Patents

Literature

82results about How to "Reduce heat convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous flame-retardant and thermal-insulated coating and preparation method thereof

InactiveCN101671523AGood weather resistanceSimple preparation processCoatingsThermal insulationEmulsion

The invention discloses an aqueous flame-retardant and thermal-insulated coating and a preparation method thereof, relates to a building coating, and provides a building thermal-insulated coating integrating flame-retardant property, thermal-insulated property and decorative function. The coating consists of emulsion, a fire retardant, titanium, hollow glass beads, water and assistants, with the respective mass parts being 35-40, 20-30, 15-20, 5-10, 19-21 and 11-15. The coating uses fire retardants of inorganic type, phosphorus type and nitrogen type and utilizes synergistic action among different fire retardants to achieve the retardant effect with less amount and without influencing the physical properties of the coating layer; better thermal-insulated effect can be achieved when the thickness of the coating layer is about 1mm through obtaining thermal insulation property by reducing thermal conductivity, thermoconvection and thermal radiation through the glass beads; and the thermal-insulation and flame-retardant properties of the coating are reflected by that the heat conduction coefficient is not more than 0.090 w / (m.k), and the oxygen index is not less than 28.0 percent.

Owner:XIAMEN UNIV +1

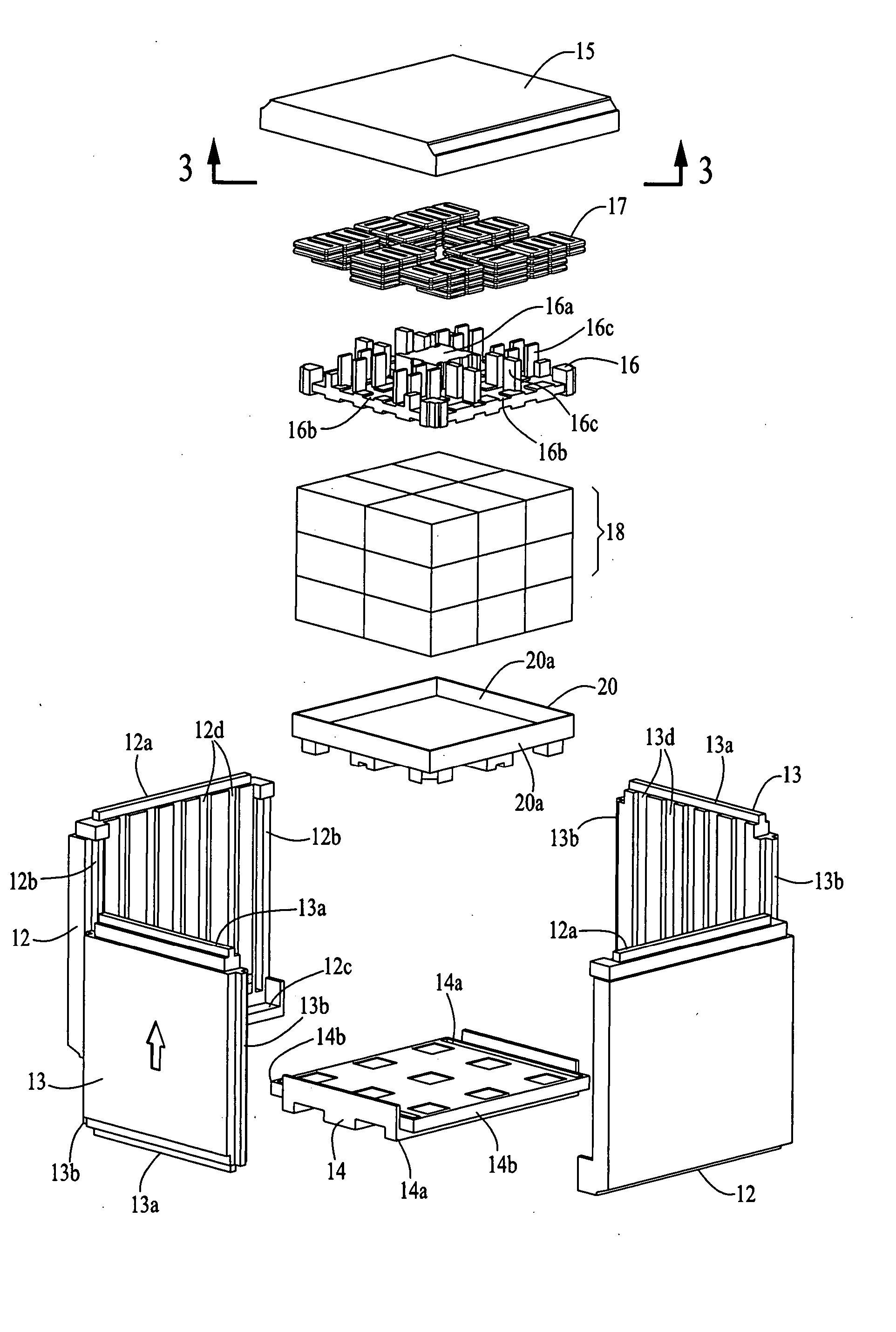

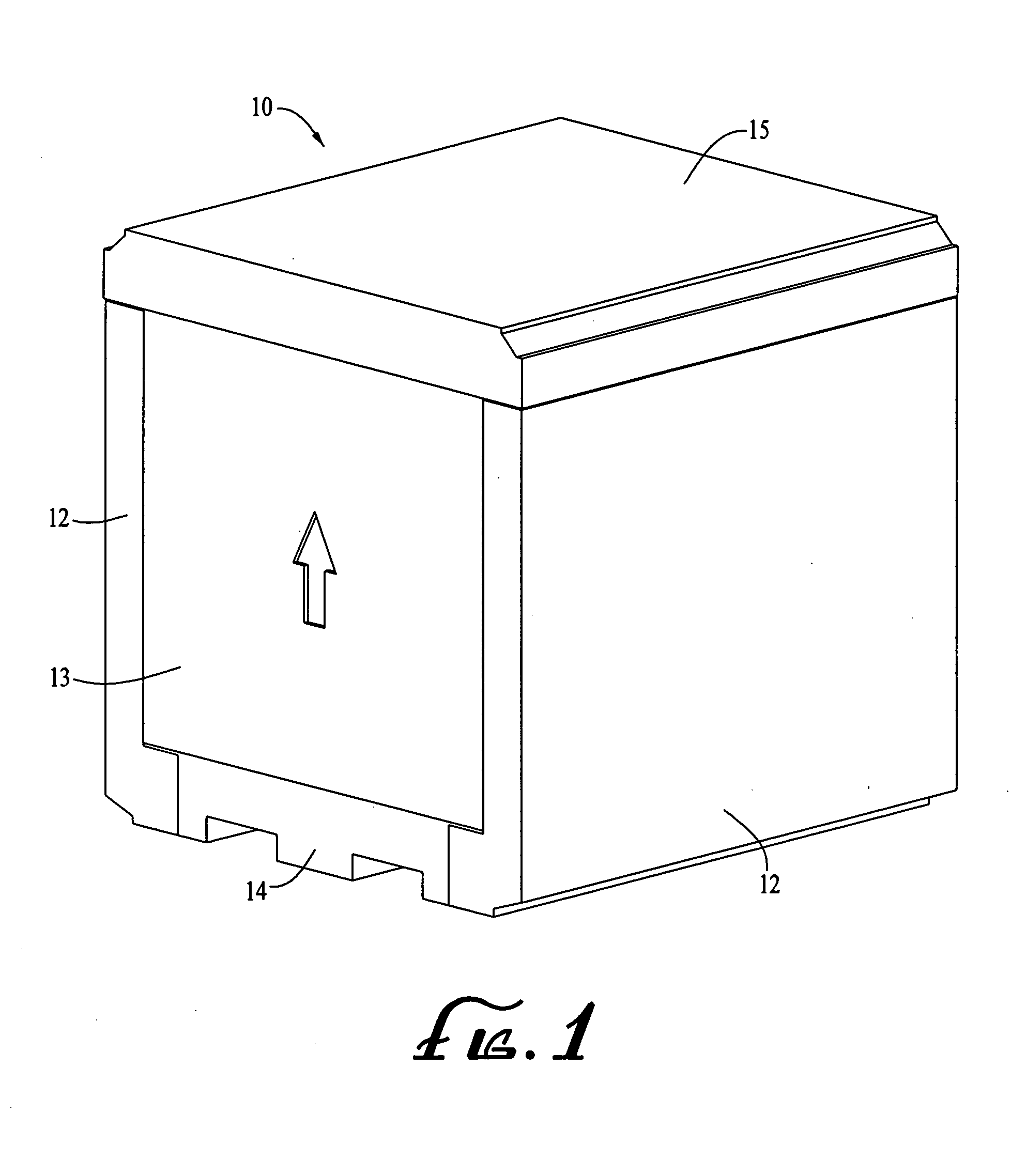

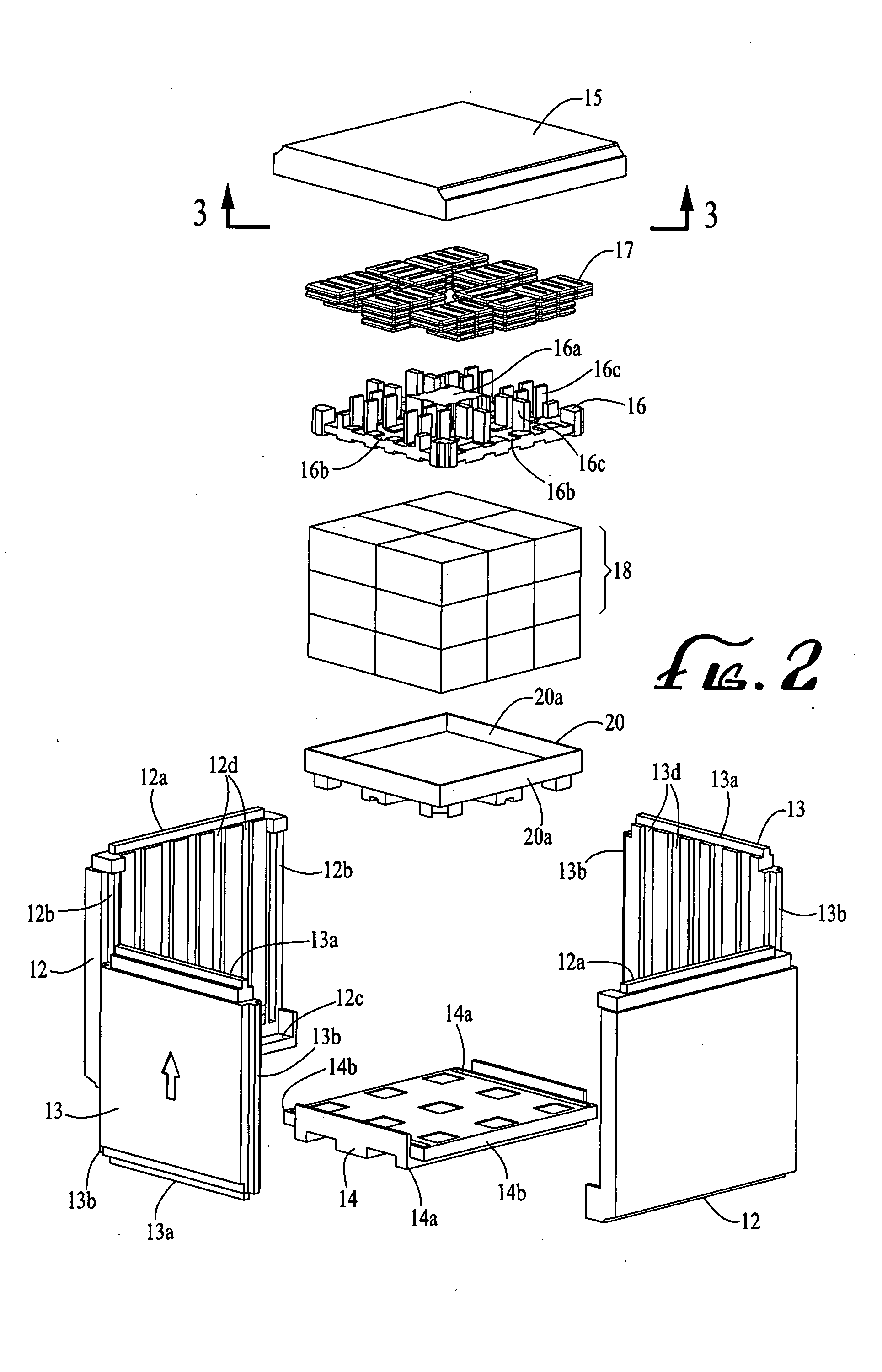

Insulated shipping containers

InactiveUS20050006272A1Reduce heat convectionEven temperature controlContainer filling methodsMachines using electric/magnetic effectsTime segmentEngineering

Shipping containers, and more particularly insulated shipping containers, for holding temperature sensitive products and coolant in a predetermined relationship to maintain a refrigerated or frozen condition for an extended period of time. Containers of this type can be molded from rigid polyurethane foam or other materials for shipping or transporting products such as biological and similar products which need to be maintained at 2° to 8° Centigrade or frozen. Specific constructions are shown and described.

Owner:ENVIROCOOLER

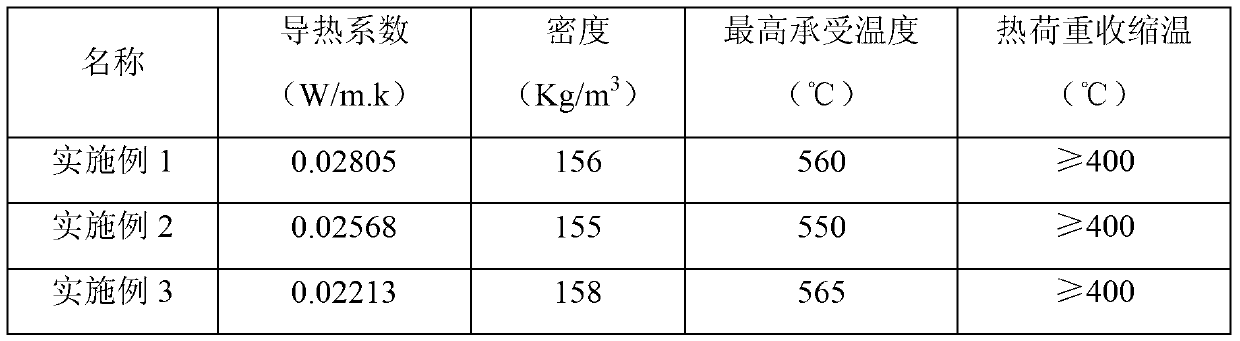

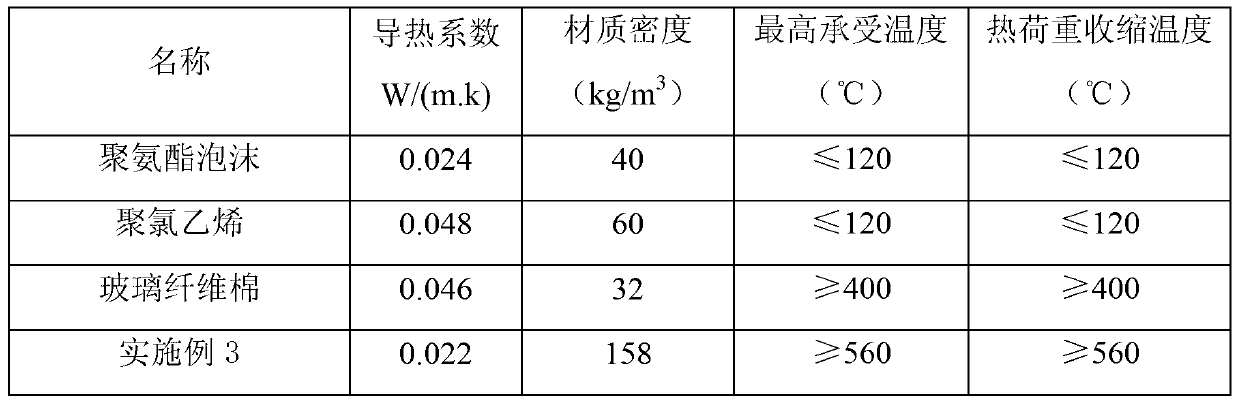

Glass-fiber vacuum insulation panel nano core material and preparation method thereof

ActiveCN103277631AUniform diameterPrevent collapseFibreboardThermal insulationGlass fiberAlkali free

The invention discloses a glass-fiber vacuum insulation panel nano core material. The core material is made of, in percentage by mass, 50-100% of medium-alkali glass fiber chopped strands with diameters of 3-6um and 0-50% of alkali-free glass fiber cotton with diameter of 0.5-1.5um. The invention further discloses a preparation method for the glass-fiber vacuum insulation panel nano core material. The preparation method includes the following steps: 1), selecting raw materials according to the matching proportion, 2), pulping to scatter the raw materials to obtain sizing agent, 3), diluting the obtained sizing agent, 4), performing deslagging treatment on the diluted sizing agent and obtaining glass fiber wet paper through wet-process forming, 5), performing dehydration treatment on the obtained wet paper to make the moisture percentage less than 20%, and 6), drying the dehydrated wet paper. The vacuum insulation panel nano core material is good in heat-insulating effect, high in mechanical strength, and long in service life; and with the preparation method, the above effects of the vacuum insulation panel nano core material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

