A kind of hot melt adhesive suitable for heat exchanger gap sealing and production method thereof

A technology of hot melt adhesive and heat exchanger, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., to achieve the effects of good mildew resistance, high peel strength and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

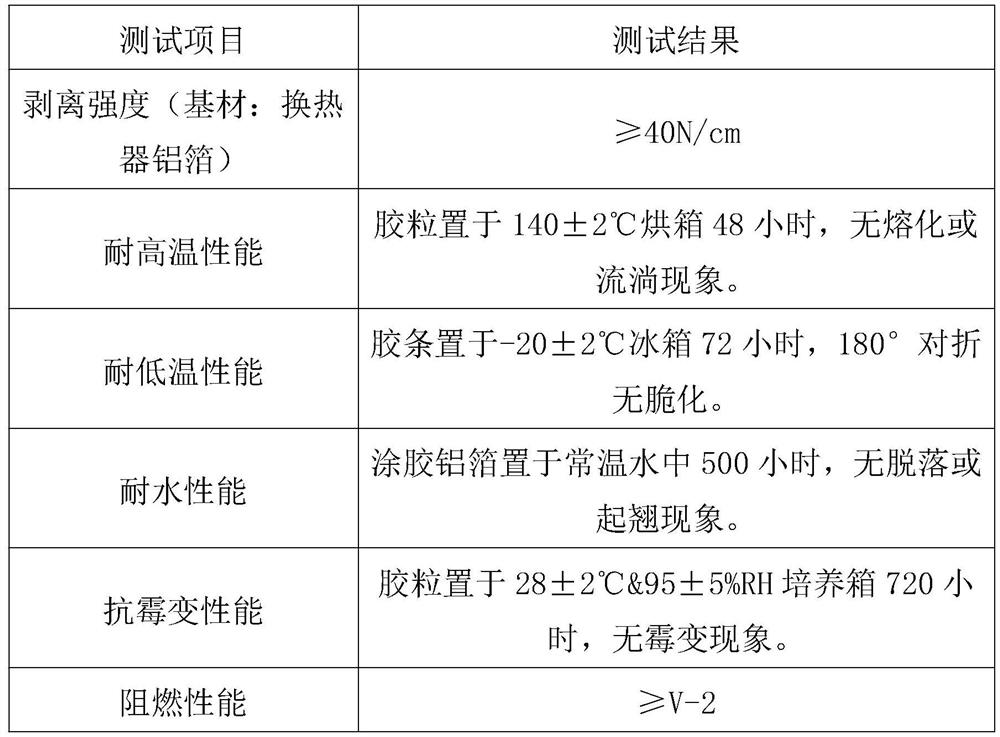

Embodiment 1

[0013] A hot melt adhesive suitable for heat exchanger gap sealing, the mass ratio composition of raw materials is: 49% amorphous α-olefin copolymer APAO (Ring and Ball softening point 135±5°C), 6.5% styrene- Butadiene-styrene block copolymer SBS (melt index 3.0 ± 0.5g / min), 26% hydrogenated C5 petroleum resin, 18% nano-sized aluminum hydroxide, 0.5% antioxidant 1010.

[0014] A production method of hot melt adhesive suitable for heat exchanger gap sealing:

[0015] ①. Take the antioxidant 1010, nano-sized aluminum hydroxide and hydrogenated C5 petroleum resin in the composition of the above formula by mass ratio as combination A, and use a high-speed mixer to mix them evenly.

[0016] ②. Take APAO and SBS in the mass ratio composition of the above formula together as combination B, and use an internal mixer to knead evenly.

[0017] ③. Use an internal mixer to further knead the above-mentioned combination A and combination B evenly, and control the mixing temperature to 125±...

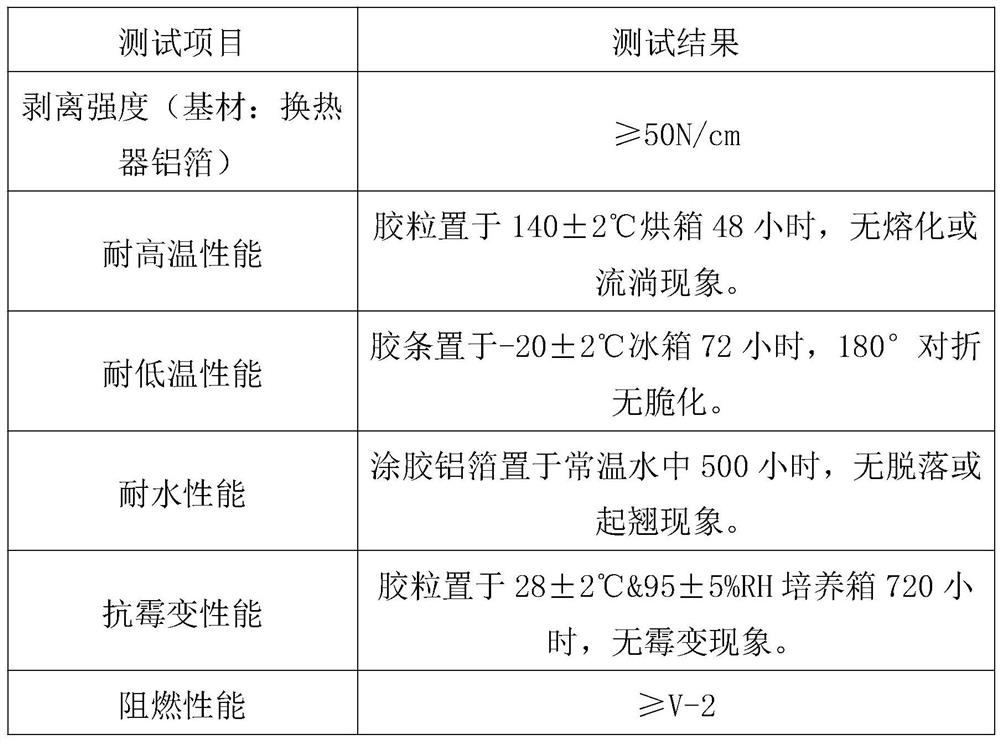

Embodiment 2

[0022] A hot melt adhesive suitable for heat exchanger gap sealing, the mass ratio composition of raw materials is: 55% APAO (Ring and Ball Softening Point 135±5°C), 9.5% SBS (melt index 3.0±0.5g / min), 20 %Hydrogenated C5 petroleum resin, 15% nano aluminum hydroxide, 0.5% antioxidant 1010.

[0023] A production method of hot melt adhesive suitable for heat exchanger gap sealing is:

[0024] ①. Take the antioxidant 1010, nano-sized aluminum hydroxide and hydrogenated C5 petroleum resin in the composition of the above formula by mass ratio as combination A, and use a high-speed mixer to mix them evenly.

[0025] ②. Take APAO and SBS in the mass ratio composition of the above formula together as combination B, and use an internal mixer to knead evenly.

[0026] ③. Use an internal mixer to further knead the above-mentioned combination A and combination B evenly, and control the mixing temperature to 125±5°C.

[0027] ④. Extrude the homogeneous mixture of combination A and combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com