Wave-transparent type heat-insulating and gas-blocking component and manufacturing method thereof

A wave-transmitting and component-based technology, applied in heat exchange equipment, chemical instruments and methods, and pipeline protection through heat insulation, to achieve the effects of low dielectric loss, reduced heat transfer, and stable electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

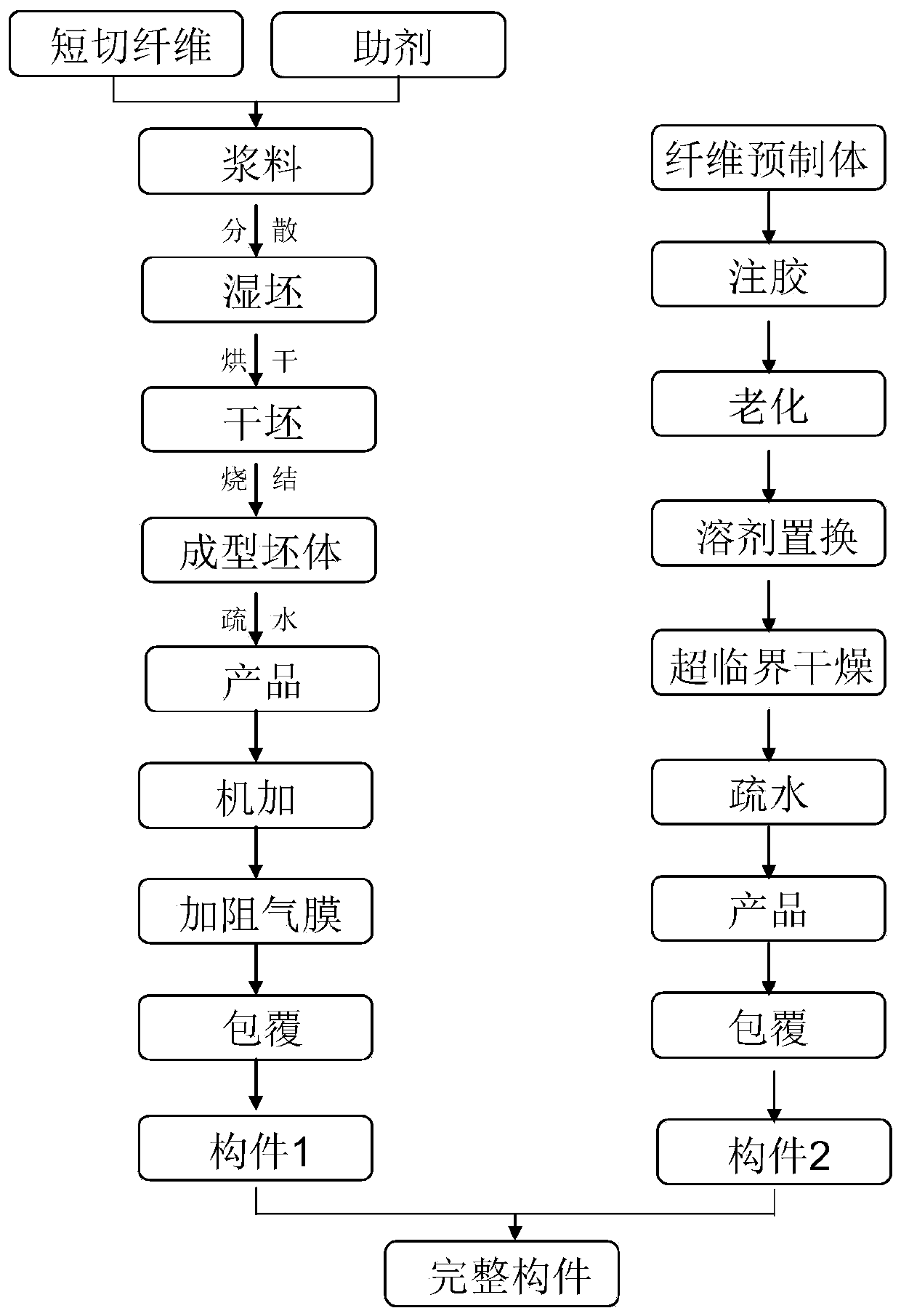

[0028] In the first aspect, the present invention provides a method for preparing a wave-transparent heat-insulating and gas-blocking component, the method comprising the following steps:

[0029] (1) A plurality of lightweight wave-transmitting heat-insulating tile materials are prepared by wet forming; in the present invention, the light-weight wave-transmitting heat-insulating tile materials are also recorded as low-density heat-insulating tiles or low-density heat-insulating tile materials; In the present invention, specifically, the preparation of the low-density heat-insulating tiles is, for example, dispersing fibers and additives in proportion, and then forming, drying, sintering, and hydrophobic treatment to prepare low-density heat-insulating tiles of different densities and thicknesses. Density heat insulation tile material, and machine-cut low-density heat insulation tile material products of different densities and thicknesses into multiple low-density heat insulat...

