Patents

Literature

61results about How to "Reduce specific gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

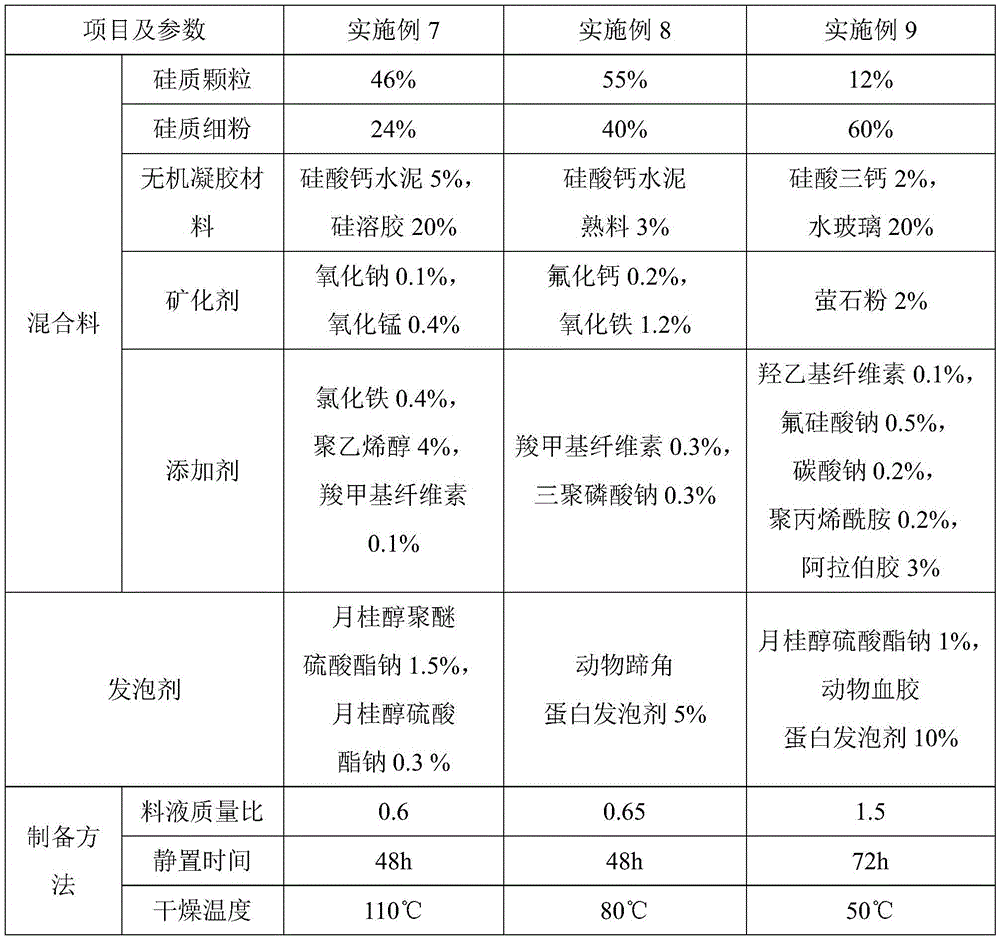

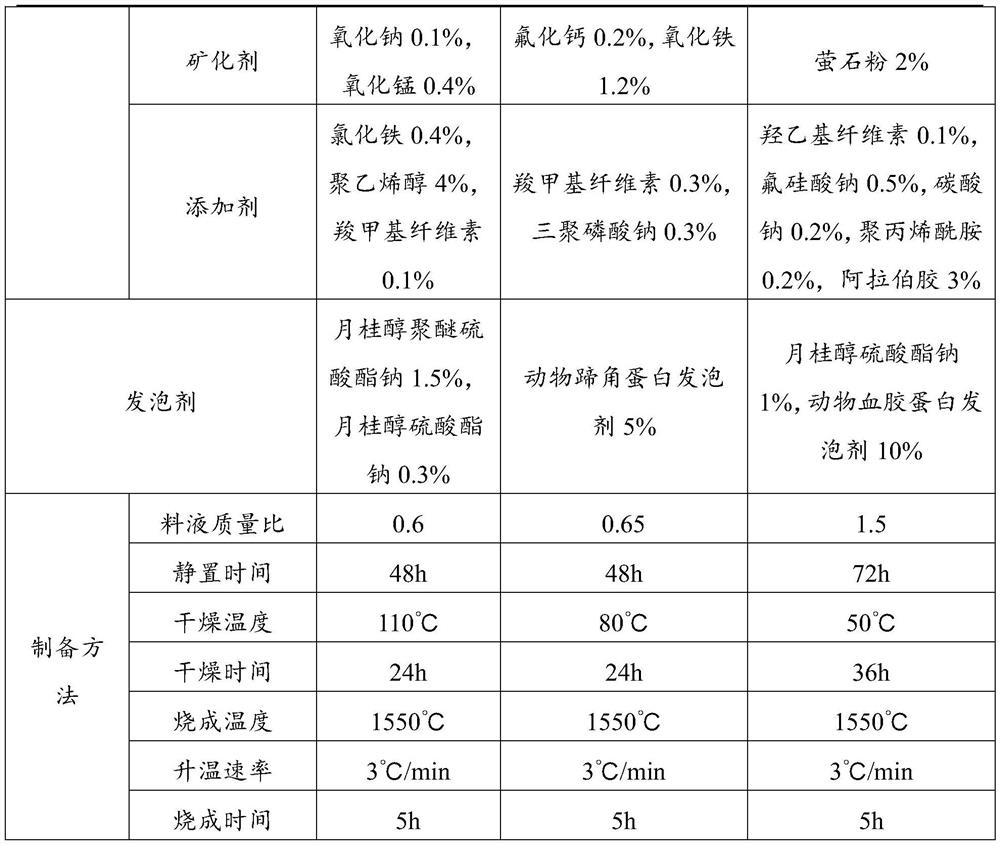

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

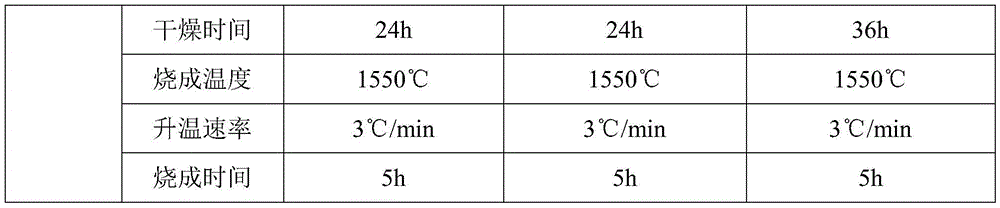

Super-light plastic formula for sports shoe soles

The invention discloses a super-light plastic formula for sports shoe soles, and the formula comprises the following components in parts by weight: 59-69 parts by weight of ethylene-vinyl acetate copolymer, 11-21 parts by weight of polyolefin elastomer, 5-15 parts by weight of metallocene polyethylene, 5-15 parts by weight of acidic ethylene copolymer, 6-8 parts by weight of talc powder, 0.7-1.0 part by weight of zinc oxide, 0.5-0.8 part by weight of stearic acid, 0.6-1.0 part by weight of zinc stearate, 0.5-0.8 part by weight of flowable agent A, 0.3-0.6 part by weight of accelerated bridging agent, 0.25-0.5 part by weight of bridging agent and 4.8-5.4 parts by weight of foaming agent. Plastic soles of sports shoes produced by the technical scheme have super-light performance and the comfort which are unmatched by the ordinary plastic formula, have durable comfort, durable damping performance and other performances and can greatly reduce the consumption of physical strength of athletes.

Owner:ANTA CHINA

A bipolar plate for conductive ceramics/graphite proton exchange membrane fuel cell and its manufacture method

InactiveCN1964113ALow priceReduce specific gravityFinal product manufactureCell electrodesFinenessMechanical properties of carbon nanotubes

The related preparation method for bipolar plate of proton exchange membrane fuel cell comprises: mixing 50-90vt% conductive ceramics and 10-50vt%graphite, hot pressing, and sintering. Wherein, the artificial graphite powder has purity over 97wt% and particle size less than 30 mum; while the conductive ceramics can be TiSiC, TiAlC, TiO2 or TiC every with purity over 95wt% and particle size less than 30 mum. This invention has well physical and chemical performances.

Owner:WUHAN UNIV OF TECH

Polyetheretherketone composite material for tridimensional orienting headstock and method for producing the same

InactiveCN101508821AReduce specific gravityImprove performanceDiagnosticsInstruments for stereotaxic surgeryFiberEpoxy

The invention discloses a polyether ether ketone composite used for a solid positioning head frame and a preparation method thereof. The polyether ether ketone composite comprises the components with the weight percentage as follows: 35-52 percent of inorganic filling, 3-5 percent of modifier, 25-35 percent of matrix resin and 20-25 percent of reinforcing fiber. The reinforcing fiber is arranged in epoxy acetone solution to be soaked, subjected to gamma ray irradiation treatment and is dried subsequently; the polyether ether ketone is arranged in oxygen, hydrogen or argon plasma atmosphere to be irradiated for 30 minutes and then is subjected to banburying with the modifier and the inorganic filling in proportion as above; a product and chopped carbon fiber are added into a double-screw extruder to be extruded and granulated; plastic granules are dried, injected and pressurized at constant temperature and then are molded into the solid positioning head frame. In the invention, the proportion for producing the raw materials is lightened and the performance of the polyether ether ketone composite in CT / MRI working environment is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

