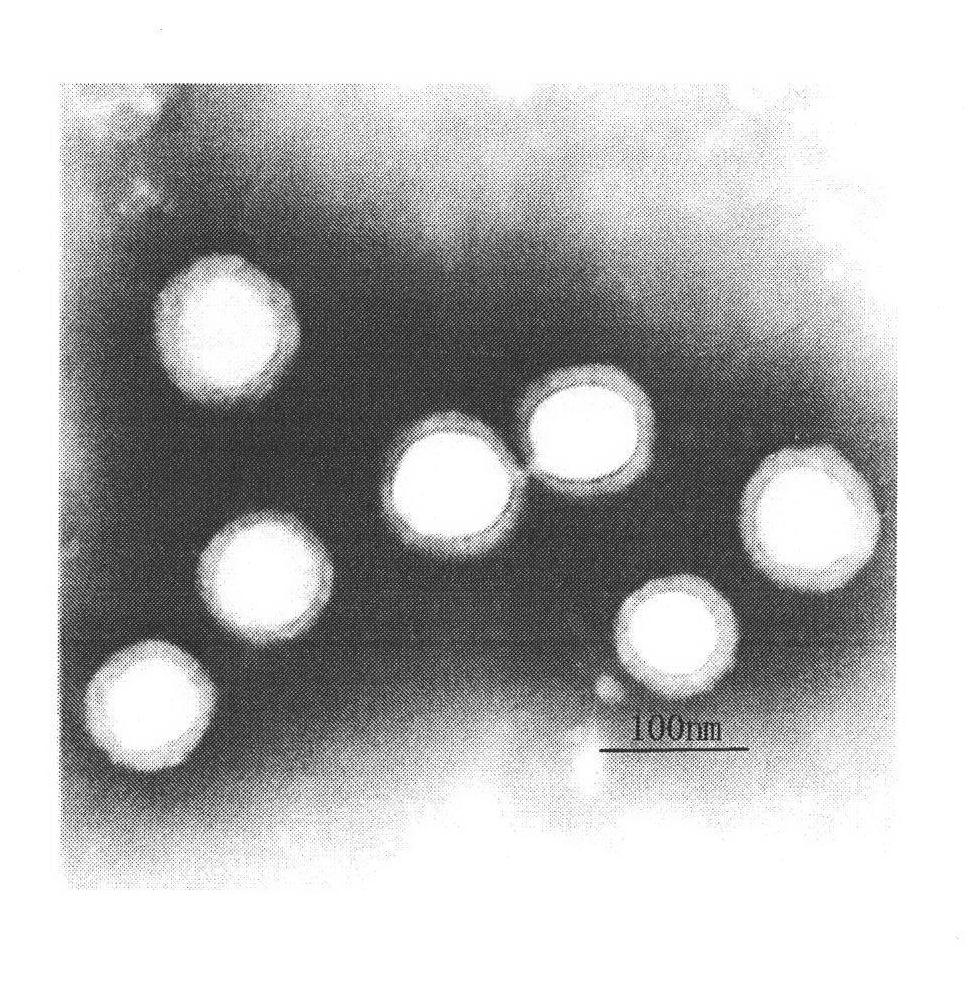

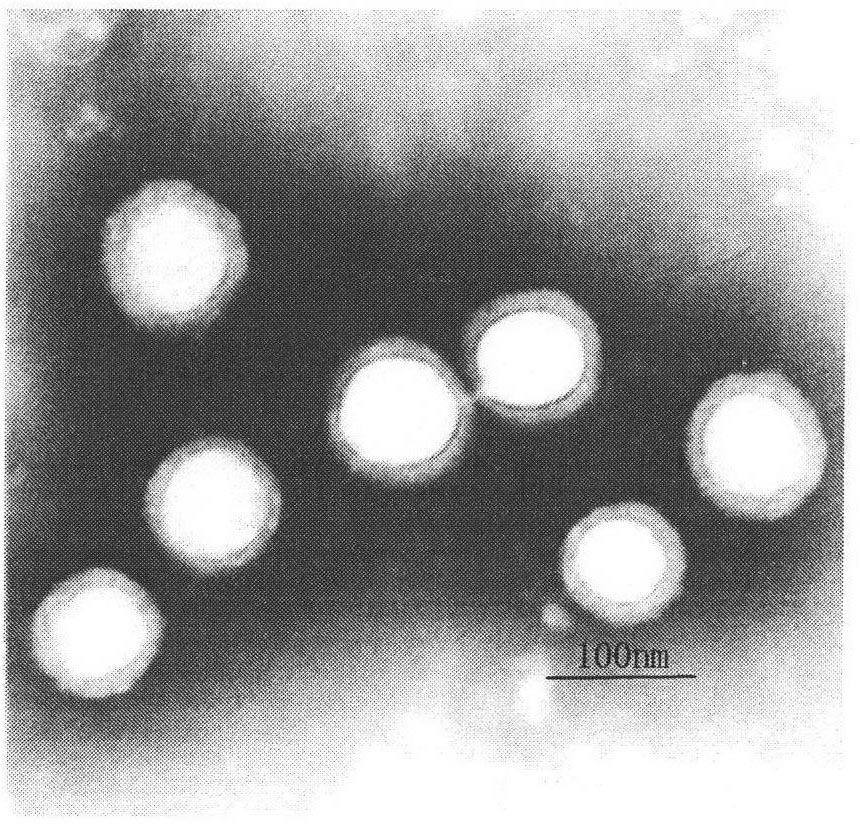

Preparation of nano silicone-acrylate core shell type composite latex for latex paints

A technology for latex coatings and composite emulsions, applied in coatings and other directions, can solve the problems of difficult cost and performance unification, poor emulsion stability, complex preparation process, etc., to ensure yield, stable polymerization process, and ensure compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] I. Monomer pre-emulsification

[0040]The three-necked flask is heated to 40°C in a water bath, and the emulsifier and the core monomer of the core layer monomer (accounting for 40wt% of the total monomer) or shell layer monomer consumption (accounting for 60wt% of the total monomer) of 0.6wt% are added or Deionized water with an amount of 35wt% shell monomer, after emulsification and dissolving uniformly, add the active monomer dropwise at a speed of 1.5g / min, after the dropwise addition, stir at a high speed of 400rpm for 30min, then stir at a low speed for 5min. Stop, the operation is completed, and the stable pre-emulsion of the core layer or the shell layer is obtained.

[0041] II. Seed emulsion polymerization

[0042] Heat the three-necked flask in a water bath to 50°C, add all the remaining amount of emulsifier and deionized water, after the emulsification and dissolution are uniform, add 30wt% of the core layer pre-emulsion, stir for 20min, add 30wt% of the to...

Embodiment 2

[0048] I. Monomer pre-emulsification

