Hot-melt pressure-sensitive adhesive and preparation technology thereof

A technology of hot-melt pressure-sensitive adhesives and thermoplastic polyurethanes, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as loss of adhesion and embrittlement of the rubber surface, and reduce energy consumption and eliminate Oxidation, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

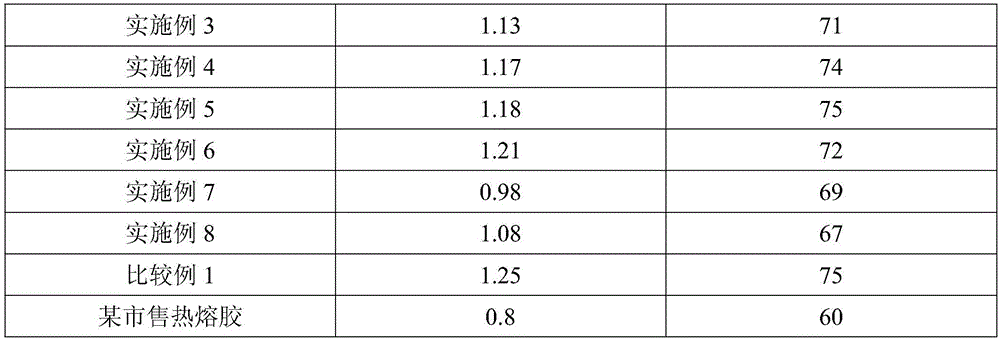

Examples

Embodiment 1

[0023] A hot-melt pressure-sensitive adhesive, in terms of mass percentage, its raw material composition is: thermoplastic polyurethane elastomer 3%, hydrogenated styrene-butadiene block copolymer 13%, tackifying resin 50%, plasticizer 33.9% , Antioxidant 0.1%.

[0024] Described tackifying resin is selected from KA100L rosin resin.

[0025] The plasticizer fat is selected from 4010 naphthenic oil.

[0026] The antioxidant fat is selected from antioxidant 1010.

[0027] Its concrete preparation steps are:

[0028] (1) take each raw material in proportion, for subsequent use;

[0029] (2) Under vacuum conditions, heat the plasticizer to 105°C, add antioxidant, hydrogenated styrene-butadiene block copolymer and thermoplastic polyurethane elastomer under stirring, keep stirring for 3 hours until all materials melt , heated up to 135°C, added the remaining other raw materials, kept stirring for 3 hours until transparent and homogeneous viscous liquid, degassed at constant temp...

Embodiment 2

[0032] A hot-melt pressure-sensitive adhesive, in terms of mass percentage, its raw material composition is: thermoplastic polyurethane elastomer 1%, hydrogenated styrene-butadiene block copolymer 10%, tackifying resin 55%, plasticizer 33.9% , Antioxidant 0.1%.

[0033] Described tackifying resin is selected from KA100L rosin resin.

[0034] The plasticizer fat is selected from 4006 naphthenic oil.

[0035] The antioxidant fat is selected from antioxidant 268.

[0036] Its concrete preparation steps are:

[0037] (1) take each raw material in proportion, for subsequent use;

[0038] (2) Under vacuum conditions, heat the plasticizer to 145°C, add antioxidant, hydrogenated styrene-butadiene block copolymer and thermoplastic polyurethane elastomer under stirring, keep stirring for 2 minutes until all materials melt , heated up to 160°C, added the remaining other raw materials, kept stirring for 2 hours until transparent and homogeneous viscous liquid, degassed at constant tempe...

Embodiment 3

[0041] A hot-melt pressure-sensitive adhesive, in terms of mass percentage, its raw material composition is: thermoplastic polyurethane elastomer 3%, hydrogenated styrene-butadiene block copolymer 13%, tackifying resin 55%, plasticizer 27.8% , 1% solid filler, 0.2% antioxidant.

[0042] Described tackifying resin is selected from KA100L rosin resin.

[0043] The plasticizer fat is selected from white oil.

[0044] The antioxidant fat is selected from antioxidant 268.

[0045] Its concrete preparation steps are:

[0046] (1) take each raw material in proportion, for subsequent use;

[0047] (2) Under vacuum conditions, heat the plasticizer to 125°C, add antioxidant, hydrogenated styrene-butadiene block copolymer and thermoplastic polyurethane elastomer under stirring, keep stirring for 2.5 hours until all materials melt Afterwards, raise the temperature to 148°C, add the remaining other raw materials, keep stirring for 3 hours until it becomes a transparent and uniform visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com