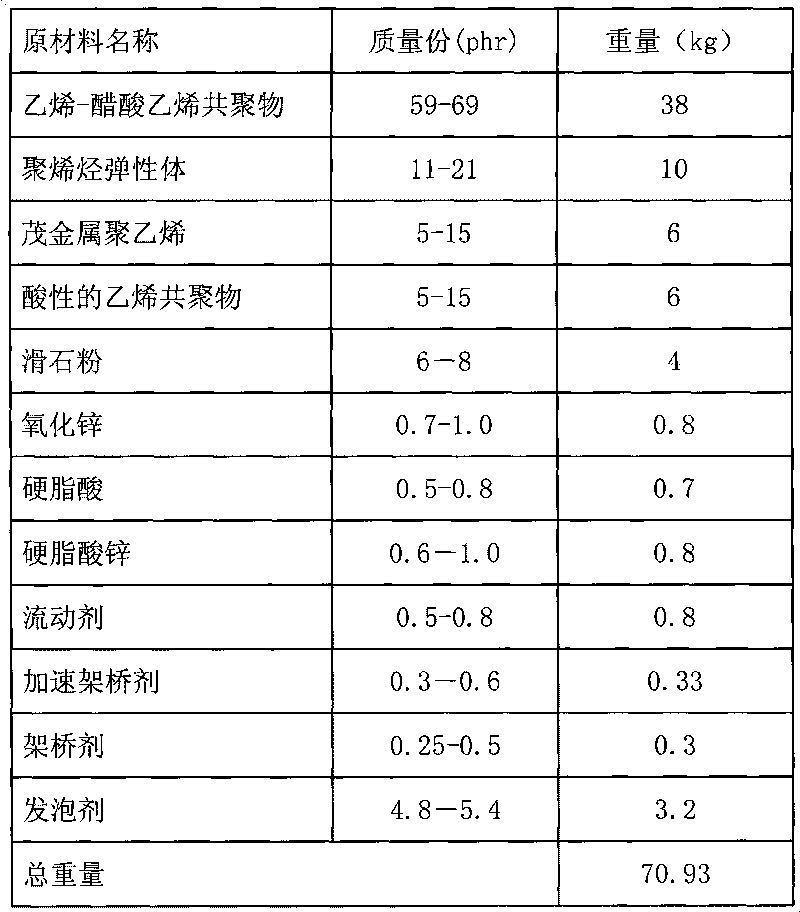

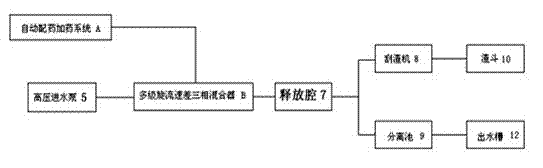

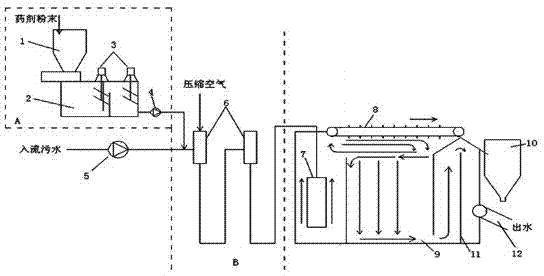

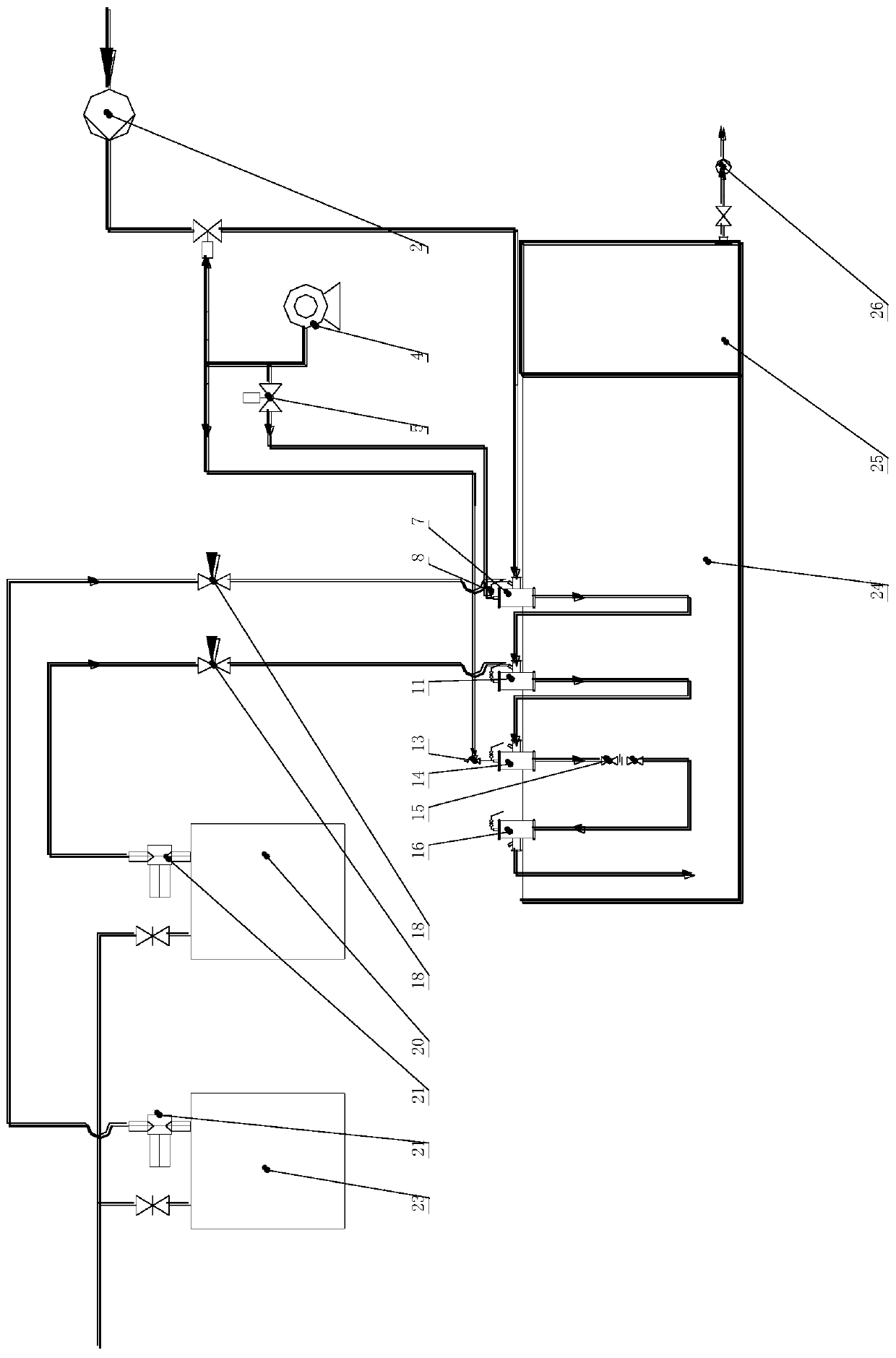

Oil-contained sewage treatment method and eddy energy fast-cyclone separating system of special equipment for method

ActiveCN102642884AIncrease profitIncreased chance of collisionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationCycloneSludge

The invention discloses an oil-contained sewage treatment method and an eddy energy fast-cyclone separating system (Haynes) of special equipment for the method. Oil-contained sewage enters a multilevel cyclone speed three-phase mixer together with a prepared reagent and compressed air, the multilevel three-phase mixer makes the reagent be adequately contacted with the contaminants to form micro floc and makes the compressed air enter a releasing cavity after being adequately dissolved in the sewage, the dissolved gas in the floc is slowing released in the releasing cavity as the pressure is reduced, so the moisture inside the floc is squeezed out, the gas and solid floc form a porous hollow shape, the moisture content is remarkably reduced, the specific gravity is lighter, finally the floc after forming the scum enters a separating tank, the scum is scraped by a scraping machine above the separating tank, the scraped scum is discharged by a connected hopper to be subsequently dehydrated, the separated water overflows to a water outlet groove through a water outlet weir plate to be discharged through a water outlet pipe. According to the oil-contained sewage treatment method and the separating system, advantages of good treatment effect, reagent conservation, less sludge, less investment, simpleness in control, low maintenance expense and the like can be realized.

Owner:上海齐国环境科技有限公司

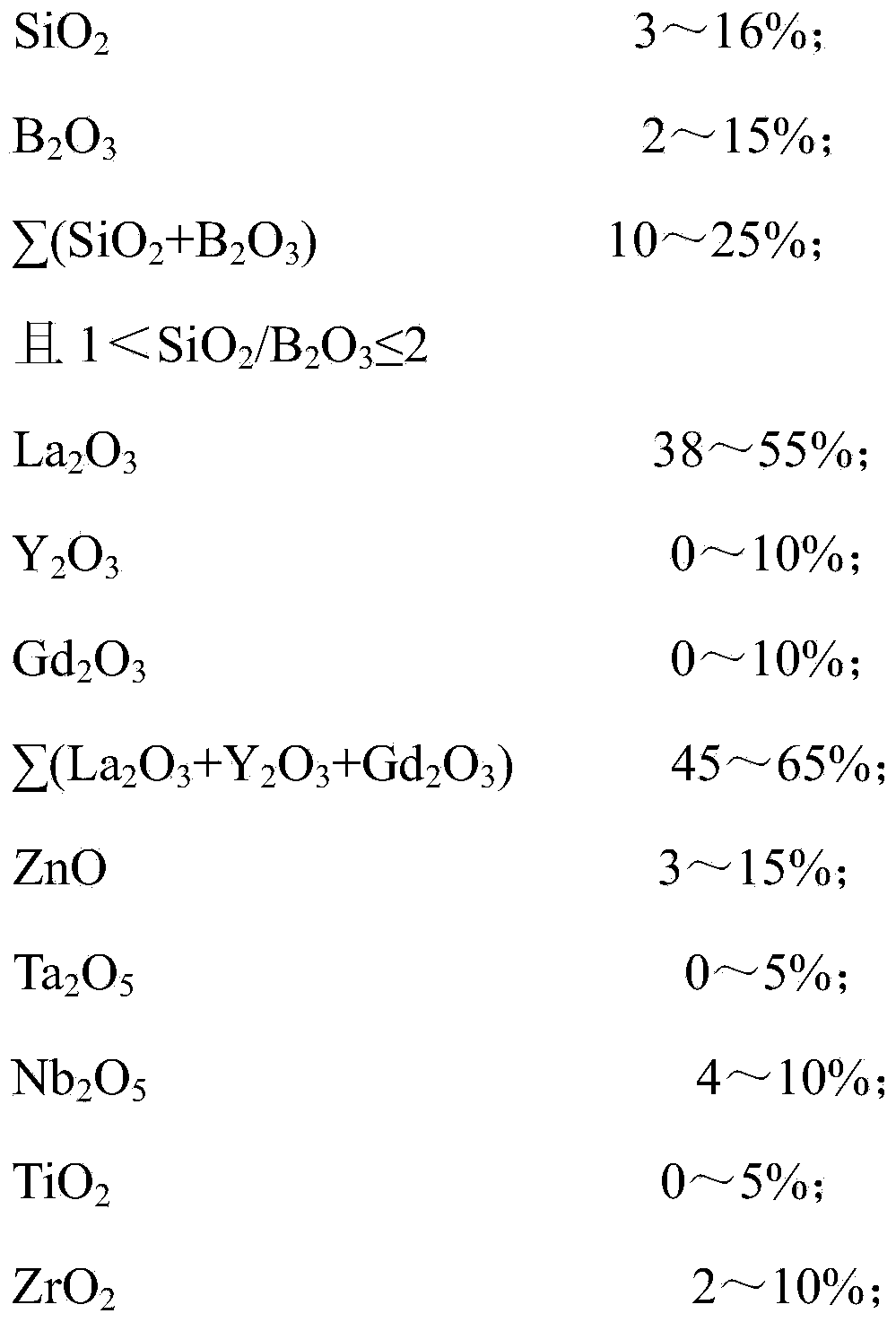

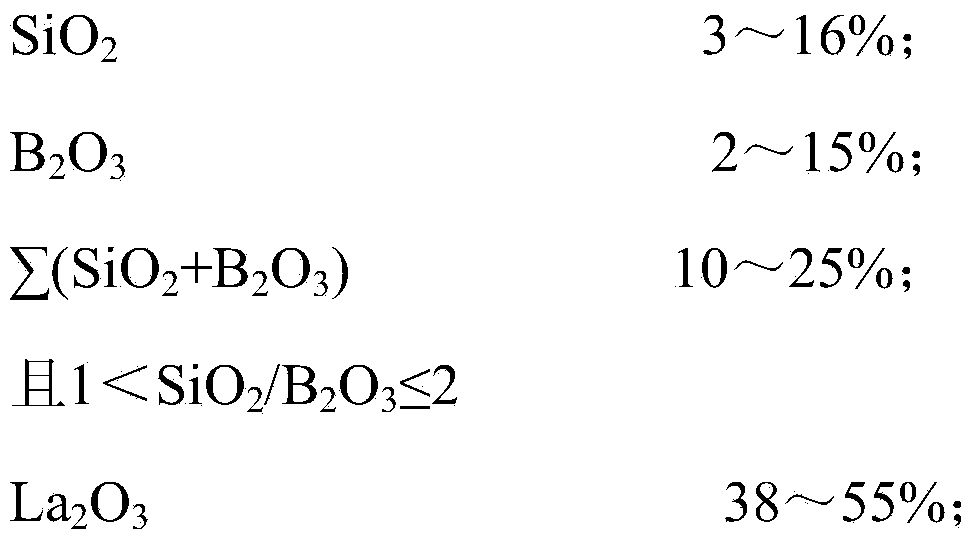

Optical glass and optical element

The invention provides optical glass and an optical element. The optical glass comprises following components by weight percent of oxides: 3-16% of SiO2, 2-15% of B2O3, 10-25% of sigma (SiO2 and B2O3), 38-55% of La2O3, 0-10% of Y2O3, 0-10% of Gd2O3, 45-65% of sigma (La2O3 and Y2O3 and Gd2O3), 3-15% of ZnO, 0-5% of Ta2O5, 4-10% of Nb2O5, 0-5% of TiO2, 2-10% of ZrO2, and 0-0.2% of Sb2O3, wherein SiO2 or B2O3 is greater than 1 and less than or equal to 2. The optical glass contains no oxides of alkali metal and alkaline-earth metal, such as Yb2O3, WO3, GeO2, TeO2, thorium, lead, arsenic, cadmium and mercury. The optical glass has the refractive index nd in 1.89-1.92, abbe number upsilon d in 36.5-39, specific gravity less than 5.10g / cm<3>, glass-transition temperature lower than 680DEG C, low devitrification tendency and high transmittance, the transmittance can reach over 70% in 390nm or shorter wave length, the devitrification temperature is lower than 1150DEG C, so that the optical glass is suitable for volume production and is mainly used in digital products, cameras, liquid crystal projection and the like. The optical element is made of the optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

All scrap baked brick

InactiveCN101666131AReduce pollutionLow densityBuilding componentsCeramic materials productionBrickPotassium

The invention discloses an all scrap baked brick and relates to the field of scrap brickmaking. The baked brick is prepared from the following raw materials by weight percent: 30-90% of river mud, 5-60% of sludge of the paper mill and 5-40% of cinder, wherein the used river mud is dried and baked river mud, the used cinder is purified and grinded cinder and the used sludge of the paper mill comprises the following components by weight percent: 40-80% of short vegetable fiber, 10-20% of nitrogen, 5-20% of phosphorus and 5-20% of potassium. The all scrap baked brick of the invention adopts rivermud, sludge of the paper mill and cinder as raw materials so as to greatly reduce the specific gravity of the brick product; the test shows that the density of the baked brick of the invention is reduced by about 15% compared with the clay solid brick and by about 20% compared with the brick prepared from pure sludge. The all scrap baked brick has good economic benefit and environmental value andprominent comprehensive benefit.

