Patents

Literature

51results about How to "Realized production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

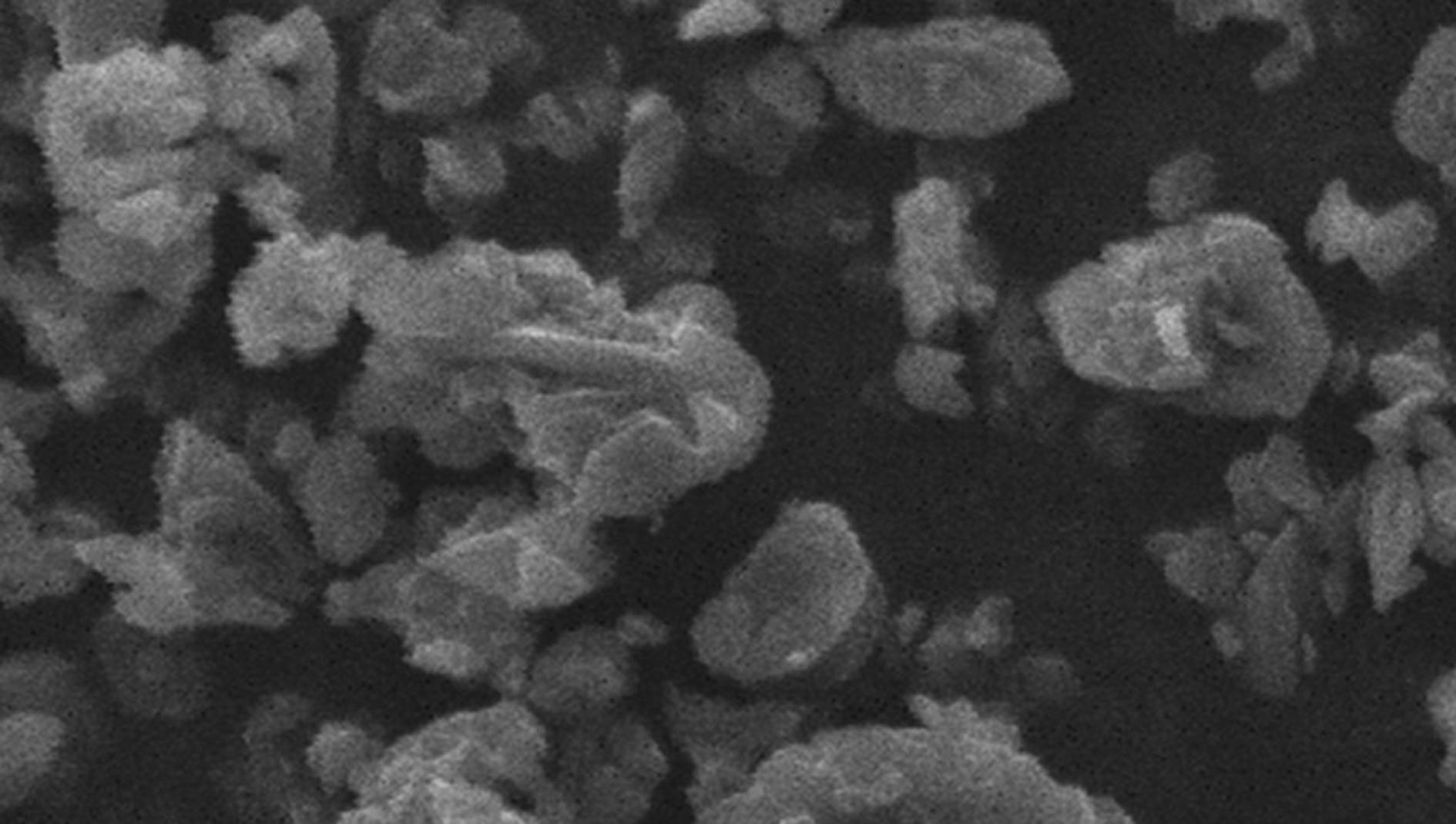

Composite graphite cathode material for high-capacity lithium ion battery, and its preparation method

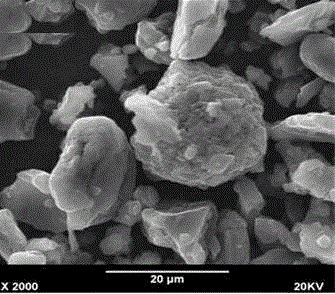

ActiveCN103078089ALow costThe preparation process is simpleCell electrodesChemistryElectrical battery

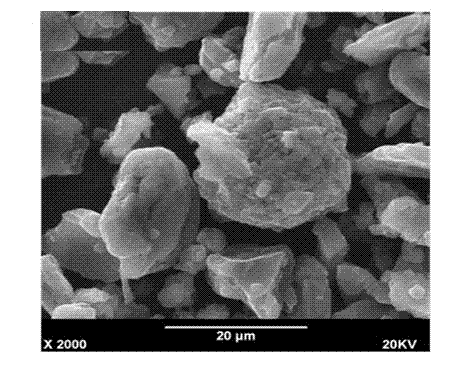

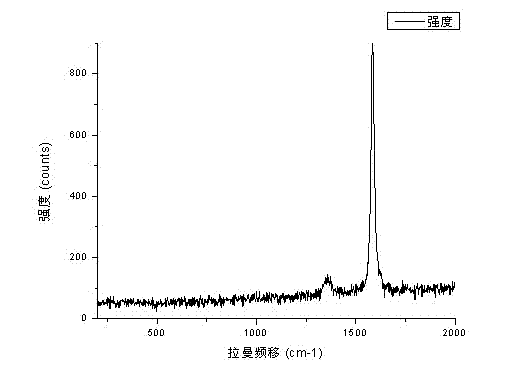

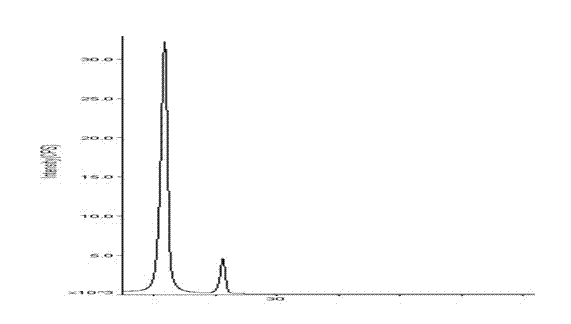

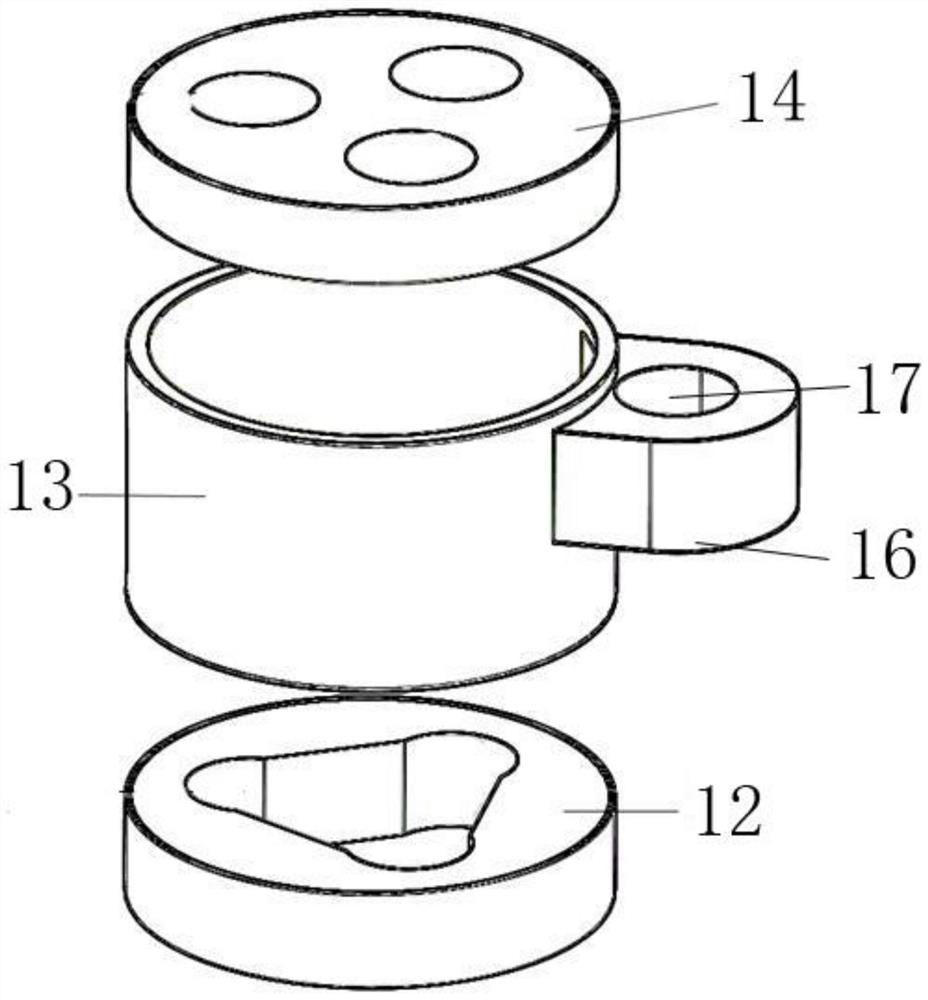

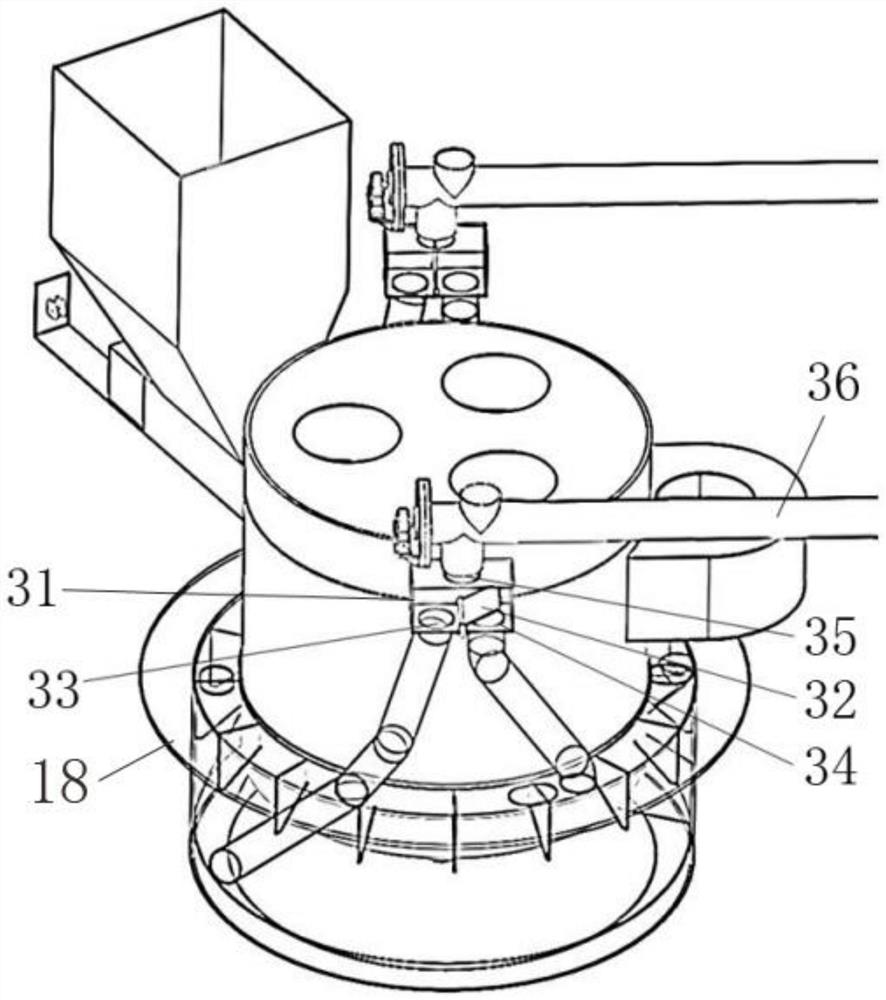

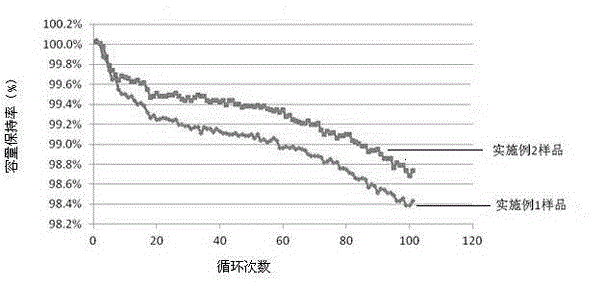

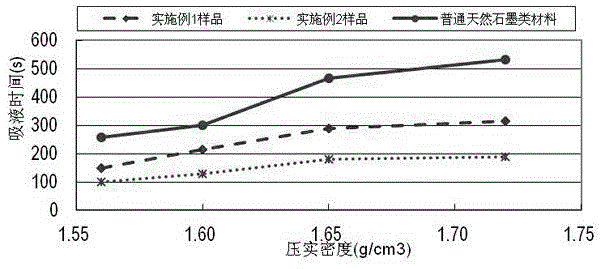

The invention relates to a composite graphite cathode material for a lithium ion battery, and its preparation method, mainly relates to a composite graphite cathode material for a high-capacity lithium ion battery, and its preparation method, and belongs to the field of cathode materials for the lithium ion battery. The composite graphite cathode material for the high-capacity lithium ion battery is formed by blocky powder and spheroidic powder, and is characterized in that the specific surface area is 1.5-3.5m<2> / g, the average particle size is 7-30mum, the Raman ratio R is 0.1-0.3, and the interlamellar spacing of a crystal face (002) is 0.335-0.337nm. The composite graphite cathode material for the lithium ion battery has the advantages of excellent compact density, excellent gram specific capacity and excellent cycle stability, so the energy density per unit volume of the lithium ion battery is improved, and the electrical performances of the cathode material in the lithium ion battery are comprehensively improved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

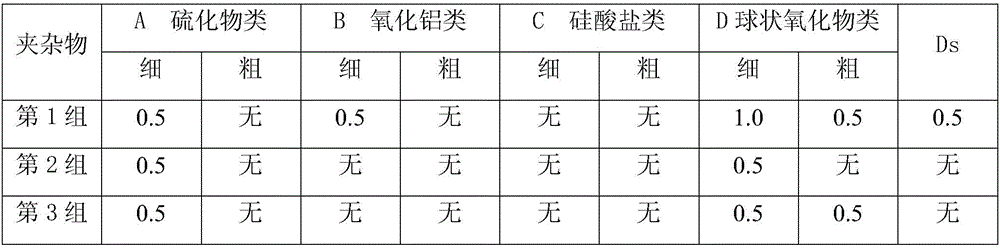

Production process for high-purity bearing steel

InactiveCN106591536ALow residual elementsReduce gas contentProcess efficiency improvementLow nitrogenSlag

The invention belongs to the technical field of steel preparation, and particularly relates to a production process for high-purity bearing steel. The production process comprises the following steps: firstly, adding blast-furnace molten iron and steel scrap in an electric converter and smelting; secondly, alloying a steel ladle by virtue of an alloy, an aluminium cake and a low-nitrogen carburant; thirdly, discharging molten steel into the steel ladle subjected to the alloying treatment after the smelting is completed, slagging and enabling the slagging result to meet the requirements of while slag in the earlier stage of refining, obtaining the while slag and then carrying out aluminium line feeding operation; fourthly, hoisting molten steel qualified after the refining into a vacuum tank and carrying out vacuum treatment; and finally carrying out continuous casting. Cancel of molten steel modification treatment is realized; and moreover, the molten steel is high in castability and meets the production requirements of high-standard bearing steel.

