Dispensing process of white light-emitting diode

A dispensing process, white light technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as high viscosity, inconsistency, and increased factory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] A dispensing process method for white light LEDs, comprising the following steps:

[0036] (1) Phosphor powder and glue are added in proportion to the glue mixing container; the phosphor powder of the present invention is YAG series or silicate series or nitride series phosphor powder; the glue of the present invention is silica gel or silicone resin glue;

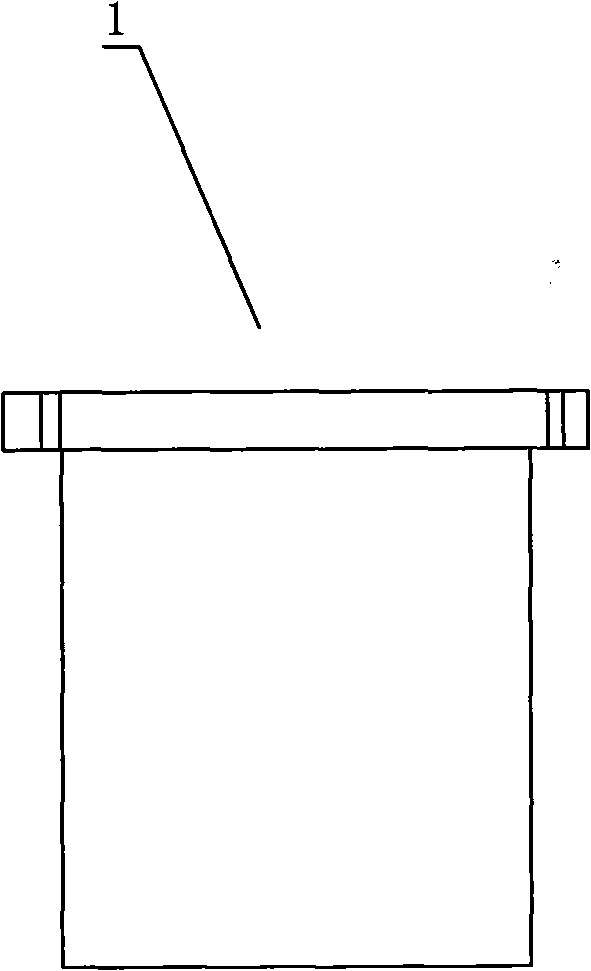

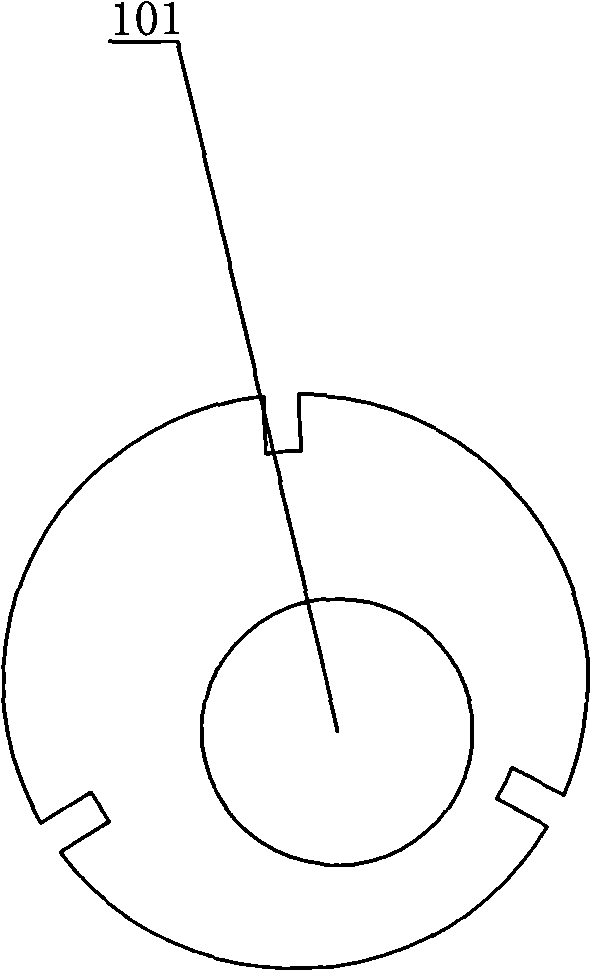

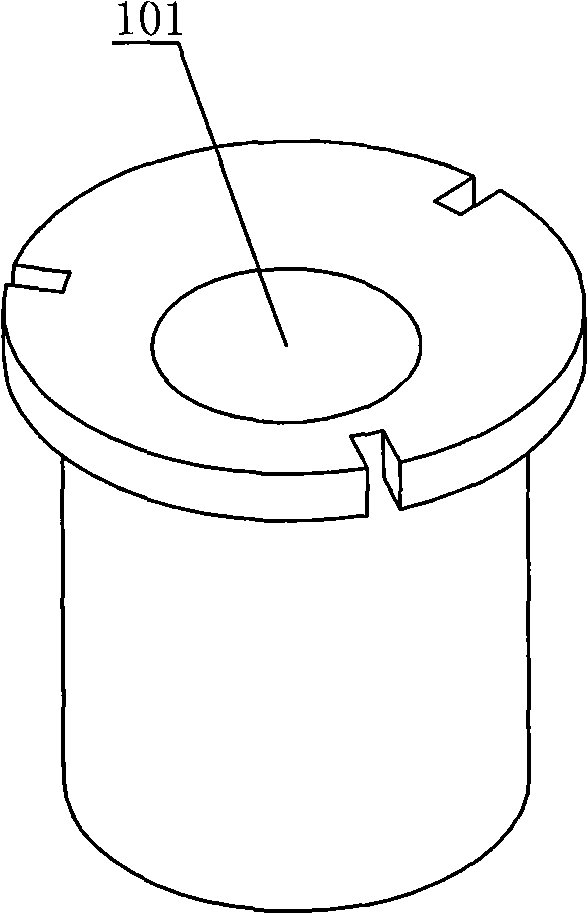

[0037] (2) Fix the glue dispensing container with an eccentric fixture and put it into the airtight cavity of the planetary centrifugal mixer; if Figure 1 to Figure 3 The shown eccentric clamp includes a glue dispensing container placement cavity 101 , and the central axis of the glue dispensing container placement cavity 101 deviates from the rotation center of the eccentric clamp 1 .

[0038](3) Start the planetary centrifugal mixer to make the glue dispensing container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com