[0049] The three-necked flask water bath is heated to 42 ℃, adds the emulsifying agent of 0.7wt% emulsifier and core layer monomer or the shell layer monomer consumption (accounting for 57wt% of total monomer) of core layer monomer (accounting for total monomer 43wt%) or Deionized water with an amount of 38wt% shell monomer, after emulsification and dissolving uniformly, add the active monomer dropwise at a constant speed of 1.5g / min. Stop, the operation is completed, and the stable pre-emulsion of the core layer or the shell layer is obtained.

[0050] II. Seed emulsion polymerization

[0051] Heat the three-necked flask in a water bath to 52°C, add all the remaining amount of emulsifier and deionized water, after the emulsification and dissolution are uniform, add 33wt% of the core layer pre-emulsion, stir for 20min, add 30wt% of the total amount of the initiator to initiate After stirring for 20 minutes, adjust the temperature to 77°...

Embodiment 3

[0057] I. Monomer pre-emulsification

[0058] The three-necked flask water bath is heated to 44 ℃, adds the emulsifying agent of 0.8wt% emulsifier and core layer monomer (accounting for 46wt% of total monomer) or shell layer monomer consumption (accounting for total monomer 54wt%) or Shell monomer dosage 41wt% deionized water, after emulsification and dissolving evenly, add active monomer dropwise at a constant speed of 1.5g / min, after dropwise addition, stir at high speed of 460rpm for 30min, then stir at low speed for 5min. Stop, the operation is completed, and the stable pre-emulsion of the core layer or the shell layer is obtained.

[0059] II. Seed emulsion polymerization

[0060] Heat the three-necked flask in a water bath to 54°C, add all the remaining emulsifier and deionized water, after the emulsification and dissolution are uniform, add 36wt% of the core layer pre-emulsion, stir for 20min, then add 30wt% of the initiator aqueous solution After stirring for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com