Owner:HAIYAN DABEIR NEW BUILDING MATERIALS

Cement-imitated wood and preparation method thereof

The invention discloses cement-imitated wood which comprises a substrate, an antioxidant layer, a decorative layer and an enamel layer, wherein the substrate comprises the following raw materials in parts by weight: 300-500 parts of coarse aggregates, 100-150 parts of fine aggregates, 300-400 parts of Portland cement, 20-40 parts of alumina ore, 50-100 parts of mineral slag, 50-100 parts of furnace slag, 15-30 parts of boiled slag, 40-90 parts of municipal wastes, 5-10 parts of expanded perlite, 30-50 parts of coal gangue, 20-30 parts of plant straws, 30-50 parts of coal ash, 30-35 parts of waste rubber powder, 8-15 parts of waste wood flour, 50-70 parts of fibers, 20-40 parts of titanium oxide, 2-5 parts of a water reducing agent, 5-9 parts of an accelerator, 6-12 parts of a de-foaming agent, 5-8 parts of an anti-rusting agent, 1-5 parts of an early strength agent, 4-9 parts of polyvinyl formal or polyvinyl acetate emulsion, 5-10 parts of borax, 15-25 parts of white sludge, 45-65 parts of tourmaline powder, 20-35 parts of silica sand, 20-25 parts of gypsum and 500-1000 parts of water.

Owner:祝莉玲

High-refractive index and low-dispersion heavy lanthanum flint optical glass

The invention relates to a high-refractive index and low-dispersion heavy lanthanum flint optical glass which is prepared from the following components in percentage by mass of oxides: 9.25-13.37 percent of B2O3, 5.48-7.34 percent of SiO2, 43.60-51.63 percent of La2O3, 3.53-9.12 percent of Y2O3, 4.18-10.23 percent of Gd2O3, 3.47-6.52 percent of Nb2O5, 3.47-6.62 percent of ZrO2, 0.81-1.50 percent of WO3, 3.96-6.95 percent of TiO2, 3.28-6.79 percent of ZnO and 0.61-1.52 percent of Al2O3; and in the composition, the following conditions are also met: B / Si is larger than 1.33 and smaller than 2.54 (by mass percentage), a sum of the mass percentages of La2O3, Y2O3 and Gd2O3 is 58.61-60.32 percent, and a sum of the mass percentages of WO3 and TiO2 is 4.85-8.34 percent. The optical glass does not contain Ta2O3 with high cost to facilitate reduction of the cost of the glass, does not contain alkali metals, alkaline-earth metals and toxic components including Pb, As and Cd either, has the refractive index nd being 1.883-1.915 and an abbe number vd being 35.65-38.32, is excellent in crystallization resistance and is suitable for batch production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Active iron carbon catalyst for treating industrial wastewater

ActiveCN107349933AHigh activityLow costWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsOxygenTitanium alloy

The invention discloses an active iron carbon catalyst for treating industrial wastewater. The active iron carbon catalyst is prepared from 40 wt%-60 wt% of iron-titanium alloy powder, 20 wt%-40 wt% of active fiber carbon powder, 5 wt%-10 wt% of bauxite, 3 wt%-5 wt% of Guangdong black clay, 3 wt%-5 wt% of Pingxiang white clay, 1 wt%-2 wt% of tin oxide powder and 2%-3% of a pore forming agent. The active iron carbon catalyst is roasted at the high temperature, iron and carbon are fused together, the inside of the catalyst is of a honeycomb netty-hole structure, the catalyst has the high specific area and gap rate, it can be effectively avoided that the catalyst is hardened and passivated, wastewater is rapidly sucked through honeycomb netty holes inside the catalyst, the reacting efficiency is improved, micro currents are formed through the iron-carbon electric potential difference generated through microelectrolysis to excite industrial wastewater, and new ecological hydrogen and oxygen are generated; through the reducibility and the oxidability of hydrogen and oxygen, wastewater is subjected to a strong oxidation-reduction reaction, and therefore hardly degradable substances are converted into easily degradable substances.