Owner:ZENITH STEEL GROUP CORP

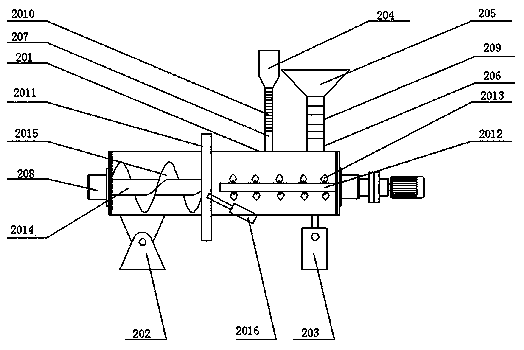

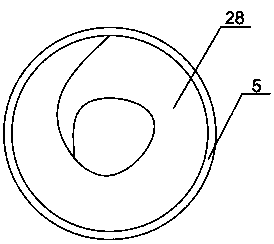

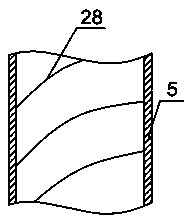

Method of preparing carbon anode active material of lithium-ion battery

ActiveCN101552333ARich sourcesEasy to getElectrode manufacturing processesCarbonizationMicroparticle

The invention relates to a method of preparing carbon anode active material of lithium-ion battery. The prepartion method includes following steps: a materials selection step, selecting heavy products of coal tar processing, heavy products of petroleum processing, heavy products of hydrocarbon polycondensation or, one or multiple of their low-temperature carbonization products as materials; a crushing step, crushing materials obtained from the material selection step into micro-particles with an average grain diameter of 3-80 Mum and granularity distribution range of 0-160 Mum; a thermal chemistry reforming step, in inert atmosphere, the micro-particles obtained by the crushing step is thermal chemistry reformed in moving state; a carbonization or carbonization, graphitization step, products from the thermal chemistry reforming step is proceeded with carbonization or carbonization, graphitization. The lithium-ion battery of carbon anode active material prepared by using the invention is provided with advantages of stable quality, excellent circulation performance, outstanding antidamping ability, high volume electrochemicalspecific capacity.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

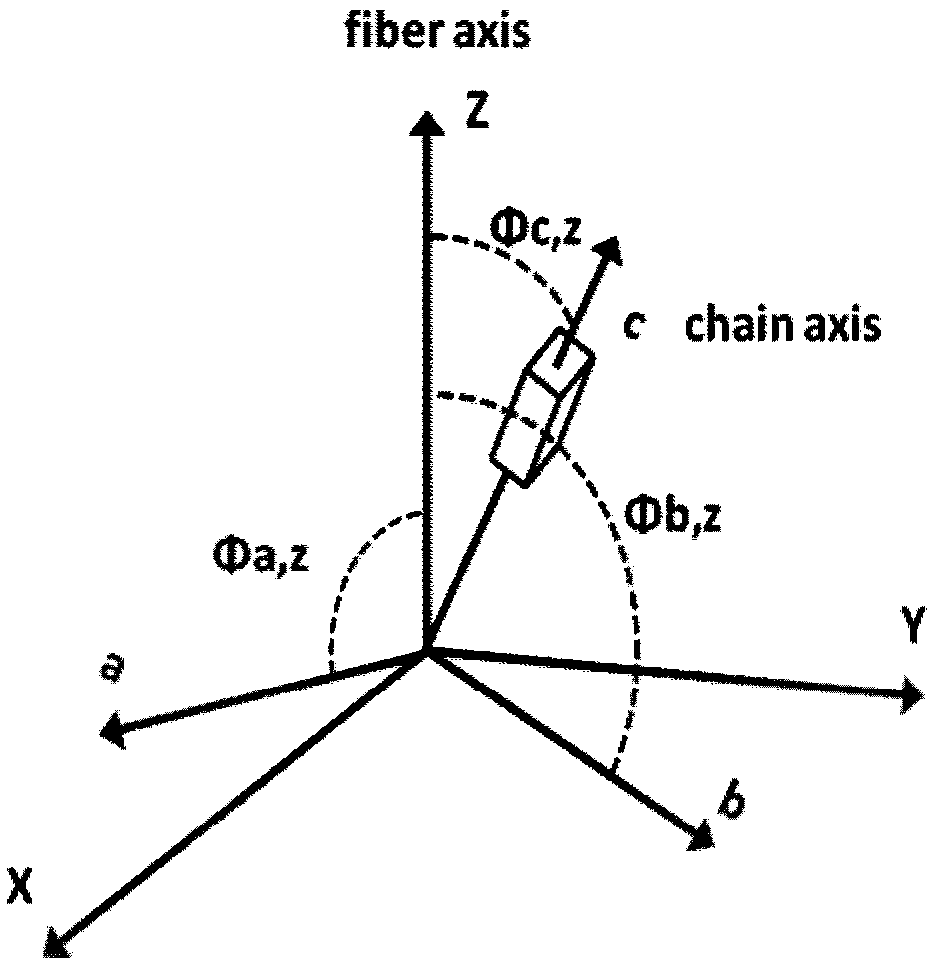

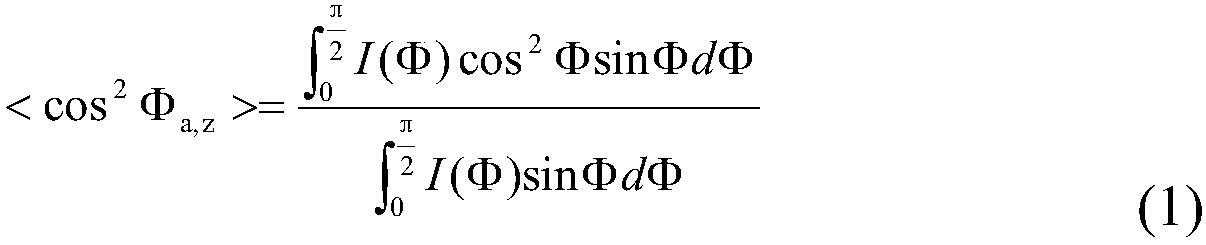

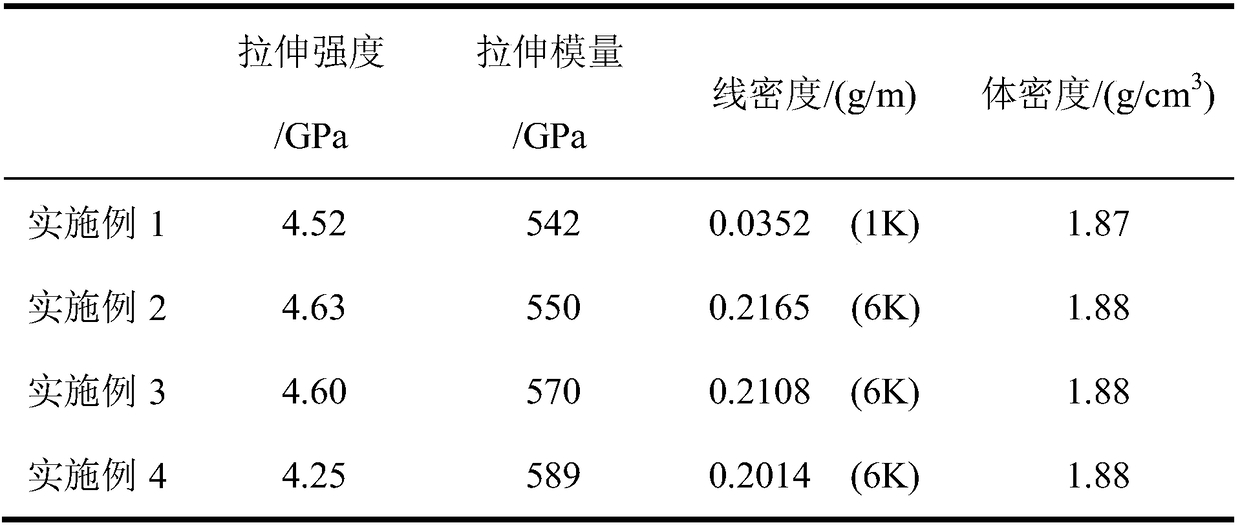

Preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers

ActiveCN108286090AImprove stretching efficiencyLow processing temperatureFibre chemical featuresCarbonizationPolyacrylonitrile

The invention relates to a preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers. After polyacrylonitrile (PAN) precursors are subjected to conventional pre-oxidationand low-temperature carbonization, the carbon crystalline orientation can be effectively controlled by increasing the high-temperature carbonization temperature and matching a certain stretching, or increasing the high-temperature carbonization stretching ratio to obtain high-temperature carbonized fibers with an orientation angle of being not greater than 17.5 degrees, and high-temperature graphitization hot drawing treatment is conducted at a relatively low temperature to obtain the high-strength high-modulus carbon fibers with tensile strength of 3.8-5.0 GPa and tensile modulus of 500-600 GPa. The preparation method reduces the requirements on equipment for high-temperature graphitization, which is beneficial to energy saving and cost reduction, and the operation is simple and easy.

Owner:BEIJING UNIV OF CHEM TECH

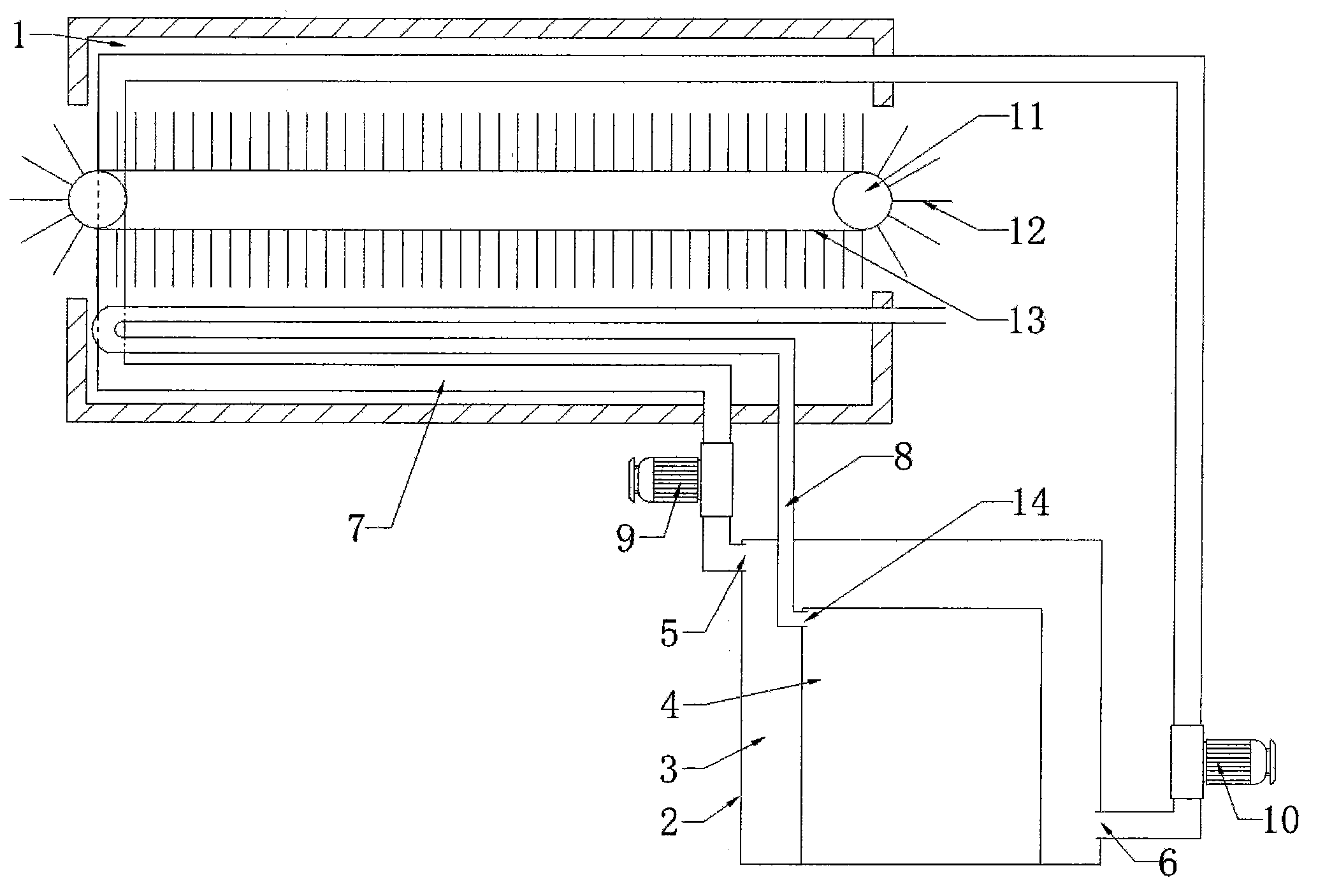

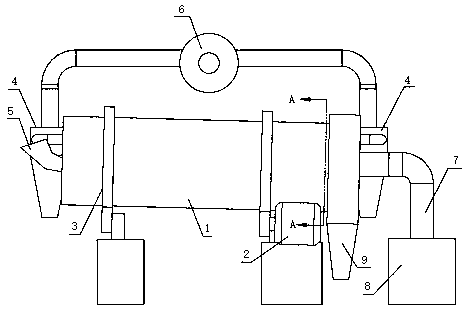

Plate drying system

InactiveCN104344700ASmooth dischargeEvenly heatedDrying gas arrangementsDrying machines with progressive movementsCombustion chamberProcess engineering

The invention discloses a plate drying system. The plate drying system consists of a drying chamber (1), a combustion furnace (2), a heat conduction system and a plate conveying system, wherein the drying chamber (1) is arranged into a rectangular shape, the roof and the side walls of the drying chamber (1) are built through the laying of thermal insulating materials, a combustion furnace thermodetector is arranged outside the drying chamber (1), and the combustion furnace (2) is provided with a combustion chamber (4) and a hot air chamber (3). The adopted plate drying system improves the plate drying rate, reduces the production cost and improves the consistency of plate quality.

Owner:JIANGXI XIANGHE IND

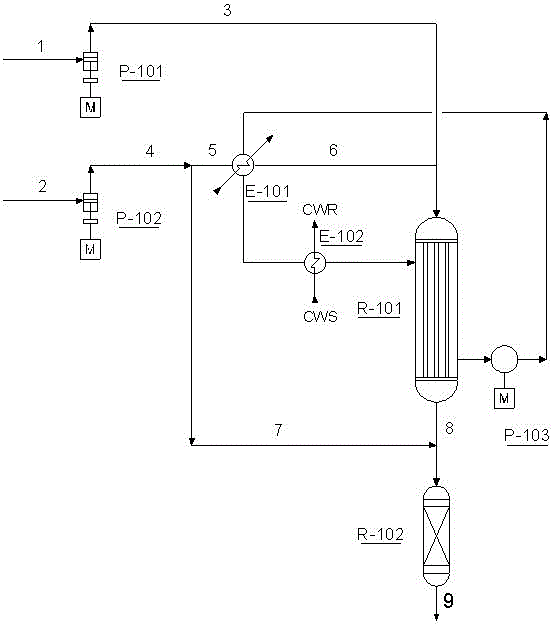

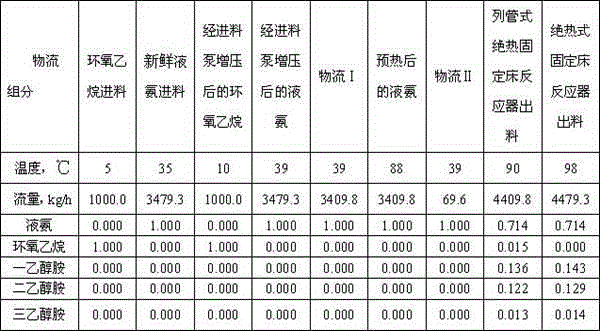

Method of producing ethanolamine from liquid ammonia

ActiveCN104557571AGuaranteed conversionReduce volumeOrganic compound preparationAmino-hyroxy compound preparationMolecular sieveState of art

The invention relates to a method of producing ethanolamine from liquid ammonia and mainly aims to solve the technical problems of a large amount of byproducts, low security, high investment in equipment and high energy consumption in the prior art. According to the technical scheme, ethylene oxide and fresh liquid ammonia are respectively added into a tubular fixed-bed reactor by a feeding pump, the product of reaction is added into an adiabatic fixed-bed reactor, and the tubular fixed-bed reactor and the adiabatic fixed-bed reactor are both filled with a binder-free ZSM-5 zeolite molecular sieve catalyst so as to catalyze ammoniation to generate ammonia-containing ethanolamine. By adopting the technical scheme, the problems can be well solved. The method provided by the invention can be applied to the industrial production of ethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products

InactiveCN102534741AImprove surface qualityFast Galvanizing EfficiencyCellsLiquid surface applicatorsElectrogalvanizationPower flow

The invention relates to a production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products, which belongs to the technical field of metal plating coating processes. The production process for rapidly achieving the galvanization and the PVF paint coating of the tubular products enables a plurality of tubes to move parallelly, achieves process integration of galvanization PVF paint coating, achieves high-speed electrogalvanization and PVF coating surface processing, and simultaneously meets organic combination of trivalent chromium galvanization passivation and trivalent chromium PVF paint with the speed as high as 20m / min. Surface quality of produced tubular products is excellent, galvanization efficiency is high, yield is improved, and production cost is reduced. Key technical problems that an existing electroplating device has poor environment protection, tightness and product operation stability, large current can generate heat during electroplating, and the like are solved. When the process is utilized, tubes do not generate electric sparks during continuous galvanization operation, the plating is free of burns and rough black phenomena. Besides, due to large current density, high galvanization efficiency and fast electroplating speed in galvanization, the production purposes of high efficiency and low cost are achieved.

