PP (polypropylene)-coated thermoplastic elastomer

A thermoplastic elastomer and formulation technology, applied in the field of medical supplies, can solve problems such as poor coating effect and weak coating

Inactive Publication Date: 2015-09-09

ZHEJIANG WANG YANG POLYMER MATERIALS

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Obviously, TPE with polyurethane can't cover the PP material well, which eventually leads to poor coating effect and weak coating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

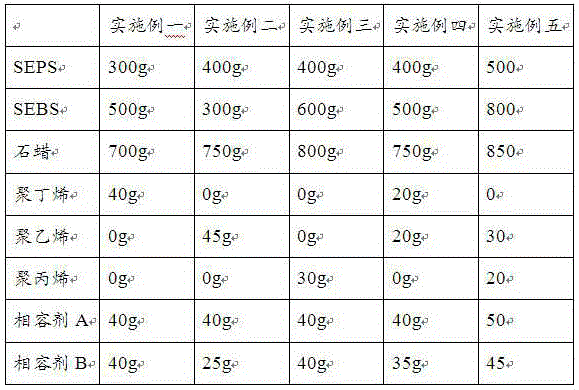

Embodiment 1

[0043] Tensile strength (MPa): 14.3; Tensile deformation (%): 650; Peel strength (N / m): 6;

Embodiment 2

[0045]Tensile strength (MPa): 14.8; Tensile deformation (%): 680; Peel strength (N / m): 6;

Embodiment 3

[0047] Tensile strength (MPa): 13.6; Tensile deformation (%): 630; Peel strength (N / m): 5;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a PP (polypropylene)-coated thermoplastic elastomer which is composed of the following components in parts by weight: 20-50 parts of SEPS (styrene-ethylene / propylene-styrene), 50-80 parts of SEBS (styrene-ethylene-butadiene-styrene), 70-90 parts of softening agent, 20-50 parts of polyolefin, 35-50 parts of compatilizer A and 25-45 parts of compatilizer B. The SEBS is a linear triblock copolymer using an ethylene-butene copolymer as the middle elastic block; and the SEPS is a hydrogenated styrene-isoprene block copolymer. The compatilizer A is SEBS grafted maleic acid or SEBS grafted maleic anhydride, and the graft ratio is 8-11%. The compatilizer B is SEPS grafted maleic acid or SEPS grafted maleic anhydride, and the graft ratio is 6-10%. By proportioning the SEPS and SEBS, the PP-coated thermoplastic elastomer has higher flexibility and higher elastic deformation capacity.

Description

technical field [0001] The present invention relates to a medical product, more specifically, it relates to a thermoplastic elastomer formulation coated with PP. Background technique [0002] Thermoplastic elastomer TPE is a material with high elasticity, high strength and high resilience of rubber, and can be processed by injection molding. It is environmentally friendly, non-toxic and safe, has a wide range of hardness, excellent colorability, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, no need for vulcanization, can be recycled to reduce costs, and can be used for secondary injection molding. It can be coated and bonded with PP, PE, PC, PS, ABS and other base materials, and can also be formed separately. [0003] At present, the Chinese patent with application number CN200810060252.8 on the market discloses a thermoplastic elastomer that can be coated and bonded with nylon, which contains matrix resin, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L91/06C08L53/02C08L51/00C08L23/20C08L47/00C08L23/06C08L23/12

Inventor 汪德兴汪德柱

Owner ZHEJIANG WANG YANG POLYMER MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com