Styrene acrylic emulsion for interior wall coating material, and preparation method thereof

A technology of interior wall coating and styrene-acrylic emulsion, applied in coating and other directions, can solve problems such as low cost performance, achieve the effects of excellent performance, enhanced scrub resistance, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

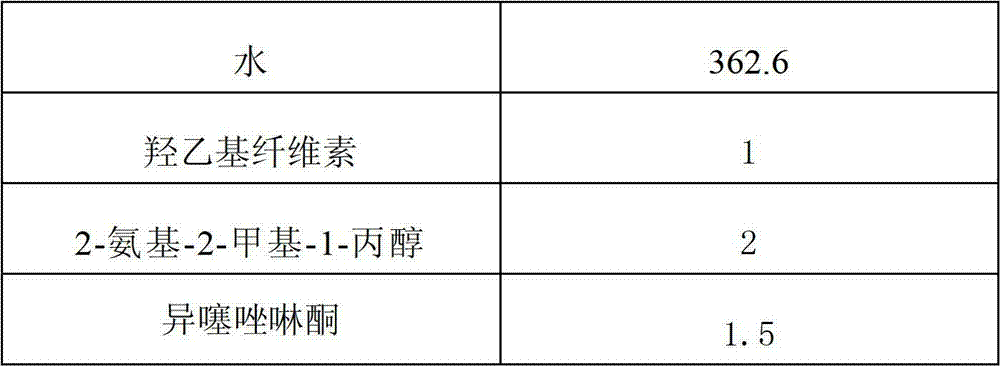

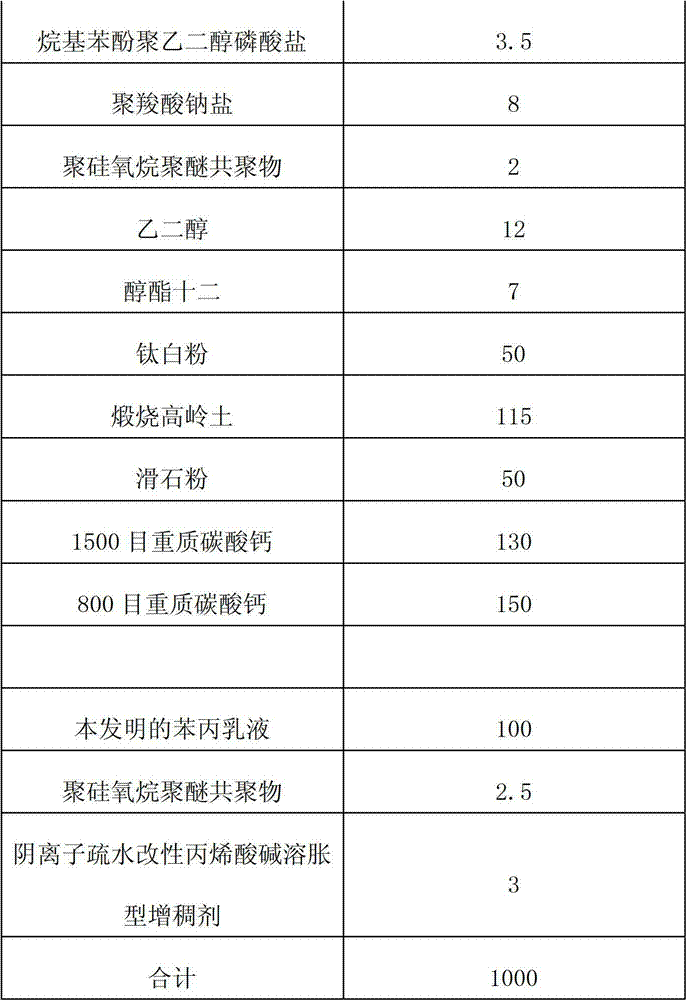

Method used

Image

Examples

Embodiment 1

[0044] (1) In parts by weight, mix 16 parts of deionized water, 0.3 parts of alkylphenol ether ammonium sulfate, 0.3 parts of nonylphenol polyoxyethylene ether, and add 27 parts of styrene and 21 parts of butyl acrylate. A mixture consisting of 1 part of acrylic acid and 2.4 parts of acrylamide aqueous solution with a weight concentration of 50% was emulsified for 30 minutes to prepare pre-emulsion A.

[0045] (2) Add the reactive silicone to the above-mentioned pre-emulsion A, emulsify for 15 minutes to prepare pre-emulsion B;

[0046] 0.7 parts of reactive organosilicon and 63.46 parts of pre-emulsion A.

[0047] The reactive organosilicon monomer is γ-methacryloxypropyltrimethoxysilane;

[0048] (3) Mix 25 parts of water, 0.3 parts of alkylphenol ether ammonium sulfate, 0.2 parts of nonylphenol polyoxyethylene ether, 1 part of methanol, and 0.08 parts of sodium bicarbonate, stir at 170r / min, blow nitrogen, and turn on the condensed water , Warm up to 77°C, add 3.34 parts of pre-em...

Embodiment 2

[0059] (1) In parts by weight, mix 16 parts of water, 0.3 parts of alkylphenol ether ammonium sulfate, and 0.3 parts of alkylphenol polyoxyethylene ether, and add 25 parts of styrene and 24 parts of butyl acrylate that have been evenly stirred. A mixture of 1 part of methacrylic acid and 2.4 parts of 50% acrylamide aqueous solution was emulsified for 30 minutes to obtain pre-emulsion A.

[0060] (2) Add the reactive silicone to the above-mentioned pre-emulsion A, emulsify for 15 minutes to prepare pre-emulsion B;

[0061] 0.7 parts of reactive silicone, 67.8 parts of pre-emulsion;

[0062] The reactive organosilicon monomer is vinyl triethoxy silane;

[0063] (3) Mix 25 parts of water, 0.3 parts of alkylphenol ether ammonium sulfate, 0.2 parts of alkylphenol polyoxyethylene ether, 1 part of methanol, and 0.08 parts of sodium bicarbonate, stir at 170r / min, blow nitrogen, and turn on the condensed water , Warm up to 77°C, add 3.39 parts of 5% pre-emulsified emulsion A, keep the tempera...

Embodiment 3

[0074] (1) In parts by weight, mix 16 parts of deionized water, 0.4 parts of sodium alkylphenol polyether sulfosuccinate monoester, 0.35 parts of nonylphenol polyoxyethylene ether, and add 20 parts of styrene, A mixture composed of 7 parts of methyl methacrylate, 21 parts of butyl acrylate, 1 part of methacrylic acid and 2.0 parts of 50% acrylamide aqueous solution by weight concentration was emulsified for 30 minutes to prepare pre-emulsion A.

[0075] (2) Add the reactive silicone to the above-mentioned pre-emulsion A, emulsify for 15 minutes to prepare pre-emulsion B;

[0076] 0.7 parts of reactive silicone, 66.75 parts of pre-emulsion A;

[0077] The reactive organosilicon monomer is vinyl triethoxy silane;

[0078] (3) Mix 25 parts of water, 0.25 parts of sodium alkylphenol polyether sulfosuccinate monoester, 0.15 parts of nonylphenol polyoxyethylene ether, 1 part of methanol and 0.08 part of sodium bicarbonate, and stir at 170r / min , Blow nitrogen, turn on the condensed water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com