Owner:COOPER STANDARD JINGDA JINGZHOU AUTOMOBILE FITTINGS

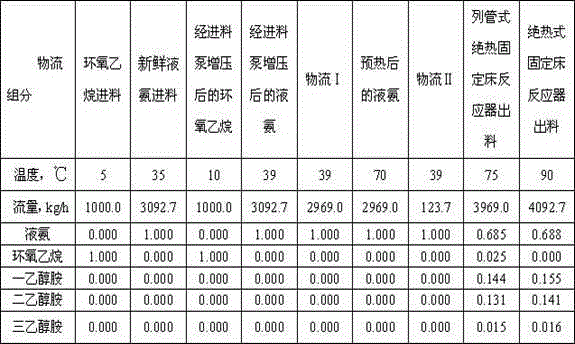

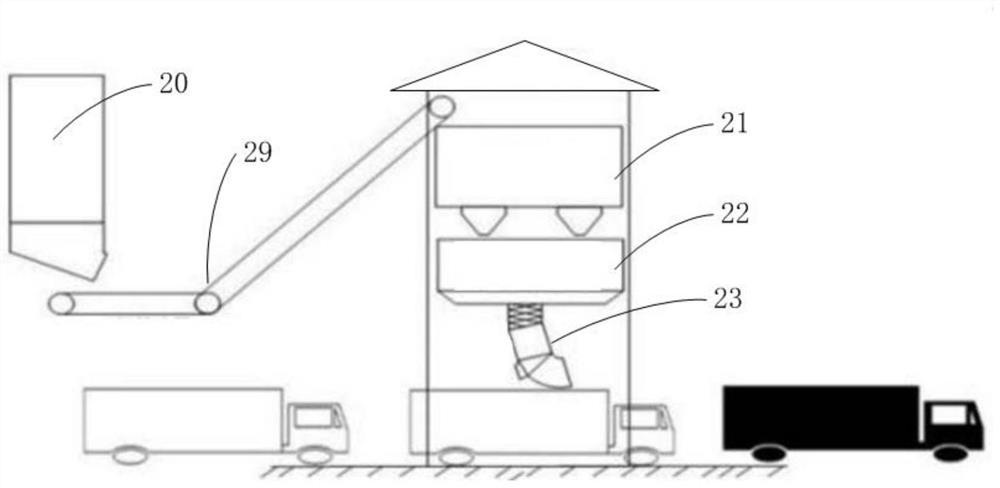

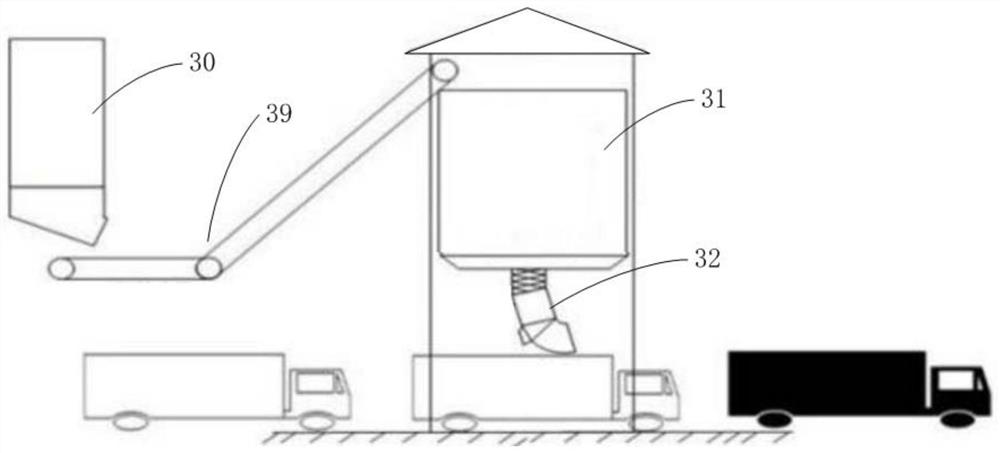

Intelligent loading control system and method

InactiveCN112299049ARealize the whole process automationGo onlineLoading/unloadingControl systemControl engineering

The invention discloses an intelligent loading control system and method. The system comprises a plurality of information identification subsystems, an automatic weighing subsystem, an AI visual identification subsystem and a control processor. Accurate positioning of a parking position and an unloading position of a transport vehicle and accurate measurement of a unloading weight can be achieved,unmanned, intelligent and scenarized loading is achieved, an unloading speed can be increased, the continuity of automatic unloading is ensured, the unloading time is controllable, and the unloadingprecision and a loading full load rate are improved.

Owner:上海平奥供应链管理有限公司

Continuous casting production method of sulfur-containing and aluminum-containing high calcium steel

ActiveCN110343802AImprove purityInhibits the formation of CaSManufacturing convertersSlagDeoxygenation

The invention discloses a continuous casting production method of sulfur-containing and aluminum-containing high calcium steel. The continuous casting production method of the sulfur-containing and aluminum-containing high calcium steel includes working procedures of converter smelting, LF (ladle furnace) ladle refining, VD (vacuum distillation) vacuum refining and continuous casting. The continuous casting production method of the sulfur-containing and aluminum-containing high calcium steel uses high alkalinity refining slags in the earlier stage of the LF ladle refining process, thereby facilitating deoxygenation and desulfurization, and absorbing inclusions in steel liquid, and then reduces alkalinity of the refining slags in the middle and later stages, thereby inhibiting generation ofCaS, and improving the yield of Ca; and performs wire feeding process alloying and soft blow after vacuum breaking of the VD vacuum refining, achieves even steel liquid constituents and temperature for the steel liquid, facilitates upward floating of the inclusions in the steel liquid, improves purity of the steel liquid, achieves the upward floating of the inclusions in the steel liquid throughstanding, and further improves the purity of the steel liquid. The continuous casting production method of the sulfur-containing and aluminum-containing high calcium steel reduces occurrence rate of anozzle clogging problem in the continuous casting process of the sulfur-containing and aluminum-containing high calcium steel, and compared with a current traditional mold casting process, the continuous casting production method of the sulfur-containing and aluminum-containing high calcium steel can substantially improve production efficiency of the sulfur-containing and aluminum-containing highcalcium steel, and substantially reduces production cost.

Owner:SHIJIAZHUANG IRON & STEEL

Method for preparing carbon cathode material of lithium ion battery, carbon cathode material and lithium ion battery

ActiveCN101707246ARich sourcesEasy to getElectrode manufacturing processesSecondary cellsDepolymerizationSodium-ion battery

The invention relates to a method for preparing a carbon cathode material of a lithium ion battery, the carbon cathode material prepared by the method and the lithium ion battery prepared from the carbon cathode material. The method for preparing the carbon cathode material of the lithium ion battery orderly comprises the steps of: (1) material selection; (2) grinding; (3) mixing-reforming; and (4) graphitization or charring and graphitization. The preparation method is based on the theory of selective catalysis possessed by iron series compounds in a process of reforming raw materials meeting the requirements of characteristic values, in complex phase reactions such as complex depolymerization, hydrogen migration, condensation and the like of heavy hydrocarbons with functional groups and during the charring or graphitization of reformates, so that the defects in internal structures of the materials are improved, the extent of ordered arrangement of material molecules is improved, and the aim of improving the compressive performance of specific cathode materials is finally achieved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

Production method and product of lithium-ion power battery rate cathode material

The invention relates to a production method of a lithium-ion battery carbon cathode active material, comprising the following steps: (1) selecting heavy products from coal-tar processing and / or heavy products from petroleum processing as raw materials, and crushing the raw materials; (2) adding additives in the crushed raw materials; (3) mixing the crushed particles with the additives, then carrying out thermo-chemical reforming to obtain a reformed product; and (4) cooling the reformed product to room temperature, then crushing and grading to obtain micro powder, and then carbonizing or graphitizing the micro powder; or directly carbonizing or graphitizing the reformed product. The produced product has the advantages of high electrochemical specific capacity, good processing property, and strong adaptability of other matching materials.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

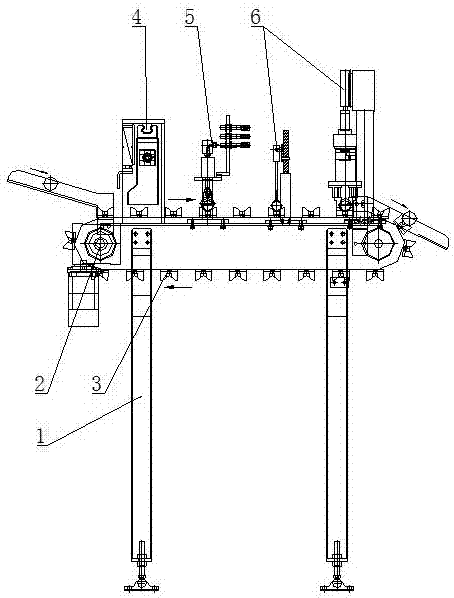

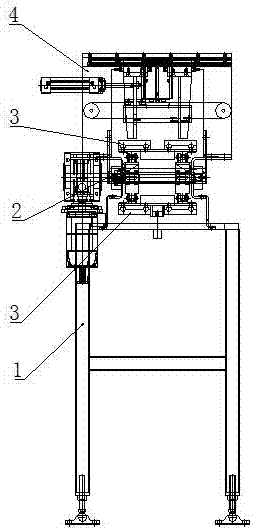

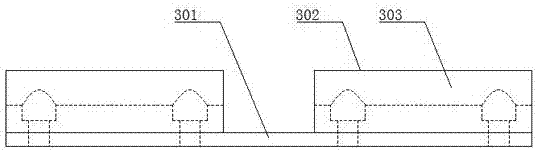

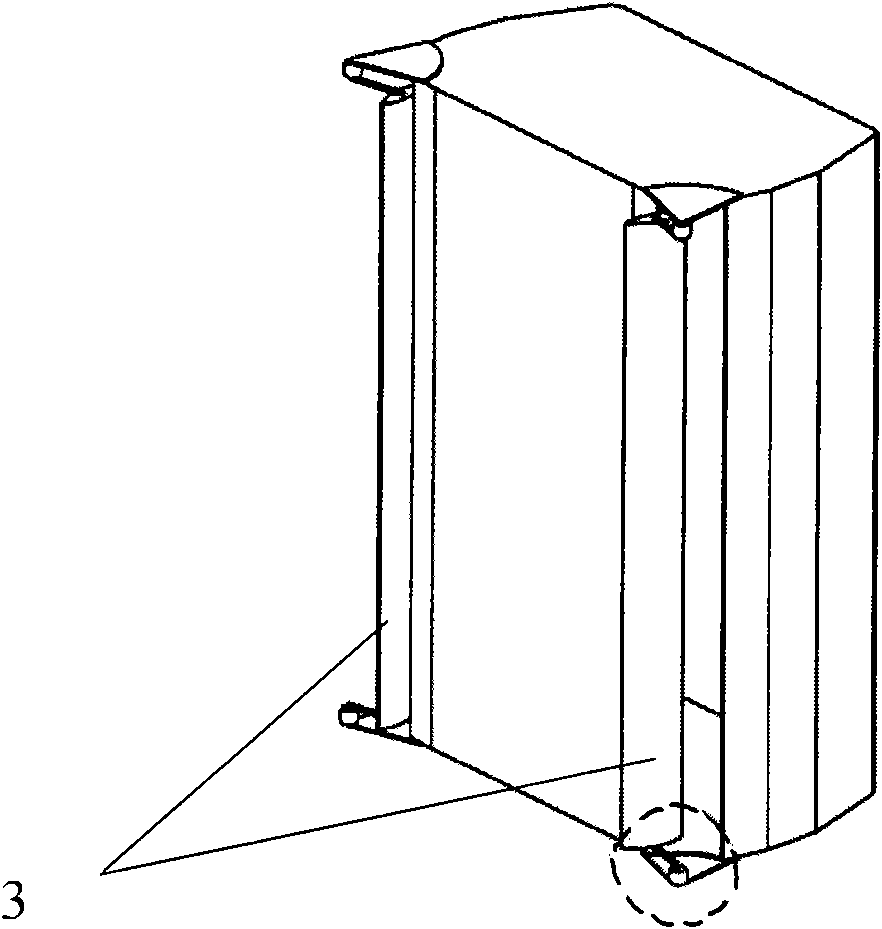

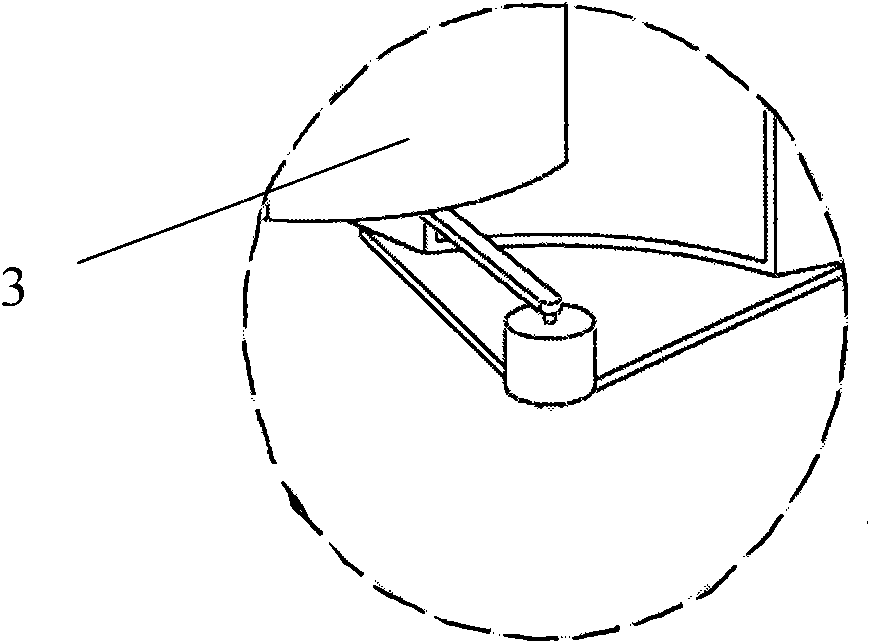

Pin shaft mistake proofing device used on automatic production line

ActiveCN107244533AReduce labor intensityGuaranteed accuracyControl devices for conveyorsMechanical conveyorsEngineeringManufacturing line

The invention discloses a pin shaft mistake proofing device used on an automatic production line. The pin shaft mistake proofing device comprises a rack. A workpiece conveying device is arranged in the rack. Multiple accompanying tools evenly distributed at intervals are arranged on the workpiece conveying device. An axial centering positioning mechanism, a diameter detection mechanism and a ring groove position detection and correcting mechanism are sequentially arranged on the rack from the front end to the tail end. The accompanying tools on the workpiece conveying device sequentially pass through cavities of the axial centering positioning mechanism, the diameter detection mechanism and the ring groove position detection and correcting mechanism. The axial centering positioning mechanism can conduct clamping and centering on workpieces on the accompanying tools, and the types of the workpieces can be recognized according to the length dimension. The diameter detection mechanism can be used for detecting the diameters of the workpieces on the accompanying tools, and the types of the workpieces can be recognized according to the diameter dimension. The ring groove position detection and correcting mechanism can be used for conducting ring groove position detecting and correcting on the workpieces on the accompanying tools. The pin shaft mistake proofing device is used for replacing a traditional manual detection manner in the past, the detection accuracy is ensured, reliability is high, and the device conforms to accuracy and stability of the production line.

