A kind of 250mm extra-thick EH36 steel plate for offshore platform and its preparation method

An offshore platform, EH36 technology, applied in the field of iron and steel metallurgy, to achieve the effects of stable production process, high impact toughness, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Preparation method of extra thick EH36 steel:

[0049] (1) Select high-quality scrap steel as the raw material for smelting, use high-quality raw and auxiliary materials for steelmaking, and smelt 2 furnaces, each furnace is 50 tons. The molten steel is smelted in an electric furnace, LF refined, and VD vacuum degassed in sequence, and then cast into 2 steel ingots in a steady state, each 45 tons. The section of steel ingot is greater than 900mm to ensure that the compression ratio of the final product is greater than 3. Control harmful residual elements in molten steel: S≤0.0030%, P≤0.0070%, O≤12ppm. Considering the requirement of fully floating inclusions and controlling the porosity and segregation inside the steel ingot to the degree of superheat, it is cast under the condition of superheat of 25-40 ℃, and the casting is protected by argon gas throughout the casting, and the flat steel ingot with a thickness of ≥900mm is cast. After the steel ingot is uncapped, it...

Embodiment 1

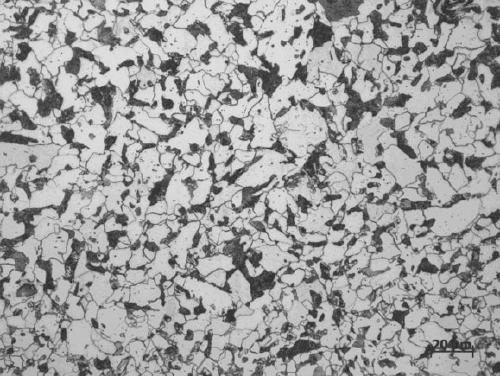

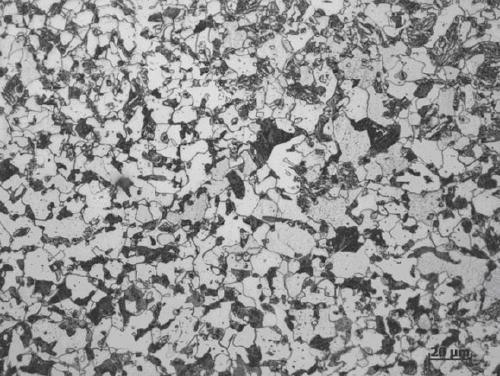

[0055] Examples 1 and 2 are extra-thick EH36 plates of 250mm, and the total level of inclusions A, B, C, and D is controlled at 2.0. As far as extra-thick plates are concerned, the uniformity of the steel plate in the thickness direction is directly related to the performance of the steel, and the uniform structure is the safety guarantee for the normal use and service of the steel plate. There is no obvious gradient structure in the thickness direction of the steel plate of the present invention, and the quenching structure is composed of pearlite ferrite structure. The accompanying drawing shows the structure at 1 / 4 thickness and 1 / 2 thickness of the steel plate in Example 1, the difference is not obvious, there is no obvious structure gradient in the thickness direction, the pearlite is evenly distributed, and it is diffusely distributed around the ferrite. Segregation forms flakes. The average grain size of ferrite is between 6 and 12 mm.

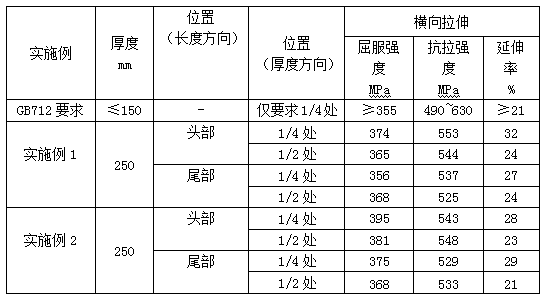

[0056] Table 2 shows the tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com