Thermoplastic elastomer material for refrigerator sealing strip and preparation method thereof

A thermoplastic elastomer and sealing strip technology, applied in the field of thermoplastic elastomer materials, can solve the problems of poor surface fineness, poor melt strength, poor dimensional accuracy, etc., and achieve flexible product design, good welding performance, and good dimensional accuracy. and surface fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

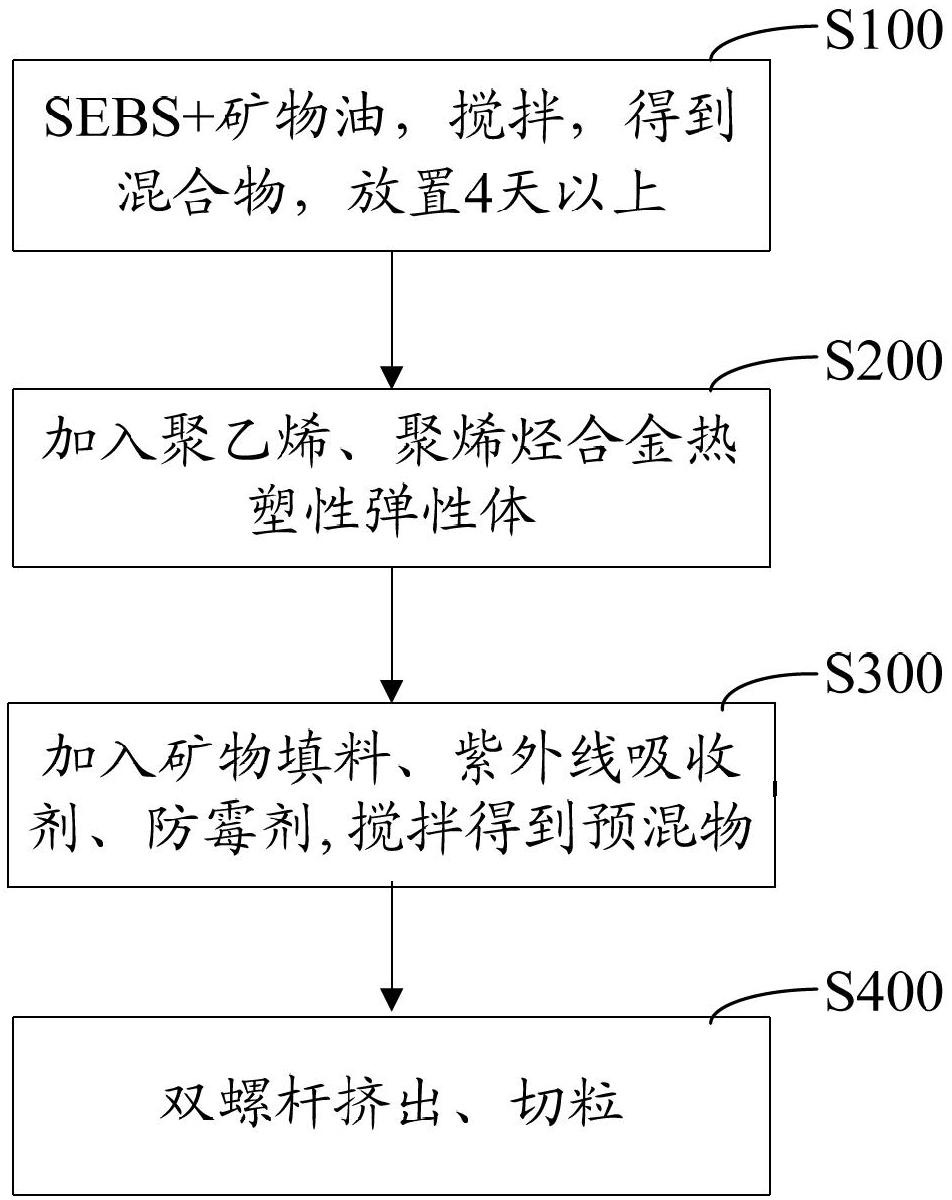

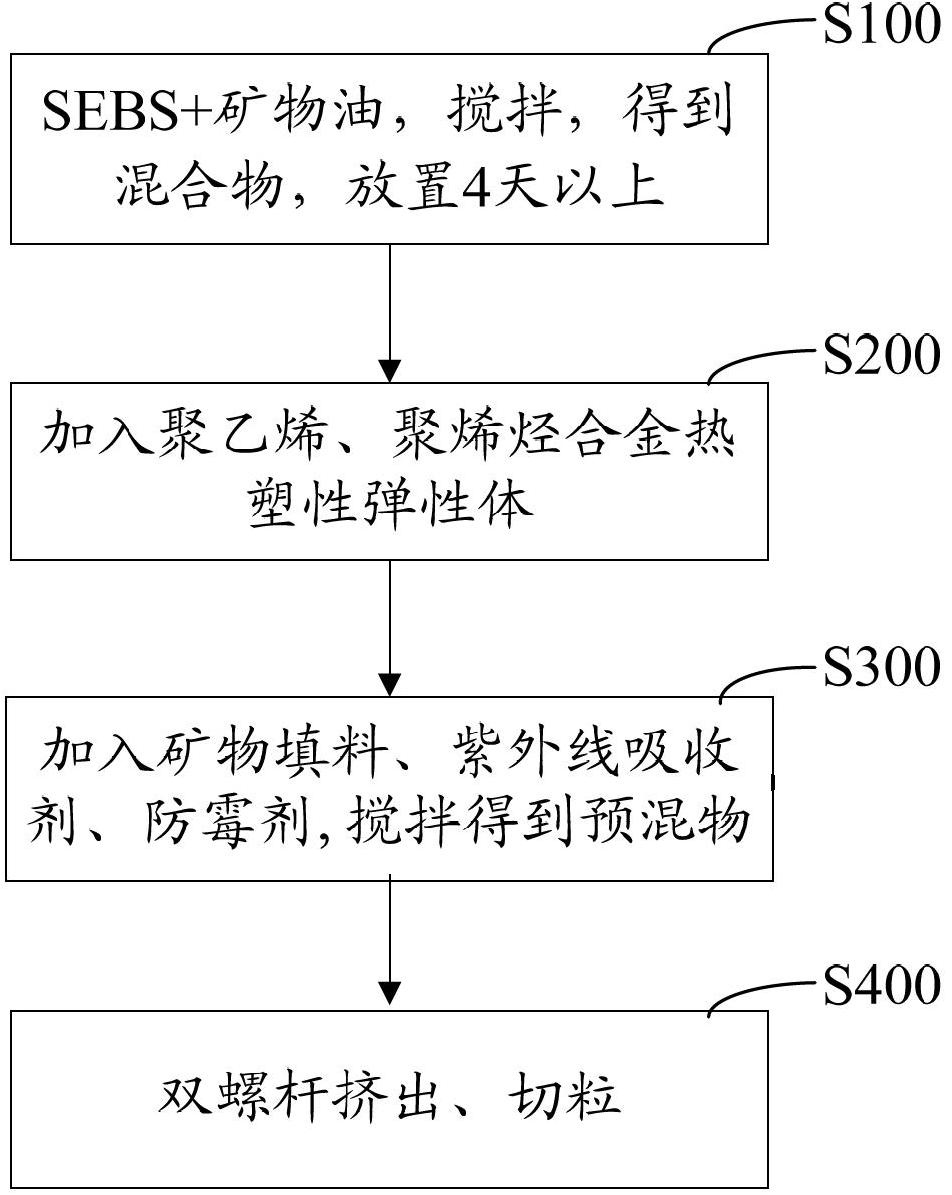

[0052] see figure 1 , the preparation method of the thermoplastic elastomer material for refrigerator sealing strip of an embodiment, comprises the following steps:

[0053] Step S100, put 20-40 parts by weight of SEBS into a horizontal mixer, evenly add 20-45 parts by weight of mineral oil, stir for 5-15 minutes, pack the mixture, and place it for more than 4 days;

[0054] Step S200, put the mixture into the horizontal mixer, add 20-50 parts by weight of polyethylene and 10-30 parts by weight of polyolefin alloy thermoplastic elastomer, and stir for 3-7 minutes;

[0055] Step S300, adding 5-20 parts by weight of mineral filler, 0.5-2 parts by weight of ultraviolet absorber, and 0.5-2 parts by weight of anti-fungal agent, stirring for 5-15 minutes until uniformly mixed to obtain a premix; and

[0056] Step S400, putting the premix in a twin-screw extruder to extrude and pelletize to obtain a thermoplastic elastomer material for refrigerator sealing strips.

[0057] Preferab...

Embodiment 1

[0065] Put 33 parts by weight of SEBS YH503 into a horizontal mixer, evenly add 32 parts by weight of mineral oil KNH4006, stir for 10 minutes, pack the mixture and let it stand for 4 days.

