Manufacture method of TPR (thermoplastic rubber) soft rubber insole

A manufacturing method and insole technology, which is applied in the field of insole manufacturing, can solve problems such as unstable soft colloid molding quality, difficult process control, and unstable screw feeding and feeding, so as to eliminate material shortage and flashing and meet Melt glue process requirements, the effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The manufacture method of TPR soft rubber insole of the present invention may further comprise the steps:

[0026] 1. Raw material preparation of soft colloid

[0027] The soft colloid raw material of the present invention needs to go through specific preparation process. First of all, the soft colloid formula should meet the requirements of strength, elasticity and other physical properties, appearance, melt processing technology, hot-pressing composite technology, etc.; secondly, the formula material should go through a special modulation process to ensure the uniformity of the soft colloid raw material . The purpose of the preparation process of the formula material is to make all other formula components penetrate evenly and deeply mix with the SEBS resin.

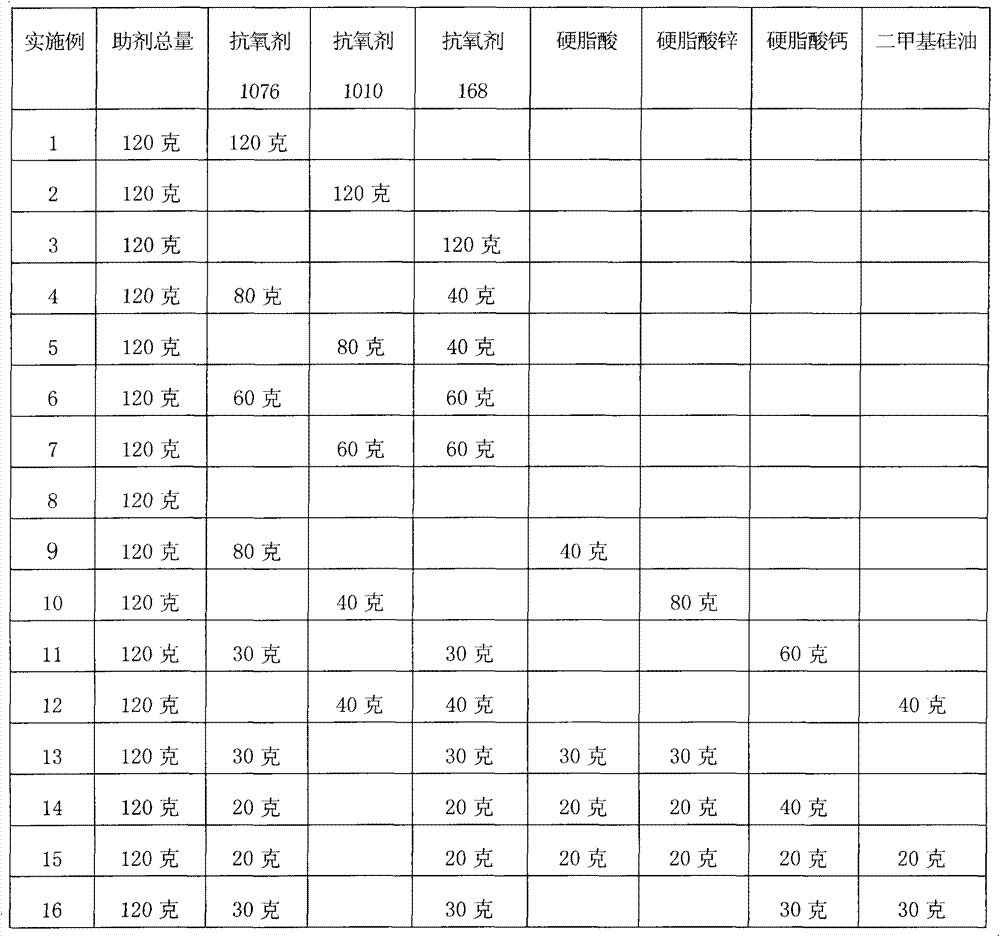

[0028] The raw material of soft colloid of the present invention contains the SEBS resin of raw material mass percentage content 20-29%, the white oil of 70-79%, the pigment of 0.1-1%, the auxiliary agent of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com