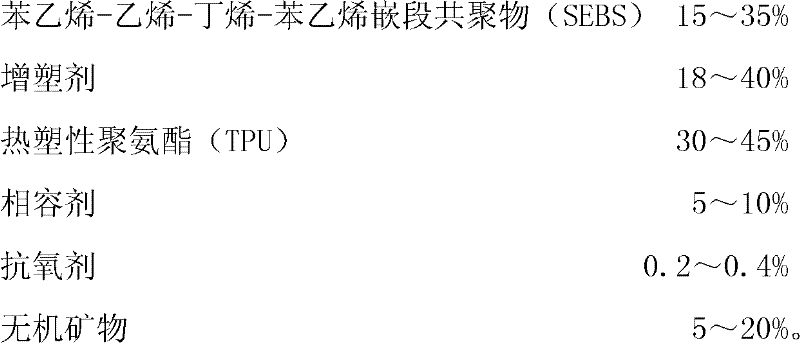

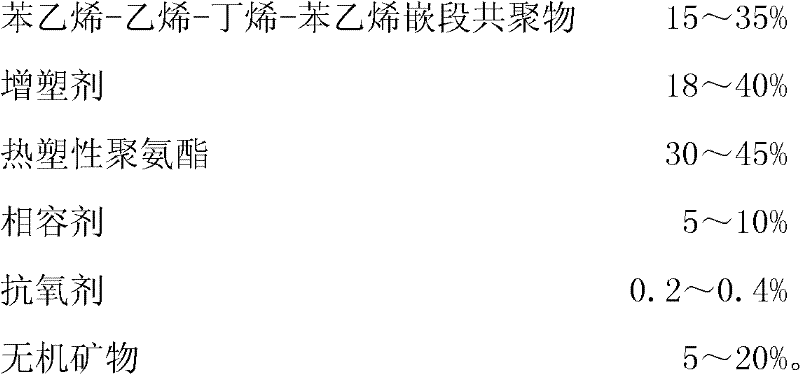

Thermoplastic elastomer composition of encapsulation PETG (poly(ethylene terephthalate) glycol) and preparation method thereof

The invention relates to a thermoplastic elastomer composition of encapsulation PETG (poly(ethylene terephthalate) glycol) and a preparation method of the thermoplastic elastomer composition. The composition is prepared from the following raw materials in weight percentage: 15-35% of SEBS (styrene-ethylene-butadiene-styrene), 18-40% of a plasticizer, 30-45% of TPU (thermoplastic polyurethane), 5-10% of a compatilizer, 0.2-0.4% of an antioxidant, and 5-20% of an inorganic mineral. The preparation method comprises weighing raw materials proportionally by weight; mixing SEBS and the plasticizer in a high mixing machine for 20-30min, adding other raw materials, mixing, and taking out; and placing into a double screw extruder for extrusion granulation, wherein the rotation speed of the main machine of the screw is 200-350rpm, and the processing temperature is in the range of 180-220 DEG C. The thermoplastic elastomer composition of the invention has the following advantages: the polarity of SEBS is changed, resulting in chemical reaction of surfaces of the elastomer and the copolymer polyester and high bonding strength of secondary injection molding, and after stripping, a layer of the elastomer completely adheres on the surface of the PETG backing material, resulting in comfort handfeel and strong gripping strength; and the composition is a non-toxic and innocuous environment-friendly material for human and environment, and fully meets the requirements of high-end toothbrushes for PETG encapsulation.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