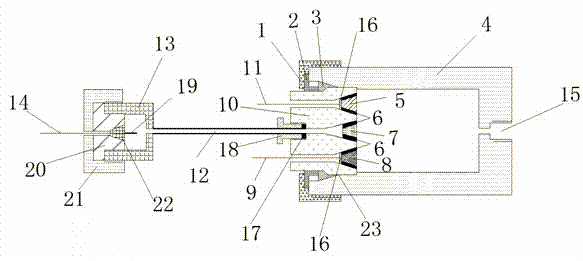

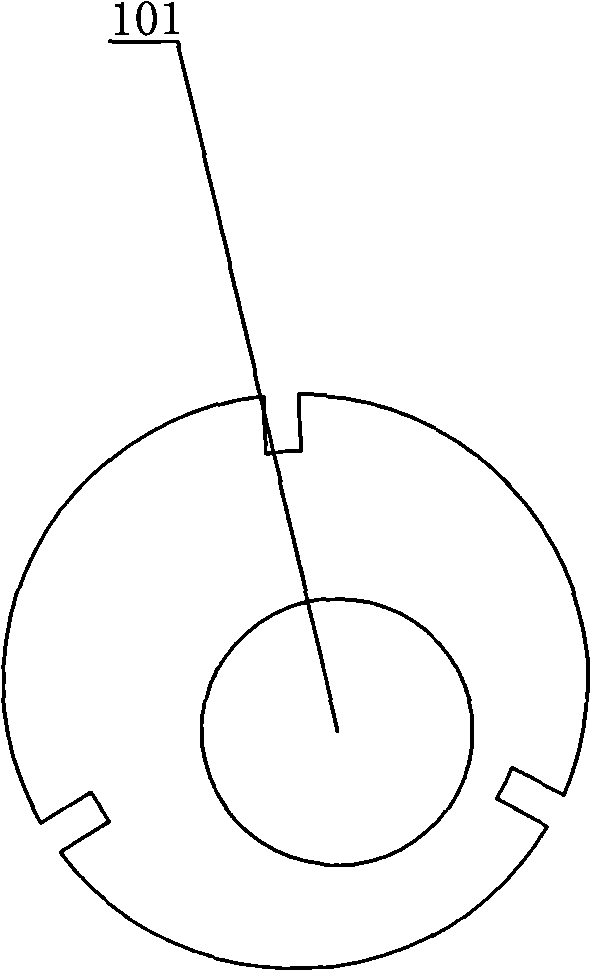

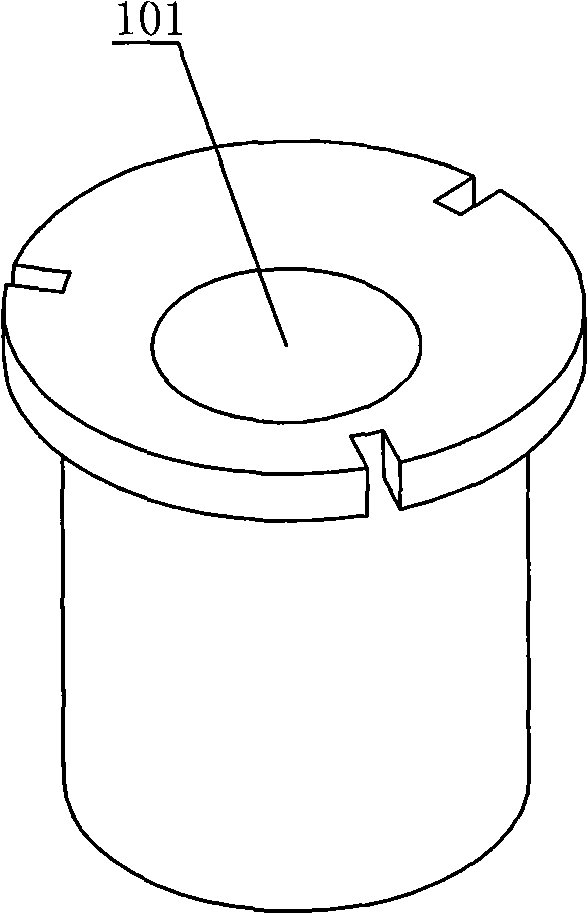

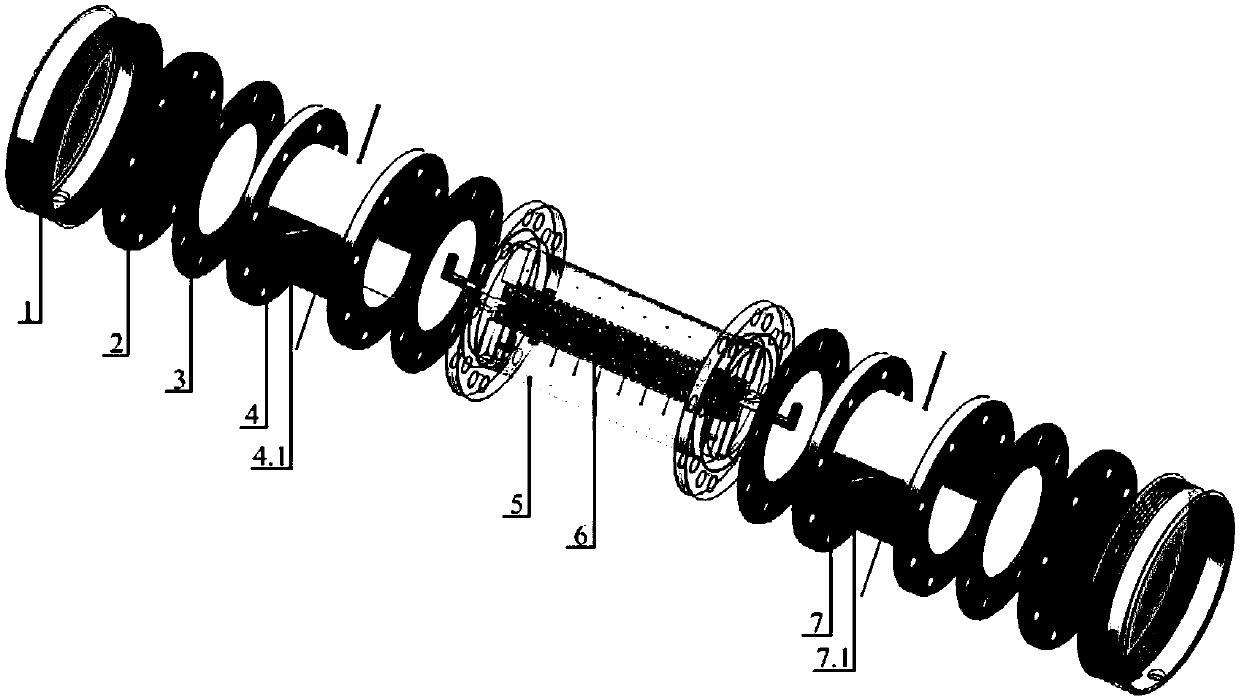

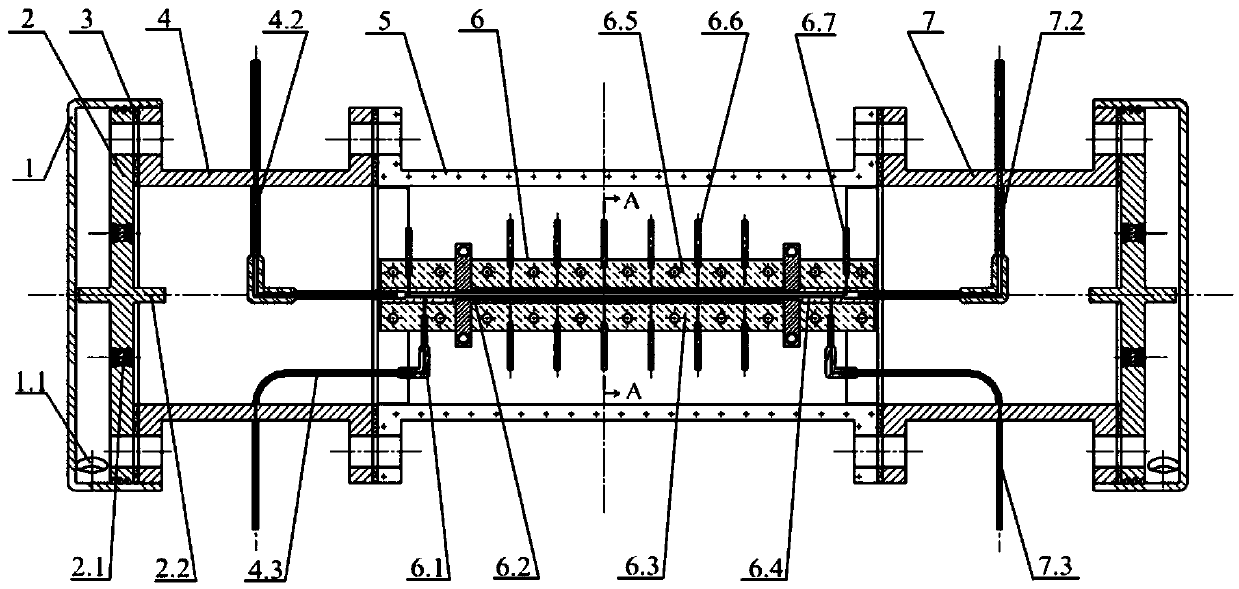

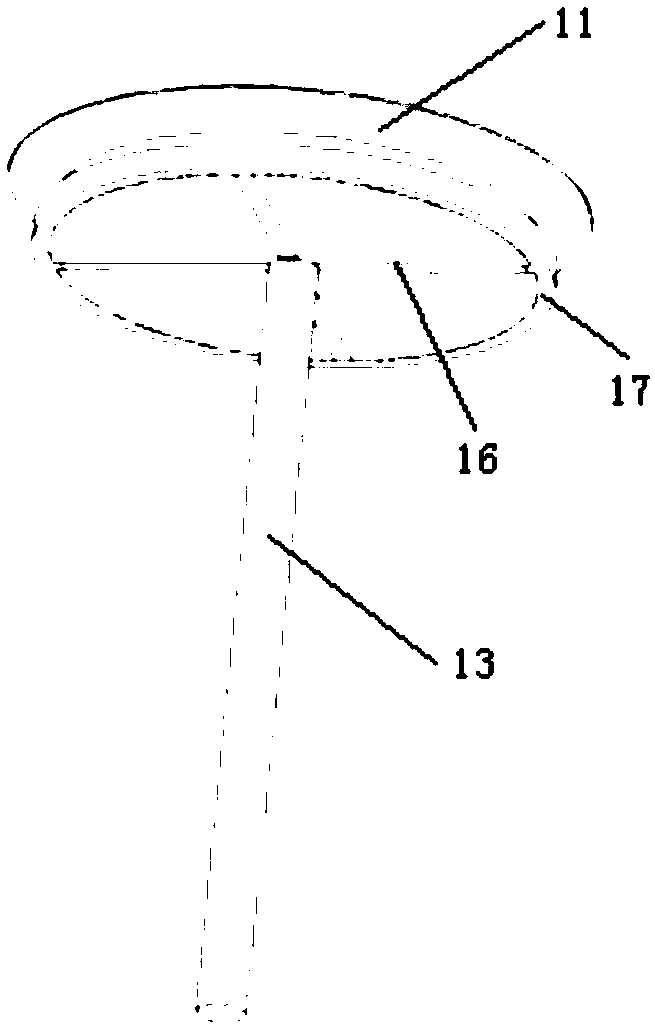

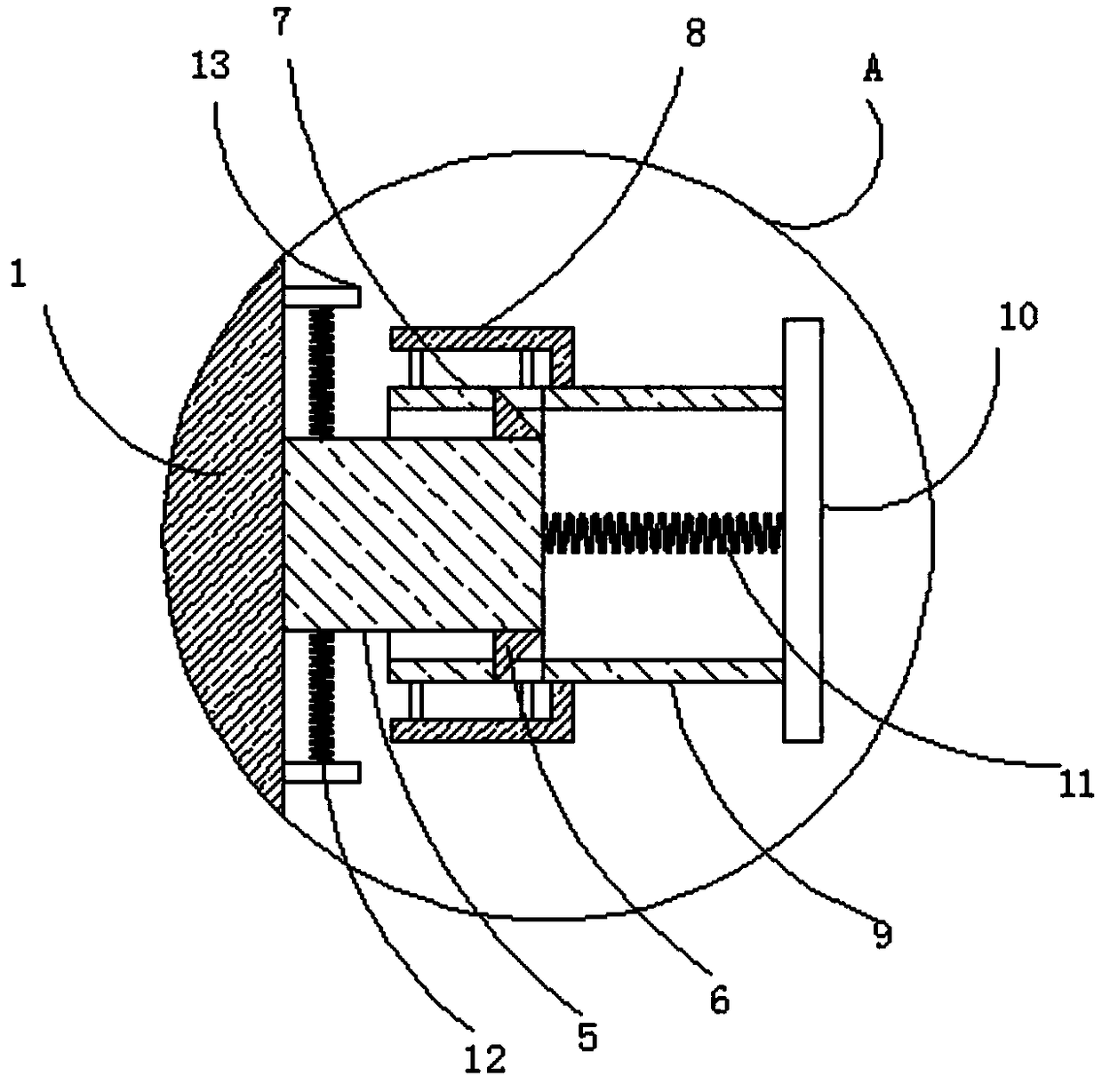

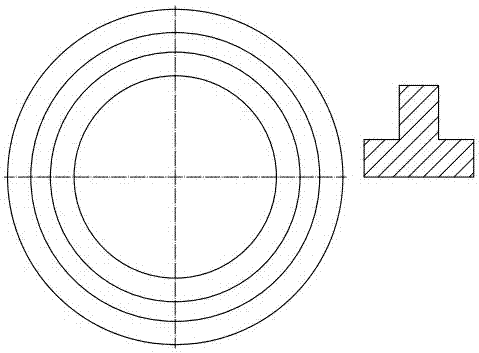

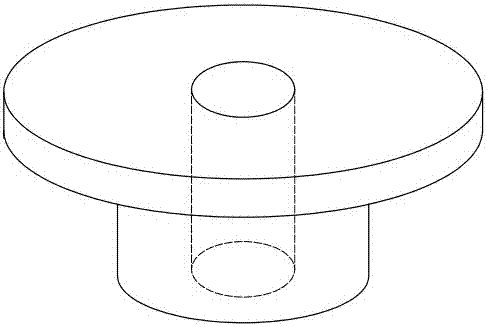

Three-electrode electrochemical measurement system for high-pressure hydrothermal systems and preparation method of three-electrode electrochemical measurement system

ActiveCN104777210AModerate hardnessGood thermochemical stabilityMaterial analysis by electric/magnetic meansElectricityEngineering

The invention discloses a three-electrode electrochemical measurement system for high-pressure hydrothermal systems and a preparation method of the three-electrode electrochemical measurement system. An electrode base is fixed in a mounting hole of a high-temperature high-pressure cavity through a metal sealing ring, a sealing ring compression ring and a compression nut; three conical holes which are communicated with three through holes at the outer end are formed in the axial inner end of the electrode base; a circular truncated cone-shaped working electrode, a circular truncated cone-shaped auxiliary electrode and a circular truncated cone-shaped porous ceramic are respectively mounted in the three conical holes; the through hole which is communicated with the conical hole which is provided with the circular truncated cone-shaped porous ceramic is communicated with a reference electrode capillary tube; the other end of the reference electrode capillary tube is communicated with an electrode chamber which is formed by a reference electrode nut, a reference electrode shell, a reference electrode compression ring and a circular truncated cone-shaped reference electrode. According to the three-electrode electrochemical measurement system, the working electrode, the reference electrode and the auxiliary electrode are capable of bearing high temperature and pressure under high-pressure electrochemical condition through a formed conical self-tightening type sealing mechanism, and good sealing efficiency and insulating property are provided.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

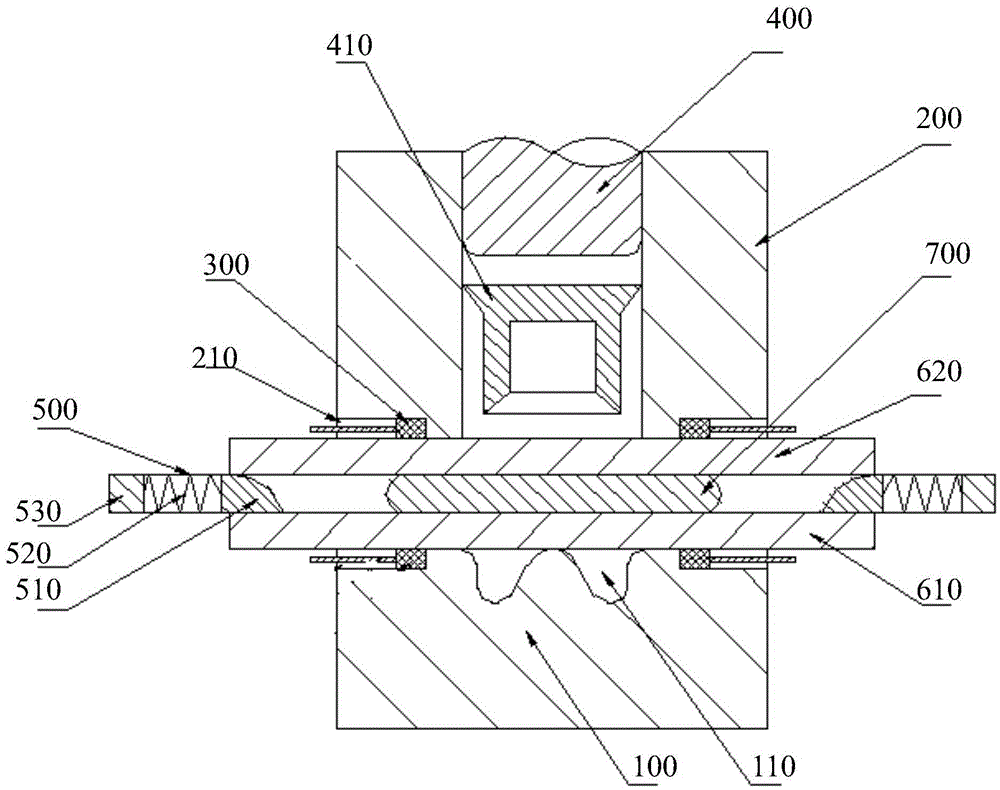

Self-punching bond-riveting connecting device and bond-riveting method

InactiveCN105458147ASelf-piercing riveting is possibleReduce intensityFurnace typesHeat treatment furnacesPunchingEngineering

A self-punching bond-riveting connecting device comprises a compound female die, a compound edge pressing ring, heat conduction electrodes and a punch, wherein an annular groove is formed in the compound female die, the compound edge pressing ring is opposite to the compound female die in the vertical direction, the compound edge pressing ring can move in the vertical direction and is used for pressing to-be-riveted pieces, the heat conduction electrodes are arranged at the bottom of the compound edge pressing ring and the upper portion of the compound female die and can heat the different to-be-riveted pieces independently, and the punch is a solid circular structural piece, is arranged in a central hole of the compound edge pressing ring and can slide up and down in the axial direction of the central hole. The expanding performance of super-strength steel nearby riveting points is greatly improved, and the problems that super-strength steel is difficult to deform and effective connectors can not be formed are solved. The invention further provides a self-punching bond-riveting connecting method. By precisely controlling the punching speed of the punch, the requirements for the strength of the rivet, the punch riveting capacity of the device and the rigidity of a C-shaped frame of a riveting gun are lowered, and production cost is reduced.

Owner:JILIN UNIV

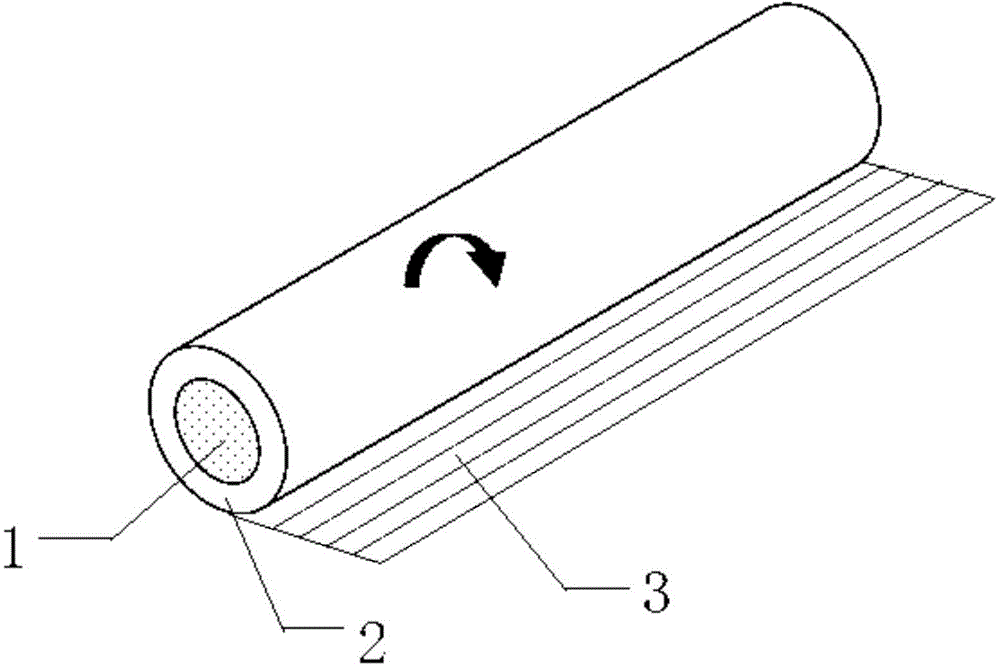

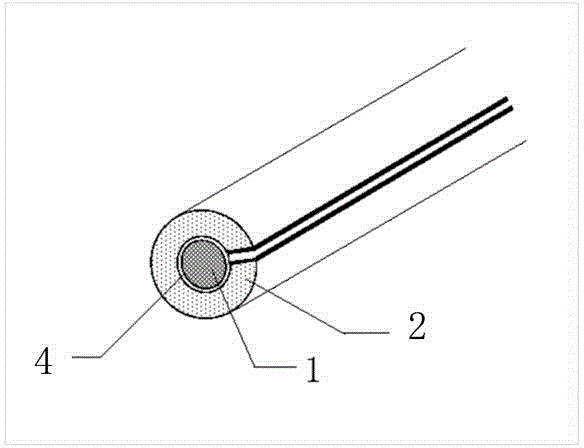

Rubber oil pipe with efficient heat protection structure and preparation method of rubber oil pipe

InactiveCN104553089AThe preparation method is simple and efficientLow costThermal insulationFlexible pipesInsulation layerComposite film

The invention discloses a rubber oil pipe with an efficient heat protection structure and a preparation method of the rubber oil pipe. The preparation method comprises the following steps: preparing an inner rubber pipe, adhering a heat insulation layer and adhering a high-reflection metal / textile composite film. The high-reflection metal / textile composite film can be used for reflecting heat radiation; the heat insulation layer can be used for effectively reducing heat transferring and heat convection; the heat insulation material layer meeting the size requirements is compounded and fixed on the rubber oil pipe; and the high-reflection composite film is paved on the surface of a heat insulation felt and is combined with the heat insulation felt very well by using an adhesive. The rubber oil pipe has high heat protection efficiency, low cost and good reliability; and the prepared rubber oil pipe with the efficient heat protection structure has excellent mechanical property and heat insulation property and can be widely applied to industries including steel, chemical engineering, petroleum, ship building, automobile manufacturing and the like.

Owner:HEBEI SIBERIA SPECIAL RUBBER

Dispensing process of white light-emitting diode

ActiveCN101783383AReduce heat convectionPlay a role in heat preservationSemiconductor devicesEngineeringWhite light

The invention discloses a dispensing process of a white light-emitting diode (LED), in particular to a method for increasing the color centrality and reliability of the white LED and reasonably utilizing resources and energy to the maximum limit. The method comprises the following steps: mixing and stirring fluorescent powder and water, storing the mixture of fluorescent powder and water under constant temperature, stirring the mixture, pouring the mixture in a syringe of which temperature is adjustable, dispensing with a mechanical screw dispenser, placing the product in a special thermostatic feed box to send to a thermostatic oven for roasting, shortening roasting time and storing the finished product in a thermostatic rack. By using the process of the invention, the consistency of the emitting color, chromaticity coordinate and color temperature of the white LED is increased, the yield rate and reliability of the product are improved, the production process cycle of the white LED is shortened, energy is saved, resources are reasonably utilized and the production cost is reduced.

Owner:HONGLI ZHIHUI GRP CO LTD

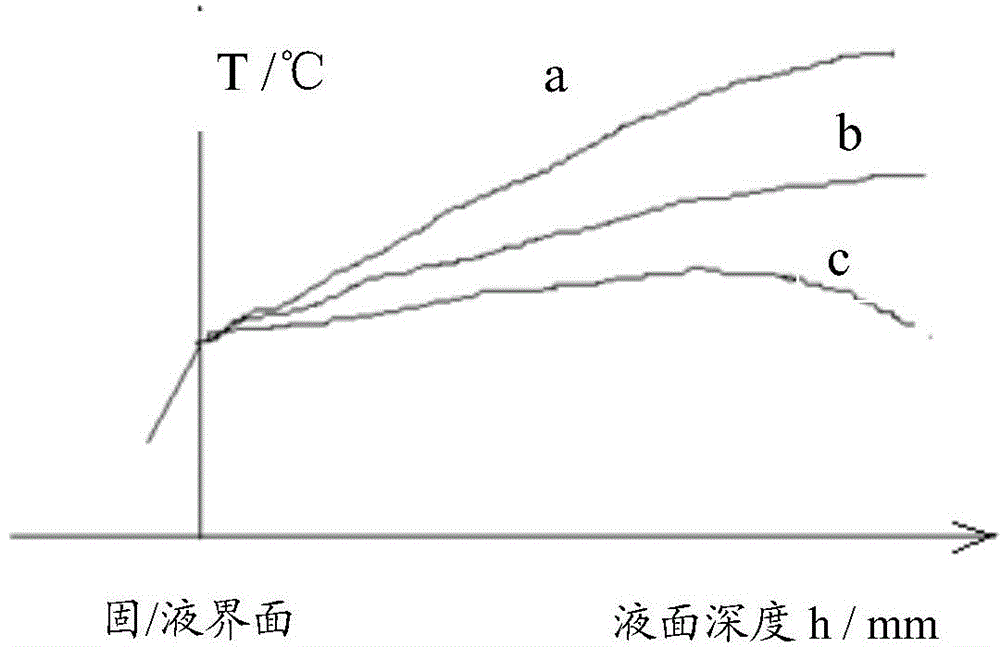

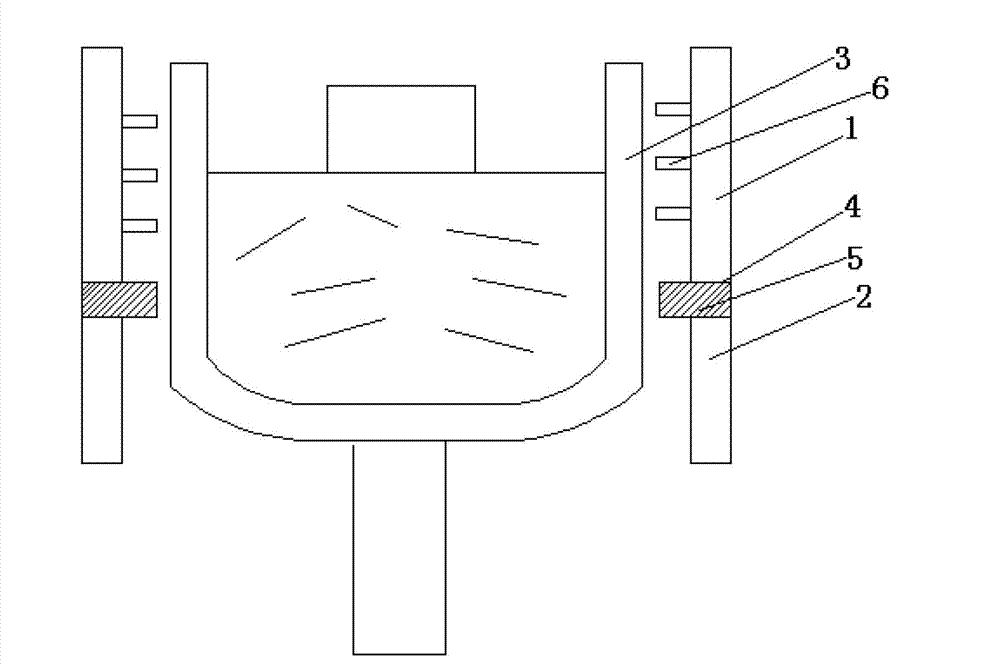

Method and heater for improving quality of monocrystal silicon grown by Czochralski method

InactiveCN104818524AExtend your lifeReduce temperature gradientPolycrystalline material growthBy pulling from meltMolten stateCzochralski method

The invention discloses a method and a heater for improving quality of monocrystal silicon grown by Czochralski method. The method includes putting raw silicon into a crucible of a crystal furnace; heating the crucible to melt the raw silicon in the crucible by the heater and keeping a melt in a molten state; soaking a rod-shaped seed crystal in a solution; injecting inert gas to the liquid level of the melt and controlling furnace pressure; rotating the crucible and lifting the rod-shaped seed crystal reversely rotating relative to the crucible to obtain a cylindrical monocrystal silicon crystal, and controlling heating quantity along the depth direction of the crucible during crystal pulling to enable the temperature gradient of the melt from the growth interface to the bottom of the crucible to decrease. The heater is used for implementing the method. The method and the heater have the advantages that heat convection is reduced effectively, microdefects and deleterious impurities in the monocrystal silicon are reduced, the monocrystal silicon with low defects, ultralow oxygen and high minority carrier lifetime is obtained, cost is low and easiness in implementation is achieved.