Owner:杨昆

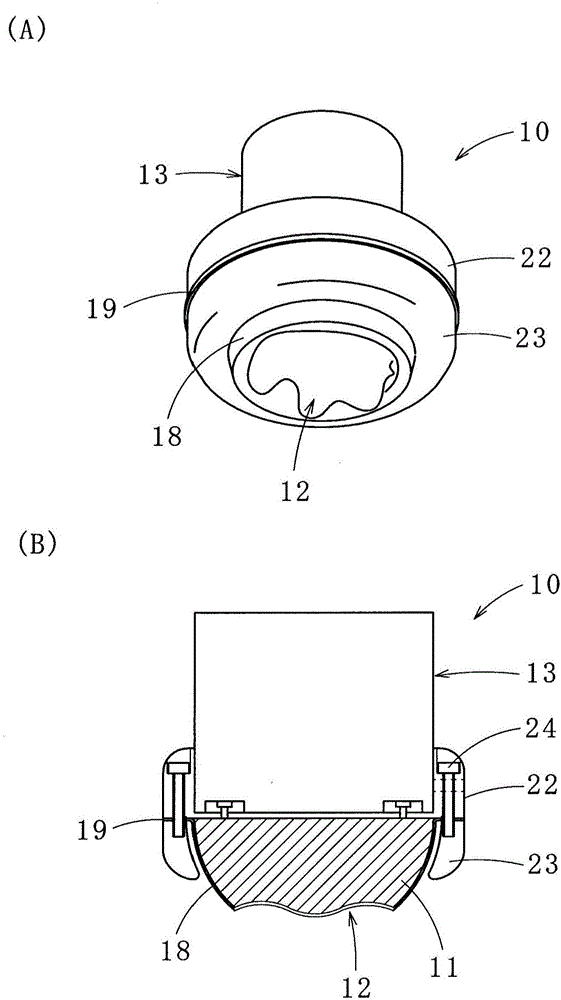

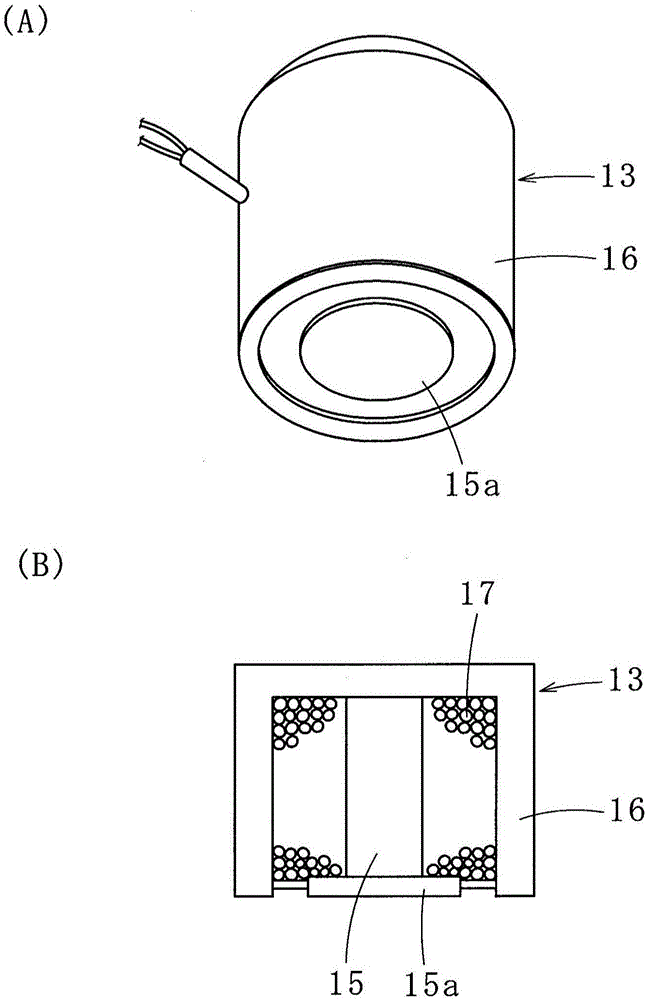

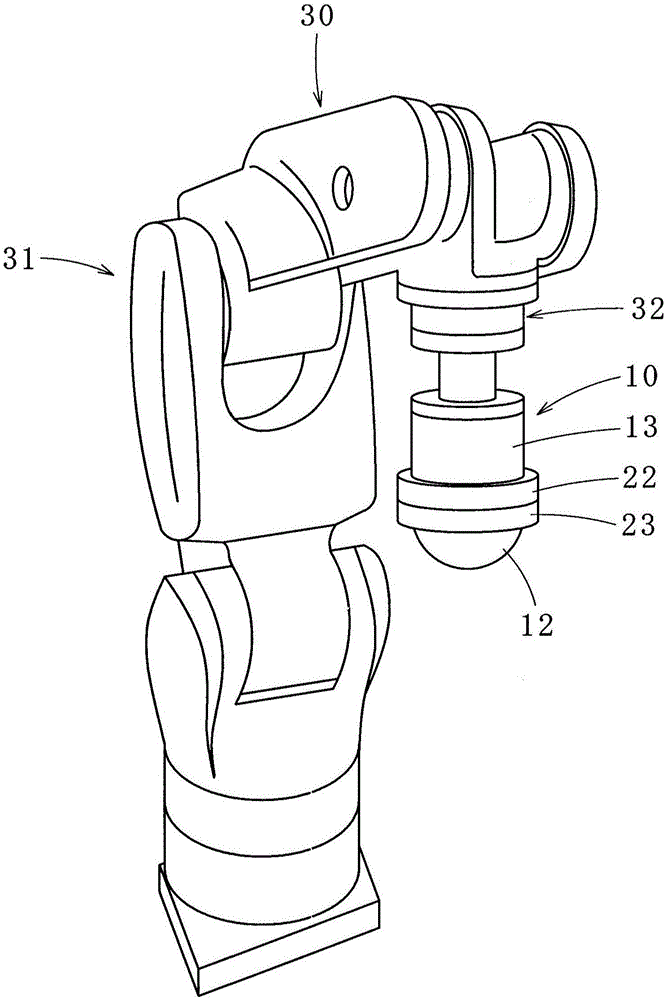

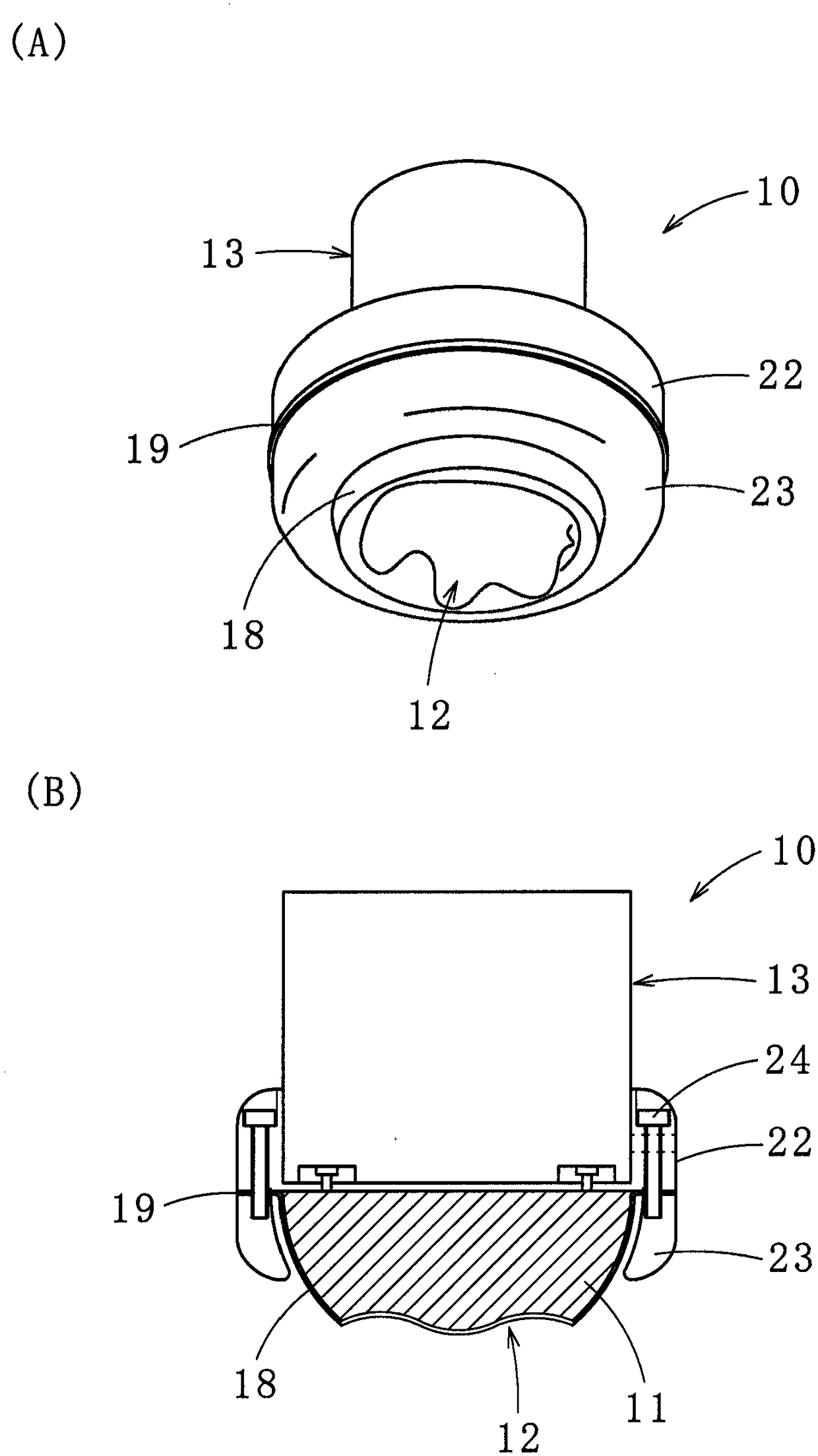

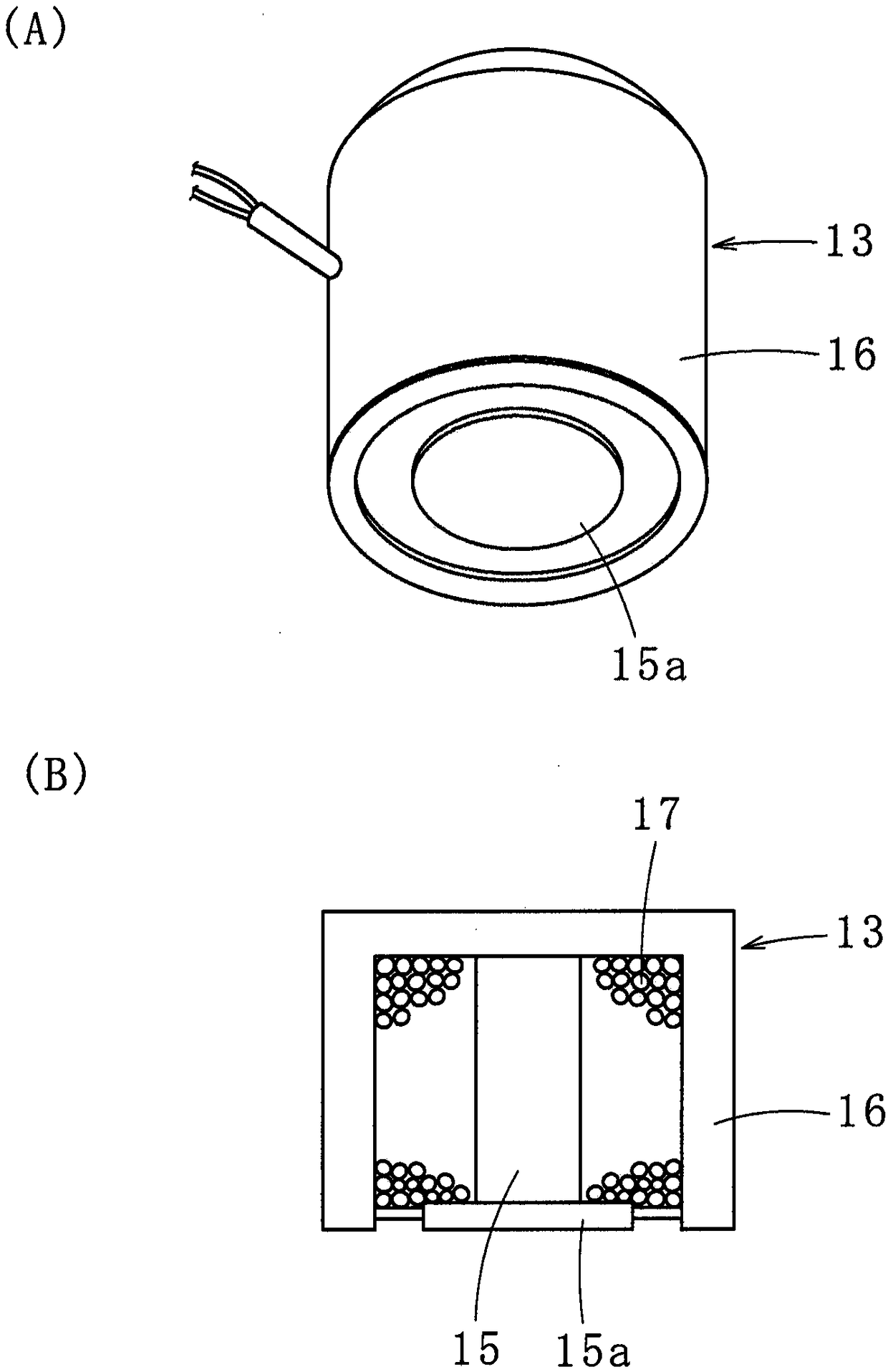

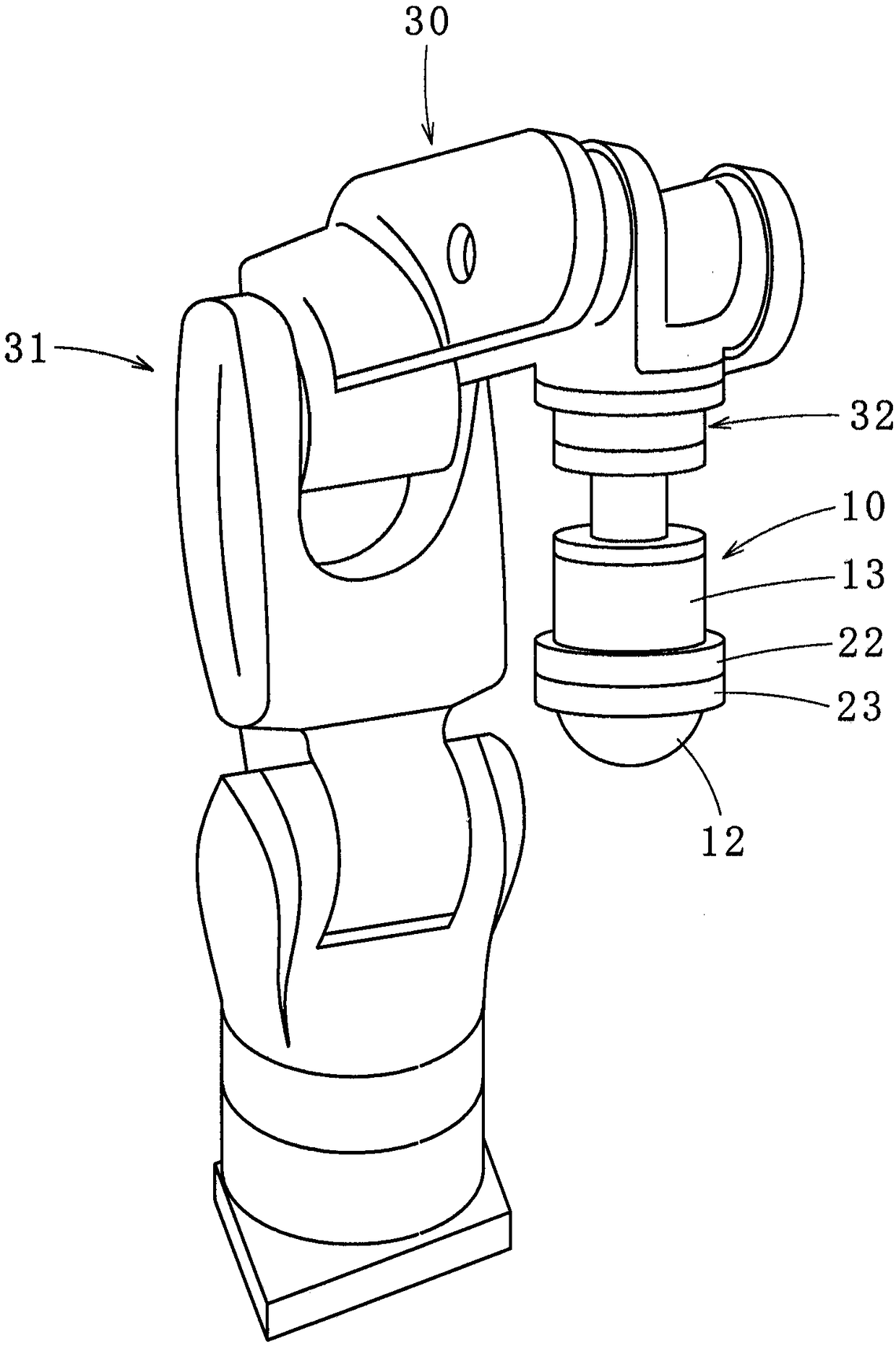

Reformed magnetic fluid, and gripping mechanism and gripping device which use reformed magnetic fluid

ActiveCN106165029AImprove retentionIncreased shear strengthGripping headsInorganic material magnetismMagnetizationEngineering

The present invention provides a reformed magnetic fluid (11) which achieves improved holding strength during magnetization by mixing, into a magnetic fluid (27) having a base liquid and ferromagnetic fine particles (25) present in a dispersed state in the base liquid, nonmagnetic powder (26) having a larger size than that of the ferromagnetic fine particle (25) and a smaller specific gravity than that of the ferromagnetic fine particle (25), and a gripping mechanism (10) and a gripping device (30) which use the reformed magnetic fluid (11).