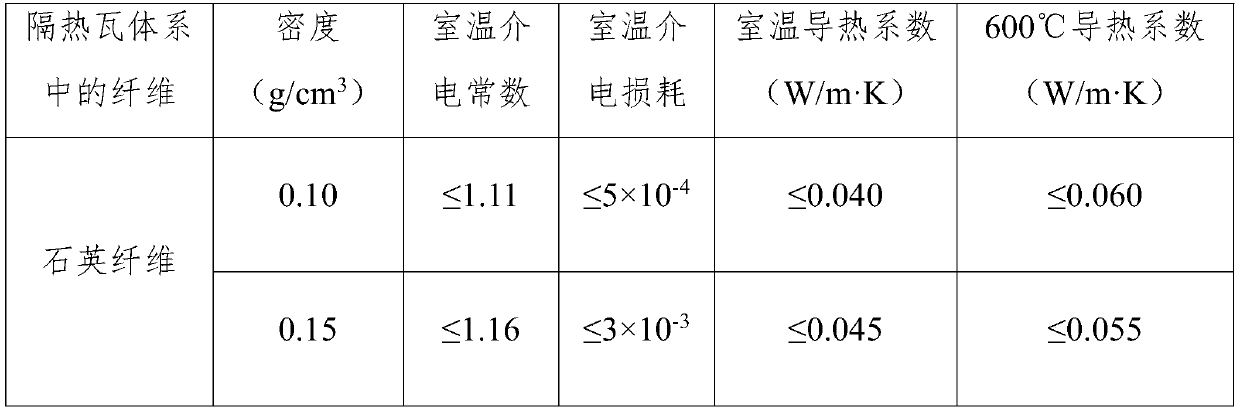

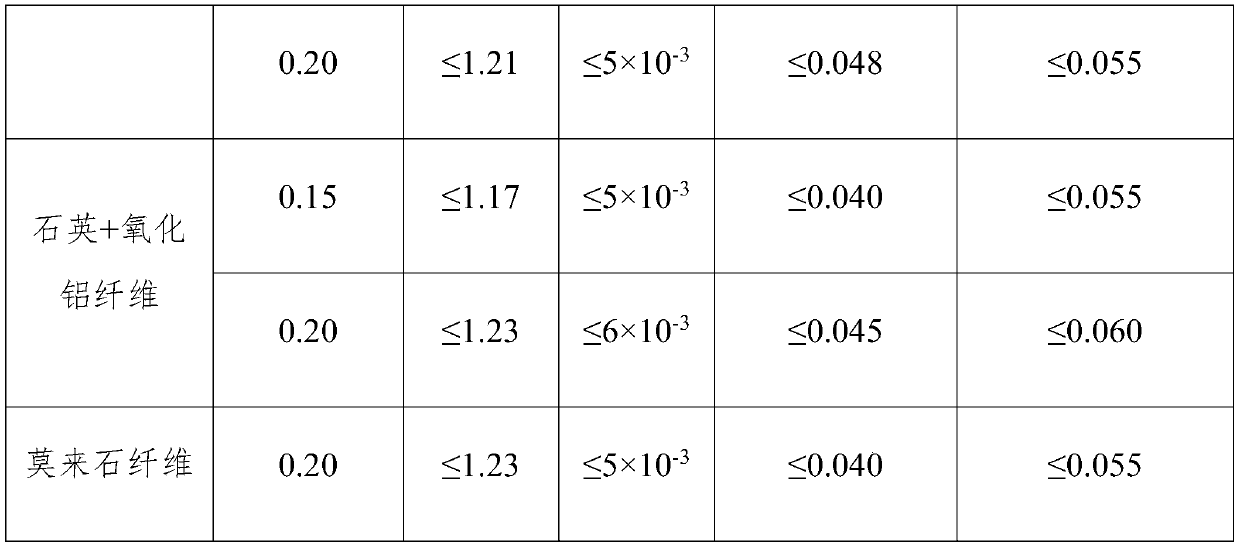

Embodiment 1

[0056] ① Use chopped quartz fiber as raw material, mix and disperse the fiber and water at a ratio of 1:100, pour the dispersed slurry into the tooling, adjust the suction filter control valve to gear 3, and wait until there is no water stain on the surface of the wet billet After remaining, perform mold release treatment. After the demoulding process, the height of the wet billet is positioned, and the height of the wet billet is controlled at 120mm by light pressing. The wet billet with a fixed thickness is placed in an oven for drying. After the dry billet is obtained, it is sintered in a muffle furnace, and the product is naturally cooled. After reaching room temperature, carry out hydrophobic treatment to obtain a density of 0.1g / cm 3 , 120mm thick low-density thermal insulation tile rough, and then machine-cut into two 30mm thick, two 20mm thick low-density thermal insulation tile flat boards for use.

[0057] ② Use quartz fiber as the composite material reinforcement (...

Embodiment 2

[0061] ① Use chopped quartz fiber as raw material, mix and disperse the fiber and water at a ratio of 1:100, pour the dispersed slurry into the tooling, adjust the suction filter control valve to gear 3, and wait until there is no water stain on the surface of the wet billet After remaining, perform mold release treatment. After the demoulding process, the height of the wet billet is positioned, and the height of the wet billet is controlled at 90mm by light pressing. The wet billet with a fixed thickness is placed in an oven for drying. After the dry billet is obtained, it is sintered in a muffle furnace, and the product is naturally cooled. After reaching room temperature, carry out hydrophobic treatment to obtain a density of 0.15g / cm 3 , 90mm-thick low-density heat-insulating tile blank, and then cut into three 30mm-thick low-density heat-insulating tile flat plates by machine.

[0062] ② Use quartz fiber as the composite material reinforcement (fiber reinforcement), impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com