Owner:XIAN LONGJI SILICON TECH

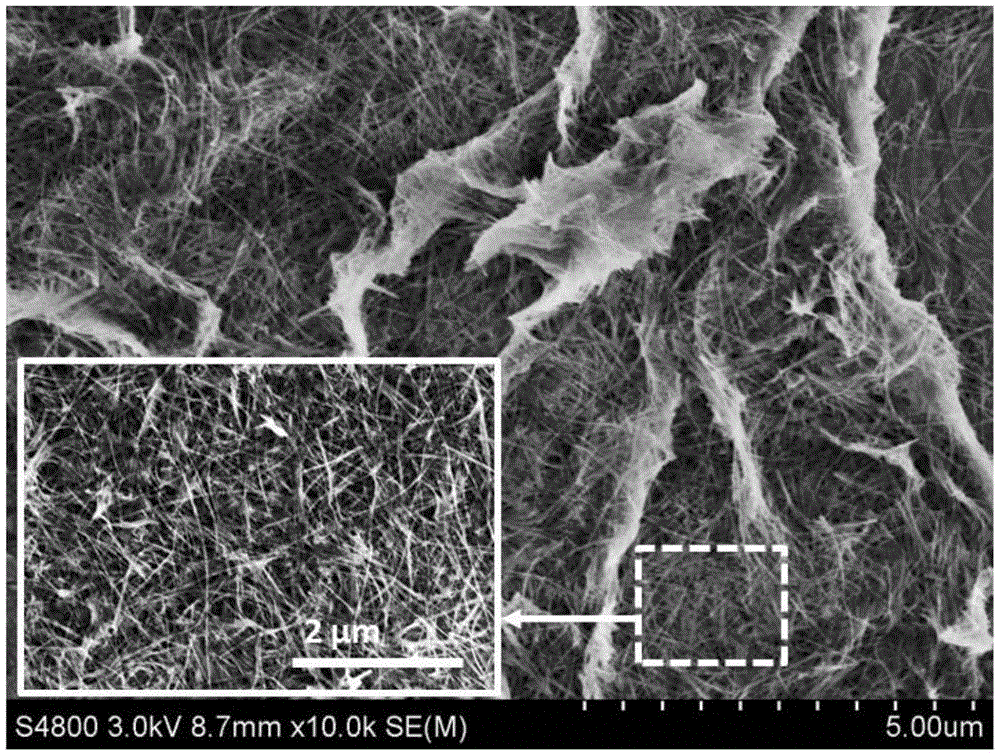

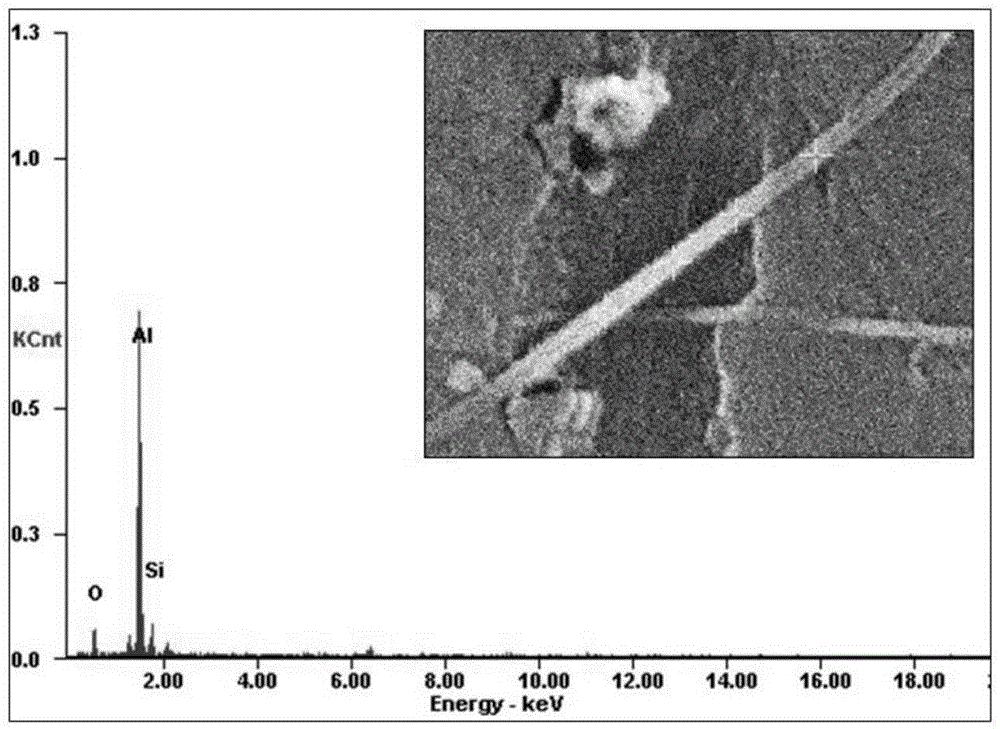

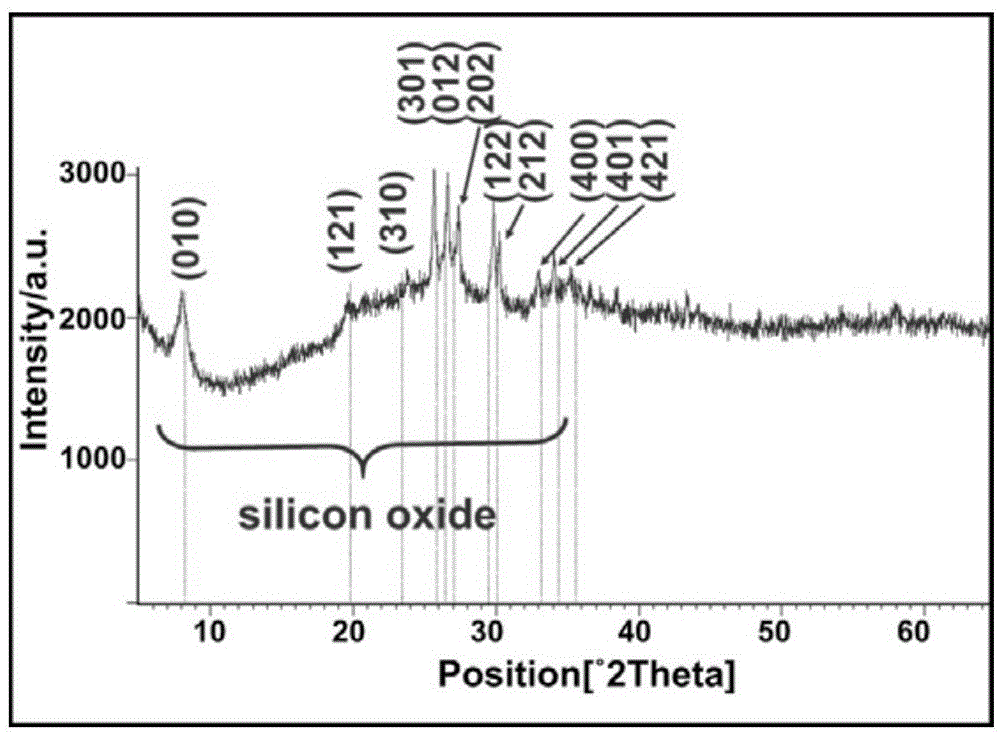

Method for preparing silicon oxide nanofiber

InactiveCN105600793AThe preparation method is convenient and efficientLow costMaterial nanotechnologySilicaPolytetrafluoroethyleneHydrothermal synthesis

The invention discloses a method for preparing silicon oxide nanofiber. The method comprises the following steps of mixing silica sol with a nitrate solution, performing ultrasonic dispersion on the solution, adding ethylenediamine after the dissolution of the nitrate solution, and stirring uniformly to obtain a mixed solution; putting the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner, standing the reaction kettle in a high-temperature baking oven after the closing of the reaction kettle, and performing a hydrothermal reaction; taking out the reaction kettle and cooling the reaction kettle to room temperature after the completion of the reaction, collecting precipitates in the reaction kettle, and washing the precipitates to obtain a silicon oxide nanofiber crude product; adding the silicon oxide nanofiber crude product into a hydrochloric acid solution, stirring in a thermostatic water bath, removing impurity components from the silicon oxide nanofiber crude product, and performing centrifugal separation to obtain a silicon oxide nanofiber finished product. The method disclosed by the invention has the advantages that not only can the high energy consumption in a nanofiber preparation process through a traditional chemical vapor deposition and thermal evaporation technology be avoided, but also the production is easily expanded by utilization of a hydrothermal synthesis technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

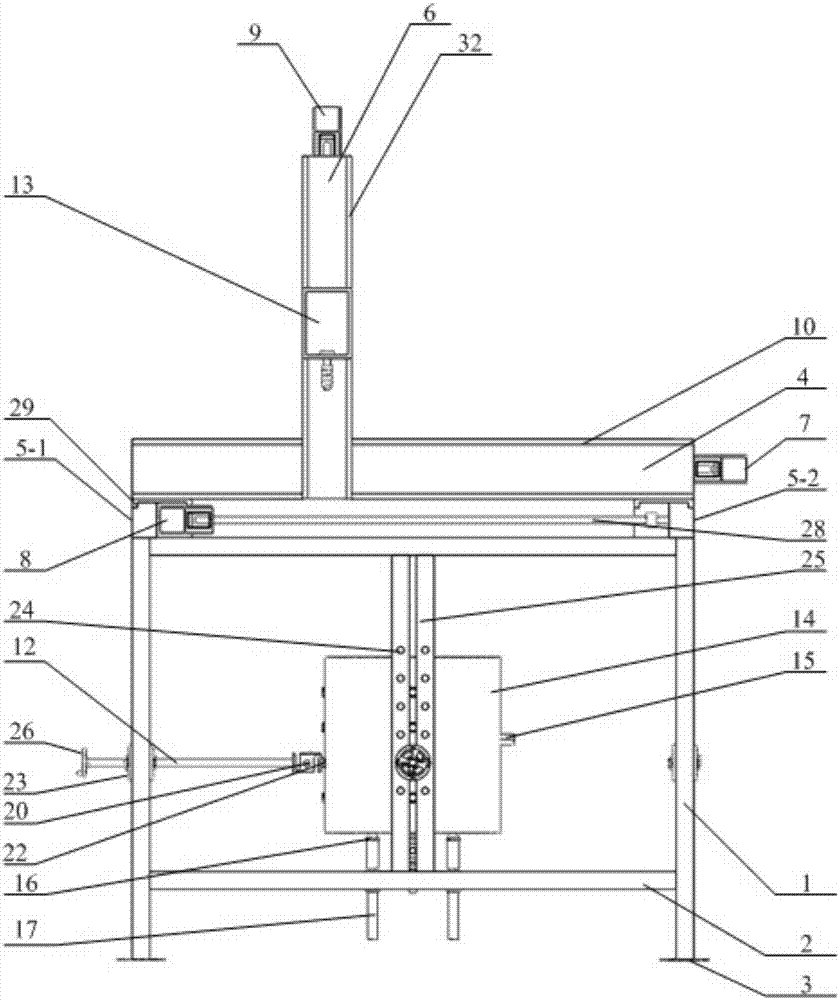

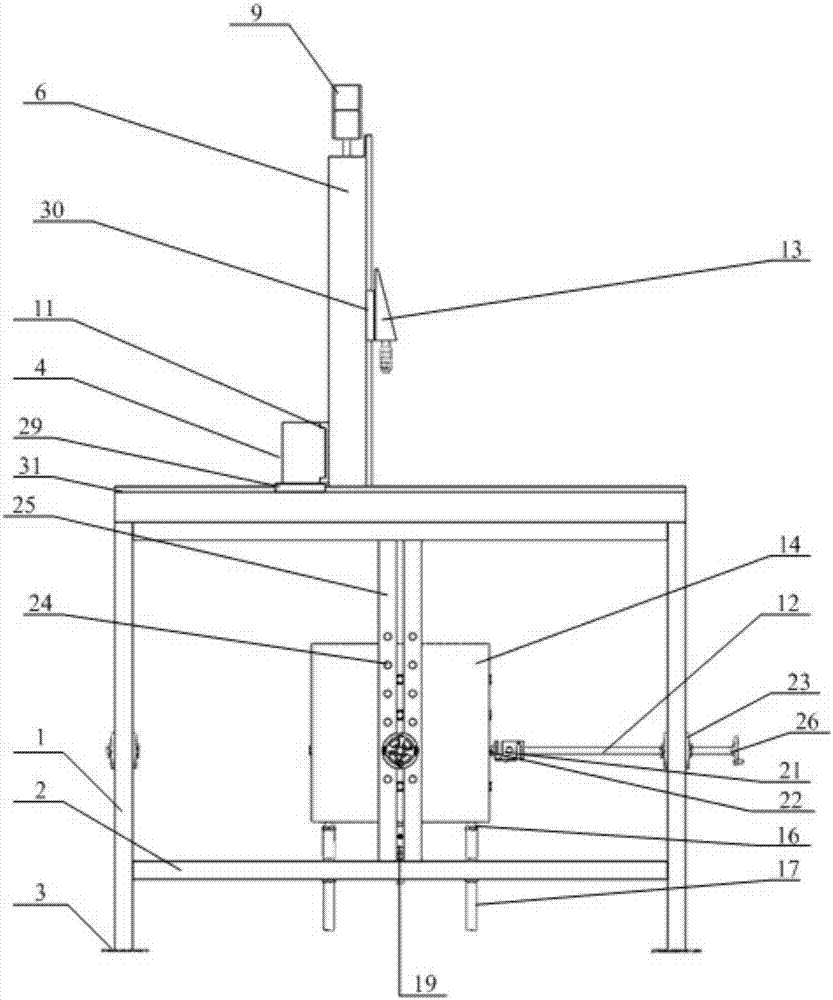

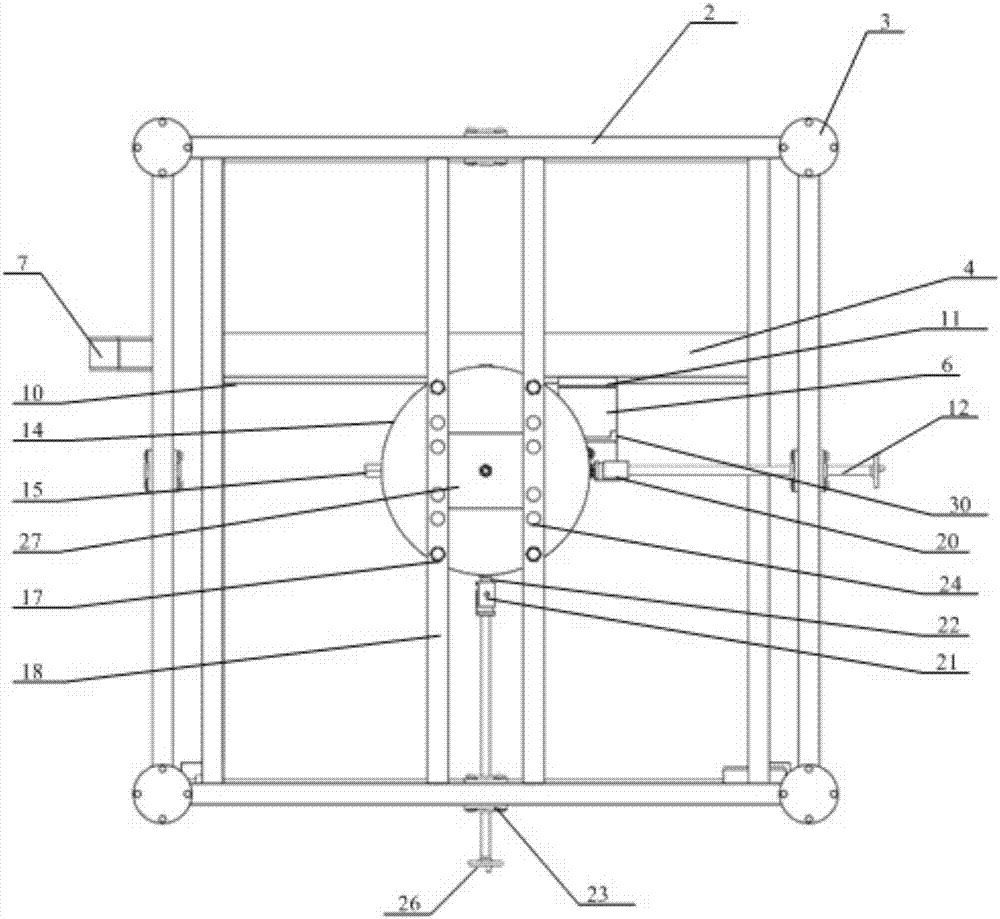

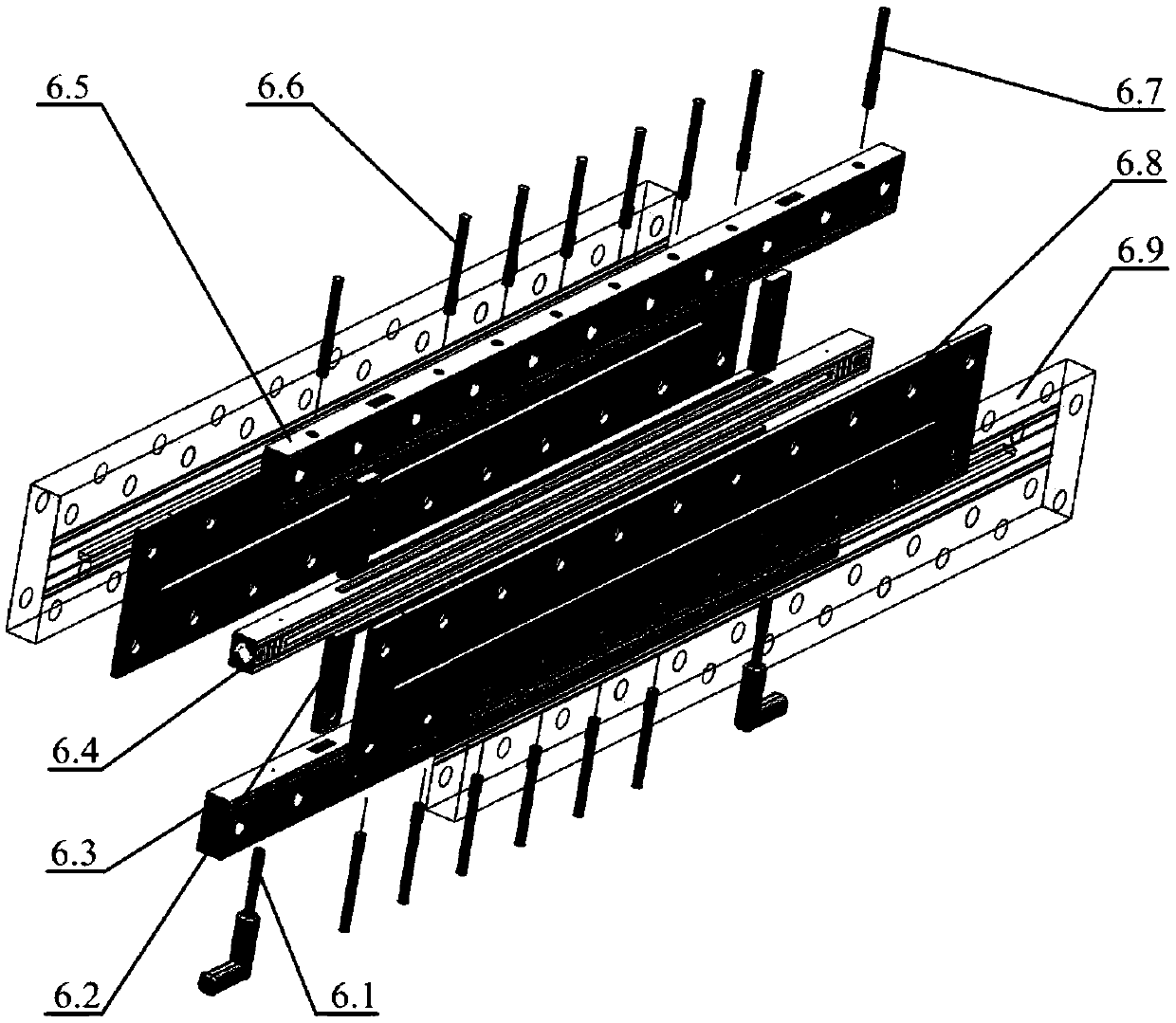

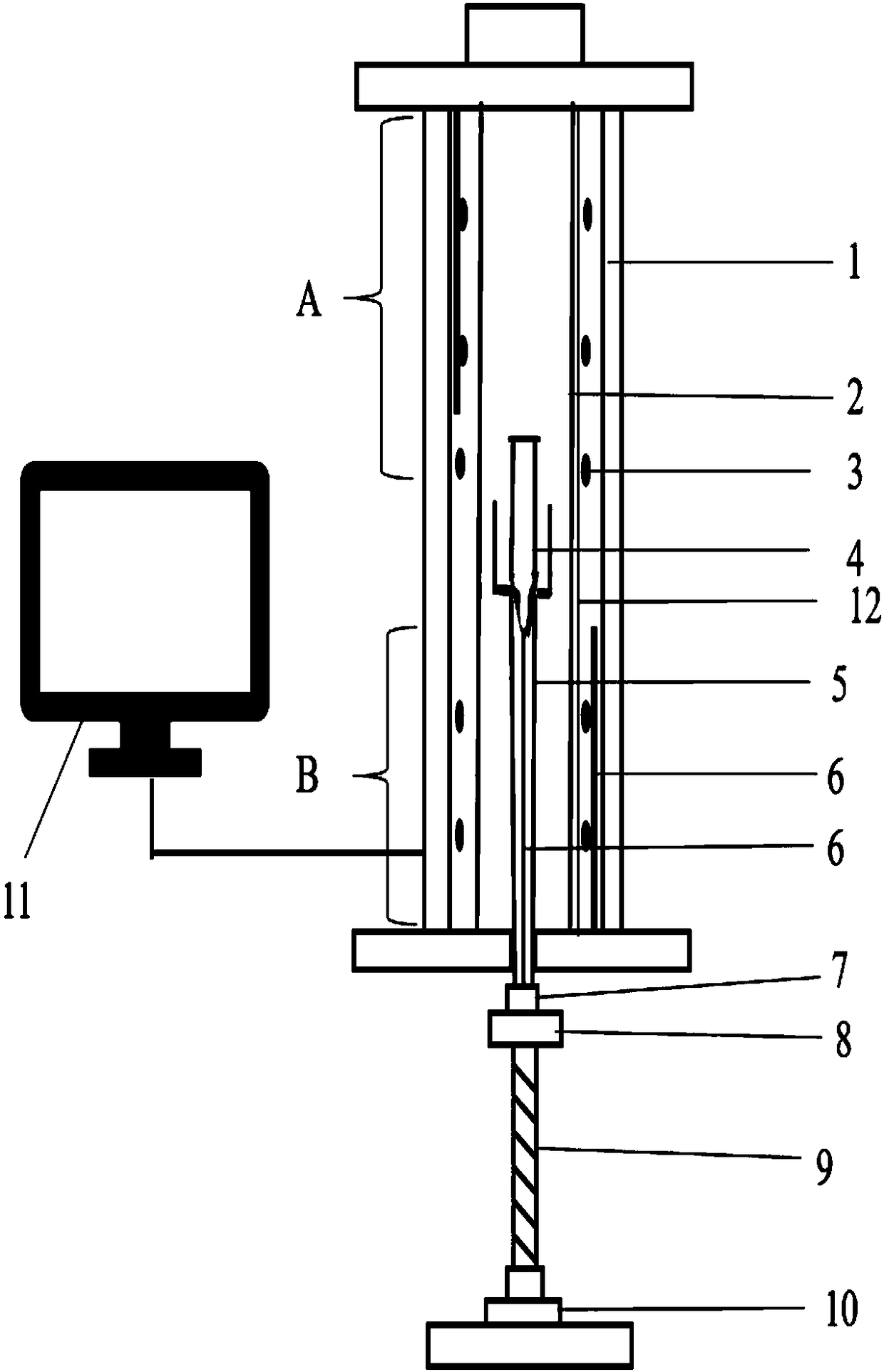

Three-dimensional measuring device for suspension characteristics of high-temperature superconducting magnetic suspension bearing

InactiveCN107219476APrecisely control any displacementIncrease heightMachine bearings testingMagnetic property measurementsPermanent magnet rotorAutomatic control

The invention relates to a three-dimensional measuring device for suspension characteristics of a high-temperature superconducting magnetic suspension bearing. A permanent-magnet rotor fixing device (13) is installed at a sliding block (30) of a vertical mechanical arm (6) of a triaxial movement manipulator; the back surface of the permanent-magnet rotor fixing device (13) is in contact with the upper end surface of the sliding block (30); and the lower end surface of the permanent-magnet rotor fixing device (13) is perpendicular to the upper end surface of the sliding block (30). A double-layer low-temperature Dewar includes a Dewar unit (14) and a Dewar support device; a plurality of force cell sensors are arranged at a peripheral outer wall or bottom surface of the Dewar unit (14); one end of each force cell sensor is connected with the Dewar unit (14) and the other end is fixed at a sensor fixation unit. The sensor fixation unit is arranged at the bottom of the Dewar unit (14) or the peripheral outer wall of the Dewar. A manipulator motion control system is connected with the triaxial movement manipulator. An automatic control system is connected with the force cell sensors and the manipulator motion control system and is also connected with a serial port of an upper computer.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

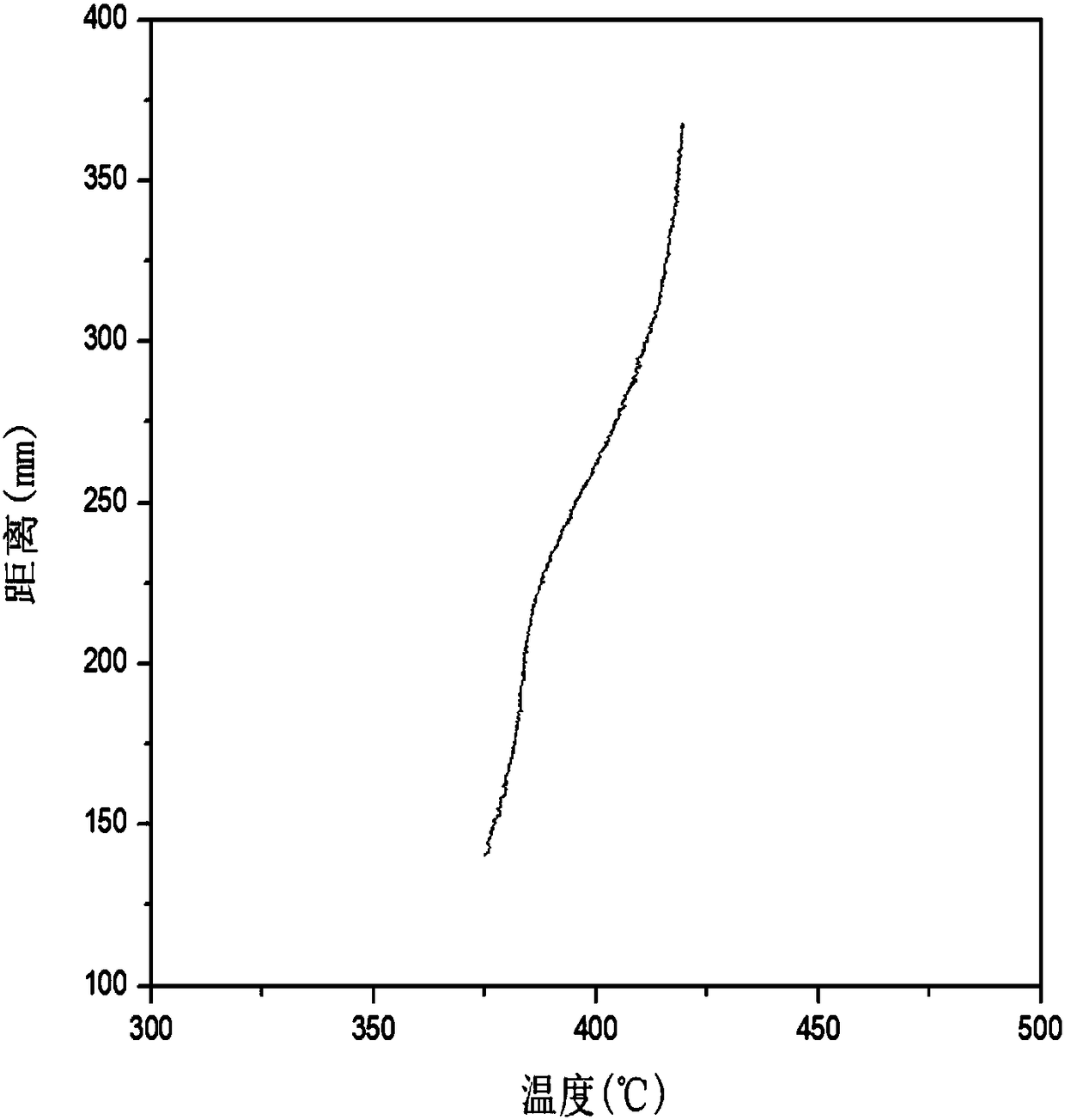

Supercritical pressure fluid flow and heat transfer visualized experimental device under constant heat flux heating condition

ActiveCN109632573AHeating boundary condition reachedHigh hardnessMaterial heat developmentFlow propertiesHeat flowHeat flux

The invention provides a supercritical pressure fluid flow and heat transfer visualized experimental device under a constant heat flux heating condition, which belongs to the field of supercritical pressure fluid flow and heat transfer. The characteristics of convective heat transfer, pulsating flow and the like of the supercritical pressure fluid in a rectangular channel under effects of couplingof multi-boundary conditions and flow pattern characteristics can be investigated, and an experimental data support is provided for clarifying a physical mechanism and triggering conditions for abnormal supercritical pressure fluid heat transfer and pulsating flow phenomena.