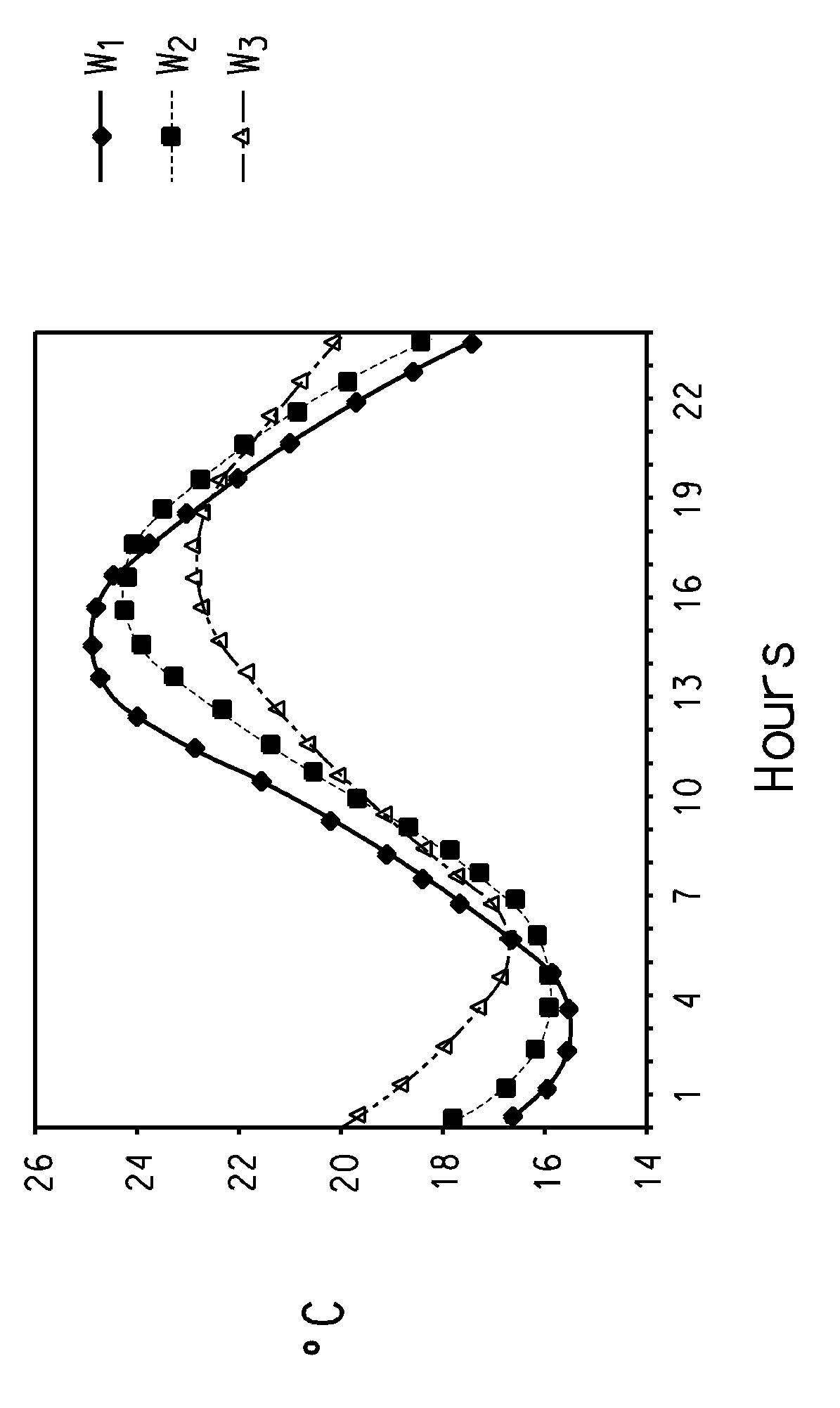

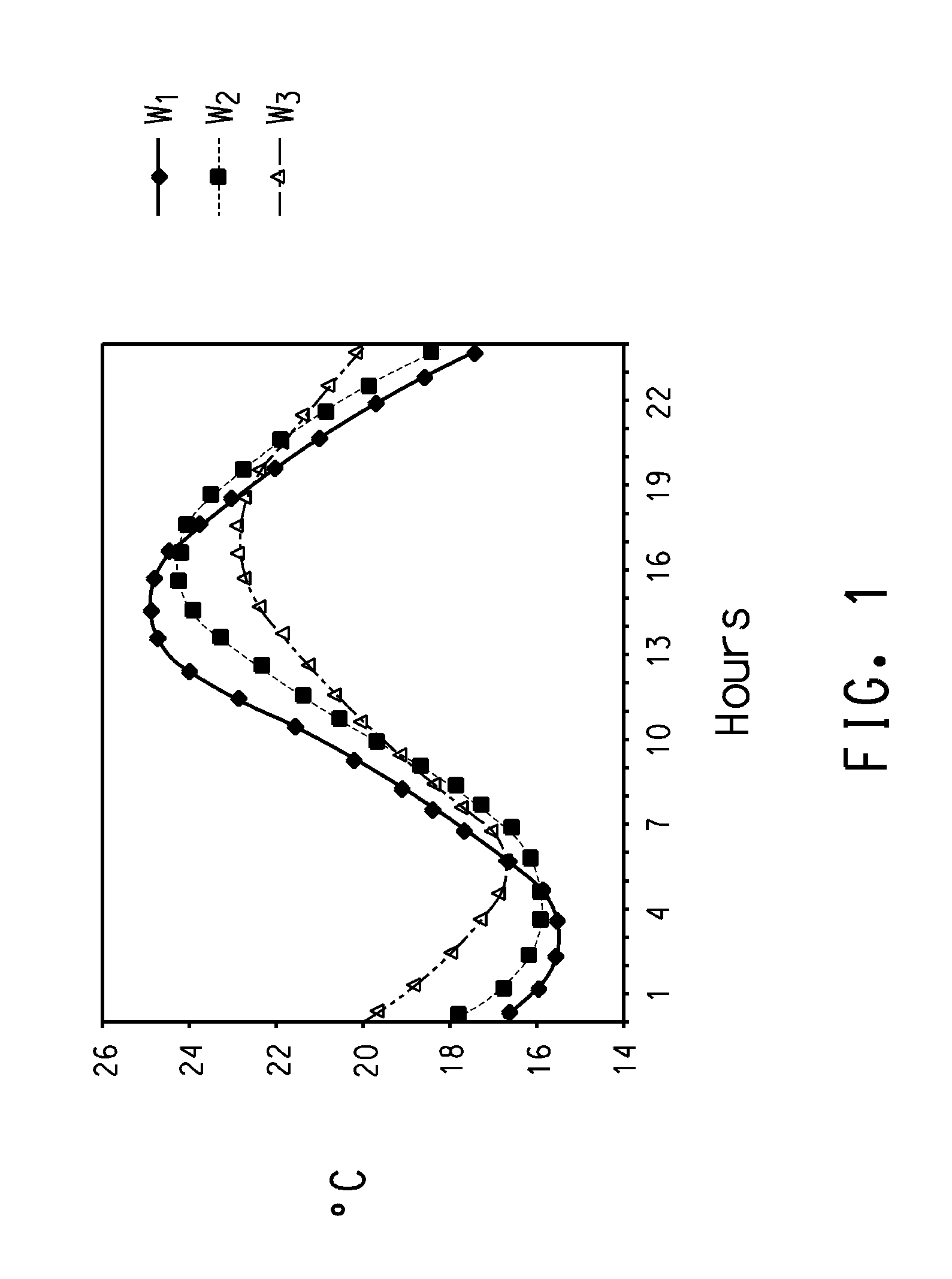

Phase change material (PCM) compositions for thermal management

InactiveUS8333903B2Domestic upholsteryHeat-exchange elementsLow-density polyethyleneVolumetric Mass Density

The present invention relates to a Phase Change Material (PCM) composition comprising a) from 20 to 80 wt % of a PCM; and b) from 20 to 80 wt % of one or more polymers chosen from the group consisting of b1) Very Low Density Polyethylene (VLDPE) having a density equal or lower than 0.910 g / cm3 measured according to ASTM 792; b2) Ethylene Propylene Rubber (EPR) having a density equal or lower than 0.900 g / cm3 measured according to ASTM 792; b3) Styrene Ethylene Butadiene Styrene (SEBS) copolymers; and b4) Styrene Butadiene Styrene (SBS) copolymers. The PCM composition of the present invention can be used in applications where thermal management is needed, like for example in building, automotive, packaging, garments and footwear.

Owner:EI DU PONT DE NEMOURS & CO +1

Hot-melt pressure-sensitive adhesive and preparation technology thereof

InactiveCN105694803APrevent agingEliminate oxidationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPlasticizer

The invention belongs to the technical field of synthetic adhesives and particularly relates to a hot-melt pressure-sensitive adhesive and a preparation technology thereof. The hot-melt pressure-sensitive adhesive is prepared from raw materials in percentage by mass as follows: 1%-5% of a TPU (thermoplastic polyurethane) elastomer, 10%-15% of hydrogenated SEBS (styrene-ethylene-butadiene styrene), 45%-55% of tackifying resin, 25%-35% of a plasticizer, 0-1% of solid filler and 0-0.5% of an antioxidant. The TPU elastomer is added and blended with SEBS for modification, a framework structure is formed, components such as the tackifying resin, the plasticizer, the solid filler, the antioxidant and the like are added, the problem of damp-heat aging of the adhesive due to seasonal change is solved, the preparation technology of the adhesive is explored, the production cycle is shortened, and energy consumption is reduced.

Owner:BINZHOU POLYTECHNIC

Phase change material (PCM) compositions for thermal management

InactiveUS20110248208A1Domestic upholsteryHeat-exchange elementsLow-density polyethyleneVolumetric Mass Density

The present invention relates to a Phase Change Material (PCM) composition comprising a) from 20 to 80 wt % of a PCM; and b) from 20 to 80 wt % of one or more polymers chosen from the group consisting of b1) Very Low Density Polyethylene (VLDPE) having a density equal or lower than 0.910 g / cm3 measured according to ASTM 792; b2) Ethylene Propylene Rubber (EPR) having a density equal or lower than 0.900 g / cm3 measured according to ASTM 792; b3) Styrene Ethylene Butadiene Styrene (SEBS) copolymers; and b4) Styrene Butadiene Styrene (SBS) copolymers. The PCM composition of the present invention can be used in applications where thermal management is needed, like for example in building, automotive, packaging, garments and footwear.

