Environment-friendly multifunctional diatom ooze and preparation method thereof

A diatom mud, environment-friendly technology, applied in the field of architectural coatings, can solve the problems of low solid content of water-based coatings, inconvenient transportation and storage, unfavorable product application, etc., and achieves excellent scrub resistance, practicability and decorative comprehensive performance. Excellent, anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

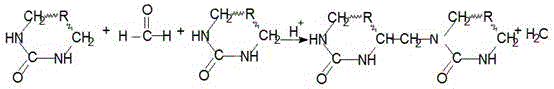

Method used

Image

Examples

Embodiment 1

[0028] Raw material consumption (wt)

[0029] Diatomaceous earth 28%;

[0030] Kaolin 5%;

[0031] Bentonite 1%;

[0032] Attapulgite 3%;

[0033] Sepiolite powder 5%;

[0034] White carbon black 5%;

[0035] Negative ion powder 4.7%;

[0036] Titanium dioxide 15%;

[0037] Amidadone 5%;

[0038] Calcite powder 5%;

[0039] Ash calcium 15%;

[0040] Redispersible latex powder 7%;

[0042] Powder wetting agent 0.2%;

[0043] Powder antifungal agent 0.2%;

[0044] Hydroxypropyl methylcellulose 0.2%;

[0045] Wood fiber powder 0.5%.

[0046] The raw materials in the above formula of Example 1 were mixed for 1 hour by a double-screw mixer, then sieved and packaged to obtain an environment-friendly multifunctional diatom mud.

[0047] The construction process is as follows: add the prepared environmentally friendly multifunctional diatom mud into clean water according to the proportion, stir well, let it stand for half an hour, then mak...

Embodiment 2

[0049] Raw material consumption (wt)

[0050] Diatomaceous earth 35%;

[0051] Kaolin 8%;

[0052] Bentonite 1%;

[0053] Attapulgite 4%;

[0054] Sepiolite powder 5%;

[0055] White carbon black 2%;

[0056] Negative ion powder 5%;

[0057] Titanium dioxide 5%;

[0058] Amidadone 4%;

[0059] Calcite powder 5%;

[0060] Ash calcium 18%;

[0061] Redispersible latex powder 6%;

[0062] Powder defoamer 0.2%;

[0063] Powder wetting agent 0.2%;

[0064] Powder antifungal agent 0.2%;

[0065] Hydroxypropyl methylcellulose 0.4%;

[0066] Wood fiber powder 1%.

[0067] With the raw materials in the formula of the above-mentioned examples, the production method of Example 1 is used to obtain an environment-friendly multifunctional diatom ooze.

[0068] The construction process is as follows: add the prepared environmentally friendly multifunctional diatom mud into clean water according to the proportion, stir well, let it stand for half an hour, then make up water, ad...

Embodiment 3

[0070] Raw material consumption (wt)

[0071] Diatomaceous earth 20%;

[0072] Kaolin 6%;

[0073]Bentonite 3%;

[0074] Attapulgite 6%;

[0075] Sepiolite powder 7%;

[0076] White carbon black 8%;

[0077] Negative ion powder 6%;

[0078] Titanium dioxide 7%;

[0079] Amidadone 5%;

[0080] Calcite powder 8%;

[0081] Ash calcium 12%;

[0082] Redispersible latex powder 10%;

[0083] Powder defoamer 0.2%;

[0084] Powder wetting agent 0.2%;

[0085] Powder antifungal agent 0.2%;

[0086] Hydroxypropyl methylcellulose 0.5%;

[0087] Wood fiber powder 0.9%.

[0088] With the raw materials in the formula of the above-mentioned examples, the production method of Example 1 is used to obtain an environment-friendly multifunctional diatom ooze.

[0089] The construction process is as follows: add the prepared environmentally friendly multi-functional diatom mud into clean water in proportion and stir well, let it stand for half an hour, then make up water, adjust to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com