Free ring contact type gapless sealing technology

A technology of contact sealing and sealing structure, which is applied in the directions of preventing leakage, reducing greenhouse gas, and hydroelectric power generation. It can solve the problems of reducing turbine efficiency, steam or gas leakage, etc., and achieves the effect of easy processing and lower processing accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

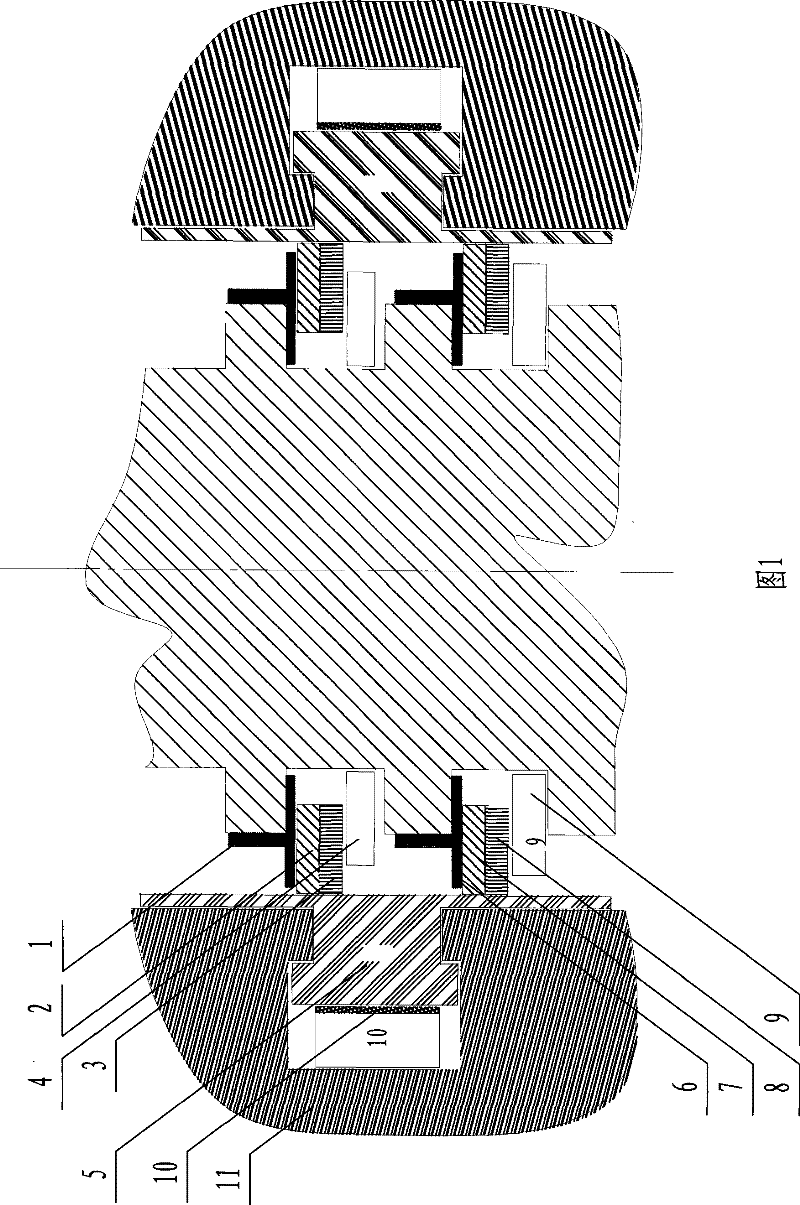

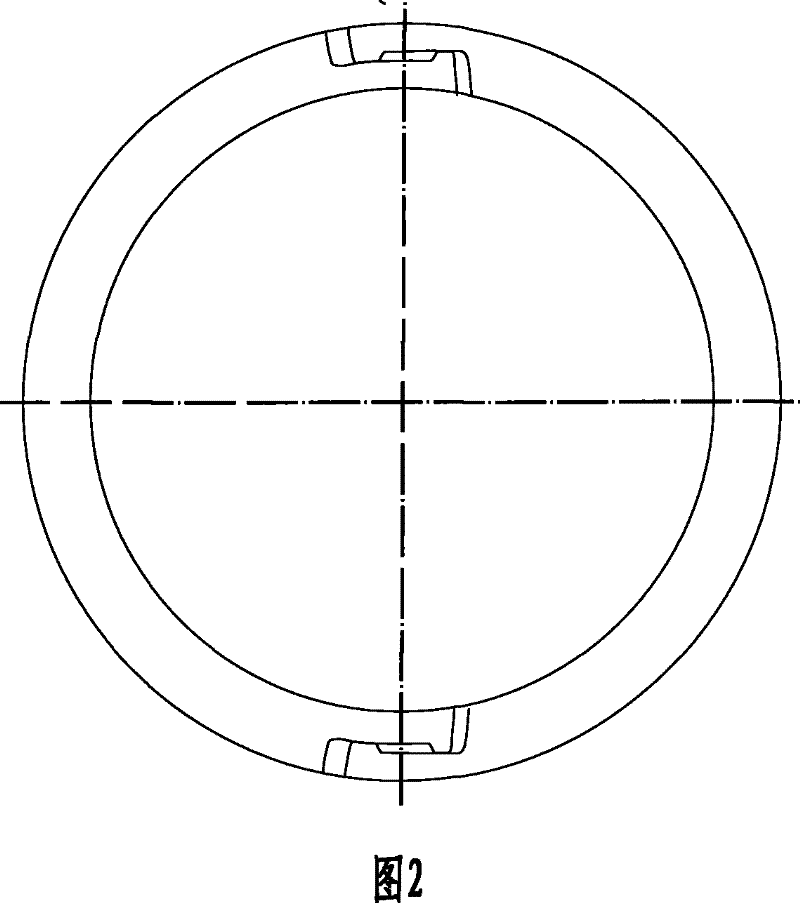

[0034] as attached figure 1 , 2 As shown, a free ring contact sealing structure of the present invention includes a seal 5 and a leaf spring 10 fixed on the turbine cylinder block or partition 11, the axial section of the seal 5 is I-shaped, and the outer surface of the seal 5 Plate springs 10 are additionally installed, and are embedded together in the T-shaped grooves of the turbine cylinder block or partition plate 11. Two groups of wear-resistant seals 1 and 6 are fixed on the rotor, and the outer surfaces of wear-resistant seals 1 and 6 are fixed. There is a gap between the circular surface and the inner circular surface of the sealing member 5 to prevent wear caused by the radial vibration of the rotor. The rotor is also provided with sealing rings that are in contact with