Production process for high-purity bearing steel

A production process and bearing steel technology, applied in the field of high-purity bearing steel production process, can solve the problems of increased level of spot inclusions, continuous casting nodules, inability to achieve multi-furnace continuous casting, etc., to achieve control of purity and production. Cost, good pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

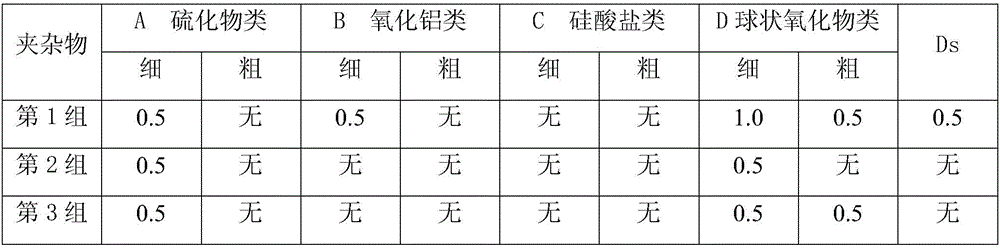

[0047] Three groups of experiments were also carried out, and it was found that the number of continuous pouring furnaces in the three groups were 3 furnaces, 4 furnaces, and 3 furnaces respectively. This also shows that in this comparative example, because the timing of feeding aluminum is different from that of the present invention, the controllability and instability of aluminum at the end of the follow-up VD furnace are poor, and the fluctuation of aluminum is large, which leads to unstable oxygen content in molten steel, and finally gives The pourability of molten steel is affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com