Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening and preparation method of deformation material thereof

A high-silicon aluminum alloy and aging-strengthening technology, which is applied in the field of preparation of Mn-containing age-strengthened high-silicon aluminum alloy and its deformed materials, can solve the problems of poor plastic deformation ability, recrystallized grains of deformed materials, and mixed crystals of aluminum matrix. Achieve the effect of inhibiting grain growth, small and uniform grains, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

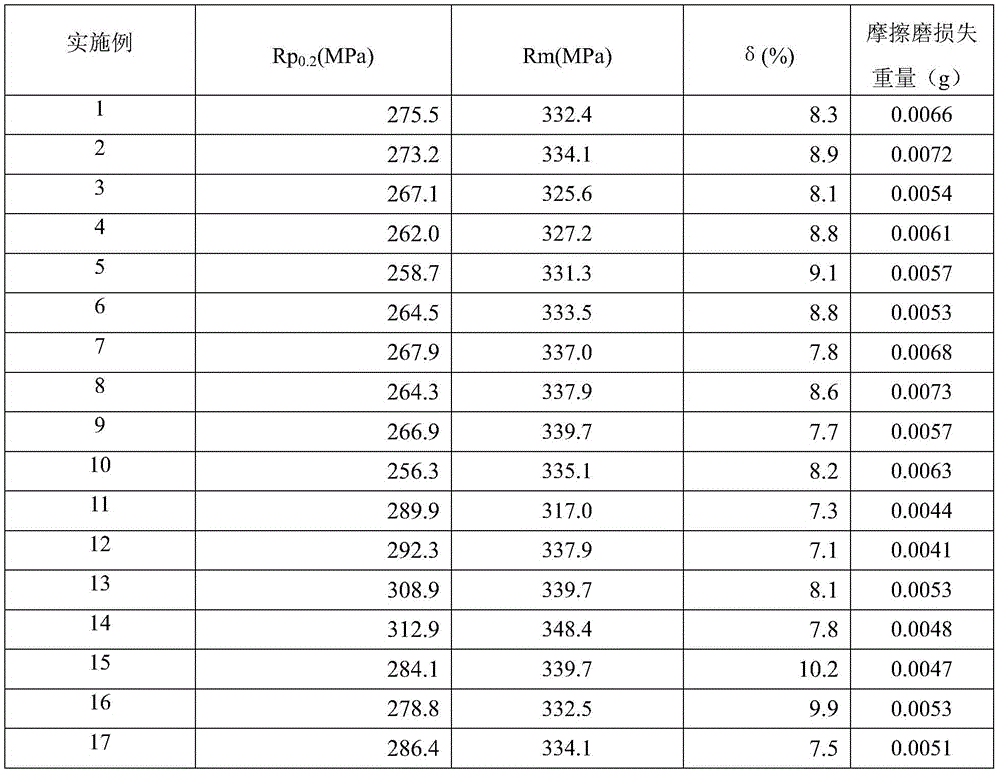

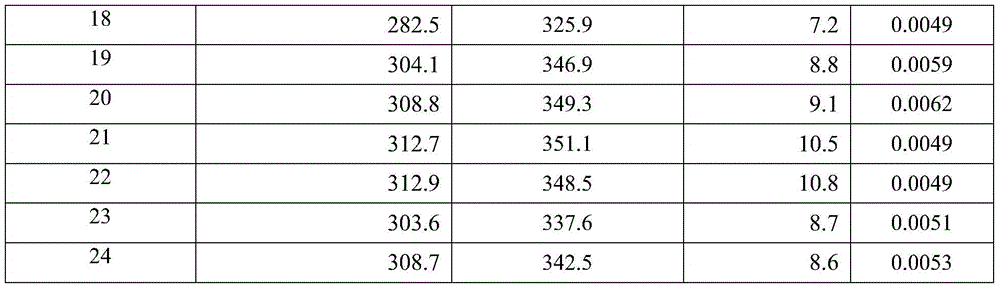

Examples

Embodiment 1

[0045] Cut a 100mm long ingot from the alloy 1# ingot for implementing the invention, put it into a circulating air furnace at room temperature for double-stage homogenization, heat it up to 200°C for 8 hours with the furnace, then heat it up to 550°C for 8 hours, and cool it out of the furnace. After the double-stage homogenization treatment, the ingot is cut and milled to obtain an ingot with a thickness of about 74mm, which is reheated to 480°C for rolling, and the rolling is divided into 8 passes, and the final thickness of hot rolling is 8mm; In the process, the hot-rolled plate is subjected to a solution treatment at 540°C×20min, and after water quenching, it is subjected to an artificial aging treatment at 165°C×12h.

Embodiment 2

[0047] Cut a 100mm long ingot from the alloy 1# ingot for implementing the invention, put it into a circulating air furnace at room temperature for double-stage homogenization, heat it up to 250°C for 10h with the furnace, then heat it up to 550°C for 7h, and cool it out of the furnace. After double-stage homogenization treatment, the ingot is cut and face-milled to obtain an ingot with a thickness of about 72mm, which is reheated to 475°C for rolling, and rolled in 6 passes, and the final thickness of hot rolling is 8mm; In the process, the hot-rolled plate is subjected to a solution treatment at 550°C for 30 minutes, and after water quenching, it is subjected to an artificial aging treatment at 185°C for 8 hours.

Embodiment 3

[0049] Cut a 100mm long ingot from the alloy 2# ingot for implementing the invention, put it into a circulating air furnace at room temperature for double-stage homogenization, heat it up to 350°C for 4 hours with the furnace, then heat it up to 550°C for 6 hours, and cool it out of the furnace. After double-stage homogenization treatment, the ingot is cut and milled to obtain an ingot with a thickness of about 73mm, which is reheated to 490°C to start rolling, and the rolling is divided into 8 passes, and the final thickness of hot rolling is 9mm; In the process, the hot-rolled plate is subjected to solution treatment at 545°C×20min, and then artificially aged at 175°C×10h after water quenching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com