Owner:EI DU PONT DE NEMOURS & CO +1

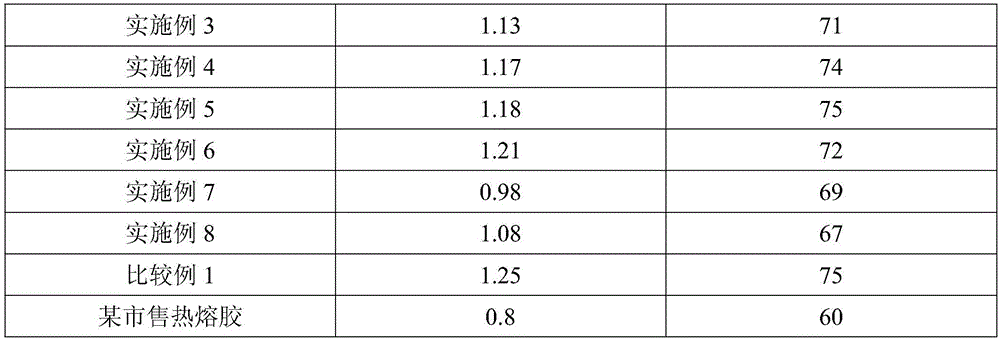

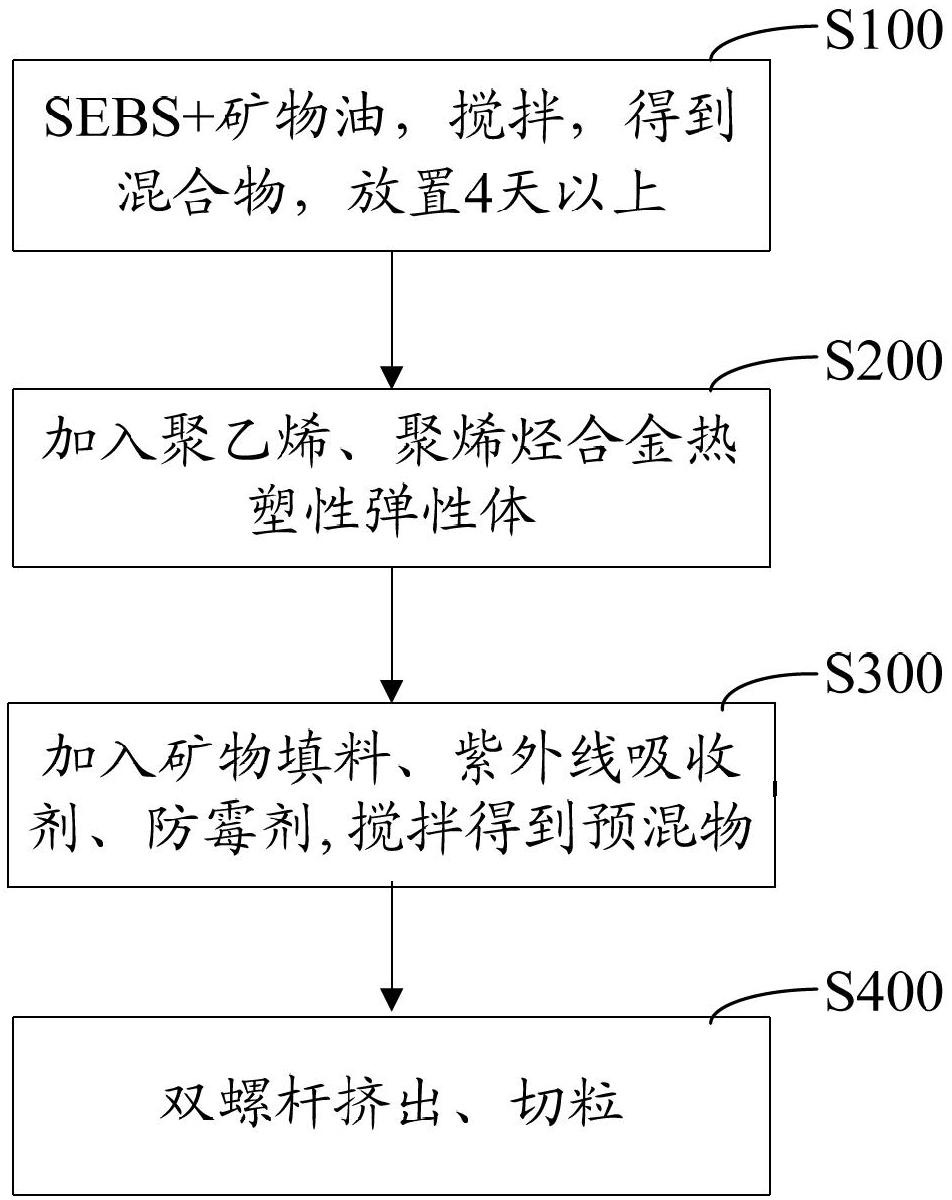

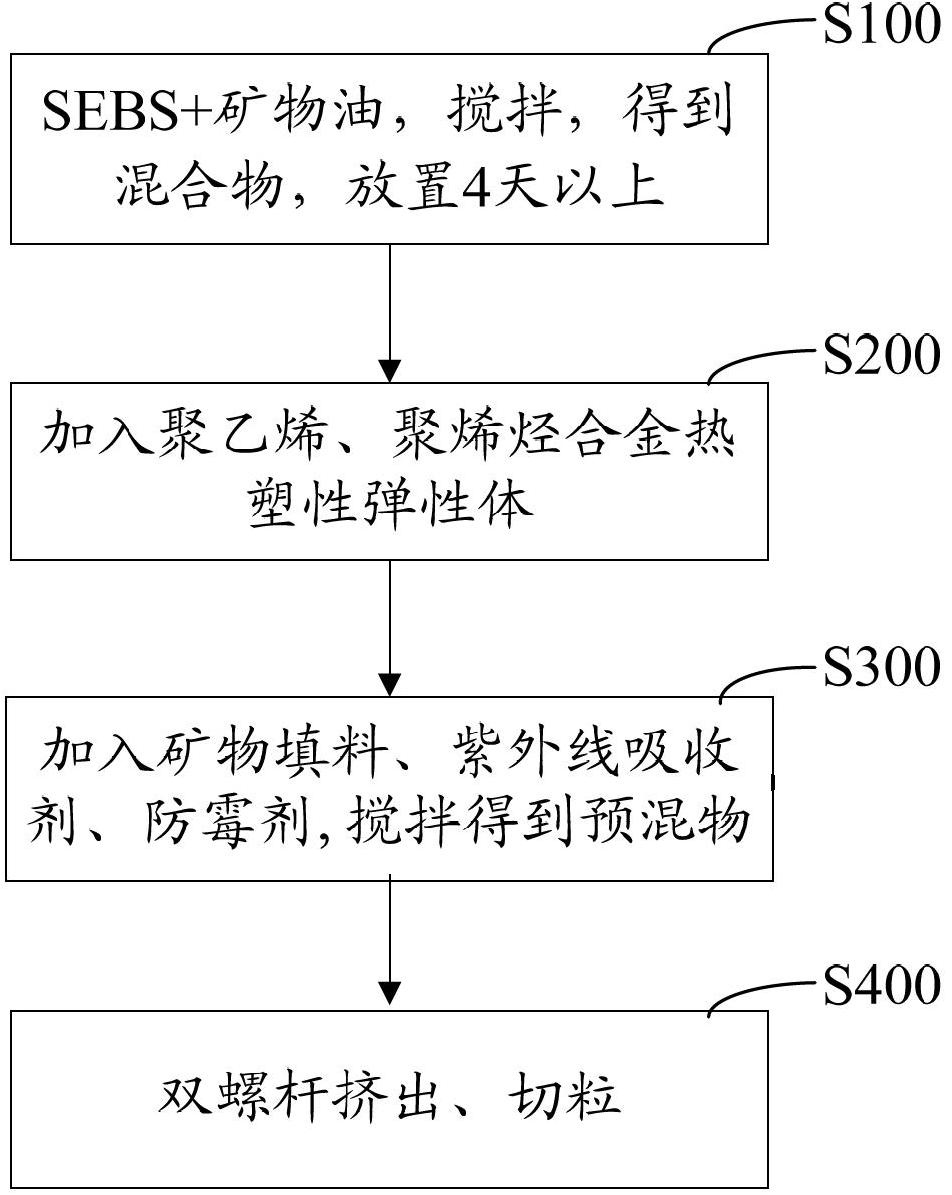

Thermoplastic elastomer material for refrigerator sealing strip and preparation method thereof

ActiveCN102675807AImproved oil and solvent resistanceIncreased thermoplastic elastomer componentPolyolefinHeat resistance

The invention provides a thermoplastic elastomer material for refrigerator sealing strip and a preparation method thereof. The thermoplastic elastomer material for the refrigerator sealing strip comprises the following components in parts by weight: 20-40 parts of SEBS (Styrene-Ethylene-Butadiene-Styrene), 20-45 parts of mineral oil, 20-50 parts of polyethylene, 5-20 parts of a mineral filler, 10-30 parts of a polyolefin alloy thermoplastic elastomer, 0.5-2 parts of an ultraviolet absorber and 0.5-2 parts of a mildew preventive. The thermoplastic elastomer material for the refrigerator sealing strip has the advantages of low density, environment friendliness, surface smoothness, soft handfeel, simple processing technic, high welding performance, flexible product design, excellent cold resistance, excellent heat resistance, higher size accuracy and higher surface fineness, and is more suitable for extruded profiled bars and refrigerator sealing strip products with air blowing requirements.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