Owner:BEIHANG UNIV

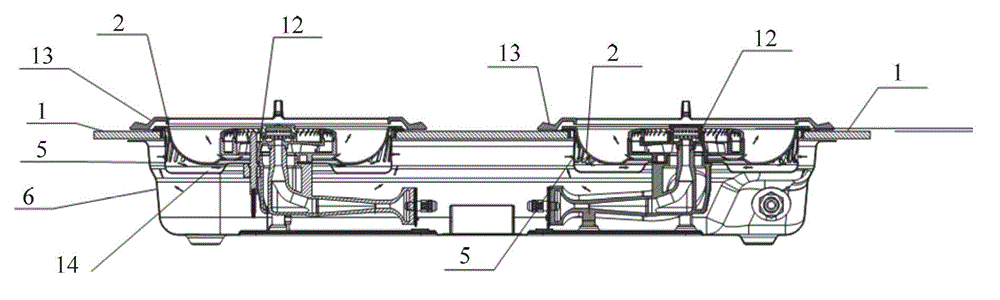

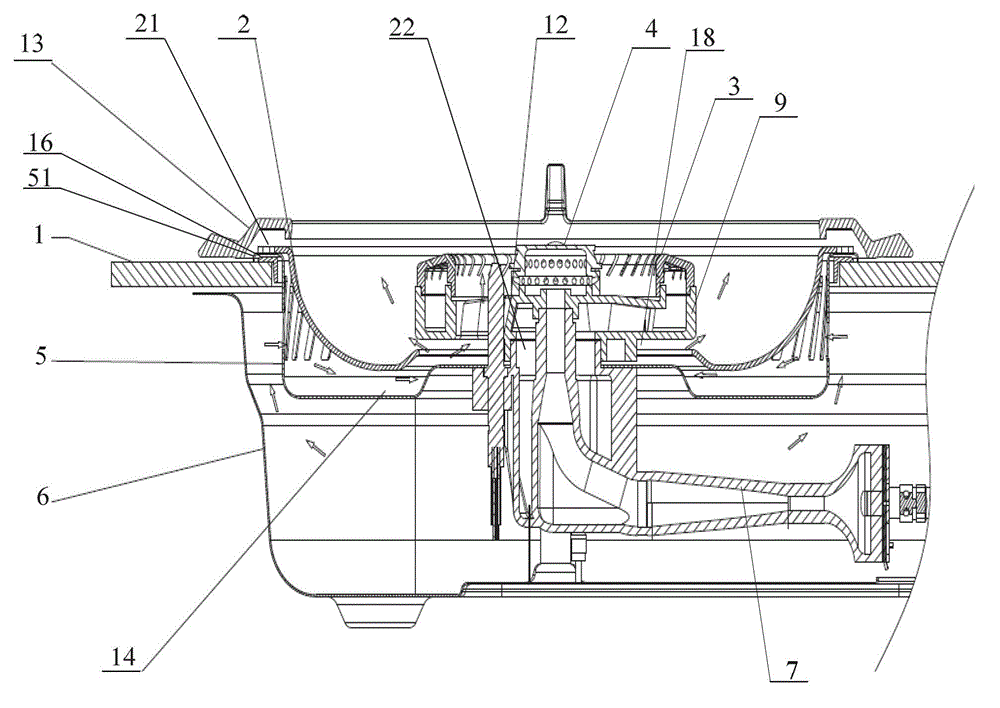

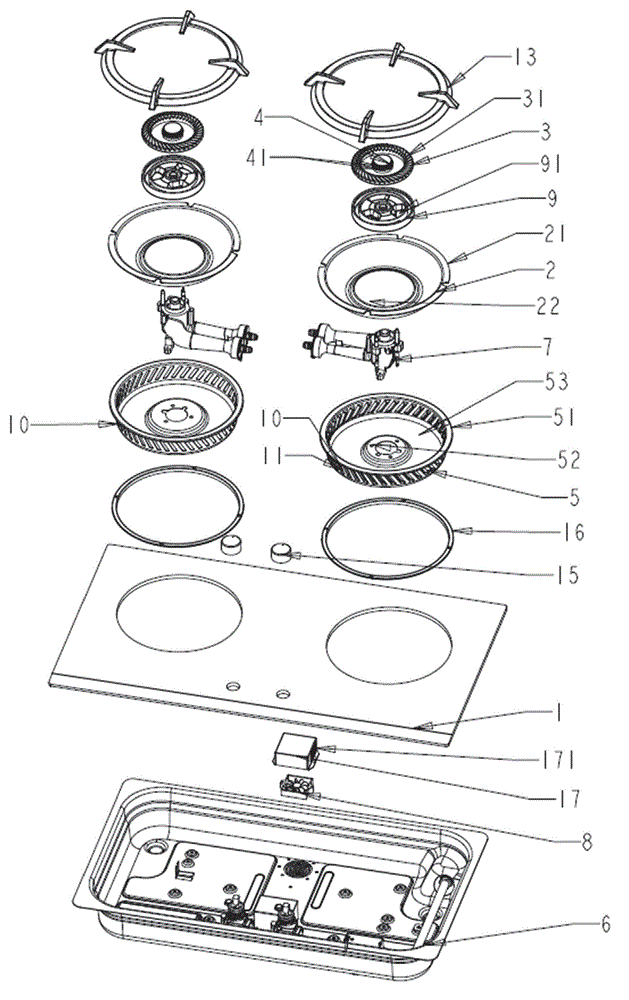

Gas stove

ActiveCN102913956AImprove combustion thermal efficiencyImprove replenishment abilityDomestic stoves or rangesLighting and heating apparatusEngineeringHeating efficiency

The invention discloses a gas stove. The gas stove comprises a panel provided with an opening, a bottom case which is used for supporting the panel, a burner and an energy-collecting disk which is arranged at a position of the opening of the panel, wherein the burner is located in the energy-collecting disk, a pressurization disk is arranged on the lower portion of the energy-collecting disk, and a secondary air supplementing hole is arranged on the side wall of the pressurization disk. The energy-collecting disk is arranged on the surrounding of the burner and is used for conducting energy-collecting reflection for energy generated by the burner, the heat emission and the heat convection are greatly reduced, the gas burning heat efficiency is improved, the pressurization disk is arranged on the lower portion of the energy-collecting disk, the secondary air supplementing hole is arranged on the side wall of the pressurization disk, the air outside the pressurization disk enters from the secondary air supplementing hole and is used for supplementing the burner with the secondary air through the channel between the energy-collecting disk and the pressurization disk, a pressurization fan is arranged on the bottom case of the gas stove, an air duct structure is arranged on the surrounding of the pressurization fan, the burning is complete, the gas burning heat efficiency is improved further and the effect of the inner temperature increment of the gas stove is reduced.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

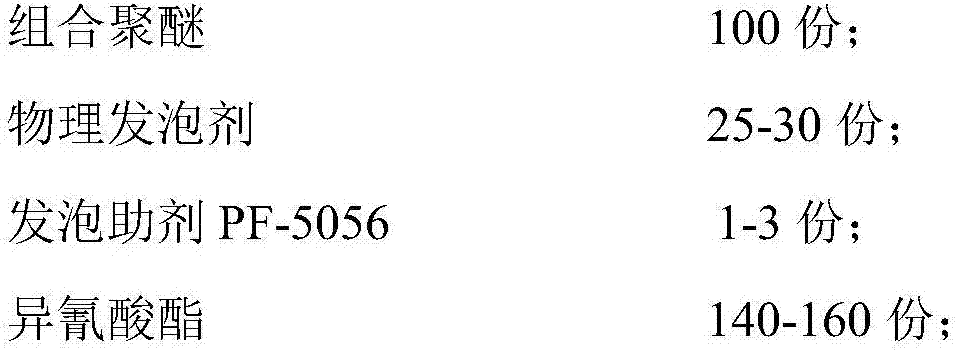

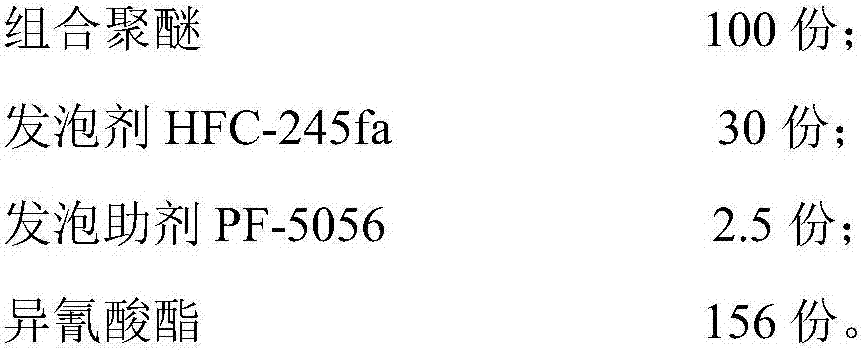

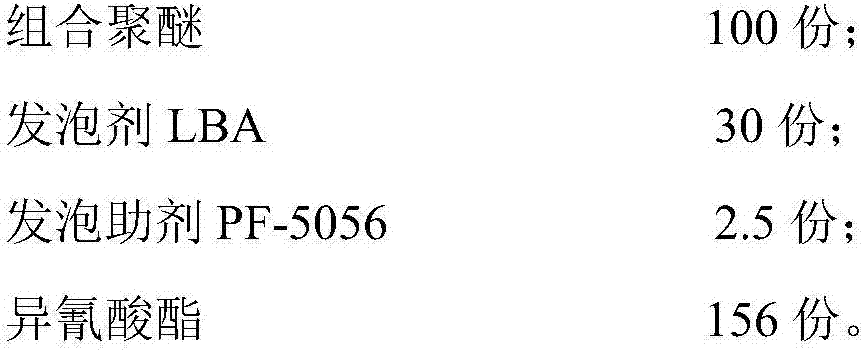

High quality polyurethane foaming system for refrigerators and refrigerator based on the same

InactiveCN107163221AImprove liquidityCombined polyether with low viscosityFoaming agentThermal insulation

The invention discloses a high quality polyurethane foaming system for refrigerators and a refrigerator based on the same. The raw materials include combined polyether, a physical foaming agent HFC-245fa or a physical foaming agent HFO-1233zd (E), a foaming assistant PF-5056 and isocyanate compounded according to certain mass fraction ratio. The polyurethane foaming system with the formula has the advantages of high fluidity, high heat preservation, high mechanical strength, and is in-combustible in-explosive. A rigid polyurethane foam prepared from the system foaming liquid has low thermal conductivity and strong mechanical properties, thereby enhancing the thermal insulation performance and structural stability of the refrigerator.

Owner:CHANGHONG MEILING CO LTD

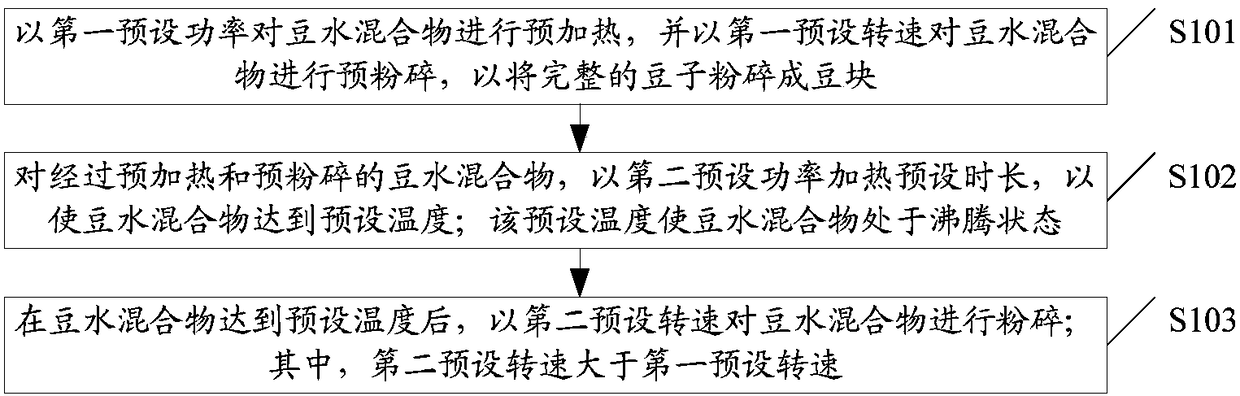

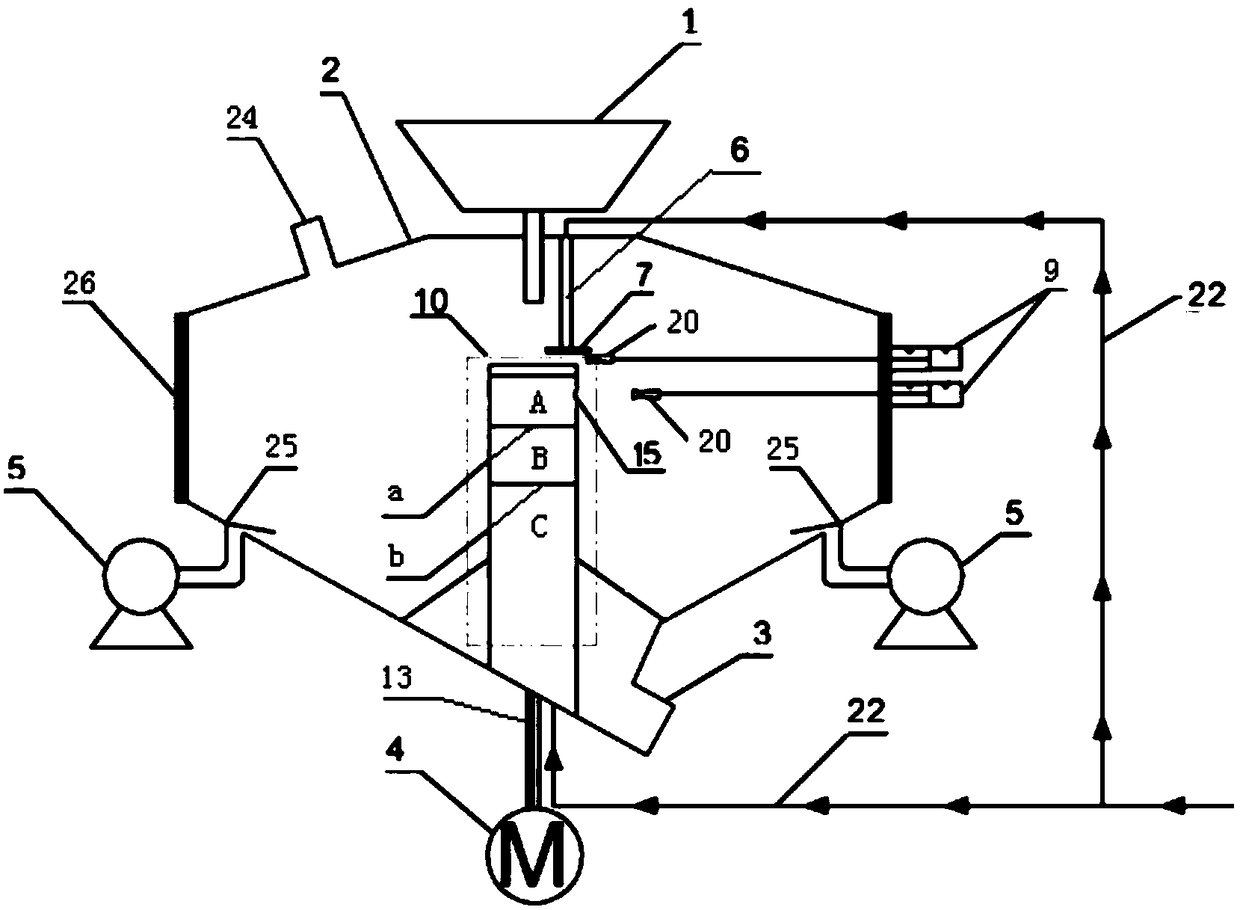

Soybean milk preparation method of soybean milk machine

ActiveCN108514346ALow powerImprove work performanceWarming devicesMilk substitutesSlurryWork Performances

The embodiment of the invention discloses a soybean milk preparation method of a soybean milk machine. The soybean milk preparation method of the soybean milk machine includes the steps that first preset power is used for preheating a bean and water mixture, the bean and water mixture is preliminarily smashed at first preset rotation speed, and therefore integrated beans are smashed into bean blocks; a second preset power is adopted to heat the preheated and pre-smashed bean and water mixture for preset time to make the bean and water mixture reach a preset temperature, wherein the preset temperature makes the bean and water mixture in a boiling state; after the bean and water mixture reaches the preset temperature, the bean and water mixture is smashed at second preset rotation speed, wherein the second preset rotation speed is greater than the first preset rotation speed. By the adoption of the soybean milk preparation method of the soybean milk machine, before a subsequent smashingprocess starts, the bean blocks in soybean milk are in a suspension state under heat convection and cannot sink to the bottom of a cup, therefore, loads generated when a motor sucks materials up are reduced, the power of the motor is reduced, the working performance of the motor is improved, and the service life of the motor is ensured; noise of bean milk beating is reduced to the maximum degree,and the user experience is improved.

Owner:JOYOUNG CO LTD

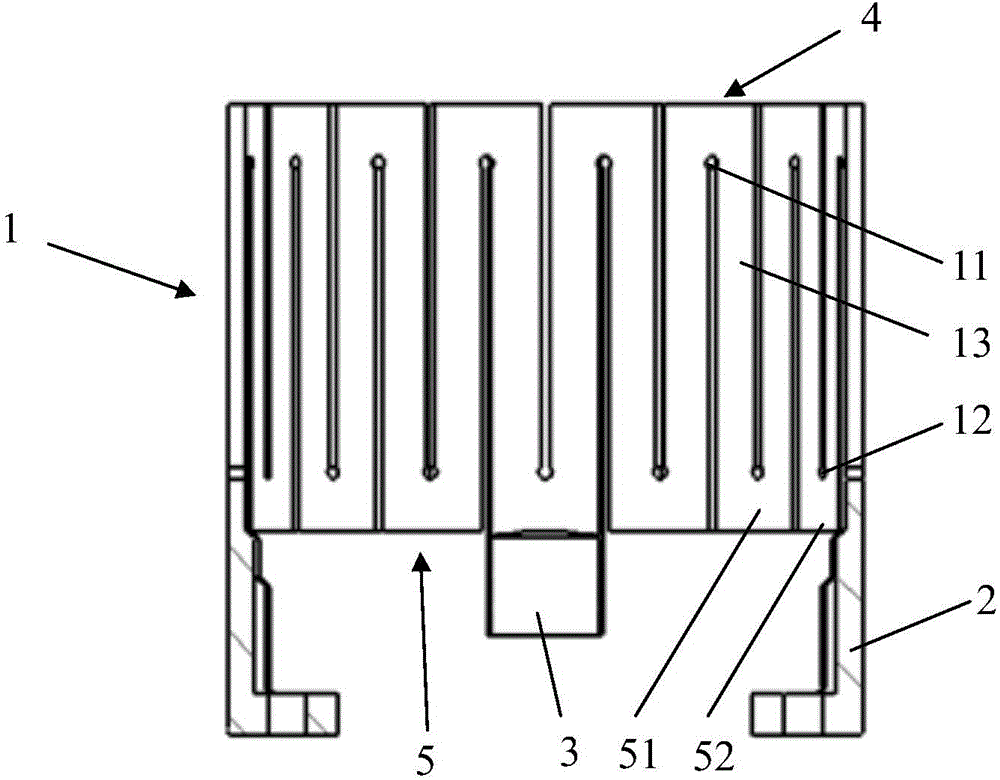

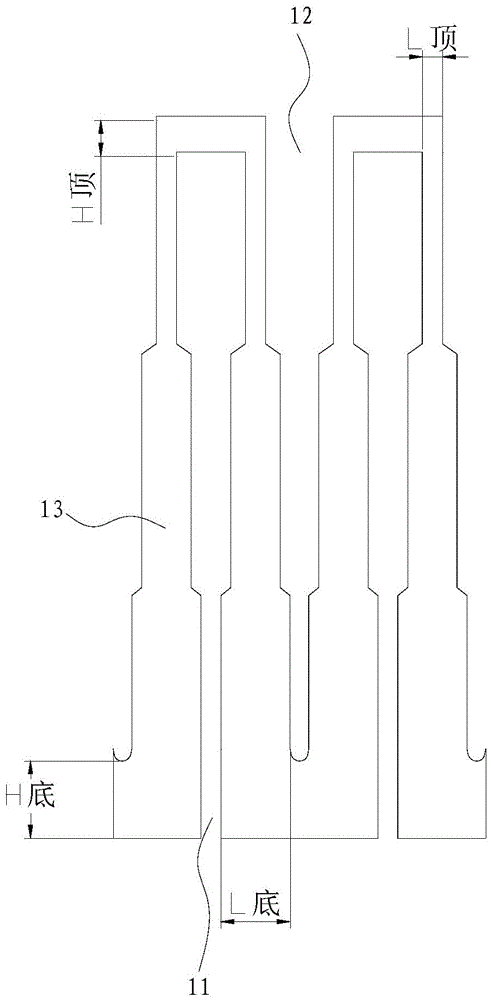

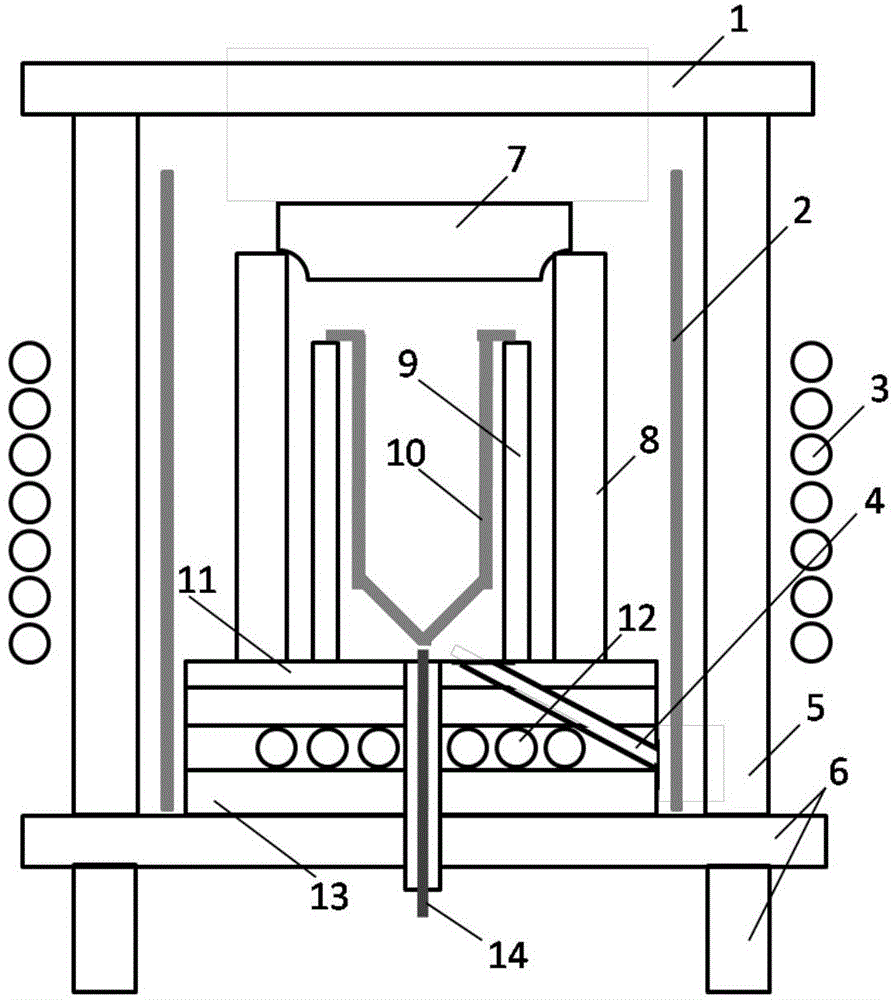

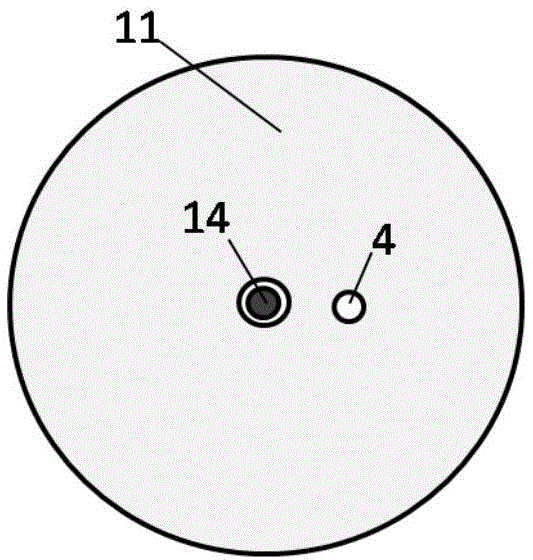

Micro-pulling-down crystal growing furnace

InactiveCN104611764AObserve the growthImprove yieldBy pulling from meltMicro-pulling-downZirconium oxide

The invention discloses a micro-pulling-down crystal growing furnace. The furnace comprises an upper heat-insulating layer and a bottom heat-insulating layer (13) which are arranged from top to bottom, wherein a tubular observation hole (4) is also formed in the bottom heat-insulating layer (13), and the included angle formed by the central axis of the observation hole (4) and the normal of the top surface of the bottom heat-insulating layer (13) is in a range of 45-60 degrees; each of an inner heat-insulating layer, a middle heat-insulating layer and the bottom heat-insulating layer (13) is formed by pressing and calcining zirconium oxide and aluminium oxide in the mass ratio of 1:9. According to the micro-pulling-down crystal growing furnace, the crystal growing condition of a crystal growing interface can be timely observed via the formed observation hole; besides, the effect caused by the observation hole on the temperature field of the crystal growing furnace is low, and the crystal growing yield can be further increased.