Owner:NAT UNIV CORP KYUSHU INST OF TECH (JP) +1

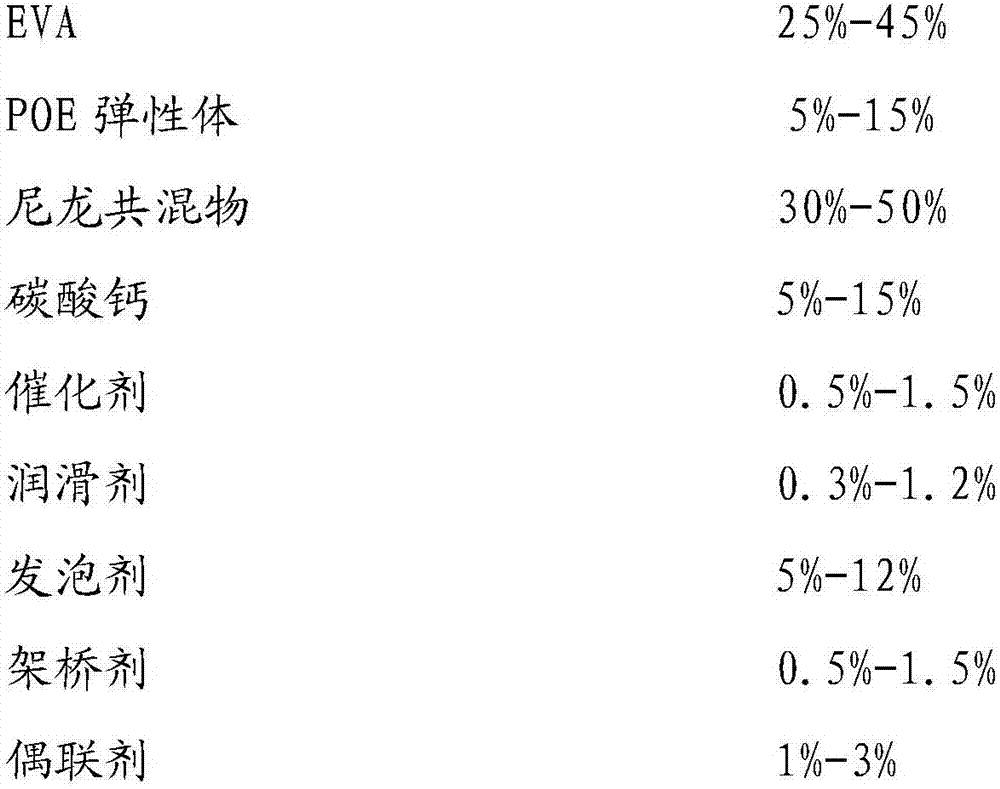

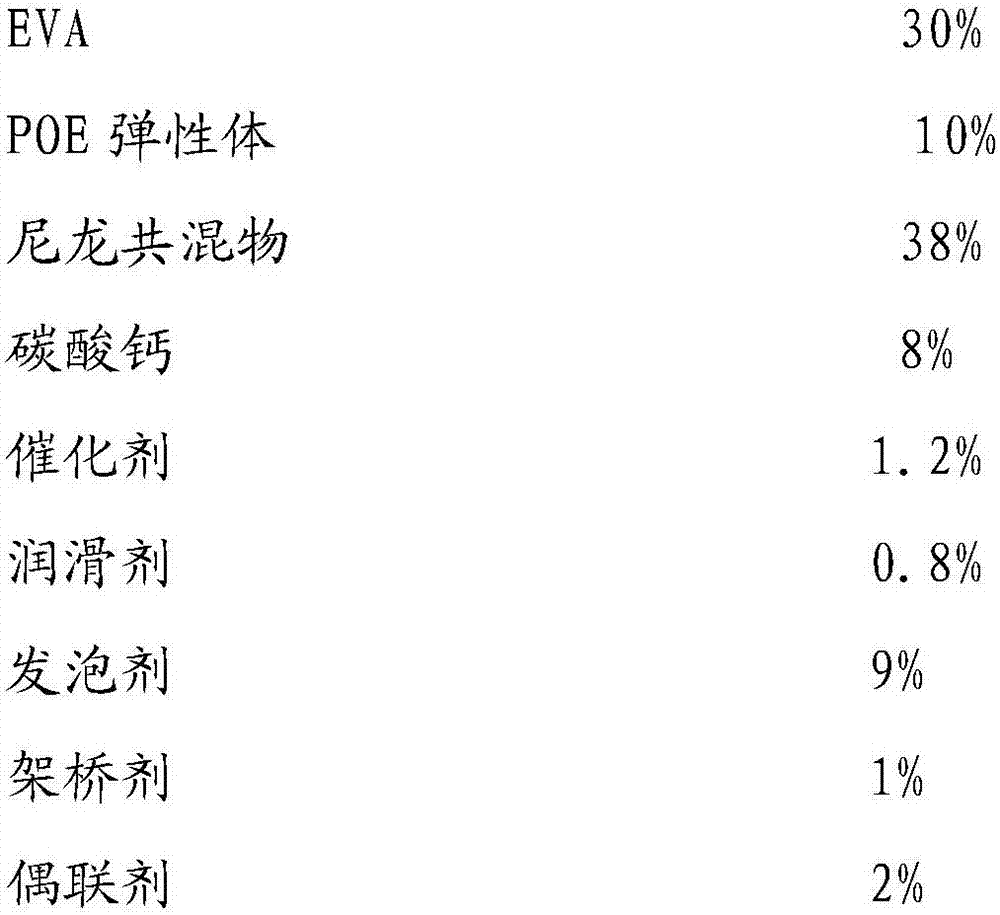

Foaming nylon shoe material and making method thereof

The invention relates to a foaming nylon shoe material. The foaming nylon shoe material is prepared from raw materials as follows: EVA (ethylene vinyl acetate copolymer), POE (Polyolefin elastomer), nylon blend, calcium carbonate, a catalyst, a lubricant, a foaming agent, a bridging agent and a coupling agent, wherein the nylon blend comprises raw materials as follows: nylon, a dispersing agent, a tackifier, polypropylene and filler. According to the technical scheme, nylon is added to an EVA foaming system for joint foaming, strength of nylon is better than that of EVA, so that the whole shoe material can be subjected to higher-amplification foaming, and the proportion of the shoe material can be reduced; compared with the traditional EVA foaming system, the proportion can be reduced to 50%, the tensile strength can be increased by about 15%, and elasticity of the shoe material is guaranteed with addition of POE.

Owner:XTEPCHINA

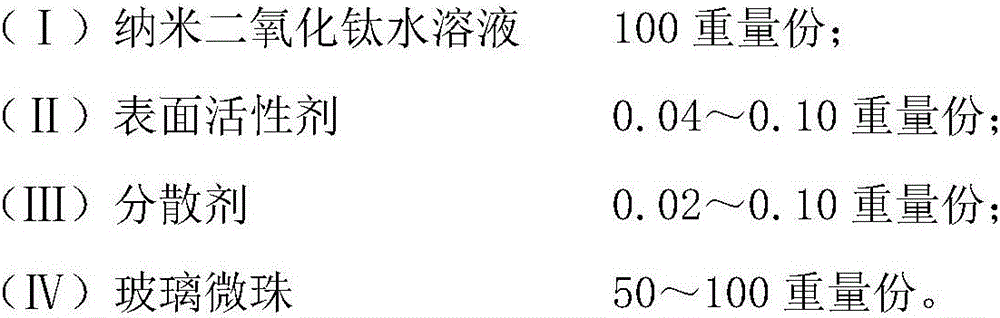

Glass bead load modified Nano-Tio2 photocatalyst, application thereof to formaldehyde removal magnesium oxide board and formaldehyde removal magnesium oxide board

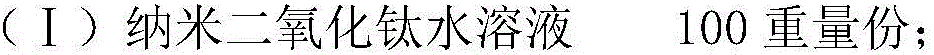

InactiveCN106238025ALarge specific surface areaHigh surface energyPhysical/chemical process catalystsDomestic upholsteryMoisture absorptionSURFACTANT BLEND

The invention discloses a glass bead modified Nano-Tio2 photocatalyst, application thereof to a formaldehyde removal magnesium oxide board and the formaldehyde removal magnesium oxide board. The photocatalyst is obtained by dispersing, dewatering and dying from a nanometer titania aqueous solution, a surfactant, a dispersant and glass beads in an appropriate ratio. By applying the photocatalyst to the preparation of formaldehyde removal magnesium oxide board, the magnesium oxide board obtained has the effect of enduringly purifying formaldehyde, and has the advantages of good thermo insulating property and good screw holding capability, without moisture absorption, active magnesia and buckling deformation.

Owner:梅州淦源建材科技有限公司

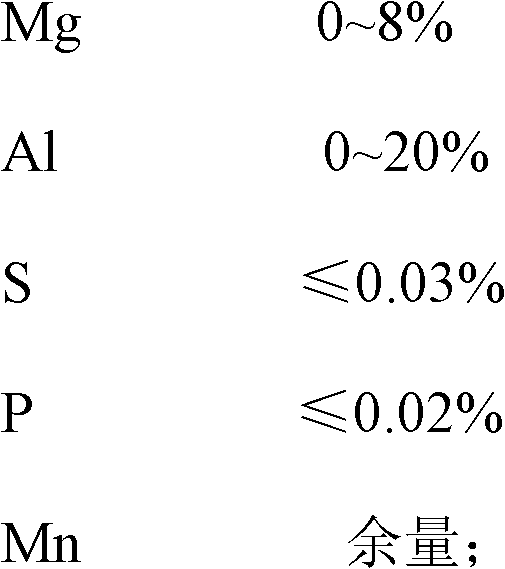

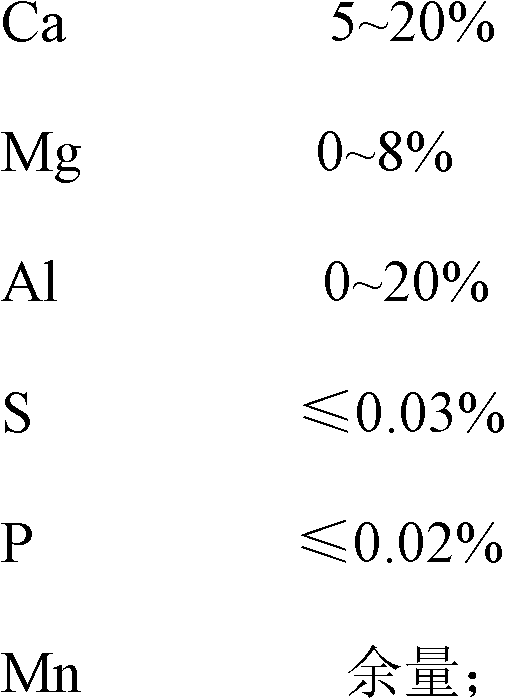

Compressing double deoxidizer for steelmaking and preparation method thereof

The invention aims at disclosing a compressing double deoxidizer for steelmaking, which, by weight percentage, comprises 5-20% of Ca, 0-8% of Mg, 0-20% of Al, less than 0.03% of S, less than 0.02% of P, 2-10% of binder and balanced Mn. The invention further aims at disclosing a preparation method of the compressing double deoxidizer for the steelmaking, raw materials are added in the binder after mixed according to the proportion and evenly mixed, the mixed raw materials are put in a compression molding press with the pressure less than 20T for pressing, the stoving temperature is set to be 60-120 DEG C to dry a compressed double deoxidizer block for 15-60min, and a dried compressed double deoxidizer block is cooled and packaged to obtain the needed compressing double deoxidizer for the steelmaking.

Owner:CHANGZHOU MAOSHENGTE ALLOY PROD +1

Novel oxidant for fireworks and preparation method thereof

The invention provides a novel oxidant for fireworks and a preparation method thereof in order to improve the performance price ratio of a fireworks powder oxidant. The novel oxidant for the fireworks is characterized in by comprises the following raw materials in part by weight: 5 to 7 parts of barium nitrate, 5 to 6 parts of potassium hyperchlorate, 3 to 10 parts of density degree regulator and 1 to 5 part of catalyst. The preparation method of the novel oxidant for the fireworks is characterized by comprising the following steps of: crushing the raw materials into 120 to 350 meshes respectively; and uniformly mixing the raw materials according to the proportions of the raw materials to obtain a special oxidant product. For a product produced by using the special oxidant, the bursting strength, the cost price and the proportion of the raw materials are close to those of potassium chlorate, the safety performance is close to that of the potassium hyperchlorate, and the performance price ratio of the product is significantly improved, so the product is highly praised and appreciated by users.

Owner:李忠良

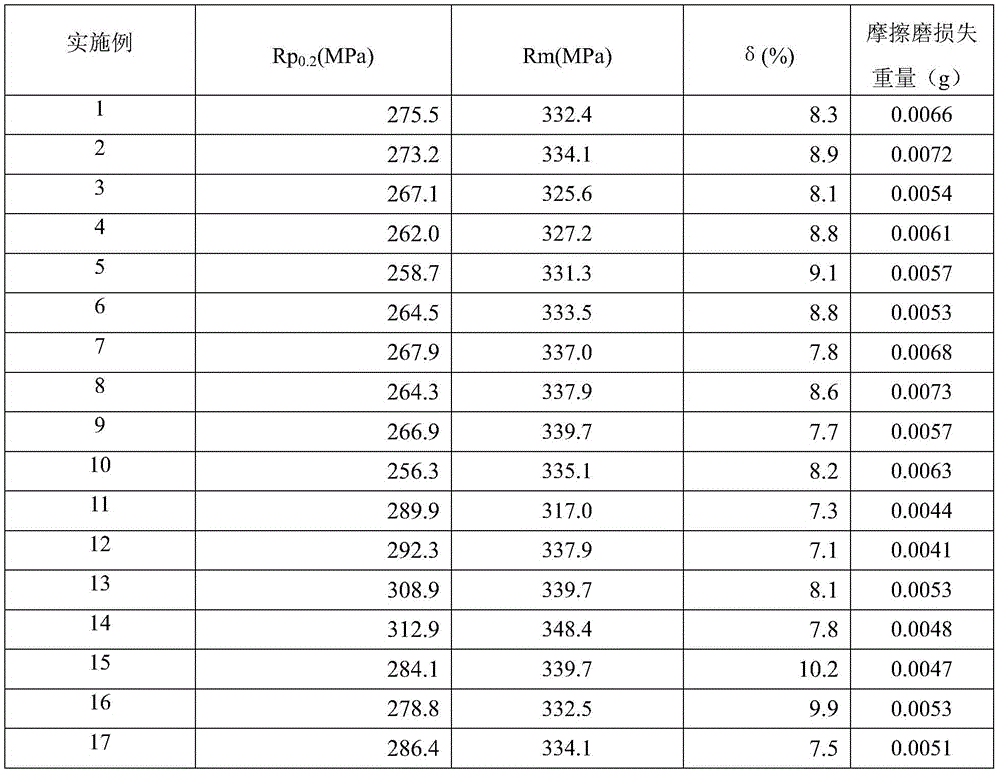

Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening and preparation method for deformation material of Ti-containing high-silicon aluminum alloy

InactiveCN105695811AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention belongs to the technical field of aluminum alloy, and relates to a Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening. The Ti-containing high-silicon aluminum alloy is characterized by being prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 0.8% of Ti, not larger than 0.5% of Fe, not larger than 0.15% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5% by weight. A preparation method for the aluminum alloy and a deformation material of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 aging. The Ti-containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, no modification is needed, a DC casting process is adopted, double-stage homogenization is combined with deformation thermal treatment, and therefore the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

Environment-friendly composite stone plate and preparation method thereof

InactiveCN102729555AEliminate pollutionConducive to the protection of the environmentCovering/liningsSynthetic resin layered productsCorrosion resistantComposite substrate

The invention relates to a decorative material, in particular to an environment-friendly composite stone plate and manufacturing method of the environment-friendly composite stone plate. The environment-friendly composite stone plate is used for decorating wallboards or floors and comprises a composite substrate, wherein a printing layer is arranged on the surface of the composite stone plate and the composite stone plate is prepared from 98-99% of master batches and 1-2% of foamed master batches in mass percent by the steps of preparing the master batches, preparing the foamed master batches, blending, cold mixing, molding, cutting and printing. The environment-friendly composite stone plate has the advantages of corrosion resistance, water resistance, moisture resistance, heat insulation and sound insulation and the characteristics of good dimensional stability and small proportion.

