Method of preparing graphene nanoplate size through nanometer-distribution collision stripping and graphene nanoplate size

A technology of graphene microflakes and graphene suspensions, applied in the direction of graphene, nano-carbon, etc., can solve the problems of reduced peeling efficiency and achieve the effects of increased collision probability, uniform particle size distribution, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0050] Take by weighing 150g tetrabutylammonium bicarbonate, and be dissolved in the 850g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant, after all dissolving, step The pretreated graphite is poured into an organic solution dissolved with a surfactant, stirred evenly and soaked for 1 hour to obtain a graphite dispersion;

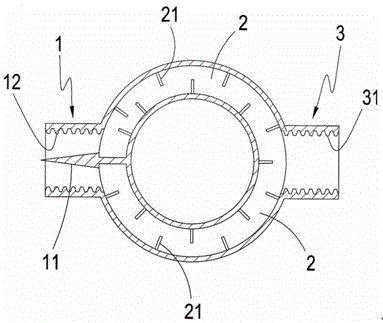

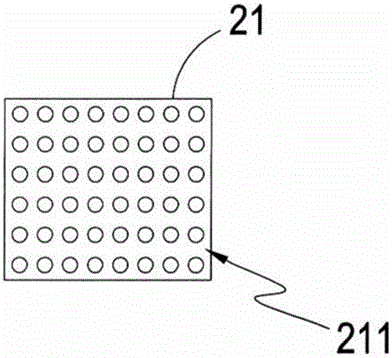

[0051] will step The graphite dispersion treated by intercalation is continuously injected into the nano-splitting and colliding homogenizer, and a certain pressure is set for the front cavity, so that the graphite dispersion passes through the nano-splitting and colliding homogenizer at a speed of 0.5m / s , the number of baffles is 20, the number of small holes on the baffle i...

Embodiment 2

[0057] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0058] Take by weighing 150g tetrabutylammonium bicarbonate, and be dissolved in the 850g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant, after all dissolving, step The pretreated graphite is poured into an organic solution dissolved with a surfactant, stirred evenly and soaked for 1 hour to obtain a graphite dispersion;

[0059] will step The graphite dispersion treated by intercalation is continuously injected into the nano-splitting and colliding homogenizer, and a certain pressure is set for the front cavity so that the graphite dispersion passes through the nano-splitting and colliding homogenizer at a speed of 2m / s. The number of baffles is 20, the number of small holes on the baffle is 40...

Embodiment 3

[0065] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0066] Take by weighing 150g tetrabutylammonium bicarbonate, and be dissolved in the 850g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant agent, after all dissolving, step The pretreated graphite is poured into an organic solution dissolved with a surfactant, stirred evenly and soaked for 1 hour to obtain a graphite dispersion;

[0067] will step The graphite dispersion treated by intercalation is continuously injected into the nano-splitting and colliding homogenizer, and a certain pressure is set for the front cavity so that the graphite dispersion passes through the nano-splitting and colliding homogenizer at a speed of 2m / s. The number of baffles is 40, the number of small holes on the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com