Owner:HUAZHONG UNIV OF SCI & TECH

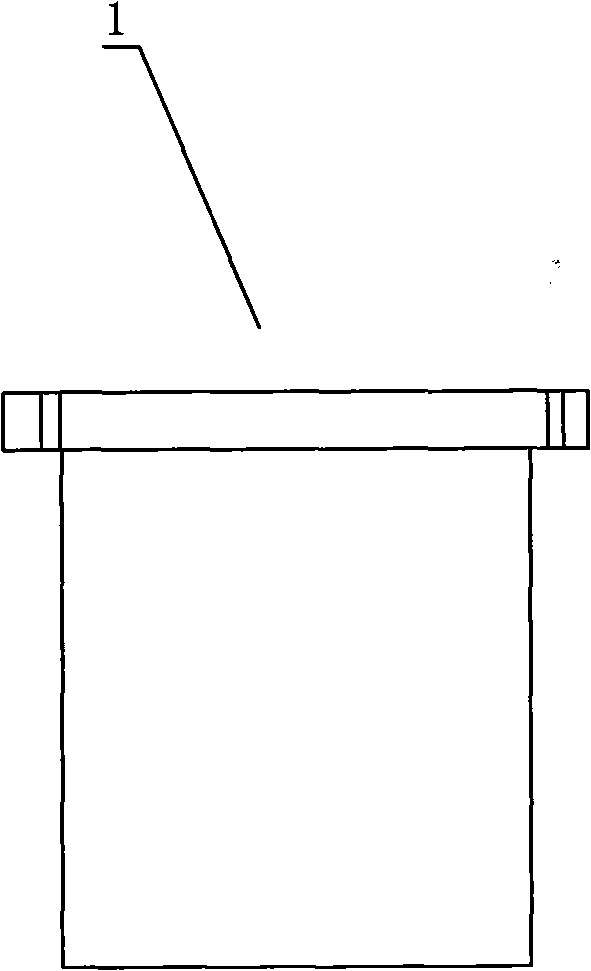

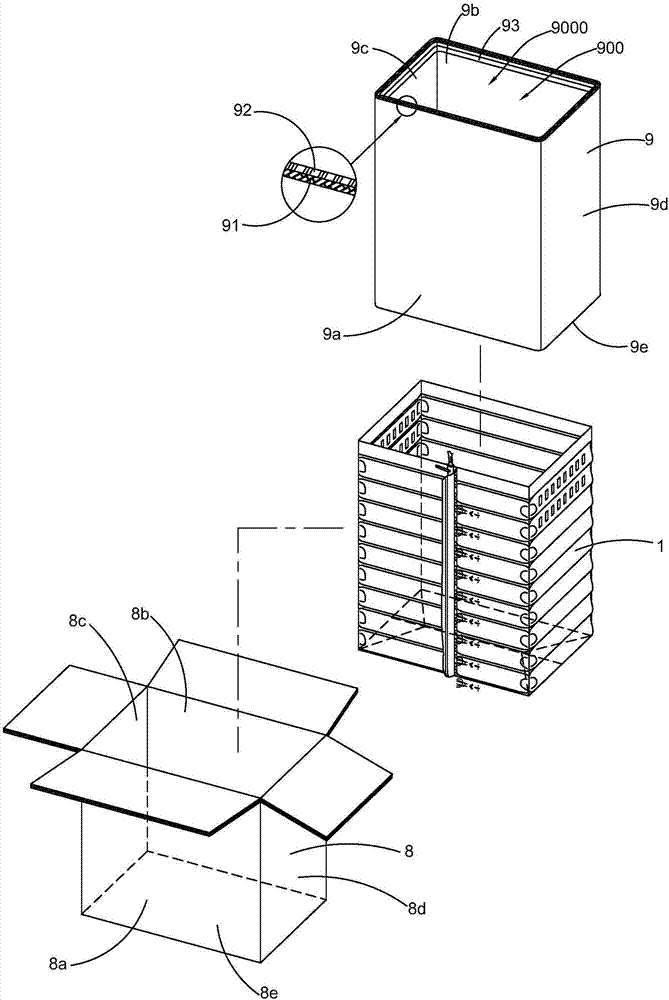

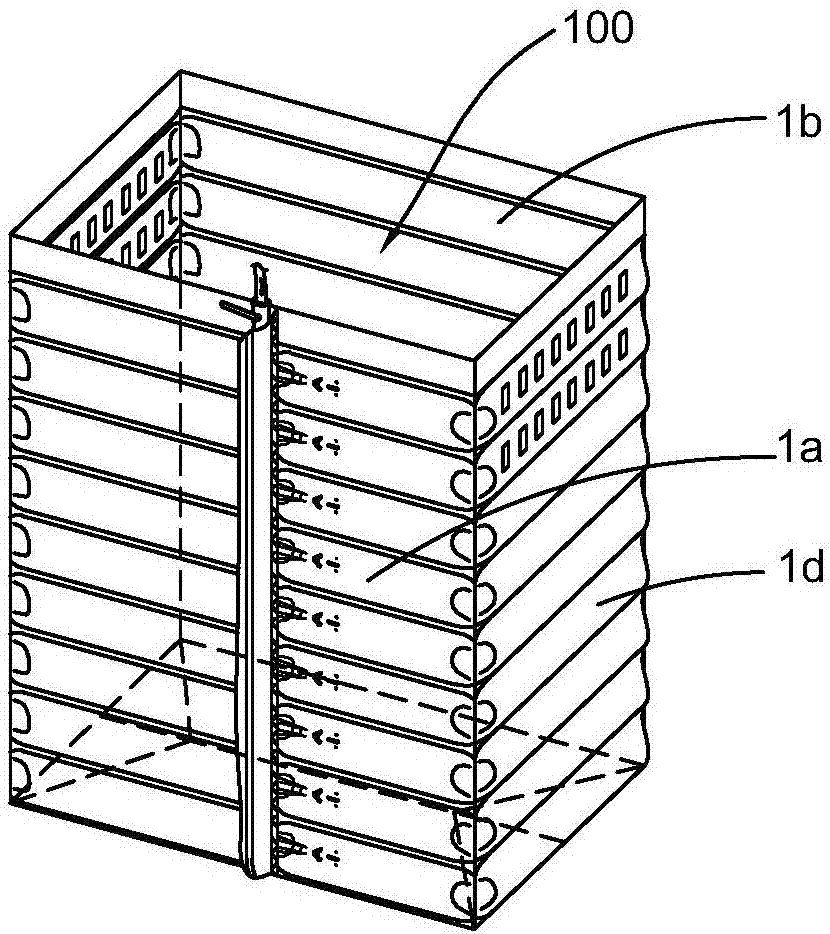

Heat preservation packing device and packing method thereof

PendingCN107472713AReduce heat convectionDomestic cooling apparatusLighting and heating apparatusEngineeringPacking method

The invention provides a heat preservation packing device and a packing method thereof. The heat preservation packing device comprises an inflatable packing device, a heat preservation packing liner and a heat preservation packing outer box. The inflatable packing device is provided with a containing cavity. The heat preservation packing liner is arranged in the containing cavity of the inflatable packing device. The heat preservation packing liner is provided with a heat preservation packing inner cavity for containing packed objects. The heat preservation packing outer box comprises a packing body and a heat preservation body, wherein the packing body and the heat preservation body are tightly attached and folded and sealed jointly, so that the heat preservation packing outer box is provided with a stereoscopic structure. The inflatable packing device is placed in the heat preservation packing outer box.

Owner:TIAN JIN SURE CREATION TECH CO LTD

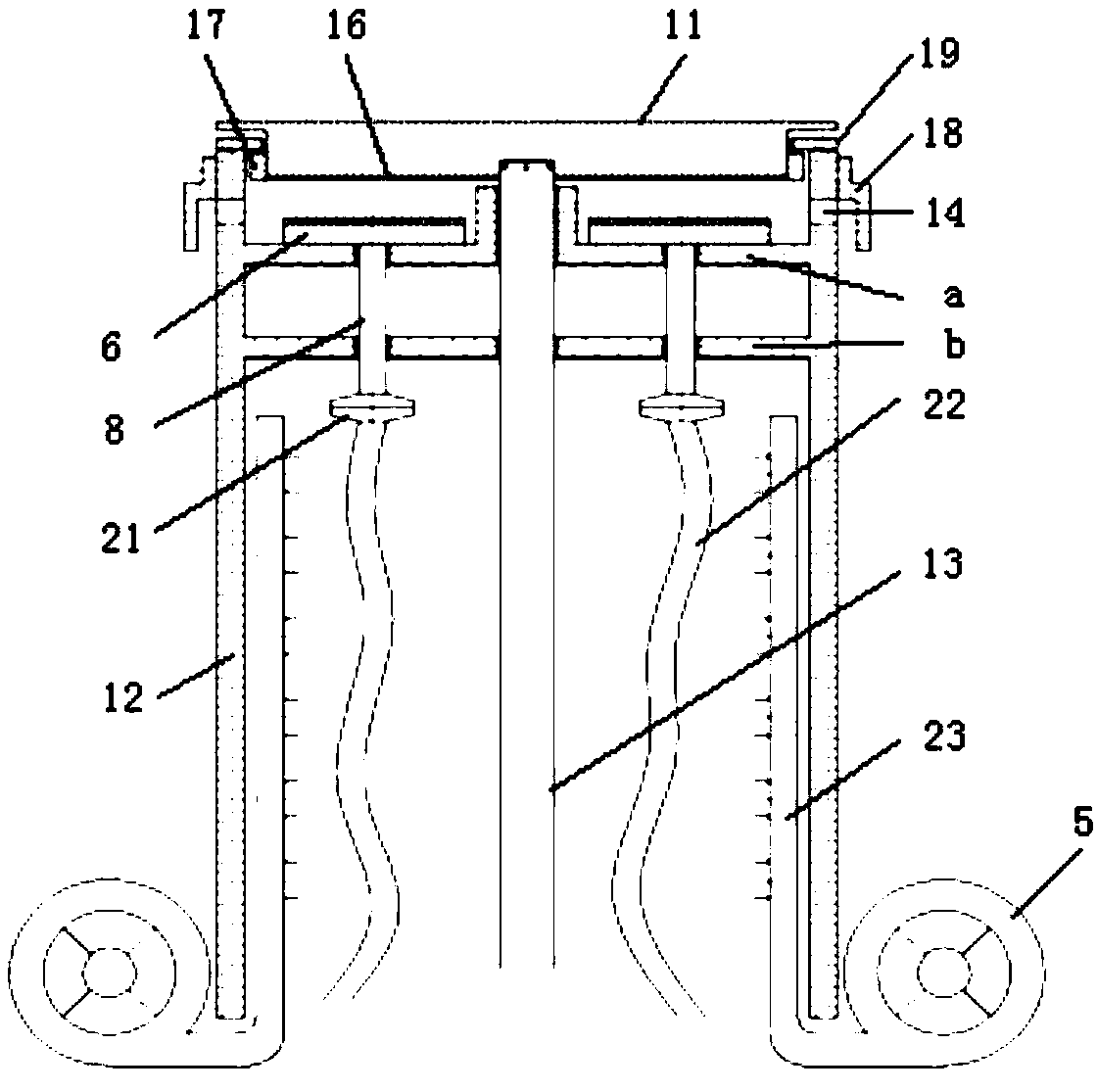

Mercurous chloride single crystal growing device and method

ActiveCN108411366APrecise control of temperature distributionSuitable for growthPolycrystalline material growthFrom frozen solutionsGas phaseSingle crystal

The invention relates to a mercurous chloride single crystal growing device and method. The device comprises a furnace body, and a rack and a supporting mechanism which are connected with the furnacebody and used for supporting the furnace body; the furnace body comprises a furnace tube and a heat preservation sleeve coating the outer surface of the furnace tube, and a heating furnace wire is arranged between the furnace tube and the heat preservation sleeve; the supporting mechanism is connected with a long crystalline style through a rotating device for controlling the rotation of the longcrystalline style, the long crystalline style is inserted in the furnace tube, the end portion, located in the furnace tube, of the long crystalline style is provided with a growing quartz ampoule; the supporting mechanism is also used for controlling the lifting of the long crystalline style through a lifting rod and a lifting bracket. The mercurous chloride single crystal growing device and method have the advantages that not only can the temperature of the crystal growing be accurately controlled, but also the situations of the crystal growing can be monitored at any time, and large-size and high-quality crystal can be easily obtained through physical vapor transport.

Owner:SHANDONG UNIV

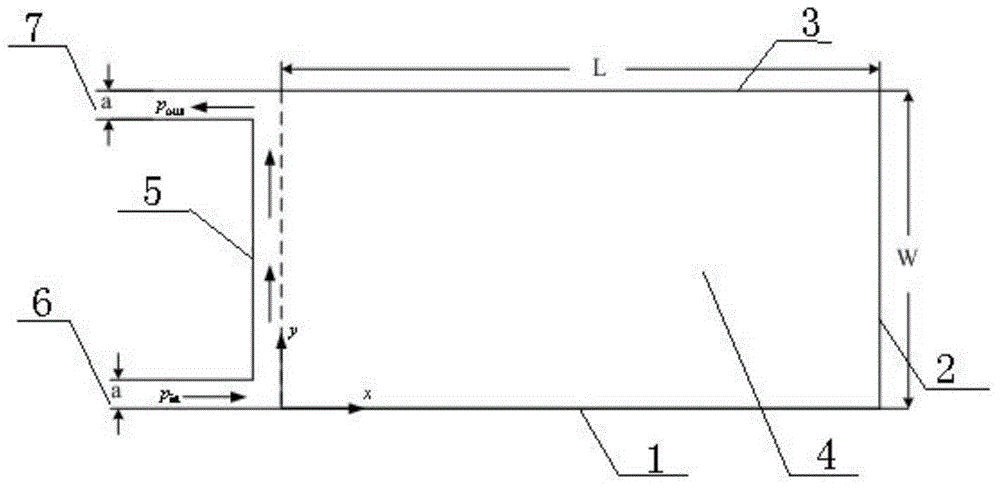

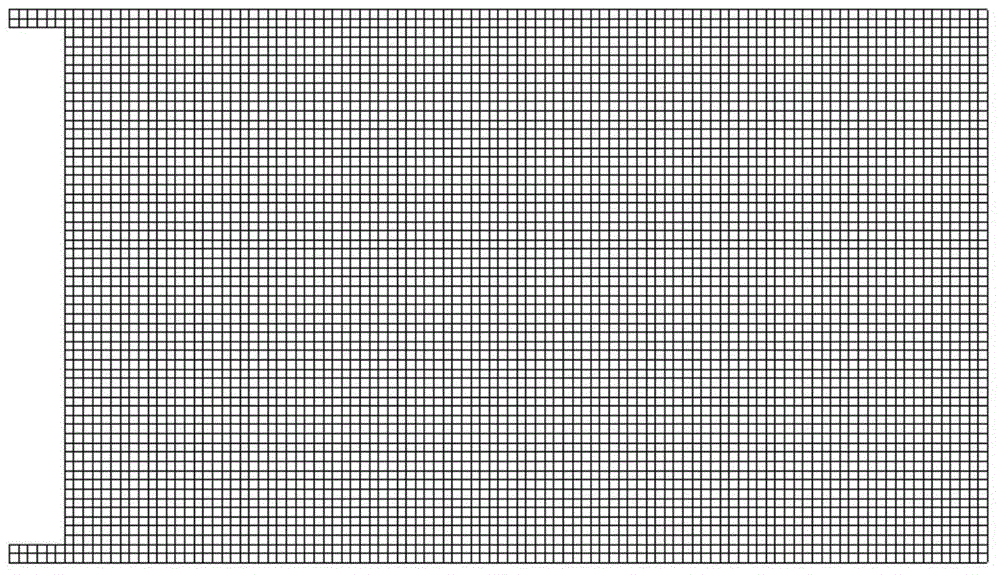

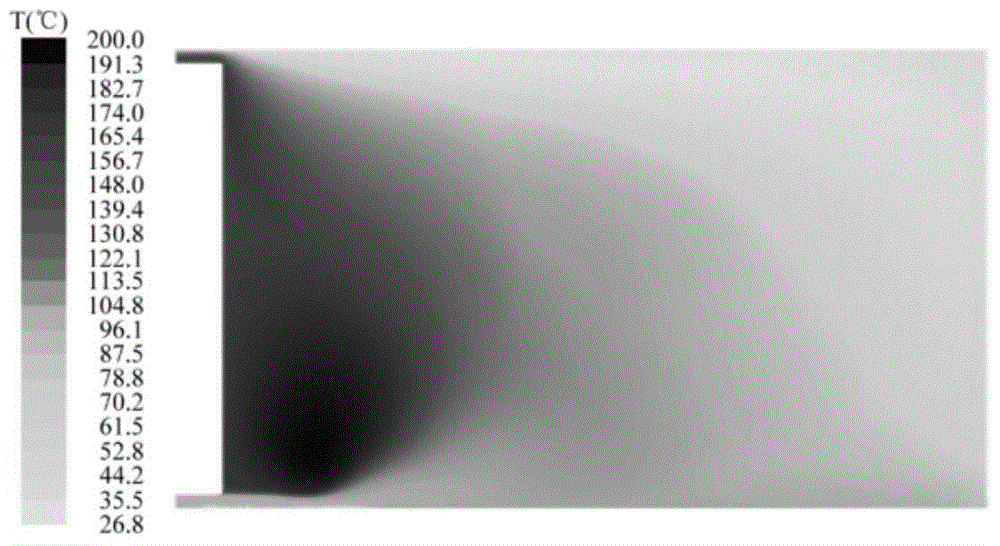

Atmospheric pressure influence considered mine goaf temperature field simulation method

ActiveCN104933230AHigh precisionReduce flow rateSpecial data processing applicationsMulti fieldCloud atlas

The invention relates to an atmospheric pressure influence considered mine goaf temperature field simulation method which is used for obtaining a total pressure value p<in> at an air inlet throat and a total pressure value p<out> at an air return throat. A set of simultaneous plane temperature field model equations is formed, and a wind pressure boundary condition equation and a thermodynamics boundary condition equation are added; a numerical solution is obtained in computational fluid dynamics software FLUENT to obtain a goaf temperature field simulation cloud atlas under certain ground atmospheric pressure; and a rule that if the atmospheric pressure is increased, the absolute pressure of air in the goaf is increased, the flow velocity is caused to decrease, and therefore low heat convection and conduction efficiency and small temperature distribution gradient is caused due to multi-field coupling is obtained, and the rule conforms to a practical situation of a mine. The method has the advantages of small error and high precision.

Owner:CCTEG SHENYANG RES INST +1

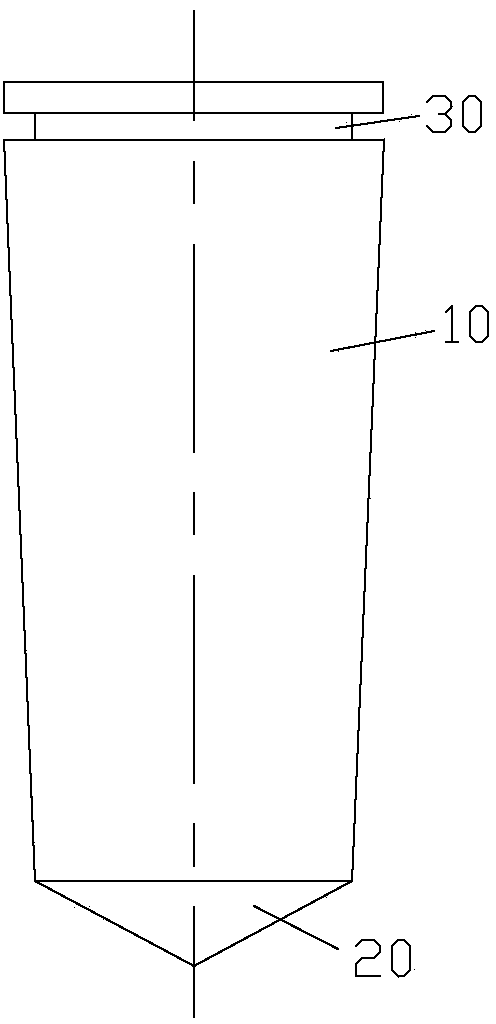

Seed crystal for seeding during manufacturing of silicon single crystal rod and manufacturing method of silicon single crystal rod

InactiveCN103436954AReduced lateral temperature gradientImprove adsorption capacityPolycrystalline material growthBy pulling from meltCrucibleCzochralski method

The invention provides a seed crystal for seeding during manufacturing of a silicon single crystal rod and a manufacturing method of the silicon single crystal rod. The seed crystal is conical; a conical shape can ensure that the adsorptive power between fused silicon and the seed crystal is increased, so that seeding cannot be interrupted easily in the seeding process. The impact to a crystal caused by the heat convection in the fused silicon is the main factor that causes seeding interruption, but when the seed crystal provided by the invention is adopted to perform seeding, a silicon rod can better withstand the impact of the heat convection, so that rotating speed of a crucible in the seeding process can be reduced, and the reduction of the rotating speed of the crucible ensures that the power consumption of the seeding process for manufacturing the silicon single crystal rod by a czochralski method is correspondingly reduced. The transverse temperature gradient on the surface of the fused silicon is reduced while the rotating speed of the crucible is reduced to ensure that the heat convection strength of a growth interface of the crystal is reduced, so that the probability that impurities impact the growth interface of the crystal can be avoided, the crystal formation rate of the seeding process is improved, the impurity content in the silicon single crystal rod is reduced, and then the quality of the silicon single crystal rod is improved.

