Water-based flame-retardant thermal insulation coating and preparation method thereof

A thermal insulation, water-based technology, applied in the direction of coating, can solve the problems of coating can not achieve fire and flame retardant, can not achieve decorative effect, poor fire retardant effect, etc., to achieve good thermal insulation effect, excellent flame retardant effect , the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Weigh 19kg of distilled water, 2kg of propylene glycol, 0.3kg of dispersant (SN-Dispersant-5040), and 0.05kg of defoamer (Foamaster111) into the reaction kettle, stir at a slow speed for about 5min, then add 15kg of rutile titanium dioxide, 15kg of magnesium hydroxide and 8kg of chlorinated paraffin were dispersed at high speed for 1 hour; then 5kg of hollow glass microspheres were added and stirred at a slow speed for 30 minutes to obtain a slurry of flame-retardant and heat-insulating coating. Add 35kg of polymer silicone acrylic emulsion, 0.05kg of defoamer (Foamaster111), 1.7kg of film-forming aid (alcohol ester-12), and 0.2kg of preservative (1,2-benzisothiazol-3-one) to the reaction In the kettle, after stirring for 20 minutes, adjust the pH to 8.5 with ammonia water, and finally use 0.4kg of thickener (HX-5430) to adjust the viscosity of the coating to about 100Ku to obtain a water-based flame-retardant and heat-insulating coating. The thermal conducti...

Embodiment 2

[0027] Example 2: Weigh 20kg of distilled water, 2kg of propylene glycol, 0.4kg of dispersant (Dispex N40), and 0.06kg of defoamer (Foamaster306) into the reaction kettle, stir at a slow speed for 5min, then add 18kg of rutile titanium dioxide, aluminum hydroxide 16kg, chlorinated paraffin 5kg, high-speed dispersion for 1h. Weigh 5 kg of hollow glass microspheres and add them to the reaction kettle and stir slowly for 30 minutes.

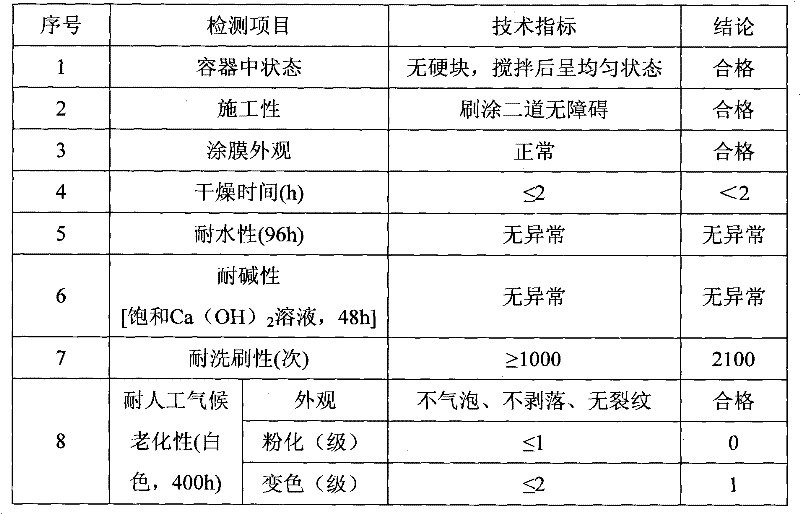

[0028] Weigh 36kg of pure acrylic emulsion, 0.05kg of defoamer (Foamaster 306), 1.8kg of coalescent (alcohol ester-12), preservative (5-chloro-2-methyl-4-isothiazoline-3- Ketone) 0.25kg was added in the reaction kettle, after stirring for 20min, the pH was adjusted to be 8 with ammonia water, and finally the thickener (PUR 2025) 0.45kg was used to adjust the coating viscosity to be about 100Ku. The thermal conductivity of the obtained water-based flame-retardant heat-insulating coating is 0.090W / (m·k), the oxygen index is 29.0%, and other propertie...

Embodiment 3

[0029] Example 3: Weigh 21 kg of distilled water, 2 kg of propylene glycol, 0.5 kg of a dispersant (SN-Dispersant-5040), and 0.07 kg of a defoamer (Foamaster111) and add them to the reactor, stir at a slow speed for 6 minutes, and then add 20 kg of rutile titanium dioxide, poly Ammonium phosphate 10kg, melamine 5kg, high-speed dispersion for 1h. Weigh 5 kg of hollow glass microspheres and add them to the reaction kettle and stir slowly for 30 minutes.

[0030] Weigh 37kg of styrene-acrylic emulsion, 0.08kg of defoamer (Foamaster111), 1.9kg of film-forming aid (alcohol ester-12), and 0.3kg of preservative (tetrachlorom-toluene dicyanonitrile) into the reaction kettle, and stir for 20min Finally, adjust the pH with ammonia water to be 9, and finally use 0.5kg of thickener (HX-5430) to adjust the viscosity of the paint to about 100Ku. The thermal conductivity of the obtained water-based flame-retardant heat-insulating coating is 0.090W / (m·k), the oxygen index is 29.0%, and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com