Owner:三翔(十堰)汽车零部件有限公司

Method of preparing graphene nanoplate size through nanometer-distribution collision stripping and graphene nanoplate size

InactiveCN106564888AIncreased chance of collisionImprove mechanical stripping efficiencyGrapheneCvd grapheneContinuous production

The invention discloses a method of preparing graphene nanoplate size through nanometer-distribution collision stripping and the graphene nanoplate size. According to the method of preparing the graphene nanoplate size through nanometer-distribution collision stripping, the graphene nanoplate size is prepared through stripping by means of shear force generated by nanometer-distribution collision; a graphite raw material is dispersed into size, the size is distributed through the nanometer distribution technology, the distributed size collides with stop sheets arranged in a channel in a staggered manner, and so that shear is formed; the size which is not blocked by the first stop sheet can be stopped by other stop sheets, so that fine particles are generated, after the size is stopped and cut layer by layer, the graphene size is shorn layer by layer, and therefore the evenly dispersed graphene size is obtained. The graphene obtained through the method is uniform in particle size, safe, free of pollution, and mass continuous production can be achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Purification method of graphite in waste residues of artificial diamond production, graphite anode material for lithium ion battery and preparation method of graphite anode material

InactiveCN109678148AAchieve purificationHigh recovery rateCarbon compoundsNegative electrodesPurification methodsSodium-ion battery

The invention belongs to the technical field of graphite materials, and particularly relates to a purification method of graphite in waste residues of artificial diamond production, a graphite anode material for a lithium ion battery and a preparation method of the graphite anode material. The purification method of graphite in the waste residues of the artificial diamond production comprises following steps: (1), the waste residues of the artificial diamond production and inorganic acid are mixed and subjected to a reaction for 24-36 h at 80-120 DEG C; inorganic acid is at least one of concentrated sulfuric acid, concentrated nitric acid and concentrated hydrochloric acid; (2), a system obtained after a reaction in step (1) is subjected to solid-liquid separation, washed and dried. The purification method of graphite is high in recovery rate and low in production cost. When modified graphite obtained through asphalt coating modification of the graphite purified with the purification method is taken as the anode material for the lithium ion battery, the modified graphite has better cycling stability.

Owner:河南烯碳合成材料有限公司

Multi-layer hog house

InactiveCN109220835ARise steadilySteady declineAnimal feeding devicesAnimal housingEngineeringReducer

The invention provides a multi-layer hog house. The multi-layer hog house comprises feeding rooms which are arranged from top to bottom in sequence, a transportation mechanism is arranged on one sideof the feeding rooms, transportation openings are formed in the side walls, close to the transportation mechanism, of the feeding rooms, feed troughs are formed in the feeding rooms, and one end of each feed trough is close to the corresponding transportation opening. The transportation mechanism comprises a steel wire rope, a motor, a reducer output shaft connected with the motor, two upright columns and a rectangular bearing table, wherein the two upright columns are spaced and parallel, and the rectangular bearing table is arranged between the two upright columns. Each feed trough comprisesa trough body with an opening in the upper portion, wherein a base is arranged on the lower portion of the trough body, the four corners on the bottom of the trough body are fixedly connected with the base through vibrating springs respectively, a vibrating motor is arranged on the outer wall on the bottom of the trough body, and a dry material uniform-distribution mechanism is arranged above thetrough body. A material mixing mechanism is fixedly installed on the rectangular bearing table, the material mixing mechanism comprises a material mixing cylinder, a dry material storage hopper and aliquid material storage hopper are arranged above the material mixing cylinder, and a hinged base and a jack are arranged below the material mixing cylinder.

Owner:郏县全民牧业有限公司

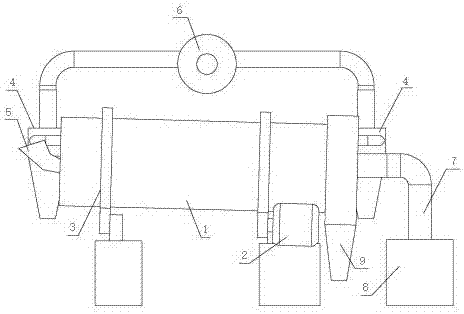

Coffee beans automatic drying and screening device

InactiveCN107495429ADry fastPrevent leakageSievingGas current separationPulp and paper industryHot blast

The present invention provides a coffee bean automatic drying and screening device. The coffee bean automatic drying and screening device comprises a roller, and a transmission mechanism and a bracket part connected with an outer surface of the roller. A material inlet is connected with a left side of the roller, a material outlet is connected with a right side of the roller, a hot blast stove is connected with the right side of the roller via an air guide pipe, two dust removers are connected with two sides of the roller and both connected with a variable frequency fan, a screening box is arranged right below the material outlet, a dust collection box is arranged at a left side of the screening box, and a material loading box is arranged at a right side of the screening box. By using the hot blast stove to blow air into the roller, a purpose of drying coffee beans is achieved and the hot air can also carry away dust, so that air in the roller circulates, the drying of the coffee beans is accelerated and a dust concentration within the roller is also reduced. The coffee bean automatic drying and screening device ensures a smooth operation of the roller, can also conduct the automatic screening after the drying is completed, reduces labor costs and improves a use value.

Owner:兰溪市奥而特农业科技有限公司

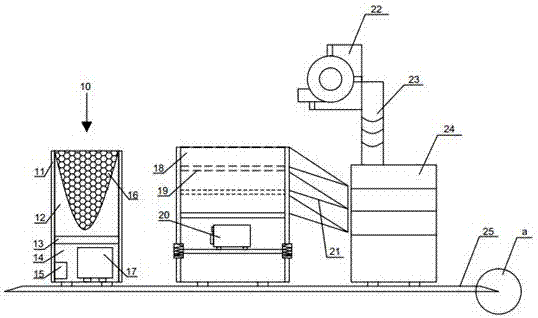

Efficient dryer facilitating fertilizer forming

InactiveCN107677070ADry fastAvoid cloggingSievingManure dryingFrequency conversionAgricultural engineering

The invention provides an efficient dryer facilitating fertilizer forming. The efficient dryer facilitating fertilizer forming comprises an obliquely arranged roller, a transmission mechanism connected with the outer surface of the roller and a bracket part. A feeding port is connected with the left side of the roller, a discharging port is connected with the right side of the roller, a hot blastheater is connected with the right side of the roller through a wind guide pipe, and dust removers are connected with the two sides of the roller; and the dust removers are both connected with a frequency conversion fan, a screening box is arranged over the discharging port, a dust collecting box is arranged on the left side of the screening box, and a charging box is arranged on the right side ofthe screening box. According to the efficient dryer facilitating fertilizer forming, the drying effect is good, fertilizer drying is even, dust removing can be conducted in the drying process and after drying is conducted, the fertilizer quality is obviously improved, cooling screening can be integrally achieved after drying is completed, the labor cost is reduced, and the market prospect of thedryer is promoted.