Owner:YINGLI ENERGY CHINA

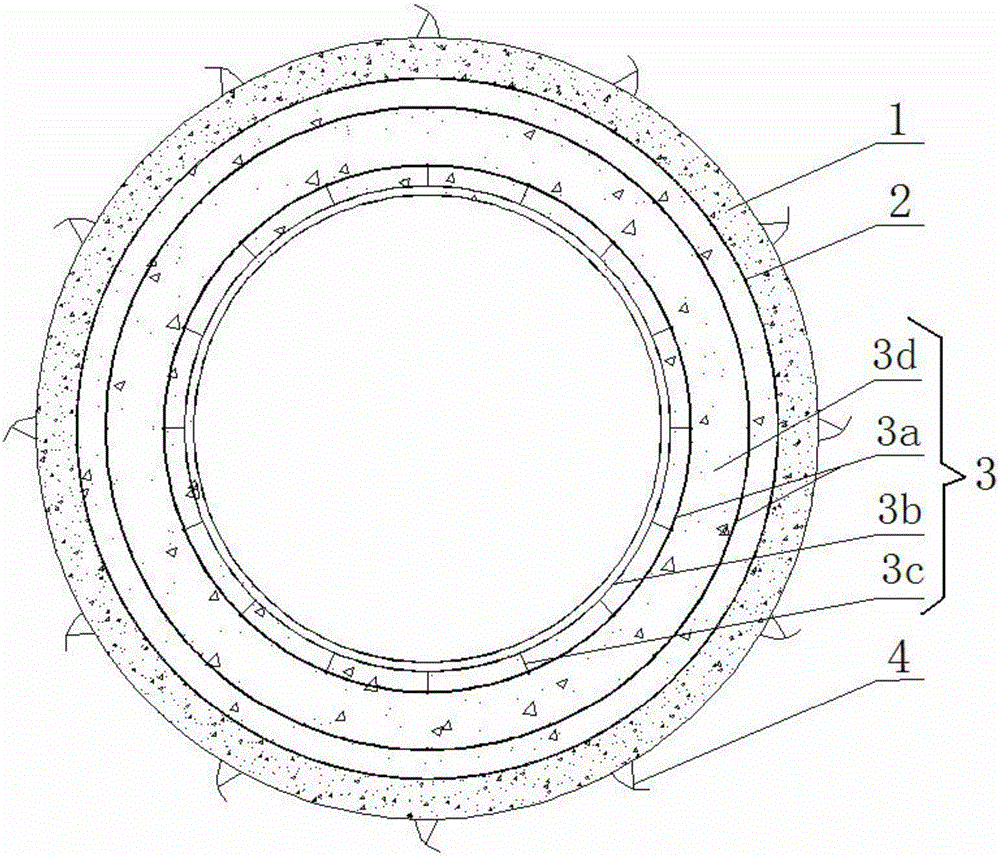

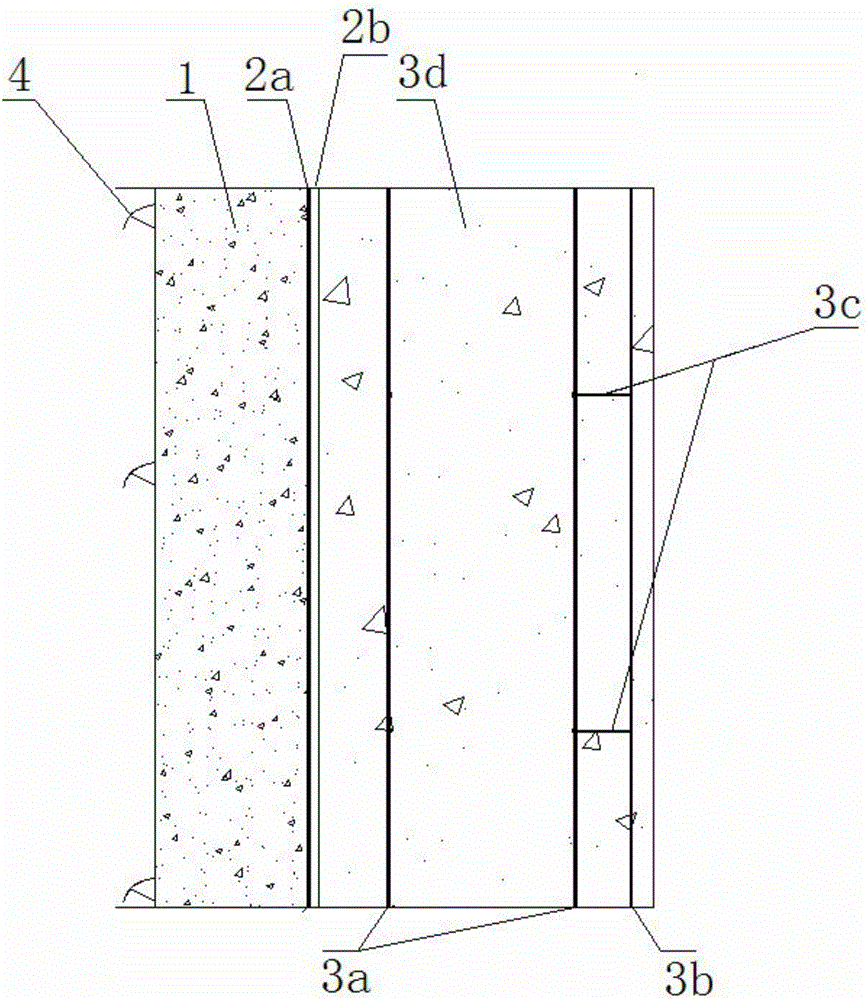

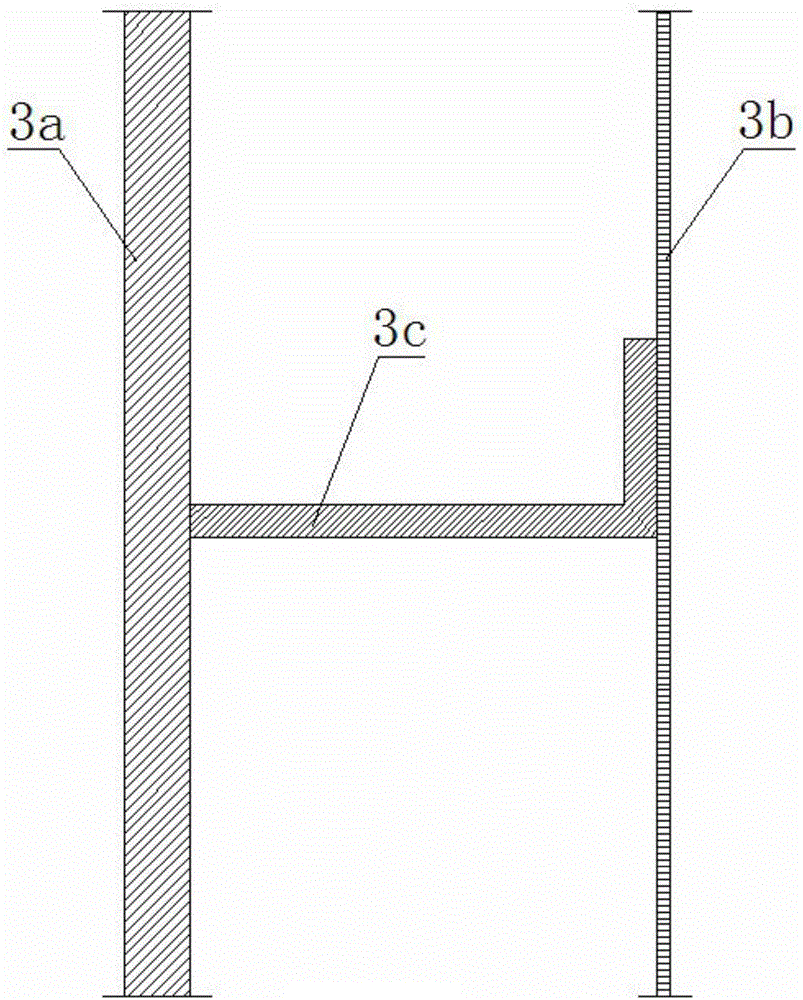

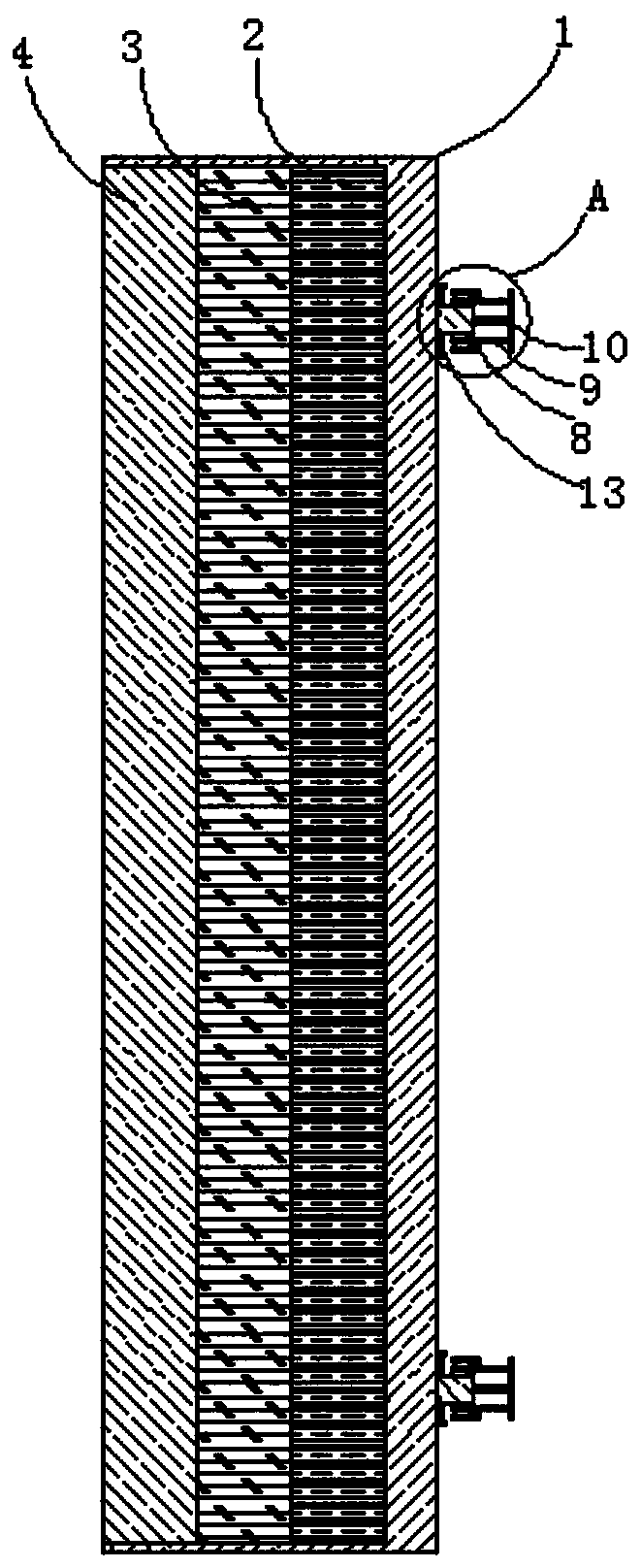

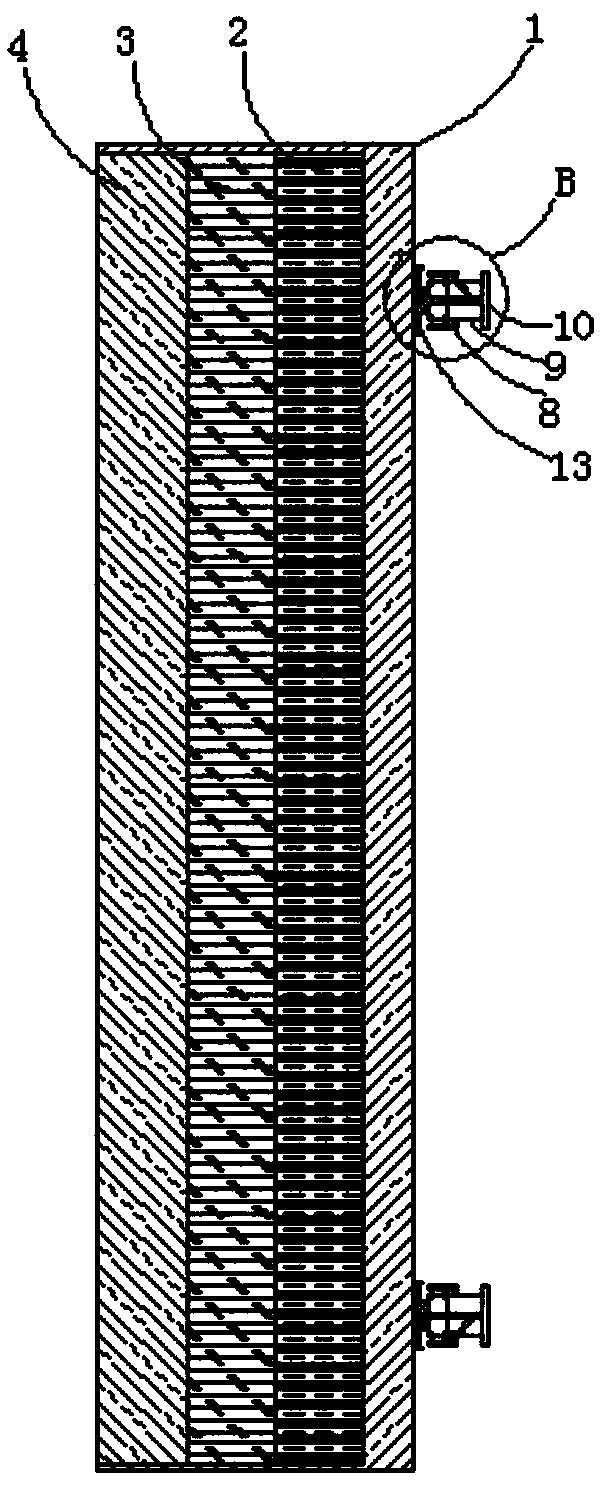

Basalt fiber grid reinforced lining structure for high ground temperature high-pressure hydraulic tunnel

InactiveCN106320296AHigh crack control abilityImprove carrying capacityWater-power plantsHydro energy generationElastomerGround temperature

The invention discloses a basalt fiber grid reinforced lining structure for a high ground temperature high-pressure hydraulic tunnel. A primary lining, a water-resisting layer and a secondary lining are sequentially arranged from the surface of a tunnel surrounding rock to the wall of a tunnel, wherein the primary lining is a reinforced concrete layer, the water-resisting layer comprises a concrete sealing primer layer on the outer wall surface of the primary lining and a polyurea elastomer layer on the outer surface of the concrete sealing primer layer, and the secondary lining is a reinforced concrete layer with basalt fiber grids embedded inside. The basalt fiber grids with high tensile bearing capacity are assembled inside the secondary lining, the reinforced concrete linings are effectively reinforced by inhibiting generation of tension cracks, polyurea elastomer is sprayed to the outer wall of the sprayed concrete primary lining to serve as a water-resisting material, unfavorable action of heat conduction between the high-temperature surrounding rock and low-temperature high-pressure water can be reduced, and the basalt fiber grids and circumferential reinforcements jointly bear circumferential tensile force generated by temperature gradient and high-pressure water load when the hydraulic tunnel is in water filling operation.

Owner:GUANGXI UNIV

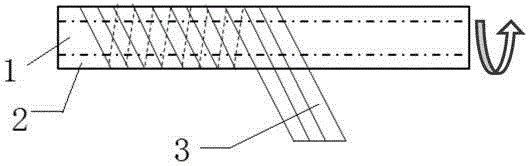

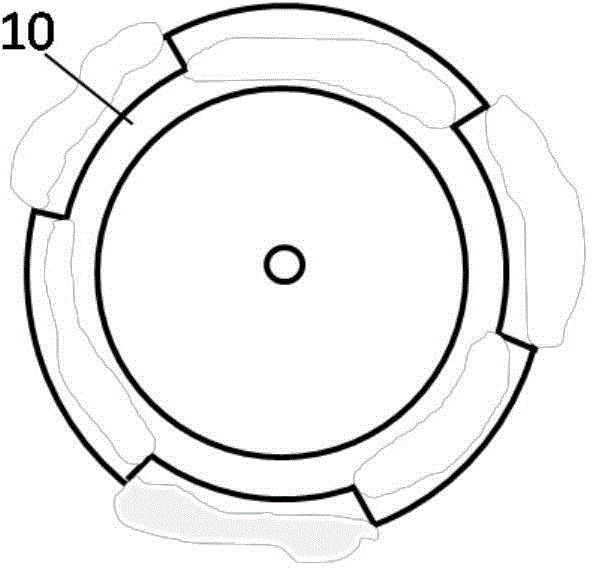

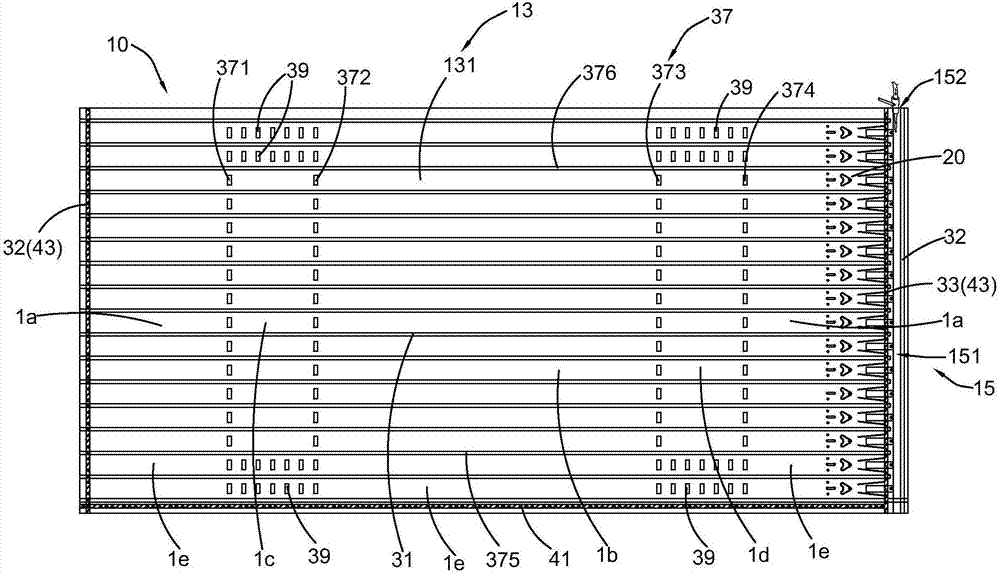

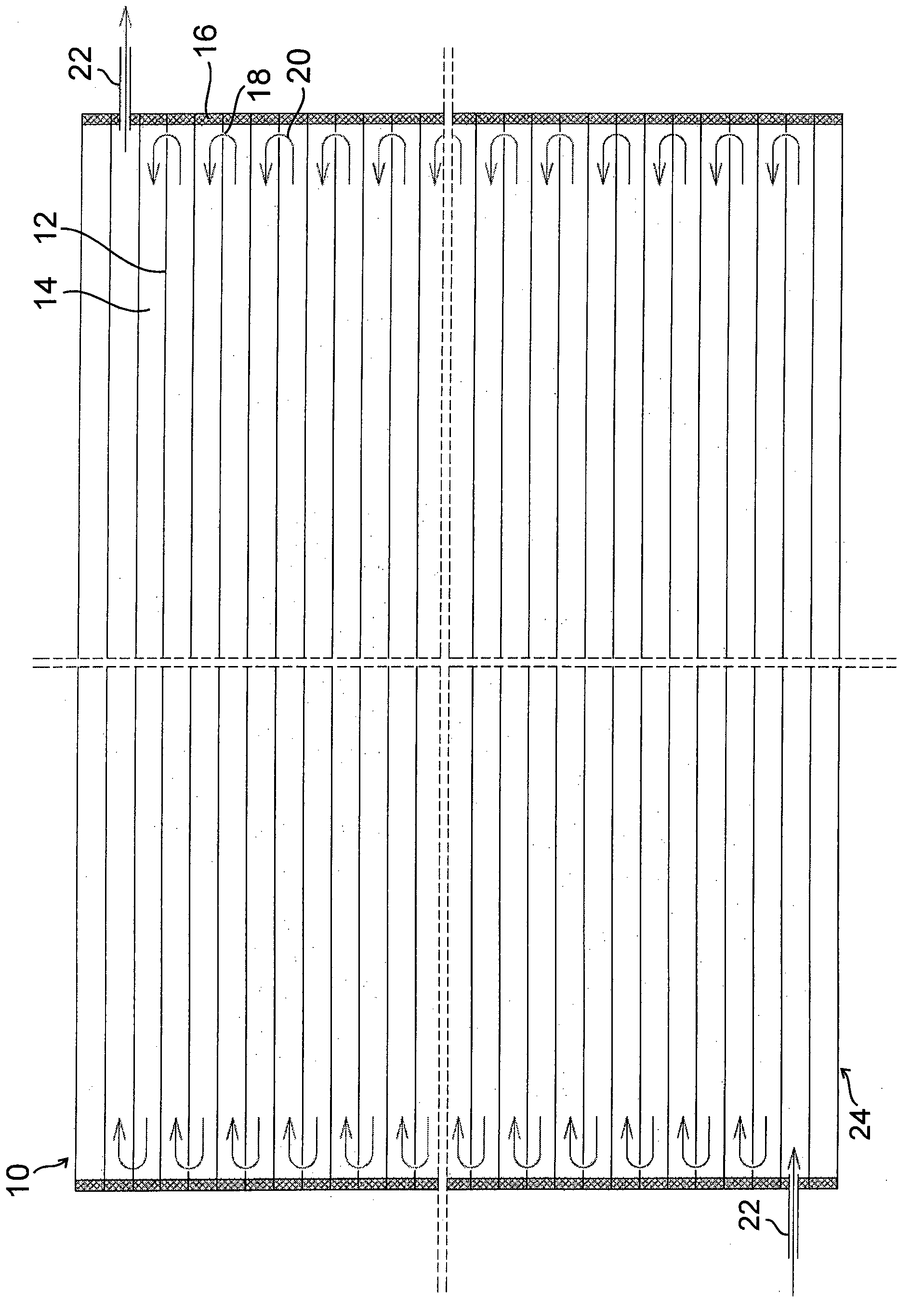

Heat exchanger panel and method for manufacturing thereof

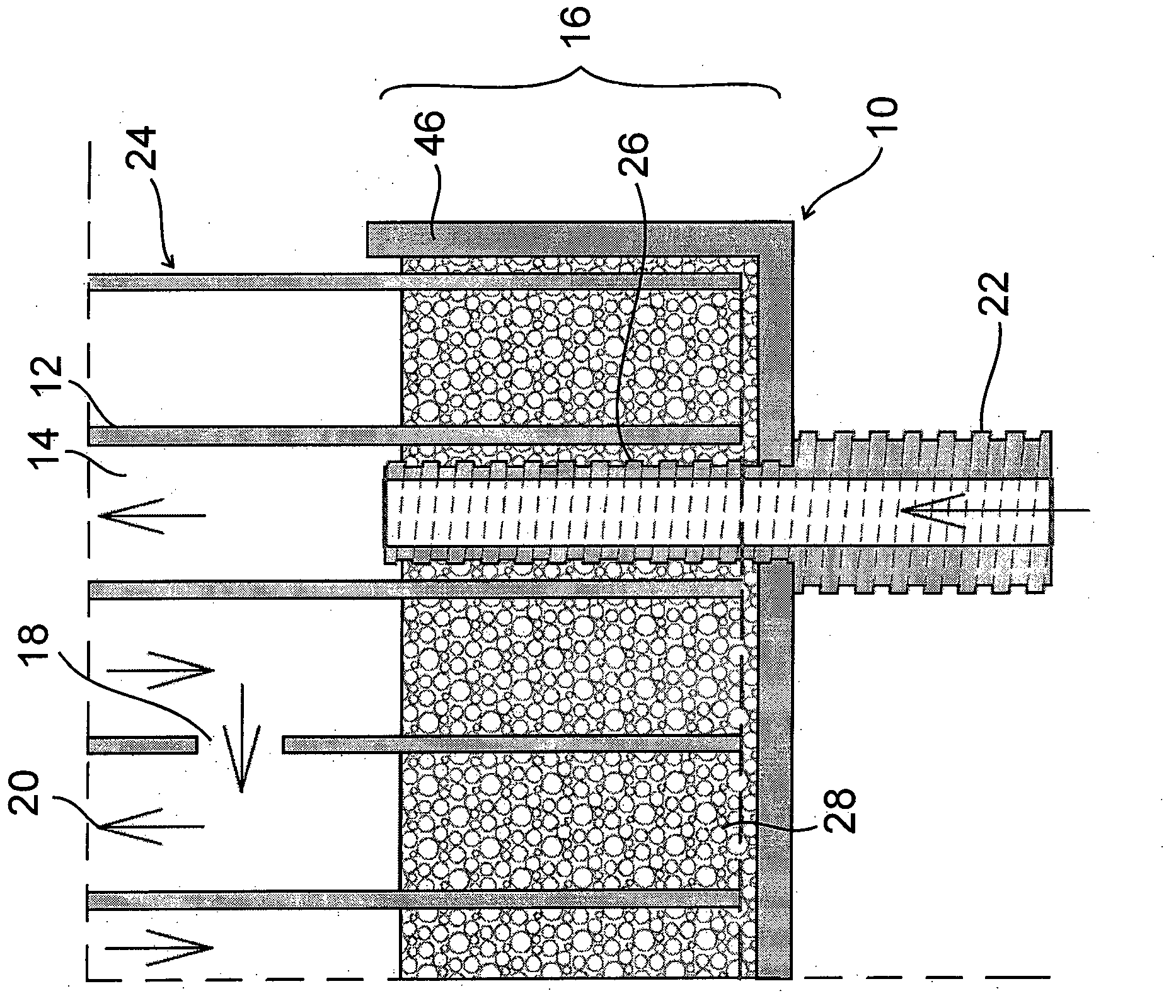

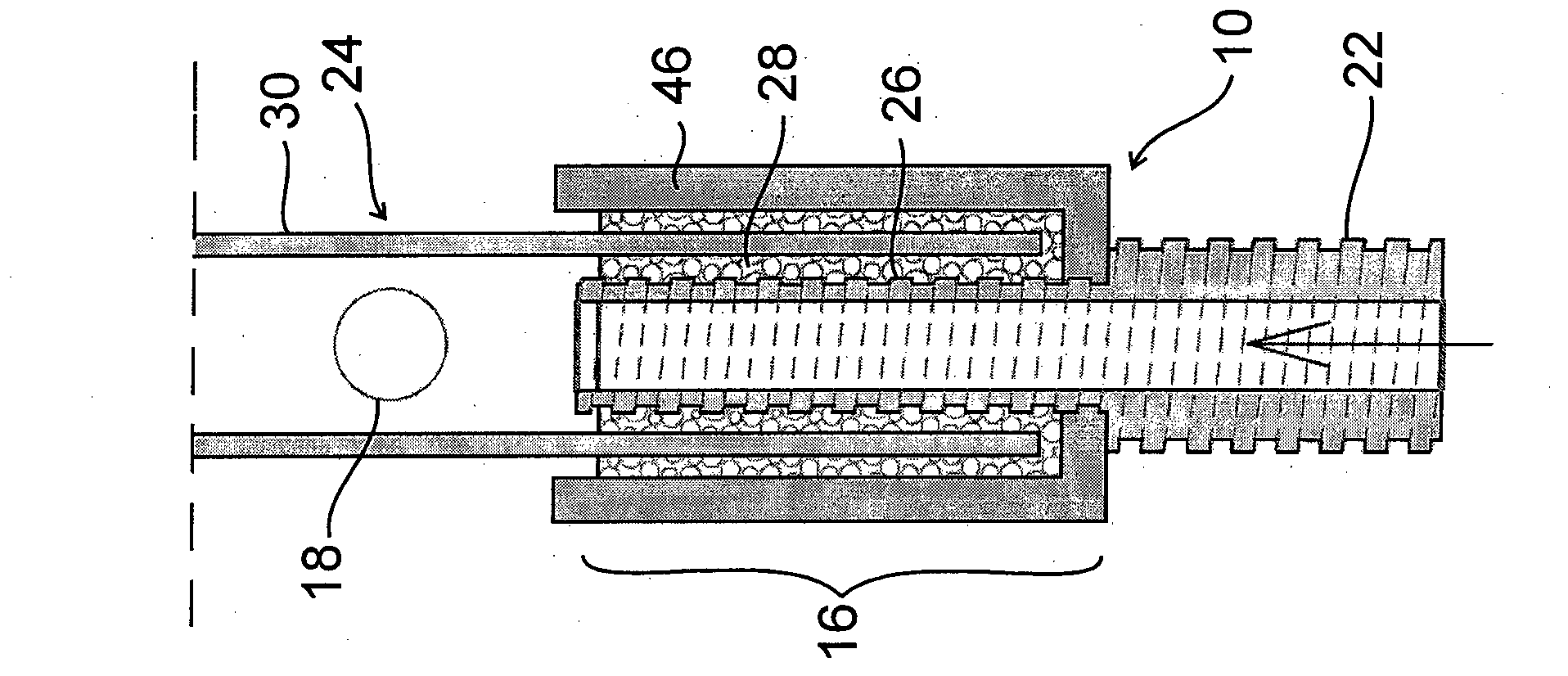

InactiveCN103348193AReduce heat convectionSolar heating energySolar heat devicesLight energyEngineering

