Tundish covering agent and application thereof

A technology of tundish and covering agent, applied in the direction of improving process efficiency, etc., can solve the problems of unsuitable titanium-containing steel production, retention, and no effective treatment of titanium-containing steel, so as to improve continuous casting production conditions, prevent corrosion, The effect of strengthening the performance of preventing secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

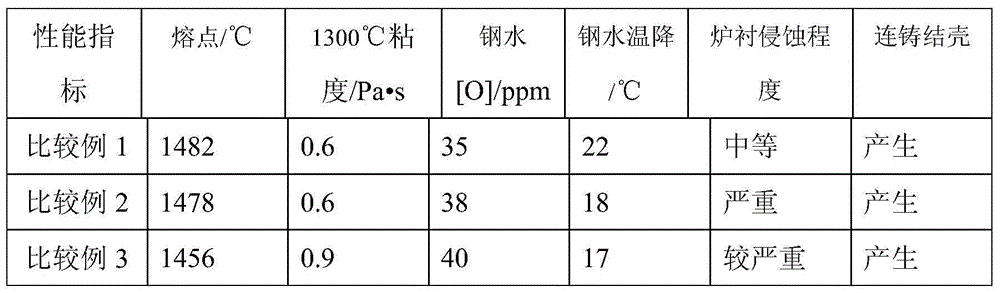

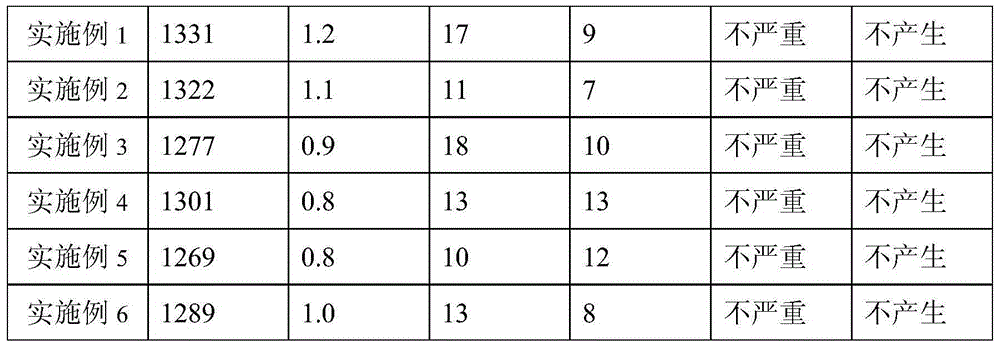

Embodiment 1

[0043] A tundish covering agent, its composition mass percentage is CaO: 43.4%, SiO 2 : 8.8%, Al 2 o 3 : 28%, MgO: 10%, B 2 o 3 : 1%, (Na 2 O+Li 2 O): 8.3%, TiO 2 : 0.5%. The alkalinity of the tundish covering agent is 4.9, and Na 2 O / Li 2 O (mass ratio) = 16:1; the main physical properties are shown in Table 1. After the tundish covering agent designed in this embodiment is applied to the tundish of titanium-containing steel continuous casting, the [O] in the tundish molten steel is less than 17ppm, the temperature drop of molten steel is less than 9°C, and the corrosion of the ladle lining is not serious. No encrustation occurs.

Embodiment 2

[0045] A tundish covering agent, its composition mass percentage is CaO: 38%, SiO 2 : 9%, Al 2 o 3 : 30%, MgO: 15%, B 2 o 3 : 2.1%, (Na 2 O+Li 2 O): 5.3%, TiO 2 : 0.6%. The alkalinity of the tundish covering agent is 4.2, and Na 2 O / Li 2 O (mass ratio) = 4:1; the main physical properties are shown in Table 1. After the tundish covering agent designed in this embodiment is applied to the tundish of titanium-containing steel continuous casting, the [O] in the tundish molten steel is less than 11ppm, the temperature drop of molten steel is less than 7°C, and the corrosion of the ladle lining is not serious. No encrustation occurs.

Embodiment 3

[0047] A tundish covering agent, its composition mass percentage is CaO: 40%, SiO 2 : 10%, Al 2 o 3 : 26%, MgO: 11.6%, B 2 o 3 : 3%, (Na 2 O+Li 2 O): 8.7%, TiO 2 : 0.7%. The alkalinity of the tundish covering agent is 4, and Na 2 O / Li 2 O (mass ratio) = 16:1; the main physical properties are shown in Table 1. After the tundish covering agent designed in this embodiment is applied to the tundish of titanium-containing steel continuous casting, the [O] in the tundish molten steel is less than 18ppm, the temperature drop of molten steel is less than 10°C, and the corrosion of the ladle lining is not serious. No encrustation occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com