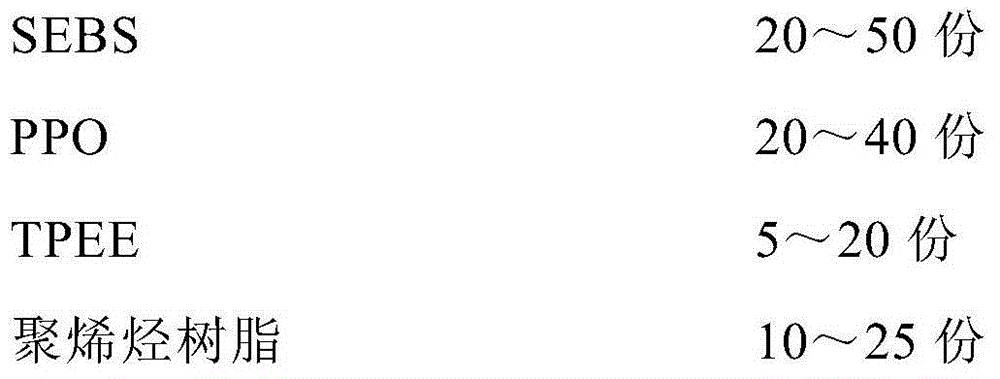

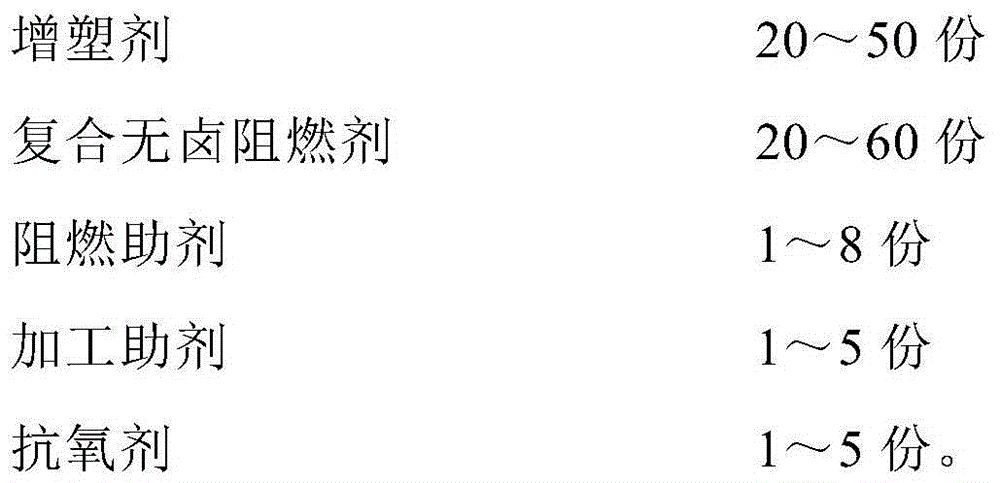

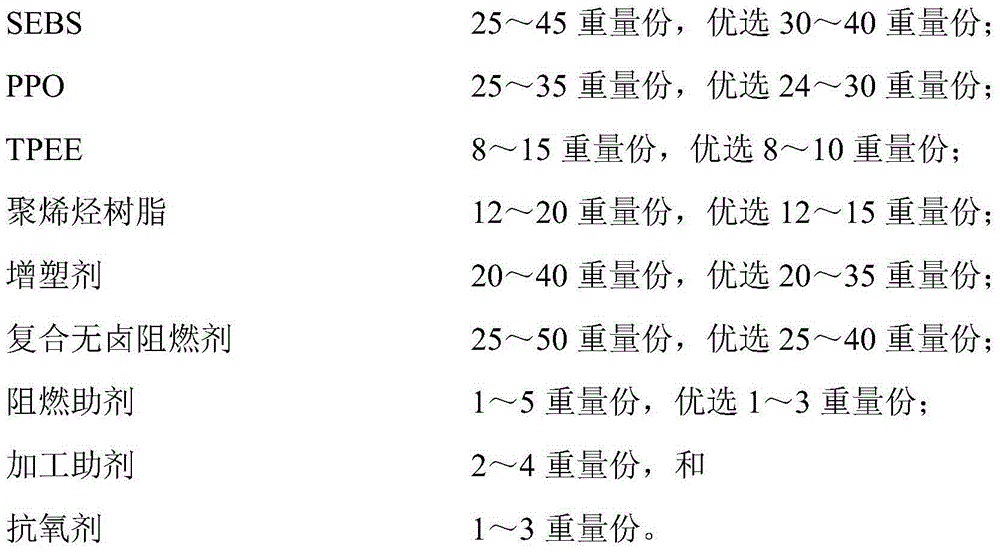

Oil-resistant TPE (thermoplastic elastomer) halogen-free flame-retardant cable material and preparation method thereof

The invention relates to an oil-resistant TPE (thermoplastic elastomer) halogen-free flame-retardant cable material and a preparation method thereof. The cable material comprises the following components in parts by weight: 20-50 parts of SEBS (styrene-ethylene-butadiene-styrene), 20-40 parts of PPO (polypropylene oxide), 5-20 parts of TPEE (thermoplastic polyether ester elastomer), 10-25 parts of polyolefin resin, 20-50 parts of plasticizer, 20-60 parts of composite halogen-free flame retardant, 1-8 parts of flame-retardant assistant, 1-5 parts of processing assistant and 1-5 parts of antioxidant. The cable material can be used as an oil-resistant cable coating material, and overcomes the defect of poor oil resistance in the SEBS / PP (polypropylene) blend TPE elastomer system and the detects of poor oil resistance and poor crack resistance in the PPO system. The obtained product has very excellent comprehensive properties in the aspects of flexibility, thermal shock resistance, strength, elongation percentage and flame retardancy.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Halogen-free flame retardant high-tear-resistance wire and cable compound for electric vehicles and wire and cable production method

InactiveCN105038087AAchieve heat resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsButadiene DioxideTear resistance

The invention discloses a halogen-free flame retardant high-tear-resistance wire and cable compound for electric vehicles. The wire and cable compound comprises the following components in parts by weight: 100 parts of styrene-ethylene / butadiene-styrene block copolymer (SEBS), 20-60 parts of polypropylene, 5-20 parts of alkene polymer, 0.3-3 parts of antioxidant, 40-90 parts of halogen-free flame retardant, 20-60 parts of charring agent, 0.5-3 parts of processing aids and 15-80 parts of softening and plasticizing agent. The invention also discloses a production method for preparing wires and cables with the wire and cable compound. Through radiation micro-crosslinking, the wire and cable products prepared with the cable compound have excellent tear resistance, higher physical and mechanical properties and good electric insulation property, achieve excellent flame retardance under the premise of satisfying environmental protection, also have the advantage of high production efficiency and can be widely applied to the field of new energy, such as cables used for electric vehicles.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

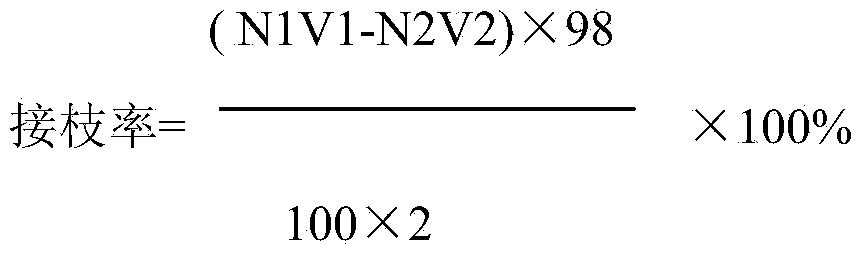

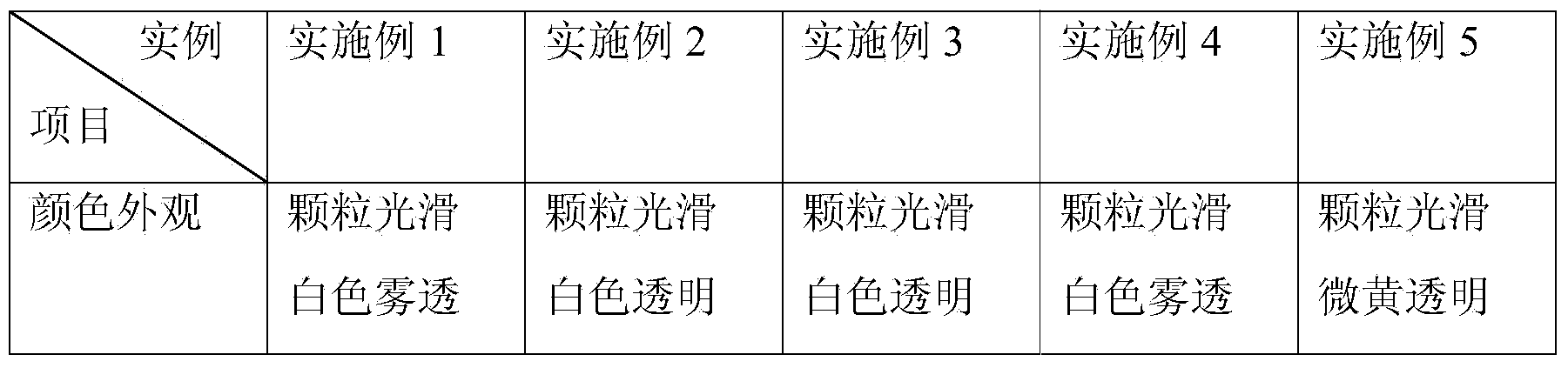

SEBS/PP (styrene-ethylene-butadiene-styrene/polypropylene) alloy melt-grafted maleic anhydride graft copolymer and preparation method thereof

ActiveCN104292729AImprove liquidityGood compatibilityPolypropyleneStyrene ethylene butadiene styrene

The invention relates to an SEBS / PP (styrene-ethylene-butadiene-styrene / polypropylene) alloy melt-grafted maleic anhydride graft copolymer and a preparation method thereof. The graft copolymer is prepared from the following raw materials in parts by mass: SEBS, PP, maleic anhydride monomer, styrene monomer, initiator, diluter and lubricant. The preparation method comprises the following steps: proportionally mixing the raw materials, stirring and blending, adding into an extruder, and carrying out melt plastification, compounding, extrusion, water ring granulation, cooling, dehydration and forced air drying on the mixture to obtain the graft copolymer. By using the double screw extruder as the melt grafting copolymerization reaction vessel, the method is high in production efficiency and can implement continuous production; and compared with other process routes, the method provided by the invention has the characteristics of environment friendliness, high efficiency and low cost.

Owner:赣州能之光新材料有限公司

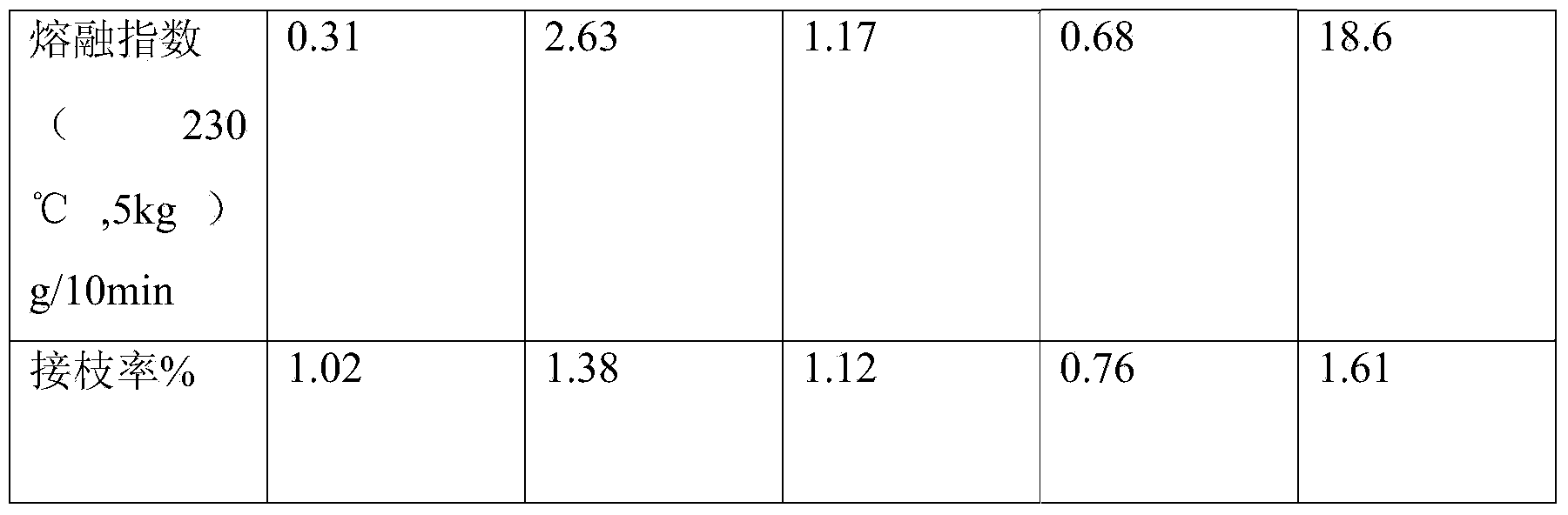

Polyphenylether/thermoplastic elastomer composition used for cables and preparation method thereof