The invention relates to a heat exchanger panel (10) preferably for heat exchange utilizing light energy, comprising a board (24) having plates parallel to each other, and partition walls (12) dividing the inner space between the plates into parallel channels (14), said partition walls (12) joining the plates and being of a same material as the plates, passages (18) in the partition walls (12), said passages enabling the flow of a heat exchanger medium between the neighbouring channels (14) and providing a flow path (20) for the medium, sealing units (16) covering openings at the ends of the channels (14) and joints (22) allowing the heat exchanger medium to enter into and exit from the panel (10). According to the invention, the sealing units (16) are made of a sealant which is thermal expansion compatible with the material of the board (24), the sealant being introduced into the ends of the channels (14). The invention also relates to a method for manufacturing the heat exchanger panel (10).

Owner:保罗·莫纳尔

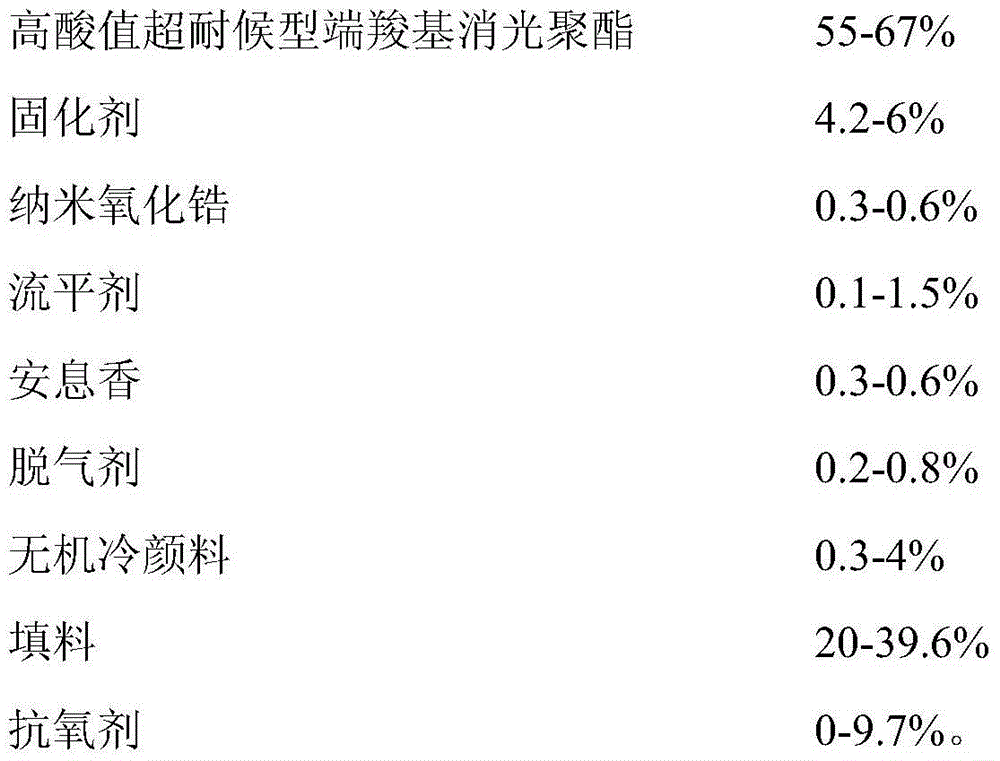

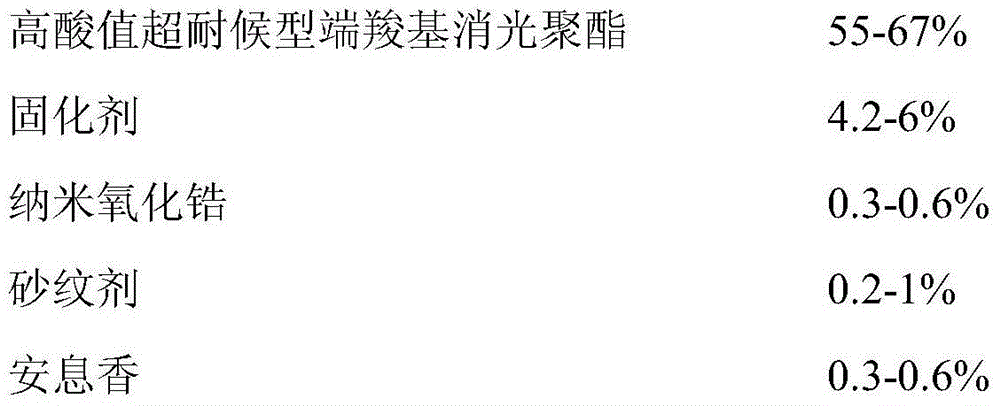

Low-gloss high-reflectivity thermal-insulation powder paint

PendingCN104164170AGreat affinityImprove adhesionPolyester coatingsReflecting/signal paintsPolyesterThermal insulation

The invention relates to a powder paint, particularly a low-gloss high-reflectivity thermal-insulation powder paint. The powder paint is prepared by adding nano zirconium dioxide, a curing accelerator, a cold pigment, a filler and assistants into high-acid-value super-weather-resistance carboxyl-terminated matting polyester used as a base material. The low-gloss high-reflectivity thermal-insulation powder paint only has 3-7 units of gloss, has the ultraviolet long-wave / medium-wave and infrared reflectivity of higher than 85%, can effectively obstruct 85-90% of the sunlight long / short-wave heat source, has greatly lower the short-wave absorptivity and low heat conductivity coefficient (not more than 0.0563 W / m.K), has favorable weather resistance and thermal insulation property, and can low lower the thermal-insulation function due to the pollution on the coated film surface. The low-gloss high-reflectivity thermal-insulation powder paint has light gloss, high reflectivity, low heat conductivity coefficient, low heat storage coefficient and other heat engineering properties, and is an energy-saving environment-friendly paint which has the advantages of zero VOC (volatile organic compound) emission, high adhesiveness, long service life, thermal insulation, moisture resistance, flame retardancy, electric insulation, fire resistance and no peculiar smell.

Owner:山东朗法博粉末涂装科技有限公司

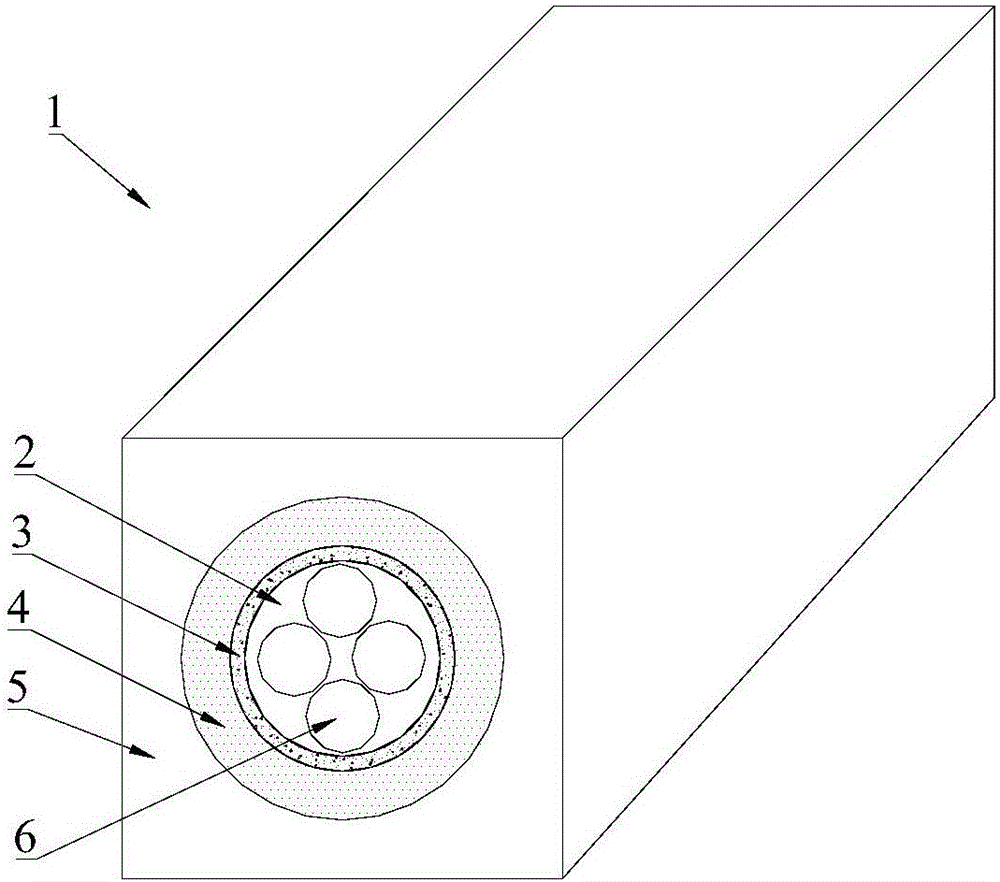

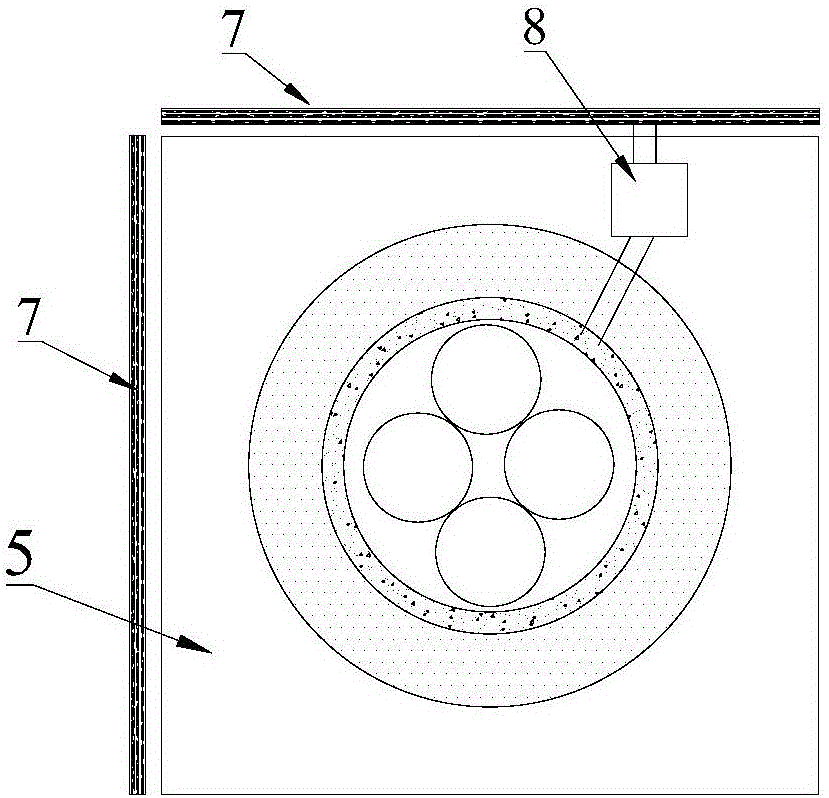

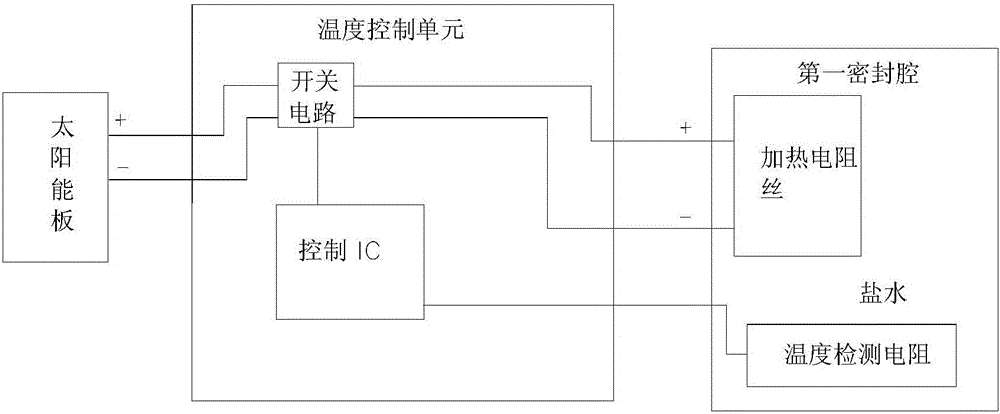

Battery box

InactiveCN106058096AReduce heat convectionPlay a heat insulation effectBattery isolationEngineeringThermal conductivity

The invention discloses a battery box. The battery box comprises a box body. The box body sequentially comprises a battery bin, a first sealing cavity, a second sealing cavity and a third sealing cavity from the center to the exterior. The first sealing cavity is filled with asbestos or saline. The second sealing cavity is filled with water or inert gas. The third sealing cavity is filled with inert gas or vacuumized. Due to multiple sealed spaces, heat convection between the battery bin and air outside the box can be effectively weakened, and the effects of heat insulation and preservation are achieved; by adopting water, saline and asbestos, heat is stored, and the battery bin is further insulated; by means of characteristics of insert gas or vacuum low thermal conductivity, the battery bin is further insulated.

Owner:深圳市优威视讯科技股份有限公司

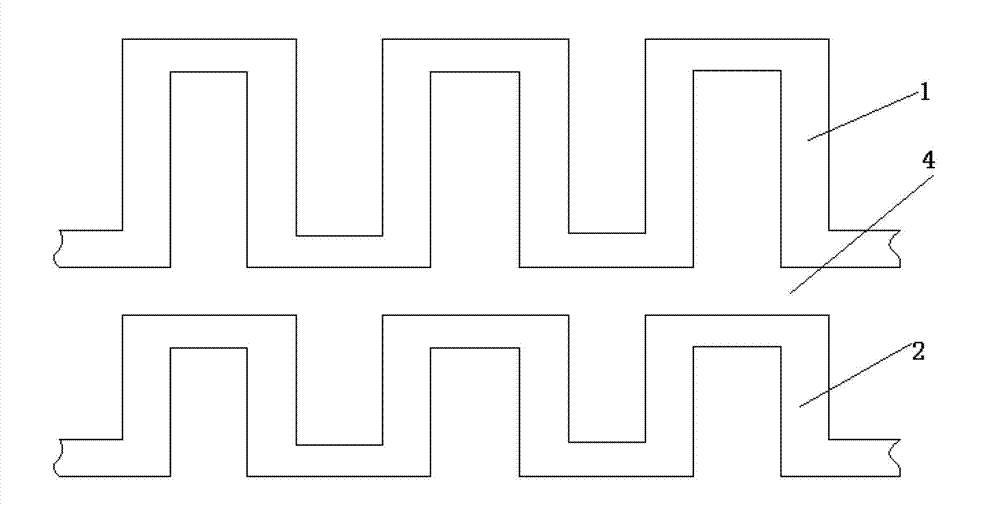

Heating system for single crystal furnace

InactiveCN102758254AInhibited transportReduce heat convectionPolycrystalline material growthBy pulling from meltSquare waveformCrucible

The invention discloses a heating system for a single crystal furnace. The heating system comprises an upper heater and a lower heater, which are arranged in a furnace body, wherein the upper heater and the lower heater are respectively over against the upper part and the lower part of a crucible, are respectively connected with a power supply system, and are respectively shaped like square waves; a gap is available between the lower end of the upper heater and the upper end of the lower heater; the vertical height of the upper heater is larger than that of the lower heater; and a heat insulating plate is arranged in the gap between the lower end of the upper heater and the upper end of the lower heater and extends into the crucible. Through the adoption of a sectional combined heater and a double power supply system, double heaters simultaneously work during fusing, so that silicon fusing time is greatly reduced; after the fusing is finished, the power of the lower heater is reduced; and the upper heater is used as a main heater for the growth of the crystal, so that the bottom temperature of a heat field is reduced without affecting the growth of the crystal and the temperature difference between the top and the bottom of the traditional heat field is reduced.

Owner:HEFEI JINGKUN NEW ENERGY

Liquid slag mechanical centrifugal granulation anti-sticking device and preheating method thereof

InactiveCN109385496AIncrease temperatureReduce temperature differenceRecycling and recovery technologiesLiquid slagDrive shaft

The invention discloses a liquid slag mechanical centrifugal granulation anti-sticking device which comprises a granulation bin, wherein a feeding buffer bag is arranged in the middle at the top of the granulating bin, and a slag outlet is formed in a position, close to one side, at the bottom of the granulation bin; a granulation disk unit is disposed below the feeding buffer bag; the granulationdisk unit comprises a cylindrical support frame and a granulation disk; a transmission shaft is fixed at the bottom of the granulation disk; the cylindrical support frame is provided with an upper partition plate and a lower partition plate; the granulation disk and the upper partition plate define a heating chamber in an encircling manner; the upper partition plate and the lower partition platedefine an insulation chamber in an encircling manner; a cooling chamber is disposed below the lower partition plate; a heating disk is arranged at the bottom of the granulation disk; a coke oven gas nozzle is connected to the bottom of the heating disk by using metal coal gas conveying pipe; a lighting-up tuyere is formed in the cylindrical side wall of the heating chamber; an ignition device is connected to the lighting-up tuyere through a piston rod end of a cylinder. The liquid slag mechanical centrifugal granulation anti-sticking device can effectively prevent formation of a slag shell onthe granulation disk, and provides a powerful guarantee for long-term and stable operation of a high-temperature slag waste heat recovery system.

Owner:QINGDAO UNIV +1

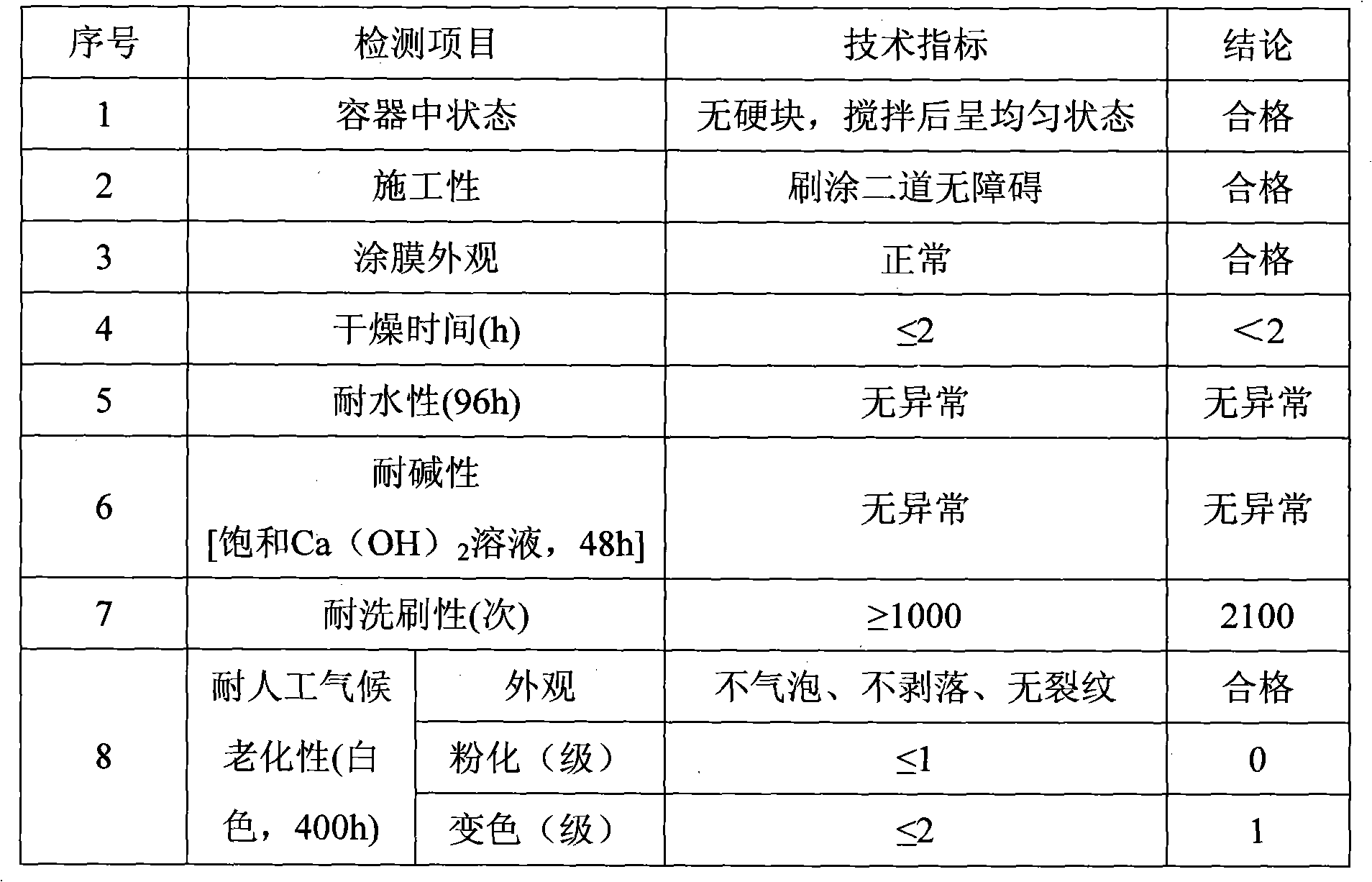

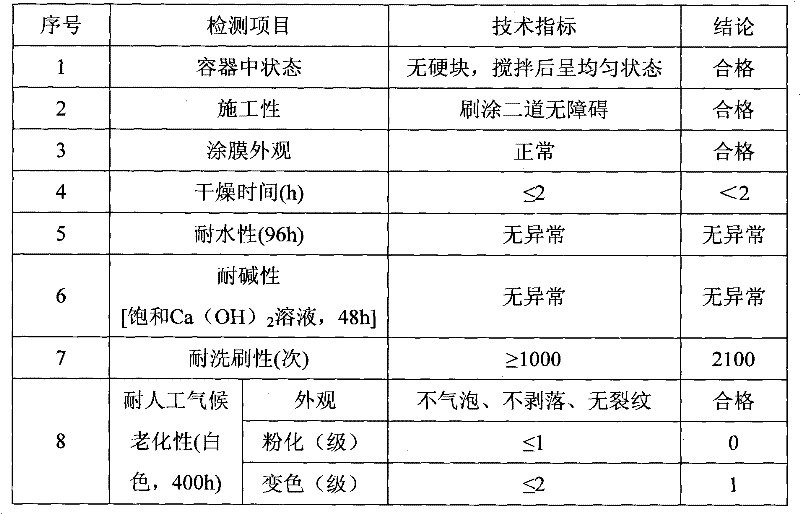

Water-based flame-retardant thermal insulation coating and preparation method thereof

InactiveCN101671523BGood scrub resistanceSimple preparation processCoatingsFire retardantPhysical property

The water-based flame-retardant heat-insulating and heat-insulating paint and a preparation method thereof relate to a building paint and provide a building heat-preserving paint integrating flame-retardant performance, heat-preserving performance and decorative functions. The coating is composed of emulsion, flame retardant, titanium dioxide, hollow glass microspheres, water and additives. The components are emulsion 35-40, flame retardant 20-30, titanium dioxide 15-20, hollow glass Microbeads 5-10, water 19-21, additives 11-15. Using a variety of inorganic, phosphorus, and nitrogen flame retardants, taking advantage of the synergistic effect between different flame retardants, can achieve flame retardant effects with a small amount of use, while not affecting the physical properties of the paint coating; Glass beads are used to reduce thermal conductivity, heat convection and heat radiation to obtain thermal insulation performance. The coating thickness is about 1mm to achieve a good thermal insulation effect. The thermal insulation and flame retardant properties of the coating are reflected in the thermal conductivity ≤ 0.090W / (mk), and the oxygen index ≥ 28.0%.

