Magnetron sputtering inlet sealing flange of magnetron sputtering machine

A magnetron sputtering and inlet sealing technology, applied in the direction of engine sealing, sputtering coating, mechanical equipment, etc., can solve the problems of cold slip deformation, chronic failure, chronic sealing failure, etc., to reduce pressure, seal reliable, The effect of high sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

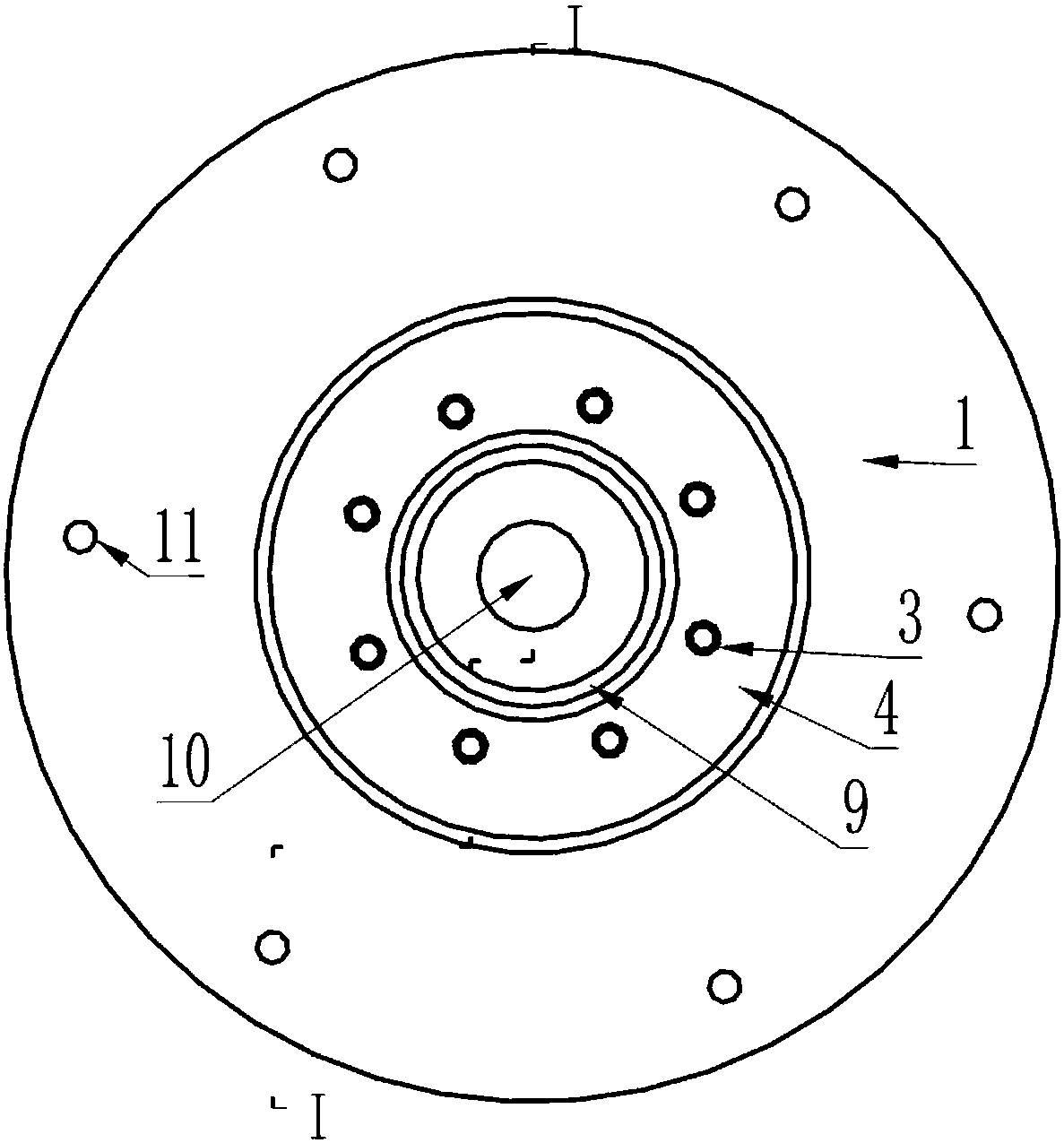

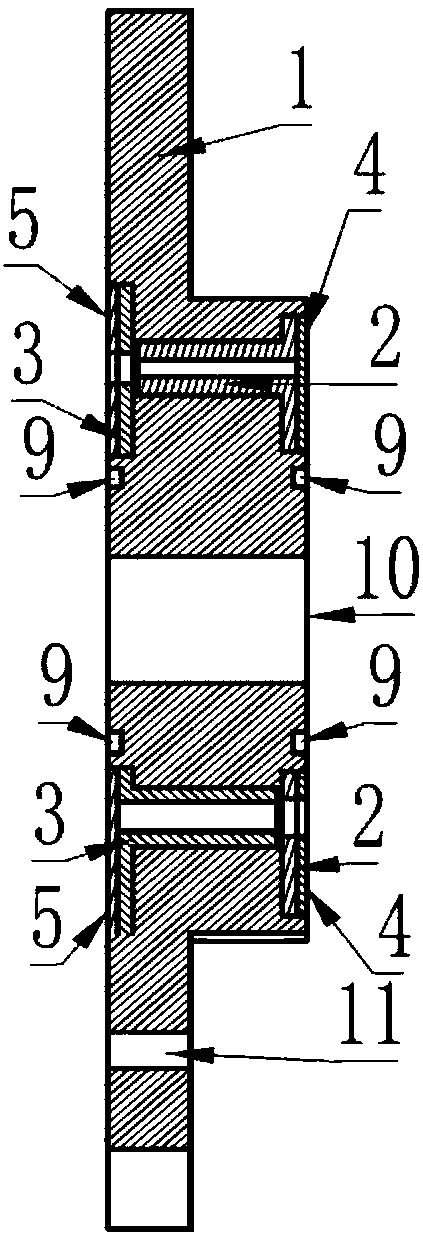

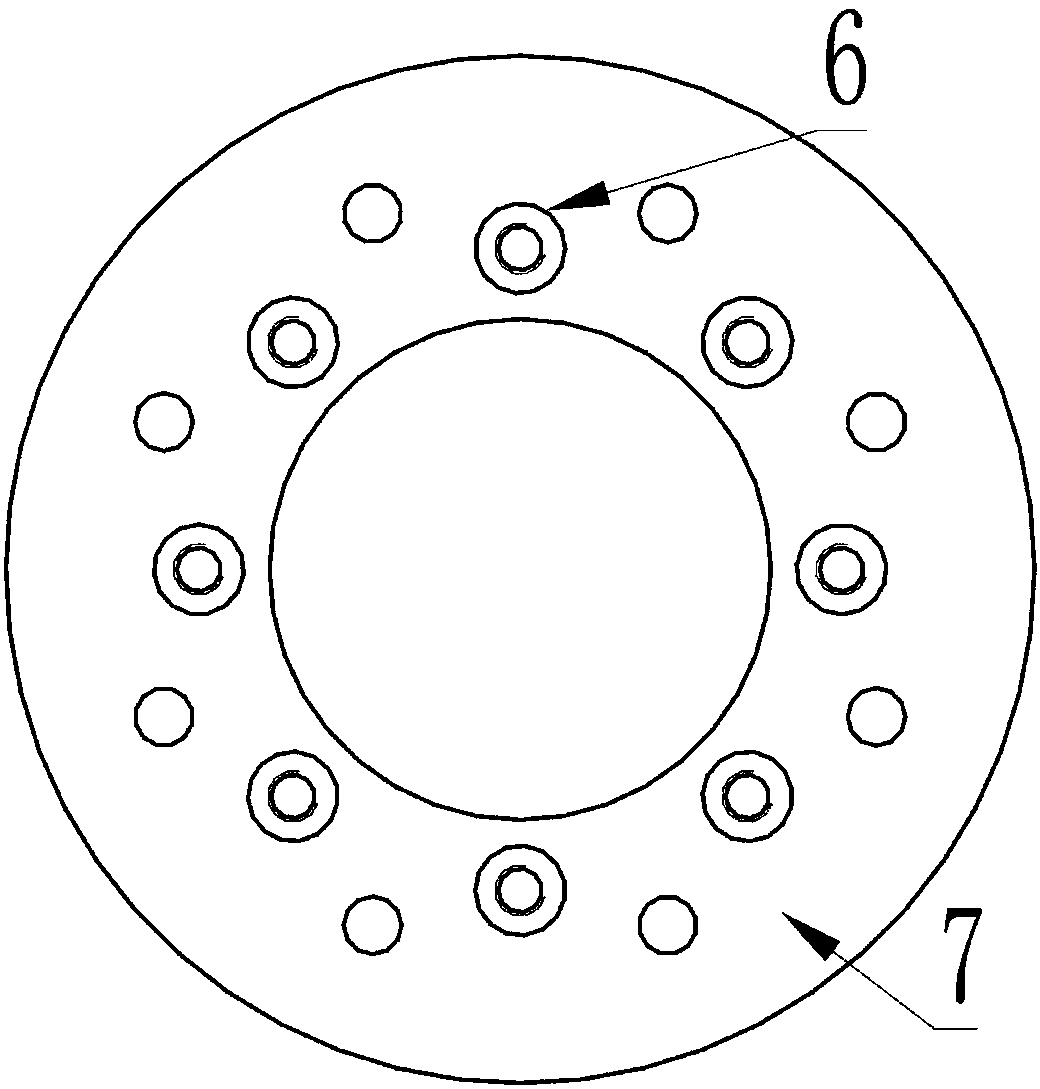

[0023] exist figure 1 In the shown embodiment, a magnetron sputtering inlet sealing flange of a magnetron sputtering machine includes: an insulator flange 1 formed with a central via hole 10 and a cylindrical step of a nut array through hole. Insulator flange 1 The surface of the central flange round table is covered with an upper insulating ring plate 4, the corresponding lower surface of the flange is covered with a lower insulating ring plate 5, and the outer side of the sealing ring 9 assembled in the central via hole 10 is formed and embedded with an upper nut The ring groove of the array ring plate 2 and the lower nut array ring plate 3 is matched, and the lower surface of the flange round table is fixedly connected to the vacuum chamber of the magnetron sputtering machine through the upper nut array ring plate 2, and fixed on the support bracket at the bottom of the vacuum chamber. The upper surface of the flange round table is fixedly connected to the top of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com