ActiveCN102226031AModerate hardnessWith high and low temperature resistancePlastic/resin/waxes insulatorsInsulated cablesThermoplasticElastomer

The invention relates to a polyphenylether / thermoplastic elastomer composition used for cables and a preparation method thereof, relating to halogen-free, flame-retardant, high-temperature and low-temperature resistant and environmentally-friendly materials. The polyphenylether / thermoplastic elastomer composition comprises the following components in parts by weight: 10-15 parts of polyphenylether, 30-45 parts of SEBS (styrene-ethylene-butadiene-styrene block copolymer), 30-45 parts of POE (polyoxyethylene), 25-45 parts of flame retardant, 5-10 parts of smoke suppressant, 0.5-6 parts of flame-retardant synergist, 0.1-9 parts of compatibilizer, 0.1-2 parts of antioxidant and 0.01-2 parts of processing aid. According to the invention, the addition of a functionalized thermoplastic elastomereffectively improves the compatibility between the non-polar elastomer and polyphenylether, and the complex synergistic effect of red phosphorus and magnesium hydroxide improves the flexibility, flame retardancy, high-temperature and low-temperature resistance, water resistance and electrical insulation properties of wire and cable coating materials prepared by using a Swiss BUSS four-screw reciprocating mixing machine.

Owner:溧阳常大技术转移中心有限公司

Coverlay adhesive composition

The present disclosure is directed to a coverlay adhesive. The coverlay adhesive contains 40 to 80 wt % maleic anhydride grafted styrene ethylene butadiene styrene copolymer having greater than 1 wt % maleic anhydride, 3 to 14 wt % epoxy resin, 0.5 to 1.5 wt % hardener, 0.05 to 0.1 wt % catalyst, 10 to 26 wt % organic flame retardant, and optionally polypheneylene ether.

Owner:EI DU PONT DE NEMOURS & CO

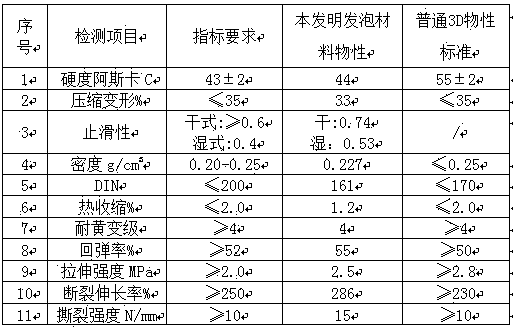

Manufacture method of TPR (thermoplastic rubber) soft rubber insole

InactiveCN103192573ALow costImprove yieldInsolesSynthetic resin layered productsPolymer scienceInjection molding process

The invention discloses a manufacture method of a TPR (thermoplastic rubber) soft rubber insole. The manufacture method comprises the steps of: preparing raw materials of soft rubber, cutting a fabric, forming the soft rubber, gluing and trimming. The raw materials of the soft rubber comprise the following components in percent by mass: 20-29 percent of SEBS (styrene-ethylene-butadiene-styrene) resin, 70-79 percent of white oil, 0.1-1 percent of pigment and 0.2-2 percent of an assistant. The raw materials of the soft rubber are prepared by adopting the steps of: preparing pigment paste, preparing an assistant dispersing system and preparing the raw materials of the soft rubber. The technical scheme of the invention has the advantages of being high in yield of formed soft rubber, low in manufacture cost and simple in compound operation process of the soft rubber and the fabric, easily controlling the quality, and easily changing different styles of dies, is suitable for volume production, and is capable of reducing the production cost of the TPR soft rubber insole. Experiments prove that the manufacture method of the TPR soft rubber insole has the advantage that the processing cost is only 50-60 percent that of an existing injection molding process.

Owner:上虞舜美高分子材料有限公司

High bi-directional strength monolayer polymeric film and method of fabrication

InactiveUS6703447B2High orientation and heat stabilizationReduce and eliminate curlingBottlesSynthetic resin layered productsPolyvinyl chlorideInvestment material

A polymeric film and method for making the film. Mixing a structural material with a secondary material to form a unitary mixture prior to processing forms the film. For a printable film, the secondary material is a printable material. The unitary mixture is extruded and heated so as to cause the printable material to bloom to the surface of the mixture. The result is a film that is stiffer and that lays flatter than prior multi-layered films that were prone to curling. The rollers used to stretch the film during this heat-setting stage are preferably very smooth so as to enhance the transverse-direction strength and stiffness of the film. In another embodiment of the invention, the secondary material is a clarity-enhancing material that may be styrene-ethylene-butadiene-styrene block copolymer. The blend combination is a suitable replacement for polyvinyl chloride films in that it is soft, conformable, flexible and clear.

Owner:COBURN THEODORE R

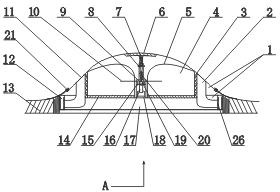

Emergency life jacket

The invention relates to an emergency life jacket. The emergency life jacket is mainly composed of two parts, wherein the first part is a life jacket material, which can be made of PU (polyurethane), or thermoplastic elastic rubber SEBS (Styrene Ethylene Butadiene Styrene), or PU and SEBS; the second part is an electric igniting device located on the life jacket; sodium azide, potassium nitrate and SiO2 are placed in a reaction region (4) of the electric igniting device; and in emergency, by pressing a button region (6) located on the electric igniting device, chemicals in the reaction region (4) react to instantaneously generate a large amount of nitrogen gas, generated nitrogen gas enters an air channel (2) through a filter layer (3) and finally enters an air bag through a channel (26) between an external thread (12) and an internal thread (23), and thus the life jacket is inflated to rapidly expand to save a drowning person. The emergency life jacket has the advantages of strong airtightness, high flexibility, lightweight, strong fitness, comfort in wearing, foldability, convenience in carrying and the like.

Owner:王德保

Special halogen-free anti-static flame-retardant material for TPE (thermal plastic elastomer) molding and preparation method for special halogen-free anti-static flame-retardant material

The invention discloses a special halogen-free anti-static flame-retardant material for TPE (thermal plastic elastomer) molding. The special halogen-free anti-static flame-retardant material comprises the following raw materials: SEBS (styrene-ethylene-butadiene-styrene) rubber resin, a softening plasticizer, a flame retardant, an anti-static agent, polypropylene resin, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method for the special halogen-free anti-static flame-retardant material. The preparation method is simple in process step and easy to realize, and can be used for quickly preparing the special halogen-free anti-static flame-retardant material product for TPE molding. The special halogen-free anti-static flame-retardant material for TPE molding is reasonable in formula, has the advantages of no halogen, yellowing resistance, good flame resistance, good adhesion property, high fluidity, difficulty for dust adhesion, easiness for injection molding and the like, effectively avoids release of harmful substances in a heating process due to no halogen and flame resistance, cannot threaten human health or environment, and can be widely applied to an outer film of a high-grade headphone wire plug, an outer film of a data wire plug and other wire products.

Owner:DONGGUAN JISU PLASTIC TECH

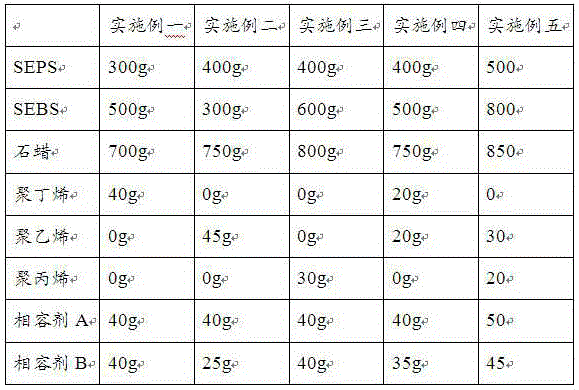

PP (polypropylene)-coated thermoplastic elastomer

The invention discloses a PP (polypropylene)-coated thermoplastic elastomer which is composed of the following components in parts by weight: 20-50 parts of SEPS (styrene-ethylene / propylene-styrene), 50-80 parts of SEBS (styrene-ethylene-butadiene-styrene), 70-90 parts of softening agent, 20-50 parts of polyolefin, 35-50 parts of compatilizer A and 25-45 parts of compatilizer B. The SEBS is a linear triblock copolymer using an ethylene-butene copolymer as the middle elastic block; and the SEPS is a hydrogenated styrene-isoprene block copolymer. The compatilizer A is SEBS grafted maleic acid or SEBS grafted maleic anhydride, and the graft ratio is 8-11%. The compatilizer B is SEPS grafted maleic acid or SEPS grafted maleic anhydride, and the graft ratio is 6-10%. By proportioning the SEPS and SEBS, the PP-coated thermoplastic elastomer has higher flexibility and higher elastic deformation capacity.