the wear-resistant sealing bodies 1, 6 and the sealing member 5 respectively. There is also a thin steel plate spring piece 4 between the seal ring at the grinding seal body 1 and the wear-resistant s...

Embodiment 2

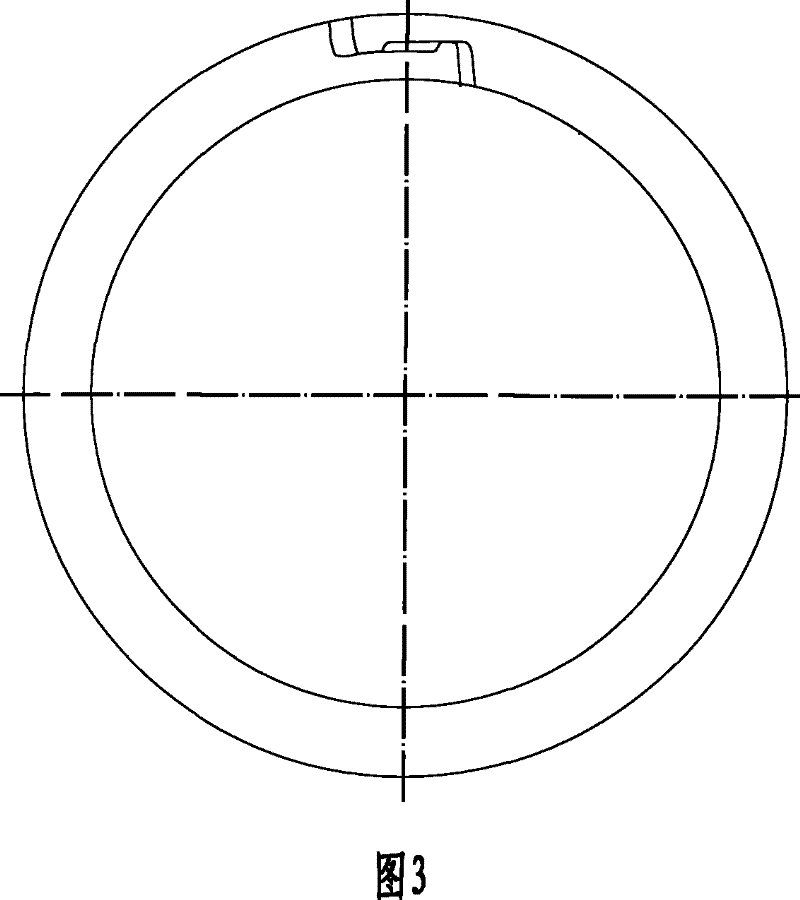

[0037] as attached figure 1 , 3 As shown, a free-ring contact sealing structure of the present invention includes a seal 5 and a leaf spring 10 in a split structure fixed on the turbine cylinder block or a partition 11, and the axial section of the seal 5 is I-shaped. A plate spring 10 is installed on its outer surface, and they are embedded together in the T-shaped groove that has been opened in the turbine cylinder block or partition plate 11. Two groups of wear-resistant sealing bodies 1, 6 are fixed on the rotor, and the wear-resistant sealing body There is a gap between the outer circular surfaces of 1 and 6 and the inner circular surface of seal 5 to prevent wear caused by the radial vibration of the rotor. A thin steel spring sheet 4 is also arranged between the sealing ring near the wear-resistant sealing body 1 and the wear-resistant sealing body 6, and a thin steel spring sheet 9 is arranged on the side of the sealing ring near the wear-resistant sealing body 6, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com