Oil-contained sewage treatment method and eddy energy fast-cyclone separating system of special equipment for method

A treatment method and sewage technology, applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as cumbersome installation, high investment costs, releaser blockage, etc., and achieve floc water content and specific gravity Effects of lowering, strong self-floating ability, and increased charge utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Treatment of emulsified oil sewage in a factory

[0040] Raw water situation: sewage flow 5m 3 / hr. Raw water emulsified oil 5,000~8,000mg / L, containing aluminum chips, aluminum ions, PH 8~9.

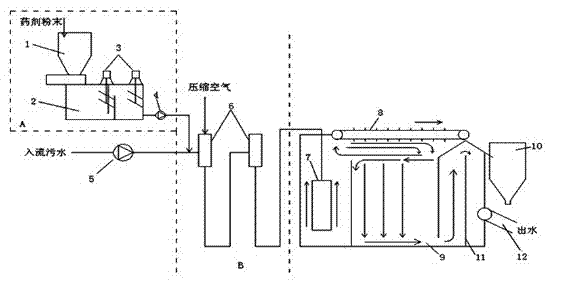

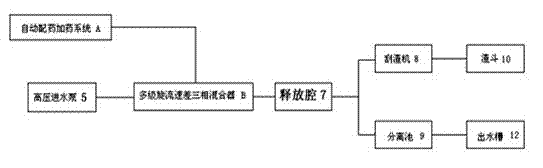

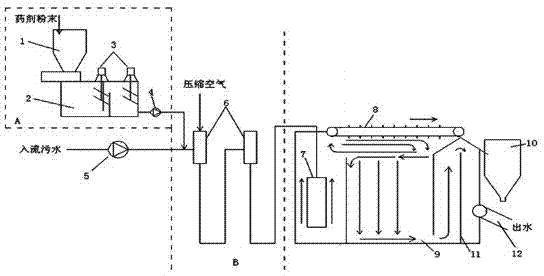

[0041] Such as figure 1 with figure 2 As shown, after quantitatively adding the medicament polyacrylamide powder into the mixing tank 2 through the hopper 1, turn on the mixer 3, and evenly stir with the tap water added quantitatively to form a solution with a certain concentration;

[0042] Use the high-pressure water inlet pump 5 to input the above-mentioned raw (sewage) water into the swirl speed difference three-phase mixer 6 to form a vortex, and then use the dosing metering pump 4 to enter the prepared medicine and compressed air into the swirl speed difference three-phase mixer 6 Dissolved in the influent wastewater, because the sewage forms multiple vortices in the three-phase mixer 6 with a swirl velocity difference, a sufficiently long streamline is generated, whic...

Embodiment 2

[0055] Pretreatment of kitchen waste water in an airport, with a flow rate of 20m 3 / hr

[0056] Raw water condition: raw water BOD=3,000mg / L, COD=4,000-8,000mg / L, oil 1,500mg / L and basically emulsified oil, contains a lot of surfactant, TSS=2,500mg / L, PH=4~13

[0057] The original treatment process: the traditional air flotation is used for pretreatment.

[0058] Original process problem: Coagulation and demulsification often fail, and the oil content in the effluent seriously exceeds the standard, resulting in the failure of the subsequent biochemical system to operate normally. Oily sludge is difficult to deal with, and the foam is serious.

[0059] The treatment results of the vortex energy speed spin separator (Haines) of the present invention:

[0060] The removal rate of oil is as high as 98%, and the oil content in the effluent is only 20-30 mg / L, which greatly saves the area occupied. The generated sludge is less than 1 / 3 of the original system, and it is very eas...

Embodiment 3

[0063] Reinjection water treatment in an oilfield, flow rate 5m 3 / hr

[0064] Original treatment process: The reinjection water treatment station is divided into two levels. The first-stage process is: primary settling tank→secondary settling tank→boost buffer tank→coarse sand filter tank. After the first-stage treatment, the oil content in the effluent is 30mg / L, and the suspended matter is about 20mg / L; the effluent enters the second stage. The process, the secondary process is: primary settling tank → secondary settling tank → multimedia filter → walnut shell filter → external infusion water.

[0065] Original process problem: Since the oil field uses oil from the ternary zone, part of the oil in the reinjection water has been emulsified, and the emulsified oil cannot be removed by oil separation + filtration. Therefore, after the secondary treatment process, the effluent can only reach: suspended solids <30mg / L, oil <30mg / L, seriously exceeding the standard, and failing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com