Owner:ZHEJIANG WANG YANG POLYMER MATERIALS

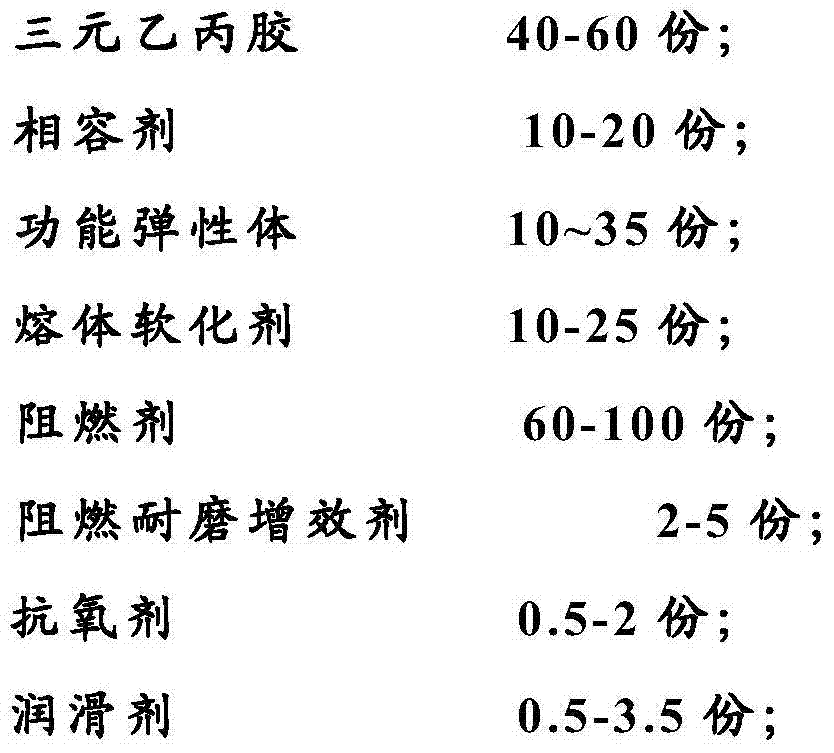

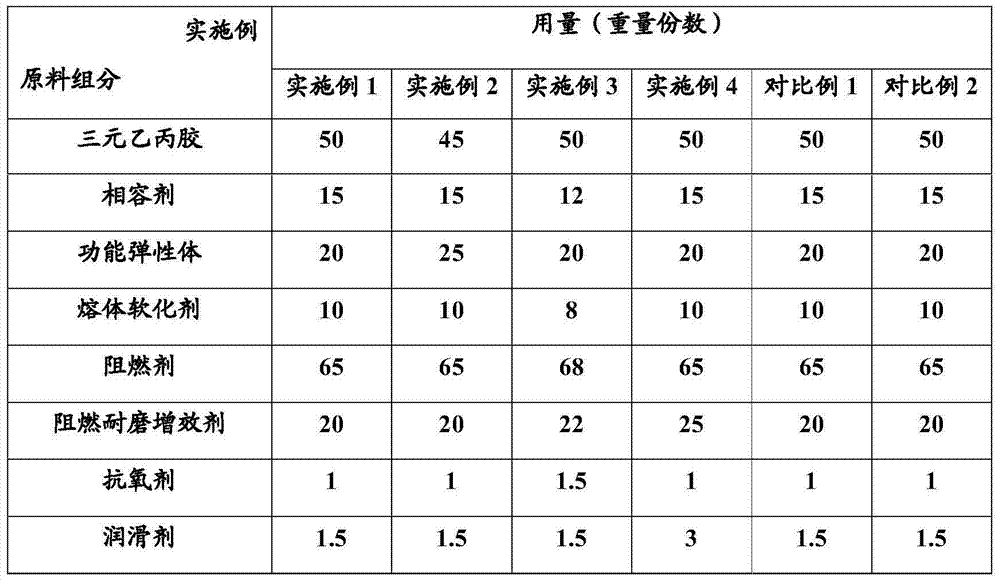

Wear-resistant halogen-free flame-retardant elastic material for high-speed elevator flat cable and preparation method thereof

ActiveCN103881242AGood physical and mechanical propertiesImprove heat resistanceRubber insulatorsAntioxidantWear resistant

The invention relates to a wear-resistant halogen-free flame-retardant elastic material for a high-speed elevator flat cable and a preparation method thereof. The wear-resistant halogen-free flame-retardant elastic material disclosed by the invention contains the following raw material ingredients in parts by weight: 40-60 parts of EPDM (Ethylene-Propylene-Diene Monomer), 10-20 parts of compatibilizer, 10-35 parts of functional elastomer, 5-25 parts of melt softener, 60-100 parts of flame retardant, 2-5 parts of flame-retardant and wear-resistant synergist, 0.5-2 parts of antioxidant and 0.5-3.5 parts of lubricant. According to the wear-resistant halogen-free flame-retardant elastic material disclosed by the invention, the functional elastomer is a mixture of TPU (Thermoplastic Polyurethane) and SEBS (Styrene-Ethylene-Butadiene-Styrene block copolymer), the physical and mechanical properties, heat resistance and wear resistance of the product can be improved due to the mixture, and the final performance of the product fully meets the requirements of materials for the high-speed elevator flat cable, so that the product can replace the existing PVC (Polyvinyl Chloride) flat cable elastic materials and is halogen-free and environmental-friendly. The preparation method disclosed by the invention is simple in process, easy in operation and low in cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Method for making a quasi-incompressible phase-change material, shear-thinned and with low heat conductivity

InactiveUS7320770B2Low thermal conductivityReduce heat convectionOther chemical processesThermal insulationAlkaneDicarbonate

The process according to the invention includes the combination, with a liquid phase change material (PCM), of a texturing agent chosen so as to greatly reduce the thermal convection and whose viscosity is decreased reversibly under shearing. The material formed has a gelled consistency when at rest, and fluidized under shearing. The PCM comprises a mixture of chemical compounds from the alkane family: paraffins, waxes, fatty alcohols, fatty acids etc., and the texturing agent is a high mass polymer (hydrocarbonate polymers, ester or ether polymers, mixed ester-hydrocarbon polymers), an ionomer polymer or a di, tri or multi-block styrene copolymer (SBS: styrene-butadiene-styrene, SEBS: styrene-ethylene-butadiene-styrene).Applications: thermal insulation of vessels or lines, and more especially, for hydrocarbon transport lines.