Owner:浦江县元寿农业科技有限公司

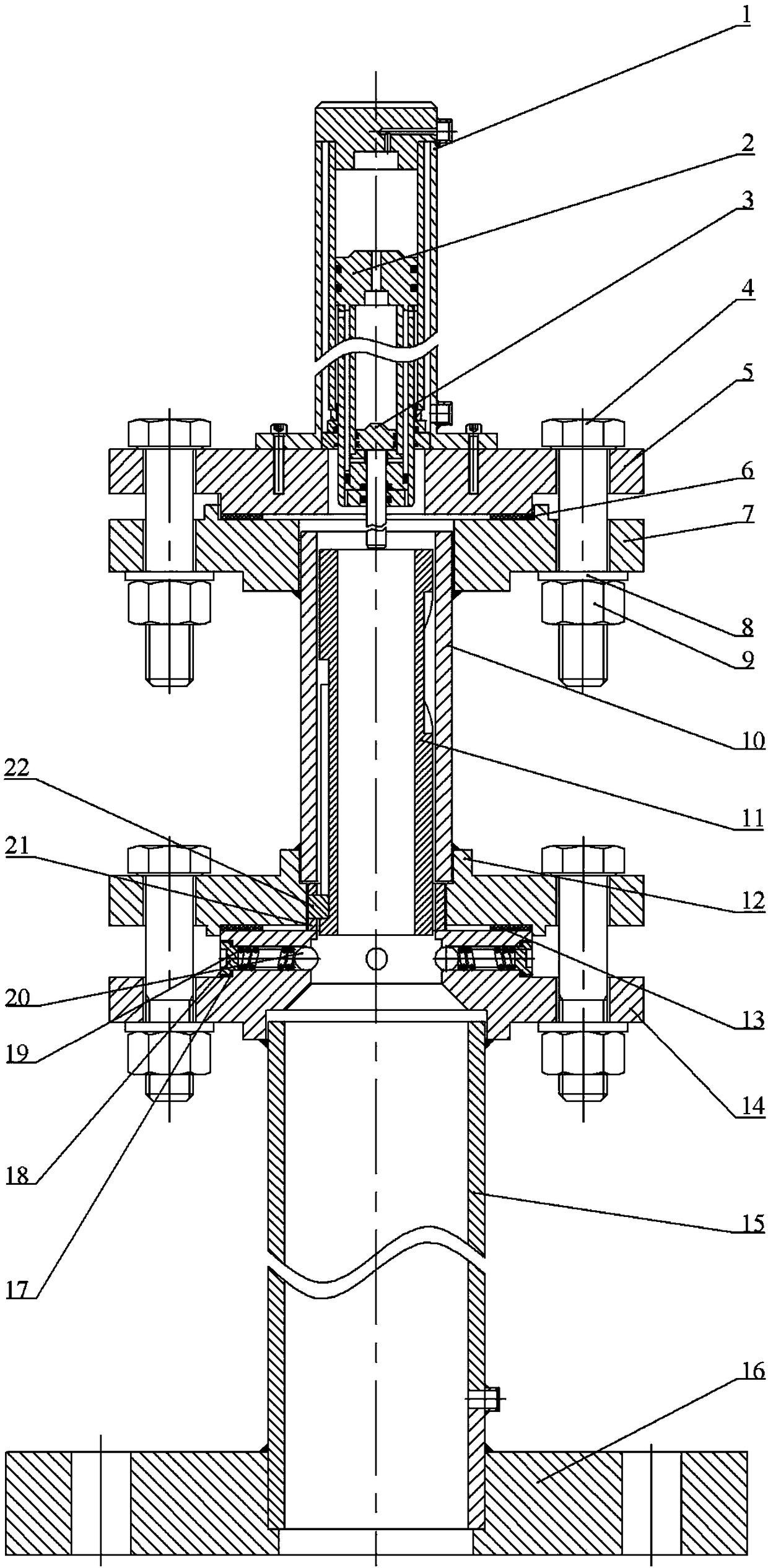

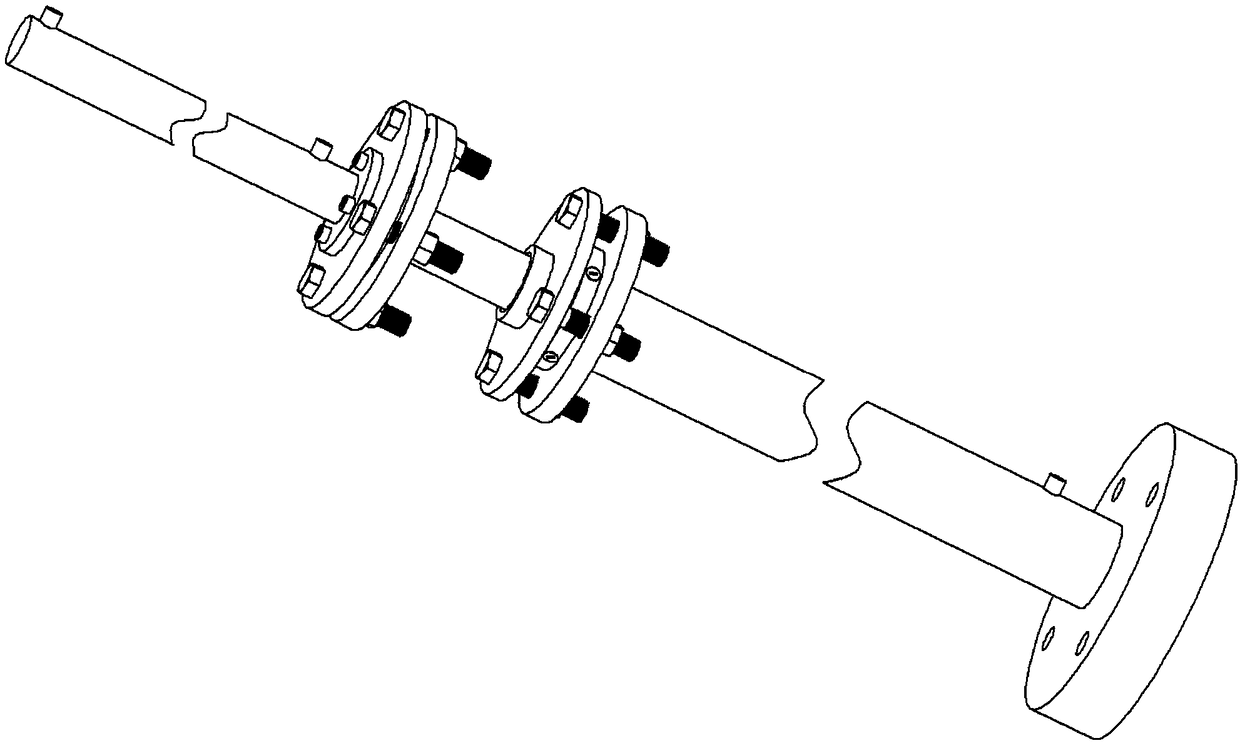

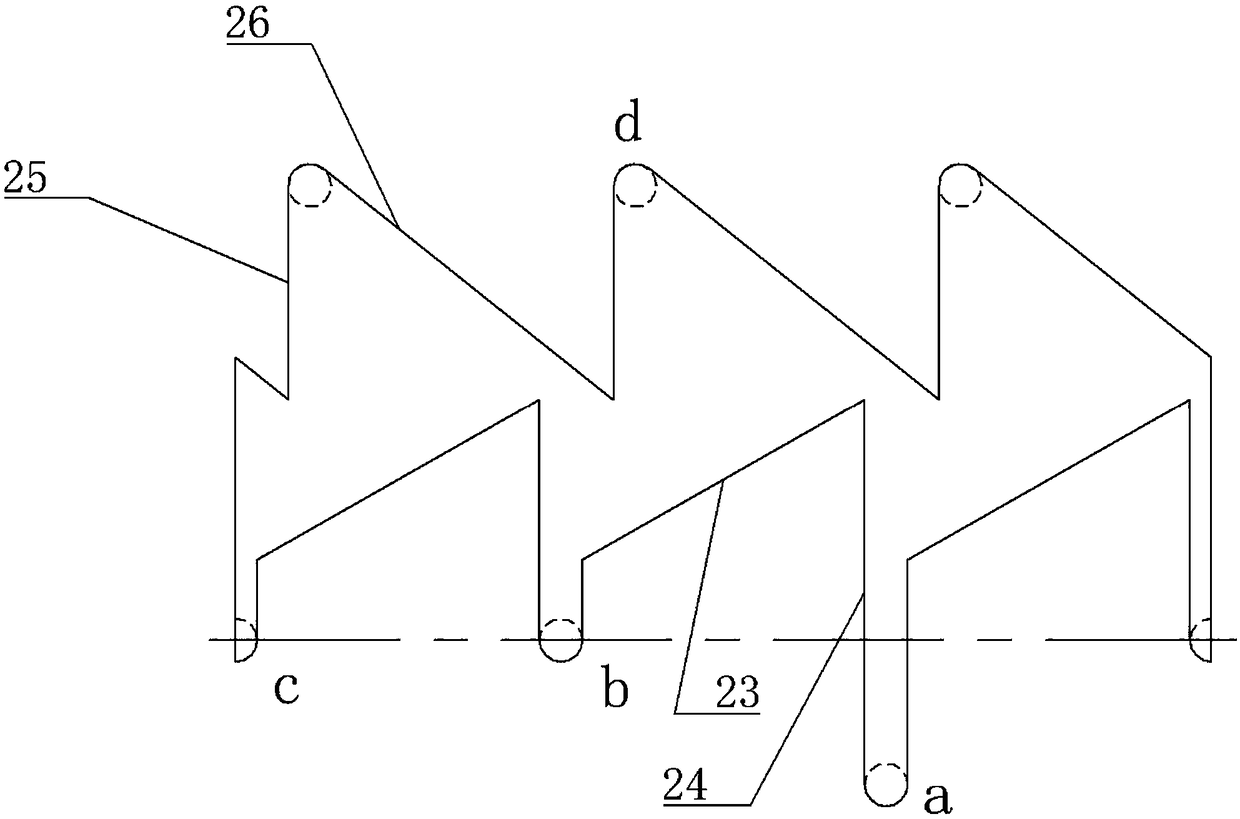

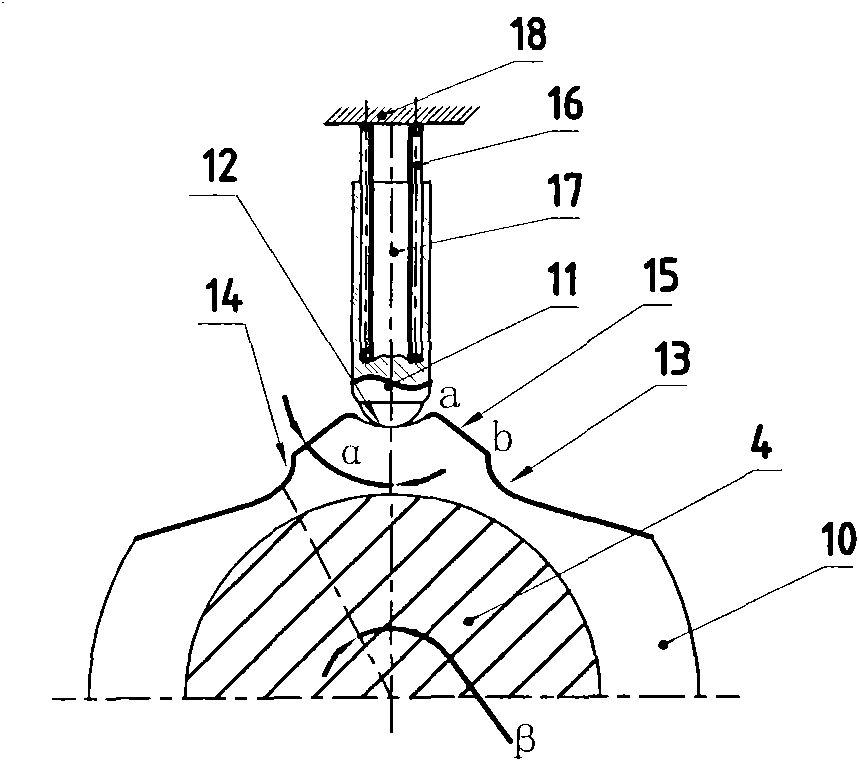

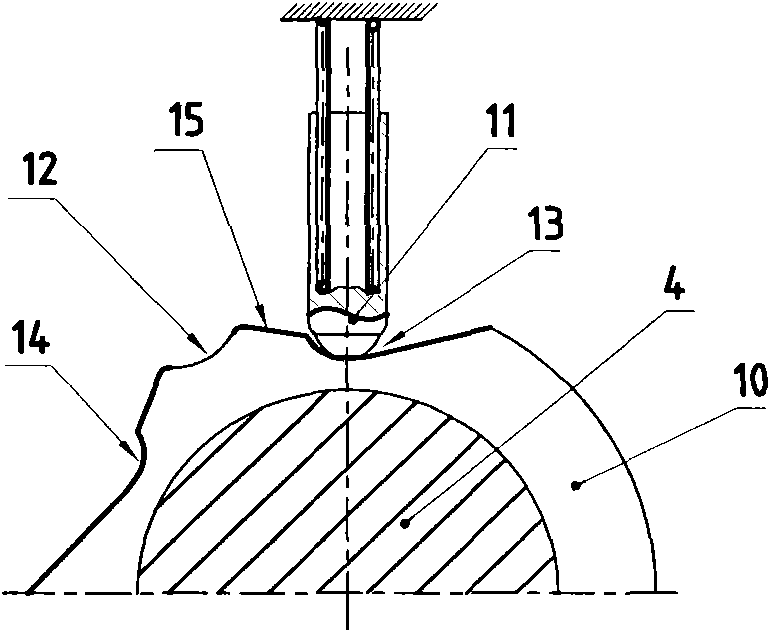

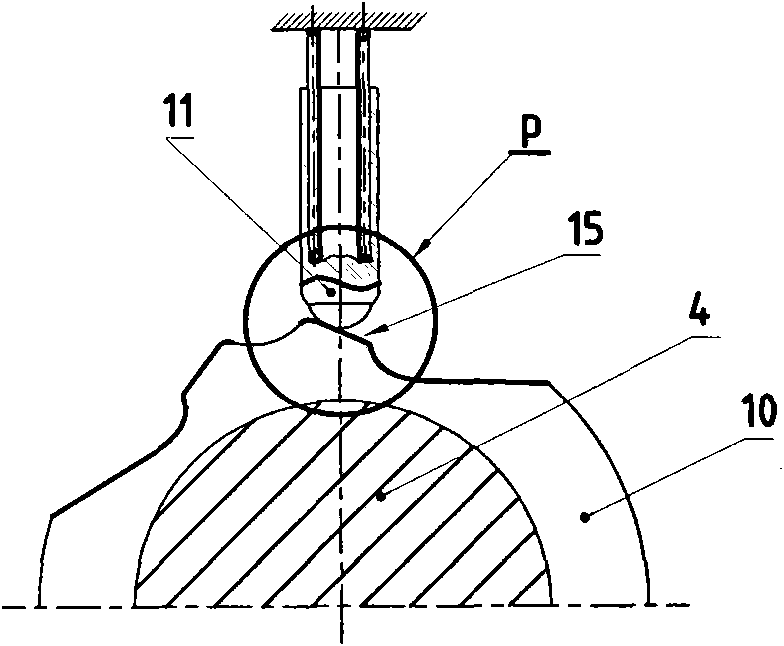

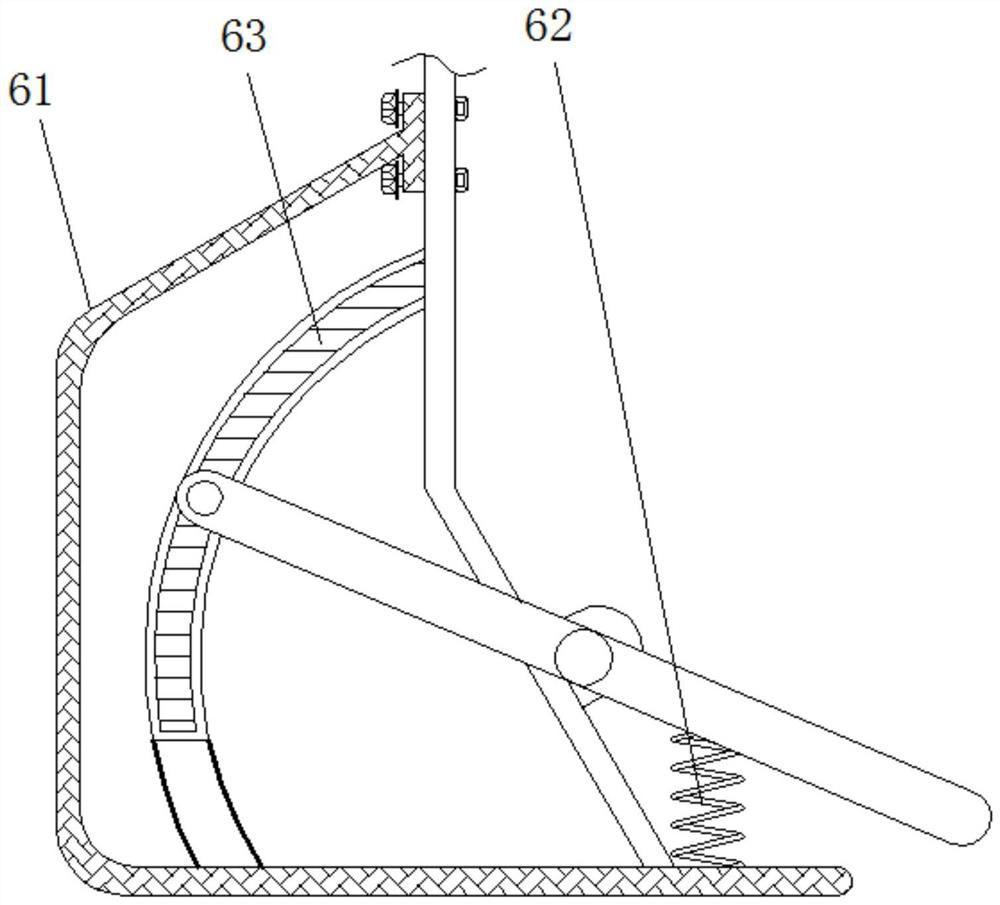

Rodless pump hydraulic wax remover wellhead putting and recycling device

The invention provides a rodless pump hydraulic wax remover wellhead putting and recycling device, and mainly aims at putting and recycling a rodless pump oil extraction well hydraulic and automatic wax removing device at a wellhead. The device is characterized by comprising the structures of an upper portion and a lower portion, the upper portion is a hydraulic cylinder, the lower portion is a wax remover recycling unit, and a telescopic hydraulic cylinder is used for pushing a hydraulic wax remover to move downwards; the hydraulic cylinder is connected with the remover recycling unit at thelower portion through a flange type cylinder, and the wax remover recycling unit is mainly composed of a retracting cylinder, a sliding pipe, a sliding ring, a spring pin and the like, wherein a railpin penetrates through the sliding ring and is placed in a sliding pipe rail, the unfolded structure of the sliding pipe is two rails with different lengths, under the effect of the hydraulic wax remover, the sliding pipe can move up and down, and the sliding ring is fixed to the primary retracting cylinder through a lower flange; a spring pin structure is composed of the lower flange, a steel ball, a compression spring, a sealing ring and a lateral bolt and is used for clamping the wax remover initially and after the third time of wax removing of the wax remover is finished.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for rapidly cultivating Bletilla striata seedlings under natural light

InactiveCN108651275AImprove stress resistanceEasy to operatePlant tissue cultureHorticulture methodsBletilla striataPhases of clinical research

The invention provides a method for rapidly cultivating Bletilla striata seedlings under natural light, and relates to the technical field of plant bioengineering. The method includes the following steps: (1) selecting mature capsules of Bletilla striata as explants; (2) inoculating the capsules on a germination medium after disinfection treatment, seeds turning to green after 7-10 days, and protocorms being formed after 40-50 days; (3) inoculating the protocorms on a subculture multiplication and differentiation medium to cultivate; and (4) cutting cluster buds off multiplicated and differentiated seedlings, performing subculture multiplication, inoculating seedlings whose plant heights are above 3 cm to seedling hardening and rooting mediums, and transplanting the seedlings when the seedlings grow to 5-7 cm. 1-5 g / L of self-made artemisia argyi dry leaf powder is added in subculture multiplication and rooting culture phases; the cultivation process of test tube seedlings is to cultivate the seedlings under outdoor natural light; and therefore, the stress resistance of tissue culture seedlings can be strengthened, production costs can be reduced, a large amount of sterile proliferating seedlings can be obtained, and the seedlings can be put into production one year in advance under artificially controlled conditions; and compared with traditional breeding methods, the method has a transplanting survival rate increased by about 30% and a production cost reduced by 20%, and is suitable for large scale production of seedlings.

Owner:YUNNAN DEHONG TROPICAL AGRI RES INST

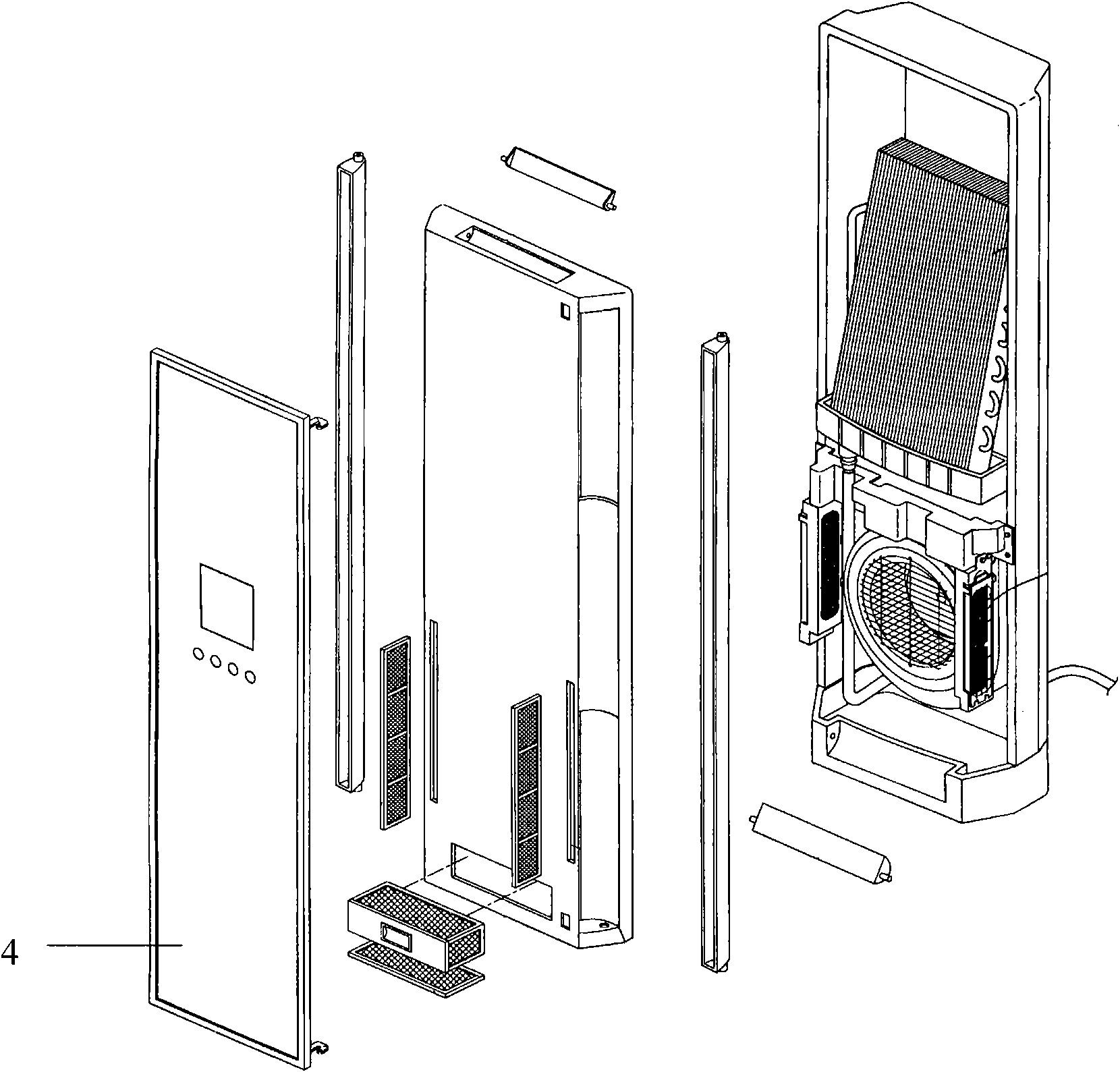

Cabinet air conditioner indoor unit with integrated side exhaust device

InactiveCN101660806ARealize wide-angle air supplyReduce the possibility of badLighting and heating apparatusAir conditioning systemsPulp and paper industryStepper

