Optical glass and optical element

A technology of optical glass and oxide, which is applied in the field of optical glass and optical components, can solve the problems of reducing the thermal shock resistance of glass, increasing the expansion coefficient of glass, and improving, so as to reduce the cost of raw materials, avoid volatile streaks, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~30 and comparative example 1~5

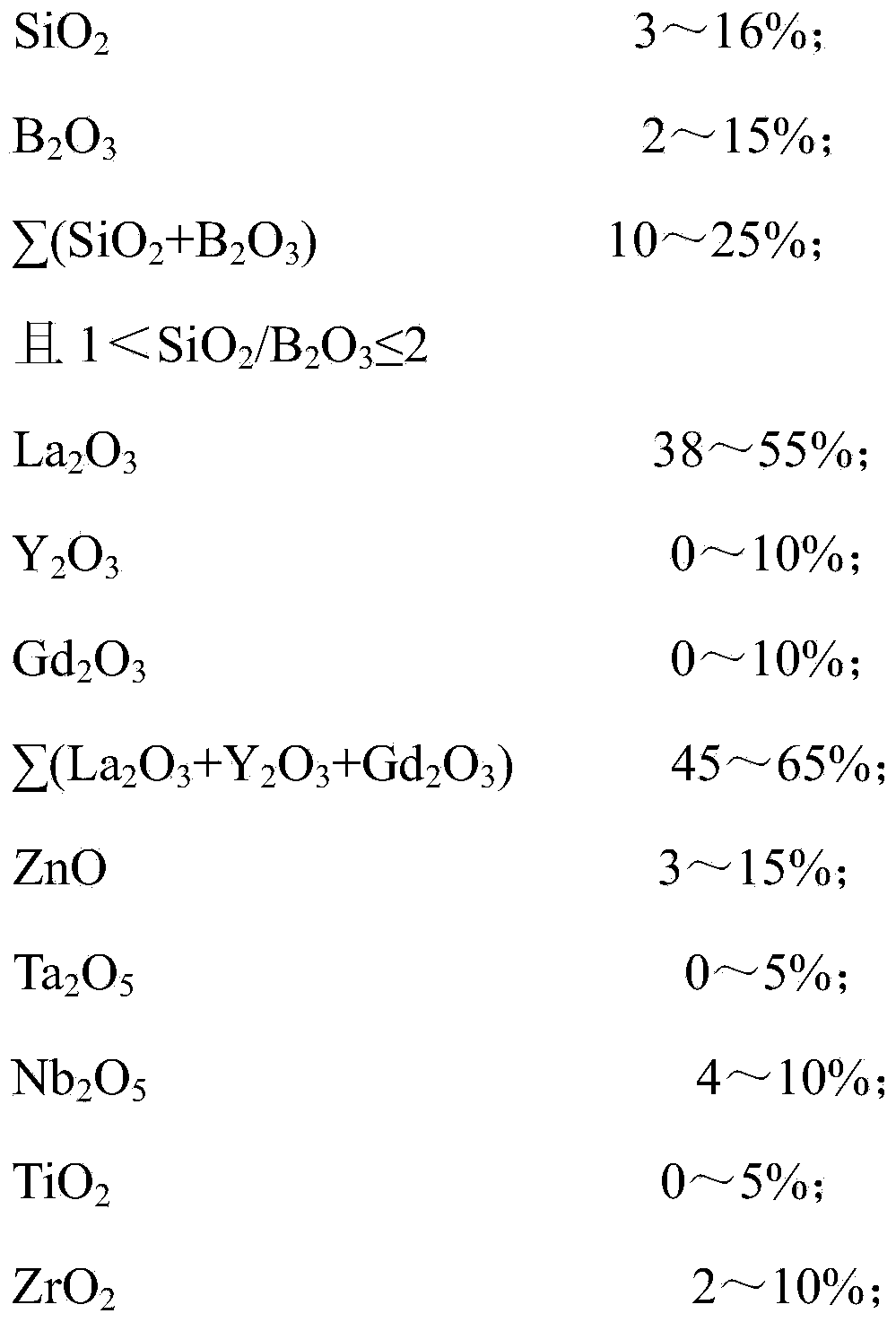

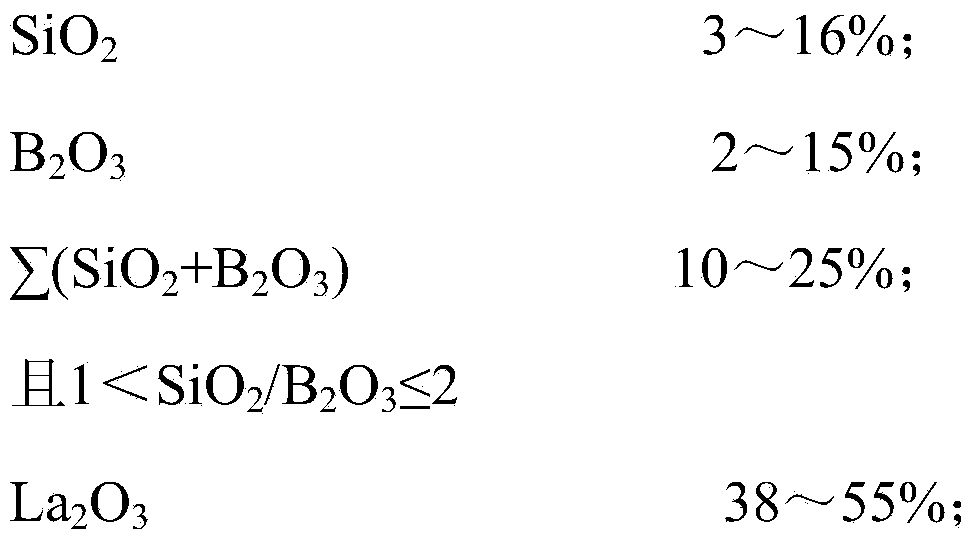

[0053] SiO 2 , B 2 o 3 , La 2 o 3 , Y 2 o 3 、Gd 2 o 3 , ZnO, Ta 2 o 5 , Nb 2 o 5 、TiO 2 , ZrO 2 , Sb 2 o 3 The raw materials such as the corresponding oxides, carbonates, nitrates, etc. are selected from the raw materials with a purity greater than 99% used in ordinary optical glass, and are weighed and proportioned according to the weight content shown in Table 1 and continued Table 1. Mix evenly and add to the platinum crucible. The difficulty of melting varies with the components. Generally, at a temperature of 1250-1350 ° C, it takes about 2-4 hours to melt and stir evenly, then pour into the mold and cool slowly , These glass samples can be obtained. Then process it into a high refractive index optical glass sample according to the methods commonly used in this field.

[0054] Performance Testing

[0055] The refractive index (nd), Abbe's number (υd), glass transition temperature (Tg), 20 ℃ to Coefficient of linear expansion at 120°C (α 20~120℃ ), dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com