Owner:SAIPEM SA +1

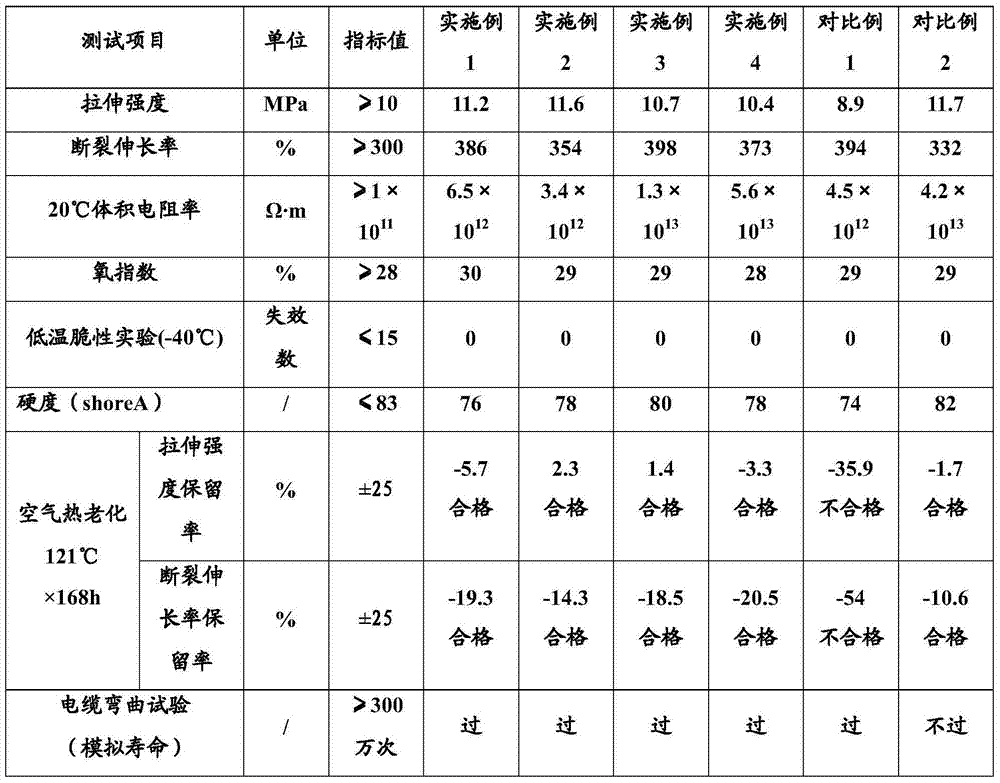

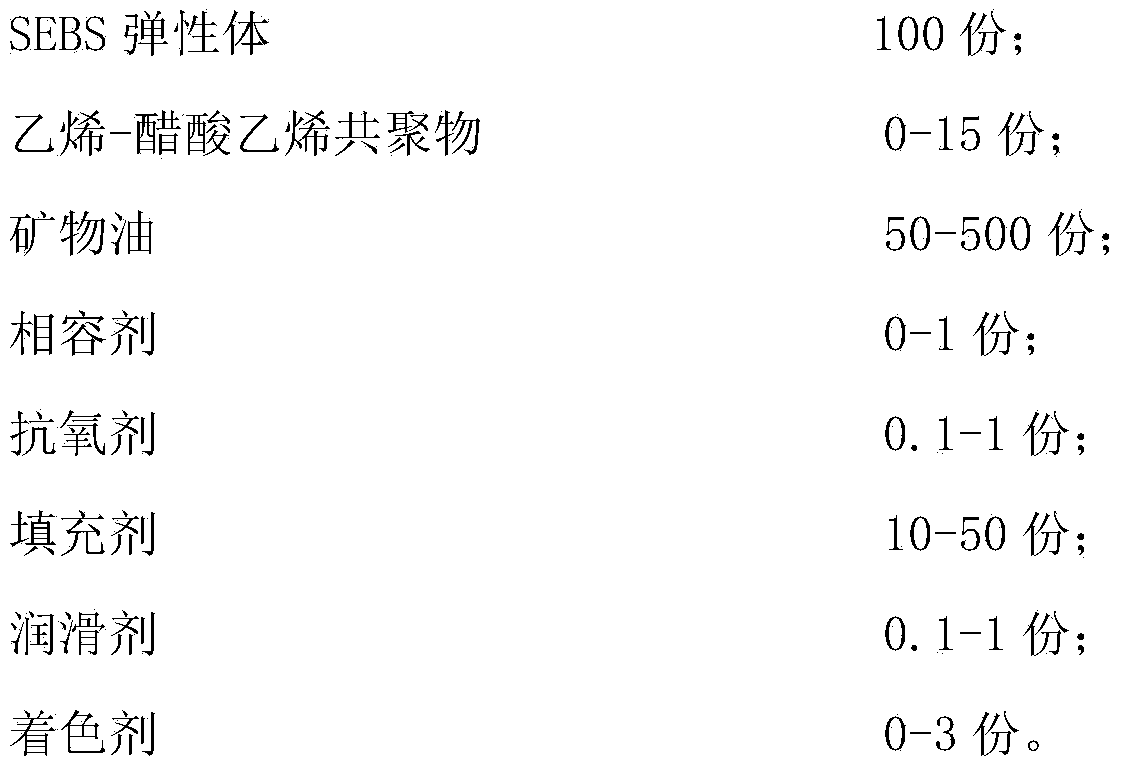

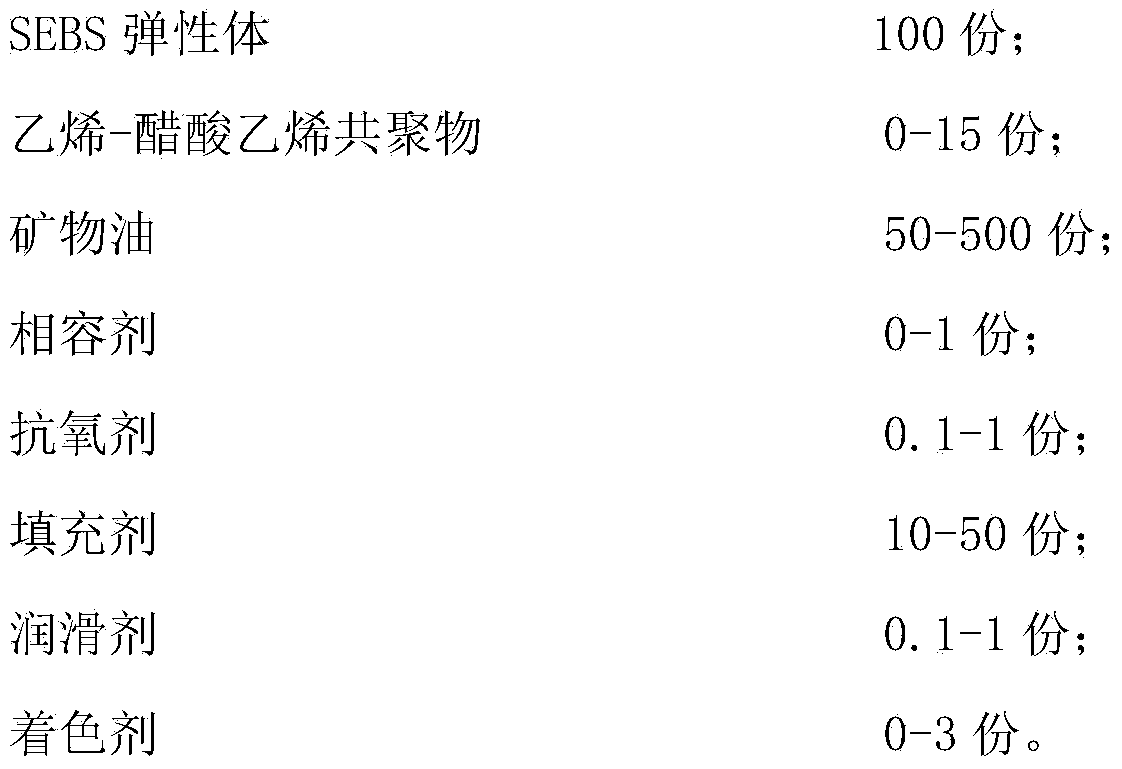

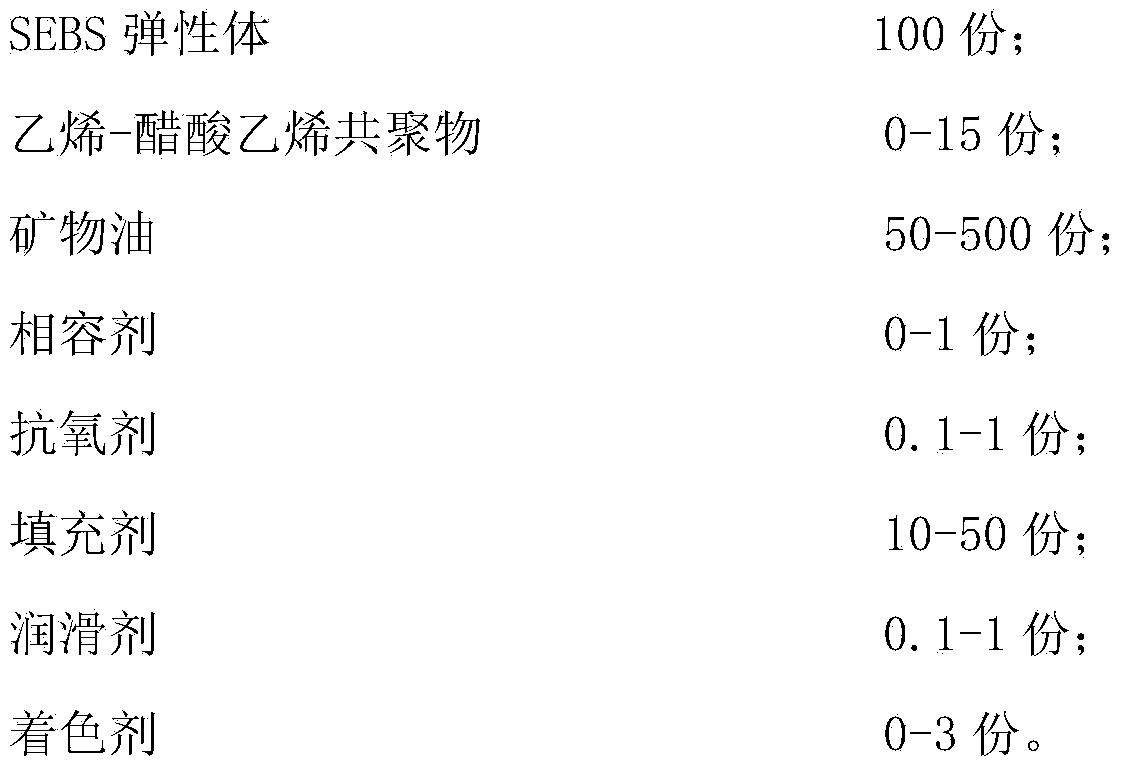

Styrene-ethylene-butadiene-styrene (SEBS) thermoplastic elastomer bra lining material as well as preparation method and application thereof