The invention provides a cabinet air conditioner indoor unit with an integrated side exhaust device. The air conditioner indoor unit comprises air outlets on panels on two sides of the cabinet unit and the exhaust devices at the air outlets connected with a driving device, wherein the air outlets on the two sides of the cabinet unit have a bias angle of 45 degrees corresponding to a front panel ofthe cabinet unit respectively; the exhaust devices of the air outlets on the two sides form an integrated exhaust part; and a rotating shaft of the part is connected with the driving device respectively. The cabinet air conditioner indoor unit with the integrated side exhaust device achieves the effect of effectively enlarging the exhaust scope and realizing the wide-angle air supply of an air conditioner. At the same time, sheet guide vanes and sliding doors are replaced by curved guide vanes, thereby effectively reducing the possibility of defects in the running of the air conditioner. Exhaust on the left side and the right side can be controlled individually to realize diversified air supply modes. Due to the single part which replaces the original guide vanes and sliding doors, the product cost is reduced, and the use and the installation of one to two stepper motors are saved. Therefore, the product function is strengthened; and the curved guide vanes make the product appearancefashionable and have strong visual impact.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

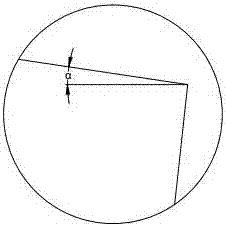

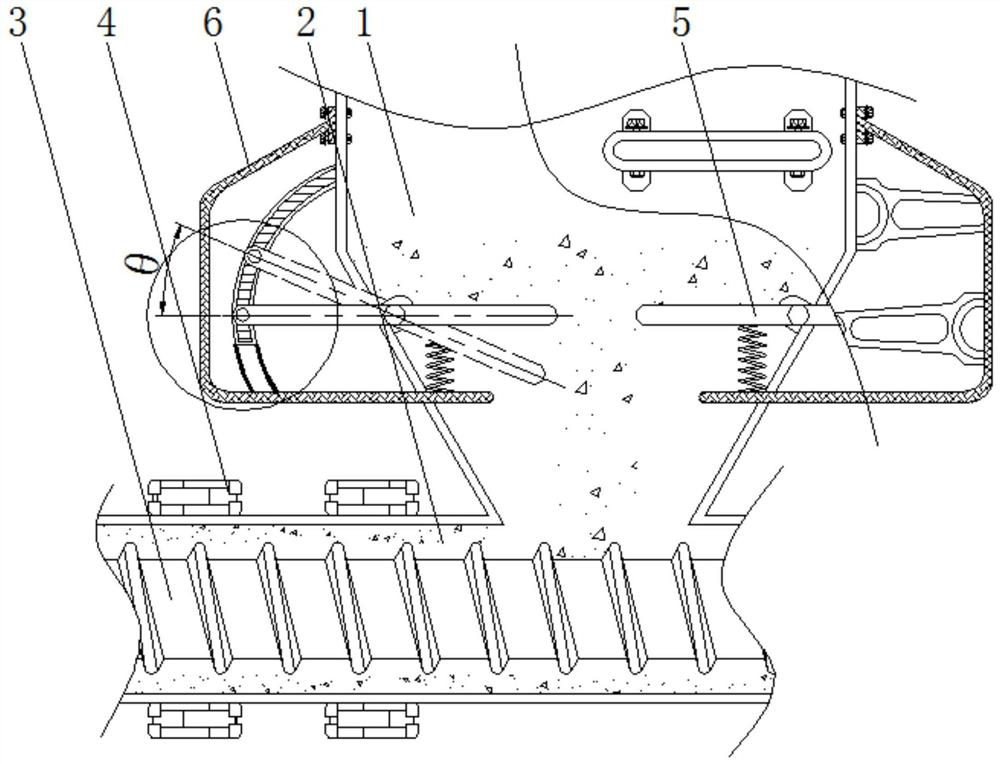

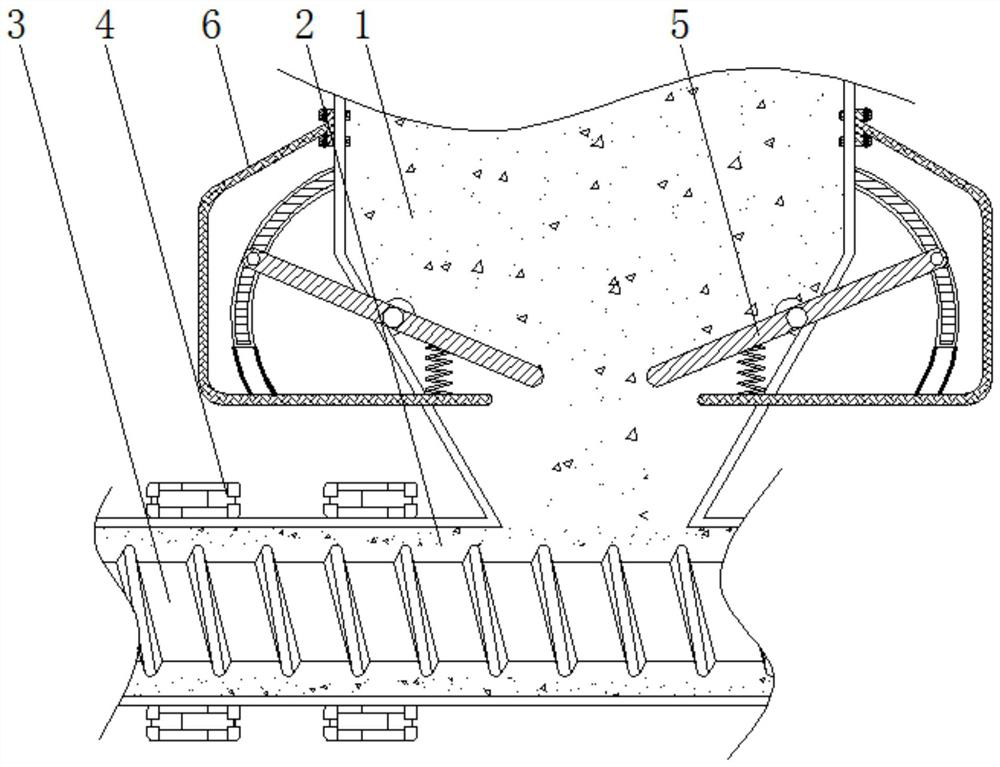

Gear shift assistor of vehicle

The invention relates to a gear shift assistor of a vehicle, which comprises a gear shift self-locking block and a spring self-locking pin, wherein the gear shift self-locking block is arranged on a gear shift shaft, the spring self-locking pin is used for locking the gear shift self-locking block, a gear shift travel section between a neutral-position arc-shaped groove and a forward engagement-position arc-shaped groove and a gear shift travel section between the neutral-position arc-shaped groove and a backward engagement-position arc-shaped groove on the gear shift self-locking block are both arranged into inclines, the distance between the starting points of the gear shift travel sections close to one end of the neutral-position arc-shaped groove and the centre of the circle of the gear shift shaft is greater than the distance between the terminal points of the gear shift travel sections and the centre of the circle of the gear shift shaft, and the included angle formed by the gear shift travel sections and a straight line between the center of the neutral-position arc-shaped groove and the axle center of the gear shift shaft is 40-65 degrees. By improving the structure of a self-locking mechanism of a gear shift position, the invention can realize the locking of the gear shift position, can also form gear shift assistance during gear shift, lightens the gear shift strain of a driver, meets the driving comfort and also lowers the production cost.

Owner:QIJIANG GEAR TRANSMISSION

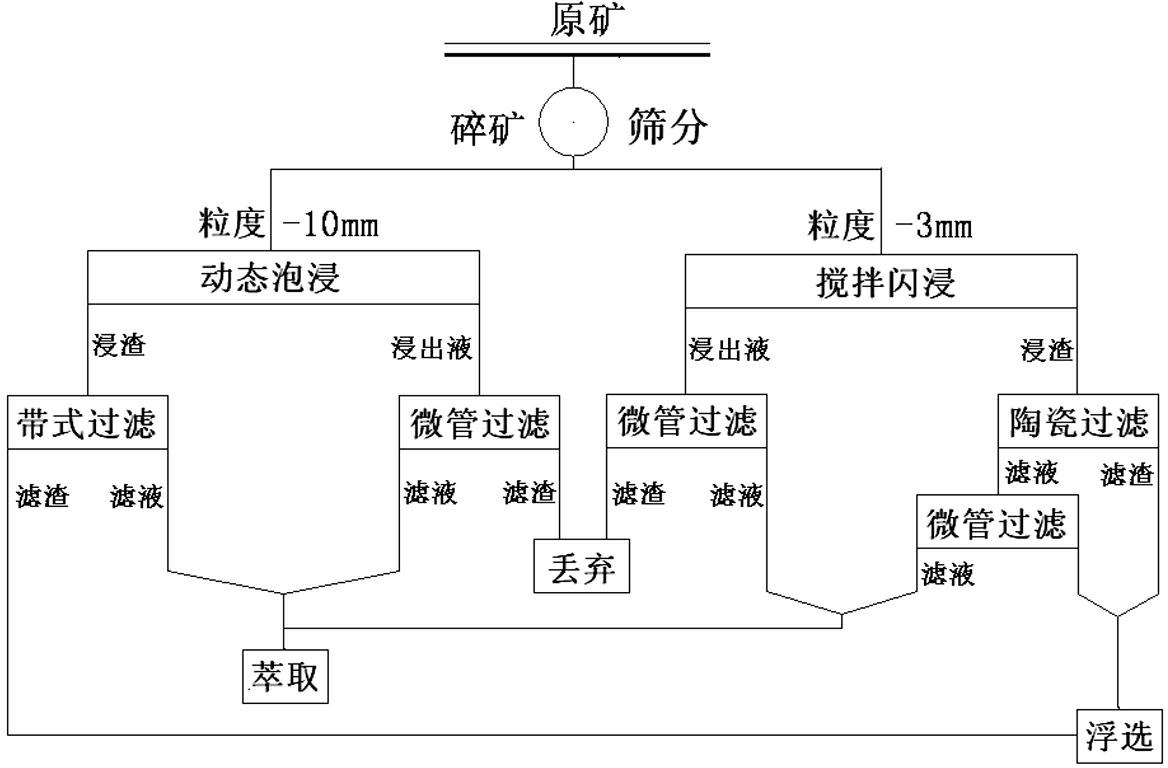

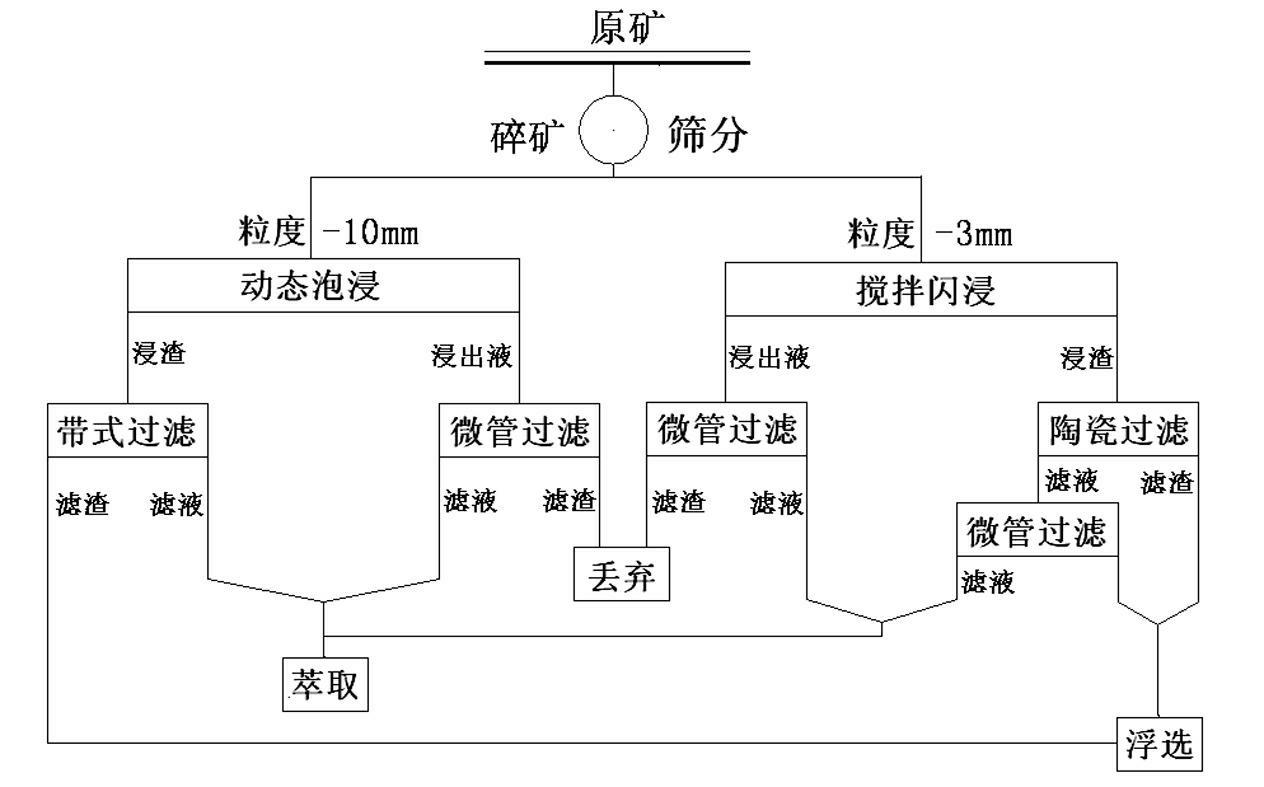

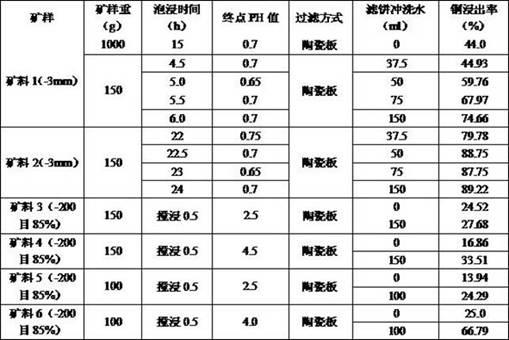

An energy-saving combined beneficiation process for high-oxidation, high-combined oxygen-sulfur mixed copper ore

ActiveCN102296174AReduce crushing costsHigh recovery rateSolid separationProcess efficiency improvementFiltrationCopper sulfide

Owner:云南楚雄矿冶有限公司

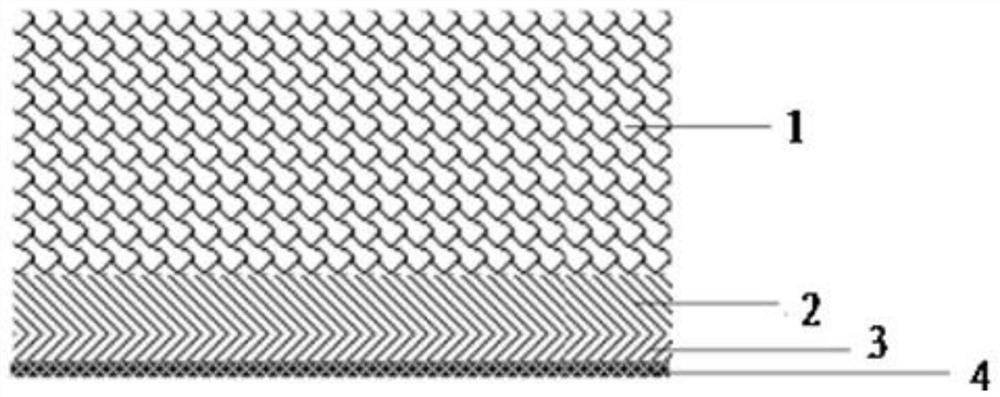

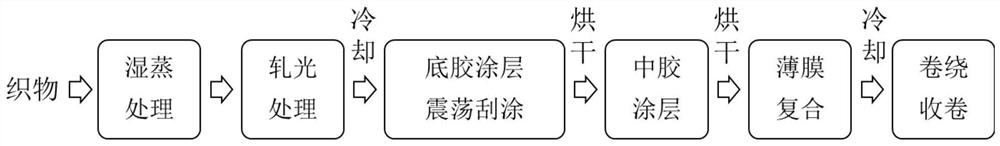

Technology for flame-retardant and water-proof coating of fabric

PendingCN111996809AAchieving Flame RetardancyAchieve waterproof effectTextile shapingCoated surfacePolymer science

