A kind of high thermal conductivity silicone potting glue and its preparation method and application

A silicone potting compound, high thermal conductivity technology, applied in the field of materials, can solve the problems of weak flame retardant performance, easy aging, only 1.5W, etc., to achieve the effect of excellent tensile strength, excellent thermal conductivity, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

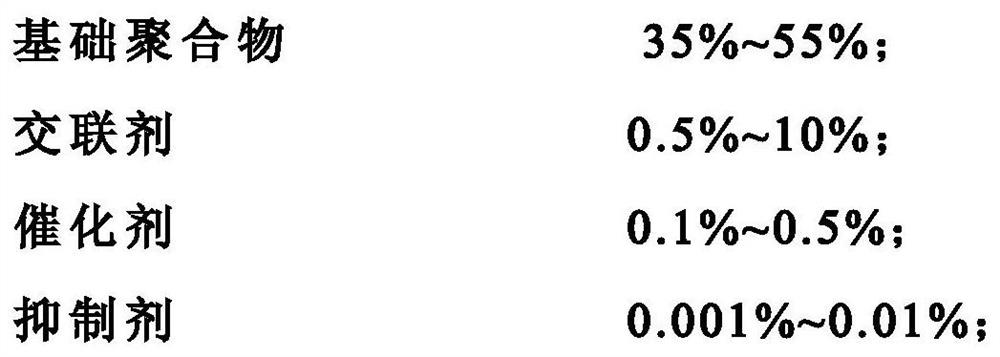

Method used

Image

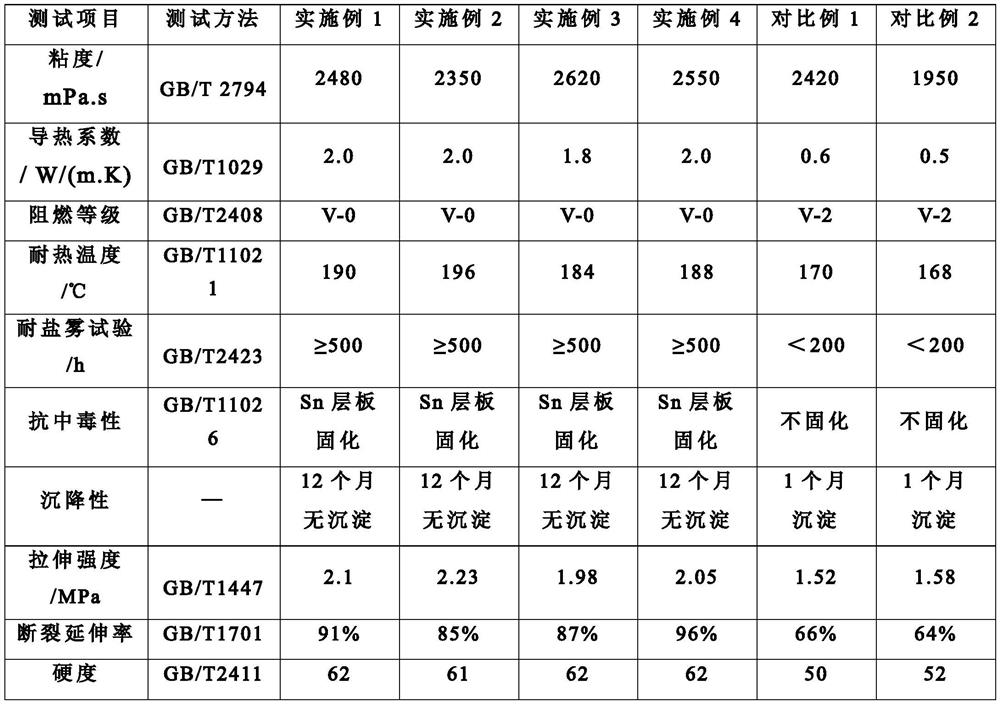

Examples

Embodiment 1

[0036] (1) Weigh 25g 3-methacryloxypropylmethyldimethoxysilane, 2g hexamethyldisiloxane, 15g octamethylcyclotetrasiloxane, 25g tetramethylcyclotetrasiloxane Add oxane and 2g of water into a three-necked flask, add 3g of concentrated sulfuric acid under stirring conditions, react at 30°C for 11h, add sodium carbonate to adjust the pH value to neutral, and distill under reduced pressure at 80°C for 3h to obtain the Acrylate based polymethylhydrogensiloxane crosslinker.

[0037] (2) Weigh 40g of low-viscosity end vinyl silicone oil (rotational viscosity of 300mPa.s at 25°C), 60g of high-viscosity end-vinyl silicone oil (rotational viscosity of 1000mPa.s at 25°C), 3g of crosslinking agent, 0.38g Custer catalyst, 0.01g inhibitor, 15g nano-alumina and 100g micro-silicon nitride are uniformly mixed, and then uniformly dispersed under high shear at a line speed of 10m / s, and vacuum degassed in a vacuum drying oven for 15min, namely Obtain the potting glue.

[0038] (3) Pour it into ...

Embodiment 2

[0040] (1) Weigh 30g 3-methacryloxypropylmethyldimethoxysilane, 3g hexamethyldisiloxane, 10g octamethylcyclotetrasiloxane, 20g tetramethylcyclotetrasiloxane Add oxane and 3g of water into a three-necked flask, add 2.5g of concentrated sulfuric acid under stirring conditions, react at 28°C for 11h, add sodium carbonate to adjust the pH value to neutral, and distill under reduced pressure at 90°C for 2.5h to obtain The acrylate-based polymethylhydrogensiloxane crosslinking agent.

[0041] (2) Weigh 35g low-viscosity end vinyl silicone oil, 65g high-viscosity end vinyl silicone oil, 5g crosslinking agent, 0.4g Castel catalyst, 0.01g inhibitor, 30g nano-alumina and 100g micron silicon nitride and mix evenly , and then under high shear at a linear speed of 15m / s, uniformly disperse, and vacuum defoam in a vacuum oven for 20min to obtain the potting compound.

[0042] (3) Pour it into a mold, cure at 120°C for 4 hours, and make samples for various tests.

Embodiment 3

[0044](1) Weigh 20g 3-methacryloxypropylmethyldimethoxysilane, 4g hexamethyldisiloxane, 10g octamethylcyclotetrasiloxane, 25g tetramethylcyclotetrasiloxane Add oxane and 4g of water into a three-necked flask, add 2g of concentrated sulfuric acid under stirring conditions, react at 25°C for 13h, add sodium carbonate to adjust the pH value to neutral, and distill under reduced pressure at 100°C for 2h to obtain the Acrylate based polymethylhydrogensiloxane crosslinker.

[0045] (2) Weigh 40g of low-viscosity end vinyl silicone oil, 60g of high-viscosity end-vinyl silicone oil, 10g of crosslinking agent, 0.42g of Custer catalyst, 0.01g of inhibitor, 60g of nano-alumina and 60g of micron silicon nitride and mix evenly , and then under high shear at a linear speed of 20m / s, uniformly disperse, and vacuum defoam in a vacuum oven for 30min to obtain the potting compound.

[0046] (3) Pour it into a mold, cure at 140°C for 1.5 hours, and make samples for various tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com