The invention relates to a bra backing material and a preparation method of the bra lining material. The preparation method comprises the steps of: 1) adding a powder-shaped styrene-ethylene-butadiene-styrene (SEBS) thermoplastic elastomer into a high-speed mixing machine, stirring, adding mineral oil with regulated parts and stirring again to obtain an oil-charging type SEBS elastomer; 2) adding antioxygen, lubricating agents, coloring agents and filling agents into the oil-charging type SEBS elastomer obtained in the step 1), uniformly stirring the mixture in the high-speed mixing machine and adding an ethylene-vinyl acetate copolymer and a compatilizer to be mixed; 3) extruding and pelletizing the mixture obtained in the step 2) in a double-screw extruder. The bra lining material has the beneficial effects that the lining material has the characteristics of anti-aging, low cost, low hardness, high elasticity, high flexibility and comfortable handfeel, and is difficult to soak and convenient to clean; through an injection process, the bra liner is conveniently and directly molded; moreover, pouring materials can be recycled, so that the liner is simple in process, low in energy consumption, high in efficiency, high in repeatability and easy to operate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Hot melt adhesive composition for sealing automobile lamp and preparation method thereof

ActiveCN102925087ADelay agingReduce shear loadMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWeather resistancePolymer science

The invention relates to a hot melt adhesive composition for sealing an automobile lamp and a preparation method thereof and belongs to the technical field of macromolecule adhesive. The method includes: adding styrene-ethylene-butadiene-styrene (SEBS), an antioxygen and a light stabilizer into a conduction oil reaction kettle, heating, warming, adding a part of tackifying resin, heating till the tackifying resin melts completely, adding polyolefin, vacuum heating till the polyolefin melts completely, adding the remained tackifying resin continuously, heating, mixing till the tackifying resin metls, mixing evenly, discharging and packaging to obtain the hot melt adhesive composition for sealing the automobile lamp. The preparation method is simple, no harmful substance is emitted in a production process, no solvent is used, and the hot melt adhesive is environment-friendly adhesive. When users use the hot melt adhesive, coating process is simple, and device investment is less. Compared with the existing sealing adhesive for the automobile lamp in the market, the hot melt adhesive composition is good in a sealing effect and weather-resistance.

Owner:WUXI WANLI ADHESION MATERIALS

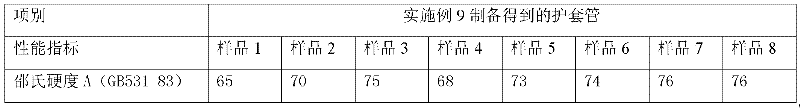

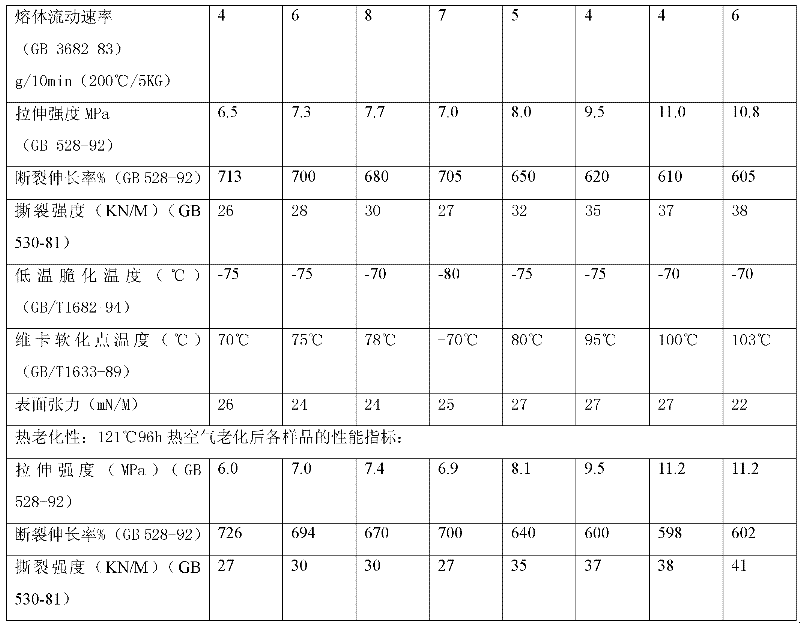

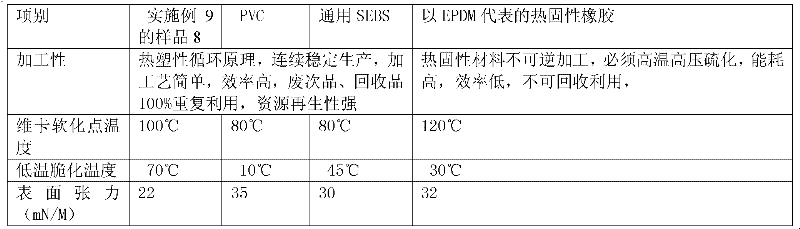

Thermoplastic elastomer, preparation method thereof, application thereof and cable sheathing tube made therefrom

InactiveCN102477204AOvercome the defect of easy embrittlement at low temperature and easy softening at high temperatureImprove heat resistanceInsulated cablesInsulated conductorsHeat resistancePolypropylene

The invention provides a thermoplastic elastomer which comprises the following ingredients in parts by weight: 100 parts of SEBS (Styrene-Ethylene-Butadiene-Styrene), 60-120 parts of chain hydrocarbon mineral oil, 20-80 parts of polypropylene, 5-20 parts of polyphenylether, 30-70 parts of flame retardant, 0.2-0.3 part of reactive polysiloxane, 0.2-0.6 part of stabilizer and 0.4-1.0 part of processing additive. The invention further provides a preparation method of the thermoplastic elastomer, application of the thermoplastic elastomer and a cable sheathing tube made from the thermoplastic elastomer. Compared with the prior art, the thermoplastic elastomer has the beneficial effects that: the thermoplastic elastomer shows excellent heat resistance, the temperature of the Vicat softening point of the thermoplastic elastomer is 100DEG C, meanwhile, the thermoplastic elastomer has excellent low temperature resistance, the temperature for low-temperature embrittlement of the thermoplastic elastomer is -70DEG C, therefore, the defects that the existing material easily embrittles at low temperature and softens at high temperature are overcome; the obtained formed product has balance in elasticity and plasticity and the function of strong surface hydrophobicity; and the thermoplastic elastomer is lightweight, good in weather resisting property and environmentally-friendly.

Owner:SHANGHAI FRONTIER ELASTOMER

Door and window edge banding material based on thermoplastic elastomer SEBS (styrene-ethylene-butadiene-styrene copolymer) and preparation method thereof

The invention discloses a door and window edge banding material based on thermoplastic elastomer SEBS (styrene-ethylene-butadiene-styrene copolymer), and the door and window edge banding material comprises the following components: SEBS rubber resin, a softening plasticizer, a polyolefin elastomer, ethylene-propylene-diene monomer, polypropylene resin, a vulcanizing agent system, an antioxidant, a light stabilizer and a processing aid. The invention also discloses a preparation method of the door and window edge banding material. The door and window edge banding material based on the thermoplastic elastomer SEBS has the advantages of being halogen-free, high temperature and low compression deformation resistant, weather-proof, low temperature resistant, excellent in mechanical properties, easy to extrude to form, long in service life and the like. Door and window edge banding material products based on the thermoplastic elastomer SEBS can be quickly prepared by the preparation method, the products can be widely used in high-grade building door and window edge bandings, automobile door and window edge bandings and other fields, and the process steps are simple, and easy to implement.

Owner:DONGGUAN JISU PLASTIC TECH

Thermal synthetic preparation method of SEBS-PLA branched copolymer solvent

The invention relates to a preparation method for SEBS-PLA graft copolymer using the method of solvent thermal synthesis, the block copolymer SEBS of styrene-ethylene-butadiene-styrene, the lactic acid PLA, the initiator, the comonomer and the antioxidant are added into an autoclave, and dissolve in a good solvent of SEBS or PLA, the SEBS can be fully contact with the PLA, initiator by controlling the temperature and time. When the reaction is completed, after drying and cleaning, the SEBS-PLA graft copolymer can be got. The SEBS-PLA can be used to as compatilizer of SEBS and PLA or other blended polymer, emulsifier of other reaction systems, dispersing agent, cosolvent, medical coating material, coloring agent of SEBS and other members.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com