The invention provides a technology for a flame-retardant and water-proof coating of a fabric. The technology comprises the following steps that the fabric is subjected to wet steaming first, and theto-be-coated surface of the fabric is polished and flatted by using a high-temperature metal smooth face to obtain a fabric with a flat and smooth reverse side; under the combined action of oscillation and blade coating, the reverse side of the fabric is coated with a primer coating adhesive to obtain a primer adhesive coated fabric; under the combined action of oscillation and blade coating, theprimer adhesive coated surface of the primer adhesive coated fabric is coated with a middle coating adhesive to obtain a primer-middle adhesive coated fabric; and a hot-melt elastic polyurethane filmand the coated surface of the coated fabric are subjected to hot pressing, adhesion and combination to obtain the flame-retardant and water-proof coating.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

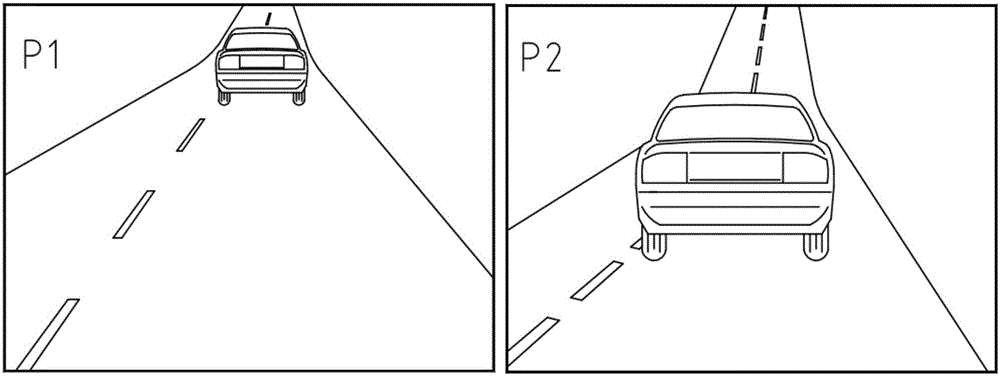

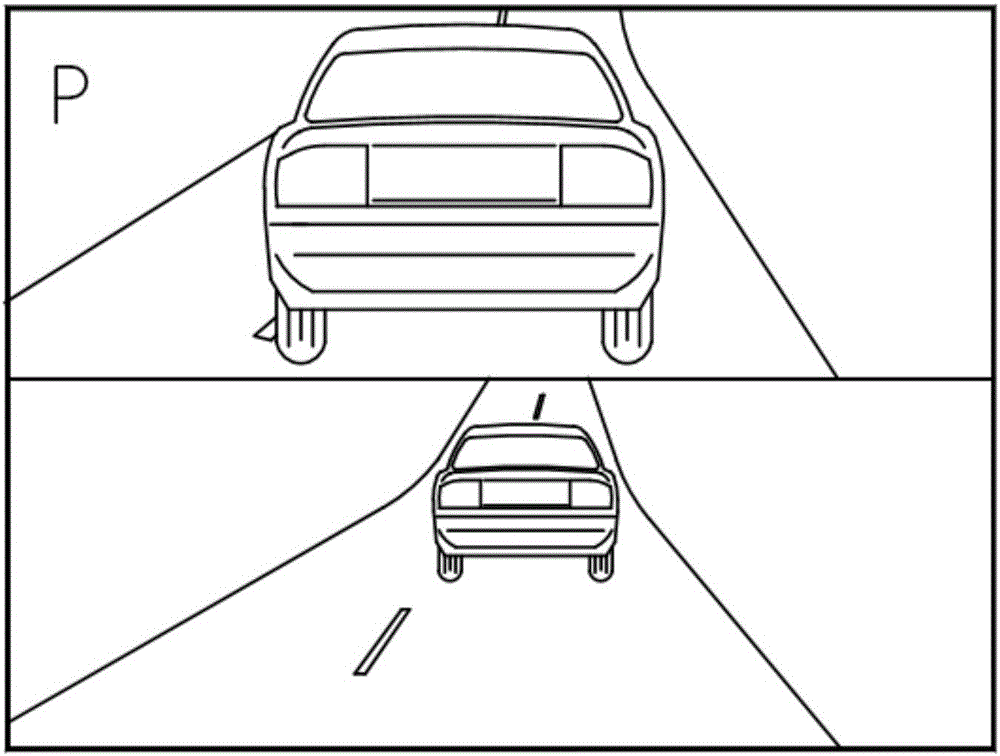

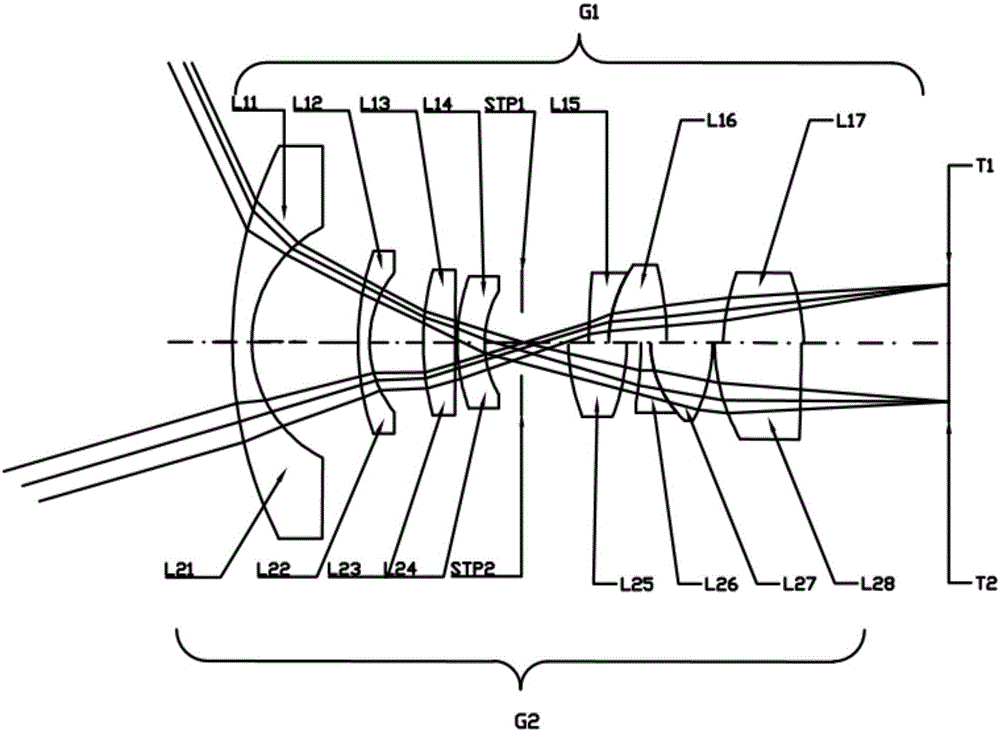

Optical system

PendingCN106791293AImprove yield rateReduce manufacturing costTelevision system detailsColor television detailsPhysicsOptical axis

The invention relates to an optical system comprising a first lens group G1 and a second lens group G2. Optical axes of the two lens groups are overlapped completely. The field angle of the first lens group G1 is smaller than 60 degrees; and the first lens group G2 of the second lens group G2 is larger than 90 degrees. All lenses of the front segment of the first lens group G1 and the front segment of the second lens group G2 are shared and all lenses of the rear segment of the first lens group G1 and the rear segment of the second lens group G2 are in semicircular shapes along the optical axis direction from the object space. The semicircular lenses, below the horizontal plane where the optical axis is located, of the lenses at the rear segment of the first lens group G1 are kept and the semicircular parts above the horizontal plane are removed completely; and the semicircular lenses, above the horizontal plane where the optical axis is located, of the lenses at the rear segment of the second lens group G2 are kept and the semicircular parts below the horizontal plane are removed completely. The semicircular lenses at the rear segments of the two lens groups are assembled into a same lens cone.

Owner:JIAXING ZHONGRUN OPTICAL TECH

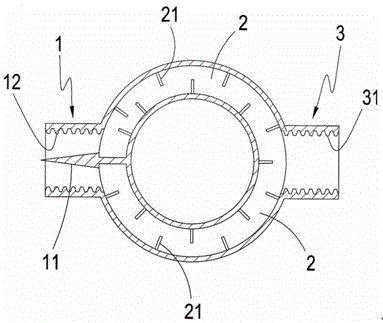

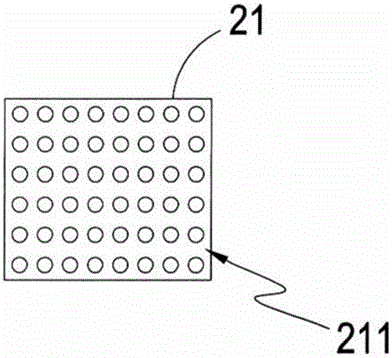

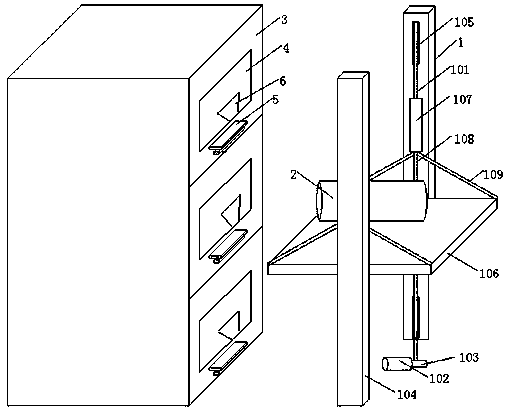

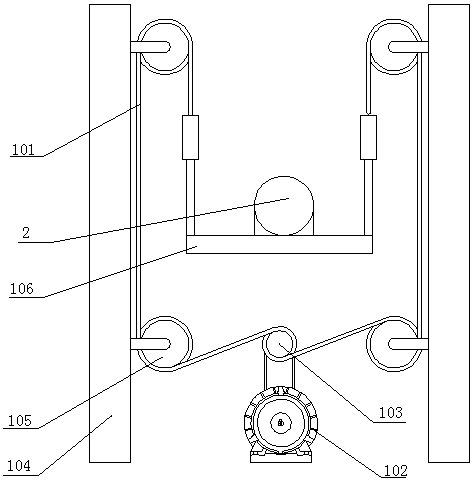

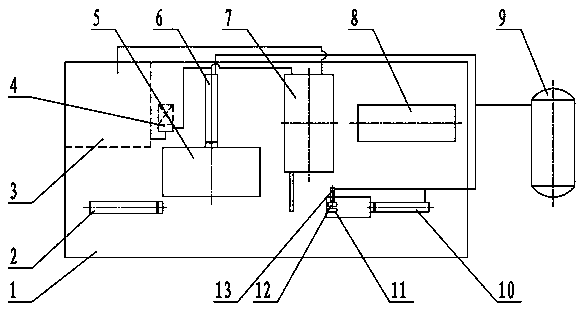

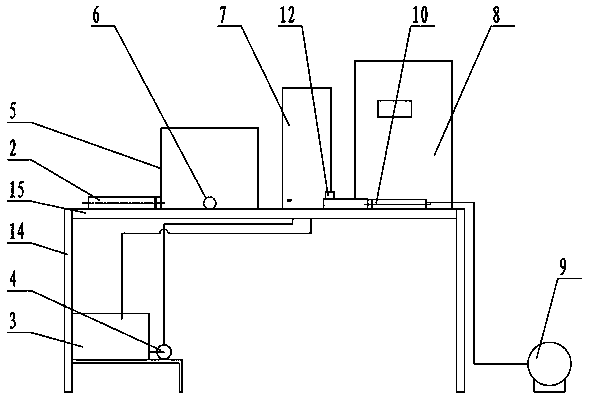

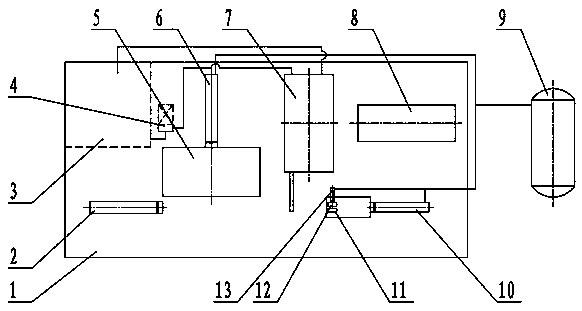

Automatic injection pipe production device

InactiveCN109703042ARealize automatic productionRealized production costNumerical controlCirculator pump

The invention belongs to the technical field of an injection pipe production device, and particularly relates to an automatic injection pipe production device. The device can achieve automatic injection pipe production through automatic feeding, and hot melting abut joint. The device comprises a worktable, and further comprises a high-frequency hot melt machine, a discharging feeding device, a pneumatic linkage device, a computer numerical control device, a cooling circular pump, a water tank and an air pump. The aim that according to the injection pipe production device, through automatic feeding and hot melting abut joint, injection pipe automatic production is achieved can be achieved.