[0066] Put the mixture into a horizontal mixer, add 18 parts by weight of LLDPE7042, 5 parts by weight of HDPE5000S and 10 parts by weight of GP610-85, and stir for 5 minutes.

[0067] Add 10 parts by weight of calcium carbonate, 0.3 parts by weight of antioxidant 168, 0.3 parts by weight of antioxidant 1076, 0.5 parts by weight of UV-P, 0.5 parts by weight of DAW502 and 2 parts by weight of MB50-001, stir for 10 minutes until uniformly mixed, and obtain the prepared mixture.

[0068] The premix is placed in a twin-screw extruder, extruded and pelletized to obtain a thermoplastic elastomer material for refrigerator sealing strips.

Embodiment 2

[0070] Put 35 parts by weight of SEBS YH503 into a horizontal mixer, evenly add 32 parts by weight of mineral oil KNH4006, stir for 8 minutes, pack the mixture and let it stand for 5 days.

[0071] Put the mixture into a horizontal mixer, add 20 parts by weight of LLDPE7042, 4 parts by weight of HDPE5000S and 15 parts by weight of GP610-85, and stir for 5 minutes.

[0072] Add 12 parts by weight of gypsum powder, 0.3 parts by weight of antioxidant 168, 0.3 parts by weight of antioxidant 1076, 0.5 parts by weight of UV-P, 0.5 parts by weight of DAW502 and 2 parts by weight of MB50-001, stir for 8 minutes until the mixture is uniform, and obtain the prepared mixture.

[0073] Pour the premix into the hopper of a co-rotating twin-screw extruder, shear and disperse through the co-rotating twin-screw, pelletize, pass through a vibrating sieve, blow dry, cool, and pack to obtain a thermoplastic Elastomer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com