Owner:夏丽蓉

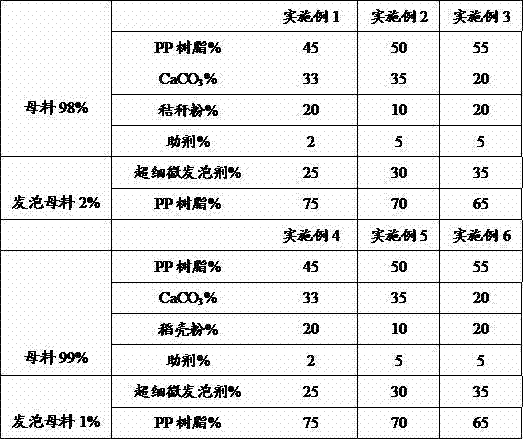

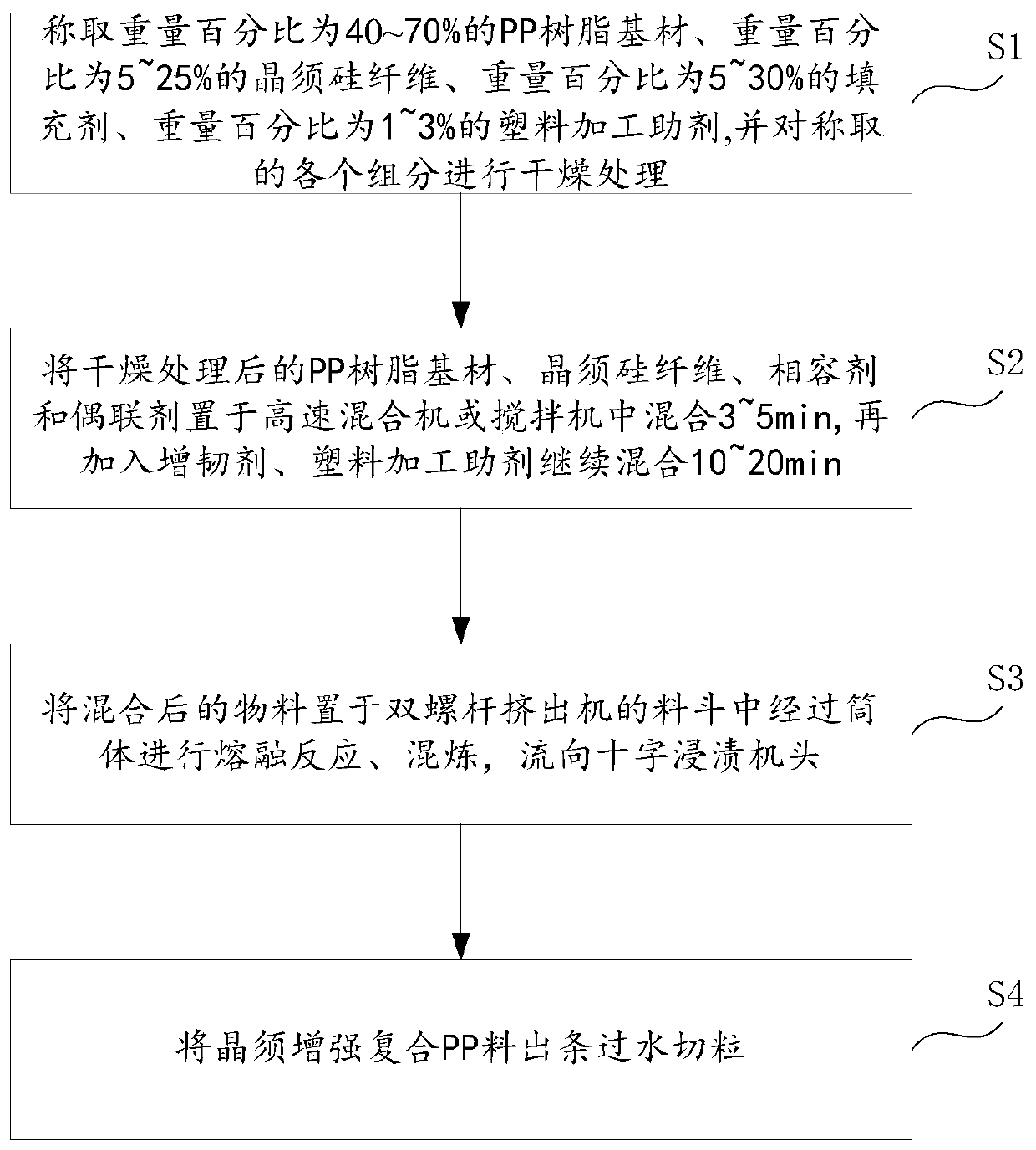

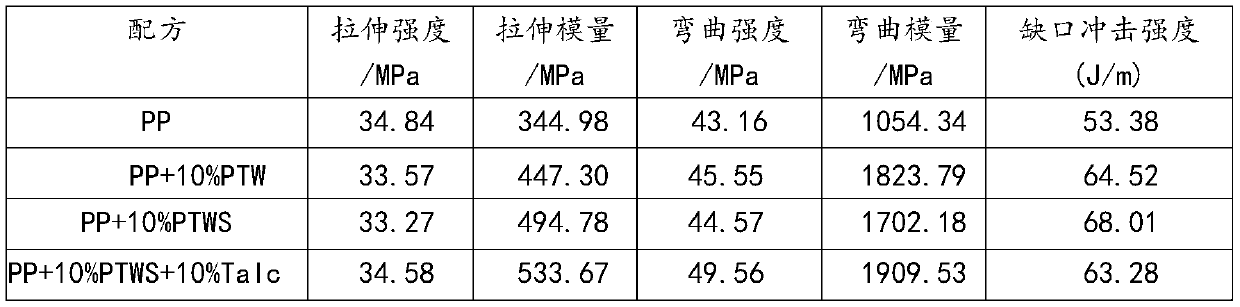

Whisker reinforced composite PP material, preparation method thereof and plastic pipeline

The invention discloses a whisker reinforced composite PP material, a preparation method thereof and a plastic pipeline. The whisker reinforced composite PP material is prepared from the following components in percentage by weight: 40 to 70 percent of PP resin base material, 5 to 25 percent of whisker silicon fiber, 5 to 30 percent of filler and 1 to 3 percent of plastic processing aid. Accordingto the whisker reinforced composite PP material, the preparation method thereof and the plastic pipeline, the strength, the chemical stability, the dispersity, the high temperature resistance and theinsulativity of the composite material can be improved, and the ignition loss and the oil absorption rate are reduced. By adopting the whisker reinforced modified material, glass fiber exposure can be eliminated, the appearance of the plastic pipeline can be improved, the flatness of the inner wall can be improved, the friction coefficient can be reduced, the thermal deformation temperature can be increased, the flame retardancy can be improved, the shrinkage deformation rate can be reduced, warping can be overcome, the processability can be improved, the product rigidity can be improved, thematerial specific gravity can be reduced, and the production cost can be reduced.

Owner:顾顺昌

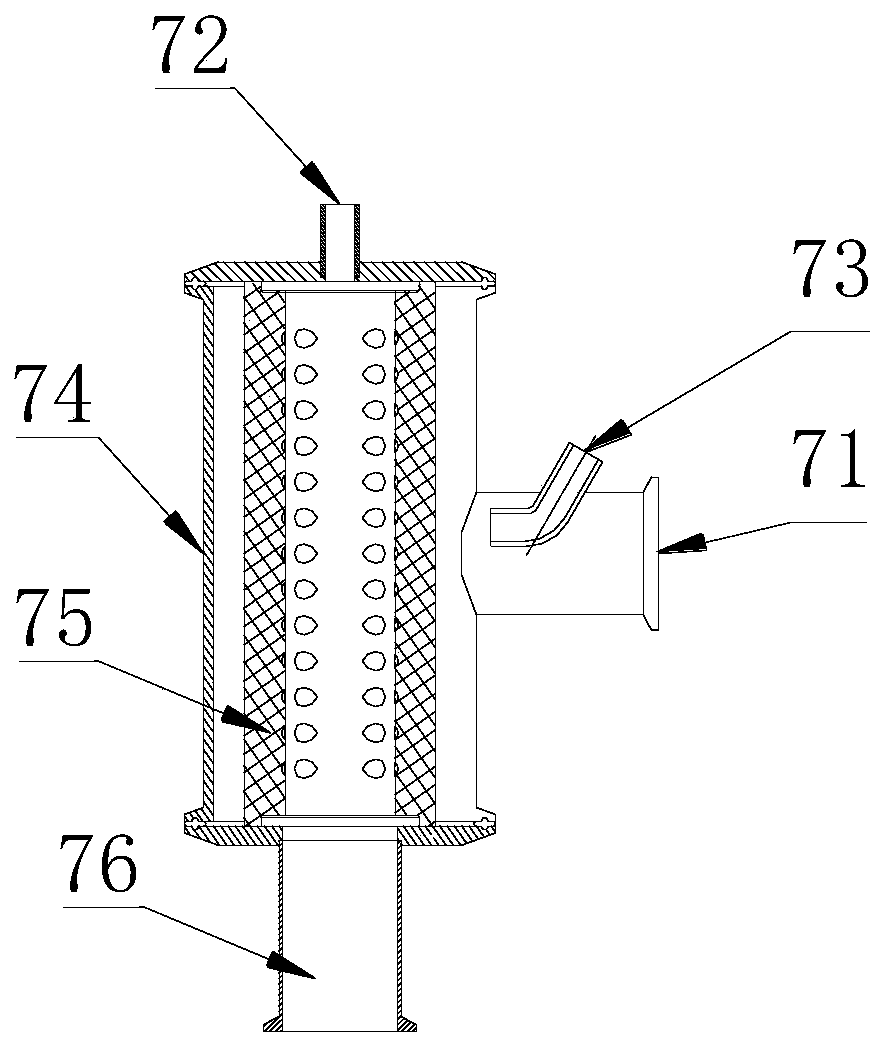

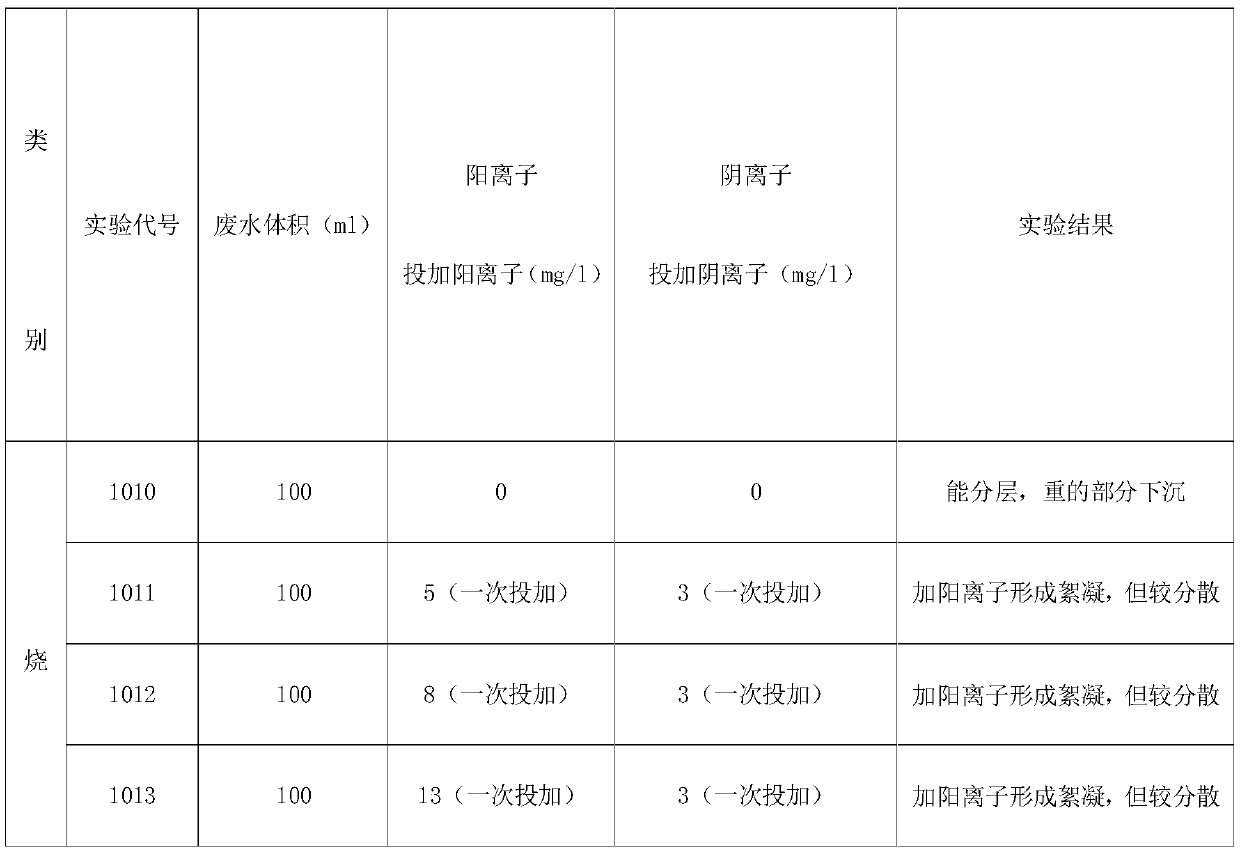

Efficient air floatation device for sewage treatment

PendingCN110950414AStrong ability to adsorb monovalent ionsLow costWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationFlocculationSludge

The invention relates to an efficient air floatation device for sewage treatment. The efficient air floatation device for sewage treatment comprises a water inlet device connected with a booster pump,an air inlet device connected with an air compressor, and a chemical feeding device connected with a chemical adding pump, and further comprises at least two vortex mixers; the chemical feeding device comprises an anion flocculation box and a cation flocculation box; a cationic flocculant in the cationic flocculation box flows into a first-stage vortex mixer; an anionic flocculant in the anion flocculation box flows into a second-stage vortex mixer; fluid in the first-stage vortex mixer enters the second-stage vortex mixer through a connecting pipeline; fluid in the second-stage vortex mixeris discharged into the buffer pool through a water outlet, particles wrapped by bubbles rapidly float upwards, treated clear water is discharged through a baffle plate at the bottom, and floating sludge is scraped into a scum pool through a scum scraper at the top of the buffer pool. According to the invention, liquid, gas and chemical agent can be in full contact, the container is not limited ina sealing manner, and the application range is wide.

Owner:HUNAN ZHONGTUO ENVIRONMENTAL ENG CO LTD

Graphene compound vinyl ester heavy anti-corrosion coating and preparation method thereof

InactiveCN107057532AEnhanced barrier functionReduce specific gravityFireproof paintsAnti-corrosive paintsCross-linkVinyl ester

The invention discloses a graphene compound vinyl ester heavy anti-corrosion coating, which comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 60-75 parts of phenolic vinyl ester resin, 0.5-2 parts of graphene, 20-30 parts of precipitated barium sulphate, 5-10 parts of sericite, 0.5-2 parts of a nano assistant, 0.5-1 part of an anti-settling agent, 0.5-2 parts of an accelerant; and the component B is 2-4 parts of a cross-linking agent. The preparation method comprises the steps of (1) adding the anti-settling agent, the nano assistant and the accelerant to the phenolic vinyl ester resin under a stirring state, stirring for 10min, adding graphene, stirring evenly, finally adding the sericite and the precipitated barium sulphate and stirring evenly to obtain a paste coating; and (2) mixing the paste coating and the cross-linking agent evenly to obtain a finished product coating. The heavy anti-corrosion coating which has excellent properties such as light weight, good chemical resistance, good solvent resistance and high wear resistance can be prepared.

Owner:DEYANG CARBONENE TECH

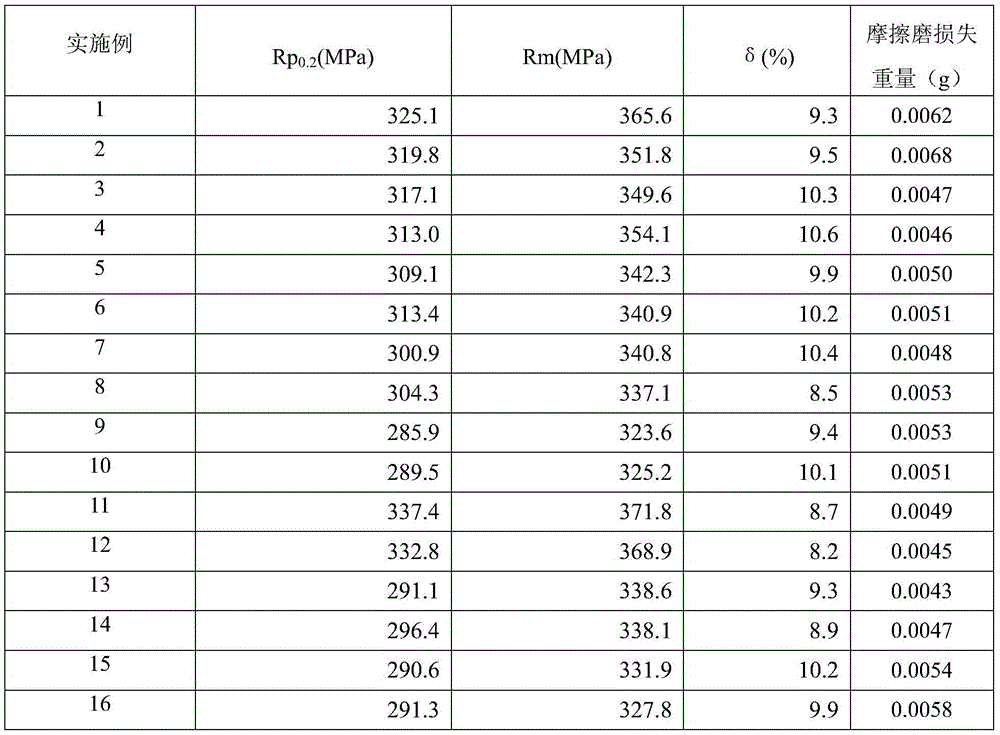

Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening and preparation method of deformation material thereof

ActiveCN105695810AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention discloses an Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening, and belongs to the technical field of aluminum alloy. The Mn containing high-silicon aluminum alloy is characterized in that the alloy is prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 3.0% of Mn, not larger than 0.5% of Fe, not larger than 0.2% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5%. The preparation method of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 ageing. The Mn containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, a DC casting melt casting process is adopted, and modification is not needed; and double-stage homogenization is combined with deformation thermal treatment, the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance, and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

Unfired clay tile and production technology thereof

The invention discloses an unfired clay tile and a production technology thereof. The clay tile comprises, by weight, 10-15 parts of natural colored sands, 10-15 parts of natural colored quartz sands, 3-5 parts of polyester resin, 2-5 parts of a shrinkage agent, 5-8 parts of alkali-free glass fibers, 0.5-1 part of zinc stearate, 1-2 parts of a skeleton reinforced material, 2-5 parts of light magnesium oxide and 0.02-0.05 part of an antioxidant. The production technology comprises the following steps: (1) mixing the polyester resin, polystyrene resin and zinc stearate according to the above formula, stirring the mixed raw materials, adding the natural colored sands, continuous stirring the mixed raw materials and the natural colored sands, adding the alkali-free glass fibers, the light magnesium oxide, the antioxidant and the natural colored quartz sands, and stirring all above raw materials; and (2 ) placing a product obtained in step (1) in a molding chamber, adding the skeleton reinforced material, and molding the product and the skeleton reinforced material to obtain the unfired clay tile. The unfired clay tile produced through the method has the advantages of high strength, high flexural and compressive strength, good toughness and light weight and is suitable for various roofings.

Owner:四川尚典建材有限公司

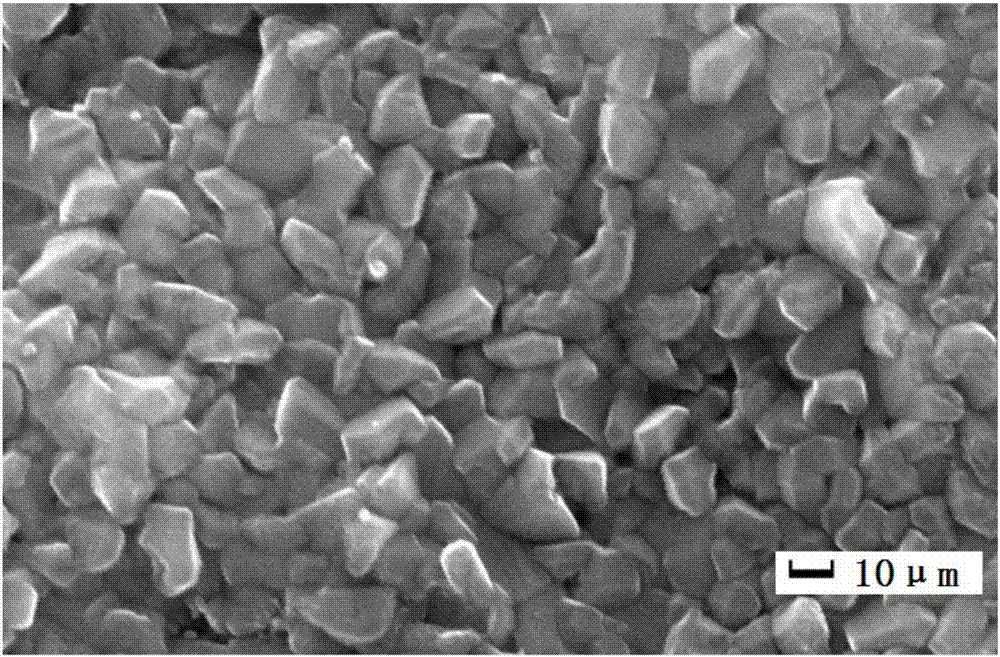

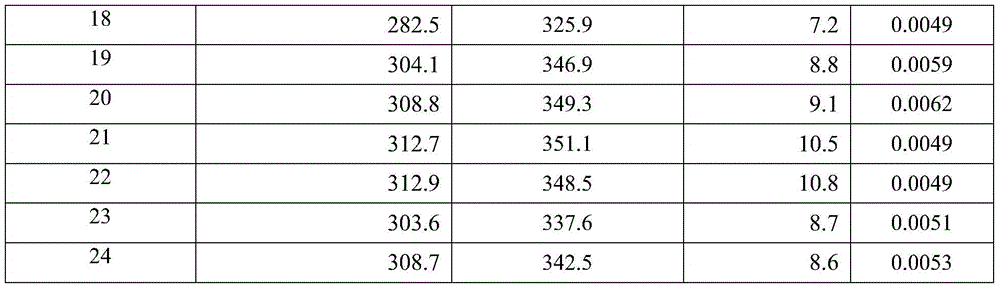

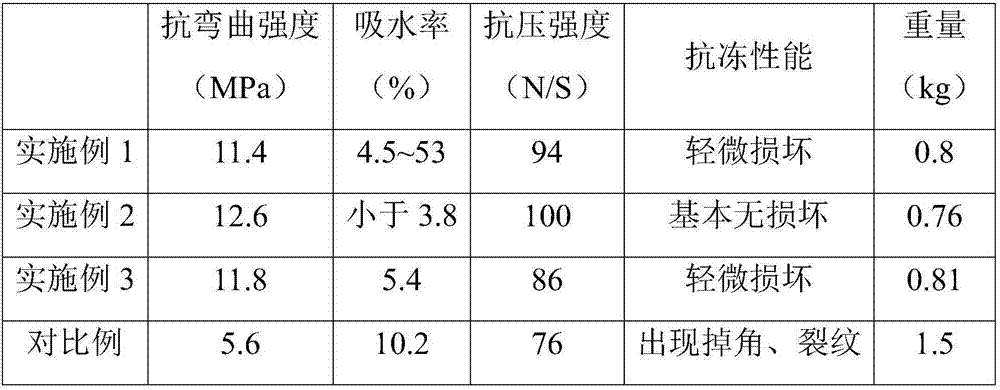

Microporous lightweight silica brick and preparation method thereof

The invention discloses a microporous lightweight silica brick and a preparation method thereof, the lightweight silica brick is mainly prepared from a mixture and a foaming agent, and the dosage of the foaming agent is 0.1-10% of the mass of the mixture; the mixture is prepared from the following components in percentage by mass: 70%-95% of a siliceous material, 1%-25% of an inorganic cementing material, 0.1%-15% of a mineralizing agent and 0.1%-5% of an additive; wherein the siliceous material is composed of siliceous particles and siliceous fine powder, the particle size of the siliceous particles is 0.1-3 mm, the particle size of the siliceous fine powder is smaller than or equal to 0.075 mm, and the mass ratio of the siliceous particles to the siliceous fine powder is (1-65): (35-99). The obtained microporous lightweight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical strength, good high-temperature volume stability, strong acid atmosphere and slag erosion resistance and the like, is low in preparation cost and good in heat insulation effect, meets harsh high-temperature environment and heat insulation requirements of thermal equipment, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