Owner:XIAMEN UNIV +1

Inner-layer nanometer micropore heat insulation structure for smelting furnace

InactiveCN109405552ASmall heat capacityLow thermal conductivityLining supportsFurnace liningsHeat stabilityEngineering

The invention relates to the technical field of heat insulation, in particular to an inner-layer nanometer micropore heat insulation structure for a smelting furnace. The inner-layer nanometer micropore heat insulation structure for the smelting furnace comprises an installation frame, wherein one side of the installation frame is opened; the installation frame is of a rectangular structure; a nanometer material is fixed to the bottom part of an inner cavity of the installation frame; an infrared radiation reflection material is fixed to the side surface, facing the opening direction of the installation frame, of the nanometer material; a barrier type heat insulation material is fixed to the side surface, far away from the nanometer material, of the infrared radiation reflection material;cylindrical plugs are rotatably arranged on four corners of the side surface, far away from the opening, of the installation frame; and two symmetrical clamping blocks are fixed to one ends, far way from the installation frame, of the cylindrical plugs. According to the inner-layer nanometer micropore heat insulation structure for the smelting furnace provided by the invention, the nanometer material is low in heat capacity, low in heat conductivity, good in elasticity, long in service life, excellent in chemical stability, excellent in heat stability and seismic performance, not easy to pulverize at high temperature, and easy to form and cut; and the device can be beneficial to reducing heat conduction, reducing heat convection and blocking heat radiation.

Owner:浙江智远新材料有限公司

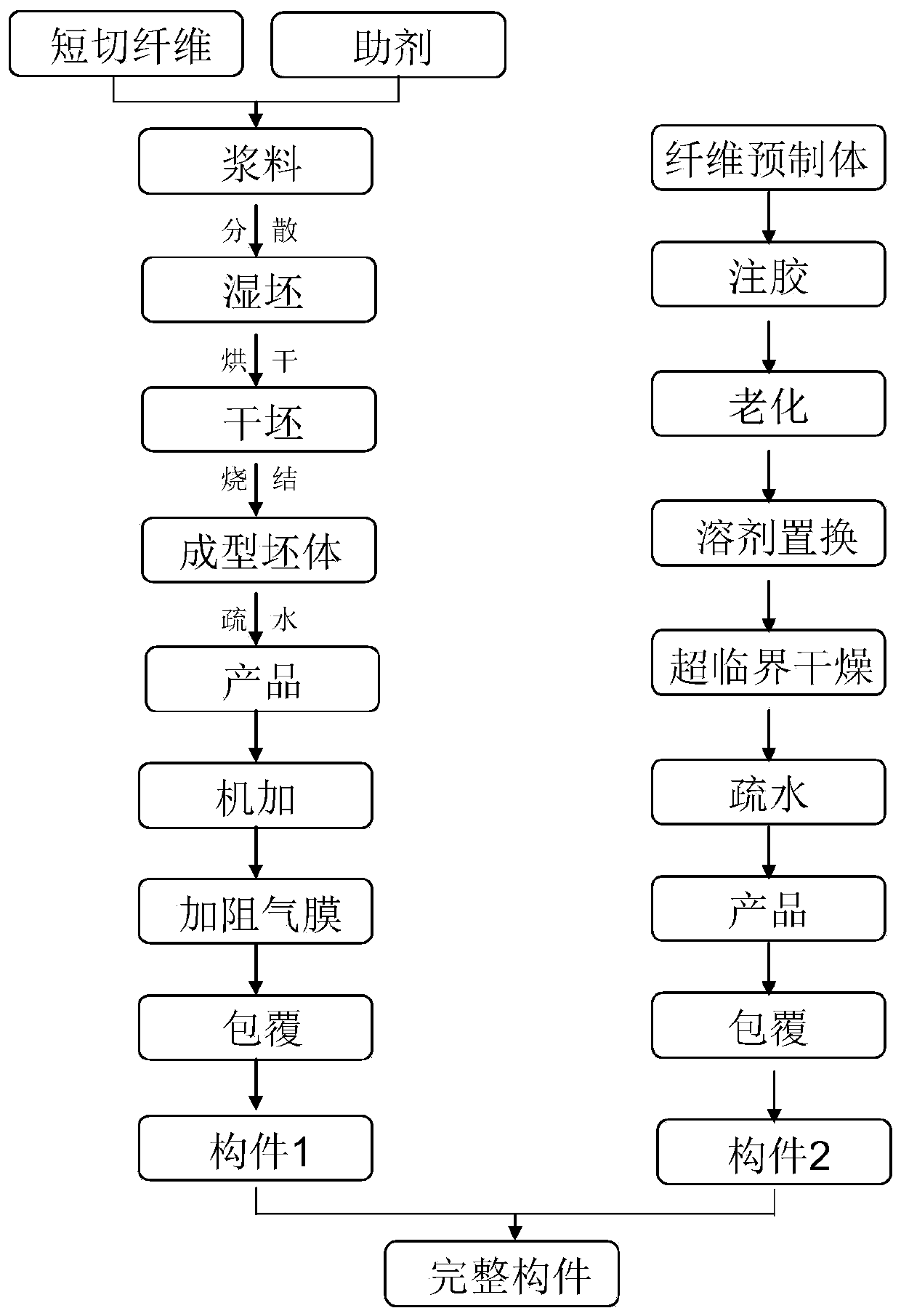

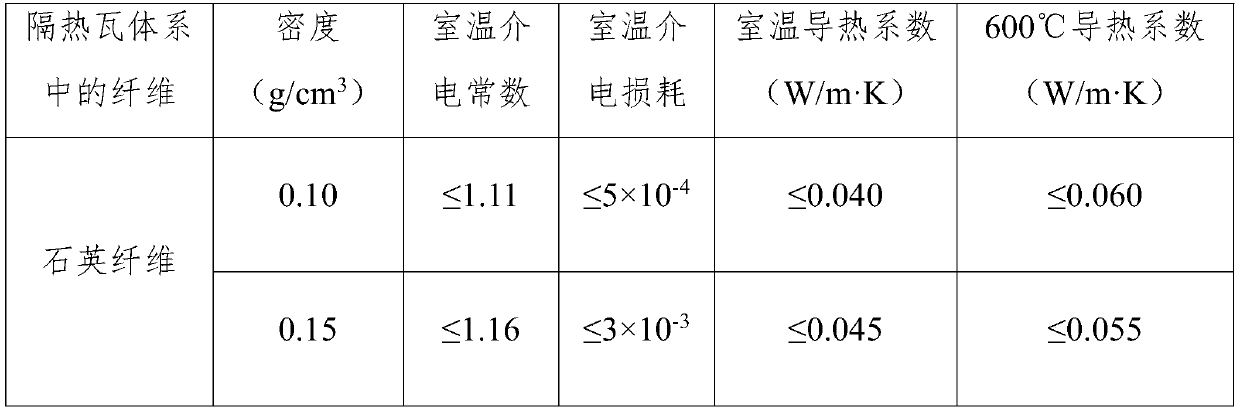

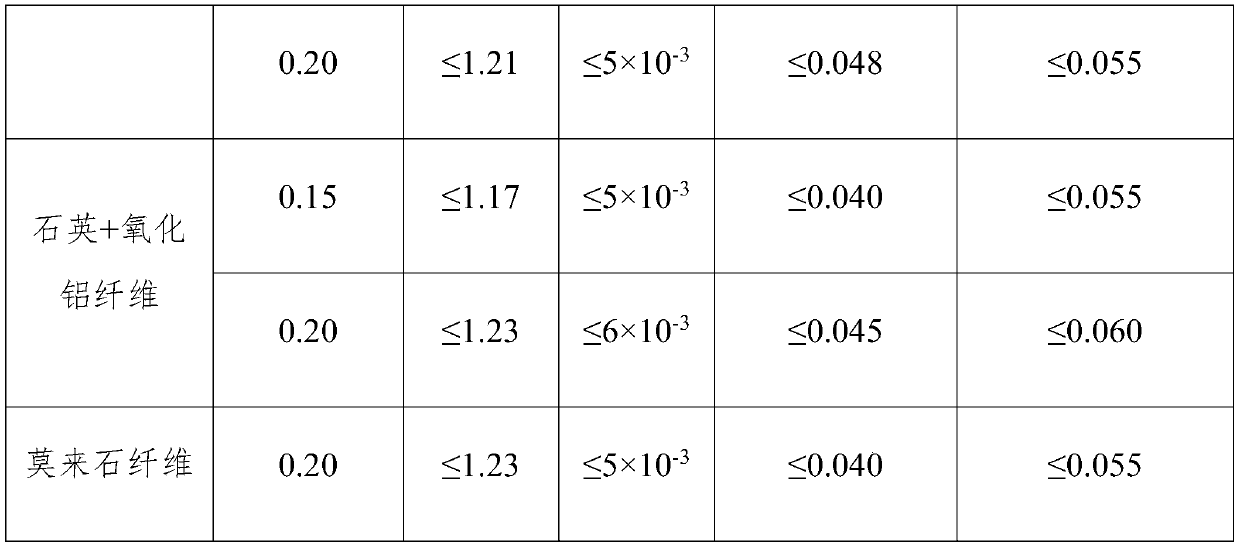

Wave-transparent type heat-insulating and gas-blocking component and manufacturing method thereof

ActiveCN111043450AGuaranteed insulation effectHigh wave transmittanceThermal insulationSynthetic resin layered productsYarnDielectric loss

The invention relates to a wave-transparent type heat-insulating and gas-blocking component and a manufacturing method thereof. The manufacturing method comprises the following steps: manufacturing aplurality of pieces of light wave-transmitting heat-insulating tile materials through wet-process forming; stacking the multiple pieces of the light wave-transmitting heat-insulating tile materials, and arranging a layer of wave-transparent gas-blocking films between every two adjacent two pieces of the light wave-transmitting heat-insulating tile materials, thereby obtaining a wave-transparent gas-blocking component material; soaking fiber reinforcement with silica sol, thereby obtaining a fiber reinforced aerogel heat-insulating material; and utilizing quartz cloth to coat the wave-transparent gas-blocking component and the fiber reinforced aerogel heat-insulating material to obtain a first sub component and a second sub component, and connecting the first sub component and the second sub component to the wave-transparent type heat-insulating and gas-blocking component through quartz fiber yarns. The method can manufacture the wave-transparent type heat-insulating and gas-blocking component which has low dielectric loss, is resistant to a temperature of 1100 DEG C and block thermal convection conduction at a high temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

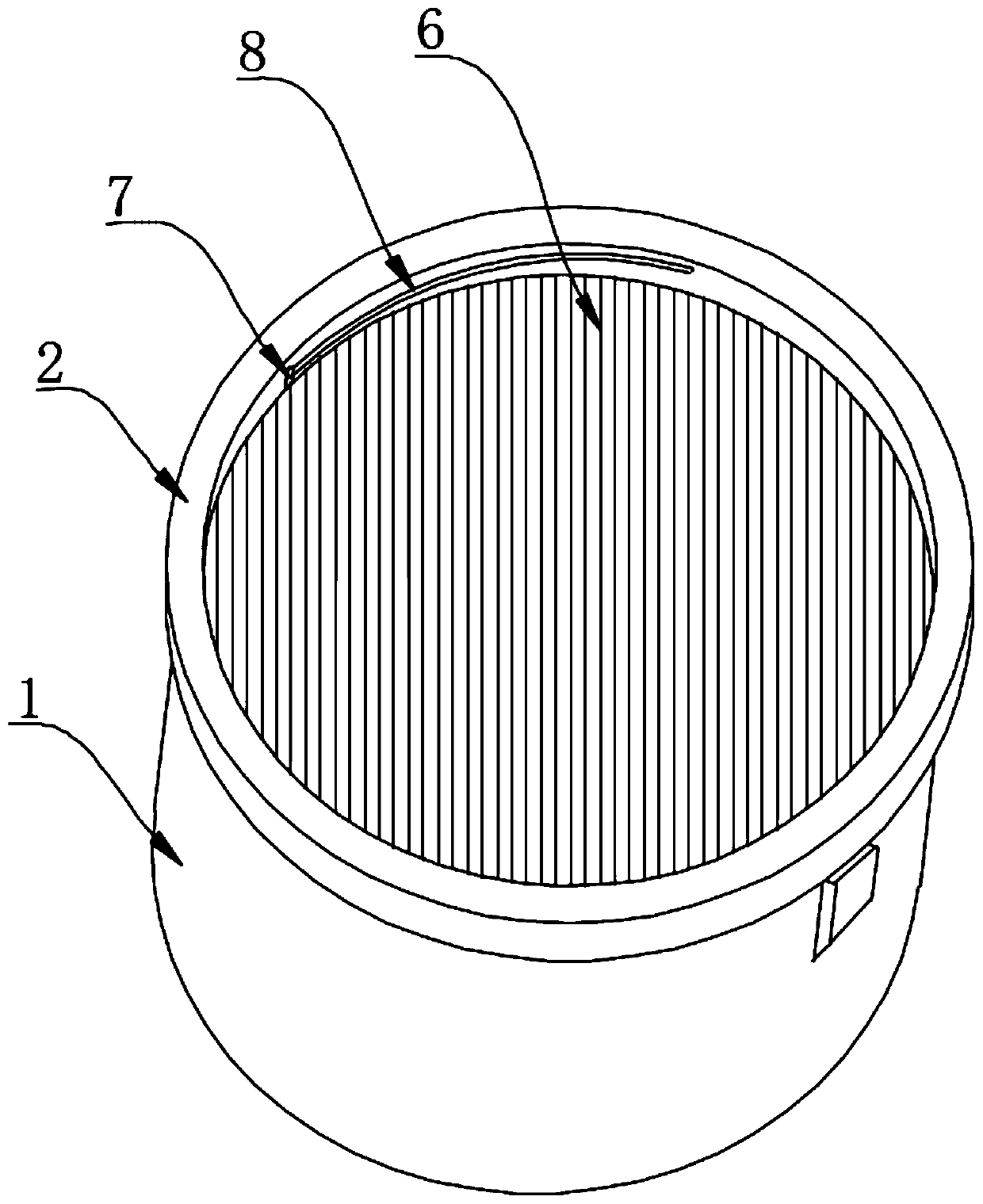

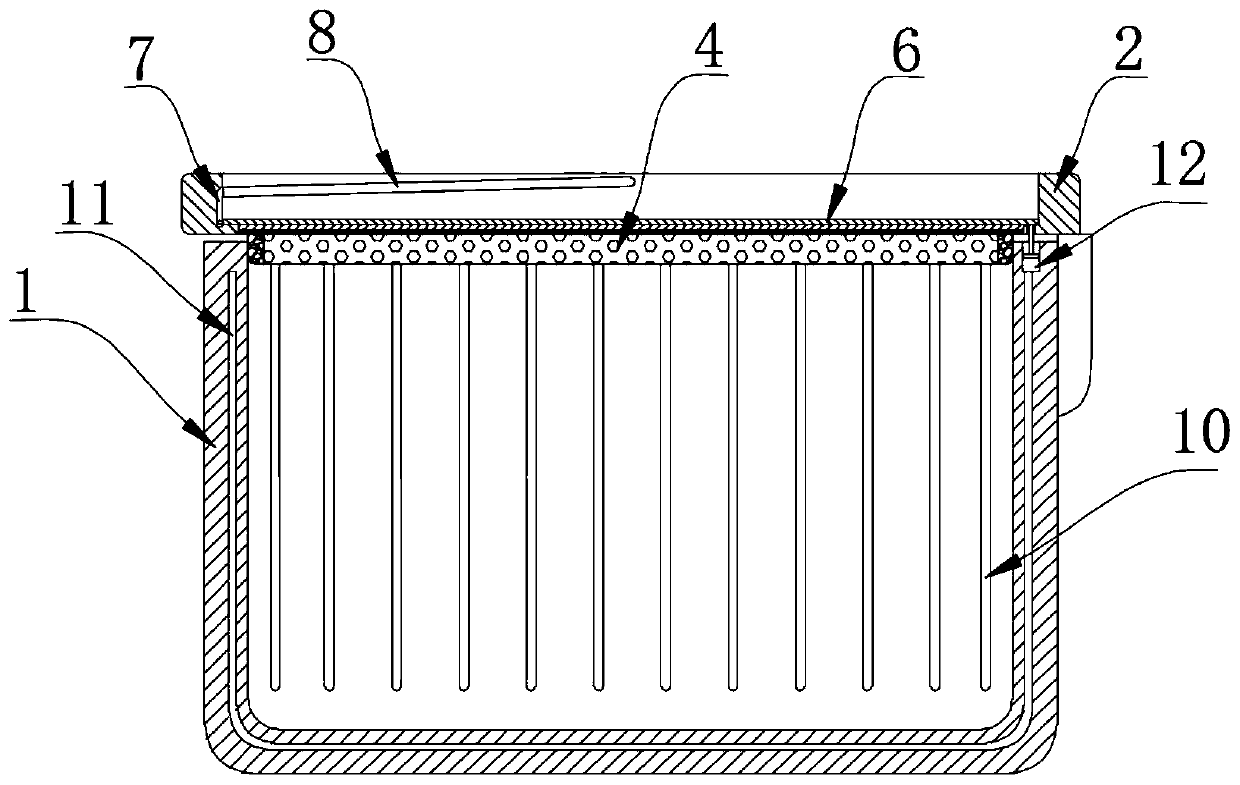

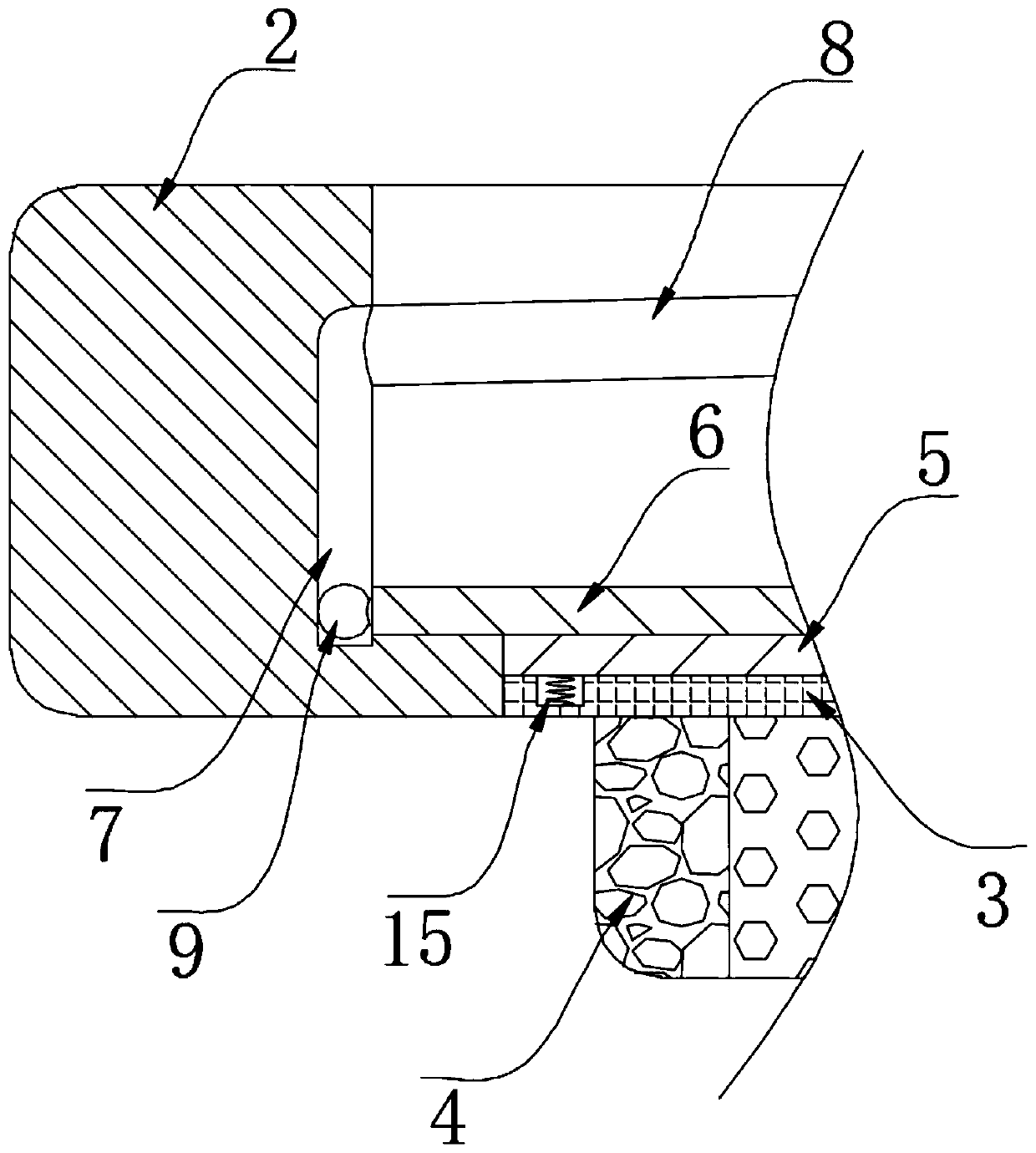

Outdoor constant-temperature biological incubator

InactiveCN111154640AReduce heat convection and heat conductionChange the heating levelBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsEngineering

The invention discloses an outdoor constant-temperature biological incubator. The outdoor constant-temperature biological incubator comprises a cylindrical box body and an upper cover rotationally connected to the upper end of the cylindrical box body, wherein the upper cover is of an annular structure, an annular step is arranged on the inner ring of the upper cover, a heat absorbing plate for sealing the upper cover is fixed on the inner wall of the lower side of the upper cover, a circle of sealing gasket is fixed on the lower wall of the heat absorbing plate, a vertical groove in the vertical direction and an inclined groove which is inclined upwards are formed in the inner ring of the upper cover, the projection of the inclined groove on the vertical surface is a quarter circle, a sliding ball is connected to the inside of the vertical groove in a sliding mode, and the sliding ball is fixedly connected with an upper transparent plate. The outdoor constant-temperature biological incubator has the advantages that the incubator capable of automatically realizing constant temperature under sunlight irradiation is provided, and when the temperature in the box body does not reach apreset temperature, the two layers of transparent plates abut against the heat absorbing plate; and when the temperature is gradually increased to be close to the preset temperature, operations are carried out as shown in the specification until the sunlight cannot irradiate the heat absorbing plate completely.

Owner:范金婷

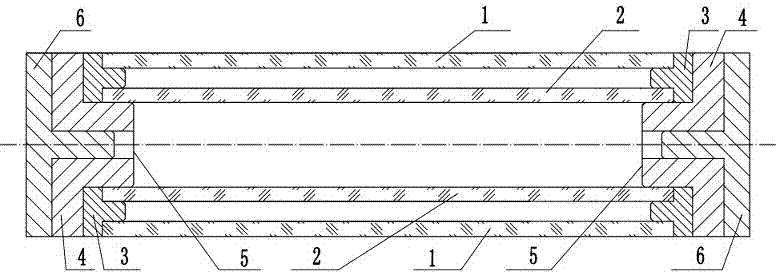

Disposable thermal-stable micro-reactor

InactiveCN107413286AWide variety of sourcesSimple structureChemical/physical/physico-chemical microreactorsSingle useInterference fit

The invention provides a micro-reactor, which can maintain thermal stability, is low in cost and is disposable after use. The micro-reactor includes: a reactor outer tube, a reactor inner tube, two supporting rings, two seal caps, two filter screens and two sealing plugs. The reactor inner tube is sleeved with the reactor outer tube to form an air gap. Bulge rings of the supporting rings are embedded into the air gap at the two ends of the reactor outer tube and the reactor inner tube through interference fit. Holes are formed in the seal caps along axial lines and serve as an inlet and an outlet of the disposable thermal-stable micro-reactor. The filter screens are respectively located at the inner sides of the seal caps. The micro-reactor has good heat insulation property and simple structure, is easy to manufacture, is low in cost, has high adaptability, and can be applied to biochemical analysis, especially calorimetric principle detection of environmental toxins.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com