Foaming nylon shoe material and making method thereof

A production method and nylon technology, applied in footwear, application, clothing and other directions, can solve the problems of small foaming ratio, unsatisfactory tensile strength, heavy weight of foamed shoe materials, etc., and achieve the effect of reducing specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

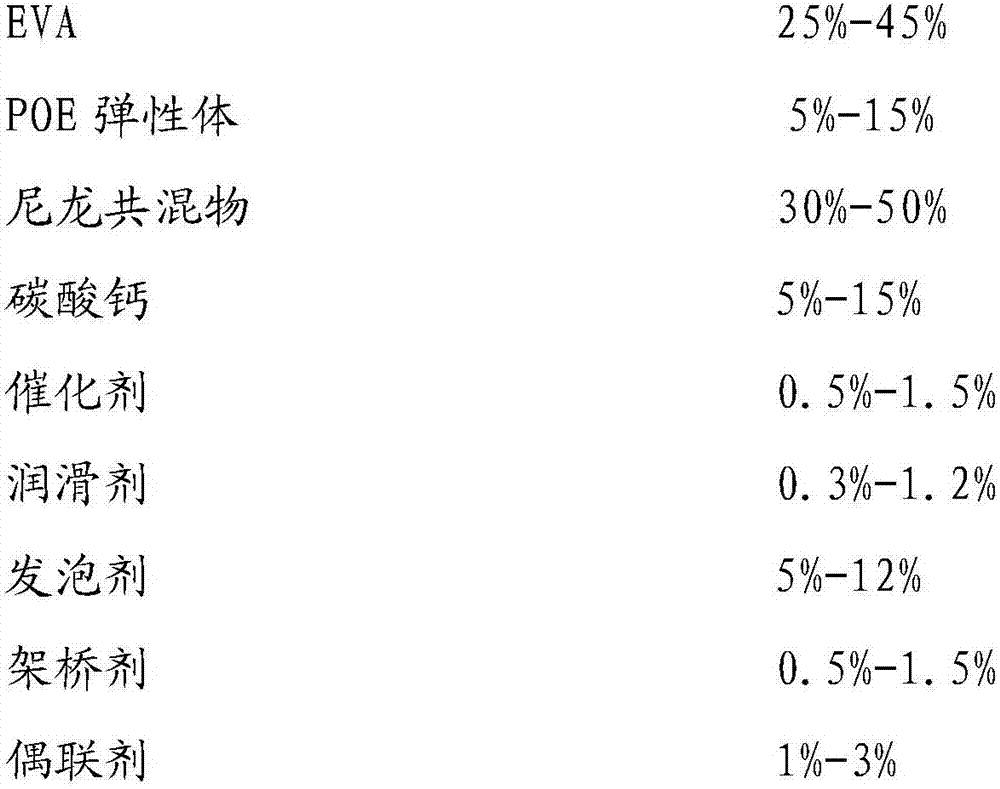

[0031] A nylon foam shoe material, the nylon foam shoe material comprises the following raw materials by weight percentage:

[0032]

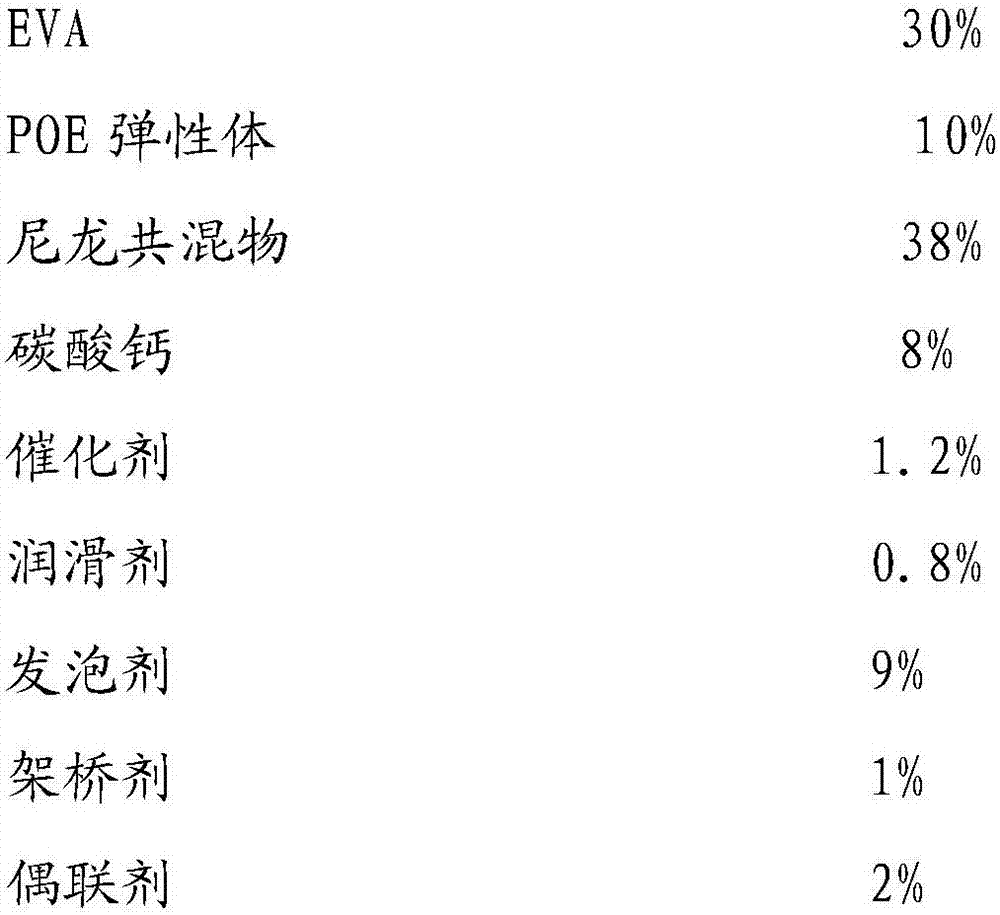

[0033]

[0034] Wherein, nylon blend comprises the raw material of following weight percent:

[0035]

[0036] As a preferred form of the present invention, the nylon is nylon 6, which is also called polyamide 6, and its melting point is low. After blending and modification, it can be compatible with the EVA foaming system, and its strength is better than that of polyamide 6. EVA. The tackifier is the 514D tackifier of DuPont in the United States, and the dispersant EF44 dispersant of Hengshui Sanyuan Materials Trading Co., Ltd., wherein the tackifier can better mix nylon and polypropylene for blending modification .

[0037] As a preferred mode of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com