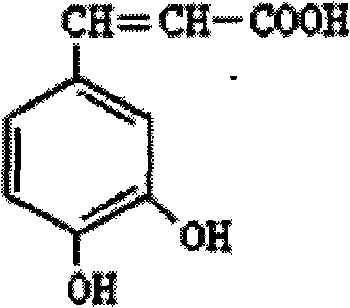

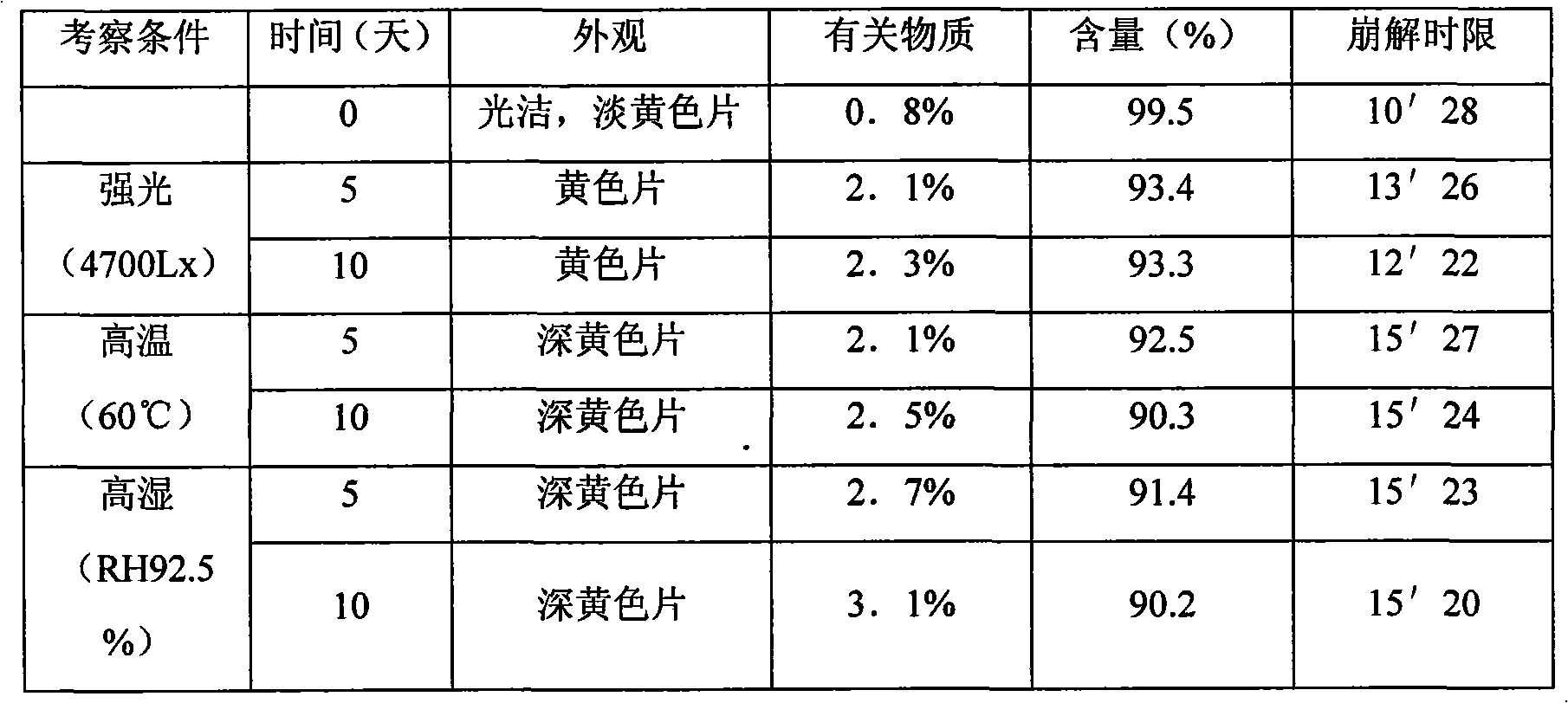

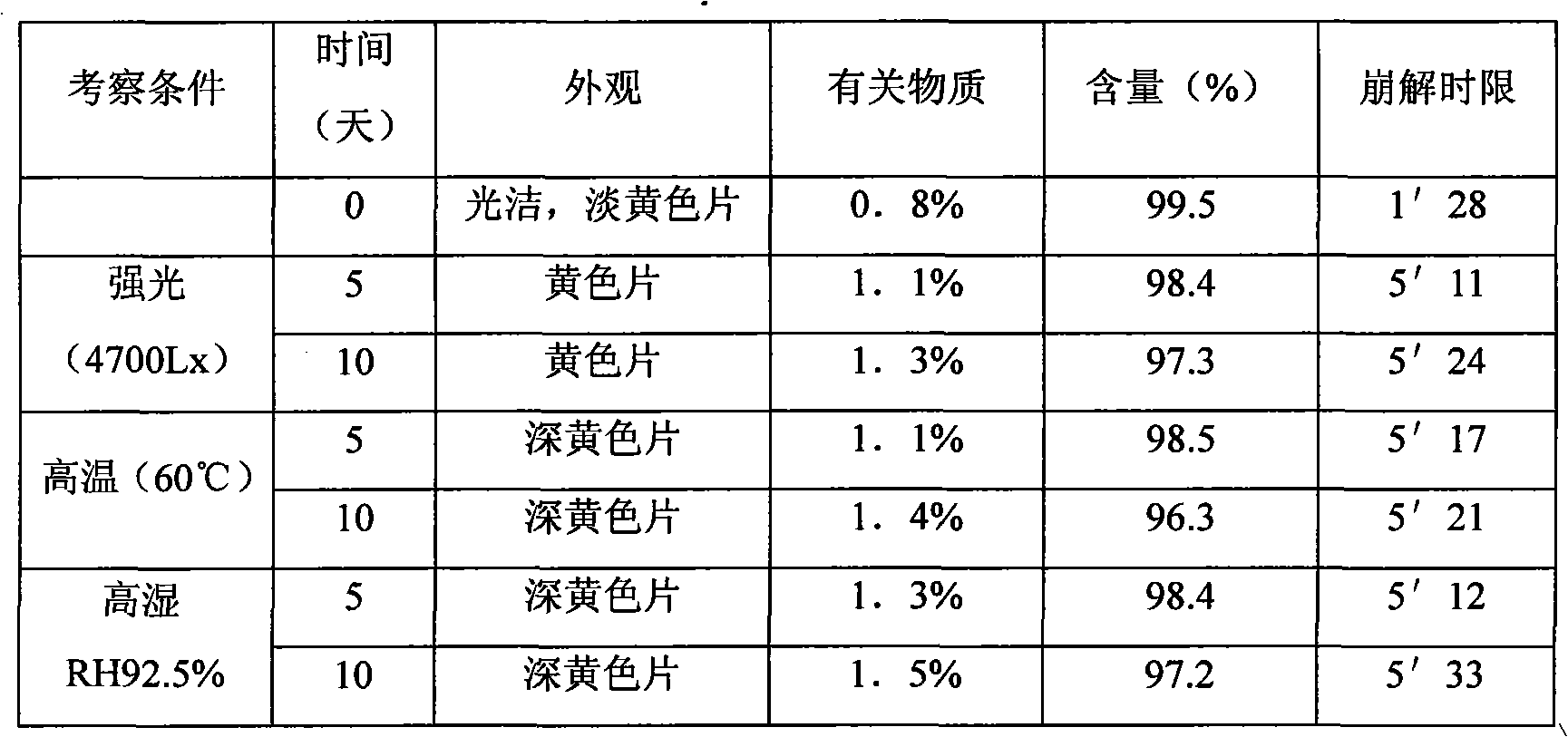

Caffeic acid composition and preparation method thereof

ActiveCN101554373AAbsorb thoroughlyFacilitated releaseOrganic active ingredientsPharmaceutical non-active ingredientsCaffeic acidBioavailability

The invention relates to a caffeic acid composition which is characterized by comprising an A composition, a B composition, surface active agent, quick-effect disintegrant and lubricant; the A composition is caffeic acid and a medicinal accessory, and the B composition is a medicinal accessory; the weight ratio of the A composition and the B composition ranges from 1: 5.5 to 1: 1; and the caffeic acid accounts for 15 percent (W W) of the A composition at 10 DEG C. The standard of the caffeic acid composition is 0.95-0.105 weight part, wherein 0.1 weight part is the best. The caffeic acid composition and the preparation method thereof solves the problems concerning fast medicine disintegration and fast medicine effect and in particular greatly improves the bioavailability and the tablet stability of a caffeic acid tablet in the body.

Owner:DEZHOU DEYAO PHARMA

Ceramic particle for water treatment and preparation thereof

InactiveCN101348383AAppropriate proportionSmall expansion coefficientSustainable biological treatmentCeramicwareCeramic particleCoal

The invention discloses a ceramic particle for water treatment and a preparation method thereof, belonging to the production field of water treatment filter material. The ceramic particle is made from granite powder, bentonite, coke powder, sawdust and pulverized coal in a certain proportion. Compared with the prior art, the ceramic particle has the characteristics of good water purifying effect, low production cost, little energy consumption, and so on, and can be widely applied to sewage treatment in various fields.

Owner:商士强

Foaming regeneration environment-friendly plastic sheet and preparation method thereof

ActiveCN103832031ASolve the problem of overweightSolve the shortcomings of overweightSynthetic resin layered productsLaminationFoaming agentPlastic film

The invention relates to a foaming regeneration environment-friendly plastic sheet. The foaming regeneration environment-friendly plastic sheet comprises a PS base material layer and a foaming layer, wherein the PS base material layer comprises the following raw materials in percentage by weight: 75%-90% of PS, 5%-20% of PE and 1%-20% of a reinforcing agent; the foaming layer comprises the following raw materials in percentage by weight: 60%-70% of PS, 5%-20% of PE, 0.1%-20% of a foaming agent, 1%-10% of a reinforcing agent and 0.1%-8% of toner. A preparation method of the foaming regeneration environment-friendly plastic sheet comprises the following steps: (1) mixing the raw materials of the PS base material layer and the raw materials of the foaming layer in the ratio, and uniformly stirring; (2) feeding the raw materials into co-extrusion equipment through feeding equipment, extruding the PS base material layer and a foaming raw material layer, heating for forming in a double screw extruder, and simultaneously carrying out flow thermal compounding on the foaming layer and the PS base material layer at a joint of extruder screws to discharge sheets with uniform thickness, wherein the foaming raw material layer is foamed to obtain the foaming layer; and (3) drawing the PS base material layer and foaming layer composite sheets to a three-roller cooler for regulating flatness of the sheets, and trimming, forming and rolling through a tractor so as to obtain the finished product. The foaming regeneration environment-friendly plastic sheet provided by the invention has the advantages that the problem that the specific gravity of a traditional PS regeneration sheet is too large is solved, the cost is greatly reduced, and the environment pollution caused by plastics is alleviated.

Owner:上海浔猎优包新材料科技有限公司

Modified magnetic fluid, holding mechanism and holding device using the modified magnetic fluid

ActiveCN106165029BImprove retentionIncreased shear strengthGripping headsInorganic material magnetismMagnetizationEngineering

Owner:NAT UNIV CORP KYUSHU INST OF TECH (JP) +1

Ceramic particle for water treatment and preparation thereof

InactiveCN101348383BLow costImprove performanceSustainable biological treatmentCeramicwareFilter materialSewage treatment

The invention discloses a ceramic particle for water treatment and a preparation method thereof, belonging to the production field of water treatment filter material. The ceramic particle is made from granite powder, bentonite, coke powder, sawdust and pulverized coal in a certain proportion. Compared with the prior art, the ceramic particle has the characteristics of good water purifying effect,low production cost, little energy consumption, and so on, and can be widely applied to sewage treatment in various fields.

Owner:商士强

a block

ActiveCN103774781BImprove toughnessAvoid crackingConstruction materialSolid waste managementFiberFoaming agent

The invention relates to a building block. The building block comprises a skeleton and a core body, wherein the skeleton and the core body are molded synchronously; the skeleton comprises the following materials in percentage by weight: 25 to 45 percent of cement, 25 to 45 percent of lightweight aggregate, 10 to 20 percent of basalt stone, 8 to 15 percent of mineral powder, 10 to 20 percent of plant fibers and 1 to 2 percent of admixture; the core body comprises the following materials in percentage by weight: 25 to 45 percent of cement, 25 to 45 percent of ultra-lightweight particles, 15 to 25 percent of mineral powder and 5 to 15 percent of foaming agent. The building block has the advantages that a skeleton body has high toughness, and is not easy to crack or generate microcracks; the core body is made of a lightweight heat insulation material, so that the specific gravity of the overall building block is reduced, and a heat insulation effect is enhanced; therefore, the overall weight of a built wall body is light, and the heat insulation performance is high.

Owner:JIANGSU FANGJIAN ENG QUALIFICATION TESTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com