A double-end mechanical seal for follow-up kettle

A mechanical seal and double-end face technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as the failure of the seal to meet the design life cycle, the impact of the stability of the seal, and the relative displacement of the mechanical seal. Compact, good sealing effect, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

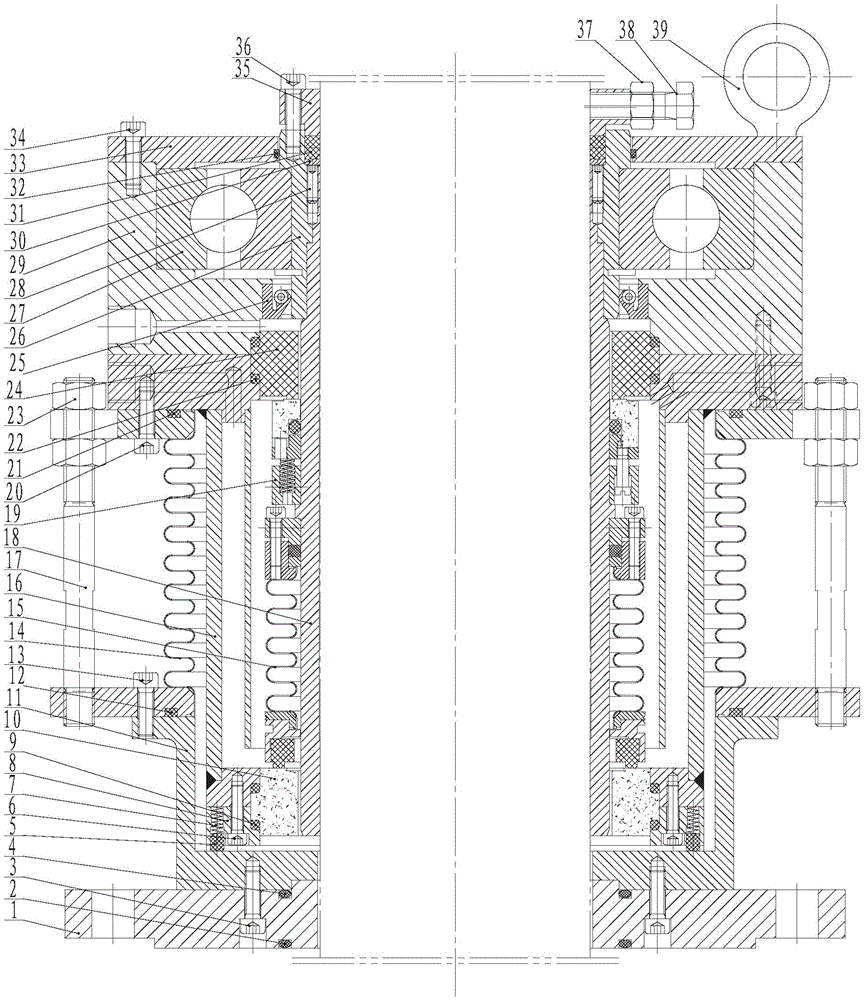

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the present invention includes shaft sleeve 18, static ring I10, dynamic seal assembly I15, dynamic seal assembly II19, static ring II24, bearing 27, bearing seat 29, bellows assembly 14 and positioning sleeve 11, wherein static ring I10, dynamic The sealing assembly I15, the dynamic sealing assembly II19, the static ring II24 and the bearing 27 are sleeved on the shaft sleeve 18 in sequence along the axial direction. The outer sleeve of the bearing 27 is connected with the bearing seat 29, and the inner sleeve of the bearing 27 is connected to the shaft through a set screw 28. The sleeve 18 is connected, and a skeleton oil seal 25 is provided between the inner sleeve and the bearing housing 29 . The end of the inner sleeve of the bearing 27 is connected with a pressure sleeve 35, and a giant sealing ring 31 and a flat washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com