Laser shock peening method and device for outer intensified electric field

A technology of laser shock strengthening and external strengthening, which is applied in the field of intense pulse laser processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

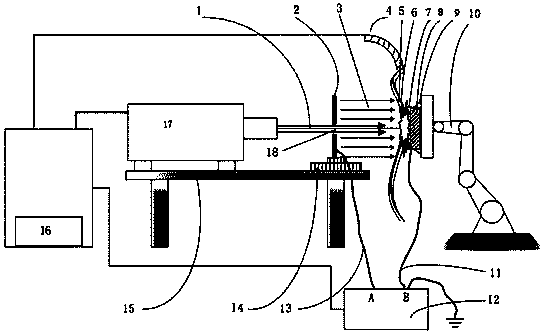

[0015] See attached figure 1 As shown, the laser shock peening device of the present invention with an externally strengthened electric field includes a high-power Q-switched laser shock peening power supply 16, a Q-switched high pulse energy laser 17, a high-voltage power supply 12, a 6-axis manipulator 10, a workbench 15, and a metal workpiece 8 to be strengthened. And the high-voltage electrode plate 2, the high-voltage end A of the high-voltage power supply 12 is connected to the electrode plate 2 through the wire II13, the electrode plate 2 is fixed on the workbench 15 through the first clamp 14 made of PTFE material, and the center of the electrode plate 2 is opened. Through the light hole 18 to ensure the passage of the laser light, a Q-switched high-pulse energy laser 17 is fixed on the workbench 15, and the automatic water spray device 4 sprays deionized water on the surface of the metal workpiece 8 to be strengthened as the constrained layer 5 of the laser shock treat...

Embodiment 2

[0028] See attached figure 1As shown, the laser shock peening device of the present invention with an externally strengthened electric field includes a high-power Q-switched laser shock peening power supply 16, a Q-switched high pulse energy laser 17, a high-voltage power supply 12, a 6-axis manipulator 10, a workbench 15, and a metal workpiece 8 to be strengthened. And the high-voltage electrode plate 2, the high-voltage end A of the high-voltage power supply 12 is connected to the electrode plate 2 through the wire II13, the electrode plate 2 is fixed on the workbench 15 through the first clamp 14 made of PTFE material, and the center of the electrode plate 2 is opened. Through the light hole 18 to ensure the passage of the laser light, a Q-switched high-pulse energy laser 17 is fixed on the workbench 15, and K9 optical glass with a thickness of 3 mm is used to cover the surface of the metal workpiece 8 to be strengthened in advance as the constraining layer 5 of the laser sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com