Owner:山东新雪矿井降温科技有限公司

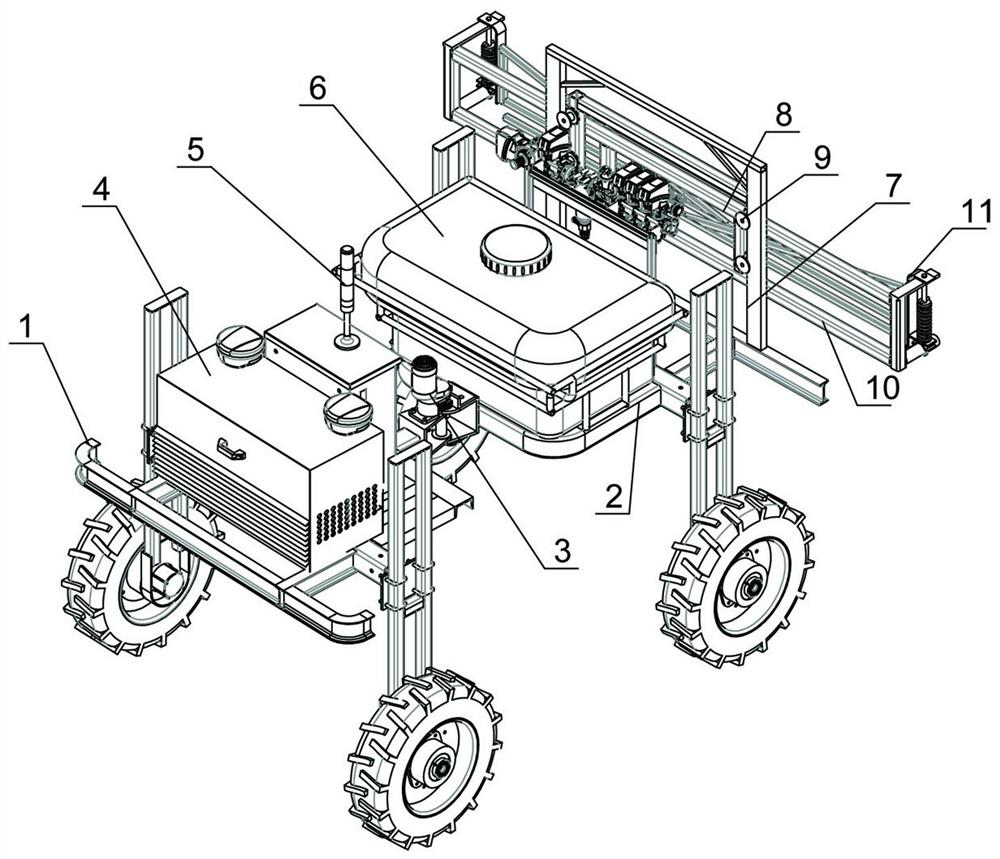

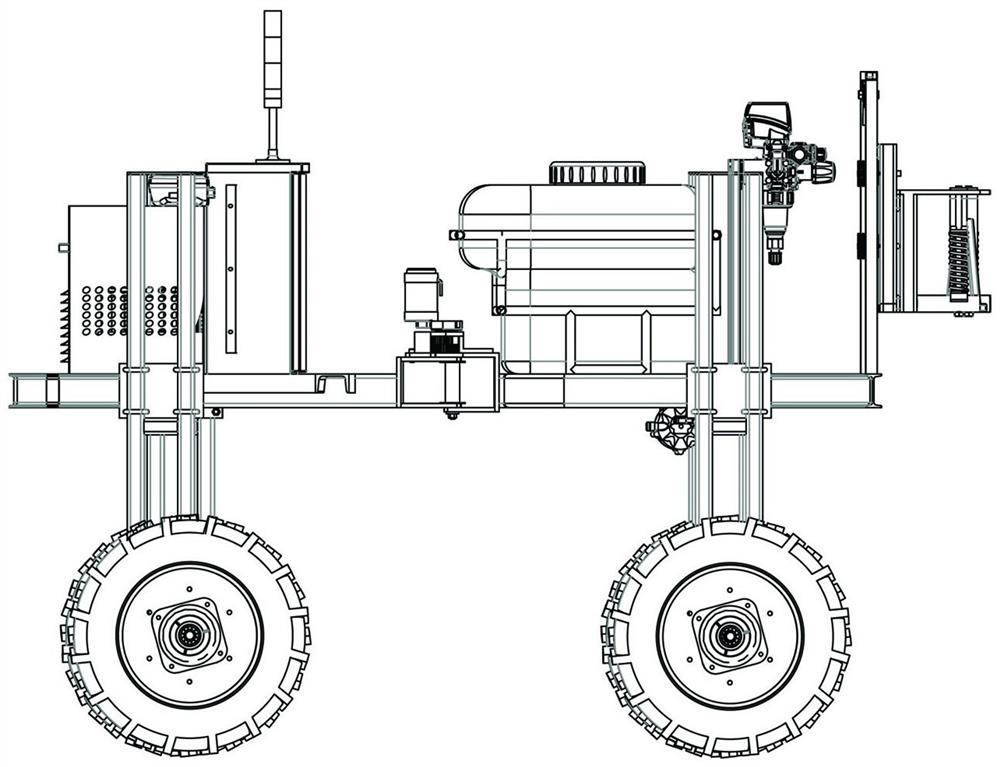

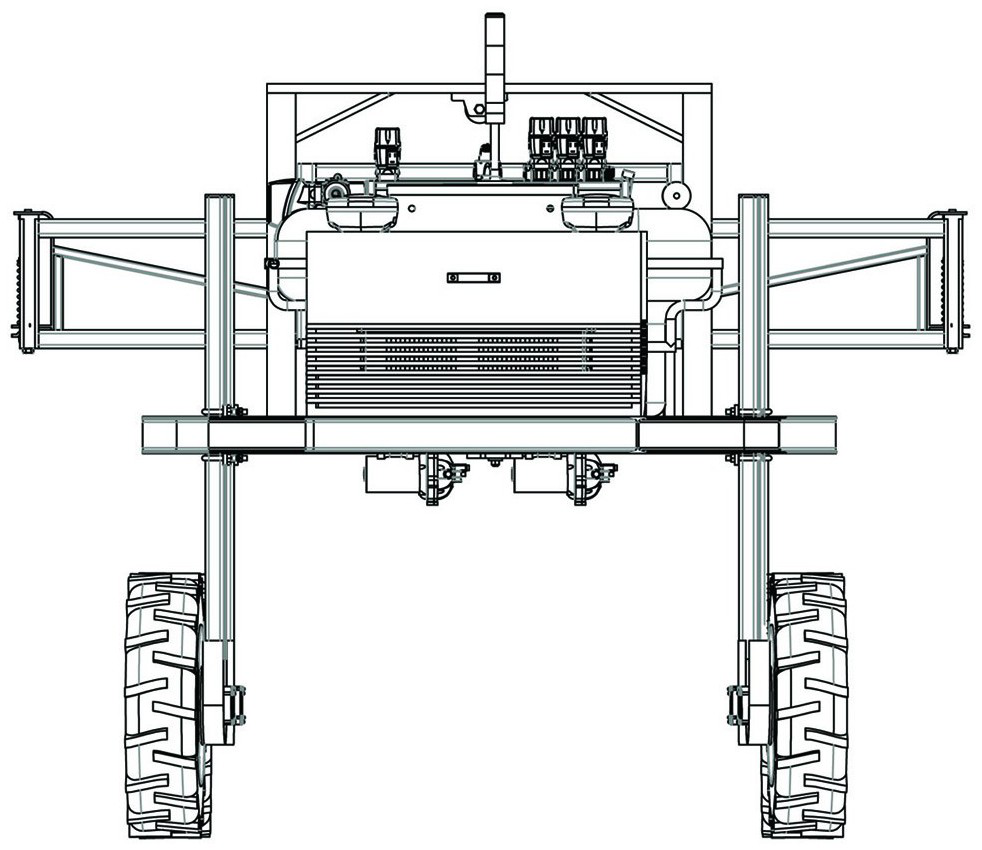

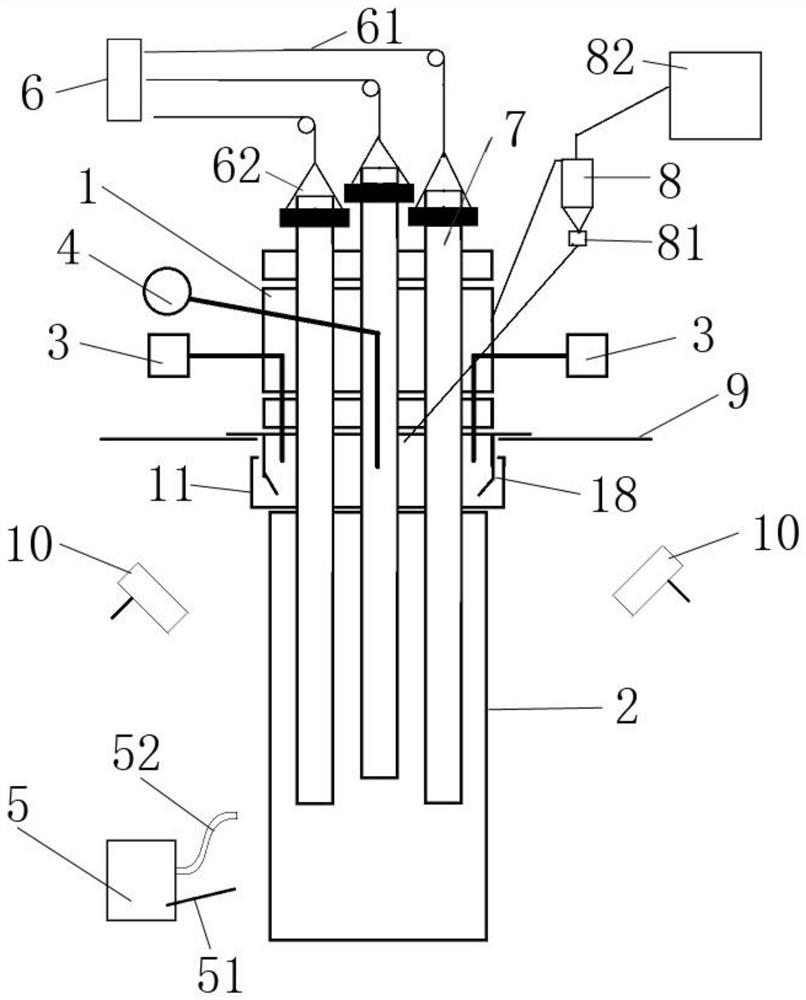

Intelligent driving electric plant protection operation vehicle with adjustable height and wheel track

PendingCN112471111AReduce land compactionImprove the level of intelligent controlUnderstructuresInsect catchers and killersVehicle framePesticide

The invention belongs to the technical field of agricultural machinery, and particularly relates to an intelligent driving electric plant protection operation vehicle with an adjustable height and wheel track. The vehicle comprises a front vehicle frame, a rear vehicle frame, a bowing steering mechanism, a wheel track adjusting mechanism, a height adjusting mechanism and a spray rod mechanism. A pesticide box, a diaphragm pump and a portal frame are mounted on the rear vehicle frame, and the wheel track adjusting mechanism is arranged between moving wheels and the vehicle frames. The height adjusting mechanism comprises a connecting seat, a U-shaped bolt and a wheel frame, and the spray rod mechanism comprises a lifting frame, side wheels, an electric push rod, a main spray rod and a sidespray rod. The side wheels are arranged on the two sides of the lifting frame, and the side wheels are embedded in rails on the two sides of the portal frame. The main spray rod is fixed to the lifting frame, the side spray rod is arranged on the main spray rod in a folded mode so that adaptive adjustment can be conducted according to the line spacing and the plant height of operation, the vehiclecan be suitable for plant protection whole-period spraying, universality is high, remote control is adopted in the control mode, and the intelligent degree of plant protection operation is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Submerged arc furnace equipment for producing macrocrystalline fused magnesite

ActiveCN112254526AReduce totalReduce power requirementsFurnace safety devicesFurnace typesMineralogyMining engineering

The invention provides submerged arc furnace equipment for producing macrocrystalline fused magnesite. The submerged arc furnace equipment for producing the macrocrystalline fused magnesite comprisesa submerged arc furnace cylinder, a furnace cover system, a material input system, a broken electrode conveying system and a dust removal and material return system, the furnace cover system is arranged at an upper opening of the submerged arc furnace cylinder, and the material input system and the broken electrode conveying system are arranged on the furnace cover system. The furnace cover systemis provided with a dust removal pipeline, the dust removal pipeline is connected with a dust removal and material return system, and the dust removal and material return system can collect coarse particles in dust and timely return the coarse particles into a submerged arc furnace to be used again. According to the submerged arc furnace equipment for producing the macrocrystalline fused magnesite, by reasonably designing the systems, the systems are organically combined and matched, so that the production efficiency of the submerged arc furnace is improved, an environment-friendly productionenvironment is realized, the labor intensity of workers is reduced, accidents are effectively prevented, automatic treatment is realized, and the production cost of a manufacturer is reduced.

Owner:岫岩满族自治县恒锐镁制品有限公司

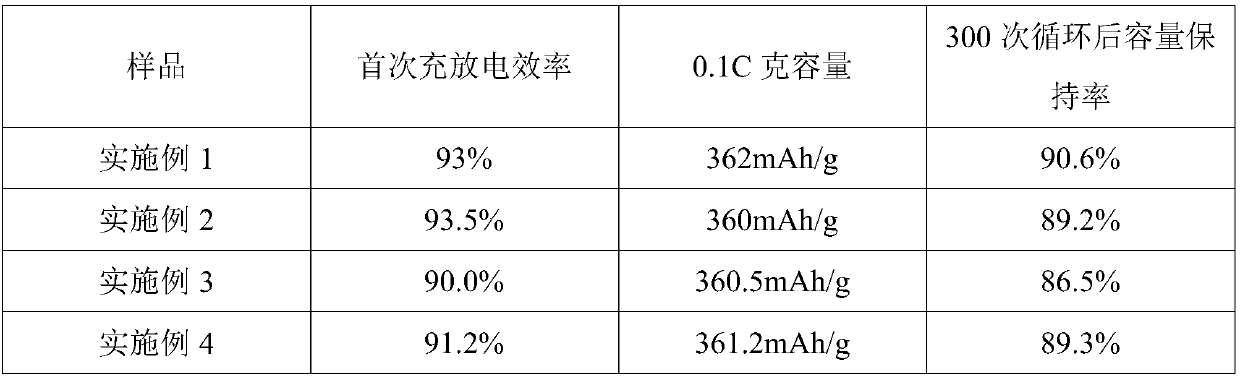

Composite graphite cathode material for high-capacity lithium ion battery, and its preparation method

The invention relates to a composite graphite cathode material for a lithium ion battery, and its preparation method, mainly relates to a composite graphite cathode material for a high-capacity lithium ion battery, and its preparation method, and belongs to the field of cathode materials for the lithium ion battery. The composite graphite cathode material for the high-capacity lithium ion battery is formed by blocky powder and spheroidic powder, and is characterized in that the specific surface area is 1.5-3.5m<2> / g, the average particle size is 7-30mum, the Raman ratio R is 0.1-0.3, and the interlamellar spacing of a crystal face (002) is 0.335-0.337nm. The composite graphite cathode material for the lithium ion battery has the advantages of excellent compact density, excellent gram specific capacity and excellent cycle stability, so the energy density per unit volume of the lithium ion battery is improved, and the electrical performances of the cathode material in the lithium ion battery are comprehensively improved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

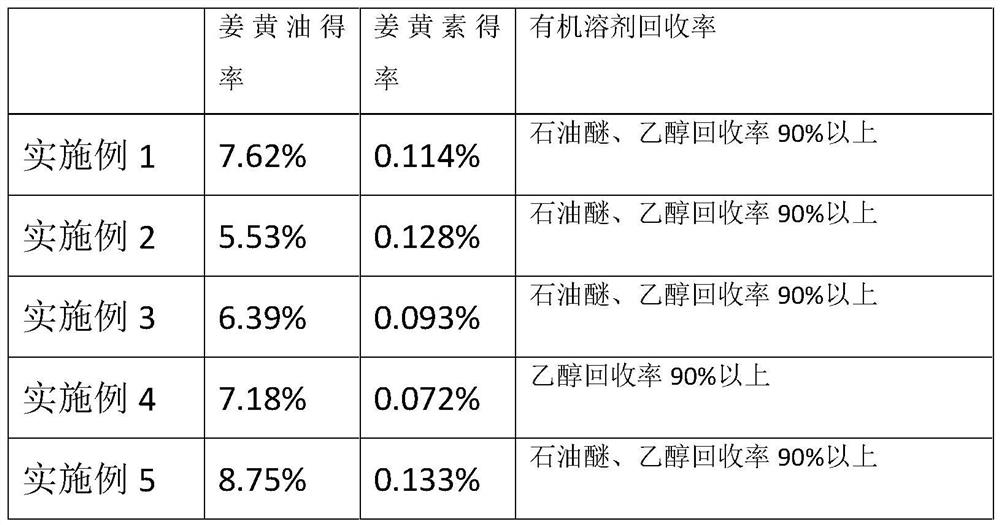

Method for continuously extracting curcuma oil and curcumin

PendingCN113501750ALow extraction rateHigh extraction rateFood ingredient as colourNatural extract food ingredientsMedicinal herbsBiochemical engineering

The invention discloses a method for continuously extracting curcuma oil and curcumin, the method comprises the following steps: 1) preparation of turmeric medicinal material powder: cleaning and drying a turmeric raw material, crushing, and sieving with a 60-mesh sieve to prepare the turmeric medicinal material powder with the water content of 6-10%; 2) extraction of curcuma oil: mixing and extracting the curcuma medicinal material powder and a first solvent to obtain a curcuma oil extracting solution and filter residues, wherein the filter residues are deoiled curcuma powder; (3) preparing turmeric extract: adding the deoiled turmeric powder and a second solvent into a continuous ultrasonic extraction device to obtain a curcumin extracting solution, and concentrating to remove the solvent to obtain the turmeric extract; 4) removing a surfactant: eluting the turmeric extract with distilled water to remove the surfactant; and 5) preparation of curcumin powder: drying the turmeric extract to obtain the curcumin powder. The method realizes continuous extraction of curcuma oil and curcumin, has a good extraction effect, and can realize large-scale industrial continuous production.

Owner:哈工大机器人南昌智能制造研究院

Plastic injection molding raw material melting device based on energy-saving and environment-friendly technology

The invention relates to the technical field of network engineering construction equipment, and discloses a plastic injection molding raw material melting device based on an energy-saving and environment-friendly technology. The device comprises a charging barrel and is characterized in that an ejecting pipe is arranged at the bottom of the charging barrel, a screw rod is arranged in the ejectingpipe, a heating block is arranged on the outer side of the ejecting pipe, and a baffle is hinged to the side surface inside the charging barrel. According to the plastic injection molding raw materialmelting device based on the energy-saving and environment-friendly technology, through cooperative use of the baffle and a variable resistance mechanism, when the quantity of raw materials is relatively large, the resistance is increased, the heat of the heating block is increased, more raw materials are heated, when the raw materials are few, the resistance is reduced, the heat of the heating block is reduced, and the effect of automatically adjusting the heating temperature according to the quantity of the raw materials is achieved, so that the raw materials can be evenly heated all the time, the percent of pass of finished products is increased, the production cost is reduced, enterprise benefits are increased, and the energy-saving and environment-friendly effects are achieved to a certain extent.

Owner:南京广庆网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com